Page 1

ServO

2

Oxygen Control System

Operation, Maintenance &

Service Manual

S

erv

O

2

Oxygen Control System

%

Oxygen

(V/V)

™

+ -

Alarms

High

Defect

Low

Low

Sensor

Enable

Battery

Enable

%

Oxygen

Set

Incubator

Headbox

Calibrate

Page 2

User Responsibility

This Product will perform in conformity with the description thereof contained in this

operating manual and accompanying labels and/or inserts, when assembled, operated,

maintained and repaired in accordance with the instructions provided. This Product must

be checked periodically. A defective Product should not be used. Parts that are broken,

missing, plainly worn, distorted or contaminated should be replaced immediately. Should

such repair or replacement become necessary, Ohmeda recommends that a telephone or

written request for service advice be made to the nearest Ohmeda Regional Service

Center. This Product or any of its parts should not be repaired other than in accordance

with written instructions provided by Ohmeda and by Ohmeda trained personnel. The

Product must not be altered without the prior written approval of Ohmeda’s Quality

Assurance Department. The user of this Product shall have the sole responsibility for any

malfunction which results from improper use, faulty maintenance, improper repair, damage, or alteration by anyone other than Ohmeda.

CAUTION w U.S Federal and Canadian law restrict this device to sale by or on the order of a

licensed medical practitioner.

Page 3

Table of Contents

Table of Contents

General Precautions

Warnings........................................................................................................................ iii

Cautions..........................................................................................................................v

1/General Information

Introducing the ServO2 Oxygen Control System .........................................................1-1

Oxygen Environment ...................................................................................................1-1

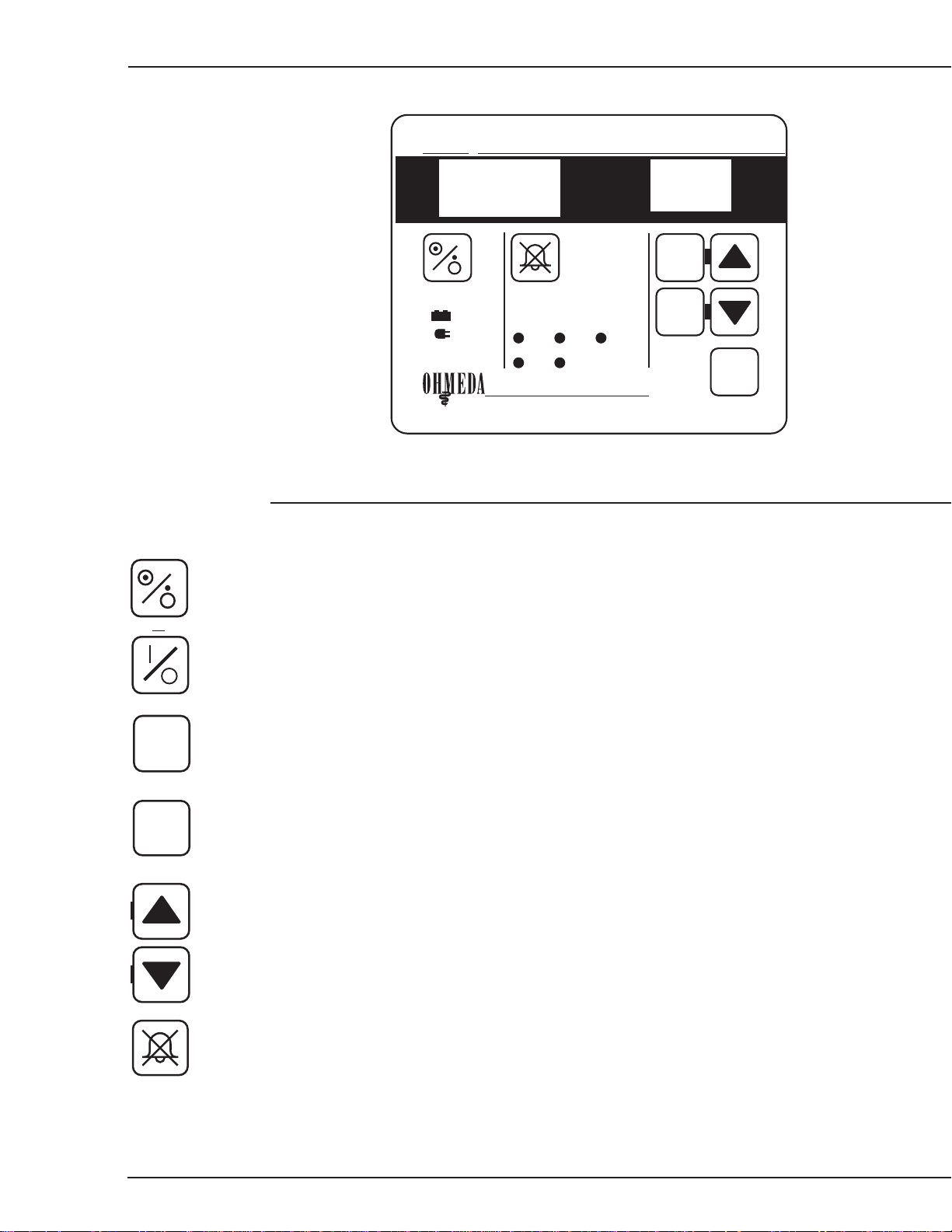

Control Panel ...............................................................................................................1-2

Controls...............................................................................................................1-2

Displays...............................................................................................................1-3

Alarms .................................................................................................................1-3

Low Cell Indicator ........................................................................................................1-4

Operating Modes .........................................................................................................1-4

Mounting Options.........................................................................................................1-5

2/Operation

Preoperative Checkout Procedure...............................................................................2-1

Set-Up..........................................................................................................................2-2

Calibration....................................................................................................................2-3

Calibration Schedule ...........................................................................................2-3

Calibration Procedure .........................................................................................2-3

Using the ServO2 Oxygen Control System ..................................................................2-5

Incubator mounting bracket .........................................................................................2-6

Mounting the sensor............................................................................................2-6

Assembly.............................................................................................................2-7

Disassembly........................................................................................................2-8

3/Maintaining the ServO2 Oxygen Control System

Cleaning.......................................................................................................................3-1

4/Service procedures

4.1 Repair Policy..........................................................................................................4-2

4.2 Maintenance schedule..........................................................................................4-2

4.3 Troubleshooting .....................................................................................................4-3

4.4 Repair Procedures.................................................................................................4-4

4.5 Service Calibration...............................................................................................4-11

4.6 Service Checkout Procedure ...............................................................................4-14

i

6600-0241-000 06/30/97

i

Page 4

Table of Contents

5/Illustrated parts

Exterior parts ...............................................................................................................5-1

Base, manifold and solenoid parts...............................................................................5-2

Interior parts.................................................................................................................5-3

Sensor mounting bracket.............................................................................................5-4

Service Kits..................................................................................................................5-4

Complete units.............................................................................................................5-4

