Page 1

g

GEH-6412

GE Industrial Systems

Control System Toolbox

For an AV-300i Version 2 Drive

Page 2

Page 3

Publication: GEH-6412

Issued: 2000-03-03

Control System Toolbox

For an AV-300I Version 2 Drive

Page 4

© 2000 General Electric Company, USA.

All rights reserved.

Printed in the United States of America.

These instructions do not purport to cover all details or variations in equipment, nor to provide

every possible contingency to be met during installation, operation, and maintenance. If further

information is desired or if particular problems arise that are not covered sufficiently for the

purchaser’s purpose, the matter should be referred to GE Industrial Systems, Salem, Virginia,

USA.

This document contains proprietary information of General Electric Company, USA and is

furnished to its customer solely to assist that customer in the installation, testing, operation,

and/or maintenance of the equipment described. This document shall not be reproduced in whole

or in part nor shall its contents be disclosed to any third party without the written approval of GE

Industrial Systems.

ARCNET is a registered trademark of Datapoint Corporation.

Ethernet is a trademark of Xerox Corporation.

IBM is a registered trademark of International Business Machines Corporation.

Intel is a registered trademark of Intel Corporation.

Pentium is a registered trademark of Intel Corporation.

PC is a registered trademark of International Business Machines Corporation.

Series 90 is a trademark of GE Fanuc Automation North America, Inc.

Windows is a registered trademark of Microsoft Corporation.

Windows NT is a registered trademark of Microsoft Corporation.

Page 5

Safety Symbol Legend

Indicates a procedure, condition, or statement that, if

not strictly observed, could result in personal injury or

death.

Indicates a procedure, condition, or statement that, if

not strictly observed, could result in damage to or

destruction of equipment.

Indicates a procedure, condition, or statement that

should be strictly followed in order to optimize these

applications.

Note Indicates an essential or important procedure, condition, or statement.

Page 6

To prevent personal injury or equipment damage

caused by equipment malfunction, only adequately

trained personnel should modify any programmable

machine.

The example and setup screens in this manual do not

reflect the actual application configurations. Be sure to

follow the correct setup procedures for your application.

Page 7

5HDGHU&RPPHQWV

*HQHUDO(OHFWULF&RPSDQ\

:HZHOFRPHFRPPHQWVDQGVXJJHVWLRQVWRPDNHWKLVSXEOLFDWLRQPRUHXVHIXO

7R

*(,QGXVWULDO6\VWHPV

'RFXPHQWDWLRQ'HVLJQ5P

5RDQRNH%OYG

6DOHP9$86$

)D[

*(,QWHUQDO'&

<RXU1DPH 7RGD\¶V'DWH

<RXU&RPSDQ\¶V1DPHDQG$GGUHVV -RE6LWH

*(5HTXLVLWLRQ1R

3XEOLFDWLRQ1R<RXU-RE)XQFWLRQ+RZ<RX8VH7KLV3XEOLFDWLRQ

3XEOLFDWLRQ,VVXH5HYLVLRQ'DWH

*HQHUDO5DWLQJ

([FHOOHQW *RRG )DLU 3RRU $GGLWLRQDO&RPPHQWV

&RQWHQWV BBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBB

2UJDQL]DWLRQ BBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBB

7HFKQLFDO$FFXUDF\ BBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBB

&ODULW\ BBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBB

&RPSOHWHQHVV BBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBB

'UDZLQJV)LJXUHV BBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBB

7DEOHV BBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBB

5HIHUHQFLQJ BBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBB

5HDGDELOLW\ BBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBB

,IQHHGHGKRZFDQZHFRQWDFW\RX"

)D[1R

3KRQH1R

(PDLO

$GGUHVV

6SHFLILF6XJJHVWLRQV

3DJH1R &RPPHQWV

&RUUHFWLRQVLQIRUPDWLRQWKDWFRXOGEHH[SDQGHGRQDQGVXFK

______ __________________________________________________________________________________

______ __________________________________________________________________________________

______ __________________________________________________________________________________

______ __________________________________________________________________________________

______ __________________________________________________________________________________

______ __________________________________________________________________________________

2WKHU&RPPHQWV:KDW\RXOLNHZKDWFRXOGEHDGGHGKRZWRLPSURYHDQGVXFK BBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBB

___________________________________________________________________________________________

___________________________________________________________________________________________

___________________________________________________________________________________________

___________________________________________________________________________________________

___________________________________________________________________________________________

___________________________________________________________________________________________

2YHUDOOJUDGH&RPSDUHGWRSXEOLFDWLRQVIURPRWKHUPDQXIDFWXUHUVRIVLPLODUSURGXFWVKRZGR\RXUDWHWKLVSXEOLFDWLRQ"

6XSHULRU &RPSDUDEOH ,QIHULRU 'RQRWNQRZ &RPPHQW BBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBB

'HWDFKDQGID[RUPDLOWRWKHDGGUHVVQRWHGDERYH

Page 8

)ROGKHUHDQGFORVHZLWKVWDSOHRUWDSH

BBBBBBBBBBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBBBBBBBBBB

*(,QGXVWULDO6\VWHPV

'RFXPHQWDWLRQ'HVLJQ5P

5RDQRNH%OYG

6DOHP9$86$

3ODFH

VWDPS

KHUH

)ROGKHUHILUVW

Page 9

••••

Contents

Chapter 1 Overview 1-1

Introduction...................................................................................................................... 1-1

Before Beginning.............................................................................................................. 1-1

Chapter 2 Installation 2-1

Introduction...................................................................................................................... 2-1

Computer Requirements.................................................................................................... 2-1

Installing Control System Solutions .................................................................................. 2-2

Chapter 3 Using the Toolbox 3-1

Introduction...................................................................................................................... 3-1

Upgrading from Previous Releases.................................................................................... 3-2

Starting the Toolbox ......................................................................................................... 3-3

Accessing Online Help...................................................................................................... 3-5

Privileges and Passwords.................................................................................................. 3-5

Toolbox Options............................................................................................................... 3-8

Connecting the Toolbox...................................................................................................3-12

How To Use This Manual ................................................................................... 1-1

Conventions........................................................................................................ 1-2

Registration License Agreement.......................................................................... 2-2

Destination Directory .......................................................................................... 2-3

Product Selection ................................................................................................ 2-3

Uninstall Products............................................................................................... 2-4

Maintaining Multiple Releases of Toolbox........................................................... 3-2

Work Area.......................................................................................................... 3-3

Privilege Levels .................................................................................................. 3-5

Change Password or Default Password Directory................................................. 3-7

General............................................................................................................... 3-8

Directories .......................................................................................................... 3-9

Trend Recorder ..................................................................................................3-10

AVDV Series Drive ...........................................................................................3-11

Chapter 4 Configuring an AV-300i Version 2 Drive 4-1

Introduction...................................................................................................................... 4-1

Creating an AV-300i Version 2 Drive ............................................................................... 4-1

Pattern and Version............................................................................................. 4-2

Drive Size........................................................................................................... 4-2

Enter User Identification ..................................................................................... 4-3

Configuring the Drive....................................................................................................... 4-4

Modifying Drive Properties................................................................................. 4-4

Validating the Drive............................................................................................ 4-5

Entering Job-Specific Information....................................................................... 4-5

Working with Files and Menus.......................................................................................... 4-6

GEH-6412 Toolbox for AV-300i Version 2 Drive Contents

i

Page 10

••••

File Types........................................................................................................... 4-6

Opening and Closing Files................................................................................... 4-7

Saving Files ........................................................................................................ 4-7

Upgrading a Configuration.................................................................................. 4-7

Exporting Configuration Files ............................................................................. 4-9

Exporting and Opening Project Files.................................................................... 4-9

Menu Commands...............................................................................................4-10

Concepts..........................................................................................................................4-15

Configuration ..................................................................................................................4-16

Parameters.........................................................................................................4-16

Toolbox/Drive Communications.........................................................................4-17

Connecting to an AV-300i Version 2 Drive ........................................................4-18

Uploading Parameter Values ..............................................................................4-18

Downloading Parameter Values..........................................................................4-19

Downloading Firmware......................................................................................4-19

Block Diagram ................................................................................................................4-20

Links to Other Pages ..........................................................................................4-20

Modify Parameters from Diagram ......................................................................4-21

Parameter Jumpers.............................................................................................4-21

Live Data Display..............................................................................................4-21

Drag-and-Drop Variables ...................................................................................4-22

Printing Diagrams ..............................................................................................4-22

Drive Controls.................................................................................................................4-23

Wizards...........................................................................................................................4-23

Choose a Wizard................................................................................................4-24

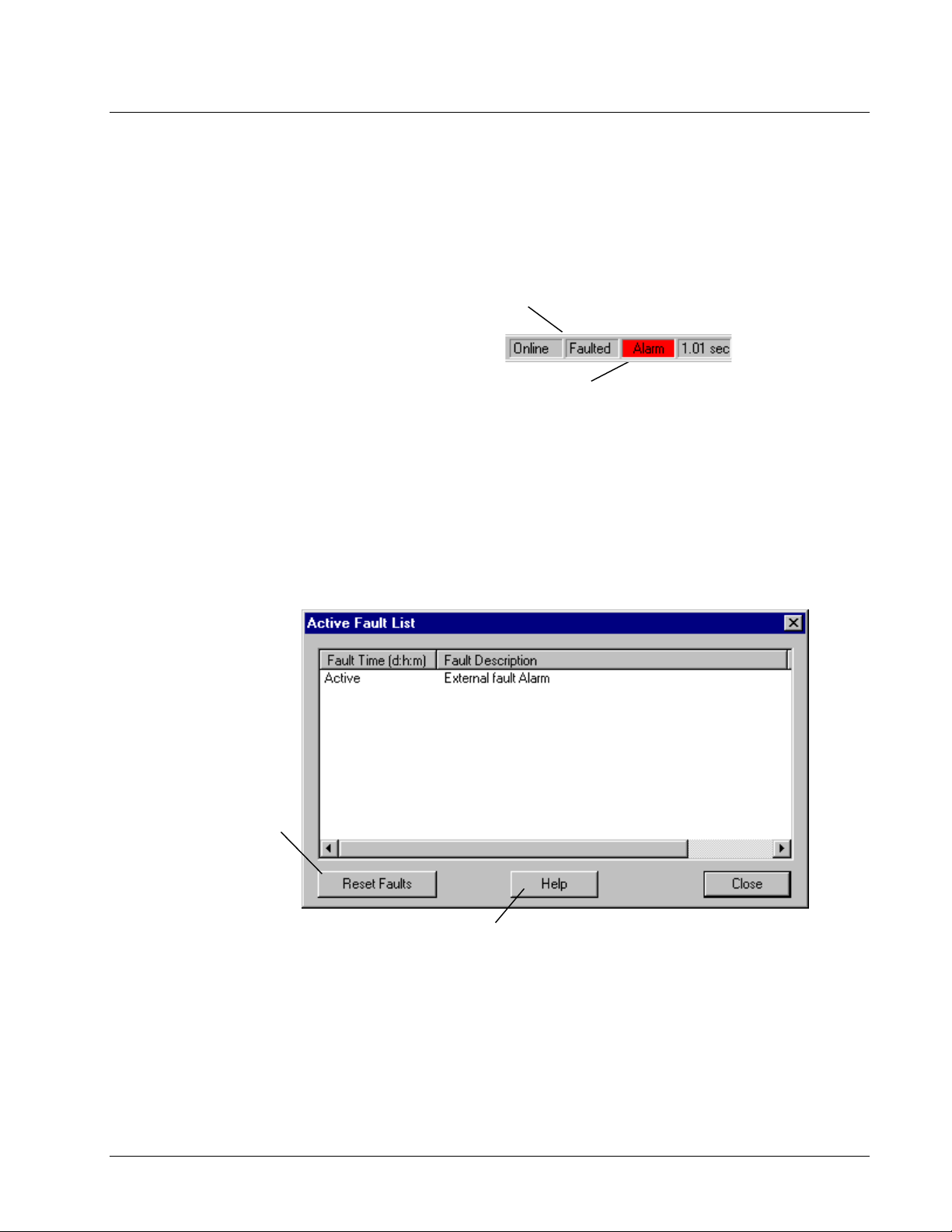

Fault Display ...................................................................................................................4-25

Active Fault .......................................................................................................4-25

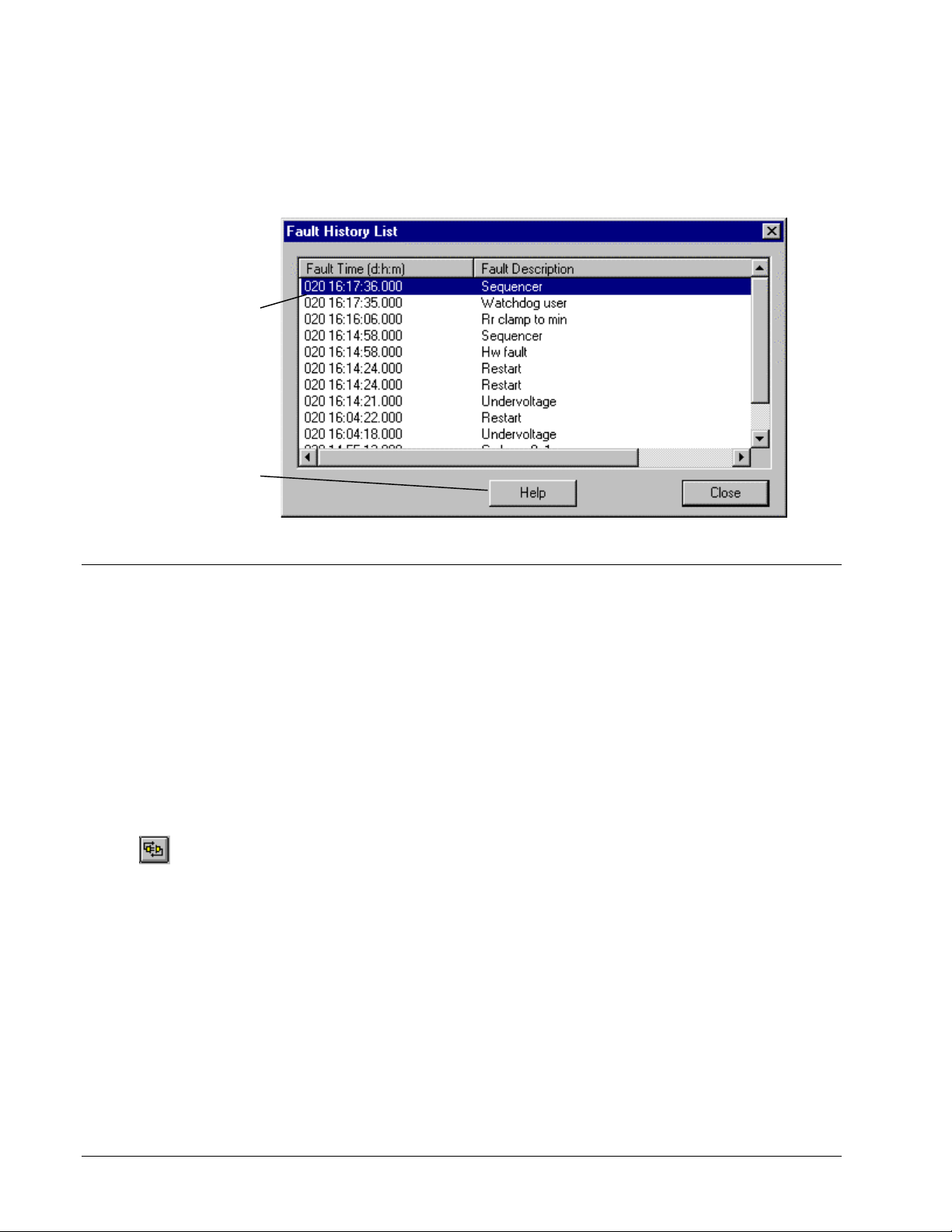

Fault History......................................................................................................4-26

