Page 1

g

p

g

quip

p

y

DEH059 Installation Instructions R02

Spectra Series™ Power Panelboards

Bolt-On Circuit Breaker Kits

WARNING: Danger of electrical shock or injury.

OFF

Turn

switchboard before workin

ment or removing any component. Do

e

not remove circuit

other component until the power is turned

OFF.

ower ahead of the panelboard or

inside the

rotective devices or an

General

These instructions apply to the following catalog numbers:

• Bolt-on circuit breaker kits AMCB6FJ, AMCB3FJ,

AMCB2FJ, and AMCB4FJ

• Circuit breaker types SFH, SFL, SFP, TF, a nd TH

• Circuit breaker cover kits AFP3SFS, AFP3SFD,

AFP3TFS, and AFP3TFD

Table 1 lists the parts included in the bolt-on circuit

breaker kits for main and single-branch configurations.

Table 2 lists the parts included in the kits for doublebranch configurations. The replacement hardware kit has

catalog number AHKBF1.

Installation

Numbers in brackets in the following instructions and

figures refer to the Item numbers in Tables 1 and 2.

1. Install the circuit breaker straps. Before installing into

Spectra APNB bolt-on–style interiors, locate the side of

the panel interior at which the dimension from the

nearest vertical bus face to the inner face of the bus

support rail is 2.75 inches, as illustrated in Figures 2

and 5. Mount the straps on this side of the vertical

bus.

a. Main and single-branch breakers. Install the circuit

breaker straps beginning with the outermost poles,

as shown in Figures 1 and 3. Slide an antiturn clip

[16] over the square shank of a carriage bolt [2].

Insert the carriage bolt assembly into the front

square hole so that the pin rests on top of the

vertical bus.

For a right-hand cable connection, align the

square hole in the strap [1] with the carriage bolt

[2] and slide it against the vertical bus, so that the

pin on the antiturn clip [16] is inserted into the

small hole on the strap, as shown in Figure 1.

For a left-hand cable connection, position the strap

[1] and the spacer [17] so that the square hole and

hole above are aligned, then insert the carriage

bolt [2] and antiturn clip [16] so that the pin of

the clip is inserted into the small hole in the strap

and spacer, as shown in Figure 3.

