GE Industrial Solutions Commercial Metering Switchboards Splicing and joining sections User Manual

Page 1

DEH41036 Installation Instructions R01

g

Commercial Metering Switchboards

Splicing and joining sections

Application

These instructions are provided for the installation of

splice bars, and to join switchboard sections at the

installation site for ease of installation. These steps must

be performed prior to setting the switchboard sections on

the final pad and termination of cables.

1. Check installed hardware. Make sure hardware is

installed at the end of the bus bar on each section as

shown in the picture in below:

Installation

WARNING: Danger of electrical shock or injury.

OFF power ahead of the switchboard

Turn

before working inside the equipment or

removing any component

installed and maintained by properly trained

and qualified personnel only.

K

eep in mind this hardware is loose and is held to

the bus by a rubber band. To avoid losing any

hardware, do not remove the rubber band until the

splice bars are going to be installed. The splice bars

are located in the Section marked with the yellow

label “ Splices in this section.”

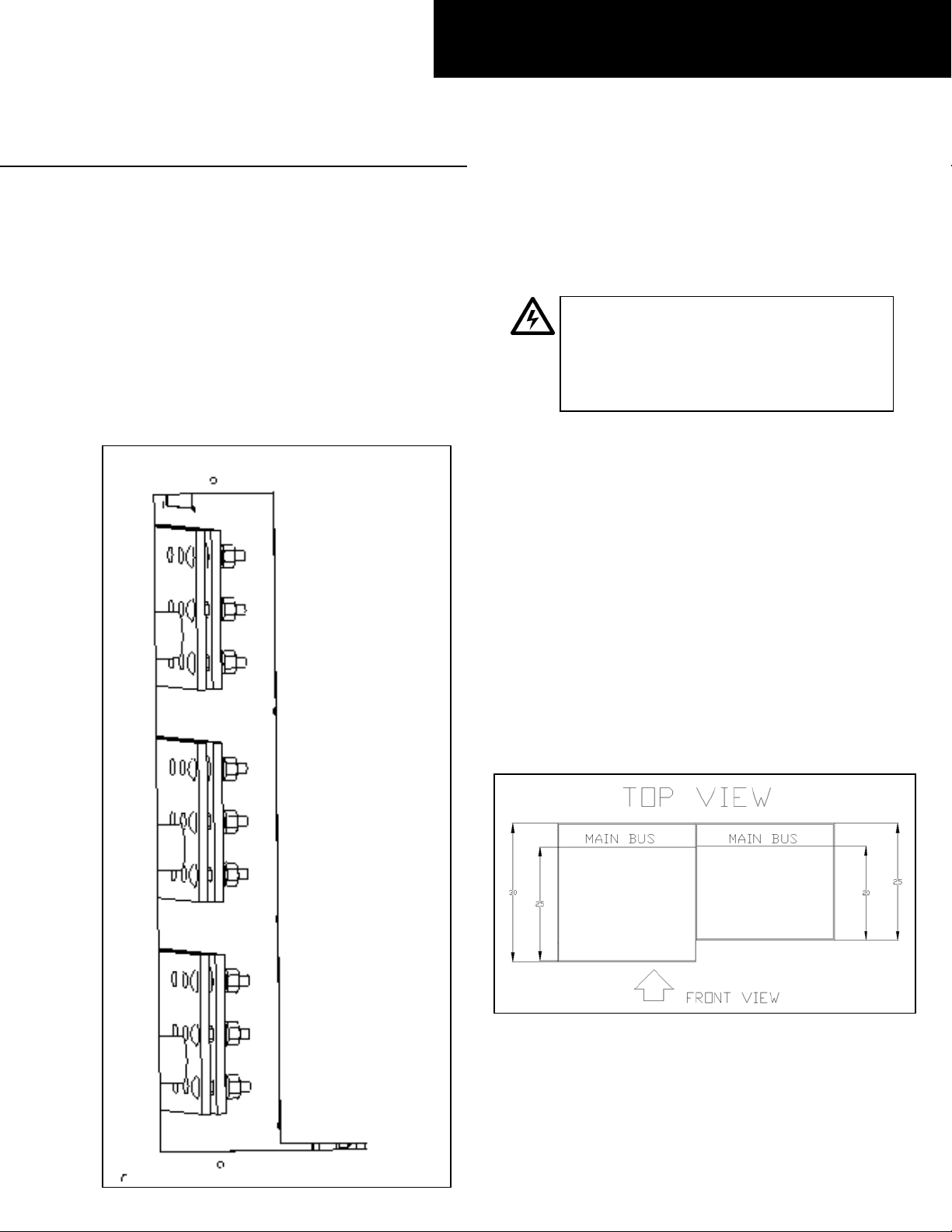

2. Check splice dimensions. Compare the dimensions of

the bus against the splice bars to ensure the 2 sections

are going to be joined successfully. First, measure

from the front of each section to the horizontal bus,

then subtract the distance of the first sections from

the second. This should be equal to the length of the

splice bars.

the picture above the first section is 5” deeper then

In

the second one, and the main bus is located an equal

distance from the rear. Therefore flat bus splices are

required.