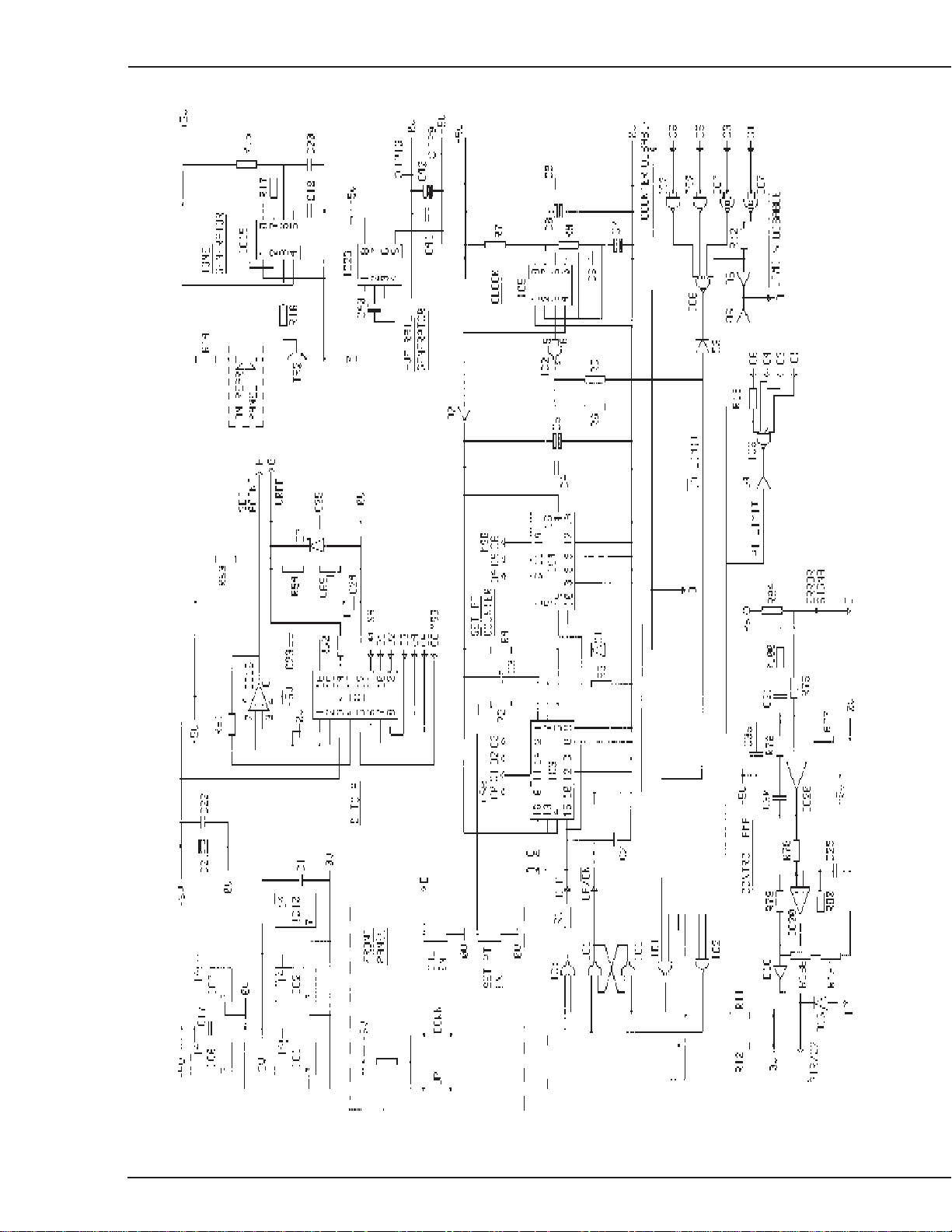

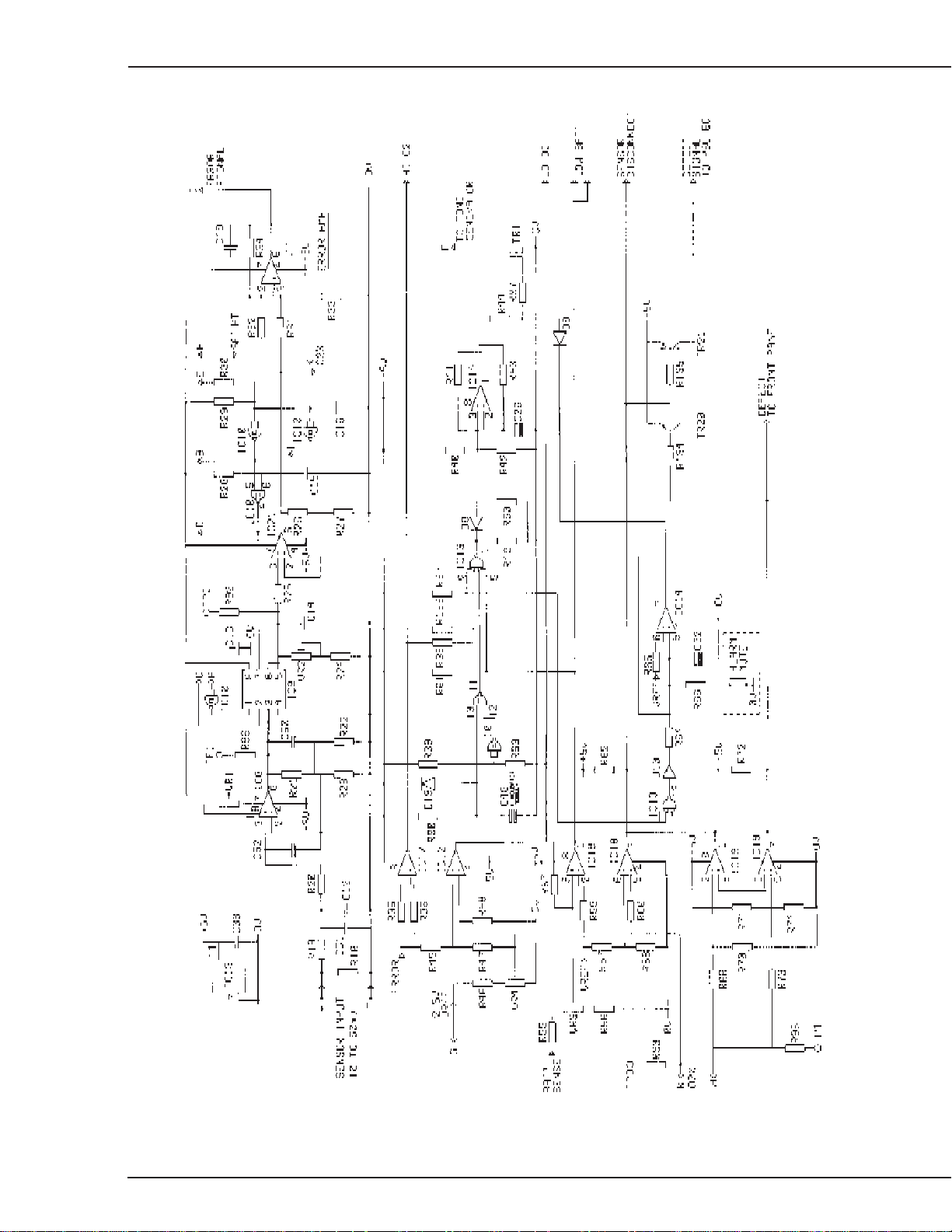

6/Schematics

Pneumatic diagram......................................................................................................6-1

Control board schematic..............................................................................................6-2

Control and PSU board layout .....................................................................................6-4

PSU board schematic ..................................................................................................6-5

Display board schematic..............................................................................................6-6

Display board layout ....................................................................................................6-7

Appendix

Warranty

Specifications.............................................................................................................. A-1

ii

6600-0241-000 06/30/97

ii

Page 5

General Precautions

Table of Contents

Definitions

What the attention symbol means

Next to each warning or caution, we have placed an “attention, readaccompanying

documents” symbol to alert you to the presence of these important statements. This is

the attention symbol:

w

When the attention symbol appears in front of text that is printed on the system itself, it

means that the text is elaborated upon in the operation manual.

WARNING: A Warning statement is used when the possibility of injury to the patient or

the operator exists.

CAUTION: A Caution statement is used when the possibility of damage to the equipment exists.

~ Indicates alternating current.

m Indicates IEC Type BF equipment.

Important: An Important statement is similar to a note but is used for greater emphasis.

Note: A Note provided additional information to clarify a point in the text.

The following are general Warnings and Cautions. Precautions specific to certain

procedures are found in the text of the manual.

w W arnings

Before using the ServO2 Oxygen Control System, read through this entire manual. As

with all medical equipment, attempting to use this device without a thorough understanding of its operation may result in patient or user injury.

Always disconnect the power and gas supplies before performing service or maintenance procedures detailed in this manual. Apply power only if you are specifically

instructed to do so as part of the procedure.

Indicates drip proof as stipulated in BS5724/IEC 601-1.

Indicates Class II equipment: earth connection not required for protection against

shock. Protection is provided by the inclusion of double and/or increased insulation.

When servicing use only identical replacement parts.

iii

6600-0241-000 06/30/97

iii

Page 6

General Precautions

Table of Contents

Oxygen concentrations higher than 40% can increase the risk of retrolental fibroplasia

(retinopathy of prematurity). It is probable that even concentrations of 40% or less

oxygen (formerly considered safe) could be dangerous to some infants. Therefore,

arterial blood gas measurements are extremely important for regulation of the concentration of inspired oxygen when an oxygen-enriched environment is considered necessary. (See current edition of “Standards and Recommendations for Hospital Care of

Newborn Infants” prepared by the Committee of Fetus and Newborn of the Academy of

Pediatrics.)

Complete the “Preoperative Check-out ” section of this manual before putting the unit

into operation. If the ServO2 Oxygen Control System fails any portion of the checkout

procedure it must be removed from use and repaired.

To prevent the possible depletion of the oxygen supply, disconnect the ServoO

Oxygen Control System from gas supplies when not in use.

Do not use the ServO2 Oxygen Control System in the presence of flammable anesthetics; an explosion hazard exists under these conditions.

Do not use oil bearing materials on or near the pneumatic parts of this unit. Oils and

grease oxidize readily, and in the presence of oxygen, they will burn violently. The air

or oxygen parts must be discarded if they are contaminated with oil or grease.

Fire hazard! Even material that will not normally burn will ignite readily and burn rapidly

in high concentrations of oxygen. Keep all sources of ignition away from the incubator

or headbox. Display “NO SMOKING” signs prominently.

Spontaneous and violent ignition may occur if oil, grease or greasy substances come in

contact with oxygen under pressure. Keep oil and grease away from regulators,

cylinder valves, tubing and connections, and all other oxygen equipment.

Use only approved reducing or regulating valves marked for oxygen service on high

pressure oxygen cylinders. Do not use valves for air or gases other than oxygen, since

they may be hazardous when returned to oxygen service. Operate all oxygen equipment strictly in accordance with the manufacturer’s directions.

High pressure oxygen and medical air equipment should always be located outside of

the nursery. Securely fix cylinders in place so that they can not be knocked over while

in use. Locate cylinders as far from the incubator or headbox as possible.

2

Use only equipment designed for use in hazardous locations in delivery rooms. Mixtures of oxygen and flammable vapors, such as alcohol, ether, ethylene and cyclopropane may explode if ignited. Electrical static spark discharges or high temperature

surfaces, in addition to all other more common sources of ignition, may ignite these

mixtures. Refer to Article 517 of the National Electrical Code, ANSI/NFPA 70, for the

use of flammable anesthetics.

iv

6600-0241-000 06/30/97

iv

Page 7

General Precautions

Table of Contents

w

Cautions

Only competent individuals trained in the repair of this equipment should attempt to

service it as detailed in the Manual.

Detailed information for more extensive repairs is included in the service manual solely

for the convenience of users having proper knowledge, tools and test equipment, and

for service representatives trained by Ohmeda.

Precautions specific to certain procedures are found in the text of the manual.

v

6600-0241-000 06/30/97

v

Page 8

Notes

Table of Contents

vi

6600-0241-000 06/30/97

vi

Page 9

1/General Information

In this section

Introducing the ServO2 Oxygen Control System ....................................................... 1-1

Oxygen environment.................................................................................................. 1-1

Control Panel ............................................................................................................. 1-2

Controls............................................................................................................. 1-2

Displays............................................................................................................. 1-3

Alarms ............................................................................................................... 1-3

Operating Modes............................................................................................... 1-4

Mounting options............................................................................................... 1-5

Introducing the ServO2 Oxygen Control System

The ServO2 oxygen control system controls a patient’s oxygen environment. By automatically changing the delivered gas ratio, it maintains the oxygen concentration level

set by the clinician.

