Page 1

GE Industrial Control Systems

EAK

Instruction Book

guidelines

GE/-

100353

Page 2

These instructions do notpurport to cover all details or variations in equipment, nor to provide everypossible contingency

to be met during installation, operation, and maintenance. If further information is desired or if particular problems

arise that are not covered sufficiently for the purchaser’s purpose, the matter should be referred to GE industrial

Control Systems.

This document contains proprietary information of General Electric Company, USA and is furnished to its customer

so/e/y

to assist that customer in the installation, testing, operation, and/or maintenance of the equipment described.

This document shall not be reproduced in whole or in part nor shall its contents be disclosed to any third party without

the written approval of GE industrial Control Systems.

0

1998 by General Electric Company, USA.

All

rights reserved.

Page 3

TABLE OF CONTENTS

1. EMC DIRECTIVE, INTERPRETATION CEMEP AND APPLICABLE STANDARDS . . . . . . . 5

2. IMMUNITY: ESD AND FAST TRANSIENT (BURST)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3. EMISSIONS: RADIO-FREQUENCY CONDUCTED AND RADIATED

4.

EMI

FILTERS

4.1 ECF FILTERS

4.2

EMI

FILTERS (FN,

4.3 TABLES OF FILTERS SELECTION

5. EMC COMPLIANT ELECTRICAL CABINET WIRING RULES

..............................................................................................................

.................................................................................................................................

COMPACT,RANGER,S-mu.)

............................................................................................

...........................................................................

...........................................

PANELS

REMOVAL OF THE PAINT FROM THE SUPPORT AREAS

GROUND TERMINALSOFTHE INVERTER

GROUND TERMINALS OF THE CONVERTER

GROUND

SHIELDOFCABLES FOR ANALOG SIGNALS

GROUND CONNECTION OF THE ANALOG ZERO VOLT AND

GROUND CONNECTION OF THE ANALOG ZERO VOLT FOR OPTIONAL TBO CARD

MIN.DISTANCE BETWEEN SIGNAL AND POWER CABLES: SINGLE AND DOUBLE CABINETS1 4

SHIELDING OF THE SUPPLY FOR AN AC MOTOR

GROUND CONNECTION TO BOTH SIDES OF THE CABLE SHIELD (AC MOTOR)

PIGTAIL AVOIDING .............................................................................................................

SUPPLYCABLES OF THEDCMOTOR

DIRECT CONNECTION BETWEEN GROUND BUS AND MOTOR CHASSIS..

MAX LENGTH OF THE AC MOTOR’S CABLES INSIDE THE CABINET

ENCODER CABLES

MOUNTING SEQUENCE FOR FN, COMPACT AND RANGER FILTERS WITH CONVERTER AND

LINE REGEN CONVERTER

GROUNDING OF THE FN, COMPACT AND RANGER FILTERS WITH CONVERTER AND ‘LINE

REGEN CONVERTER

MOUNTING SEQUENCE FOR FN, COMPACT AND RANGER WITH INVERTER

GROUNDING OF THE FN, COMPACT AND RANGER FILTERS WITH INVERTER

MOUNTING SEQUENCE FOR ECF FILTERS

GROUNDING OF THE ECF FILTERS

MOUNTING SEQUENCE OF THE FILTERS:

Filtering connection using

Filtering connection using ECF filters..................................................................................

AND

CABINETS

TERMINALOFTHE CHOKE..

....................................................................................................

.............................................................................................................

...................................................................................................

...........................................................................................................

FN, COMPACT or RANGER

.....................................................

..........................................................................

.......................................................................

................................................................................

......................................................................

+24

V REFERENCE POTENTIAL13

...............................................................

.................................................................................

........................................................................

....................................................................................

SUMMARY TABLE ............................................

filters: ............................................

.,,........,.......,,.......

.............

..................

.........................

..................................

....................

..................

6

7

8

8

9

10

73

13

13

13

13

13

13

14

14

14

14

14

14

15

15

15

15

15

15

15

16

16

16

17

ATTACHMENT A

AlTACHMENT

...............................................................................................................

B

. . . . . .

..~....................................,,.....,,.,......,........~,..............,.,...,,...,.,.,...

26

27

Page 4

LIST OF FIGURES

AN,D

TABLES

1 m EMC DIRECTIVE, INTERPRETATION CEMEP AND APPLICABLE- STANDARDS

2. IMMUNITY: ESD AND FAST TRANSIENT (BURST)

3. EMISSIONS: RADIO-FREQUENCY CONDUCTED AND RADIATED

4.

EMI

FILTERS

Figure 4. I: ECF filters

Figure

4.2. I:

Figure

4.2.2: Filter

Figure

4.2.3:

Tab/e1:Selection of the filters

Table

2/A:

Table

2/B:

Table

3:

Filters

Table 4: Filters

Table 5: Filters

..............................................................................................................

8

connection

Filter

connection on Converter..

Filter connection on Line Regen

for DV-300 converters

Filters

Filters for

DV-300

for AV-300

for AV-300i

for RS-300

on

lnverter

.................................................................................................................

converters

invetters..

inverters..

line regen

.........................................................................................................

....................................................................................................

Converter

..........................................................................................................

..........................................................................................................

...............................................................................................................

..............................................................................................................

converters..

..................................................................................

...........................................................................................