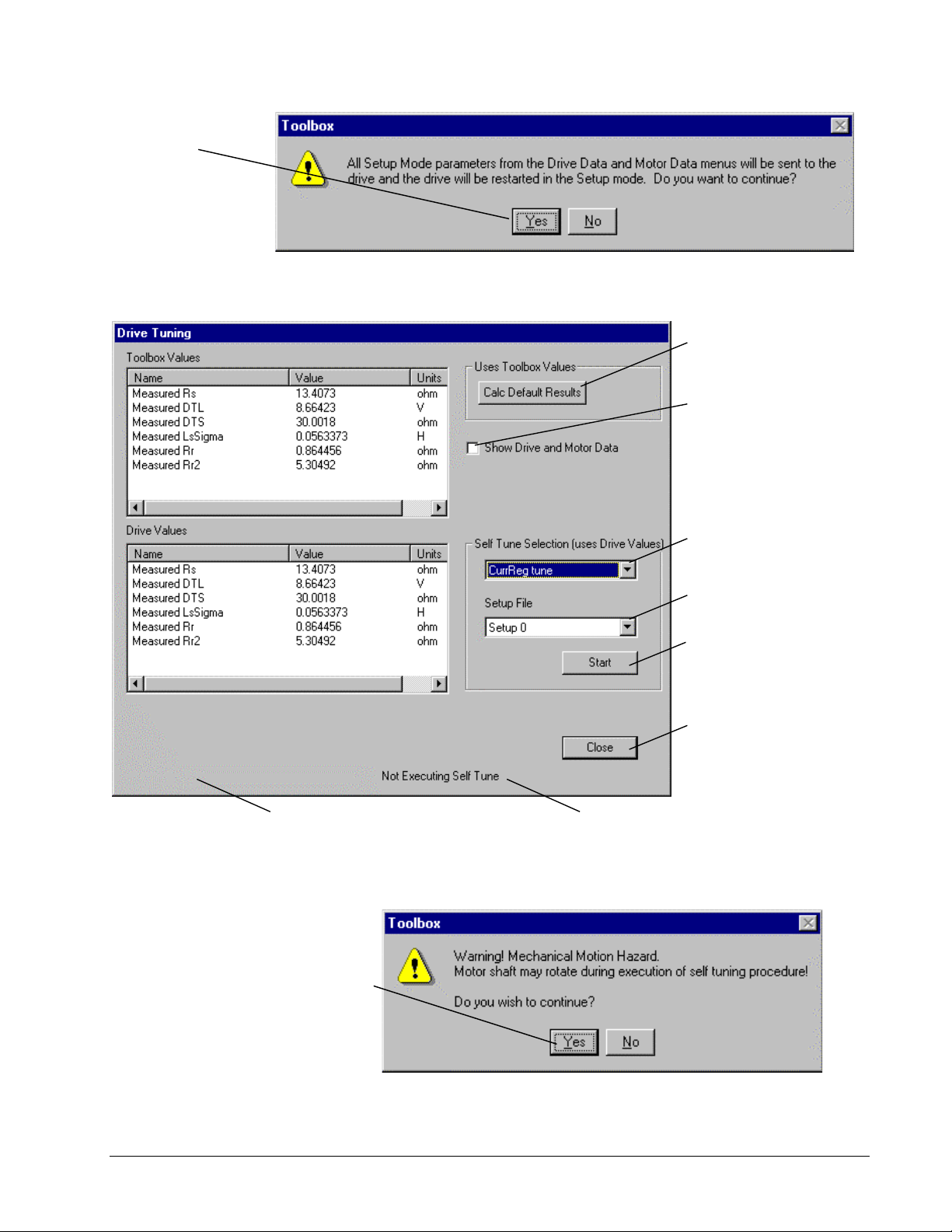

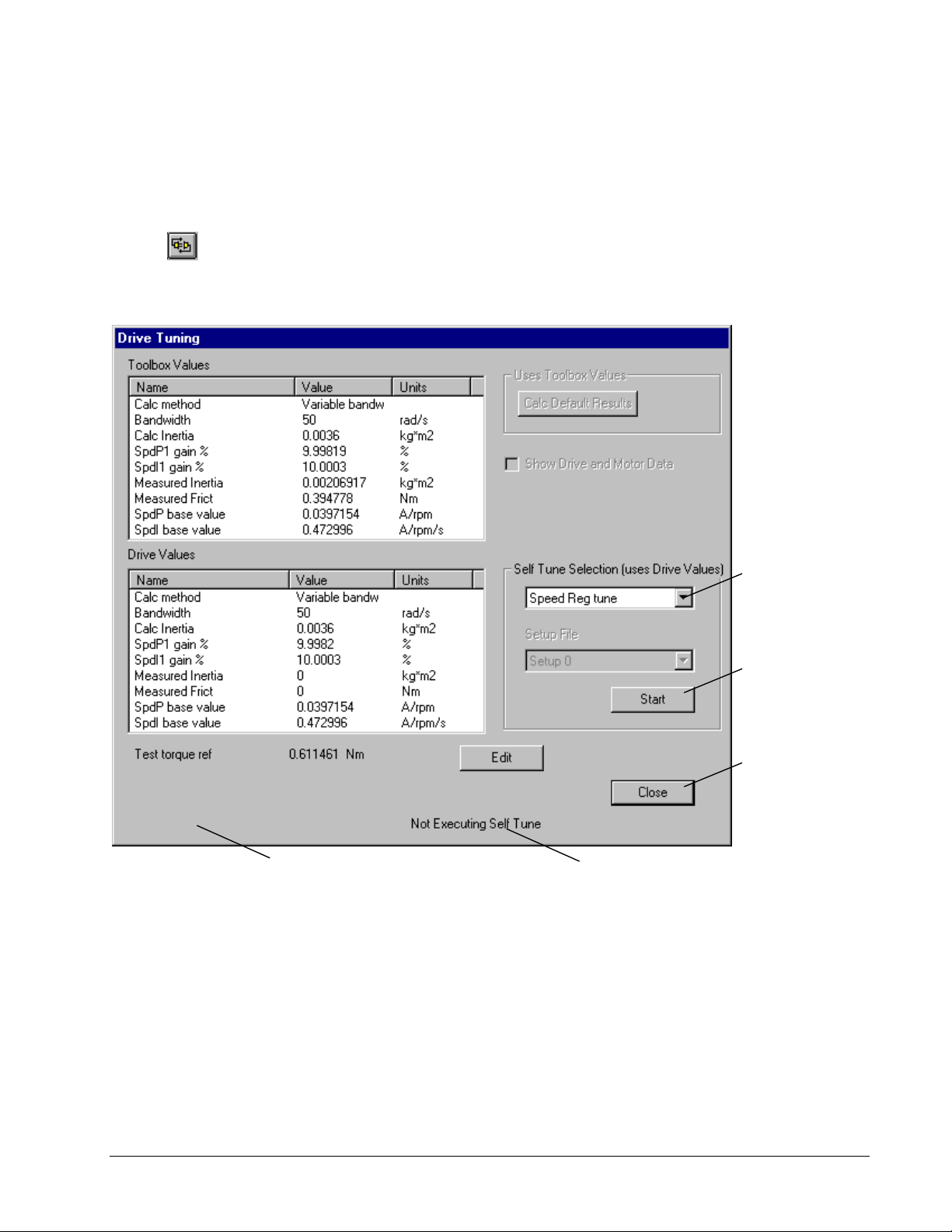

Self-Tune.........................................................................................................................4-26

Self-tune the Current Regulator ..........................................................................4-26

Self-tune the Speed Regulator ............................................................................4-29

Using the Finder ..............................................................................................................4-30

Finder Window..................................................................................................4-30

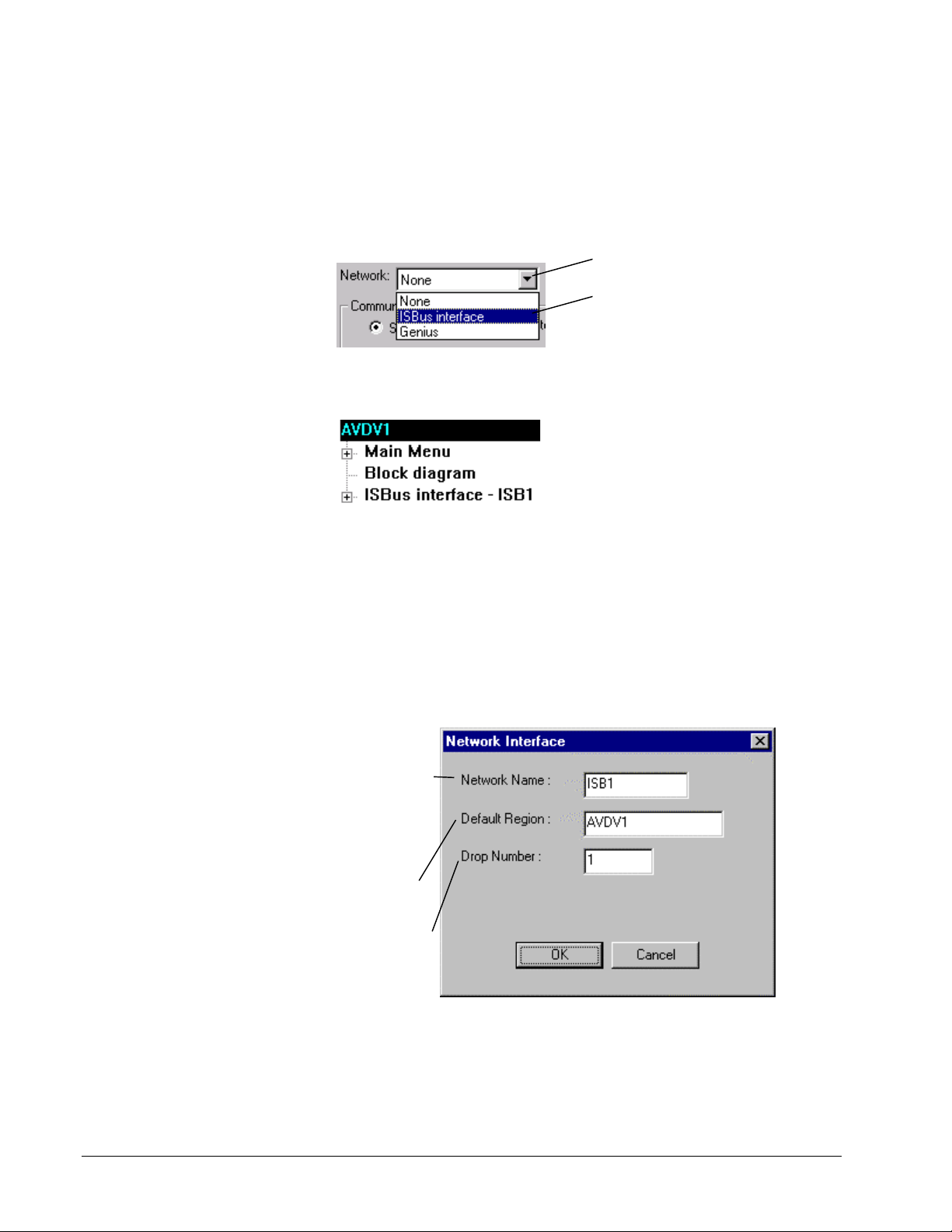

ISBus Configuration ........................................................................................................4-31

Adding an ISBus to Configuration......................................................................4-32

Editing an ISBus ................................................................................................4-32

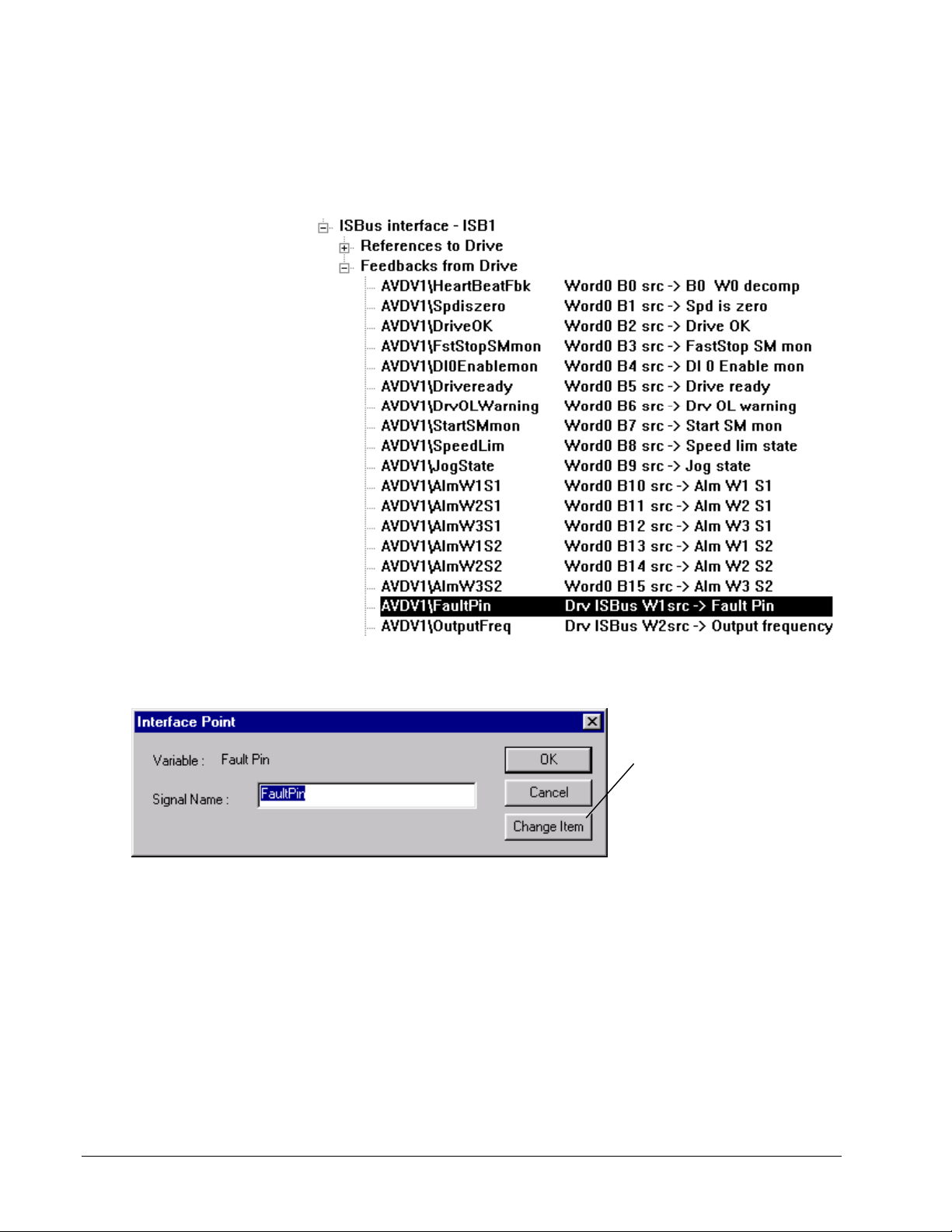

ISBus Pages.......................................................................................................4-33

Setting References from ISBus to Drive..............................................................4-33

Feedbacks from Drive to the ISBus.....................................................................4-34

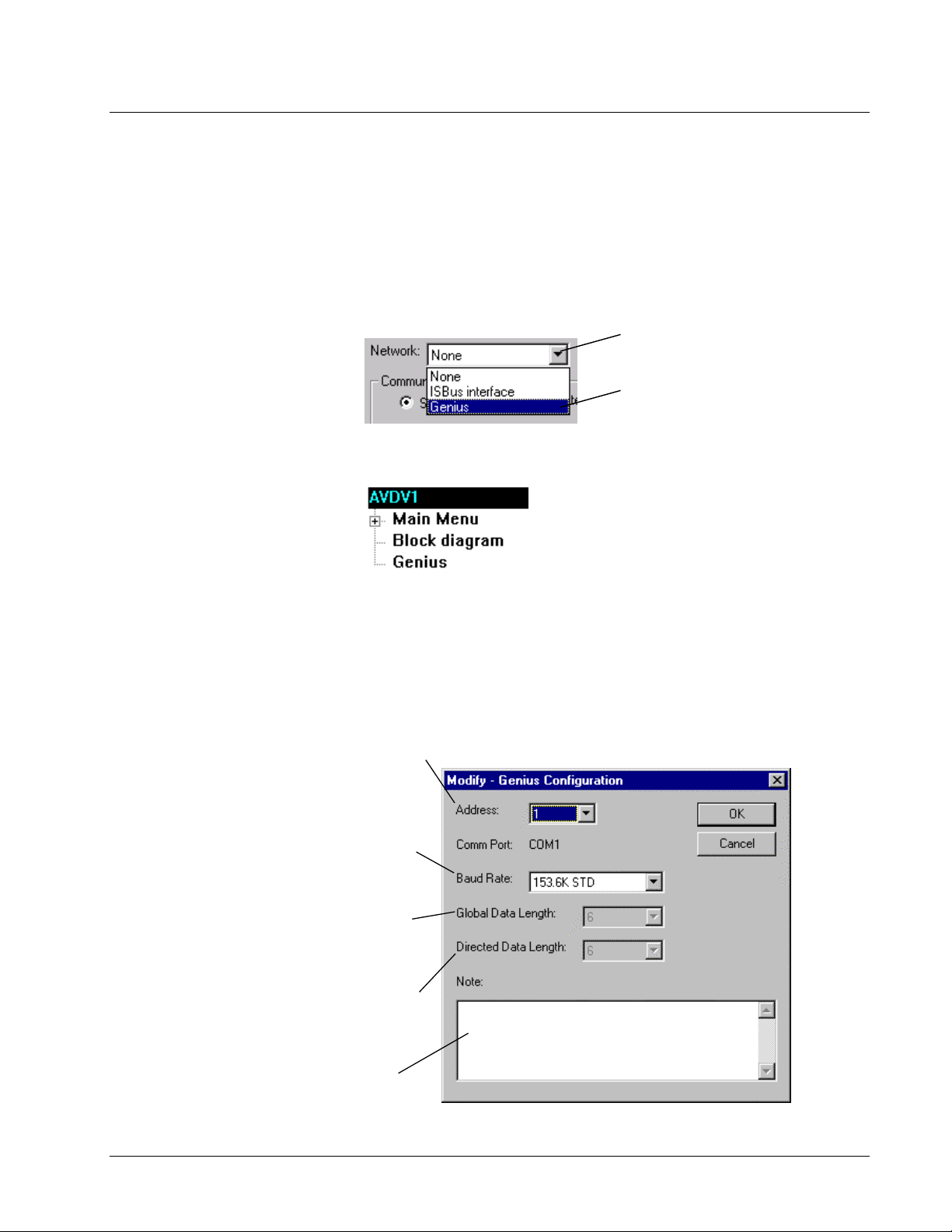

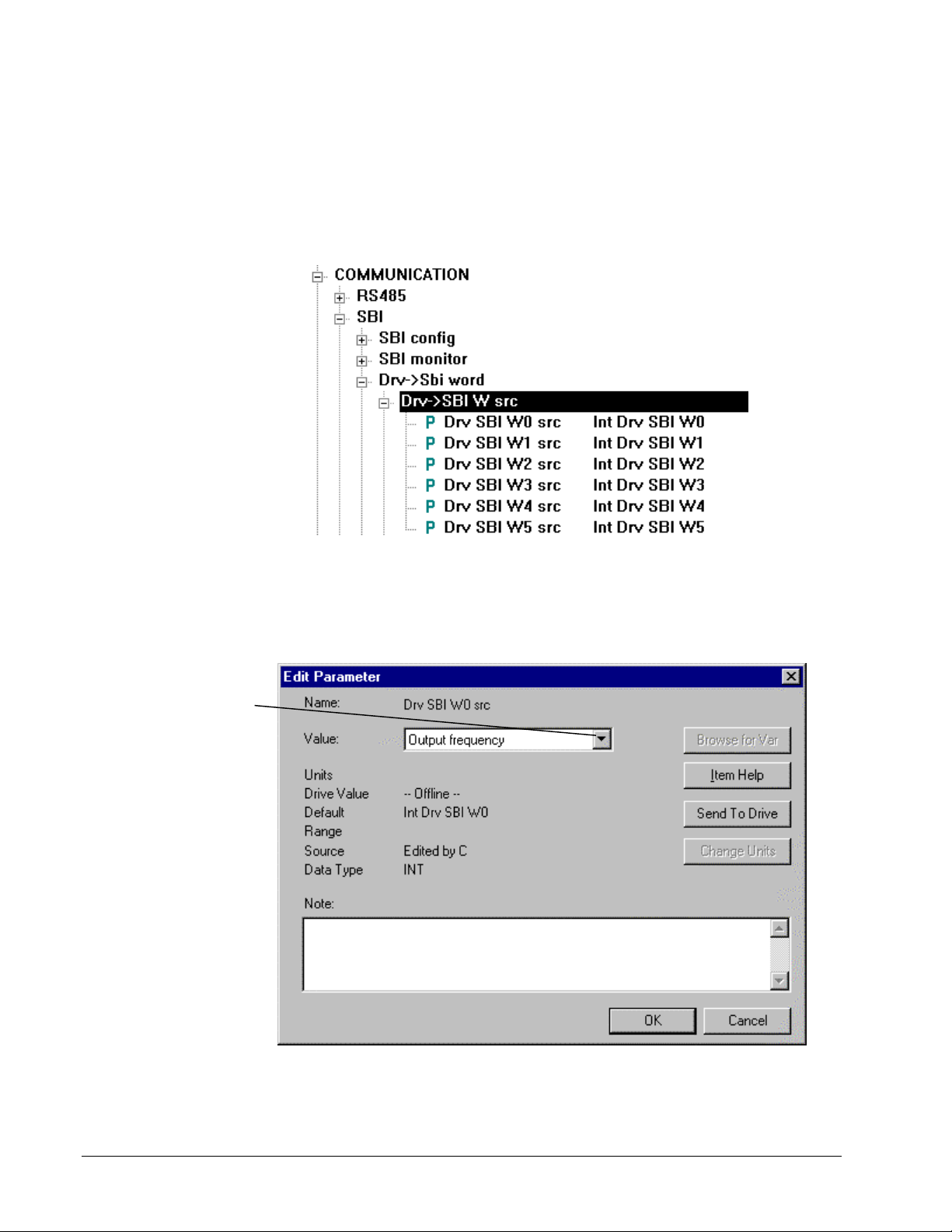

Genius Configuration.......................................................................................................4-35

Global Data and Directed Control Data...............................................................4-36

Downloading and Uploading..............................................................................4-37

Glossary of Terms

Index

ii

Contents GEH-6412 Toolbox for AV-300i Version 2 Drive

Page 11

••••

Chapter 1 Overview

Introduction

This manual describes the Control System Toolbox, which is personal computer

(PC)-based software used to configure and maintain the AV-300i™ Version 2 drive.