A comprehensive series of alarms include high and low oxygen concentration, sensor

disconnected, short circuit or failure, battery running low and internal malfunction. The

system has two modes of operation which allow it to be used with both incubators and

head boxes.

Oxygen Environment

The ServO2 oxygen control system has a finite flow capacity. If the rate of escape from

the patient enclosure exceeds this flow, the unit will be unable to maintain the specified

concentration and will indicate a low oxygen alarm condition. Therefore sealing the

enclosure at high oxygen concentration levels is important.

When the enclosure is opened, oxygen concentration levels rapidly deplete. To react to

such a situation, the ServO2 system uses an oxygen boost system to quickly return the

environment to the specified level. The boost automatically turns on when demand is

highest, and turns off when the actual concentration level nears the specified level. (It is

important to point out that with the unit at its highest setting and the chamber leaking at

the greatest possible rate, it would take approximately 26 minutes to deplete a full Etype cylinder.)

In most cases, the ServO2 will control oxygen concentration levels within incubators or

similar large enclosures, and allows the nursing staff to dispense with headboxes. This

reduces the number of changes in oxygen concentration that the patient would experience with the removal of its headbox. It also improves O2 stabilization in headboxes/

beds when incubators are not available or clinically indicated.

1-1

6600-0241-000 06/30/97

1-1

Page 10

1/General Information

Control Panel

S

Figure 1-1

Control Panel

Oxygen Control System

erv

O

2

888

+ -

Alarms

High

Low

%

Oxygen

(V/V)

Defect

Sensor

Low

Battery

88

Enable

Enable

Calibrate

%

Oxygen

Set

Controls

On/Stand by button. Press to turn unit on. Press again to turn unit off. A short delay has

been set into the ‘off’ function to avoid inadvertent switch-off.

or

Enable

Calibrate

Note: The On/Stand by button does not control the electrical power supply. Whenever the

ServO2 system power cord is connected the internal battery is being charged.

Enable button. Used in conjunction with the M or ? buttons to change the required

oxygen concentration level.

Calibrate button. Used to check that the unit is within calibration. When the Calibrate

button is pressed, the ServO2 system automatically delivers 100% oxygen to the output

tube and the Oxygen Set display goes blank. You must press the Calibrate button and the

M or ? buttons to change the calibration setting.

M & ? buttons. Used with Calibrate and Enable buttons to change the calibration and

Oxygen Set point. Pressing the button changes the display by one digit. Holding the

button in continuously changes the display one digit at a time.

Alarm silence button. Cancels the audible alarm on High O2, Low O2, and Low Battery

alarms for a period of approximately 2 minutes, but the alarm indicator remains on.

Sensor and Defect alarms cannot be silenced.

1-2

At the end of the alarm silence period the audible alarm will automatically resume if the

alarm condition has not been resolved.

6600-0241-000 06/30/97

1-2

Page 11

1/General Information

Displays

% Oxygen (V/V) display. Three digit display indicates the actual oxygen concentration

%

Oxygen

level monitored by the oxygen sensor. This is displayed as a percentage of oxygen by

888

(V/V)

volume(v/v).

88

Alarms

High

Low

+ -

%

Oxygen

Set

Defect

Sensor

% Oxygen Set display. Two digit display indicates the required oxygen concentration

level set by the clinician. This is displayed as a percentage of oxygen by volume (v/v).

When the environment is stable the Oxygen Set and Oxygen V/V displays should be

within one digit of each other.

Battery indicator. When on indicates that the ServO2 system is running from its internal

battery.

Line indicator. When on indicates that the ServO2 system is using power from the wall

outlet. This is the normal mode of operation. This also indicates that the internal battery

is being automatically recharged.

Alarms

High alarm indicator. Actual Oxygen concentration level is greater than 3% (v/v) above

that displayed on Oxygen Set. Alarm condition immediately lights the High indicator on

the front panel. After a delay period of 2 minutes (nominal) an audible alarm sounds.

Both the visual indicator and audible alarm will automatically reset when the alarm

condition is resolved.

Low alarm indicator. Actual oxygen concentration level is greater than 3% (v/v) below that

displayed on Oxygen Set. Alarm condition immediately lights the Low indicator on the front

Low

panel. After a delay period of 2 minutes (nominal) an audible alarm sounds. Both the visual

Battery

indicator and audible alarm will automatically reset when the alarm condition is resolved.

Immediately following first pressing the On/Stand by button the Low audible alarm is

deactivated for approximately 2 minutes. This allows time for the gases to fill larger

chambers such as incubators, avoiding unnecessary alarms.

Sensor alarm indicator. The oxygen sensor is disconnected or there is an open or short

circuit in the sensor wiring. The indicator lights and the alarm sounds immediately, and

cannot be silenced. The % Oxygen display reads “00” and the oxygen solenoid is

automatically disabled.

Defect alarm indicator. Internal malfunction causes the indicator to light and the alarm to

sound immediately. This alarm cannot be silenced. Oxygen supply is automatically

disabled for safety purposes.

WARNING w Do not use the ServO2 Oxygen Control System if a Defect alarm is indi-

cated. The unit must be immediately removed from use and repaired.

Low Battery alarm indicator. Indicator lights immediately when the battery has only

7 minutes (nominal) remaining life. Delay of 2 minutes before the audible alarm sounds.

The audible alarm can be silenced.

1-3

6600-0241-000 06/30/97

1-3

Page 12

1/General Information

WARNING w If the low battery alarm remains unattended for a period of 7 minutes the

ServO2 Oxygen Control System will automatically turn itself off to prevent

permanent battery damage. The internal battery is provided as an emergency back-up only.

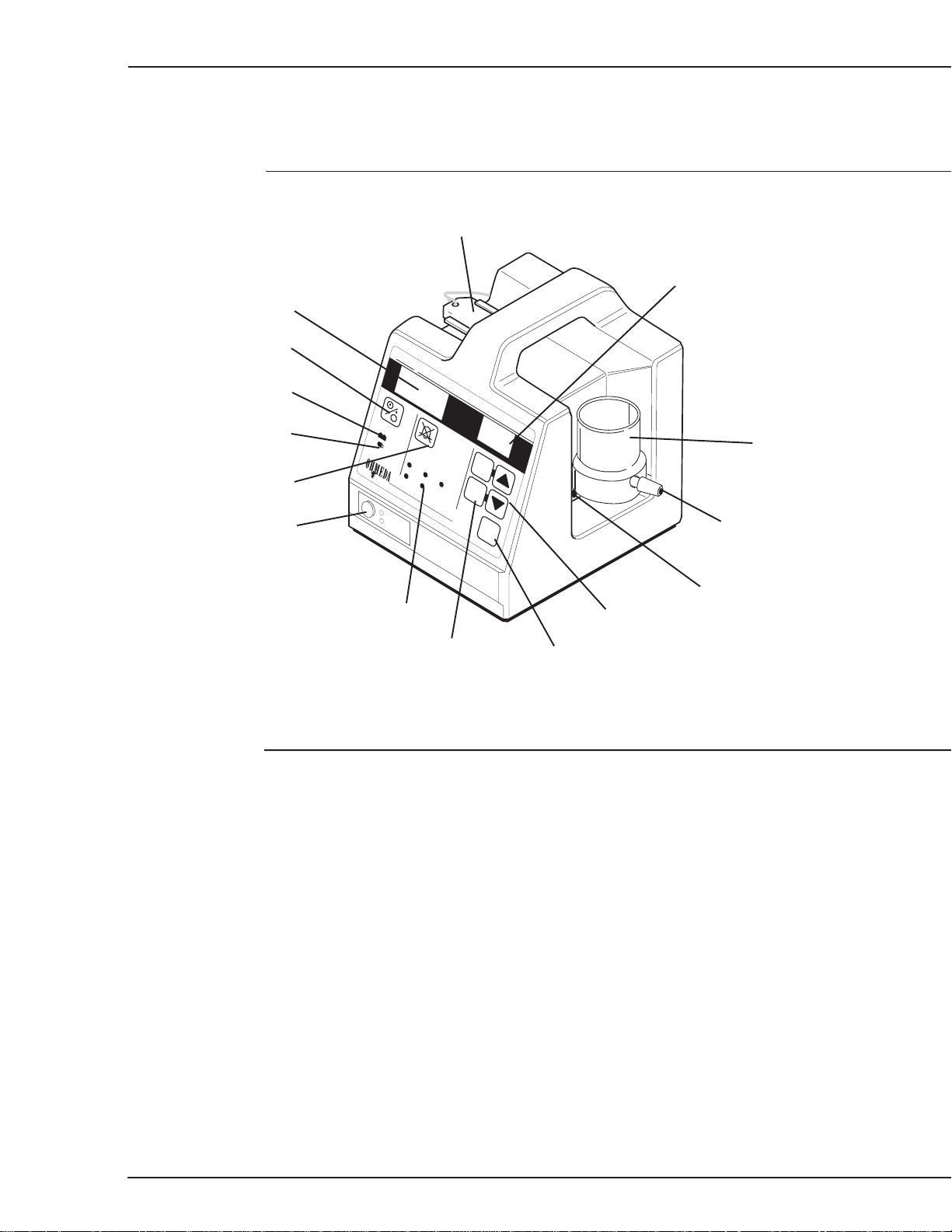

Mode key and holder

% Oxygen Set

Actual % Oxygen

On/Off button

Battery indicator

Line indicator

Alarm Silence button

Mode indicator

Figure 1-2

ServO2 Oxygen Control System front view

S

+ -

Incubator

Headbox

Alarm indicators

Enable buttons

erv

O

2

Oxygen Control System

Alarms

High

Low

%

Oxygen

(V/V)

%

Oxygen

Set

Defect

Sensor

Enable

Low

Enable

Battery

Calibrate

Calibration Port

Input barb connector

Sensor connector

% Oxygen control buttons

Calibrate button

Operating Modes

The ServO2 system can work in either Incubator or Headbox mode.

