Page 1

GEH6290

g

Type SCH1/1X, SCH2/2X Flange-Mounted

Handle Assemblies, Cable Series SC3L–SC10L

and Type SC0M1A, SCOM1EF, and SCOM1G

Breaker-Mounted Operating Mechanisms

General

GE Cable Operating Mechanisms are suitable for

application with GE circuit breakers mounted in a wide

variety of flanged enclosure types and sizes.

Flange-mounted handle assemblies are available for

NEMA Type 1, 3R, 12, or 13 enclosures in either 6-inch,

Model SCH1, or 10-inch handle lengths, Model SCH2.

Corresponding assemblies, SCH1X and SCH2X, are

available for NEMA Type 4/4X enclosures. Handle

assemblies are suitable for either left or right flange

operation.

The handle assembly is combined with one of eight

operating cables, with lengths from 3 to 10 feet, to cover a

broad range of breaker mounting locations in the

enclosure. The cable links the handle assembly to the

breaker-mounted operating mechanism and transmits the

mechanical force and motion of the handle mechanism to

the breaker-mounted mechanism. The force and motion

is transmitted independently of the breaker mounting

plane or location relative to the location of the handle

assembly, provided only that the bending radius of the

Cable Operator Mechanisms for

E150, SE150, SF250, and SG600

Spectra RMS™ Circuit Breakers

cable is no less than 3 inches. No mounting reinforcement

of the breaker or enclosure flange is required.

The breaker operating mechanism mounts directly to the

face of the breaker and does not involve any mounting

interface with the enclosure. Standard breaker mounting

screws for tapped holes are furnished with each

mechanism to mount the breaker in the enclosure.

Examine Table 1 to ensure that the handle assembly,

cable, and breaker operating mechanism you have are

correct for the job. Check Table 2 to ensure that the cable

is long enough to reach the breaker and that the 3-inch

minimum bending radius requirement is not violated.

Installation of the handle assembly onto the enclosure

flange can be performed independently from installation

of the breaker operating mechanism onto the circuit

breaker and from installation of the circuit breaker in the

enclosure. Installation of the cable between the handle

assembly and the breaker mechanism should be the final

step. The breaker operating mechanism is to be installed

onto the circuit breaker after the breaker has been

mounted in the enclosure.

