Page 1

Back Connected Terminations

Envelope 2, 3200A ANSI, Fixed type

Terminal assemblies are supplied with the

Entelliguard breaker. Fixed breakers have Back or

Front Connected Terminations available. This

instruction is for Back Connected Terminations

M12 Mtg

M12 Plain

M12 Plain

washer

washer

M12 Spring

M12 Spring

washer

washer

M12 Mtg

Hardware

Hardware

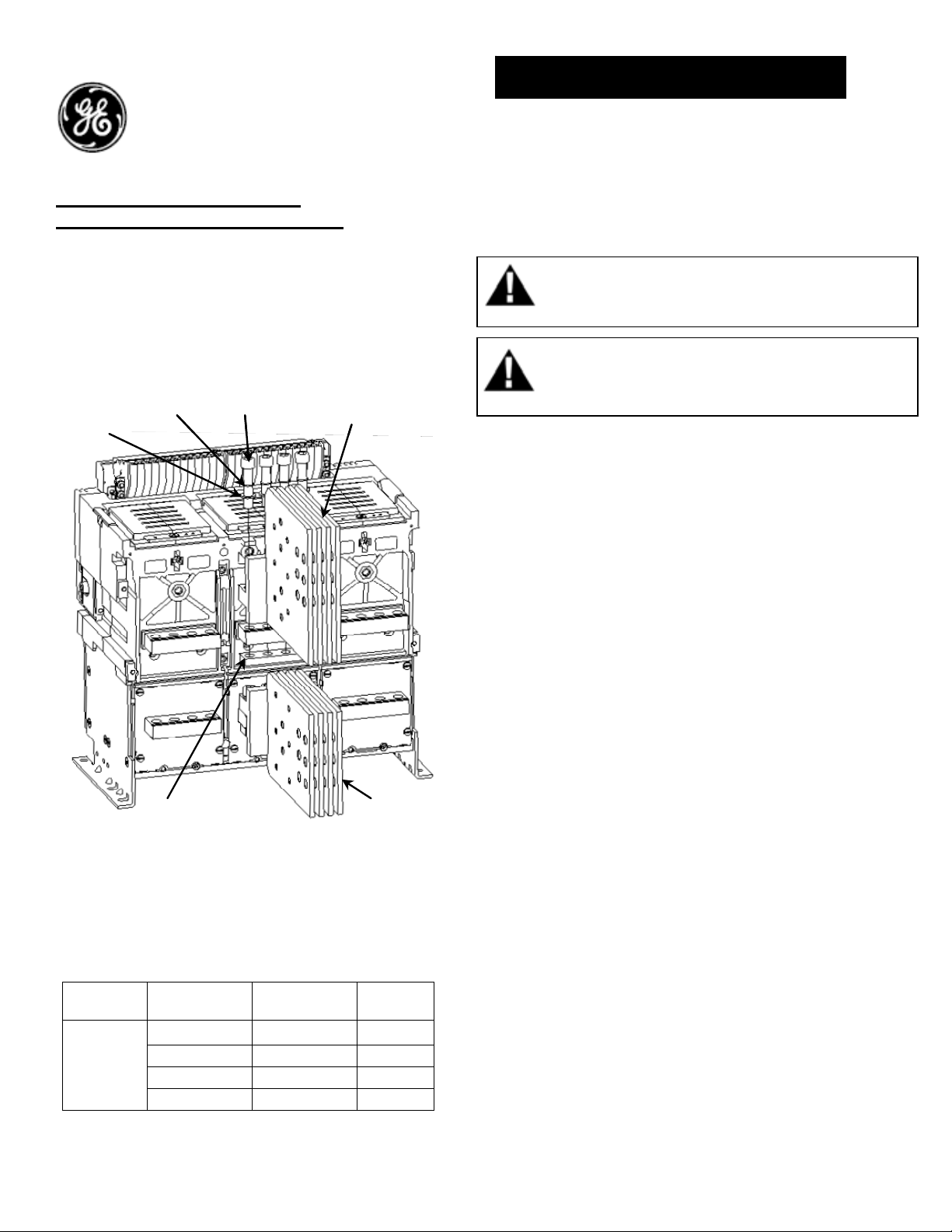

Fig A. Back Connected Terminations assembly, (Middle pole)

For 3200 Amperes (ANSI) 3 pole, fixed type

Table 1. Back Connected Terminations

Envelope

Size

Envelope 2

Nut plate

Nut plate

Catalog numbers

Catalog # Description TYPE

GBB232TBB3

GBB232BBB3

GBB232TBB4

GBB232BBB3

Top side

Bottom side

Top side

Bottom side

Top terminal

Top terminal

assembly

assembly

Bottom terminal

Bottom termin

assembly

assembly

3 pole

3 pole

4 pole

4 pole

al

DEH- 41443 Installation Instructions

EntelliGuard ® G Circuit Breaker

Accessories

Back Connected Terminations for

Fixed Breaker

WARNING: Before installing any accessories, turn the

breaker OFF, disconnect it from all voltage sources,

and discharge the closing spings.