The toolbox is a Windows

higher PC.

Primary functions of the toolbox include:

®

-based application, which runs on a Pentium® 166 or

The toolbox software configures

various control equipment.

Therefore, each product package

can consist of the toolbox,

product files for the drive, and

Trend Recorder. To order the

toolbox software and specific

product support files, refer to the

Product Catalog, GEP-9145.

Before Beginning

Windows-based screen

borders may vary in

appearance.

• Configuration wizards

• Live data block flow diagrams

• Online Help files

• Input/Output (I/O) configuration and monitoring

• Signal management and signal trending

• Generate reports

This manual describes the features of the toolbox and presents step-by-step

procedures for using the software applications provided. It presumes that the user

has already installed Windows. This manual also assumes that the user possesses at

least a medium-level knowledge of Windows. Hardware requirements and

instructions for installing the products are provided in Chapter 2.

How To Use This Manual

This manual provides information on installing the toolbox and other products used

to configure control equipment. It also describes other features provided in the

toolbox software package. This manual is organized as follows:

Chapter 1 Overview. This chapter defines functions of the toolbox, contents of this

manual, and the conventions used.

Chapter 2 Installation. This chapter describes the PC and installation requirements

for the AV-300i Version 2 drives.

GEH-6412 Toolbox for AV-300i Version 2 Drive Chapter 1 Overview

1-1

Page 12

••••

Chapter 3 Using the Toolbox. This chapter provides basic startup procedures and

features for using the toolbox to configure a product.

Chapter 4 Configuring an AV-300i Version 2 Drive. This chapter describes how

to use the toolbox to configure a drive.

Glossary. The Glossary provides definitions of configuration terms and toolbox

concepts.

Refer to the Table of Contents for the organization of these chapters.

Conventions

The following conventional terms, text formats, and symbols are used throughout

this documentation for the toolbox.

Convention Meaning

Bold

Arial Bold Indicates the menu, actual command or option that is chosen

Italic Indicates a word used as a word or a letter used as a letter. For

UPPERCASE

Monospace

Ø Indicates a procedure.

w Indicates a procedure with only one step.

•

The following list presents some basic guidelines for working with menus:

When a menu is displayed, press the up/down arrow keys to highlight a command

name. Then press Enter to choose the menu command. The menu can also be

selected by clicking with a cursor-positioning device (CPD), such as a mouse.

Indicates that the word is being defined.

from a menu, a button, or title of a dialog box.

example, the display should now read SDB has stopped. Italic

also indicates new terms, margin notes, and the titles of figures,

chapters, and other books in the toolbox package.

Indicates a directory, filename, or block name. Lowercase letters

can be used when typing names in a dialog box or at the

command prompt, unless otherwise indicated for a specific

application or utility.

Represents examples of screen text or words and characters that

are typed in a text box or at the command prompt.

Indicates a list of related information, not procedural steps.

When a command ends in an ellipsis (…), the application displays a dialog box that

asks the user to supply more information.

If a command turns a feature on and off, a checkmark (ü) is displayed by the

command name when the feature is on.

When a command ends with an arrow (

command names.

If a command name is grayed out, it indicates that the command does not apply to

the current situation or there is another selection or action before choosing the

command.

1-2

Chapter 1 Overview GEH-6412 Toolbox for AV-300i Version 2 Drive

), the menu cascades to display more

Page 13

••••

Related Publications

GE provides system instruction manuals that include publications for the different

components of each product. If additional manuals are needed or for questions about

the publications, contact the nearest GE sales office or authorized GE sales

representative. Also, refer to the following publications for more information about

AVDV Series equipment:

• GEH-6641, AV-300i Version 2 User's Manual

• GEI-100275, 6KCV300CTI Instruction Book

• GEI-100360, AV-300i Adjustable Speed Drives

• GEI-100429, AV-300i Version 2 Hardware Manual and Quick Startup Guide

GEH-6412 Toolbox for AV-300i Version 2 Drive Chapter 1 Overview

1-3

Page 14

••••

Notes

1-4

Chapter 1 Overview GEH-6412 Toolbox for AV-300i Version 2 Drive

Page 15

••••

Chapter 2 Installation

Introduction

This chapter describes the PC and installation requirements for the products in

Control System Solutions. The contents of this CD depend on the products that are

ordered. Some orders are issued a License Key. Available products display in the

Product Selection dialog box (see the section, Product Selection).

Section Page

Computer Requirements...................................................................................... 2-1

Installing Control System Solutions..................................................................... 2-2

Registration License Agreement ................................................................... 2-2

Destination Directory ................................................................................... 2-3

Product Selection ......................................................................................... 2-3

Uninstall Products........................................................................................ 2-4

Computer Requirements

The minimum PC requirements are determined by the selected product combination

and the topology configuration of the PC(s). The minimum requirements to use the

Control System Solutions products are as follows:

• 100 MHz processor (Pentium 166 or higher recommended)

A cursor-positioning device is

highly recommended.

GEH-6412 Toolbox for AV-300i Version 2 Drive Chapter 2 Installation

• Microsoft

• VGA display (640 x 480 x 16 color or gray scale)

• 16 MB RAM in Windows 95 (32 MB recommended) or 24 MB RAM in

Windows NT (32 MB recommended)

• Serial port for direct connection to a drive

• Printer (with appropriate Windows driver installed)

®

Windows® 95 or Windows NT® 4.0

2-1

Page 16

••••

Installing Control System Solutions

For assistance, contact:

GE Industrial Systems

Product Service Engineering

1501 Roanoke Blvd.

Salem, VA 24153-6492 USA

Phone:

+ 1 800 533 5885

(USA, Canada, Mexico)

+ 1 540 378 3280

(International)

Fax: + 1 540 387 8606 (All)

(replace + with the

international access code)

Install the desired products

from CD, following the

directions on the screen.

Then, install each product

file.

Control System Solutions installs various products for control systems as selected in

the setup program. It is recommended that you exit all Windows programs before

beginning. A dialog box may prompt you for a License Key, which can be found on

the actual CD. Also, you must agree to the standard Software License Agreement for

these products.

A default destination directory is set for all products selected. This directory can be

modified, but only during the first installation. Setup installs the required

components and checks available disk space before copying files. You can also

choose to cancel setup and exit at any time before you initiate the selected products.

ØØØØ To install from a CD

1. Place the Control System Solutions CD in the disk drive.

2. The Setup program executes automatically.

3. Follow the Setup instructions from the screen.

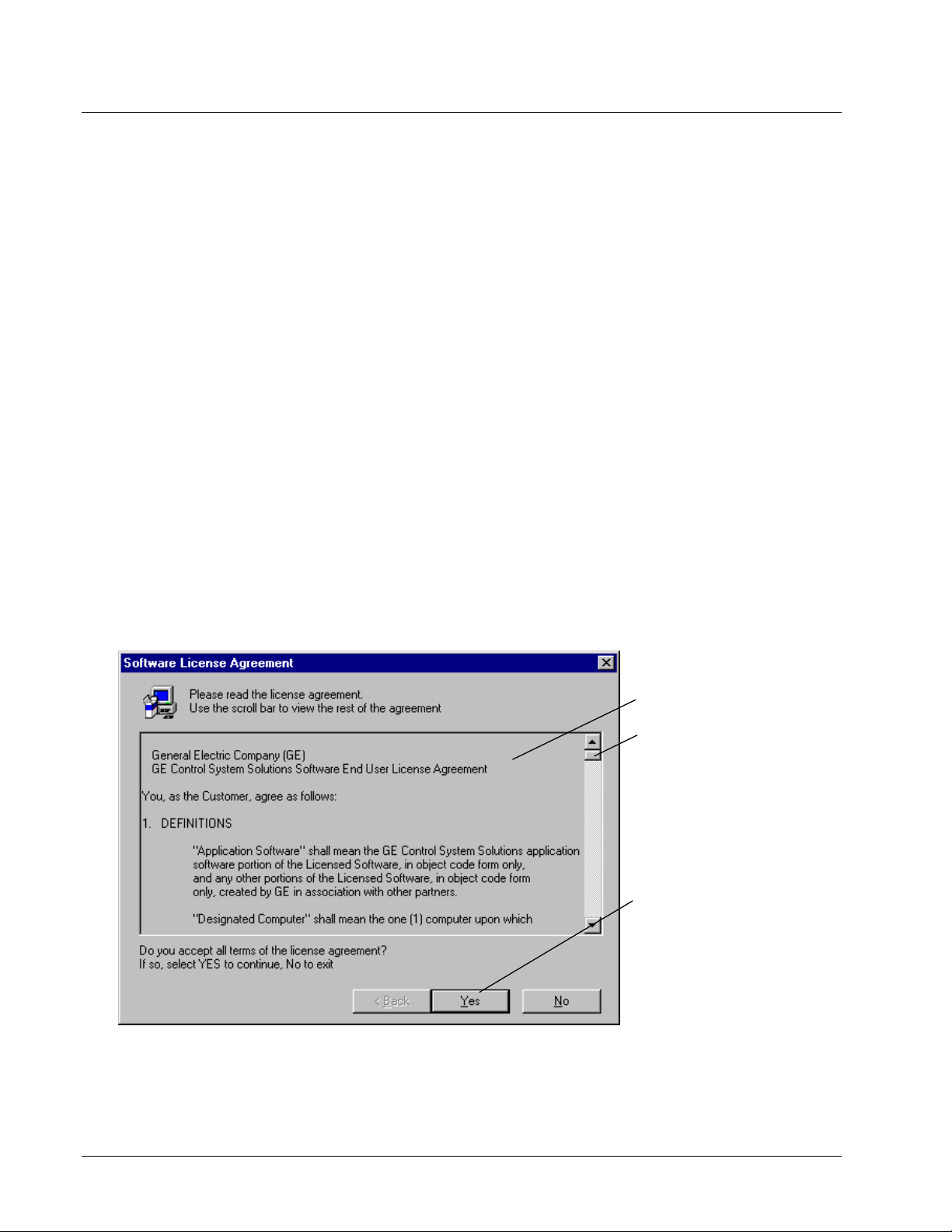

Registration License Agreement

The Software License Agreement dialog box displays during installation. The license

must be read and agreed to before installation can continue.

Please read the entire

agreement (scroll bar

must be at the bottom of

the dialog box).

Click

Yes

to accept the

agreement.

2-2

Chapter 2 Installation GEH-6412 Toolbox for AV-300i Version 2 Drive

Page 17

••••

Destination Directory

The Choose Destination Directory dialog box displays during the initial installation.

All future installs and upgrades default to the first directory selected.

The destination directory for

each product is set to the

default directory

Files\GE Control System

Solutions

different directory to load the

products.

Click to advance

through the setup.

C:\Program

. If desired select a

Setup automatically continues to load. The GE Control System Solutions product

selection dialog box displays to allow you to select desired products.

Product Selection

Tip ÄÄÄÄ From the Product Selection dialog box, click on a product (highlight) to

display its description and required disk space. The total required space for all

checked items and the space available displays at the bottom of the dialog box.

Click to the left of each

product you want to install.

A check mark displays

beside the product name.

Selecting a product name in

the left column checks all the

application for that group.

Click again to uncheck all.

The number beside each

product indicates the amount

of space required for the

selected product.

A description of each product

displays when it is selected.

Click to advance in the setup

process.

GEH-6412 Toolbox for AV-300i Version 2 Drive Chapter 2 Installation

2-3

Page 18

••••

Uninstall Products

Although it is not necessary,

it is highly recommended that

you uninstall the earlier

version when upgrading to

the new release.

Note Before upgrading to Release 6, product components should be uninstalled

and then installed again using the Release 6 CD or network installation.

ØØØØ To uninstall product(s)

1. Click Windows

click

2. From the Control Panel dialog box, double-click on Add/Remove

Programs. The Add/Remove Program Properties dialog box displays.

3. Click on the tab Install/Uninstall. A list of all installed programs displays.

4. From the list box, click on the program to uninstall.

5. Click

The following screen displays to show when uninstall is complete and the status of

all items deleted.

Control Panel.

button, select Settings, and then

.

2-4

Chapter 2 Installation GEH-6412 Toolbox for AV-300i Version 2 Drive

Page 19

••••

Chapter 3 Using the Toolbox

Introduction

Settings options should be

determined before starting a

configuration.

This chapter provides basic instructions for using the toolbox. It defines the toolbox

menu commands, including the Options menu, which has a Settings dialog tab for

each product. Methods of communication and toolbox connections are also

described.

Section Page

Upgrading from Previous Releases ...................................................................... 3-2

Maintaining Multiple Releases of Toolbox.................................................... 3-2

Starting the Toolbox............................................................................................ 3-3

Work Area ................................................................................................... 3-3

Accessing Online Help........................................................................................ 3-5

Privileges and Passwords..................................................................................... 3-5

Privilege Levels............................................................................................ 3-5

Change Password or Default Password Directory.......................................... 3-7

Toolbox Options ................................................................................................. 3-8

General ........................................................................................................ 3-8

Directories ................................................................................................... 3-9

Trend Recorder ...........................................................................................3-10

AVDV Series Drive.....................................................................................3-11

Connecting the Toolbox .....................................................................................3-12

GEH-6412 Toolbox for AV-300i Version 2 Drive Chapter 3 Using the Toolbox

3-1

Page 20

••••

Upgrading from Previous Releases

Note To upgrade to Version 6 of the toolbox, it is recommended that you first

uninstall any previous version of toolbox.

Maintaining Multiple Releases of Toolbox

To maintain different releases of the toolbox on a single system, consider the

following:

• Multiple versions of Release 5 or higher cannot be installed on one system.

The installation directory for Release 5 or higher of the toolbox is chosen only

once, the first time that the Control System Solutions products are installed. The

default directory is C:\Program Files\GE Control System Solutions.

• There is only one set of toolbox options settings for a given user on a given

computer. There are several toolbox options settings that may need to be unique

to a particular release of toolbox. For example, Release 4 of the toolbox would

probably need a different directory setting for standard library .tre files than that

of Release 5 or 6. In order to use multiple releases, it is recommended to use

different user accounts for each release.

• Opening a toolbox file from the Windows Explorer is not recommended if

multiple copies of toolbox are installed. When you open a file from the

Windows Explorer, the application that starts up depends on what is registered

for that file type. Releases of toolbox prior to Release 5 register each time they

execute. Release 5 or higher of toolbox, however, registers only at installation.

• Modifying a toolbox file can make the file unusable to older releases of

toolbox. A warning dialog displays when the toolbox opens a file that was

written by a previous release. Do not save the file if it must be used by the

previous release.

3-2

Chapter 3 Using the Toolbox GEH-6412 Toolbox for AV-300i Version 2 Drive

Page 21

••••

Starting the Toolbox

The toolbox is started from the Windows NT or 95 Workstation.

ØØØØ To start the toolbox

To create a device, refer to

Chapter 4.

1. Click Windows

Solutions and Control System Toolbox.