Incubator mode. To put the unit in Incubator mode press the metal switch on the back

of the unit (see Figure 1-3) and insert mode key into the slots . When connected to an

oxygen or air supply, the mode indicator on the lower left front of the unit will show a

series of red dots to indicate the Incubator mode.

Headbox mode. With the mode key removed (default) the unit is in low flow or

headbox mode. The mode indicator on the lower left front of the unit will show a series

of black dots (see Figure 1-2).

To put the unit back into Headbox mode simply remove the mode key. A holder located

on the top of the unit is provided for the safe storage of the mode key.

1-4

6600-0241-000 06/30/97

1-4

Page 13

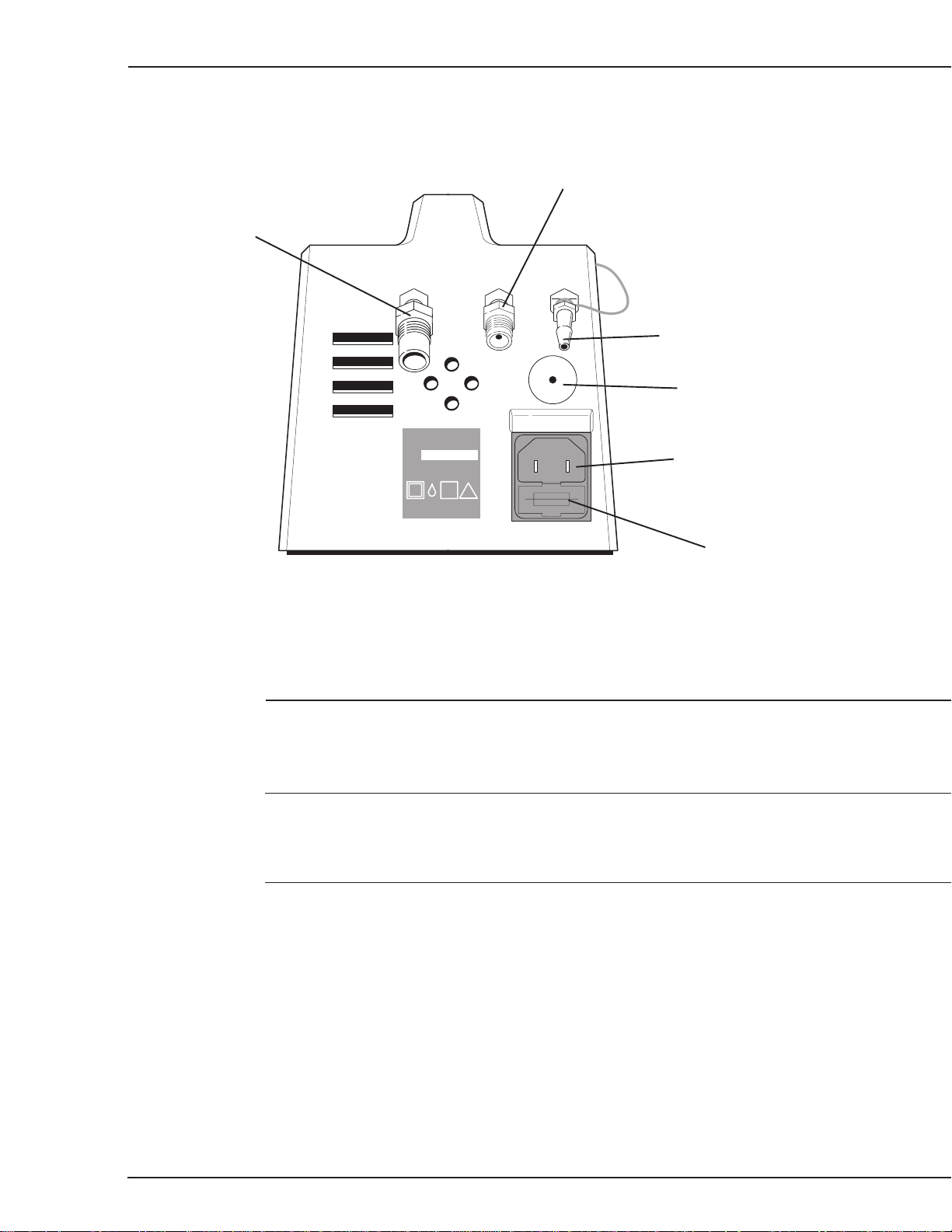

1/General Information

Medical air inlet

Oxygen inlet

Gas outlet

Headbox/Incubator switch

Power cord input

Fuse holder

Figure 1-3

ServO2 Oxygen Control System rear view

Mounting options

CAUTION w It is recommended that the ServO2 Oxygen Control System be used in con-

junction with a mounting bracket to prevent the unit from falling and being

damaged.

There are two mounting options available:

Dovetail mounting bracket (fits rails used on Ohmeda equipment) ......... 6600-0236-910

C-clamp/Universal rail mounting bracket (fits European style rails) ........ 6600-0236-913

1-5

6600-0241-000 06/30/97

1-5

Page 14

Notes

1/General Information

1-6

6600-0241-000 06/30/97

1-6

Page 15

2/Operation

WARNINGS w Do not perform the preoperative checkout procedure when the unit is

being used with a patient.

w Complete the “Preoperative Checkout ” section of this manual before

putting the unit into operation. If the ServO2 Oxygen Control System fails

any portion of the checkout procedure it must be removed from use and

repaired.

w Oxygen concentrations higher than 40% can increase the risk of

retrolental fibroplasia (retinopathy of prematurity). It is probable that even

concentrations of 40% or less oxygen (formerly considered safe) could be

dangerous to some infants. Therefore, arterial blood gas measurements

are extremely important for regulation of the concentration of inspired

oxygen when an oxygen-enriched environment is considered necessary.

(See current edition of “Standards and Recommendations for Hospital

Care of Newborn Infants” prepared by the Committee of Fetus and Newborn of the Academy of Pediatrics.)

w Do not use oil or oil bearing materials on or near the pneumatic parts of

this unit. Oils and grease oxidize readily, and in the presence of oxygen,

they will burn violently. The air and oxygen parts must be discarded if

they are contaminated with oil or grease.

In this section

Preoperative checkout Procedure ............................................................................. 2-1

Set-Up........................................................................................................................ 2-2

Calibration.................................................................................................................. 2-2

Calibration Schedule ......................................................................................... 2-2

Calibration Procedure ....................................................................................... 2-3

Using the ServO2 Oxygen Control System ................................................................ 2-3

Preoperative checkout procedure

1. Visually inspect the ServO2 Oxygen Control System, its power cord and sensor

cable for signs of damage.

2. Connect an oxygen supply to the unit, ensuring correct gas connection if no cross

connection system is in use such as DISS or NIST. Turn the unit on and check that

gas exhausts from the outlet barb on the back of the unit. Disconnect the oxygen

supply.

2-1

6600-0241-000 06/30/97

2-1

Page 16

2/Operation

3. Repeat step 2 with an air supply connected to the ServO2 Oxygen Control System.

4. Connect both gas supplies to the unit. Turn the unit on. Press the mode switch on

5. Disconnect the sensor to verify that the sensor indicator lights and that the alarm

6. Unplug the unit's power cord and verify that the battery indicator lights and that the

7. Calibrate the unit according to the instructions in Calibration in this section.

Set-up

1. Connect the Sensor cable to ServO2 Oxygen Control System.

2. Install the appropriate air and oxygen connections to the 1/8" NPT fittings on the

the back of the unit and check that the flow rate increases (there will be an audible

difference in sound level). When the mode switch is depressed and the unit is

connected to a gas supply, check that the mode indicator on the front of the unit

shows red dots.

sounds. Reconnect the sensor and verify the alarm is silenced and the indicator

goes out.

unit continues to function on battery power.

back of the unit.

3. Connect oxygen and air supplies to the inlets on the back of the unit (See Figure

1-3). Gas supplies greater than 65 PSI require high pressure ServO2 units (see

page 5-4 in section 5/Illustrated Parts).

4. Plug the power cord into the wall outlet. Check that the Line indicator is lit on the

front panel (See Figure 1-1).

5. Connect an appropriate length of tubing to the output connector at the rear of the

device (See Figure 1-3).

6. Place the unit within 6 feet (2 meters) of the incubator/cot to keep the sensor cable

from being strained.

CAUTION w It is recommend that the ServO2 Oxygen Control System be used in conjunction

with a mounting bracket to prevent the unit from falling and being damaged.

Calibration

Calibration Schedule

Calibrate the ServO2 system and its integral oxygen sensor according to the following

schedule:

• Before the equipment is first put into use.

2-2

• Before the equipment is used immediately following an extended period of storage.

• Once every 24 hours when the ServO2 system is in constant use.

6600-0241-000 06/30/97

2-2

Page 17

2/Operation

Calibration Procedure

1. Place oxygen sensor securely into the calibration port .

2. Fit the distal end of the ServO2 output hose (the end farthest away from the unit)

3. Press and hold the Calibrate button on the control panel. This will automatically

4. Allow approximately 20 seconds for the environment and sensor to stabilize.

5. While still pressing the Calibrate button, adjust the “% Oxygen (V/V)” display to

6. When the display stabilizes at 100%, release all the buttons. Remove the sensor

7. Remove the output hose from the calibration port input barb and place it in the

securely over the input barb connector on the calibration port.

blank out the “% Oxygen Set” display and deliver 100% Oxygen through the output

hose. Press and hold the Calibrate button throughout the calibration procedure.

read 100% by pressing the M or ? button. If it does not read 100%, the sensor

must be replaced.

from the port and place it in the ambient air. Check that the “% Oxygen (V/V)”

display reads 21% (± 1%). If it does not, the sensor must be replaced.

enclosure.

If a calibration port is not available the following is an alternative way to calibrate the unit.

1. Place oxygen sensor and the output tube from the ServO2 system together in a

small container such as a plastic bag.