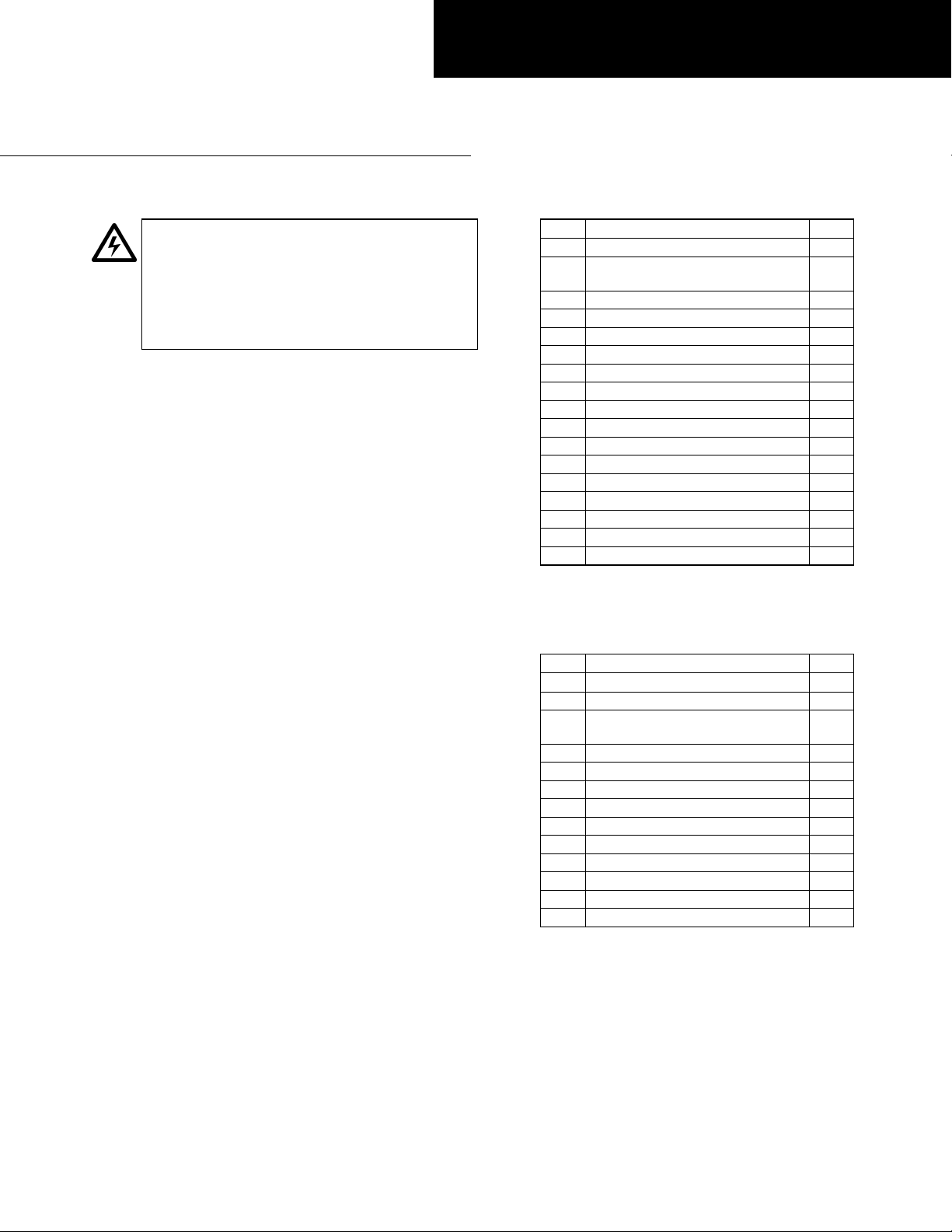

Item Description Qty.

1 A pole strap 1

1

/4-20 x 1.50 carriage bolt

2

1

/4-20 x 1.00 carriage bolt*

31/4" Belleville washer 6

41/4-20 nut 6

5 B pole strap 1

6 C pole strap 1

7 Breaker mounting bracket 1

8 Breaker mounting bracket 1

9 Thread-forming screw 4

101/4-20 x 3/4" machine screw 3

111/4" Belleville washer 3

12 #10-32 x 33/4" machine screw 2

13 #10 flat washer 2

14 #10-32 x 1/2" machine screw 2

15 #10 lock washer 2

16 Antiturn clip 6

17 Strap spacer 3

* Use with single breaker straps connected to a

vertical bus rated at 600 A or less.

Table 1. Bolt-on breaker kit parts for main and single-branch

configurations.

Item Description Qty.

18 A & C pole outer strap 2

19 A & C pole inner strap 2

/

4-20 x 1.50 carriage bolt

20

1

/4-20 x 1.00 carriage bolt*

211/4" Belleville washer 3

221/4-20 nut 3

23 B pole strap 2

24 Breaker mounting bracket 2

25 Thread-forming screw 4

261/4-20 x 3/4" machine screw 6

271/4" Belleville washer 6

28 #10-32 x 33/4" machine screw 4

29 #10 flat washer 4

30 Antiturn clip 3

* Use with single breaker straps connected to a

vertical bus rated at 600 A or less.

Table 2. Bolt-on breaker kit parts for double-branch configurations.

Secure the complete strap assembly to the vertical

bus with the Belleville washer [3] and nut [4].

Leave the connection finger tight at this time.

Repeat the process on the center-pole strap [5] and

then install the last strap [6], as shown in Figure 1

or Figure 3.

