Page 1

DEH-41413 Installation Instructions

.

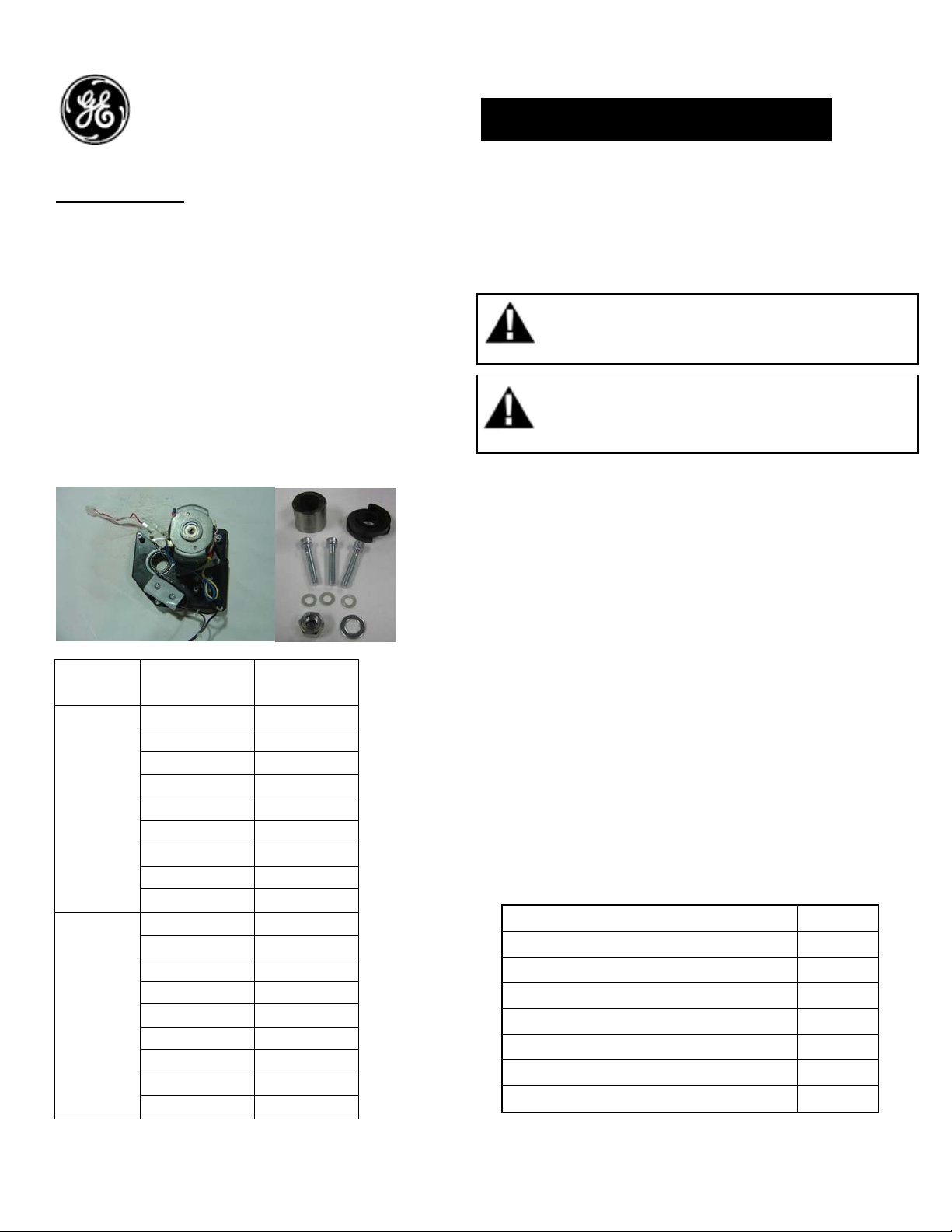

Motor Operator

The unique motor/gearbox unit is specially

designed to operate with the full range of

EntelliGuard G Circuit Breakers. It is easily fitted

with three heavy-duty bolts. After a breaker close

operation, the unit automatically recharges the

spring and makes it ready for immediate open

and re-close should the need arise. High speed

recharging ensures that the springs are fully

charged within approximately three seconds

following a release. All electrically operated (EO)

ANSI/UL breakers are equipped with “Spring

Charged, Power Rated” contacts for status

indication.