CAUTION w Do not totally seal the container - excessive pressure may develop which can

lead to incorrect calibration. Always use the gas output from the ServO2 Oxygen Control System to calibrate the unit.

2. Press and hold the Calibration button on the front panel. This will automatically

blank out the % Oxygen Set display, and deliver 100% oxygen through the output

tube. Hold in the Calibration button throughout the calibration procedure.

3. Allow approximately 20 seconds for the environment and sensor to stabilize.

4. While still pressing the Calibration button, adjust the % Oxygen V/V display to read

100% by pressing either the M or ? button.

5. Release all buttons. Remove sensor from container and place in ambient air away

from the delivery tube. Check % Oxygen (v/v) display now reads 21% (±1%).

Note: If the display cannot be adjusted to reach 100% or does not return to 21%

(±1%), then the sensor must be replaced.

Using the ServO2 Oxygen Control System

WARNINGS w Fire hazard! Even material that will not normally burn will ignite readily

and burn rapidly in high concentrations of oxygen. Keep all sources of

ignition away from the incubator or headbox. Display “NO SMOKING”

signs prominently.

2-3

6600-0241-000 06/30/97

2-3

Page 18

2/Operation

WARNING w Spontaneous and violent ignition may occur if oil, grease of greasy

substances come in contact with oxygen under pressure. Keep oil and

grease away from regulators, cylinder valves, tubing and connections,

and all other oxygen equipment.

w Use only approved reducing or regulating valves marked for oxygen

service on high pressure oxygen cylinders. Do not use valves for air or

gases other than oxygen, since they may be hazardous when returned to

oxygen service. Operate all oxygen equipment strictly in accordance with

the manufacturer’s directions.

w High pressure oxygen and medical air equipment should always be

located outside of the nursery. Securely fix cylinders in place so that they

can not be knocked over while in use. Locate cylinders as far from the

incubator or headbox as possible.

w Use only equipment designed for use in hazardous locations in delivery

rooms. Mixtures of oxygen and flammable vapors, such as alcohol, ether,

ethylene and cyclopropane may explode if ignited. Electrical static spark

discharges or high temperature surfaces, in addition to all other more

common sources of ignition, may ignite these mixtures. Refer to Article

517 of the National Electrical Code, ANSI/NFPA 70, for the use of flammable anesthetics.

1. Set-up the unit as described in Set-up section.

2. Perform the Preoperative checkout procedure.

3. Check calibration according to the calibration procedure.

Note: Before use the ServO2 system can be checked by placing the sensor in air

and ensuring the oxygen (v/v) display reads 21% ±1%.

4. Place the unit in either the Incubator or Headbox Mode.

5. Place ServO2 system sensor in the patient chamber.

WARNING w Do not place the Oxygen Sensor so close that it might obstruct the pa-

tient airway, and do not obstruct or cover the end of the oxygen sensor

during use.

6. Place the output tube in the patient chamber. Direct gas flow away from both the

patient and the oxygen sensor. Using a deflecting device is recommended to

ensure good gas circulation when using a headbox or canopy.

7. For incubators, connect the delivery tube to the oxygen inlet on the incubator or

place it in the patient chamber so that it is in heated air flow coming up from within

incubator.

2-4

8. Turn unit on by pressing I/O button. A set point of 21% will be displayed.

9. Press and hold the Enable button and adjust the % Oxygen Set display to the

required oxygen concentration by pressing the M button. Release all buttons.

6600-0241-000 06/30/97

2-4

Page 19

2/Operation

10. The ServO2 Oxygen Control System will now adjust the delivered gas to correct the

difference between the oxygen concentration within the patient enclosure and the

required level set by the user.

Note: The ServO2 Oxygen Control System will easily control oxygen set point

concentrations in the Care Plus Incubator between 40 and 50%. However, in the

unlikely event that concentrations greater than 50% are desired, incubator conditions may prevent the ServO2 unit from achieving these levels. To reach these

higher set points use a headbox with the ServO2 unit in the headbox mode, or add

supplemental oxygen through the incubator’s oxygen inlet port and adjust the flow

rate as necessary.

2-5

6600-0241-000 06/30/97

2-5

Page 20

2/Operation

Notes

2-6

6600-0241-000 06/30/97

2-6

Page 21

3/Maintaining the ServO2 Oxygen Control System

Cleaning and Disinfection

The ServO2 Oxygen Control System has been specifically designed with chamfered

edges and a minimum of sharp corners to reduce dirt traps.

The ServO2 system can be cleaned by wiping down with a cloth and using a solution of

water and a mild detergent. Use Cavicide® disinfecting cleaner to disinfect the unit.

CAUTION w Do not autoclave or expose the ServO2 Oxygen Control System to tempera-

tures or humidity outside its specifications. Do not immerse any part of the

ServO2 system

.

3-1

6600-0241-000 06/30/97

3-1

Page 22

3/Maintaining the ServO2 Oxygen Control System

Notes

3-2

6600-0241-000 06/30/97

3-2

Page 23

4/Service Procedures

In this section

4.1 Repair Policy ..................................................................................................... 4-2

4.2 Maintenance schedule ...................................................................................... 4-2

Operator maintenance ...................................................................................... 4-2

Service maintenance......................................................................................... 4-2

4.3 Troubleshooting humidifier problems ................................................................ 4-3

4.4 Repair Procedures ............................................................................................ 4-4

A. Base Control/PSU Board Removal............................................................... 4-4

B. Display Board Replacement ......................................................................... 4-5

C. Touch Panel Replacement ........................................................................... 4-6

D. Transformer Chassis Replacement .............................................................. 4-7

E. Mains Fuse Replacement ............................................................................. 4-7

F. Manifold/Solenoid Assy Removal ................................................................ 4-7

G. Filter Replacement ....................................................................................... 4-7

H. Battery Replacement ................................................................................... 4-8

I. Input Sensor Cable replacement.................................................................... 4-8

J. Mode Indicator Replacement ........................................................................ 4-9

K. IEC Inlet Receptacle Replacement............................................................... 4-9

L. Speaker Replacement................................................................................. 4-10

M. Mode Selector Replacement...................................................................... 4-10

N. Air/Oxygen/Blend Swivel Replacement ...................................................... 4-11

O. Oxygen Sensor Cell Replacement ............................................................. 4-11

4.5 Service Calibration............................................................................................. 4-12

A. Calibration Set-up ....................................................................................... 4-12

B. Calibration Amplifier - Voltage Offset Null .................................................. 4-12

C. Digitally Controlled Variable Resistor ......................................................... 4-12

D. D to A Output Calibration............................................................................ 4-13

E. High/Low Alarm Calibration ........................................................................ 4-13

F. Display DVM Calibration ............................................................................. 4-14

G. Battery Charge Rate Set ............................................................................ 4-14

H. Battery Charge Current Check ................................................................... 4-14

I. Low Battery Alarm Threshold Calibration.................................................... 4-14

J. Calibration Re-assembly ............................................................................. 4-14

4.6 Service Checkout Procedure ............................................................................. 4-15

A. Gas Flow Rate Check................................................................................. 4-15

B. User Functions Check ................................................................................ 4-15

C. Alarm Check ............................................................................................... 4-16

D. Control Check............................................................................................. 4-17

E. Electrical Safety Test .................................................................................. 4-17

4-1

6600-0241-000 05/26/98

4-1

Page 24

4/Service Procedures

4.1 Repair Policy

Warranty repair and service must be performed by an Ohmeda Service and Distribution

Center. To contact an Ohmeda Service Representative, call the nearest Ohmeda

Service Center listed on the back cover.

Do not use malfunctioning equipment. Make all necessary repairs or have the equipment repaired by an Ohmeda Service and Distribution Center. Parts listed in the

manual, for this product, may be repaired or replaced by a competent, trained person

who has experience in repairing devices of this nature. After repair, perform all applicable check procedures described in the manual.

WARNING w Do not use oil or oil bearing materials on or near the pneumatic parts of

the unit. Oils and grease oxidize readily, and in the presence of oxygen,

they will burn violently. The air or oxygen parts must be discarded if they

are contaminated with oil and grease.

CAUTIONS w Only competent individuals trained in the repair of this equipment should

attempt to service it as detailed in the manual.

w Detailed information for more extensive repairs is included in the manual

solely for the convenience of users having proper knowledge, tools and test

equipment, and for service representatives trained by Ohmeda.

4.2 Maintenance schedule

The unit should be maintained in accordance with the procedures detailed in the

manual. Quarterly and yearly maintenance must be performed by a technically competent individual as described in the Repair Policy.

Operator maintenance

This schedule lists the minimum frequencies. Always follow hospital and local regulations for required frequencies.

Daily or before each patient Calibrate the ServO2 Oxygen Control System (see

Service maintenance

This schedule lists the minimum frequencies. Always follow hospital and local regulations for required frequencies.

Every six months Perform the service checkout and electrical safety

Every year Replace filters. Perform service calibration in this

section 2, Operation).

procedurein this section.

section

4-2

Every two years Replace the battery.

6600-0241-000 05/26/98

4-2

Page 25

4/Service Procedures

4.3 Troubleshooting ServO2 Oxygen Control System problems

Symptom Possible cause(s) Recommended action(s)

Oxygen display reads 00, Sensor cable is broken, Connect or replace the sensor cord

Sensor indicator on and disconnected or short circuit assembly

non-silencable alarm sounds

Defect indicator on and Electrical failure Remove unit from use

non-silencable alarm sounds or short circuit contact service

Setpoint can not Not pressing Enable Verify you press Enable

be adjusted and Mor ? at the same time and M or ? at the same time

Electronic fault Remove unit from use

contact service

ServO

system can not reach Sensor not in the patient Verify that the delivery tube and

2

and maintain the desired chamber or sensor is covered sensor are placed in the

setpoint Gas delivery tube is not patient chamber

in the patient chamber

Oxygen is not connected Check that the O

Oxygen and air lines Check connection

misconnected

Setpoint selected is too high Reset setpoint to a level that

for the enclosure being used. enables stabilization

system has a

ServO

2

maximum flow rate determined and/or

by the mode selected .