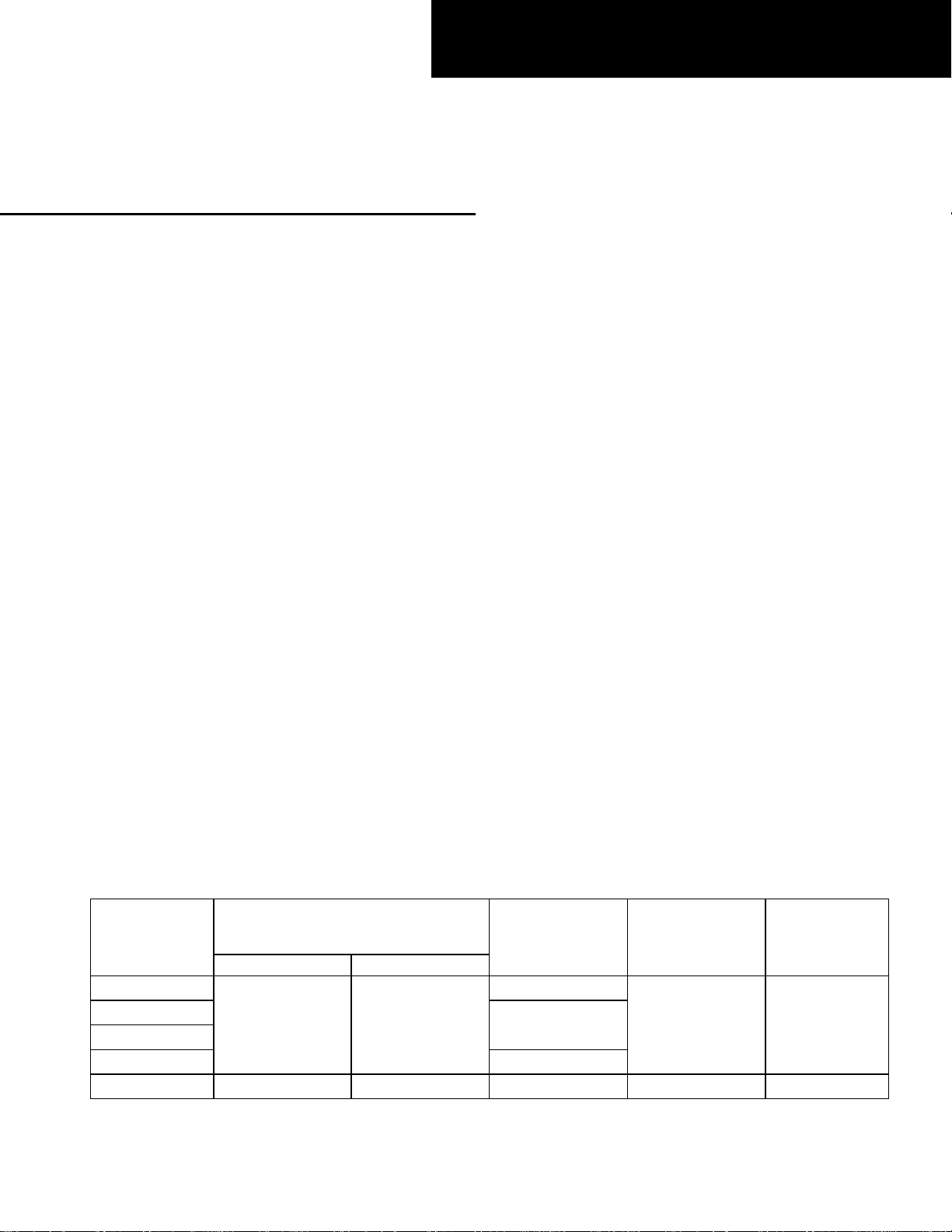

Table 1. Mechanism Selection Guide

Circuit Breaker

Type NEMA 1, 3R, 12, 13 NEMA 4/4X Cat. No. Cat. No. Series Instruction

E150 SCOM1A

SE150 SCH1 SCH1X

SF250 SCH2 SCH2X

SG600 SCOM1G

SK1200 SCH2K SCH2KX SCOM1K SC3H–SC10H GEH-6291

Handle Operating Mechanism Cat. No.

Breaker Operating

Mechanism

SC0M1EF

Operating Cable

SC3L–

SC10L

Cable Operator

Mechanism

Installation

GEH-6290

Page 2

Table 2. Circuit Breaker Mounting-Zone Dimensions

To determine maximum mounting dimensions for 60inch through 120-inch-long operating cables, add the

respective additional lengths to the 48-inch cable

maximum dimensions. (For example, add 12 inches to E,

F, and G dimensions for 60-inch cable length.)

Table 3. Circuit Breaker Mounting Dimension

Breaker Type A B C D Tap Size

E150 1.38 4.88 0.72 6.31 8-32

SE150 1.38 4.88 0.72 6.51 10-32

SF250 1.38 7.75 1.19 10.12 12-24

SG600 1.81 7.75 1.19 13.62 12-24

Maximum Dimensions in Inches

Enclosure

Depth

8 13.5 4.0 15.0 25.5 16.0 27.0

10 13.0 5.0 14.8 25.0 17.0 26.8

12 12.8 6.0 14.5 24.8 17.0 26.5

16 10.5 4.5 14.2 22.5 16.5 26.2

18 8.5 3.5 12.6 20.5 15.5 24.6

20 — 0.5 10.0 22.0 15.0 24.0

24 — — — 19.5 14.0 22.0

* Maximum E dimension only if F = 4.5”.

36” Cable 48” Cable

E* F G E* F G

When cable is installed, the minimum cable bend radius

should not be less than 3 inches. The minimum cable

bending requirement must be met to ensure a safe

operating environment.