6

3

Page 2

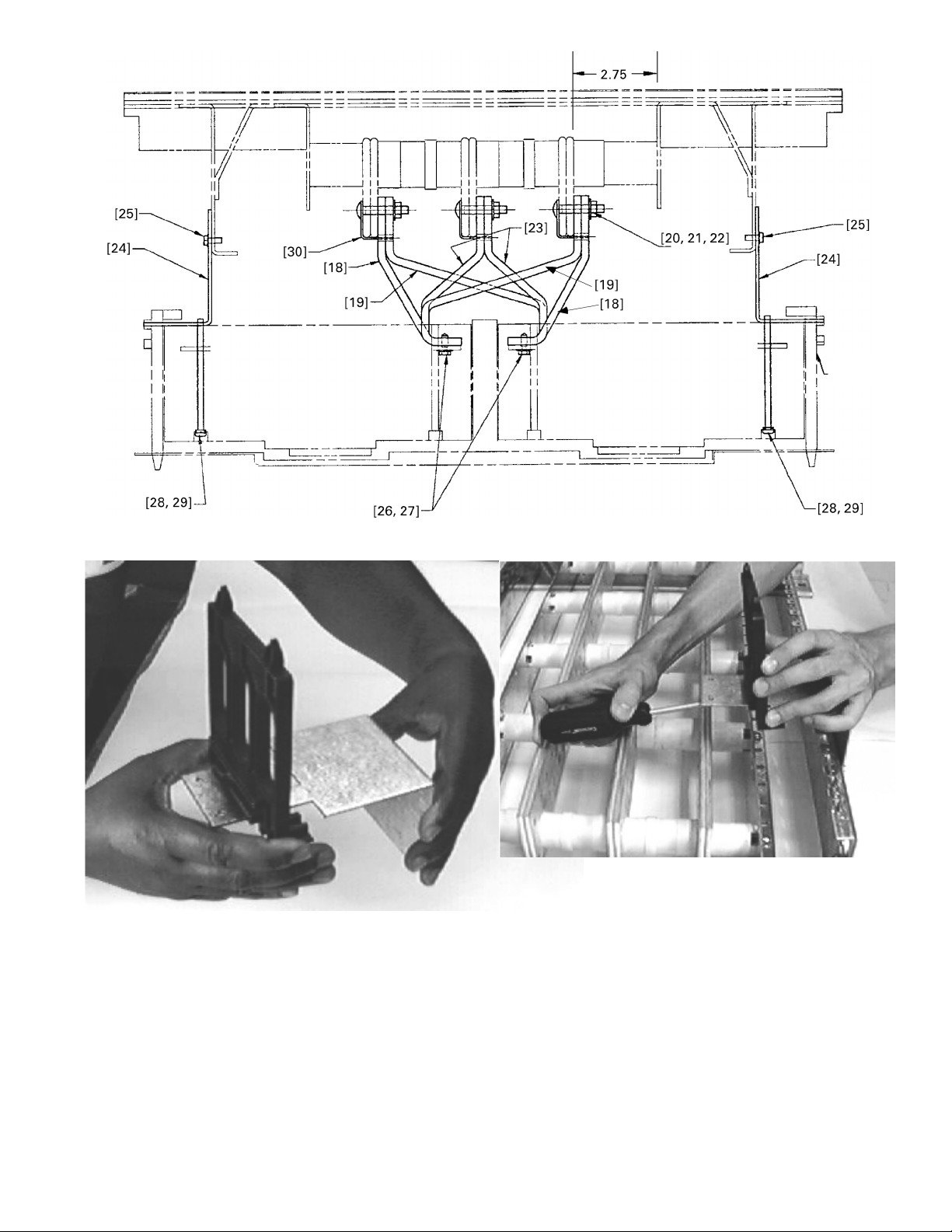

b. Double-branch breakers. Install the circuit breaker

straps beginning with the outermost poles, as

shown in Figures 4 and 5. Slide an antiturn clip

[30] over the square shank of a carriage bolt [20].

Insert the carriage bolt assembly into the front

square hole so that the pin rests on top of the

vertical bus.

Align the square hole in the straps [18 & 19] with

the carriage bolt [20] and slide it against the

vertical bus, so that the pin on the antiturn clip

[30] is inserted into the small hole on the strap, as

shown in Figures 4 and 5.

Secure the complete strap assembly to the vertical

bus with the Belleville washer [21] and nut [22].

Leave the connection finger tight at this time.

Repeat the process on the center-pole straps [23]

and then install the last straps [18 & 19], as shown

in Figures 4 and Figure 5.

2. Install the circuit breaker mounting brackets and

cover supports.

a. Main and single-branch breakers. Fasten the

breaker mounting bracket [7] to the panel side rail

with thread-forming screws [9]. Attach a cover

support (included in the breaker cover kit) to the

threaded holes in the mounting bracket with the

#10-32 x

1

/2" machine screws [14] and lock

washers [15] tightened to 18 in-lb.