It can not compensate Limit leakage from incubator or

for leakage rates greater head hood.

than this.

`

Incubator door or portholes Close doors. If clinical procedures

left open too long require doors or porthole be open

Internal leak in unit Remove unit from service and check

Mode switch not fully engaged Remove mode key, make sure you

Check that tubing access

covers, porthole seals, incubator

controller seals, humidifier seals and

tray are in place and in good condition.

for extended periods, use head

box or porthole sleeves.

for leaks

press the switch button all the way in,

then re-insert mode key. If problem

persists, re-adjust switch

connection is secure

2

controller in wrong mode Change mode

ServO

2

Actual oxygen concentration Delivery tube output to close Re-position tube

level oscillates around set point to sensor

Can not calibrate at Sensor failure or depletion Replace sensor

100% oxygen

After calibration at 100% oxygen, sensor Defective sensor Replace sensor

does not display between 20 and 22%

Unit in incubator mode, but indicator Due to infrequent use With unit in incubator mode, and O2 at

shows Headbox mode or is not fully lubricant solidified 100%, pinch out tube to make back

in Incubator mode position pressure and free up indicator

4-3

6600-0241-000 05/26/98

4-3

Page 26

4/Service Procedures

4.4 Repair Procedures

WARNING w Before any disassembly or repair, disconnect the electrical and any gas

supply connections. Do not perform any service or maintenance with the

power applied unless specifically told to do so in the procedure.

w After each repair procedure, perform the service checkout procedure.

CAUTION s Use a Static Control Work Station (0175-2311-000) for all procedures marked with the

symbol s to help ensure static charges are safely conducted to the ground. The

Velostat material is conductive. Do not place electrically powered boards on it.

Important: In cases where total disassembly is not required, replacing only the touch

panel for example, perform only the necessary steps.

Wire Harness Table

harness board position wire colors

transformer secondary harness PL4 2 black wires

battery harness BATT 2 black & 2 red wires

speaker harness PL2 1 black, 1 red, 1 green, & 1

yellow wire

sensor input harness INPUT 1 red & 1 blue wire

display harness PL1 34 wire ribbon cable

solenoid harness PL3 6 red wires

Equipment needed:

Phillips screw driver #2

Small flat blade screwdriver

T-10 Torx driver (provided in service kit)

95° T-10 Torx driver (provided in service kit)

11mm socket wrench

8mm open end wrench

6mm open end wrench

Rubber gloves or two small sheets of rubber

1/4" dia. dowel rod

Wire cutters

50 - 60 psi (3 -4 bar) static gas pressure source

ss

s A. Base and Control/PSU board Removal

ss

(Refer to Figures 4-1 & 4-2)

1. Place the unit on its side with the oxygen sensor facing up and the base facing you.

2. Remove the six Phillips head mounting screws that secure the base to the case.

3. Remove base cover taking care not to stress tubing and cable attached to the mani-

fold/solenoid assembly attached to the base.

4-4

6600-0241-000 05/26/98

4-4

Page 27

4/Service Procedures

4. Remove the three color coded luer locks that attach the tubes to the manifold.

5. Press the release clip and slide the board partially out to gain access to wire

harness connectors.

Luer lock

clear/white

Mounting screw

Manifold

Base

black

blue

Calibrate

Solenoid harness

Battery

Low

Sensor

Defect

Low

High

+ -

Figure 4-1

Removing base

6. Disconnect the transformer secondary harness, the battery harness, the speaker

harness, the sensor input harness, the display ribbon cable and the solenoid

harness.

7. Remove the control/PSU board assembly.

Note: To disconnect the display ribbon cable use a small flat blade screwdriver.

Place the blade into the connector indexing slot and pry the connectors apart.

8. To separate the control board from the PSU board remove the four T10 Torx

screws that secure control board to the PSU board and separate the boards. Take

care not to excessively flex either board.

4-5

9. To replace either the PSU board or the control board, perform steps 1 through 8 in

reverse.

6600-0241-000 05/26/98

4-5

Page 28

4/Service Procedures

s s

s B. Display Board Replacement

s s

(Refer to Figure 4-2)

1. Remove the base and the control/PSU board assembly to gain access to display

board (see section 4.4A Base and Control/PSU assembly Removal).

Board release clip

PSU board

Control board

Display board

ribbon cable

Display board

Mode indicator

Transformer

Battery

O2 Sensor

cable cover

Ni Cad 7.2V/300mAHr

IEC receptacle insulating cover

Transformer chassis

Speaker

Air inlet

Oxygen inlet

Mode selector

Gas outlet

Figure 4-2

Interior view

2. Remove the transformer chassis.

3. Using a 95 degree T-10 Torx driver, remove the two mounting screws located at

the top of the display board.

4. Using a straight T-10 Torx driver, remove the two mounting screws located at the

bottom of the display board.

5. Disconnect touch panel ribbon cable from display board connector located on the

solder side of display board and carefully separate the display board from case.

6. To replace the display board, perform steps 1 through 5 in reverse.

s s

s C. Touch Panel Replacement

s s

1. Peel touch panel off the case.

Note: Prior to installation of a new touch panel, insure the case is clean for the

panel to properly adhere. It is important that the touch panel properly adheres to

the case to help protect the unit from spills.

2. Disconnect the ribbon cable from the touch panel.

4-6

6600-0241-000 05/26/98

4-6

Page 29

4/Service Procedures

3. Connect the ribbon cable to the new touch panel.

4. Apply new panel label to the case.

s D. Transformer Chassis Replacement

(Refer to Figure 4-2)

1. Remove the base and the control/PSU board assembly to gain access to the

transformer chassis (see section 4.4A Base and Control/PSU Board Removal).

2. To remove the A.C. mains wiring from the IEC inlet receptacle, slide the insulating

cover off the receptacle, remove the faston connectors, and remove the mains

wiring from the cover.

3. Remove the three T-10 Torx screw that hold the transformer chassis to the case,

and carefully remove the chassis from case.

4. To replace the transformer chassis, perform steps 1 through 3 in reverse.

E. Mains Fuse Replacement

1. Use a straight blade screw driver to pry off fuse cover from IEC receptacle located

on rear of unit (see Figure 1-3).

2. Replace the fuse with a fuse of the same rating.

ss

s F. Manifold/Solenoid Assembly Removal

ss

1. Remove the base and the control/PSU board assembly to gain access to the

manifold/solenoid assembly (see section 4.4A Base and Control/PSU Board

Removal).

2. Peel the service warning label off the bottom of base to expose the two mounting

screws on the outside of the base.

Note: A new label must be applied.

3. Remove the two Phillips head mounting screws that hold the manifold/solenoid

assembly to the base and remove the assembly.

4. Install the new manifold/solenoid assembly with the two Phillips screws removed in

step 3 and apply a new service warning label to the base.

5. Re-assemble the unit by reversing steps 1 through 7 in section 4.4A Base and

Control/PSU Board Removal.

ss

s G. Filter Replacement

ss

1. Remove the base and the control/PSU board assembly (see section 4.4A Base

and Control/PSU Board Removal).

4-7

6600-0241-000 05/26/98

4-7

Page 30

4/Service Procedures

2. Use a 11mm socket or box wrench to remove the black and the white plastic 1/8

NPT screws from the side of the manifold. Remove any debris from the filter

chambers before removing the filters. This can be done by directing high pressure

air into the chambers. Be sure to wear eye protection while using air pressure to

clean the filters.

3. To remove the two filters from within the manifold, lightly tap the manifold from the

reverse side or use a small curved pick.

4. Install new filters and re-install the black and the white plastic 1/8 NPT screws.

5. Re-assemble the unit by reversing the steps in section 4.4A Base and Control/PSU

Board Removal.

6. Install a new output barb.

7. Remove the NIST fittings and replace filters. When re-installing the fittings, use de-

greased PTFE tape (6600-0041-300) to seal them.

8. Perform service checkout procedure.

ss

s H. Battery Replacement

ss

(Refer to Figure 4-2)

1. Remove the base and the control/PSU board assembly to gain access to the

transformer chassis (see section 4.4A Base and Control/PSU Board Removal).

2. Remove the transformer chassis (see section 4.4D Transformer Chassis Removal).

3. Remove the two plastic knurled nuts that secure the battery and battery holder to

the transformer chassis.

4. Install the new battery and reverse steps 1 through 3 to re-assemble the unit.

ss

s I. Input Sensor Cable Replacement

ss

(Refer to Figure 4-2)

1. Remove the base and the control/PSU board assembly (see section 4.4A Base

and Control/PSU Board Removal).

2. Remove the black insulation from the case connector.

3. Remove the case connector and harness.

4. Slide the black housing off the wire and connector.

5. Remove the inlet connector and wire from the unit.

6. Install the new sensor cable.

4-8

7. Re-assemble the unit reversing steps 1 through 6.

6600-0241-000 05/26/98

4-8

Page 31

4/Service Procedures

J. Mode Indicator Replacement

1. Remove the base and the control/PSU board assembly (see section 4.4A Base

and Control/PSU Board Removal).

2. Disconnect the blue tubing from mode indicator.

3. Unscrew the 90 degree plastic tubing connector from the mode indicator.

4. Unscrew the black housing from the mode indicator.

5. Push on the rear of the mode indicator to loosen the label enough to peel it off.

Note: A new label must be installed.

6. Remove the mode indicator.

Note: Before installing a new mode indicator, clean the label area to ensure

adhesion of the new label.

7. Install a new mode indicator and label.

8. Re-assemble the unit by reversing the steps in section 4.4A Base and Control/

PSU Board Removal.