2. Click the toolbox icon. The toolbox Work Area displays. It is blank until a

device is created or opened.

button, Programs, GE Control System

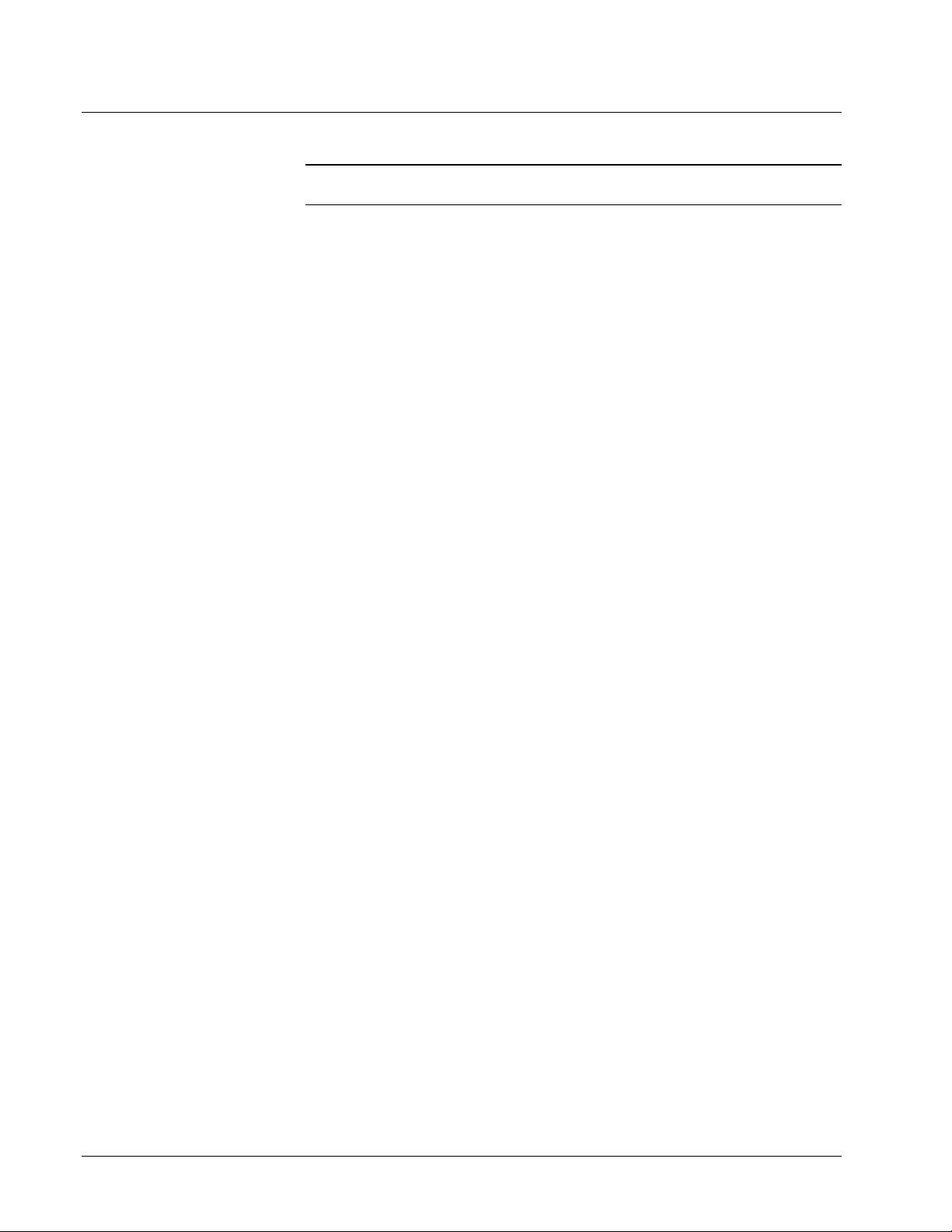

Work Area

If more than one drive is open

in the Work Area, each drive

will have a window with an

Outline View and Summary

View.

Click

Detached Summary View.

GEH-6412 Toolbox for AV-300i Version 2 Drive Chapter 3 Using the Toolbox

to display the

A drive’s runtime action is configured using the toolbox. From the File menu, begin

a New configuration or Open a previously saved configuration file. The toolbox

Work Area is the main screen and contains the following:

Outline View (left side) displays the configuration in a hierarchy, with the drive

name as the first item and other configuration items listed in levels below it.

Summary View (right side) displays information for the item highlighted in the

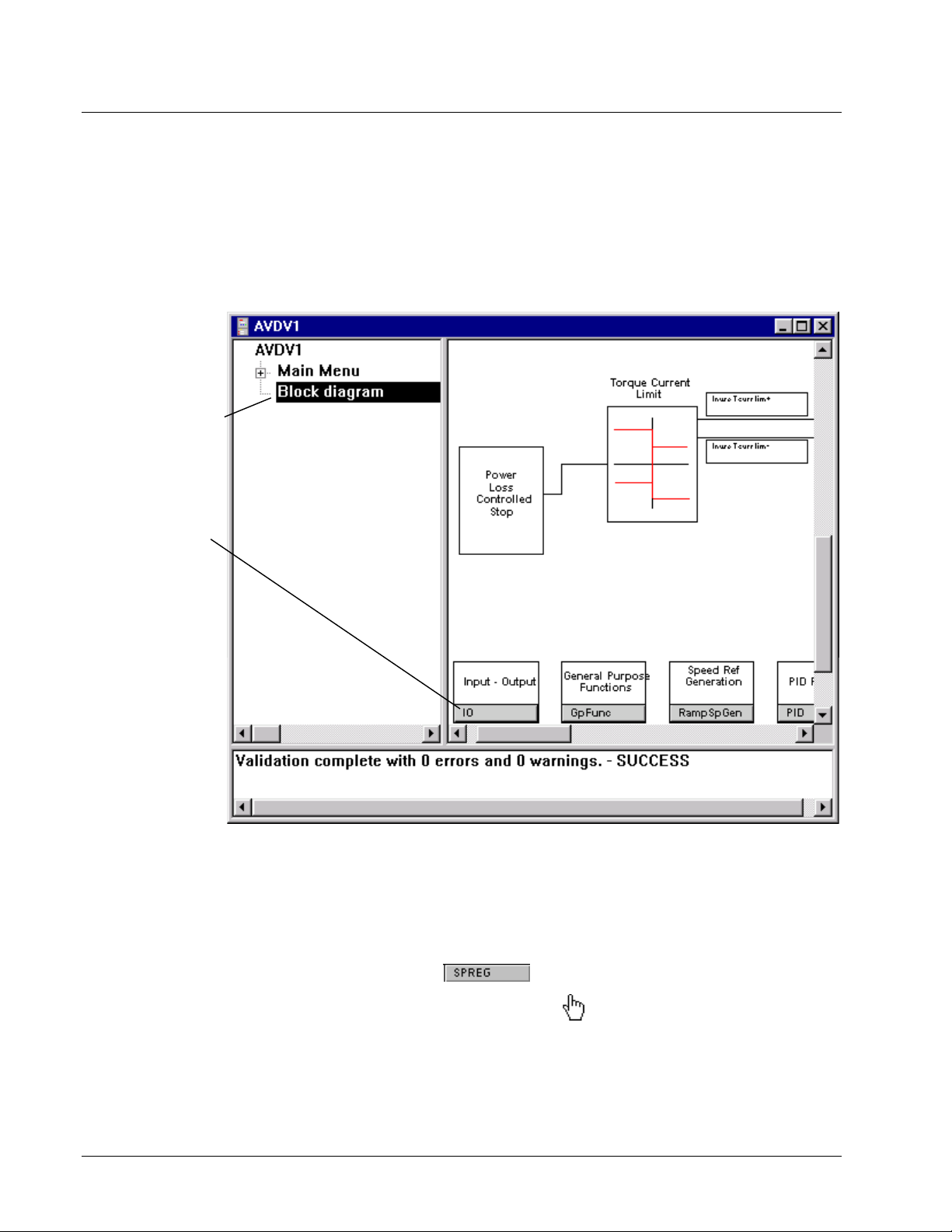

Outline View. For example, in a drive configuration, the item Block diagram

displays block diagrams, which can be configured within this view.

Detached Summary View is a separate window from the Work Area window and

displays a copy of the diagram. This window can be sized, configured, and edited.

3-3

Page 22

••••

Title bar

y

Menu bar

Toolbar

Outline View

Bookmark

Notes

When you click

on an item with

a Note icon, the

note displays in

the Summary

View.

Note The following screen represents a basic toolbox Work Area format. Menu

commands, toolbar, and Outline View items will vary with the product installed.

Click to display the Detached Summary View.

Summary View display details of the item

selected in the Outline View. For example,

the parameter T current Lim+ displays.

Log

View

For Help, Press F1

Status bar displays toolbox

information on the right

and drive information on

the left side.

Find the cause of an error by

double-clicking on the error.

Double-click

to edit the

note.

Bookmark items display the

icon.

Communication status

Drive status

Fault indication

Diagram scan rate

Read-onl

file

Log View displays status messages for toolbox activities, such as file imports,

validations, builds, or errors.

Status Bar can be toggled on and off from the View menu. When online, the left

side displays a description of various toolbox commands or notes entered by the

user. The right side displays the drive status of the current drive.

Notes can be created for most items in the drive. Select an item, then from the Edit,

select Modify. Enter a note for the item and click OK. The Note icon

displays

beside the item in the Outline View.

Bookmark enables you to mark major items in the Outline View and then return to

them easily using the Bookmark commands in the Edit menu. The Toggle Bookmark

command turns the icon on and off. The Goto Next Bookmark command jumps to

the next item marked with the

.

3-4

Chapter 3 Using the Toolbox GEH-6412 Toolbox for AV-300i Version 2 Drive

Page 23

••••

Accessing Online Help

To obtain Help for the dialog

box on the screen, press

F1

Specific Help is available for each dialog box. Press the F1 function key when the

dialog box displays. Help can also be accessed using the following methods:

.

To obtain Help on . . . Do this . . .

Menu commands Highlight the command and press F1

Dialog boxes Press F1 when the dialog box displays on the screen

Block information Click on the desired block with the right mouse button

Help contents Click the Help menu and select Contents

Help Click the Help menu and select Using Help

Specific word(s) Click the Help menu, select Contents, and click the tab

Privileges and Passwords

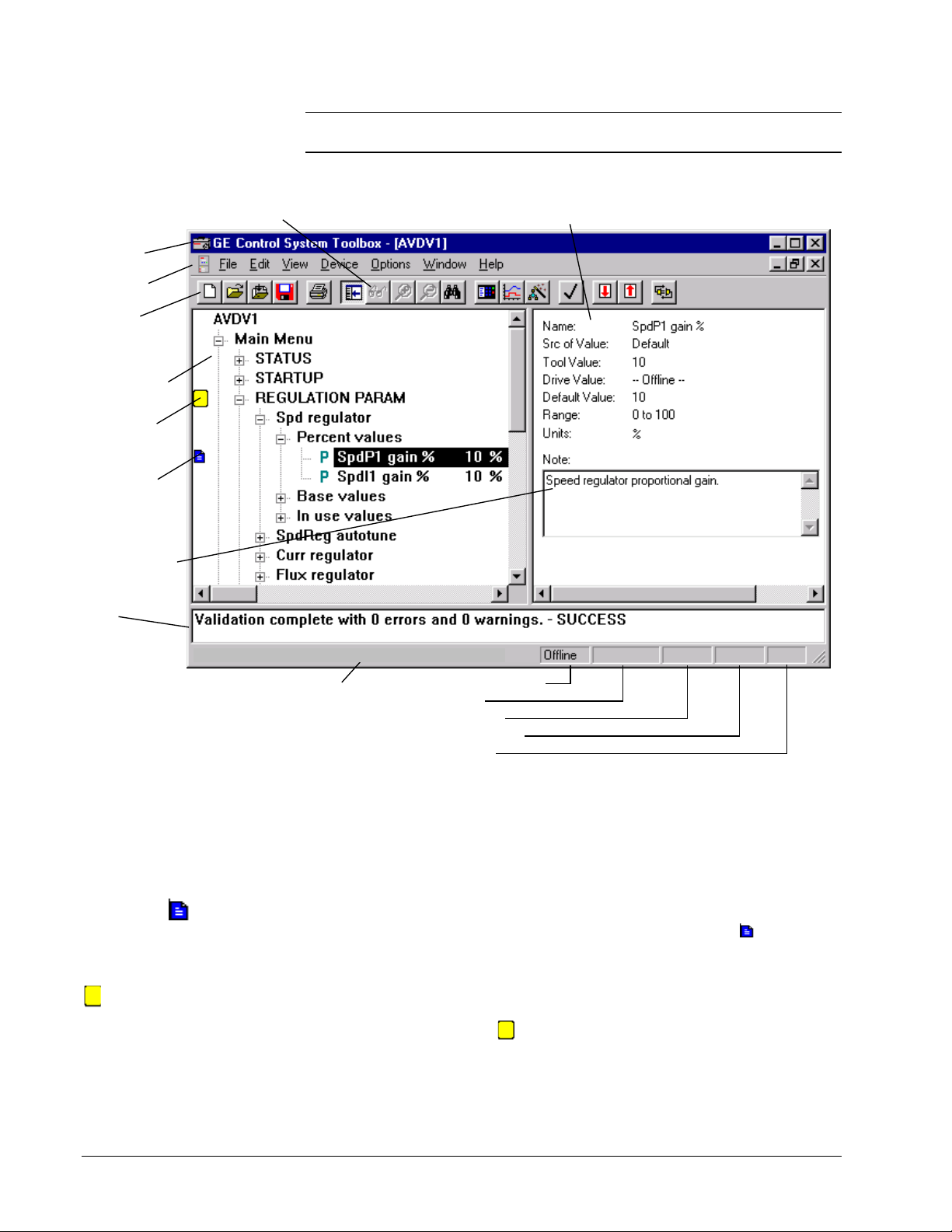

To change the password,

refer to the section,

Change Password or Default

Password Directory.

The privilege/password system assigns different levels of access to the devices.

Then, passwords can be established for the different privilege levels, so that each

user can access a device at the level necessary for the job that person is assigned.

Privilege Levels

and choose Item Help

Find, then enter the word(s) to search

To avoid this dialog box, from

the Options menu, select

Settings, and then click the

tab General. At the bottom of

the dialog box in the text box

User Identification, enter

your user ID.

ØØØØ To set a privilege level

M From the Options menu, select Privilege.

Enter a three-character ID,

such as your initials.

Click OK.

Privilege Level Functions

A password can be assigned to each of the toolbox privilege levels defined in the

following table. (Each successive level allows all the functions of the previous level.)

GEH-6412 Toolbox for AV-300i Version 2 Drive Chapter 3 Using the Toolbox

3-5

Page 24

••••

Privilege Levels

Level Functions

0: Read Only View code

Use the Finder

Monitor live data

Trend (including saving trend definitions in .TRN

files and saving collected data)

Change View attributes under Option menu,

Settings

Print blockware code and reports

Change the password for level 0

1: Change drive Advanced

Maintenance

2: Full drive Advanced

Maintenance

3: Drive Block Area and Menu

Maintenance

4: Full Drive Access Change GE parameters

All functions allowed in Level 0, including change

password levels in Levels 0 and 1

Change the value of variables

All functions allowed in Level 0 and Level 1

Make code changes

Download

Import/Export

Put in database and Get from database

Validate, build, save, backup, and pack signals

Change the password for Levels 0, 1, and 2

Change the location of the password file

Alter block area and change application menu

structure

View parameters that are not on a menu

Download firmware

3-6

Chapter 3 Using the Toolbox GEH-6412 Toolbox for AV-300i Version 2 Drive

Page 25

••••

Select the privilege

level that you want

to change.

Click

OK

.

The

Changing

password

box displays for the

selected level.

dialog

Enter the old password

in text box 1) and press

the Tab key.

Enter the new password

in textbox 2) and press

the Tab key.

Change Password or Default Password Directory

ØØØØ To change the password

M From the Options menu, select Password. The Changing Password

dialog box

Tab

Tab

displays.

Enter the new password

again in text box 3) to

verify it is correct.

Enter a directory or click

Browse...

Enter three characters that

identifies the current user.

You will not be prompted for

initializations when values

change.

to select a directory.

When a password is created, it is encoded in the file UCPASSWD.INI in the

Windows NT installation directory. This default directory can be changed by a user

at Privilege Level 2.

ØØØØ To change the default password file directory

M From the Options menu, select Settings, and then click the tab General.

Note It is recommended that the password file be kept on the local PC to avoid loss

of access in the case of downtime on a remote node.

GEH-6412 Toolbox for AV-300i Version 2 Drive Chapter 3 Using the Toolbox

3-7

Page 26

••••

Toolbox Options

Option settings are saved in

the user’s Windows registry

when the toolbox is closed.

Choose a font for the

Outline View. The default

font is System Bold.

Choose from the

following File options:

Load last file on startup

automatically loads the last

file that was in use when the

toolbox was exited.

Backup files before save

makes a backup copy of files

before saving new

information. This includes

.ucb, .dcb, .icb, and .ocb.

The toolbox’s working environment can be defined for each application. This section

describes each tab that can be set to customize the drive, such as general settings,

directories, and the Trend Recorder. These tabs are located in the Options menu,

under Settings.

ØØØØ To customize the toolbox settings

1. From the Options menu, select Settings. The Settings dialog box displays.

Click on a tab to bring it to the front and select appropriate options.

2. Click OK to apply the changes and close the dialog box. Click Cancel to exit

and not change any settings.

General

Choose a font for the

Finder.

Allows extra data to be seen, which

is useful to a Power User.

Use compact export format

compresses the .tre files

produced by exporting. Less

hard disk space is used and

is easier to read and edit.

This is recommended.

Compress files when

saving

in a compressed format,

which saves disk space.

Save Bookmarks in files

saves bookmarks between

closing and reopening files.

Auto-Save files every

minutes

the files at the set increment.

saves and stores files

automatically saves

Enter three character initials,

for use in the privilege/

password. You will not be

prompted for initializations

when values change.

Enter the directory for the password

file. A local directory is recommended.

Click

Browse…

and choose a location.

to search the directory

3-8

Chapter 3 Using the Toolbox GEH-6412 Toolbox for AV-300i Version 2 Drive

Page 27

••••

Enter the default directory

that will displays when

File

\

Open

is selected.

Click

Browse...

and select the directory.

to locate

Directories

GEH-6412 Toolbox for AV-300i Version 2 Drive Chapter 3 Using the Toolbox

3-9

Page 28

••••

Trend Recorder

The Trend Recorder tab allows you to choose specific options as follows:

Check

Horizontal Grid

Lines

to display horizontal

grid lines when in Replay

mode.

Check

Vertical Grid

Lines

to display vertical

grid lines in Replay mode.

Check

Right Vertical Axis

to display vertical axis on

the right-hand side of the

Trend Recorder.

Check to automatically

configure the Trend

Recorder with predefined

signals. (This feature

currently only works with

Innovation Series drives

and when performing

MarkVI I/O board

calibrations.)

Select the font size used in

the upper window of the

Trend Recorder.

Signal List Font

type and size used in the lower

window of the Trend Recorder.

sets the font

Check to zoom in the

Trend Recorder, using the

mouse to drag-and drop a

rectangle on the screen.

Check for a Yes/No

confirmation prompt to

display before the zoom

takes place.

Check to display

the amount of

reserved memory

that was used.

Select the default

pen width

(measured in pixels)

used to draw the

signal traces.