5. EMC COMPLIANT ELECTRICAL CABINET WIRING RULES

Figure 5.1:

Figure 5.2: Converter

Figure

Figure

Figure

Figure 5.6: Functional connection diagram of a FN, COMPACT or RANGER filter with AV300 inverters

Figure 5.7: Functional connection

Figure

Figure 5.9: Functional connection diagram of a FN, COMPACT or RANGER filter with line regen converters

Figure 5. 70: Functional connection diagram

Figure 5.7 1: Functional connection diagram of a ECF

Figure

Figure

Inverter

5.3:

5.4:

5.5:

5.8:

5.12:

5.13:

Regen Converter

Line

inverter /

OMEGA plug: grounding at

Functional connection diagram of a FN, COMPACT or RANGER filter with converters

Sing/e

Double

Converter

side

cabinets

side

cabinet’s layout..

....................................................................................................................

.......................................................................................................................

360”of

diagram of a S-...

layout.........................................................................................................

shielded cable. .....................................................................

a

filter with

of a ECF filter with inverters..

filter with converters..

......................................................................................................

..................................................

............................

.................................... 13

AV300i

inverters

.............................................

...................................................... 22

..................................................

................... 20

..,....

.

......

..........

5

6

7

8

9

9

9

70

I1

17

12

12

72

16

76

16

17

17

18

19

.21

23

24

25

AllACHMENT

A

ATTACHMENT B

. . .

..~..........,..,.......,,~.........,,..~.....,...........,........,,,...~...,,....~....,,,.......,,...

. . . . . . . . . . . .

..I.........................~.................................................................

26

27

Page 5

EMC GUIDELINES

1. EMC DIRECTIVE, INTERPRETATION CEMEP AND APPLICABLE

. .

STANDARDS’

=

The EMC directive

marketable in the CEE must be electromagnetically compatible with the external world.

This means the equipment fairly immune to admissible environmental noise-levels and low emitting according

to the allowed

Sales channels: Restricted Distribution

Unrestricted Distribution (see Glossary)

Installation environment

Inherent function of the device: direct or indirect

Assembly: Professional Assembler

Obviously, the directive does not point out in detail neither the criterions which have to be applied in order to

judge a device EM-compatible, nor the actions that have to be taken, in order to keep it in that way. That task is

up to the Product Standard concerned with the product; if this would not exist or if the part concerning EMC had

been missed, the product manufacturer must refer to the Generic Standard.

Therefore, being EMC conformant, does not mean high-immunity and low-emissions, but it implies the

adherence to the limits imposed by a product standard, which cannot foresee any limitation.

Seeing the wide range of products to which the directive refers and its legal nature, it became necessary for the

manufacturers of products of the same typology, to give an interpretation of the directive, with no official value,

but whose validity is linked with the acknowledgment of the association of some categories. (The only document

recognized by CE is the directive).

(89/336,

levelsThese

updated from the

limitations are related to the characteristics of the equipment itself.

93/68)

points out that each electrical and electronical equipment

In case of Power Device Systems (PDS, including in this category both single-drives and systems, which are the

assembling of single device, composing a machine) there exists an interpretation, well-known as Document

CEMEP, recognized by the most important European association of categories: ANIE, GAMBICA, GIMELEC,

SETELI,

The document classifies the PDS in four validity fields (CEMEP Validity Fields, see attachment B) according to

the above mentioned characteristics and it

the following points:

- CEMark

-

-

The EMC directive is applied to the GE product following the interpretation CEMEP.

In accordance with the interpretation CEMEP GE products, considered that:

-

-

ZVEI, Manufacturers - Denmark.

assignes

Declaration of conformity

Responsibility of the constructor and installer

sales channel correspond to the definition of Restricted Distribution

the products haven’t any direct function (intrinsic)

to each of the four classes duties and prohibitions concerning

!i

Page 6

GEL100353

-

the assembley must be a professional one will be considered “Complex Component” (CEMEP Validity

Field no 2) therefore

-

It is not possible to apply the CE Mark concerning EMC Standard

-

It is not possible to draw up the Declaration of Conformity regarding EMC Standard

-

The responsibility of the EMC Standard is of the installer and not of the manufacturer (GE)

-

The producer (GE) is responsible for giving the installer all the necessary indications to keep the final

product EMC conform.

CE marking and declaration of conformity, as known , are linked with the standard, who are referred. GE’s

products show the mark and, as prescribed, in the handbooks it has been specified how this mark is conformed

to the Low Voltage Directive, for which it has been also drawn up a declaration of conformity (see attachment

A). Whenever the EMC Standard is concerned, the

guidelines.

EMI

filters must be utilized and used according to installation

The product standard for the PDS, EN61800 (drawn up in

and describes completely the prescriptions in terms of immunity and emissions for PDS.

In this standard it has been assigned the noise-levels to which the equipment must be submitted under the

immunity test and the allowed emission limits.

On the whole the machine manufacturer, or GE customers, belong to the validity field CEMEP number 4 as

“System /apparatus” and therefore they have the obligation of CE Mark and Declaration of Conformity.

The machine manufacturer has the responsability of EMC conformity. They have the right to receive all the

necessary indications (filter, installation, etc.) in order to comply with EMC standard from the single component

producers.

Almost all the products do not have product standard as far as EMC concerns and they have to refer to the

generic standards, which are EN50081-1 and 50081-2 as far as emissions in residential and industrial environments

and

EN50082-1

These documents, as far as the radio-frequency emissions concern, refer to the specific standard EN55011

which define the emissions limits in industrial environment (class A limits) and residential (class B limits).

This is why, despite the less restrictive limitation imposed by the product standard

refer to the limits EN5501 1-A and B, as far as the radio-frequency emissions are concerned.

In the next two sections immunity and emission tests and limitation prescribed in

and

EN50082-2

regarding the immunity in the above mentioned environments.

1996),

in the part 3

(EN61800-3)

(EN61800-3)

EN61800-3

manages the EMC

GE’s product

are described.