9. To adjust the mode selector switch:

a) Using a 1.5 mm hex key, remove the first of the two set screws in the hole in

the center of the switch.

b) While pushing the switch all the way in, adjust the second set screw until the

mode key locating groove aligns with the groove in the mode selector housing.

c) Re-install the first set screw to lock in the adjustment setting. Check that the

adjustment does not change.

d) Check that the mode key fits smoothly into the slot when the Incubator mode is

selected.

e) Check that when the mode key is in the slot there is no free play in the mode

selector (if there is, the selector switch may not have been pressed all the way

in when the adjustment was made).

ss

s K. IEC Inlet Receptacle Replacement

ss

(Refer to Figure 4-2)

1. Remove the base and the control/PSU board assembly (see section 4.4A Base

and Control/PSU Board Removal).

2. Slide the insulating cover off the back of the IEC receptacle.

3. Pull off the Faston connectors to disconnect the brown and blue wires from the IEC

receptacle.

4-9

4. Depress the locking tabs on both sides of the receptacle, and remove the receptacle.

5. Install the new receptacle. When re-installing the wiring, the brown wire is con-

nected to phase and the blue wire is connected to neutral. The neutral tab on the

receptacle is identified by an ‘N’ next to the connector.

6. Re-assemble the unit by reversing the steps in 4.4A Base Removal.

6600-0241-000 05/26/98

4-9

Page 32

4/Service Procedures

ss

s L. Speaker Replacement

ss

(Refer to Figure 4-2)

1. Remove the base and the control/PSU board assembly to gain access to the

speaker harness (see section 4.4A Base and Control/PSU Board Removal).

2. Disconnect the speaker harness.

3. Using a 95° T-10 Torx driver, loosen the screw that secures the speaker mounting

bracket and rotate the speaker mounting bracket.

4. Remove the speaker.

5. Install the new speaker, making sure the speaker seats in the top grooves.

6. Tighten the T-10 screw that holds the speaker mounting bracket in place.

7. Re-assemble the unit by reversing the steps in section 4.4A Base and Control/PSU

Board Removal).

ss

s M. Mode Selector Replacement

ss

1. Remove the base and the control/PSU board assembly (see section 4.4A Base

and Control/PSU Board Removal).

2. Remove IEC receptacle (see section 4.4K IEC Receptacle Replacement).

3. Remove transformer chassis (see section 4.4D Transformer Chassis Replacement).

4. Disconnect the tubing from the mode selector.

Note: Refer to the pneumatic circuit diagram in section 6 for installation of tubing.

5. Remove the tubing connector guard from the mode selector.

6. Using a 8mm open end wrench, remove the diverting valve assembly.

Note: Be careful not to damage the tubing connectors.

Note: The mounting hardware and selector knob are secured to the outside of the

case and do not need to be removed.

7. Install a new mode selector by reversing steps 4 through 6.

8. Re-assemble the unit reversing steps 1 through 3.

ss

s N. Air/Oxygen/Blend Swivel Replacement

ss

4-10

1. Remove the base and the control/PSU board assembly (see section 4.4A Base

and Control/PSU Board Removal).

2. Remove IEC receptacle (see section 4.4K IEC Receptacle Replacement).

3. Remove transformer chassis (see section 4.4D Transformer Chassis Replacement).

4. Using a 6mm open end wrench, remove the hose and hose connector from the

swivel mount.

6600-0241-000 05/26/98

4-10

Page 33

4/Service Procedures

5. Remove plastic swivel cap.

6. Remove the E-clip that holds the swivel to the case and remove the swivel.

7. Install new swivel by reversing steps 4 through 6.

Note: Be certain to re-install the plastic swivel connector.

Note: Do not over tighten the hose connector.

8. Re-assemble the unit reversing steps 1 through 3.

O. Oxygen Sensor Cell Replacement

1. To disconnect the oxygen sensor, grasp the connector located on the side of the unit

at its knurled sleeve. Slide the sleeve away from the unit and pull the connector out.

2. The sensor assembly has a friction fitted housing. There is a groove in the middle of

the housing where its two halves connect. To disassemble the housing, grasp the top

of the housing in one hand and the bottom in the other, then pull and snap the two

halves apart. Chemical residue or debris may cause the housing halves to stick, so it

may be necessary to twist the housing one quarter turn and pull the housing apart. If

the housing does not fully separate, twist a quarter turn in the reverse direction.

Continue twisting back and forth in quarter turns until the housing halves separate. It

may help to use rubber gloves or sheets of rubber to improve your grip. Using a tool

like a pliers or a wrench may damage the housing and is not recommended.

3. Disconnect the wires from the oxygen sensor cell: the blue wire is connected to the

center pin and the red wire is connected to the outer pin of the sensor.

4. The oxygen cell is a friction fitted assembly. To remove the oxygen cell, apply slight

pressure to the face of the cell. Chemical residue and debris may cause the

oxygen cell to stick. A 1/4" dia. dowel rod can be used to apply pressure to the

face. Do not use a sharp tool like a screw driver since it may damage the housing.

WARNING: w The sensor may release quickly. Do not direct the oxygen cell, dowel rod

and housing toward any person.

5. Install the new cell. Place the front of the sensor housing nose down on a firm

surface to avoid fracturing the housing while installing the O2 cell. Re-assemble

reversing steps 1 through 4.

ss

s 4.5 Service Calibration

ss

(Refer to Figure 4-3 for calibration test points)

Equipment needed:

Digital Voltmeter (mV resolution)

Display board IDC extension cable (provided in service kit)

Adjustable DC Voltage source ( 35mA min.)

Millivolt source (0 to 50mV) (provided in service kit)

Pot adjustment screwdriver

4-11

6600-0241-000 05/26/98

4-11

Page 34

4/Service Procedures

A. Calibration Setup

1. Remove the base and the control/PSU assembly according section 4.4A.

2. Lift the PSU board away from the control board. Electrically re-connect the PSU

board and control boards using the 14 pin extension cable. Note the polarity of the

connector; be sure that the red stripped wire is connected to the same pins. Rest

the Control and PSU boards on the bench next to the case.

3. Re-connect the ac supply (PL4) and the dc battery supply (BATT) to the PSU

board and the display board ribbon cable with the extension wire harness to the

display board. Note the polarity of the connector; be sure that the red stripped wire

is connected to the same pins.

4 . Connect the simulator to INPUT terminals on the control board. Set the switch on

the simulator to the down position. Re-connect the AC power cord. Switch on

ServO2 unit using the control panel button.

B. Calibration Amplifier - Voltage Offset Null

1. Using a voltmeter monitor between Test point 13 (TP13) and Test Pin 1 on the

Control board, short pins 2 and 3 of IC8.

2. Adjust VR1 on the control board until monitored voltage just flips between the

positive (+5V) and negative rails (-5V).

C. Digitally Controlled Variable Resistor

1. Using the control panel buttons (CAL & ?), set the user calibration setting to

minimum (ie, when the % Oxygen display settles at a value below which it will not

move).

2. Monitor TP1 with respect to TP13. Adjust the mV input until TP1 measures 1.000V.

3. Monitor TP2 with respect to TP13 without changing the mV input setting.

4. Adjust VR2 on control board until the voltage on TP2 is 0.500V

D. D to A Output Calibration

1. Adjust the control panel buttons (ENABLE and M) to display a setpoint of 50%.

2. Monitor TP4 with respect to TP13. Adjust VR5 until the voltage on TP4 is 1.000V

4-12

6600-0241-000 05/26/98

4-12

Page 35

4/Service Procedures

Fuse

F3

VR8

VR3

VR4

Battery

connector

BATT

Transformer

secondary

connector

PL4

VR5

Display

connector

PL1

Figure 4-3

Control/PSU board assembly test points

TP10

TP12

TP2

PL5

TP1

TP4

TP13

TP3

Note: This is a simplified board diagram.

For a more complete board layout see

section 6.

Sensor

connector

INPUT

IC8

Wiper

VR4(monitor point)

Speaker

connector

PL2

PL3

Solenoid

harness

VR2

VR1

E. High/Low Alarm Calibration

1. With the setpoint at 50%, check that TP4 is 1.000V.

2. Set the mV input so that TP3 is 1.000V with respect to TP13.

3. Monitor VR4 wiper (R47) with respect to TP13. Adjust VR4 until the monitored

voltage equals 0.600V.

4. Monitor the front display. Adjust the mV input slowly to check that the High and

Low alarms activate between 2 - 4% from the setpoint respectively.

F. Display DVM Calibration

1. Monitor TP3 with respect to TP13.

2. Using the control panel buttons (CAL and M) set user calibration to maximum.

3. Set mV input such that TP3 is 1.990V.

4. Adjust VR1 on Display board until ServO2's display just changes from 99 to 100

oxygen.

4-13

6600-0241-000 05/26/98

4-13

Page 36

4/Service Procedures

G. Battery Charge Rate Set

1. Monitor TP12 (power board PL6) with respect to TP13.

2. Ensure the battery is connected.

3. Adjust VR8 on the PSU board until TP12 is 9.20V.

H. Battery Charge Current check

Allow new batteries 5 minutes charge prior to performing this test. Monitor TP12 with

respect to TP10. With the battery connected and charging, the monitored voltage

should be in the range 0.37 and 0.76V (depending upon the battery terminal voltage). If

batteries fails check replace it.

I. Low Battery Alarm Threshold Calibration

1. Remove Secondary ac wire harness connector (PL4) and replace the battery dc

wire harness connector (BATT) with a variable dc power supply (minimum 35 mA

capacity).

2. Monitor this input voltage.

3. Adjust input voltage to 6.90V. Adjust VR3 on control board until Low Battery alarm

indicator just lights. Raise input voltage to 7.25V. The indicator should go out.

J. Calibration Re-assembly

Disconnect all test harnesses and re-assemble unit performing steps 1 through 3 of

4.5A Calibration Set Up in reverse.