Table 1. Motor Catalog and Ratings

Envelope

Size

Catalog #

Voltage

Rating

GM01024D 24/30Vdc

GM01048D 48 Vdc

GM01060D 60Vdc

Envelope

1

GM01110D 110/130 Vdc

GM01250D 250 Vdc

GM01048A 48 Vac

GM01120A 120 Vac

GM01240A 240 Vac

GM01277A 277 Vac

Envelope

2

&

Envelope

3

GM02024D 24 /30 Vdc

GM02048D 48 Vdc

GM02060D 60 Vdc

GM02110D 110/130 Vdc

GM02250D 250 Vdc

GM02048A 48 Vac

GM02120A 120 Vac

GM02240A 240 Vac

GM02277A 277 Vac

EntelliGuard ® G Circuit Breaker

Accessories

Motor Operator

WARNING: Before installing any accessories, turn the

breaker OFF, disconnect it from all voltage sources,

and discharge the closing spings.

AVERTISSEMENT: Avant d’installer tout accessoire,

mettre le disjoncteur en position OFF, le déconnecter

de toute tension d’alimentation , et décharger les

resorts d’armement

• Duty Cycle = 2/min

• Spring Charge time = 4s max

• Frame 1 motors: running ~300VA

• Frame 2/3 motors: running ~450VA

• Inrush is 2 to 3 times running VA

Use the following procedure to install the Motor

Operator accessory into the circuit breaker.

1. Verify that the rating on the Motor Operator

Mechanism identification plate matches the

voltage rating required for the application, as

listed in Table 1.

2. Check that the package contains all the parts

listed in Table 2. If any components are missing,

contact the Electrical Distribution Post Sales

Service Team at 1-800-843-3742.

Table 2. Parts List

Description Quantity

Motor Operator Assembly 1

Shaft Bearing Sleeve 1

Switch Operating Cam 1

Washer M8 1

Nylock Nut M8 1

Cerrated Belleville Washer M5 3

Hex Socket Head Cap Screw M5X30 3

1

Page 2

3. Turn the breaker off and discharge the closing

springs by depressing the OFF and ON buttons in

the sequence OFF-ON-OFF. Verify that the

breaker OFF-ON indicator shows OFF on a green

background and that the charge indicator shows

DISCHARGE on a white background. If installing

in a draw-out type breaker remove breaker from

adaptor (cassette) before continuing.

4. Loosen the 6 screws on front cover (fascia)

using a pozidrive screw driver as shown in Fig. 1.B

Rotate the charging handle down and slide the

front cover over the handle to remove the front

cover as shown in Fig. 1.C

Figure 1. (A) Front Cover (B) ScrewRemoval (C) Handle

Rotation

5. Slide the sleeve (coupling bush) on the

camshaft as shown in fig 2.

Figure 3. Motor assembly mounting

7. Rotate the motor operator to align the 3

mounting holes in the side sheet. Mount the

device using three M5 bolts through the holes

provided in the gearbox endplate, torque to 7 Nm

(5.16 ft-lbs).

Figure 4. Assembly of screws

8. Before installing the cam as shown in fig. 5,

fully charge the breaker. (DO NOT CLOSE!)

Position the cam with the cutout toward the

front of the breaker as shown in fig. 6.

Assemble the cam on the drive shaft while

pressing the two switch levers as shown in

fig. 5.

Figure 2. Assembly of sleeve

6. Orient the device as shown in Fig. 3, locating

the gearbox bearing on to the cam drive shaft,

pushing it until flushes with the mechanism side

plate. If it does not move easily to the flush

position, pull the charging handle gently down to

ease movement.

Figure 5. Assembly of cam

Figure 6. Cam Orientation when charged

2

Page 3

9. Assemble the M8 nylock nut at the end of the

camshaft and torque to 12 Nm (8.85 ft-lbs) fig .7.

12. To reinstall the cover, rotate the charging

handle down and slide the front cover over the

handle to assemble the front cover to housing as

shown in Fig. 9.

Figure 7. Assembly of Nut

10. Manually charge the springs with the

charging handle and ensure the motor is

assembled properly.

11. Connect the input wire assembly plugs for the

motor and the spring charge status indicator

switch as shown in fig.8.

13. Ensure the fascia is aligned pr

operly with the

trip unit and the pad lock features of the breaker

14. Fasten the 6 mounting screws of fascia with

the housing using a pozidrive screwdriver. Apply

torque of 6 Nm (4.42 ft-lbs).

Figure 8. Assembly of connectors

Figure 9.

3

Page 4

Reference:

Secondary Disconnect Wiring Diagram

These instructions do not purport to cover all details or variations in equipment nor, to provide contingency to be met in connection

with installation, operation, or maintenance. Should further information be desired, or should particular problems arise which are not

covered sufficiently for the purchaser’s purposes, the matter should be referred to GE.

GE

41 Woodford Ave, Plainville, CT 06062

www.geelectrical.com

© 2009 General Electric Company

DEH-41413 R02 (09/13)

4

Loading...

Loading...