2. IMMUNITY: ESD AND FAST TRANSIENT (BURST)

The immunity tests which can be applied to a PDS according the

(ESD) and Fast Transient (or Burst). This standard specifies the test levels and refers to the specific standards,

which are IEC 1000-4-2 and IEC 10004-4-4, in order to describe in detail all the procedures and the test equipment.

EN61800-3

are the electrostatic discharges

Page 7

EMCGUIDELINES

3. EMISSIONS: RADIO-FREQUENCY CONDUCTED AND

RADIATED

As far as the radio-frequency emissions are concerned, in the

between First and Second Environment, stating that the equipment has to be connected to a low-voltage

mains supply whether public or industrial, which could also supply domestics buildings.

For the first Environment, assuming that the mains is less than 500V of the type

IEC364-3.

protection. In these cases the safety precautions have priority on the EMC ones: it is advisable to call the

technical support service. In case of Restricted Distribution the limits are equal to the class A ones of

Standard EN5501 1, while in case of Unrestricted Distribution equal to class B for devices with rated current

less than 25A and class A for higher current.

Regarding the second Environment (A), which is the most frequently notable case, the limits are not defined

yet. As already anticipated in the conclusion at the first section, it is to refer to the limits, defined by the

curves A-B of standard EN5501 1.

In general, to have GE equipment in its limits, whether class A or B, it would be necessary both additional

devices (filters) and the respect of strict installation rules: in the next two paragraphs it will be given either

a guide to the selection of filters according to the type of the device, the cable-length between device and

motor and the size of the device and a list of rules in order to obtain an installation in accordance with EMC

additioned with sample diagrams.

In case of IT mains, the capacity needed by EM1 filtering are not compatible with the system

EN61800-3,

there has been a distinction made

TN-IT,

in accordance with

Equally, for the radiated emissions, the

second Environment, while for the first it gives limitations equal to the EN5501 1, according to the functions,

the distribution and current size.

Both for the conducted and for the radiated emissions the relative measurements have been made, in order to

compare GE’s device to the prescribed limits, using the suitable filters and following the prescribed rules.

In the particular case of radiated emission, an additional

be assumed when the device is mounted inside a cabinet and installed according the EMC rule, a condition

that is impossible to find during the EMC tests and measurements.

EN61800-3

does not fix limits (limits under consideration) for the

10dB

attenuation has been considered, which can

7

Page 8

GEI-100353

4.

EMI

FILTERS

According to the application (installing environment and specification, in particular the length of motor cables),

the EM1 filters are being selected between the two available series:

-

ECF series for the applications of

-

FN, Compact, Ranger or S-.... series for the applications of

plant (see table 1)

converter/inverter

in the industrial plant (see table 1)