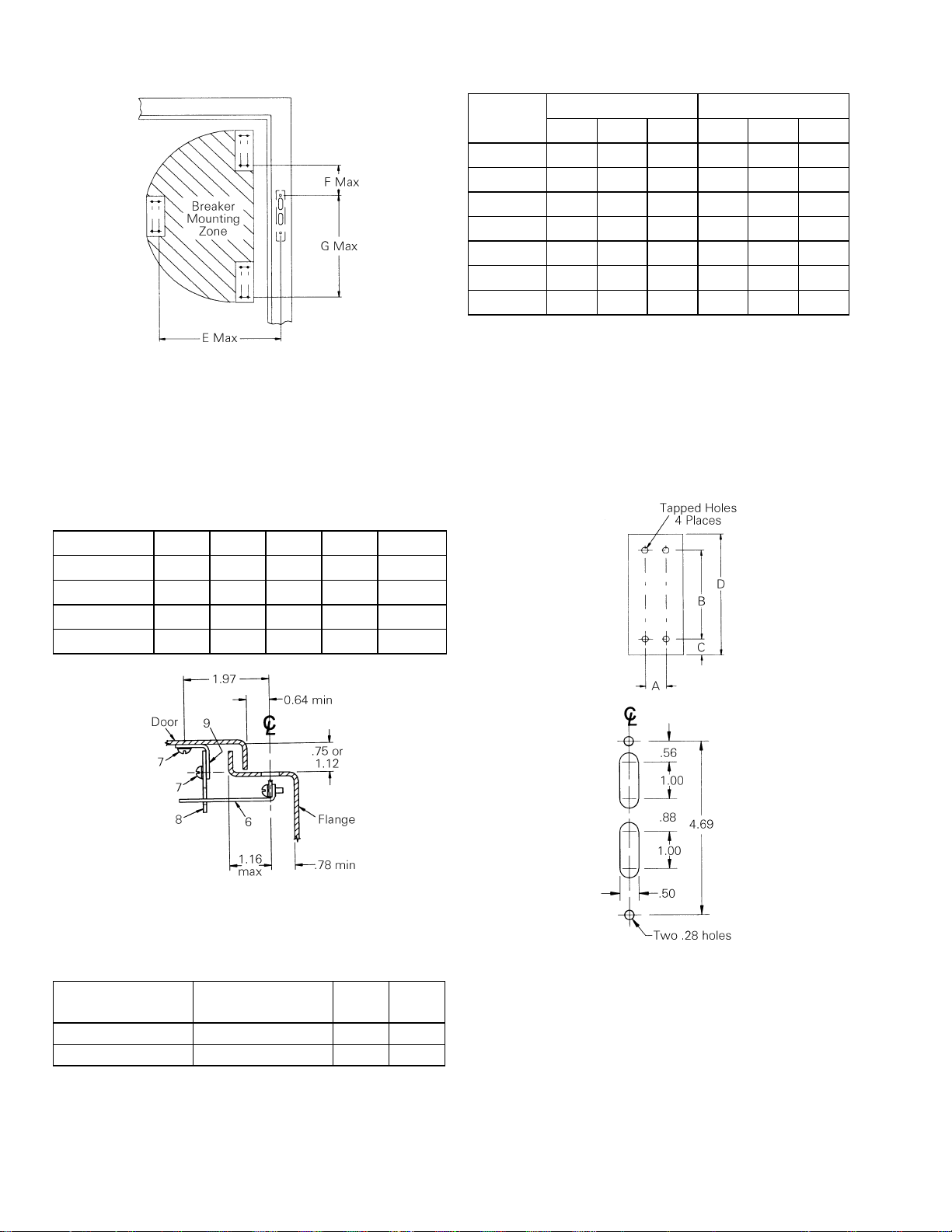

Figure 1. End view of flange and cover (right end shown).

Table 4. Handle Dimensions (see Figure 3)

NEMA 12

Handle Cat. No.

SCH1 SCH1X 6.04 2.38

SCH2, SCH2K SCH2X, SCH2KX 9.38 3.00

NEMA 4/4X

Handle Cat. No.

L

H

Figure 2. Flange details.

Page 3

Figure 3. Handle Installation.

Handle Installation

1. Referring to Figure 1, Figure 2, and Figure 3,

determine the location of the handle on the flange

of the enclosure. The handle can be mounted on

either the right or left side of the enclosure.

2. If the flange is not provided with handle holes and

slots, drill these as shown in Figures 1 and 2. Remove

any burrs.

3. Position the O-ring [5] in the groove in the handle.

Assemble the handle [1] and the cable adapter

assembly [2] to the flange of the enclosure with two

1

/4-20 x 5/8" hex-head screws [3] and lock washers

[4]. Tighten the screws to 35–45 in-lb.

4. Assemble the interlock blade [6] to the handle with

two #8-32 sems screws [7], as shown in Figure 1.

5. Assemble the drive arm extension to the handle drive

link with the connecting pin [12]. Secure the

connection with an E-ring [13], as shown in Figure 3.