Attach the breaker mounting bracket [8] to the

opposite side rail with thread-forming screws [9]

tightened to 30 in-lb. With the mounting tabs on a

cover support oriented outward, slide the lowest

slot on the support onto the breaker mounting

bracket until it snaps into place, as illustrated in

Figure 6.

The cover support can be easily removed by

inserting a screwdriver into the mounting slot on

the underside of the mounting bracket assembly

and gently prying downward, while pushing the

cover support off, as illustrated in Figure 7.

b. Double-branch breakers. Attach the breaker

mounting brackets [24] to the panel side rails with

thread-forming screws [25], tightened to 30 in-lb.

With the mounting tabs on the cover supports

oriented inward, slide the lowest slot on the

supports onto the breaker mounting brackets until

they snap into place.

Cover supports can be easily removed by inserting a

screwdriver into the mounting slot on the

underside of the mounting bracket assembly and

gently prying downward, while pushing the cover

support off.

3. Install the circuit breakers.

a. Main and single-branch breakers. For main breaker

operation, mount the device such that the load- or

OFF-side terminals rest on the straps and the

mounting bracket supports the opposite end of the

breaker housing. For single-branch operation,

position the circuit breaker such that the line- or

ON-side terminals rest on the straps and the

opposite side is supported by the mounting

bracket.

Align the holes in the circuit breaker housing with

the corresponding holes in the mounting bracket.

Secure the breaker to the bracket with the #10-32 x

3

/4" machine screws [12] and flat washers [13],

3

tightened to 30 in-lb. Attach the circuit breaker

terminals to the threaded holes in the straps using

1

/4-20 x 3/4" machine screws [10] and

the

Belleville washers [11]. Tighten each terminal

connection to 50 in-lb.

NOTE: Straps may require minor adjustments for

proper hole alignment.

b. Double-branch breakers. Position each circuit

breaker such that the line- or

ON-side terminals rest

on the straps and the opposite side is supported by

the mounting bracket. Align the holes in each

circuit breaker housing with the corresponding

holes in the mounting bracket. Fasten the breakers

3

to the brackets with the #10-32 x 3

/4" machine

screws [28] and flat washers [29], tightened to 30

in-lb. Attach the line-side circuit breaker terminals

1

to the threaded holes in the straps using the

3

/4" machine screws [26] and Belleville washers

x

/4-20

[27]. Tighten the line-side screws to 50 in-lb.

NOTE: Straps may require minor adjustments for

proper hole alignment.

4. Tighten the bolted connections. Tighten the bolted

strap connections at the main to 65 in-lb. It may be

necessary to remove the adjacent circuit breaker to

allow access to the bolted connections at the vertical

bus.