converter/inverter

in residential and industrial

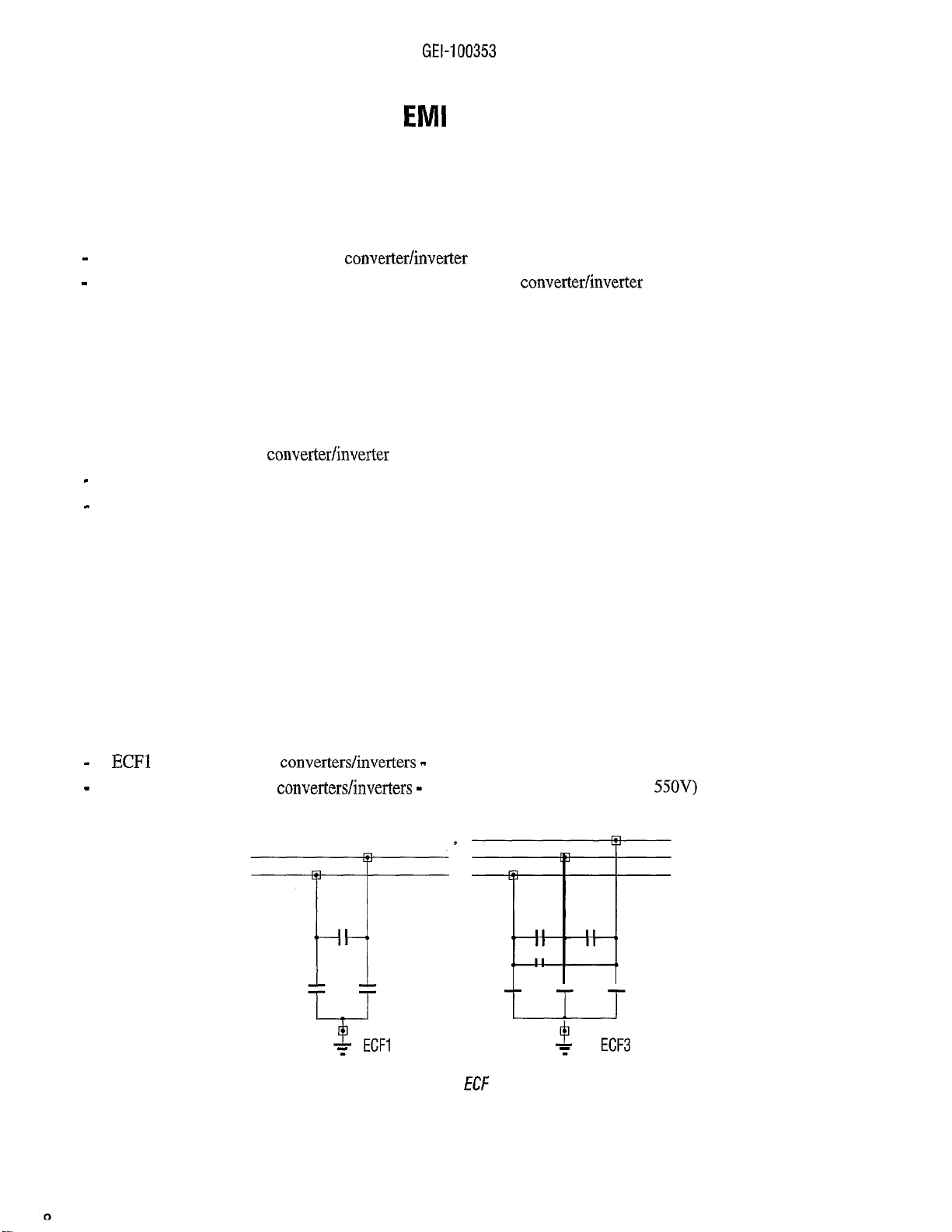

4.1 ECF FILTERS

ECF filters are needed for

-

motor cable length less then 20 m for 3015 device size and higher

-

motor cable length less then 100 m for device size up to 3011.

Applications that require long motor cable length (greater than 20 m) or residential installation environment,

will be satisfied by the FN, Compact, Ranger or S-.... filters.

The EFC filters are parallel connected on the supply line of the device.

The some kind of filter can be used for both converter and inverter. For multi-drive applications, it is enough to

use only one filter, which should be connected to the incoming line before all mains chokes, sized for the total

power rating of all units fed.

ECF filters are connected before the main choke.

ECF filters are available in two versions:

-

ECFl

(for single-phases

-

ECF3 (for three-phases

converter/inverter

converterslinverters -

converters/inverters -

in the industrial plant, with:

Max AC mains voltage allowed: 440V)

Max. AC mains voltage allowed:

55OV)

iii!

r ECU

Figure 4.1: ECF filters

k

1

ECF3

Page 9

4.2

EMI

FILTERS (FN,

EMC GUIDELINES

COMPAC~RANGER,S-....)

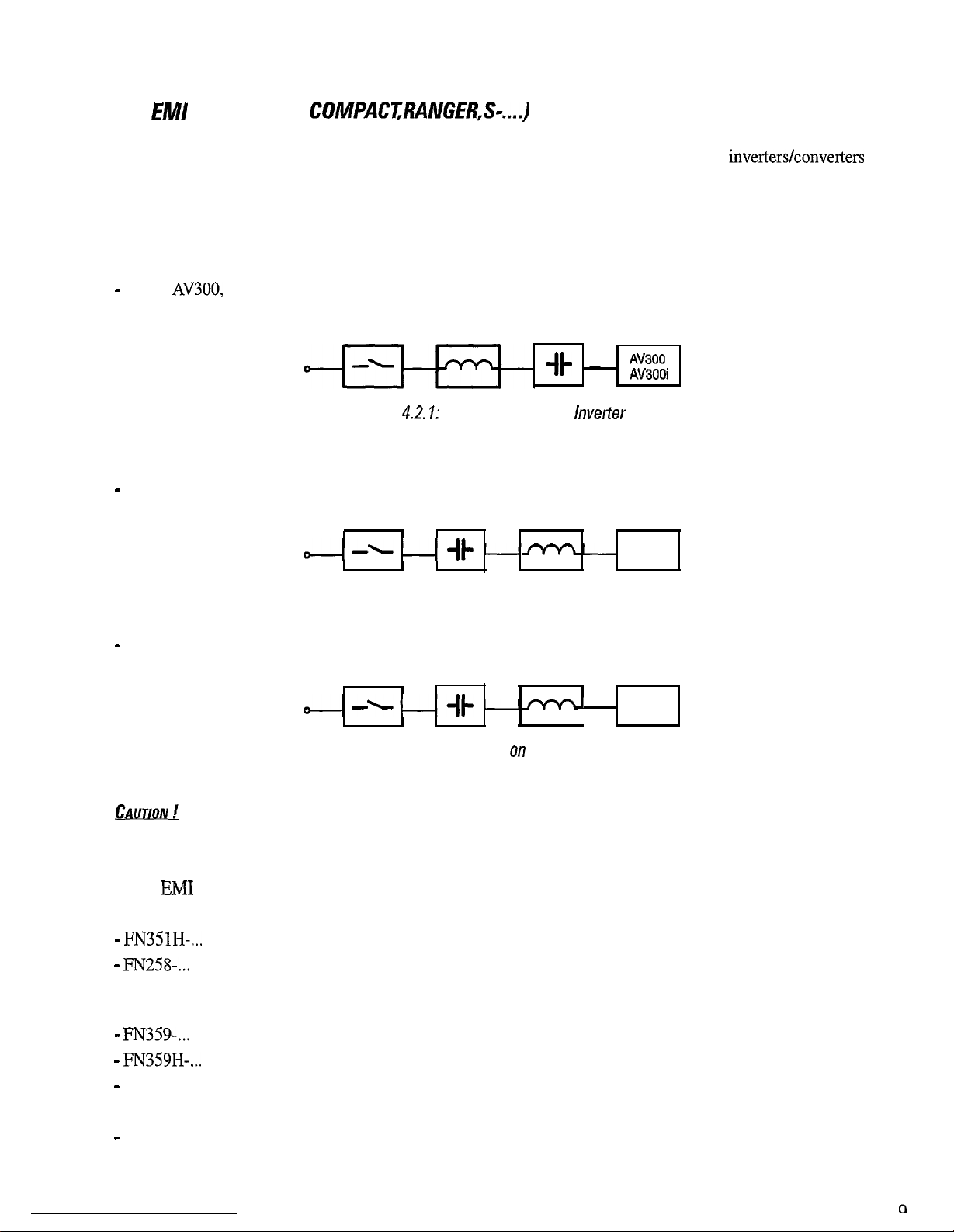

EMI-FN filters, are high attenuation filters for generic applications, which can cover also the

inverters/converters

applications during particular environmental conditions (residential) or plant (motor cables very long associated

to high-sized inverters).