6. Attach one end of the handle-return spring [14] to

the hole in the drive link and the drive arm

extension. Attach the other end to the hole in the

lower flange of the cable adapter assembly, as

illustrated in Figure 3.

7. Drill and tap two #8-32 holes in the cover, as shown

in Figures 1 and 3. Assemble the interlock bracket [9]

to the cover with two #8-32 sems screws [7] from

inside the door. Alternatively, the bracket may be

welded to the cover, using the dimensions noted with

an asterisk (*) in Figure 3, to locate the upper-left

corner of the bracket, as illustrated in Figure 1.

8. Assemble the interlock hook [8] to the interlock

bracket [9] with two #8-32 sems screws [7]. Use the

3

lower set of holes in the hook for a door with a

/4-

inch turned edge (as shown) or the upper set of

1

holes if the door has a 1.

/8-inch turned edge.

9. With the handle in the OFF position, attempt to close

the door. If the interlock blade interferes with the

interlock hook,

DO NOT

force the door closed.

Loosen the two #8-32 screws [7] and move the

interlock hook upward. The door should close

without interference. Attempt to turn the handle ON;

if the handle turns ON, loosen the two #8-32 screws

[7], secure the interlock hook, and move the hook

toward the bottom of the enclosure to provide more

depression of the interlock blade, thus preventing

the handle from engaging.

10. As the handle is moved to the ON position, the

interlock hook should engage the interlock blade,

preventing the door from opening unless the handle

interlock is manually disengaged by rotating

(clockwise) the interlock defeat button with a flatblade screw driver on the handle [1]. If the door can

be opened with the handle in the ON position

without having to defeat the interlock blade, readjust

the interlock hook downward and repeat steps 9 and

10.

11. Turn the handle to the OFF position. You should be

able to open the door. Note that if vault-type

interlock hardware (GE Cat. No. TDV1) or a similar

assembly has been installed, the door hardware must

first be defeated.

12. Proceed with installation of the drive cable and the

breaker operating mechanism per the instructions.

Page 4

Figure 4. Installation of SCOM1A

Install the E150 circuit breaker in the panel with two #8-

3

32 x 2

/4" screws [19] on the line end of the circuit

breaker.

Place the spacers [15] into the counterbore on the load

end of the E150 breaker mounting holes. With the

breaker in the OFF position, place the breaker operating

mechanism [16] on top of the breaker cover with the

breaker handle extending through the mechanism pivot

plate. Secure the operating mechanism to the breaker

on the line side with two thread-cutting screws [17].

Secure the operating mechanism and the circuit breaker

on the load side to the panel surface with two #8-32 x 4"

screws [18].

Figure 5. Installation of SCOM1EF

Install an SE150 circuit breaker in the panel with four

3

#8-32 x 2

breaker in the panel with four #12-24 x 3

/4" screws [24]. Install an SF250 circuit

3

/4" screws

[25].

Thread the spacers [20] into the counterbore (

5

/16"-dia.

holes) on the load end of the SE150 or SF250 circuit

breaker. Remove the two breaker cover screws on the

line end of the breaker, as shown, and discard. With the

circuit breaker in the OFF position, place the breaker

operating mechanism [21] on top of the breaker cover

with the breaker handle extending through the

mechanism pivot plate. Secure the operating

mechanism to the breaker line side with two 3.5 x 10

mm metric screws [22]. Secure the mechanism on the

load side with two #8-32 screws [23], threading them

into the spacers [20].

Figure 6. Installation of SCOM1G

1. Mount the circuit breaker to the panel using the

four special mounting bolts [28]. Thread size is

#10-32.

2. Secure the mechanism to the breaker using four

#10-32 screws [27], lock washers [33], and flat

washers [34].

Page 5

Figure 7. Cable Installation

Cable Installation

WARNING:

OFF power ahead of the device before accessory

installation.

until the power is turned OFF.

Use the following procedure to first install one end of the

operating cable to the operating handle, then the other

end to the breaker operating mechanism.

1. Slide a

the #10-32 x

threaded cable shank beyond the groove at the

middle of the shank. Install a

the hex nut. Screw the cable guide pin [30] onto the

same end of the cable all the way. Do not tighten.

2. Place the operating handle in the OFF position.

Position the cable behind the handle drive arm

linkage. Insert the groove of the cable (middle of the

cable shank threads) into the slot at the bottom of

the cable operator assembly. Tighten the

nut against the cable adapter assembly until it is

snug. Insert the cable guide pin [30] into the proper

mounting hole in the drive arm, as shown in Figure

7. Snap an E-ring [29] into the groove of the guide

pin [30].