AVERTISSEMENT: Avant d’installer tout accessoire,

mettre le disjoncteur en position OFF, le déconnecter

de toute tension d’alimentation, et décharger les

resorts d’armement

Back Connected Terminations Assembly (3 Pole)

Procedure:

1. Turn the breaker off and discharge the closing

springs by depressing the OFF and ON buttons in

the sequence OFF-ON-OFF. Verify that the

breaker OFF-ON indicator shows OFF on a green

background and that the charge indicator shows

DISCHARGE on a white background.

2. First assemble & orient the middle terminations

assemblies on to the breaker rear terminals as

shown in Fig A.

3. Middle top & bottom terminal assemblies to be

tightened with M12 hardware’s as shown in Fig A,

to 80 Nm (59 ft-lbs) torque.

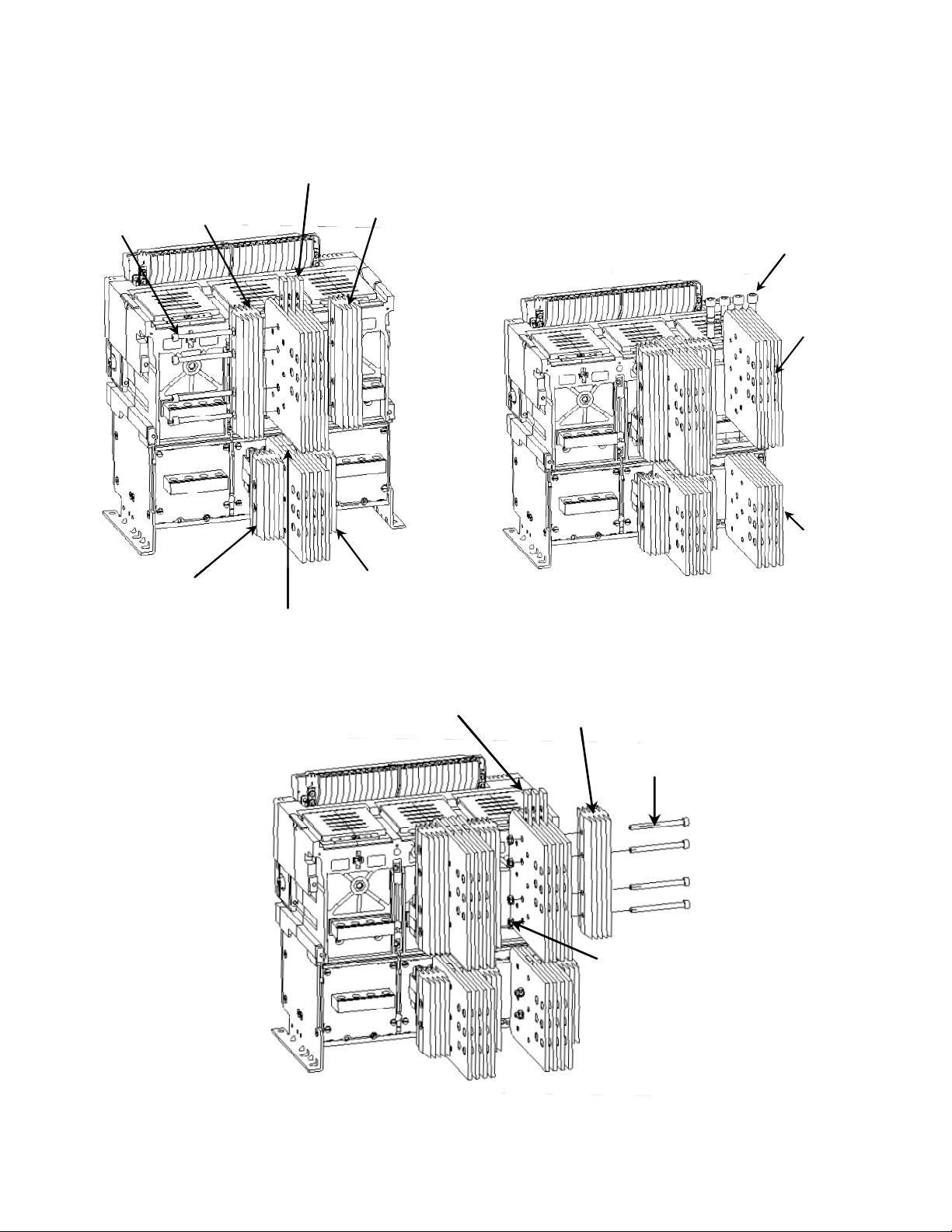

4. Assemble the heat sinks LH & RH with spacers

introduced in between the multiple pads of

terminal assemblies as shown in Fig B for bottom

& top sides. Tightened them with M8 mounting

hardware’s to 16 Nm (11.8 ft-lbs) torque.

5. Assemble the outer terminal assemblies on

bottom and top side with M12 hardware

tightened to 80 Nm (59 ft-lbs) torque as shown in

Fig C.

6. Assemble the heat sinks RH with clearance holes

& spacers introduced in between the multiple

pads of outer terminal assemblies as shown in fig

D, for bottom & top sides and tightened them

with M8 mounting hardware’s to 16 Nm (11.8 ftlbs) torque.

1

Page 2

7. Assemble remaining terminal assemblies similarly

on all poles so as to populate as 3pole / 4 pole

breaker.

M8, Mtg

M8, Mtg

hardware

hardware

Top Heat sink LH

Top Heat sink LH

(with clearance hole)

(with clearance hole)

Top Spacer

Top Spacer

Top Heat sink RH

Top Heat sink RH

(with tapping)

(with tapping)

Bottom Heat sink LH

Bottom Heat sink LH

(with clearance hole)

(with clearance hole)

Bottom Spacer

Bottom Spacer

Bottom Heat sink RH

Bottom Heat sink RH

(with tapping)

(with tapping)

Fig B. Heat sink Asm with spacers (Middle pole)

For 3200A , (ANSI) 3 pole, fixed type

Top Spacer

Top Spacer