EMI-FN filters are series-wired on the supply line of the device (see further insertion diagrams), so they have to

be sized, according to the load current of the device.

-

For

AV300,

-

For DV300, the choke should be connected between filter and drive

the filter should be connected between the mains choke and the drive

----it-

Mains supply

Figure

Mains supply

4.2.7:

Choke Filter

il- -

Filter connection on

Filter

lnverter

Choke

AV300

AV3OOi

DV300

Figure 4.2.2: Filter connection on Converter

-

For RS300, the choke should be connected between filter and drive

Mains supply

Filter Choke

------II-

.

Figure 4.2.3: Filter connection on Line Regen Converter

A wrong sequence during the installation of filters can damage the converter.

Filters

EM1

(FN, COMPACT, RANGER and S-....) are of following versions:

- FN351H-...

- FW258-...

- FN359-...

- FN359H-...

-

COMPACT-...

-RANGER-...

-

s-....

Max rated voltage 520V. Brick shaped. T amb = 104°F (40°C).

Book-shaped. Max. rated voltage 480V.

T amb = 104°F (40°C). With a derating of the rated current, it is possible the working

up to 122°F (50°C).

Max rated voltage 44OV. Brick shaped.

Max rated voltage 520V. Brick shaped.

Max rated voltage 440V. Book shaped.

Max rated voltage 520V. Brick shaped.

Max rated voltage 480V. Footprint shaped

I

RS300

Page 10

GEL100353

4.3 TABLES OF FILTERS SELECT/ON

To select a suitable filter, one has to take into account following:

kind of device (DV-300, AV-300,

RS300,;..);

size of the device;

motor cables length (important only for inverters);

class of the limits of EN5501 1 (A or B).

(overlaod are already factored in)

With the requirements above consult table 1, to pick which kind of filter to use.

ECF3: type ECF, three-phase version

ECFl

: type ECF, single-phase version

The ECF filters don’t need further specifications, while FN, COMPACT and RANGER filters have to be selected

according to the size of the device (see tables

Drive EN 55011 Motor cable length Filter

Class A No limitation

DV-300

Class B No limitation

Class A

AV-300

Class B No limitation

For sizes I 3011: maximum length 100 m

For sizes > 3011: maximum length 20 m FN COMPACT RANGER

2/A-2&

3 and 4).

ECF3 -

FN , COMPACT,

ECFl

RANGER

See tables 2/A, 2/B

ECl3

7

See

table

3

AV-300i

RS300 Class A No limitation

Class A

No limitation

Class B

Table I: Selection of the filters

s-....

See table 4

FN , COMPACT, RANGER

See table 5

eoaioge

in

Page 11

EMCGUIDELINES

Drive Recommended filter

Mains voltage 230V - 400V

6KDV30201

6KDV3040

6KDV3070

6KDV3110

6KDV3140

6KDV3185

6KDV3280

6KDV3350

6KDV3420

6KDV3500

6KDV3650

6KDV3770 QZA / Q4E

6KDV310H Q2A / Q4E

6KDV31200

* Filters not mechanically interchangable

Q2A / Q4E 1

Q2A / Q4E

Q2A / Q4E

Q2A / Q4E

Q2A/ Q4E COMFACl-‘-480-130

Q2A / Q4E COMPACT480-180

Q2A / Q4E

Q2A / Q4E

Q2A / Q4E

Q2A / Q4E

Q2A / Q4E

Q2A

COMPACT-480-30

COh4PACT-480-42

COMPACT-480-75

COMPACT-480-100

RANGER-520-280

RANGER-520-450

RANGER-520-450

RANGER-520-450

RANGER-520-600

RANGER-520-900

RANGER-520-900

RANGER-520-1200

1

FN258-30 / 07

FN258-42 / 07

FN258-75 / 34

FN258-100 / 35

FN258-130 / 35

FN258-180 / 07

FN359-300 i 99 *

FN359-400 / 99 *

FN359-400 / 99 *

FN359-500 / 99 *

FN359-600 / 99 *

lw359-900 I99

FN359-900 / 99 *

FN351H-1200 *

+/-

10%

*

eoozoge

Table

Drive Recommended filter

6KDV3017 Q2B / Q4F

6KDV3035 Q2B / Q4F

6KDV3056

6KTJV3088

6KDV3112

6KDV3148

6KDV3224 Q2B / Q4F

6KDV3280 Q2B / Q4F

6KDV3336 Q2B / Q4F

6KDV3400 Q2B / Q4F

6KDV3450 Q2B / Q4F

6KDV3560 Q2B / Q4F

6KDV3800

6KDV3850

6KDV31000 1 Q2B 1

Q2B / Q4F

Q2B / Q4F

Q2B / Q4F

Q2B / Q4F

Q2B

Q4F

RANGER-520-1200

2/A:

Filters for W-300 converters

Mains voltage 460V

COMPACT-520-30

COMPACT-520-42

COMPACT-520-75

COMPAa-520-100

COMPACT-520-130 FN351H-180 / 36

COMPACT-520-180

RANGER-520-280

RANGER-520-450

RANGER-520-450

RANGER-520-450

RANGER-520-600

RANGER-520-900

RANGER-520-900

RANGER-520-900

+/-

FN351H-36 / 33

FN351H-50 / 33

FN351H-80 / 34

FN351H-110 / 35

FN351H-180 / 36

FN359H-300 / 99 *

FN359H-400 /

FN359H-400 / 99 *

FN359H-500 / 99 *

FN359H-600 / 99 *

FN359H-900 / 99 *

FN359H-900 / 99

FN359H-900 / 99 *

1

FN351H-1200 *

10%

99

e0030ge

*

*

* Filters not mechanically interchangable

Table

2/B:

Filters for DV-300

converters

Page 12

GEI-100353

Drive

Mains voltage 230V - 400V +I- 15%

mAv3090

mAv3110

COMPACT-480-180

RANGER-520-280

6KAV3132 RANGER-520-280

FN258-180107

l?N359H-250199 *COMPACT-520-180 FN359H-250/99

FJN359H-250199 *RANGER-520-280 FN359H-250/99

Recommended filter

I

Mains voltage 460V

COMPACT-520-130

+/-

10%

F'N351H-180/36*

6KAV3160 RANGER-520-450 FN359H-300199 *RANGER-520-280 FN359H-300/99

6KAV3250 RANGER-520-600 FN359H-500/99 *RANGER-520-600

6KAV33151 RANGER-520-600 1

*

Filters not mechanically interchangable

F’N359H-600 I99

Table 3:

Filters for AV-300

* 1 RANGER-SO-600 1

inverters

F'N359H-500/99

FN359H-500 I99

*

*

*

*

*

eil050ge

Drive

6KAs743Fzi

6KAs743005

6KAV43006

6KAV43010

Model

6KRS3185-400

6KRS3280-400

6KRS3420-400

6KRS3650-400

6KRS31OH-400

6KRS3185-480

6KRS3280-480

6KRS3420-480

6KRS3650-480

6KRS31OH-480

Mains voltage 400V -15% / 480 V + 10%

Table 4:

Mains voltage 230V - 400V f 15%

Filters for

Mains filter limits according to EN55011 - Class A

RANGER-520-180

RANGER-520-280

RANGER-520-450

RANGER-520-600

RANGER-520-900

RANGER-520-180

RANGER-520-280

RANGER-520-450

RANGER-520-600

I

RANGER-520-900

Recommended filter

S-1321-24

AV-SUUiinverters

I

e0070ge

Mains voltage 460V + 10%

FN258-l&O/07*

FN359-280/99*

FN359-400/99*

FN359-600/99*

FN359-900/99*

FN351H-180/36*

FN359H-250/99*

FN359H-400/99*

FN359H-600/99*

FN359H-900/99*

eOo4oge

* Filters not mechanically interchangable

Table 5: Filters for RS-300 line regen converters

Page 13

EMCGUIDELINES

5. EMC COMPLIANT ELECTRICAL CABINET WIRING RULES

.,,*

:.:.

).’

PANELS AND CABINETS

Mounting panel and cabinet (including the doors) have to be grounded, with a direct connection to the ground

bus, using star washers if possible.

REMOVAL OF THE PAINT FROM THE SUPPORT AREAS

The paint should be removed from the choke, mounting panel and chassis, support areas.

WARNING!

GROUND

The inverters of AV-300 series are provided with two ground terminals: one must be connected to the ground

bus and the other to the filter.

TERMIIVALS

The anodized aluminium does not conduct.

OF THE

INVERTER

GROUND TERMINALS OF THE CONVERTER

DV-300 converters and RS300 line regen converters are provided only with one ground terminal which should

be connected directly to ground bus.

GROUND

The ground terminal of the choke must be connected to the

The ground terminal of the autotransformer, in case of RS300 converters must be connected to the ground bus.

TERMlNAl

OF THE CHOKE

ground,bus.

SHIELD OF CABLES FOR ANALOG SIGNALS

The cables of analog signals must be shielded (each signal must be contained in the shield connected to the zero

volt terminal), the same is valid for the constant references (E.g..

converters the shield must be ground connected at 360” using the omega connectors available on the support

panel of the regulation board, in front of the terminals strip on the bar above the board.

Note: cable shields are grounded at one end only.

GROUND CONNECTION OF THE ANALOG ZERO VOLT AND

The analog zero volt (power supply common) and the

like AV-300, DV-300 and RS300 series the following connection on the terminal strip are needed:

+24V

reference potential must be grounded. For devices

1OV).

For AV-300 inverters and DV-300

+24

V REFERENCE POTENTIAL

-

terminal 11 (analog 0 V) with terminal 10 (PE)

-

terminal 18

When many devices have,the zero volt (terminals 11 and 18) connected together, the PE connection must

be done with a 10 PF, 2 kV capacitor.

(+24

V reference potential) with terminal 20 (PE)

Page 14

GEI-100353

GROUND CONNECTION OF THE ANALOG ZERO VOLT FOR OPTIONAL TBO CARD

The common references of the TBO analog signals (terminal 2 and 4) must be connected to terminal 11 of the

drive regulation board.

For the RS300 device the common reference of the analog output signals (terminal 22) must be connected to

terminal 11 of the device regulation board.

The minimum distance between parallel signals and power cables (supply cables of the motor ) is 30cm (12

inches). Possible crossings have to be made at 90”. In case of double cabinets (entry to the inside of the cabinet

on both sides with 2 different panels installed each other reverse side) it is advisable to have all signals cables

conveyed into ducts mounted on the inverter side (front) and to pass motor cables on the other side (back) trough

a hole made in the panel at the output of the inverter’s terminals.

In case of single cabinets, it is advisable to let the power cable run vertically, while those of signal horizontally,

keeping the maximum possible distance.