3. Slide a

#10-32 x 3" thread. Install the nut onto the threaded

cable shank beyond the groove at the middle of the

Danger of electrical shock or injury. Turn

DO NOT

7

/16-20 hex nut onto the end of the cable with

7

/16-20 hex nut over the cable end with the

remove circuit protective devices

7

/8" thread. Install the nut onto the

7

/16" lock washer onto

7

/16" hex

7

shank. Install a

Thread two #10-32 hex nuts approximately 2

/16" lock washer onto the hex nut.

3

/4”

onto the threaded end of the cable. Rotate the pivot

bracket into position, as shown in Figure 7, and

insert the end of the cable through the pivot bracket.

Insert the groove of the cable into the slot on the

7

base plate. Tighten the

/16-20 hex nut against the

base plate flange until snug. With the breaker in the

OFF position, move the #10-32 hex nut up on the

cable shaft against the pivot bracket. Note the

position of the pivot bracket in Figure 7.

4. Verify that the power to the circuit breaker has been

turned off. Move the operating handle on the circuit

breaker to the ON position. Place the spring [31]

over the cable end. Thread the spring retainer [32]

onto the end of the cable and tighten to the installed

height of 1

Do not overtighten the retainer.

7

/16".

5. Move the operating handle ON and then OFF. If the

breaker does not turn ON, then, with the handle in

the OFF position, adjust the #10-32 hex nut toward

the pivot bracket until the breaker turns ON.

6. Trip the circuit breaker by pushing the TRIP button.

Move the operating handle to the OFF/RESET

position, then to ON. If the breaker resets, set the

7

spring retainer to the installed height of 1

/16". Lock

both #10-32 hex nuts against the pivot bracket.

7. If the breaker does not reset, back off the #10-32 hex

nuts, tighten the spring retainer, and repeat steps 5,

6, and 7.

Page 6

Parts List for SCH1, 1X, and SCH2, 2X

Item No. Description

1 Handle Assembly

2 Cable Adapter Assembly

3

4

5 O-Ring

6 Interlock Blade

7 #8-32 Sems Screws

8 Interlock Hook

9 Interlock Bracket

12 Connecting Pin

13 E-Ring (1/4” Shaft Dia.)

14 Handle Return Spring

29 E-Ring (3/8” Shaft Dia.)

30 Cable Guide Pin (#10-32)

Refer to Figures 3 and 7.

1

/4-20 x 5/8” Hex-Head Screw

1

/4” Lock Washer

Parts List for SCOM1EF

Item No. Description

20 Spacer

21 SE/SF Breaker Operating Mechanism

22 M3.5 x 10 mm Metric Screw

23 #8-32 x

24 #10-32 x 27/8” Screw (SE150)

25 #12-24 x 33/4” Screw (SF250)

31 Spring

32 Spring Retainer

Refer to Figures 5 and 7.

3

/8” Screw

Parts List for SCOM1A

Item No. Description

15 Spacer

16 E150 Breaker Operating Mechanism

17 #6-20 Thread-Cut Screw

18 #8-32 x 4” Screw

19 #8-32 x 23/4” Slotted RH Screw

31 Spring

32 Spring Retainer

Refer to Figures 4 and 7.

Parts List for SCOM1G

Item No. Description

20 Spacer

26 SG600 Breaker Operating Mechanism

27 #10-32 x

28 MOM Mounting Bolt

31 Spring

32 Spring Retainer

33 #10 Lock Washer

34 #10 Flat Washer

35 #10-32 Hex Nut

Refer to Figures 6 and 7.

3

/8” Screw

Replacement Parts

Description Part Number Quantity

O-Ring 343L889G15 1

Interlock Blade 343L889G2 1

Interlock Hook 343L889G3 1

Interlock Bracket 343L889G4 1

These instructions do not cover all details or variations in equipment nor do they provide for every possible

contingency that may be met in connection with installation, operation, or maintenance. Should further

information be desired or should particular problems arise that are not covered sufficiently for the purchaser’s

purposes, the matter should be referred to the GE Company.

g

GE Industrial Systems

General Electric Company

41 Woodford Ave., Plainville, CT 06062

GEH6290 R05 0508 © 1998 General Electric Company

Loading...

Loading...