4.6 Service Checkout Procedure

Equipment needed:

Calibration port

Medical air and oxygen supply 50 -60 PSI (3-4 bar)

Graduated flowmeter 0 to 20 lpm

Oxygen bubble tubing (or equivalent)

Incubator/Headbox/Electronic Load Simulator (provided in the service kit)

The ServO2 system incorporates a pneumatic switch, accessible by the user, to shift

from Incubator (high flow) to Headbox (low flow) mode as necessary.

Connect electrical mains and gas supplies to the ServO2 unit.

4-14

6600-0241-000 05/26/98

4-14

Page 37

4/Service Procedures

A. Gas Flow Rate Check

Note: To achieve the output flow rate specified in the appendix, this flow rate check

requires a pressure of 3.99 bar for both medical air and oxygen supplies.

1. Connect a graduated flowmeter to the output connector of the ServO2 unit using

the bubble tubing.

2. Switch the ServO2 unit on using the control panel button.

3. Set the ServO2 unit for the Incubator mode.

4. Adjust the setpoint to 22 % and place the sensor in ambient air (ie, reading 21%).

5. Remove the medical air gas supply and check that the flow rate indicated by the

flowmeter reads between 12 and 15 lpm while the oxygen solenoid valve is open.

Note: For the Headbox mode the normal oxygen and air flow rates are between 5

and 7 lpm; the auxiliary oxygen solenoid has no appreciable affect.

6. Increase the setpoint to >24% to open the auxiliary oxygen solenoid valve and

check that the flow rate reads between 17 and 20 lpm.

7. Remove the oxygen gas supply and re-connect the medical air gas supply.

8. With the setpoint adjusted to 21% and the user calibration set such that the actual

oxygen display reads >22%, check that the flowmeter reads between 12 and 15

lpm while the air solenoid valve is open.

9. Re-connect the oxygen gas supply.

B. User Functions Check

1. Place oxygen sensor securely into the calibration port.

2. Fit the distal end of the ServO2 out put hose (the end farthest away from the unit)

securely over the input barb connector on the calibration port.

3. Press the Calibrate button on the control panel. This will automatically blank out the

“% Oxygen Set” display and deliver 100% Oxygen through the output hose. Press

and hold the Calibrate button throughout the calibration procedure.

4. Allow approximately 20 seconds for the environment and the sensor to stabilize.

5. While still pressing the Calibrate button, adjust the “% Oxygen (V/V)” display to

read 100% by pressing the M or ? button. If it does not read 100%, the sensor

must be replaced.

6. When the display stabilizes at 100%, release all the buttons. Remove the sensor

from the port and place it in ambient air. Check that the “% Oxygen (V/V)” display

reads 21% (± 1%). If it does not, the sensor must be replaced.

4-15

6600-0241-000 05/26/98

4-15

Page 38

4/Service Procedures

C. Alarm Check

1. Disconnect the sensor cable and check that the Sensor alarm indicator lights and

audible alarm sounds immediately.

2. Check that the alarm can not be silenced by pushing the alarm silence button.

3. Re-connect the sensor cable assembly.

4. Using blended output fed directly back to the sensor, simulate and maintain a high

Oxygen condition (3% above setpoint).

5. Check that the High alarm indicator lights immediately and that after 2 minutes the

audible alarm sounds.

6. Check that this alarm can be silenced by pushing the alarm silence button.

7. Disconnect gas supplies.

8. Increase the setpoint to simulate a Low oxygen alarm condition (3% below

setpoint).

9. Check that the Low alarm indicator lights immediately and that after 2 minutes (±

10 seconds) the audible alarm sounds.

10. Check that the alarm can be silenced by pushing the alarm silence button.

Note: Before performing the battery life test, connect the ServO2 unit to a mains

electrical supply for 24 hour to ensure that the battery is fully charged.

11. With setpoint at 21% and sensor in ambient air (ie, reading 21%) the Normal Air

and Oxygen solenoids will begin to cycle. Unplug the unit and check that the it

continues to run on battery with no corruption of displays during the change-over

period.

12. Leave the unit running until the Low Battery alarm indicator lights. If the battery

does not operate for at least 60 minutes it should be replaced.

13. Using the alarm silence button, silence the alarm after it sounds.

14. Check the unit turns itself off at least 6 minutes after the indicator comes on.

15. Re-charge the battery before putting the unit back in service.

4-16

6600-0241-000 05/26/98

4-16

Page 39

4/Service Procedures

D. Control Check

The control check can be done either by setting up the ServO2 unit to control oxygen in

an incubator, or by using an electronic load simulator. This dummy load simulates an

input to the ServO2 unit and is affected by the ServO2 unit’s electrical output. The

simulator allows testing to be completed on the bench.

Incubator

1. Connect the gas supplies, electrical mains supply and gas output tube to the

ServO2 unit.

2. Connect the gas output tube from the ServO2 unit to the incubator.

3. Place the sensor on the incubator mattress.

4. Switch the unit on using the I/O control panel button and adjust setpoint to 40%.

5. Check that the ServO2 unit controls the incubator to within ± 1% of setpoint.

Note: The incubator should be operating to ensure good gas circulation.

Electronic Load Simulator

1. Connect the load simulator to the INPUT connector on the Control board and the

Solenoid connector on the PSU board (PL3).

2. Adjust setpoint to 50%.

3. Check that unit controls within ± 1% of setpoint.

E. Electrical Safety Check

Enclosure leakage current

Use approved equipment and techniques to test the unit’s enclosure leakage current.

Follow the directions supplied by the test equipment manufacturer to verify the following:

1. Normal condition: Less than 100 microamperes*.

2. Single fault condition (interruption of one supply conductor): Less than 300 microamperes*.

* Tested as a double insulated device with an insulated enclosure.

4-17

6600-0241-000 05/26/98

4-17

Page 40

4/Service Procedures

Notes

4-18

6600-0241-000 05/26/98

4-18

Page 41

5/Illustrated Parts

4

S

erv

O

2

Oxygen Control System

3

+ -

Incubator

Headbox

%

Oxygen

(V/V)

%

Alarms

High

Defect

Low

Low

Sensor

Battery

Oxygen

Set

Enable

Enable

Calibrate

2

Back

6

8

1

7

Figure 5-1

5

Exterior parts

5-1

Item stock number

1. Incubator/headbox label................................................6600-0696-223

2. Calibration port..............................................................6600-0696-246

3. Membrane switch panel ................................................6600-0696-230

4. Mode key with cord .......................................................6600-0696-225

5. Fuse ..............................................................................6600-0696-237

6. Swivel elbow, air

(includes cover, DISS connector and barb) ..................6600-0696-204

(includes cover, NISTconnector and barb)....................6600-0696-253

7. Swivel elbow, O

2

(includes cover, DISS connector and barb) ..................6600-0696-205

(includes cover, NIST connector and barb)...................6600-0696-254

8. Swivel elbow, blend (includes cover and barb) ............6600-0696-206

Parts not shown

Label kit (complete).......................................................6600-0696-224

Rubber feet (four)..........................................................6600-0696-229

Power cord, 240V..........................................................6600-0696-235

Sensor cable(with out sensor).......................................6600-0696-242

O2 Sensor .....................................................................6600-0696-209

6600-0241-000 06/30/97

5-1

Page 42

5/Illustrated Parts

1

2

Calibrate

Battery

Low

Sensor

Defect

Low

High

+ -

Figure 5-2

Base, manifold and solenoid parts

Item stock number

1. Manifold/solenoid assembly with valves & label ...........6600-0696-201

2. Case base (includes label and 4 rubber feet) ...............6600-0696-219

Not shown

Manifold fittings kit (inludes male & female luer,

1/8 NPT black plug, 1/8 NPT white plug,

& two10-32 UNF plugs).................................................6600-0696-203

5-2

6600-0241-000 06/30/97

5-2

Page 43

5/Illustrated Parts

11

12

6

7

8

1

Ni Cad 7.2V/300mAHr

5

4

3

10

2

9

Figure 5-3

Interior parts

Item stock number

1. Mode indicator (includes cover and barb) .....................6600-0696-207

2. Mode switch kit (includes actuator, valve and cover)....6600-0696-208

3. Battery kit (includes wire harness & holder)..................6600-0696-216

4. Transformer mounting chassis......................................6600-0696-220

5. Transformer, 110V (includes wire harness) ..................6600-0696-239

Transformer, 220V (includes wire harness) ..................6600-0696-240

6. PCB, PSU .....................................................................6600-0696-231

7. PCB, control board........................................................6600-0696-232

8. PCB, display board .......................................................6600-0696-233

9. IEC inlet receptacle with insulation cover......................6600-0696-234

10. Speaker (includes wire harness) ...................................6600-0696-238

11. Sensor cable assembly (internal) ..................................6600-0696-241

12. Insulating board assy. ...................................................6600-0696-221

5-3

6600-0241-000 06/30/97

5-3

Page 44

5/Illustrated Parts

Service Kits

Item stock number

Maintenance kit (includes outbarb assembly

and 4 sintered filters)................................................................ 6600-0696-210

Service Kit (includes tape, load simulator,

50 mV source, 14 pin extension cable, display

and Control/PSU board extension cable and

Torx driver set) ......................................................................... 6600-0696-211

Pneumatic tubing kit (with assembled

barbs and fittings)..................................................................... 6600-0696-202

Teflon tape (PTFE) de-greased ............................................... 6600-0696-212

Clip kit (includes metal speaker clip, PCB Clip,

Mode key holder, & swivel elbow circlip).................................. 6600-0696-226

PCB mounting kit (includes spacers and bracket) ................... 6600-0696-227

Hardware kit (includes all screws)............................................ 6600-0696-228

Air High Pressure Regulator Kit (includes regulator,

regulator holder, tubing and barbs) ......................................... 6600-0696-243

O2 High Pressure Regulator Kit (includes regulator,

regulator holder, tubing and barbs) ......................................... 6600-0696-244

Complete Units

ServO2 Oxygen Control System (100-120V, DISS, Canada) .. 6600-0236-902