SHIELDING OF THE SUPPLY FOR AN AC MOTOR

The AC motors have to be supplied through a four pole shielded cable (three phases + green/yellow ground

wire), or through four unshielded cables, which are inserted inside a metal channel, consequently needing a

higher insulation (see relative safety standards). So, it is important that, further to the three phases, it has been a

direct connection (four cables) between the panel grounding and the motor and that the fourth cable had been

inserted in a shield.

GROUND CONNECTION TO BOTH SIDES OF THE CABLE SHIELD (AC MOTOR)

The shield of the supply cable of AC motors must be grounded on both sides in order to obtain a 360” contact,

that means the whole shield. This can be realized using suitable metallic EMC cables press grounded at 360” at

the input of the cabinet and of the motor’s terminal strip. If this connection is not possible, the shielded cables

should be brought inside the cabinet and connected with an omega connector (see figure) to the mounting panel.

The same must be done on the motor side: in case the connection at 360” on the motor’s terminal strip is not

possible, the shield must be grounded before entering into terminal strip, on the metal support of the motor,

using an omega connector (see figure). In case a metal duct has to be used, it should be both-sided grounded at

360” where possible.

PIGTAIL AVOIDING

While grounding the shielding of the cables, one has to adopt a 360” connection (E.g.: omega bus as in the table)

and the pigtail connection must be absolutely avoided. As pigtail here is meant the connection to earth of the

cable shield by means of a wire (or to use the same screen, roll it up and ground-connected).

SUPPLY CABLES OF THE DC MOTOR

The supply cables of DC motor do not need to be shielded.

DIRECT CONNECTION BETWEEN GROUND BUS AND MOTOR CHASSIS

Independently from any local ground-connection of the motor’s chassis, for safety reasons, it must always be

connected to the ground wire (yellow/green) coming from the panel ground bus.

IA

Page 15

EMC GUIDELINES

MAX LENGTH OF

THE

AC MOTOR’S CABLES

INSIDE

THE CABINET

‘. .*,.

From the grounding of the screen s&cabinet of the inverter terminal strip, the supply’s cables have to measure

at max. 5 meters (16.4 feet).

ENCODER CABLES

The encoder cable must be shielded and grounded only from the side of the inverter at 360”. The female connector

on the regulation board has been foreseen for that connection, therefore it is enough to have the cable shield

connected at 360” in the conductive case of the male connector.

In order to check that the shield is not connected on the motor side remove the encoder connector from the

inverter and verify with a tester the presence of a high impedance between the shield and the metal case of the

encoder or of the motor.

MOUNTING SEQUENCE FOR FN, COMPACT AND RANGER FILTERS WITH CONVERTER AND

LINE REGEN CONVERTER

In case of converters and line regen converetrs, these filters must be series-connected between the choke and the

AC line switch. The autotrasformer, in case of RS300 device, is always connected between the choke and regen

bridge input.

tdhRAf/NG!

Do not connect, in any case, to the converter’s terminals.

GROUNDING OF THE FN, COMPACT AND RANGER FILTERS WITH CONVERTER AND LINE

REGEN CONVERTER

A grounding terminal’s filter must be connected directly to the panel bar, the other must be fixed to the mounting

panel as near as possible to the filter.

MOUNTlNG

In case of inverters, these filters have to be series-connected between the inverter and the AC mains. The

connection between the filter and inverter’s terminals must be done with a four pole cable, whose

30 cm. (12 inches). If that connection is longer, the cable must be shielded.

SEQUENCE FOR FN, COMPACT AND RANGER WITH INVERTER

maxlength

is

GROUNDING OF THE FN, COMPACT AND RANGER FILTERS WITH INVERTER

The yellow/green ground wire of the four poles cable, must be connected from one side directly to one of the two

gounding

terminals of the filter must be brought directly to the grounding bus of the cabinet.

inverter’s terminals, from the other to one of the two filters grounding terminals. The other grounding

MOUNTING SEQUENCE FOR ECF FILTERS

This kind of filter must be connected between the choke and the line switch, for whatever kind of devices

(inverters or converters).

Warning ! Never connect directly to the device’s terminals.

Page 16

GEI-I

00353

GROUNDING OF THE

The connection between device ECF and derivation point must have at maximum a length of 50

The grounding terminal of the ECF filter

ECF

FILTERS

cm.(20

inches).

must be directly connected to the ground bus of the cabinet. In case of

inverter, the same grounding terminal should be also connected to one of the two grounding’s terminals of the

inverter.

MOUNTING SEQUENCE OF THE FILTERS: SUMMARY TABLE

Device

CONVERTER

INVER~R

LINE REGEN CONVERTER

MAINS-FnTERINDUCTANCE-DEVICE

MAINS-INDUCTANCE-FILTER-DEVICE

MAINS-FILTER-INDUCTANCE-DEVICE

FN - COMPACT -RANGER ECF

MAINS-FILTER-INDUCT~CE-DEVICE

MAINS-FILmR-INDUCTANCE-DEVICE

eomge

Filtering connection using FN, COMPACT or RANGER filters:

Mains supply

Choke

Filter

Figure 5. I: lnverter

Mains supply

Filter Choke

-----IF

Figure 5.2: Converter

Mains supply Filter Choke

-----+

Figure 5.3: line Regen Converter

I

DV300

-’

. RS300

Page 17

EMCGUIDELINES

Filtering connection using ECF

Mains supply

o----m

Shield

filfers:

Filter

-

-01 ~

F

Choke

4

1 z

Figure 5.4: lnverter / Converter

AV300

DV300

Figure 5.5: OMEGA plug: grounding at

360”of

a shielded cable.

-17

Page 18

GEI-100353

’ .