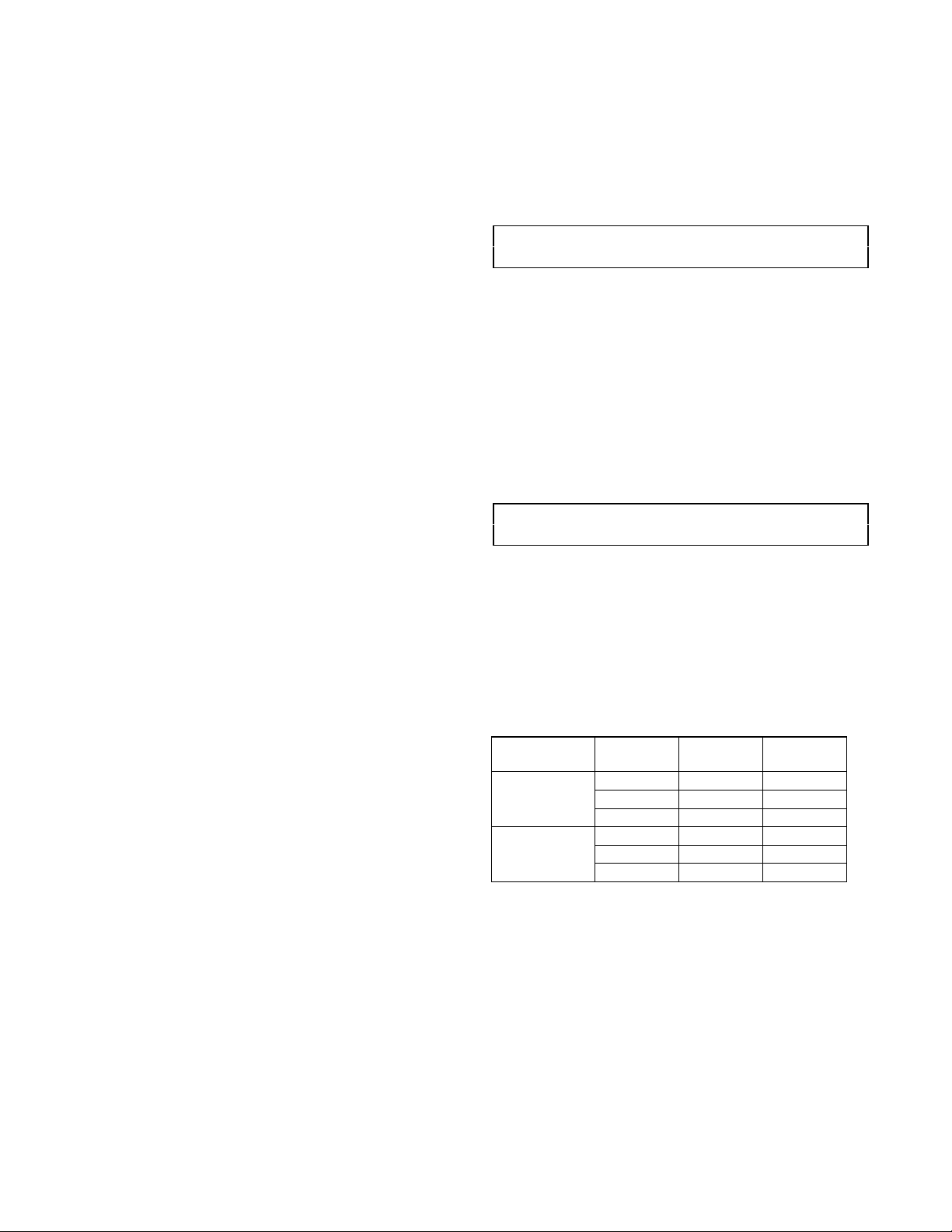

5. Two-pole configurations. For phase-balancing

purposes, single-phase panels, and dc applications, see

Table 3 for the two-pole breaker mounting

configurations available with the listed strap kits.

Strap Kit

Catalog No.

AMCB4FJ

AMCB2FJ

* Use for single-phase panels and dc applications.

A-Phase

Location

XX

X* X*

XX

X* X*

B-Phase

Location

XX

XX

C-Phase

Location

Table 3. Possible phase connection combinations with strap kits.

6. Tape unused contacts. Apply multiple wrappings of

insulation to unused strap contact surfaces, as

illustrated in Figure 8. A UL-recognized 105° C

thermoplastic tape (OANZ2, Permacel P-30-105, or

3M 66R) is required. Overlap greater than one-half of

each preceding turn, as shown, to achieve a minimum

tape thickness of 0.028 inch. This insulation thickness

requires two complete layers of overlapping turns.

Page 3

Cover

Support

Figure 1. Single bolt-on circuit breaker assembly, exploded view.

Strap Mounting Side

on Main Busbar

Figure 2. Single bolt-on circuit breaker assembly, end view.

Cover

Support

Page 4

Cover

pp

Support

Figure 3. Single bolt-on circuit breaker assembly with spacers.

Cover

Su

ort

Figure 4. Double bolt-on circuit breaker assembly, exploded view.

Page 5

pp

Strap Mounting Side

on Main Busbar

Cover

Su

ort

Figure 5. Double bolt-on circuit breaker assembly, end view.

Figure 6. Cover support assembly.

Figure 7. Cover support removal.

Page 6

Figure 8. Applying insulating tape to unused strap contact surfaces.

g

quip

y

p

These instructions do not cover all details or variations in e

ma

be met in connection with installation, operation, or maintenance. Should further information be desired or should

articular problems arise that are not covered sufficiently for the purchaser’s purposes, the matter should be referred to the

GE Company.

ment nor do they provide for every possible contingency that

GE Industrial Systems

General Electric Company

41 Woodford Ave., Plainville, CT 06062

DEH059 R02 0901 © 2001 General Electric Company

Loading...

Loading...