This sets the amount of memory

the toolbox reserves for storing

traces. The default value of 2 MB

allows 4 signals to be captured at

32 ms intervals for about 14

minutes before the oldest data

starts to be overwritten.

3-10

Chapter 3 Using the Toolbox GEH-6412 Toolbox for AV-300i Version 2 Drive

Page 29

••••

Click on the

drop-down list

and select the

communication

port.

AVDV Series Drive

The AVDV Series Drive tab allows you to choose options specific to the drive.

GEH-6412 Toolbox for AV-300i Version 2 Drive Chapter 3 Using the Toolbox

3-11

Page 30

••••

Connecting the Toolbox

The drive requires an

RS-232C to RS-485 converter

(6K6V300CTI).

AV-300

or

DV-300

or

AV-300i

AV-300

or

DV-300

or

AV-300i

Drive

9-pin

socket

9-pin

socket

9-pin

plug

A - RS-485

Multidrop

Selection

0 V Power

A - RS-485

+5 V Power

9-pin

plug

A - RS485

Multidrop

Selection

0 V Power

A - RS-485

+5 V Power

The toolbox can communicate with an AV-300i Version 2 drive through an

RS-232C/RS-485 serial port connection. Refer to the manual, GEI-100275,

6KCV300CTI Instruction Book.

Note To connect to a drive, refer to Chapter 4, the section, Connecting to an

AV-300i Version 2 Drive. Only one drive at a time can go online (communicate).

9-pin

socket

9-pin

socket

5/8

9-pin

socket

3

3

4

5

7

9

A - RS-485

4

5

A - RS-485

7

+5 V Power

9

Multidrop

Selection

0 V Powe r

9-pin

plug

3

4

5

7

PCI - 485

9

RS-232C

2

RX

3

TX

4

DTR

5

Gnd

6

DSR

7

6KCV300CTI

RTS

8

CTS

Terminating resistors switched off

Point to Point Communication

9-pin

socket

A - RS-485

3

4

5

7

9

3

4

5

7

9

Multidrop

Selection

0 V Power

A - RS -485

+5 V Power

9-pin

plug

3

4

5

7

PCI - 485

9

RS-232C

2

RX

3

TX

4

DTR

5

Gnd

6

DSR

7

6KCV300CTI

RTS

8

CTS

9-pin

plug

9-pin

plug

2

3

4

5

PC

6

7

8

2

3

4

5

6

PC/toolbox

7

8

Terminating resistors switched on

0 V +5V

5/8

external dc

power supply

2.5 A for 32 drops

9-pin socket 9-pin plug

AV-300

or

DV-300

or

AV-300i

Drive

A - RS-485

Multidrop

Selection

0 V Power

A - RS-485

+5 V Power

3

4

5

7

9

Up to 32

Drives

Multidrop Communication

3-12

Chapter 3 Using the Toolbox GEH-6412 Toolbox for AV-300i Version 2 Drive

Page 31

••••

Chapter 4 Configuring an AV-300i Version 2 Drive

Introduction

This chapter provides instructions for using the toolbox to configure and monitor an

AV-300i Version 2 drive. In addition, information on using other features of the

toolbox specific to the drive is also provided.

Section Page

Creating an AV-300i Version 2 Drive.................................................................. 4-1

Configuring the Drive ......................................................................................... 4-4

Working with Files and Menus............................................................................ 4-6

Concepts............................................................................................................4-15

Configuration.....................................................................................................4-16

Block Diagram...................................................................................................4-20

Drive Controls ...................................................................................................4-23

Wizards .............................................................................................................4-23

Fault Display......................................................................................................4-25

Self-Tune...........................................................................................................4-26

Using the Finder.................................................................................................4-30

ISBus Configuration...........................................................................................4-31

Genius Configuration .........................................................................................4-35

Creating an AV-300i Version 2 Drive

When the toolbox starts, the toolbox Work Area displays (refer to the section,

Configuring the Drive). The Work Area is used to maintain the drive configuration

file in the toolbox. You must create a new drive configuration file (.acb) or open an

existing one.

ØØØØ To create an AV-300i Version 2 drive

Or click

GEH-6412 Toolbox for AV-300i Version 2 Drive Chapter 4 Configuring an AV-300i Version 2 Drive

New

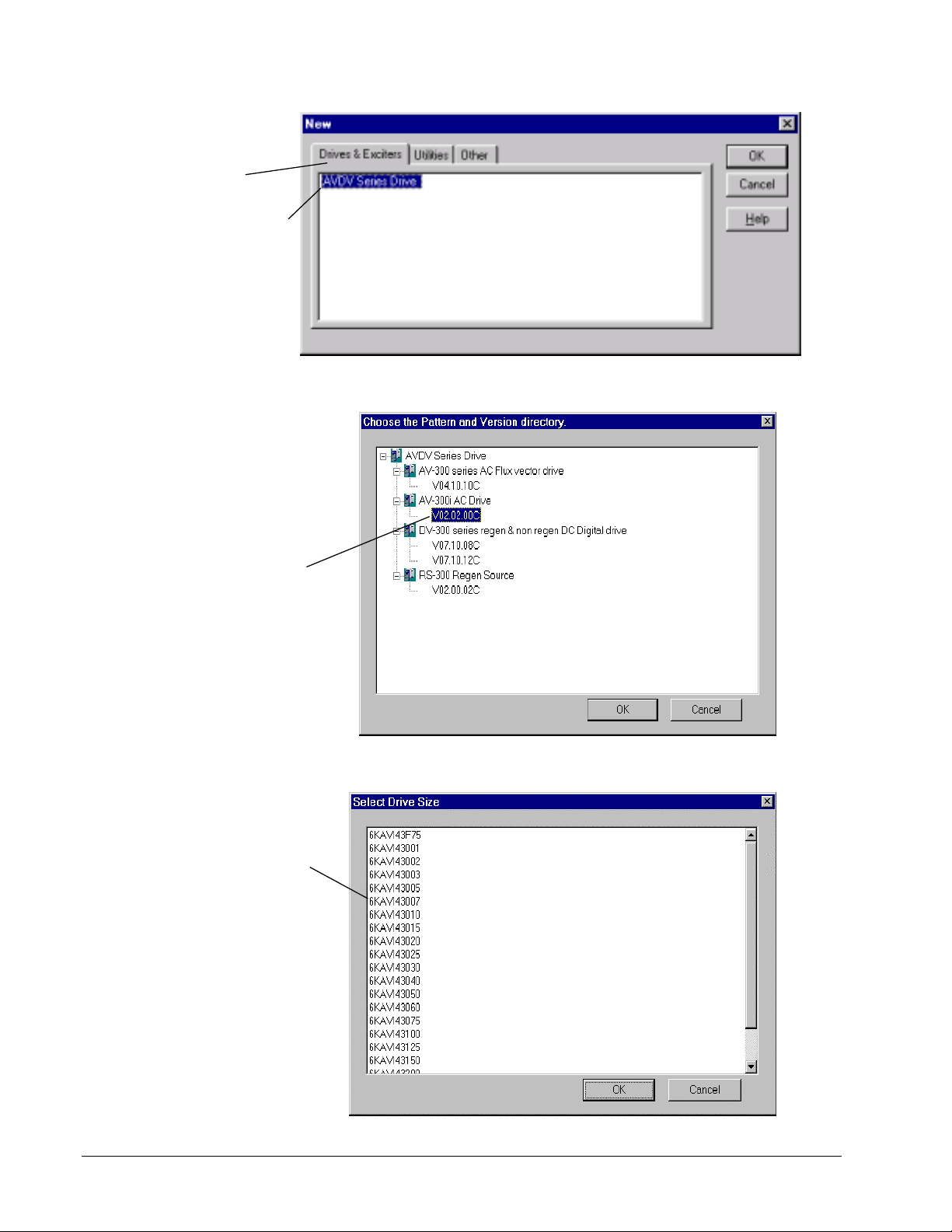

w From the File menu, select New. The New dialog box contains the installed

toolbox products.

4-1

Page 32

••••

Click on the tab,

Drives & Exciters

AVDV Series Drive

Select

and click OK.

The

Choose the Pattern

and Version directory

dialog box displays.

.

Select a Version.

OK

Click

.

Pattern and Version

If the

Enter - User ID

dialog box displays, then

enter an ID and click

(see the next section).

Otherwise, the

dialog box displays.

Size

OK

Select Drive

Drive Size

Select a file that sets the

values for the particular

bridge size being configured.

Obtain this number from the

drive nameplate

being configured. Click

The Toolbox Work Area for

the selected drive displays.

on the drive

OK

.

4-2

Chapter 4 Configuring an AV-300i Version 2 Drive GEH-6412 Toolbox for AV-300i Version 2 Drive

Page 33

••••

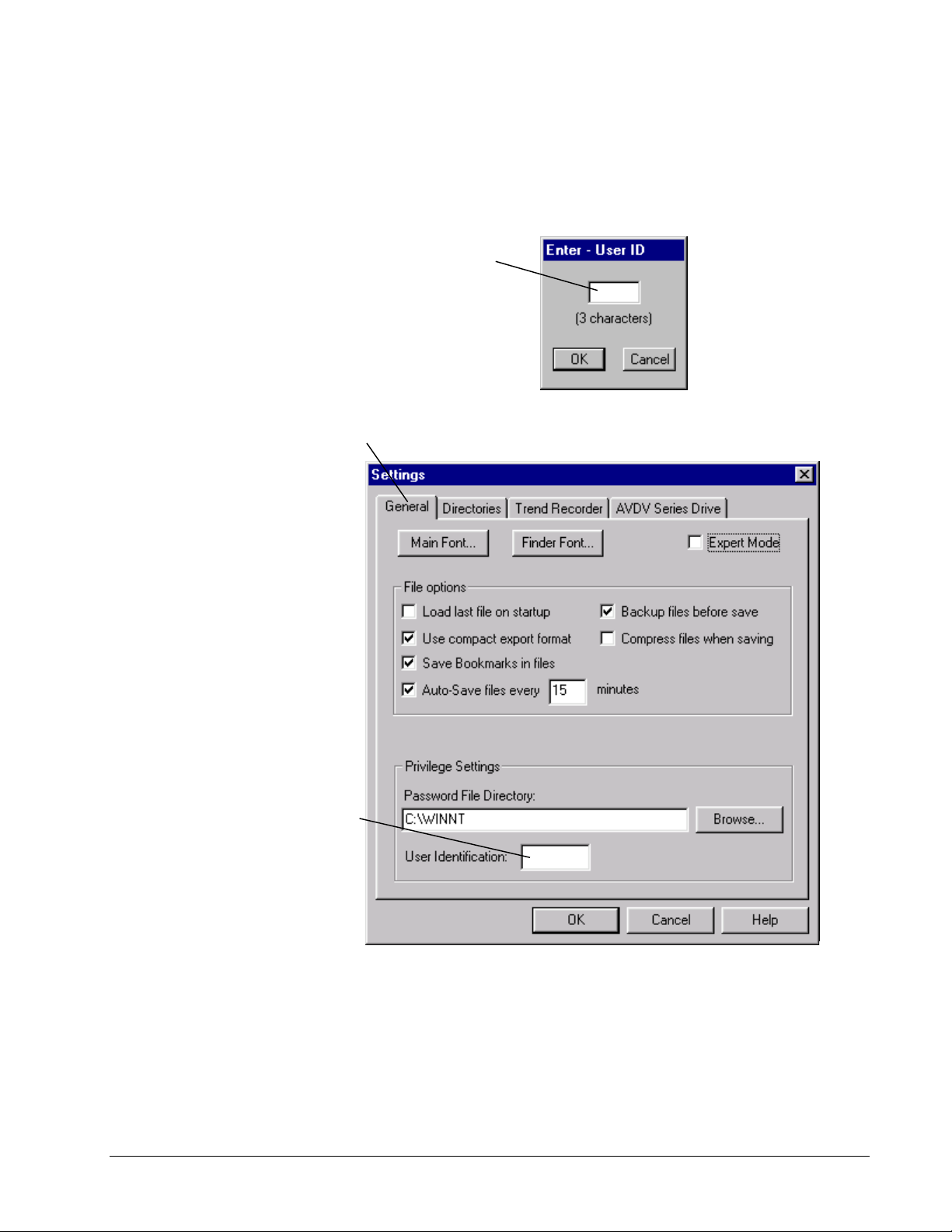

Enter User Identification

To view these configuration

changes with User ID, from

the View menu, select

Reports.

You must enter a three-character ID,

such as your initials.

If you are the only user making changes in the

toolbox are using the current login on the PC,

then you can permanently avoid this dialog box

by entering your ID. From the

select

Settings

, and click the tab

If the Enter – User ID dialog box displays, you must enter an ID to identify the user

about to make changes to the configuration.

Option

menu,

General

.

Enter your three-character ID

to avoid the

dialog box above.

GEH-6412 Toolbox for AV-300i Version 2 Drive Chapter 4 Configuring an AV-300i Version 2 Drive

Enter-User ID

4-3

Page 34

••••

Configuring the Drive

For details of the Toolbox

Work Area, see Chapter 3, the

section, Work Area.

The default device name is

new devices are incremented by one).

To modify the device name, see the next section,

Modifying Drive Properties.

Or click the right mouse

button and select Modify.

The default device name is

Additional new drives are incremented

by one. You should edit the name to

more accurately reflect the drive being

configured (for example,

This field is limited to five characters.

AVDV1

ROLL1

).

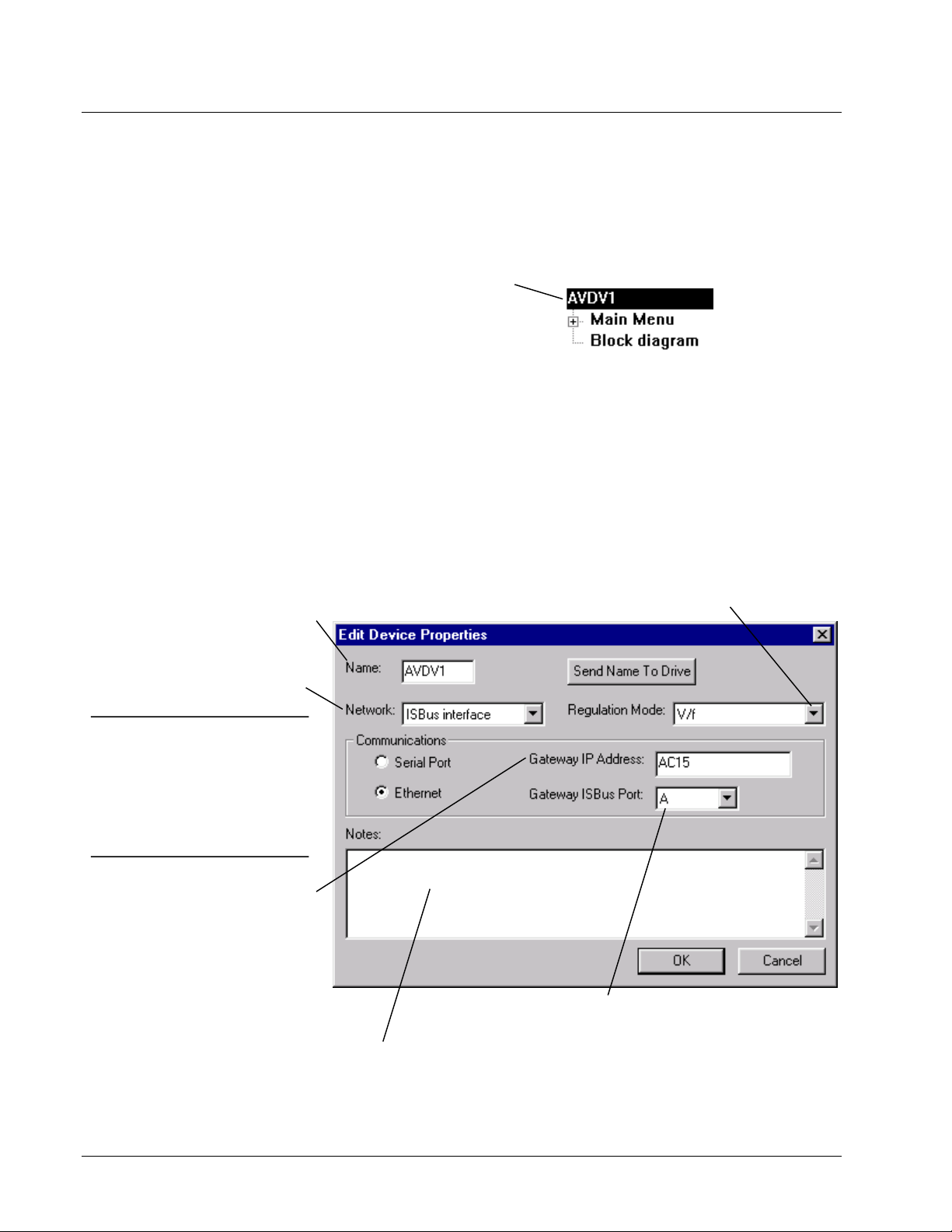

The Toolbox Work Area is the main screen of an AV-300i Version 2 drive

configuration. This area is used to configure the drive.

When a new drive is created or an existing file is opened, the Outline View displays

the drive name and two items: Main Menu and Block diagram.

AVDV1

(additional

Modifying Drive Properties

ØØØØ To modify the drive

1. From the Outline View, click on the drive name.

2. From the Edit menu, select Modify. The Edit Device Properties dialog box

displays.

.

Select the regulation mode in which the

drive wil operate. Typical modes are

Sensorless

, or

Field oriented control

V/f

,

.

Select the active communications

network from the drop-down list.

Note ISBus interface

are contained in this list because

they invoke special toolbox handling.

Other networks, such as Devicenet

and Profibus, do not require

additional handling and are directly

configured in the hardware and

communication/SBI menu.

Gateway IP Address

enter the IP address or name of the

Innovation Series Controller that is

used as a gateway to the drives via

the ISBus. (This setting is only

enabled if the drive is connected to

the ISBus and used explicitly for

asynchronous toolbox

communications to the drive.)

and

Genius

allows you to

Enter a note to describe

the drive.