Fig D. Outer pole Heat Sink with spacer assembly

For 3200 Amperes (ANSI), 3 Pole, Fixed type

8. The bus bars to be supported within 200mm

distance and tightened to 80Nm (59 ft-lbs) torque.

M12 Mtg

M12 Mtg

hardwares

hardwares

Top terminal

Top terminal

assembly

assembly

Bottom terminal

Bottom terminal

assembly

assembly

Fig C. Outer pole, Back Connected Terminations

asm For 3200 A, (ANSI) 3 Pole, fixed type

Top Heat sink (RH)

Top Heat sink (RH)

(with clearance hole)

(with clearance hole)

M8, Mtg

M8, Mtg

hardware

hardware

M8, Nuts

M8, Nuts

2

Page 3

** For 3 Pole , L2 Phase to have two heat sinks,

While outer poles L1 & L3 to have only one outer

heat sinks assembled

L1

L1

L2

L2

L3

L3

Fig E. Envelope 2, 3200A ANSI 3 Pole, fixed type, Top view

Fig G. Envelope 2, 3200A ANSI 3 Pole, fixed type

Fig F. Envelope 2 , 3200A ANSI 3 Pole, fixed type, Side

view

3

Page 4

Back Connected Terminations Assembly (4 Pole)

Procedure:

1. Similar Procedure to be followed for 4 pole

breaker with neutral on right or left.

2. For 4 Pole breaker, assemble the L2 pole with

two heat sinks first. Then assemble the

adjacent poles with only one outer heat sinks.

Refer Fig H – Fig L.

N

N

Fig H. Envelope 2, 3200A ANSI 4 Pole, Neutral Left, Top view

Fig I. Envelope 2, 3200A ANSI 4 Pole, Neutral left, fixed

type

L1

L1

L2 L3

L2 L3

L2

L3

L3

Fig J. Envelope 2 , 3200A ANSI 4 Pole ,Neutral Right, Top

view

Fig K. Envelope 2, 3200A ANSI 4 Pole, Neutral Right, fixed

type

Fig L . Envelope 2, 3200A 4 Pole, fixed type, Side

view

L2

L1 N

L1 N

4

Page 5

These instructions do not purport to cover all details or variations in equipment nor, to provide contingency to be met in connection

with installation, operation, or maintenance. Should further information be desired, or should particular problems arise which are not

covered sufficiently for the purchaser’s purposes, the matter should be referred to GE.

GE

41 Woodford Ave, Plainville, CT 06062

www.geelectrical.com

© 2009 General Electric Company

-

5

Loading...

Loading...