. Equipment is to be

Page 2

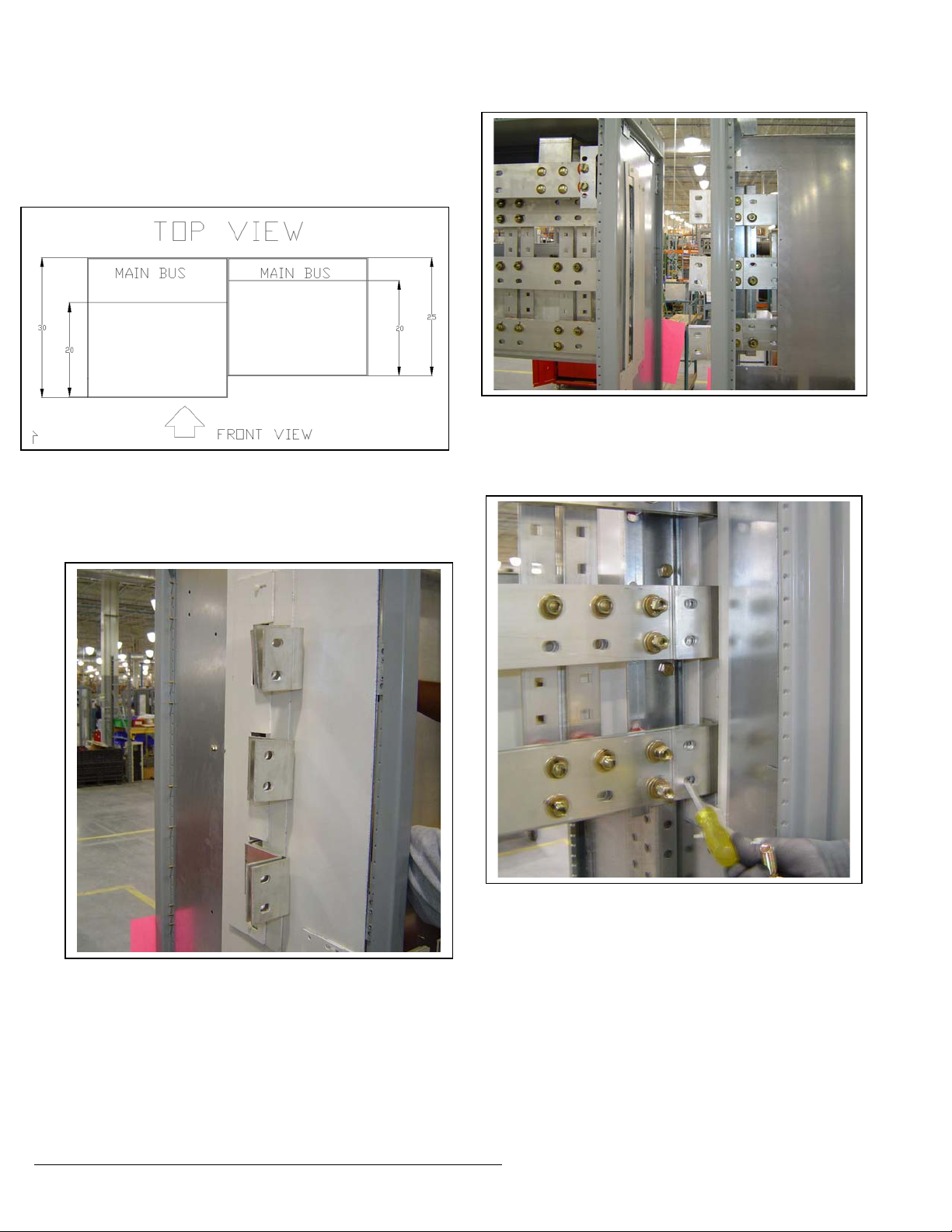

The picture below shows the main bus installed in a

different position relative to the adjoining section.

This condition makes it necessary to use a splice bar

with 5” offset.

3. Splicing sections. The first step is to install the splice

bars on one of the sections. Do not tighten these

bolts. Just add bolts, washers, and nuts and leave

loose.

Second, attach the next section and make the bus bar

holes align with the splice bar slots. There is a removable

cut out for temporary removal during the splicing of the

section.

These instructions do not cover all details or variations in equipment nor do they provide for every possible contingency that may be met in

These instructions do not cover all details or variations in equipment nor do they provide for every possible contingency that may be met in

connection with installation, operation, or maintenance. Should further information be desired or should particular problems arise that are not

connection with installation, operation, or maintenance. Should further information be desired or should particular problems arise that are not

covered sufficiently for the purchaser’s purposes, the matter should be referred to the GE Company.

covered sufficiently for the purchaser’s purposes, the matter should be referred to the GE Company.

Use a screwdriver to make sure the holes align. Then add

the hardware to join the bus and splice bars.

If Bellville washers are provided with the joints , torque to

35 lb-ft. If lock washers are provided with the joints, ,

torque to 39 lb-ft.

The last step is to bolt the sections together. To do so,

please read instruction bulletin (GEH5875), which is

included in the first section of every switchboard line up.

When connections are complete, set the switchboard on

the final pad for cable terminations.

g GE Industrial Systems

g GE Industrial Systems

General Electric Company

General Electric Company

41 Woodford Ave., Plainville, CT 06062

41 Woodford Ave., Plainville, CT 06062

Loading...

Loading...