Gateway ISBus Port

Innovation Series Controller physical ISBus port to

which this drive is connected. (This setting is only

enabled if the drive is connected to the ISBus and

used explicitly for asynchronous toolbox

communications to the drive.)

allows you to select the

4-4

Chapter 4 Configuring an AV-300i Version 2 Drive GEH-6412 Toolbox for AV-300i Version 2 Drive

Page 35

••••

Validating the Drive

y

Also, items in the hierarchy

that had problems during

validation will display in red

after the validation.

Or click

For more information, refer

to the section, Wizards.

Or click

Validation checks for errors that might prevent successful operation of the drive. If

the configuration needs to be validated, items in the Outline View display in red.

Note In most cases, the configuration is automatically validated.

ØØØØ To validate the drive configuration

wwww From the Drive menu, select Validate. The validation results display in the

Log View at the bottom of the toolbox Work Area screen.

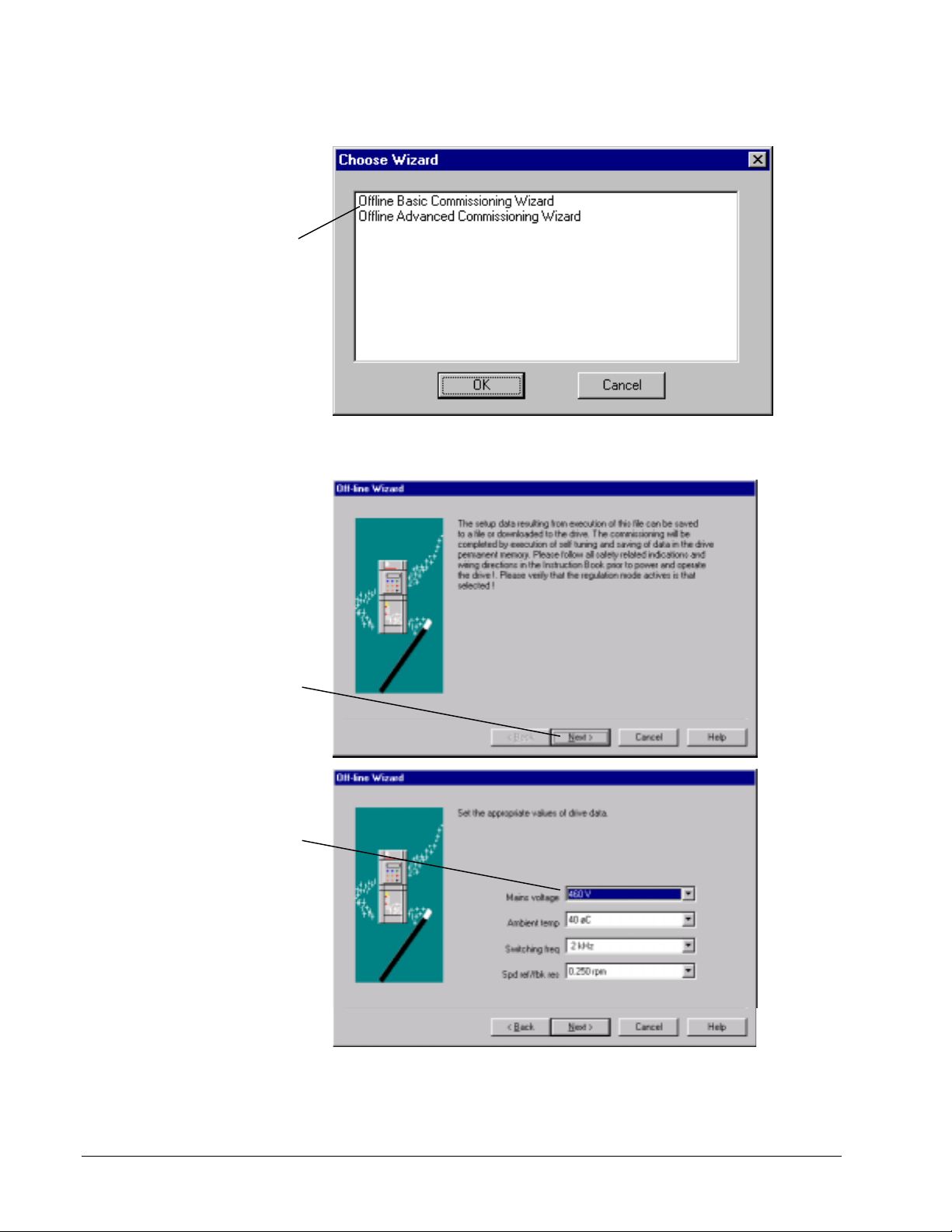

Entering Job-Specific Information

Once a new drive has been created and the properties are modified, you must enter

job-specific data, such as motor hp, motor amps, and motor speed. This information

can be entered in a new configuration using the menus or the Offline commissioning

wizard.

ØØØØ To configure the drive offline

1. From the Edit menu, select Wizards.

If more than one wizard is defined, the Choose Wizard dialog box displays.

Select Offline Basic Commissioning Wizard. However, if onl

is defined, the Offline Wizard dialog box will display immediately.

one wizard

For more information, see the

section, Wizards.

Each configuration depends on application

requirements. For more information, contact Product

Service Engineering (see Chapter 2 for the contact

information).

2. Click Next to progress through the wizard. Enter the appropriate settings .

Note By entering the Offline Basic Commissioning Wizard information and

performing the applicable tune-ups, the drive should be sufficiently configured for

basic operation.

GEH-6412 Toolbox for AV-300i Version 2 Drive Chapter 4 Configuring an AV-300i Version 2 Drive

4-5

Page 36

••••

Working with Files and Menus

An AV-300i Version 2 drive is configured using different types of files, as described

in the following sections. In addition, the menu commands are described in this

section.

File Types

The configuration files generate output files that can be downloaded to the drive.

Configuration files include:

Drive configuration file (.acb) is a binary working file that contains an exact copy

of the drive configuration used by the toolbox. Users generally work from these .acb

files. When the file is saved, the prior .acb is renamed to Backup of File. For

example AV300.acb would have a backup file named Backup of AV300.acb. To

restore the backup copy, rename the file to an .acb file.

Setup files (.dat) consist of four binary files that exist in the drive and save motor

and drive data including measured values. These setup files, combined with the

configuration file (.acb) constitute a complete backup of a drive configuration.

Diagram files (.wmf) are drawing files that contain the toolbox block diagrams.

Help files (.hlp) provide product-specific help from within the toolbox.

Tree files (.tre) are text files that contain configuration information for the drive.

Some .tre files define the parameters, faults, menus, and other items that exist within

The .tre and .prj files are not

normally used by users.

a particular drive, while others store configurations for transport between different

drives, and possibly different versions of the toolbox.

Project files (.prj) are text files that hold some drive configuration information.

They are used in conjunction with other tree files, to transport configurations across

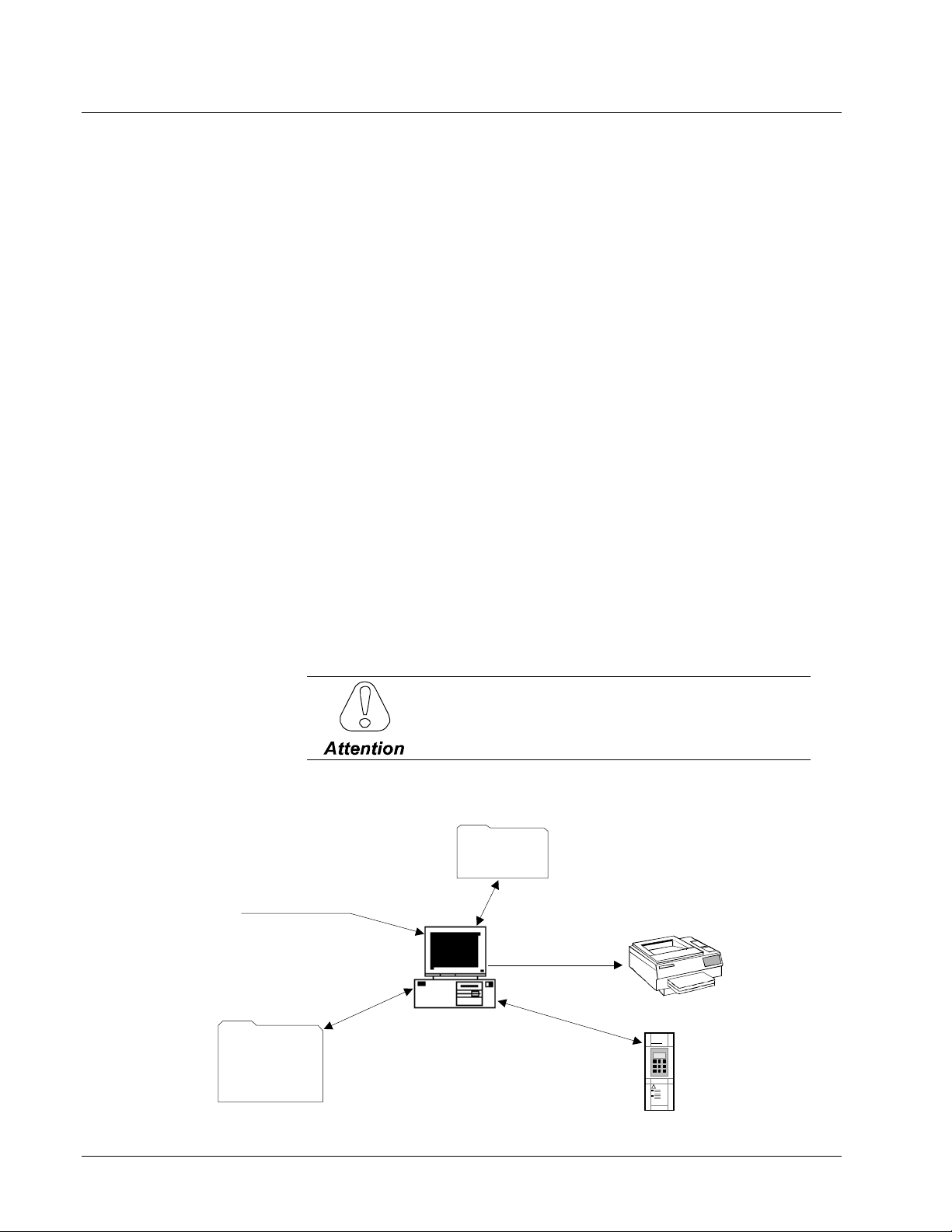

versions of drive products, and possibly different versions of the toolbox.

Back up all files often to avoid losing data.

Programmer Workstation

*.acb file

Pattern configuration files,

such as .tre, .wmf, .hlp

Create/New

Export/Import

hardware,

library, and

function .tre

files

4-6

Chapter 4 Configuring an AV-300i Version 2 Drive GEH-6412 Toolbox for AV-300i Version 2 Drive

Save

Open

Windows NT or

Windows 95

running toolbox

Print

Upload/

Download

parameters

Documentation

AV-300i

e

AV-300i Version 2

Drive

Page 37

••••

Opening and Closing Files

Opening a drive configuration file (.acb) reads a previously saved drive

configuration into the toolbox.

ØØØØ To open a file

Or click

Check the Release Notes

located in the toolbox Help

menu, under About Toolbox.

Or click

1. From the File menu, select Open. The Open dialog box displays.

2. Select the file name and click OK.

Note If an older version toolbox is used to open a drive configuration file (.acb)

that was saved with a newer version, a Warning message is displayed. Either install

the version of toolbox the drive configuration file (.acb) was saved with (listed in the

Warning) or consult the toolbox Release Notes to see if they are compatible.

ØØØØ To close a file

w From the File menu, select Close.

Closing a file removes the configuration from the toolbox. If the configuration has

not been saved, a dialog box displays and asks if the configuration should be saved.

Saving Files

Saving a file writes the entire contents of the configuration to a drive configuration

file (.acb). The prior drive configuration file (.acb) is renamed to a Backup of

filename.icb file and used as a backup file.

ØØØØ To save a file

1. From the File menu, select Save. The Save As dialog box displays.

2. Enter the file name and click OK. (Once a configuration has been saved, the

Save button saves the new file without asking for a file name.)

Refer to Chapter 3, Using the

Toolbox.

Tip ÄÄÄÄ The Save button also indicates that a change was made to the configuration

by highlighting (red) and becoming enabled. If the computer or toolbox fails when

the button is red, all changes since the last save is lost, so save files often (or make

sure that the Auto-save function is not disabled).

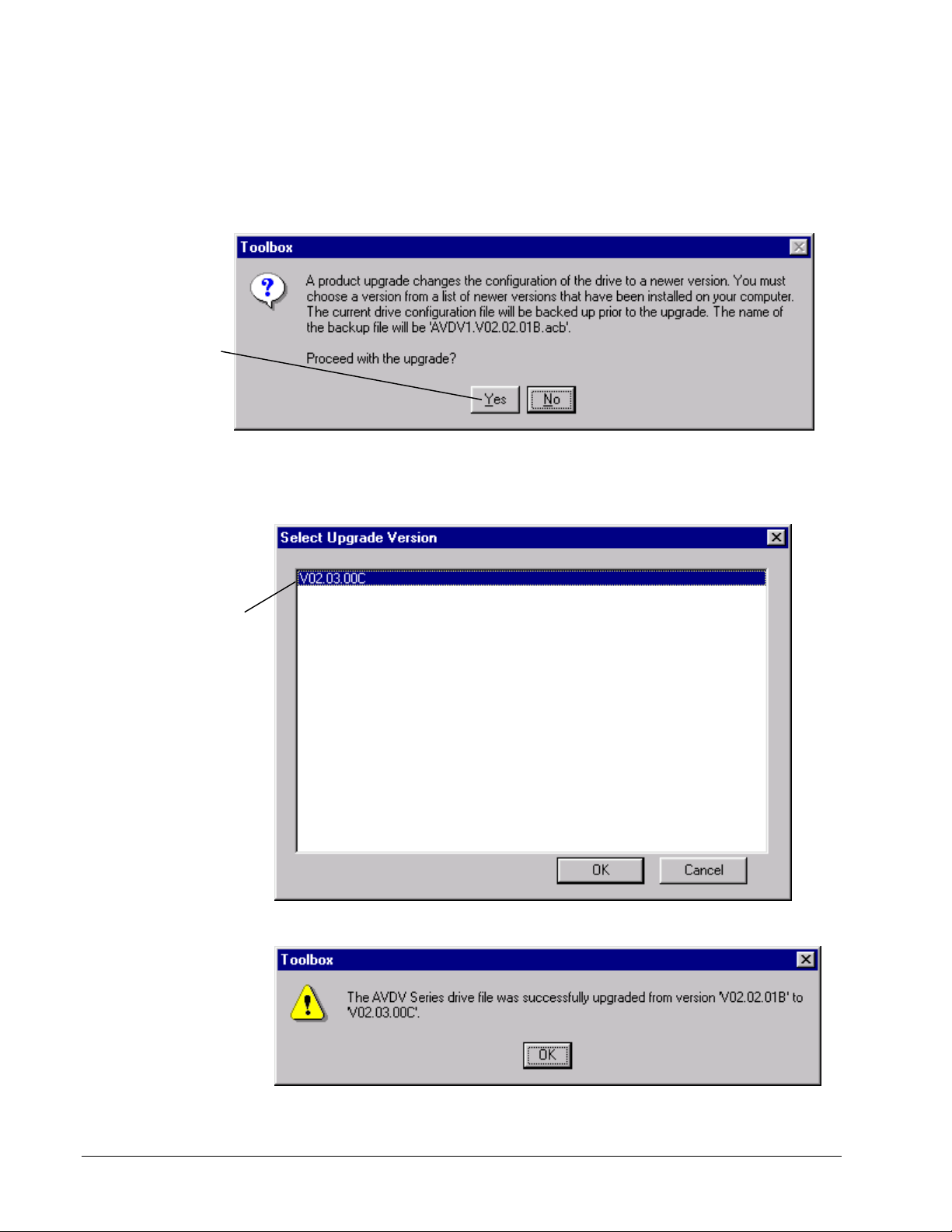

Upgrading a Configuration

The Upgrade command adds the required functions of a newer version of the product

to the current drive configuration file. For example, if the current drive configuration

file (.acb) is version V02.02.01B, and the application requires the functions of

version V02.03.00C, you would need to upgrade the .acb file.

GEH-6412 Toolbox for AV-300i Version 2 Drive Chapter 4 Configuring an AV-300i Version 2 Drive

4-7

Page 38

••••

Click

Yes

to upgrade the drive.

Select Upgrade

The

Version

displays.

dialog box

ØØØØ To upgrade a configuration file

1. Make sure the new required version is installed (refer to Chapter 3).

2. From the current drive configuration file, such as version V02.02.01B described

above, from the File menu, select Upgrade…. The following message box

prompts to proceed you with the upgrade.

Selecting the Upgrade Version

When you select to upgrade the drive, the Select Upgrade Version dialog box

displays all of the newer installed versions.

Select the

updated version.

Click

OK

.

The following dialog box displays, showing that the version upgrade was successful.