SUPPlY

RANGER

lnverter

\

Cabinet Mounting panel

/

ltor

cable

minals

IQ

figure 5.6: Functional connection diagram of a

F/V,

COMPACT or RANGER filter with

A\/300

inverters

Page 19

EMCGUIDELINES

AC Power Supply

AC

Mains

choke

EMI

filter

(S-....)

AC Mains

Ground

Bus

Jlotor

zable

Figure 5.7: Functional connection diagram of a

S-... filfer

with

AV300i inverters

Page 20

GEL100353

SUPPlY

FN,COMPACT,

RANGER filter

Converter

Cabinet Mounting panel

f

Ground

RI

IS

II I I

IL,

-

0

Encoder

Motor

“’

cabler

Motor cable

terminals

Figure 5.8: Functional connection diagram of a

FN,

COMPACT or

RAIVGER

filter with converters

Page 21

EMC GUIDELINES

SUPPlY

\

FN,COMPACT,

RANGER filter

Line

reactor

II I l-f

.;

.i. ‘,

Converter

\

’

Cabinet Mounting panel

/

Ground

Bus

Figure 5.9: Functional connection diagram of a FN, COMPACT or RANGER filter with line regen converters

31

Page 22

GEL100353

SUPPlY

\

500 mm

ECF filter

Line

reactor

ma>

lnverter

\

Cabinet Mounting panel

7

Ground

Bus

-

Encoder cable

Motor

Motor cable

terminals

J

nn

Figure 5.70: Functional connection diagram of a ECF filter with inverters

Page 23

EMC GUIDELINES

SuPPlY

500

mm max

ECF filter

Line

reactor

-

\

---.

Converter

Cabinet

Mounting panel

/

Ground

Bus

.

J

Ill

Encoder

Motor

cabler

L

\

‘I I

Figure 5. I I: Functional connection diagram of a ECF filter witti converters

Page 24

Mains switch

AC

co&actors

GEI-100353

Omega connectors for connectin

the motor cable shield

Figure 5.12: Single side cabinet’s layout

Omega connectors for connecting

the signal cable shield

\Signal

cables canal

Page 25

EMCGUIDELINES

Mains switch AC contaciors

I

3 c

/’

I

i

Figure 5.13: Double side cabinet’s layout

Page 26

GEI-100353

ATTACHMENT A

3

The possible validity fields of the

“CE

marking” summarizes the presumption of compliance with the

EMC

Directive ( 89 / 336 ) applied to

Essential Requirements of the EMC Directive, which is formulated

Clauses

numbers

[.]

refer to

Validity

Field

-I-

Complex component

sold “directly to

(clause 4.7 (4th E) and clause 4.7b]

fina

consumer”

European Commission

PIaced

Free

-

EC Declaration of conformity required - CE marking required

document “Guidelines on the Application

Brussels, 25 & 26 Oct. I993

on the market.

movement

The manufacturer of the PDS (or

based on.compliance with the EMC Directive

behaviour of the PDS (or

A

PDS

(or

CDMBDM)

of the Unrestricted Distribution

class

Additional EMC measures outside the item are described in an easy to

understand fashion and could actually be

The resulting

final product, by

EMC bchayiour

iijllowing

guidelines.

-2-

Complex componeut

only for professional

[clause 4.7

of the Rcstrictcd Distribution class

(2nd

and 3rd 1) and clause J.7a]

A

PDS (or

asscmblcrs

CDM/BDM)

sold to be included as part of an

apparatus, system

or installation

intended

competence to correctly install. Does not have intrinsic function for the end

user.

-

No EC Declaration of conformity - No CE marking

-

The manufacturer

guidelines lhal will assist lhe manufacturer of the apparalus, system

compliance.

The resulting

installation, for which its OWI standards may apply.

only for professional assemblers

PDS

should comply with

of

lhe

PDS (or

ELK

behwiour is the responsibility of the manufacturer of the apparatus. sj’dcm,

PDS

in the

Description

CDM/BDM),

is the responsibility of the assembler of the

the manufacturer’s recommendations and

IEC-22G/21/CDV

CDSVBDM)

EC

Declaration of

of

CDMfBDM)

under specified conditions.

impremented

w,ho

is

responsible

Conformity

Council Directive

is responsible

by a layman.

have a

for the provision of installation

89/336/EEC”

for

the EMC

Ieve!

of technical

or

installalion to achieve

T

or

-3-

Installation

[clause 4.61

One or more

different classes

Unrestricted -brought together at a

given

place.

qstem

PD.%,

possibly of

-

Restricted or

in or with apparatus,

or other components.

-4

Apparatus /system

[clause 4.4 and 4.5]

(A)

PDS(s)

(or CDMBDM)

of the Unrestricted Distribution

class

in finished item(s)

Not intended to be placed on the market as a single functional unit.

Each

apparatus or system included is subject to the provisions of the EMC

Directive.

-

No EC Declaration of conformity - No CE marking of the installation

- The PDSs

Resulling

following an appropriate

EMC Directive apply regarding the neighbourhood of the installation.

Has an intrinsic function for the

should comply with

EMC behariour is the

EMC

plan). Essential protection requirements of

IEC-22GIZllCDV

responsibilih,

final

user and placed on the market as a

of

the

installer (e.g.

by

single commercial unit.

-

EC Declaration of conformity required

-

CE marking required

(for the apparatus or s:stcm)

Resulting EMC’ behaviour is the responsibility of the

apparatus or

s$em.

manufacturer of the

nc

Page 27

EMC GUIDELINES

ATTACHMENT B

Page 28

, #

I

@

We bring good things to life.

GEI-100353 Rev. 0.1 (10/98)

GE Industrial Control Systems

Internet Address:

http://www.ge.com

Loading...

Loading...