4-8

Chapter 4 Configuring an AV-300i Version 2 Drive GEH-6412 Toolbox for AV-300i Version 2 Drive

Page 39

••••

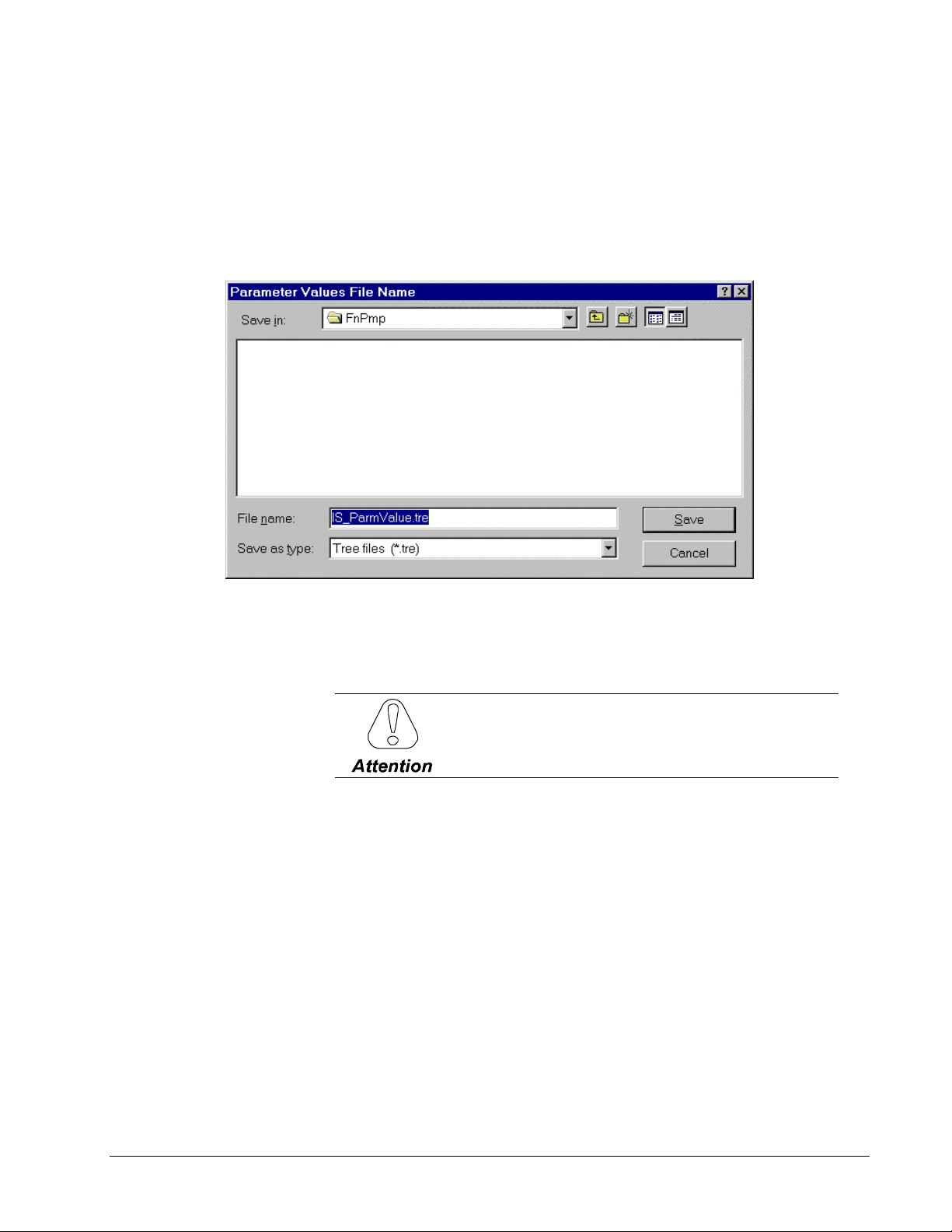

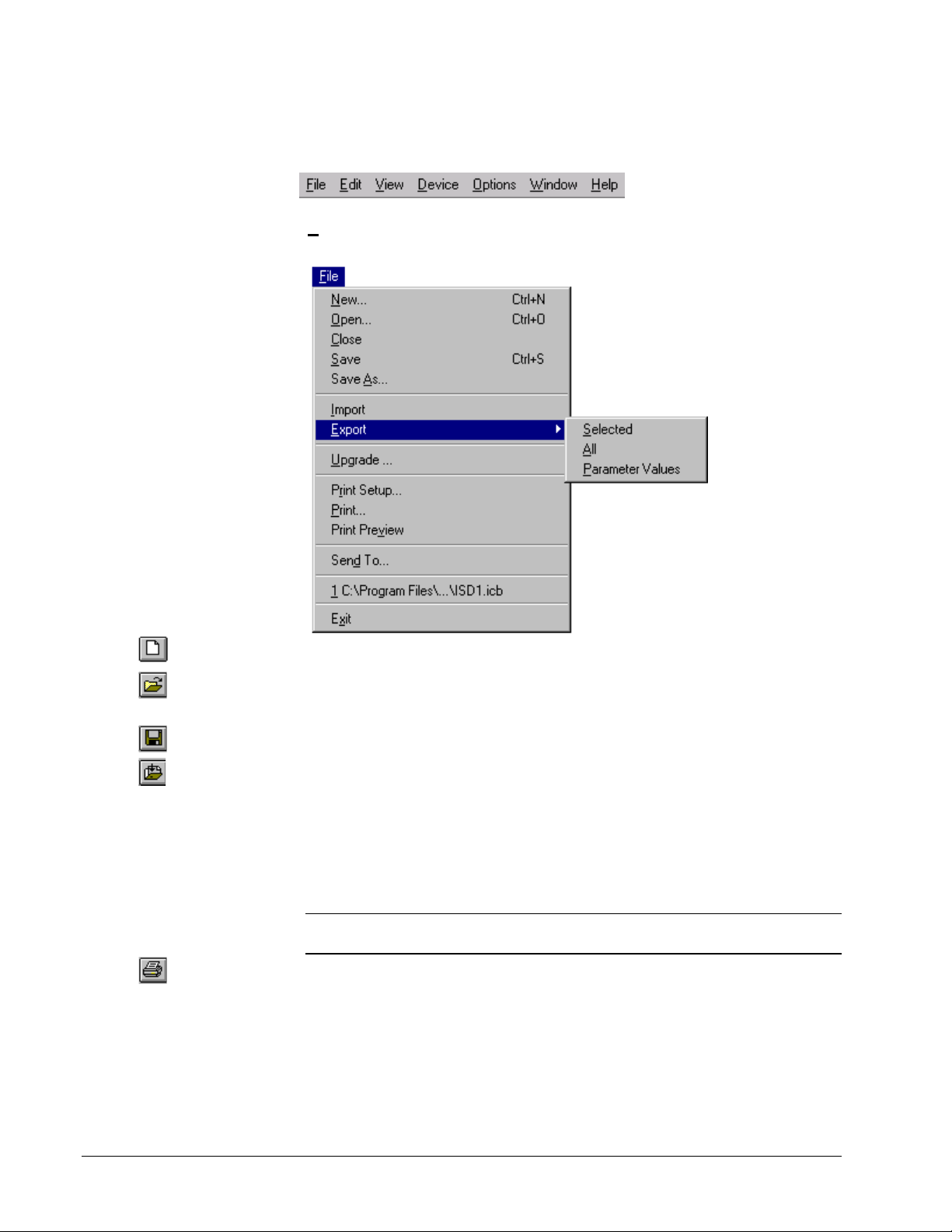

Exporting Configuration Files

The .tre files can be exported

selectively or for an entire

drive.

The parameter values contained in a drive configuration file (.acb) can be exported

in a .tre file format. Exporting drive parameters allows settings among drives to be

shared.

ØØØØ To export parameter values

1. From the File menu, select Export, and then select Parameter Values. The

Parameter Values File Name dialog box displays.

2. Confirm the current project directory and file name or select a new directory.

Click Save. The file is saved as a .tre file.

Project files allow you to

export and import a drive

configuration without having

to know about all the files it

contains.

Exporting and Opening Project Files

Generally this option is not required. It is provided if a

newer version of the toolbox makes a change to the

format of the drive configuration file (.acb) that is not

backward compatible.

Normally, newer versions of the toolbox can load drive configuration files created

by older versions. However, if there is a major change of functionality in the

toolbox, the toolbox may not be able to load the drive configuration file. In this case,

it is necessary to first export the drive configuration file to a project (.prj) file and

then import it into the new version of the toolbox. A project file is a text file, which

contains the names of all .tre files in a configuration. Project files save the drive

configuration in a form that can be loaded by all newer versions of the toolbox.

ØØØØ To create a project file

1. From the Outline View, click on the drive name.

2. From the File menu, select Export and select All. All .tre files and the .prj file

are exported.

Once a project file exists, it can be used to create a drive configuration file (.acb).

Usin g the File \ Open command, choose a .prj file. This creates an AV-300i

Version 2 drive and starts a series of file imports. The toolbox imports the files listed

in the .prj file, including the parameter values file.

GEH-6412 Toolbox for AV-300i Version 2 Drive Chapter 4 Configuring an AV-300i Version 2 Drive

4-9

Page 40

••••

Menu Commands

The toolbox work area contains the following Menu bar:

File Menu

The File menu allows you to perform file operations with the following commands:

Or click

Or click

Or click

Or click

Or click

New creates a new drive configuration file.

Open loads an existing drive configuration file into the toolbox.

Close exits an existing drive configuration.

Save/Save As saves an opened drive configuration file to a specified name.

Import retrieves values from the specified file. The values in the current

configuration are replaced with the imported values.

Export sends specified items (such as parameters and files) to a designated file.

Upgrade automatically makes the required changes to upgrade an older product

version to a newer version.

Print Setup allows you to choose a printer and printer connection.

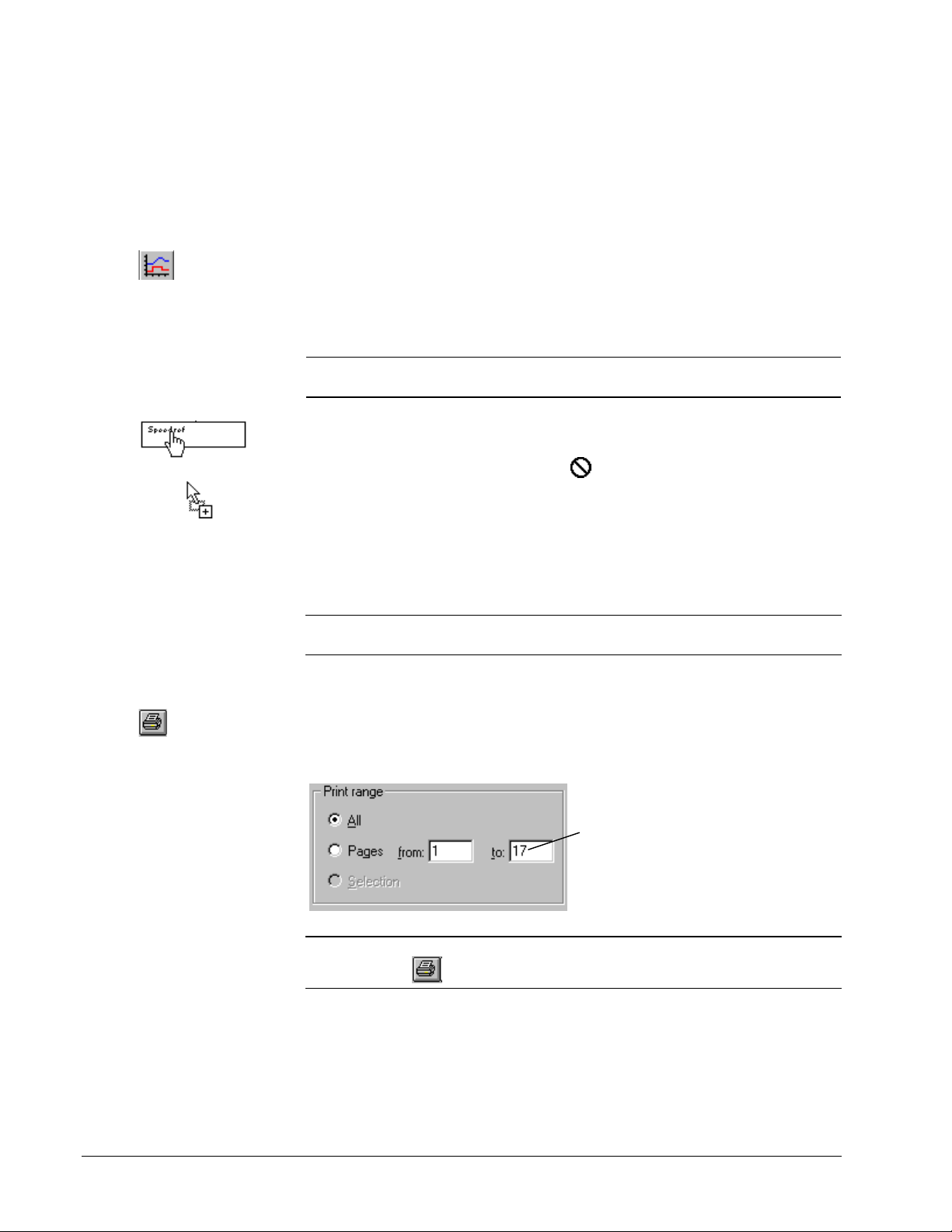

Tip ÄÄÄÄ The block diagram is designed to print best in Landscape Orientation. Refer

to the section, Block Diagrams/Printing Diagrams.

Print provides a paper (hard) copy of a specified file or page.

Print Preview displays the page as it would be printed.

Send To… opens email and provides a copy of the currently opened file to send

(you must have Window messaging, such as Exchange).

File 1, 2, 3... lists and opens the most recently used files.

Exit closes the toolbox.

4-10

Chapter 4 Configuring an AV-300i Version 2 Drive GEH-6412 Toolbox for AV-300i Version 2 Drive

Page 41

••••

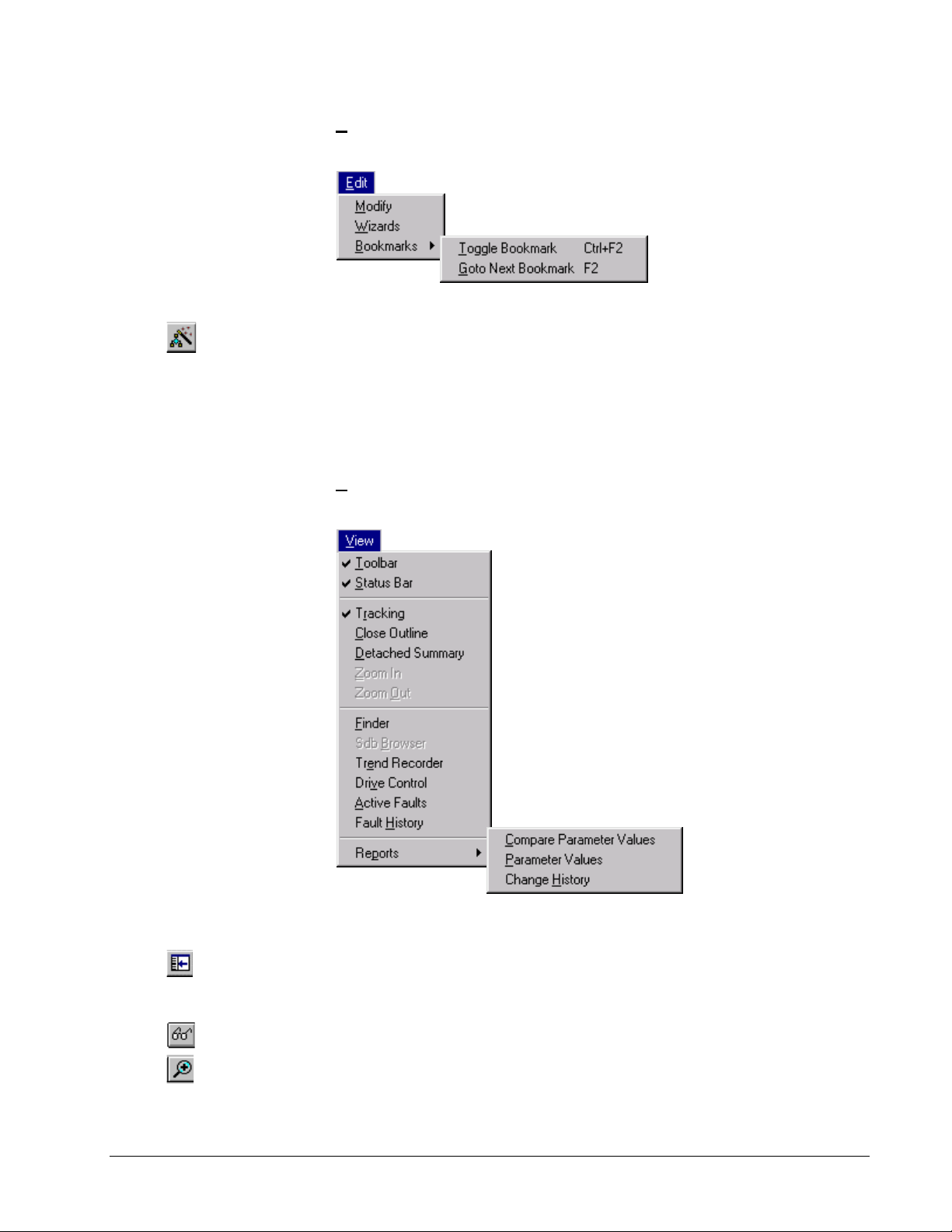

Edit Menu

ü

The Edit menu allows you to edit items with the following commands:

Modify allows you to edit the highlighted item.

Or click

Or press Ctrl+F2 to toggle

the mark and F2 to go to the

next bookmark

Some of these commands can

be toggled on and off. A check

mark (

command name when the

feature is on and it will

display in the toolbox.

) displays next to the

Wizards allows you to choose from a list of wizards used for drive configurations

commissioning, tests, and tune-ups.

Bookmarks allows you to mark major items in the Outline View by using the

Toggle Bookmark option and then move between these items easily by using

Goto Next Bookmark.

View Menu

The View menu allows you to manage the drive with the following commands:

Toolbar displays or hides the Toolbar.

Status Bar displays or hides the Status bar.

Or click

Or click

Or click

GEH-6412 Toolbox for AV-300i Version 2 Drive Chapter 4 Configuring an AV-300i Version 2 Drive

Tracking toggles the tracking feature of the Summary View on and off.

Close Outline reduces the hierarchy list of items displaying in the Outline View to

just the drive level.

Detached Summary creates a detached window of the diagram Summary View.

Zoom In enlarges the view of the block diagram area (Summary View).

4-11

Page 42

••••

Or click

Zoom Out reduces the view of the block diagram area (Summary View).

Or click

Or click

Or click

Or double-click on the status

bar (yellow indicates an

alarm or red indicates a

fault).

Finder starts the Finder view to search for items, such as text and variables within a

configuration.

Sdb Browser starts the SDB Browser window to search the System Database

(refer to the manual, GEI-100271).

Trend Recorder is a separate window in the toolbox (refer to the manual,

GEH-6408).

Drive Control starts the Drive Control view used to start and stop the drive. It also

provides specific information, such as motor speed, volts, amps and power.

Active Faults displays a list of all active faults and alarms. Each fault is time

stamped so that the order of events can be determined.

Fault History displays a list of faults that are saved in the drive.

Reports allows you to produce a Compare Parameters Values report that

shows all parameters whose values in the toolbox are not the same as in the drive, a

Parameter Values report that displays all parameters and their values in a menu

hierarchical structure, and a Change History report listing changes made to the

drive configuration file.

Device Menu

The Device menu allows you to manage the drive with the following commands:

Or click

Or click

Or click

4-12

Chapter 4 Configuring an AV-300i Version 2 Drive GEH-6412 Toolbox for AV-300i Version 2 Drive

Validate verifies that the drive configuration does not contain errors.

Online/offline toggles to start or end communications between the toolbox and the

current drive.

Download Parameter Values to Drive sends the values of all the parameters

from the loaded drive configuration files to the current drive.

Page 43

••••

Or click

Upload Parameter Values from Drive reads all the parameter values from the

current drive and replaces the values in the currently loaded drive configuration file

in the toolbox.

This option enabled only if

you are at Privilege Level 4

and in Expert Mode.

This option enabled only if a

network is enabled.

This option requires the drive

to be online and not enabled.

This option requires the drive

to be online and not enabled.

Download Firmware to Drive sends the drive firmware configuration to the

selected version number.

Save Parameters saves the current active set of parameter values in the drive to

permanent storage

Reset Faults resets all faults that are currently active in the drive.

Genius Interface allows you to upload and download the Genius Network card if

enabled.

Put into Database puts information into the Innovation Series Controller SDB to

allow drives to share signals with other drives and controllers on the network.

Change Drive Size allows you to change the drive size information in the file,

drive, or both.

Load Default Values loads the factory defaults in the drive and the currently

loaded drive configuration file in the toolbox.

Load Motor Parameters loads the motor defaults for the 400 V or 460 V motor

parameters in the drive and the currently loaded drive configuration file in the

toolbox.

Self-tune allows you to activate the self-tune process where the drive and the motor

perform predefined tests on either the Current Regulator or the Speed

Regulator to determine the best running conditions for the system.

Options Menu

The Options menu allows you to manage general options for toolbox operation.

Settings allows you to set general toolbox options.

Privilege sets the privilege level for a session.

Passwords sets the password for a privilege level.

Logout User closes the current user from the current session and sets the privilege

level back to 0.

GEH-6412 Toolbox for AV-300i Version 2 Drive Chapter 4 Configuring an AV-300i Version 2 Drive

4-13

Page 44

••••

Window Menu

The Window menu arranges multiple views of open documents in the drive window

with the following commands:

Cascade arranges the windows in an overlapped style.

Tile Horizontal arranges the windows horizontally in non-overlapped tiles.

Tile Vertical arranges the windows vertically in non-overlapped tiles.

Arrange Icons arranges the icons of closed windows.

Close All closes all open windows.

Help Menu

This option only available if

you have a connection to the

GE intranet.

The Help menu has the following commands:

Contents displays Help files for the toolbox. It also contains the Find tab with a

work list to search for specific topics.

Using Help displays general instructions on how to use Help.

Item Help displays help for the item selected in the Outline View.

Product Help displays the Help file for the currently loaded pattern. The file

contains help on parameters, faults, diagrams, and wizards.

Release Notes provides product changes in the toolbox.

Send Problem Report allows you to submit a system change request for the

toolbox.

Goto Toolbox Web Site takes you to the toolbox home page.

About … displays the version number and platform for this toolbox.

4-14

Chapter 4 Configuring an AV-300i Version 2 Drive GEH-6412 Toolbox for AV-300i Version 2 Drive

Page 45

••••

Concepts

The drive name

can be modified.

Main Menu

the configurable items.

The following section defines items and features used when configuring an AV-300i

Version 2 drive. When a drive is created, the Work Area displays as follows:

contains

Click to display a drawing of the

block diagram and signal flow.

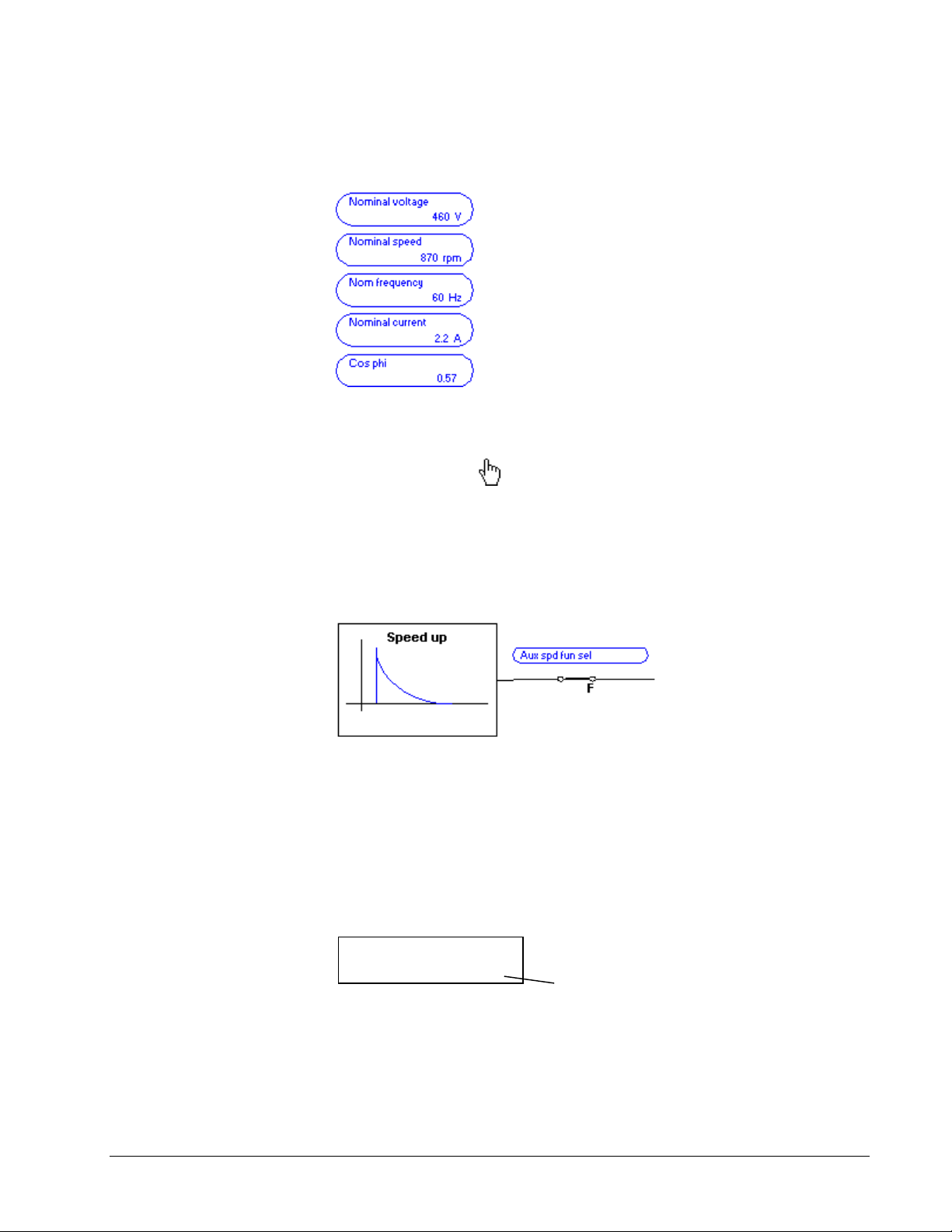

Parameters, located with the Main Menu, allow you to configure the drive behavior.

Each parameter has a name with up to 20 characters, which identifies it and helps to

convey its use. A parameter also can have units, such as RPM, displayed with the

toolbox and keypad. The unit field is limited to five characters. Each parameter

contains a value, which can be a number or a setting. The value is adjusted to modify

the drive behavior. Examples of basic parameters and their associated units are

Motor rated current (Amps), Motor rated freq (Hz), Motor rated voltage (Volts), and

Regulator type. Parameters can be set and modified from the Outline View under the

items Main Menu or Block diagram, or from a Wizard or the keypad.

Variables, similar to parameters, have a name up to 20 characters and a 5-character

unit field. However, unlike parameters, you cannot change variables. They are

changed by the drive as a result of the execution of the pattern within it. For

example, the variable Speed feedback (RPM ) gets updated on a continuous basis and

represents the drives actual speed.

Block diagrams provide an overall picture of signal flow, sequencing and regulator

control in the drive. While communicating with the drive, the diagrams display drive

variables and their real time values. Contact and coil states are also indicated. Certain

drive parameters can be modified from this view (refer to the section, Block

Diagrams).

GEH-6412 Toolbox for AV-300i Version 2 Drive Chapter 4 Configuring an AV-300i Version 2 Drive

4-15

Page 46

••••

Configuration

Parameters

For detailed information

about a parameter, click on

the parameter and press F1.

Use the Finder to easily

locate a specific parameter.

Or click the right mouse

button and select Modify.

Enter a new value (within the range) or, depending on the item, select a value

from the drop-down menu. Then, click

The drive contains a set of parameters with values, together with the pattern and

version, that define the drive behavior. In the Outline View of the toolbox,

parameters display as follows:

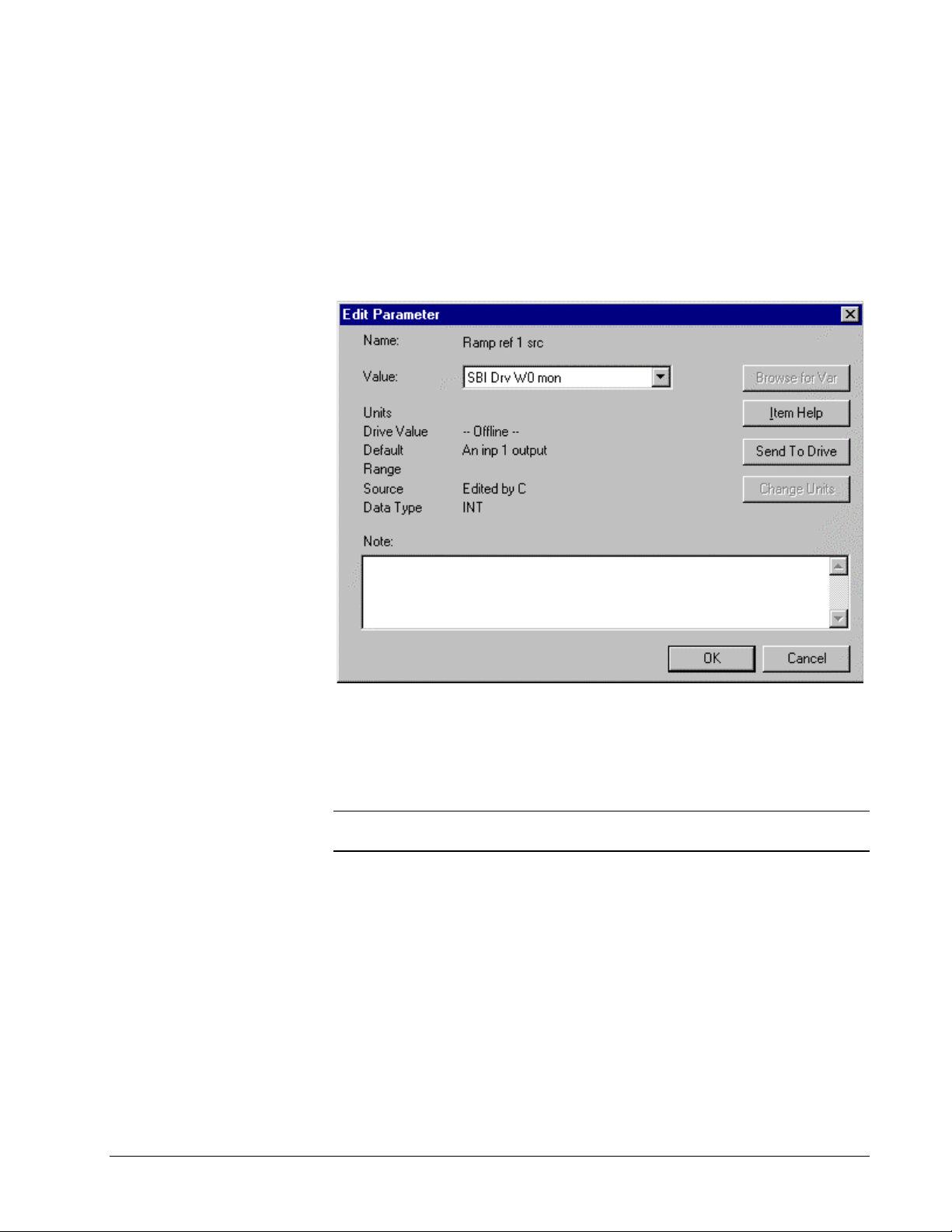

Editing Parameters

ØØØØ To modify a parameter

1. From the Outline View, click on the parameter to modify.

2. From the Edit menu, select Modify. The Edit Parameter dialog box displays.

Send To Drive

for the value to take effect.

The new value displays

under

This function is currently

not available.

Drive Value

.

Click to display the

detailed Help for this

parameter.

Click to send the new

value to the drive.

This button may not be

enabled for all parameters.

It allows you to change the

display units (only effects

the displayed values and

not the drive control.)

Enter a note for this

parameter, if desired.

Note When a parameter value is edited, you must click Send To Drive for the value

to take effect. Also, remember to permanently save the parameter, select the Device

menu and then select Save Parameters.

4-16

Chapter 4 Configuring an AV-300i Version 2 Drive GEH-6412 Toolbox for AV-300i Version 2 Drive

Page 47

••••

Toolbox/Drive Communications

For more information, refer

to the section, Connecting to

an AV-300i Version 2 Series

Drive.

The toolbox can communicate with the drive through an RS-232C to RS-485 serial

port connection. However, only one drive at a time can be selected to go online

(communicate), even if wired into a multi-drop configuration.

The serial port connection settings used by the toolbox can be defined and modified.

These settings are saved and used by the toolbox for every connection to a drive

whose drive configuration file is set to communicate serially.

Modifying Settings

ØØØØ To modify the communications setting

1. From the Options menu, select Settings.

2. Click on the tab, AVDV Series Drive.

3. Modify the Serial Port Communications - Comm Port settings as desired

and click OK.

Click on the

drop-down list

and select the

communication

port.

Note Depending on the products installed, the number of tabs displayed in the

Settings dialog box may vary.

GEH-6412 Toolbox for AV-300i Version 2 Drive Chapter 4 Configuring an AV-300i Version 2 Drive

4-17

Page 48

••••

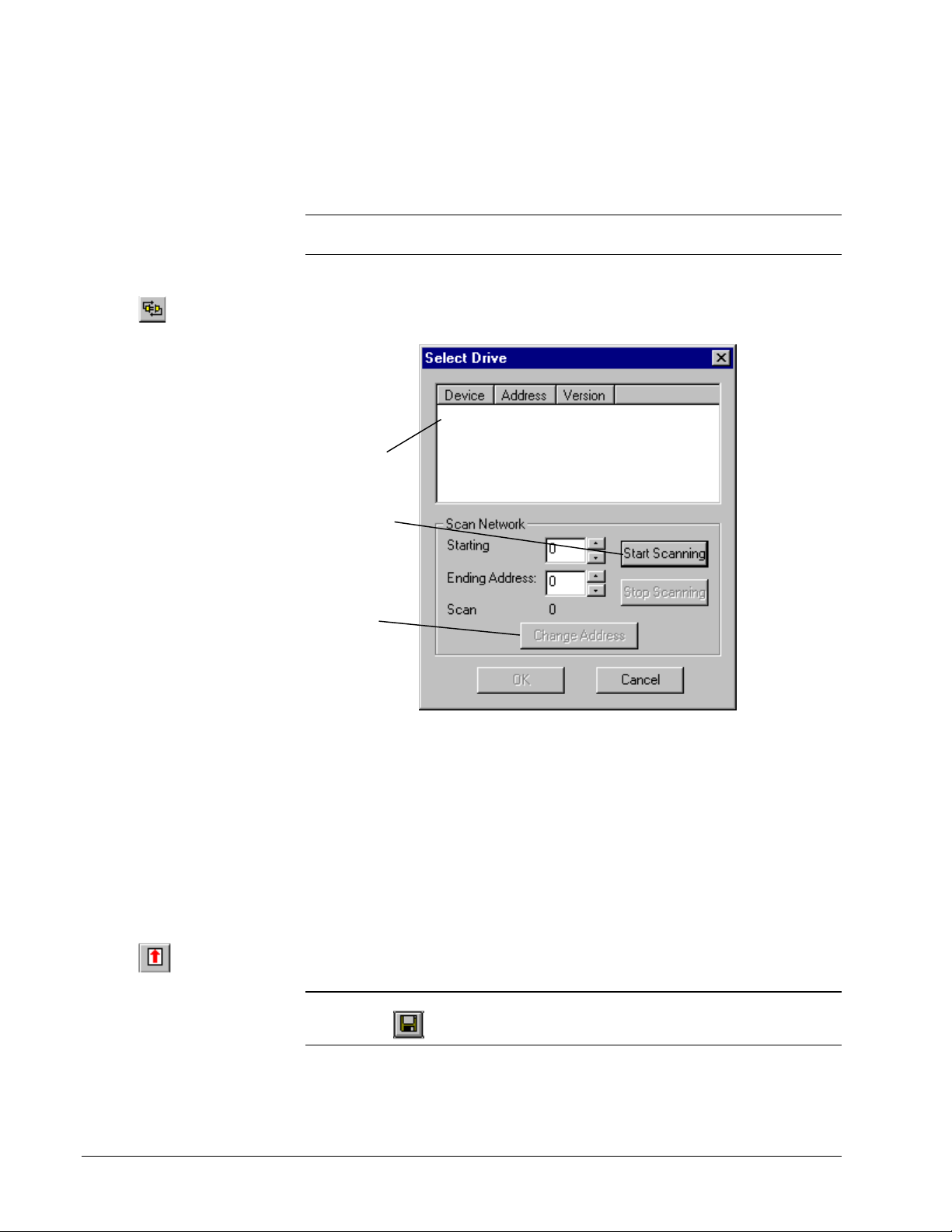

Connecting to an AV-300i Version 2 Drive

Use the Window menu to view

multiple drive windows, when

drives are offline.

Or click

When the drive first goes online

or requires updating, adjust the

range of addresses to be

scanned on the RS-485 link.

Select the drive to connect to

and click

the drive name.

Click

drives displays in the list box.

To change the device multidrop