Page 1

OBE OMNIBEAM ™ 400 LUMINAIRE

NUVATION ™ Electronic Ballast

High Bay, Open or Enclosed – Surface Mount Optical Series

APPLICATIONS

• For over 20-foot (6 meter) applications, assembly lines, inspection areas, production

bays, storage areas, warehouses, commercial and retail areas.

SPECIFICATION FEATURES:

• 1598 Listed

Suitable for Damp Location

• Choice of open/ventilated or enclosed opticals with

choice of acrylic clear or prismatic lens.

• Prismatic acrylic reector.

• 55° C ambient, standard

• Nuvation ™ electronic ballast:

• Dimming Option — dims lamp to 50% of rated

lamp wattage.

• Two piece heavy-duty die cast

aluminum housing

• Integral optical mounting design

for GELS “Surface Mount Opticals”

• Attractive round ballast housing

design with white polyester paint nish

ORDERING NUMBER LOGIC

OBE

PRODUCT

IDENT

XXX

OBE =

Omnibeam

400

Luminaire

Surface

Mount

optical

with

Nuvation

Electronic

Ballast

W

COLOR

X

W = White

Polyester

Powder

40

WATTAGE

XX

25 = 250

32 = 320

35 = 350

40 = 400

N

LIGHT

SOURCE

X

N =

Ballast

will

operate

Pulse Start

or Ceramic

Metal

Halide

Lamps

Note:

Lamp is

vertical

base up.

Lamp

is not

included.

G

VOLTAGE

X

G = 208-277

Discrete

Voltages

must be

specied

when

ordering

cord & plug

assemblies:

2 = 208

3 = 240

4 = 277

E

BALLAST

TYPE

X

E=

Electronic

C=

Dimming

V6

OPTICAL

CODE

XX

E2 = Enclosed

22-in. with

clear at

arcylic lens.

P2 = Enclosed

22-in. with

prismatic

conical acrylic

lens.

E6 = Enclosed

26-in. with at

clear acrylic

lens.

V6 = Open

and ventilated

26-in. acrylic.

AC

PHOTOMETRY

CODE

XX

XX = Select

Code from

Photometric

Selection

Table

• Integral air gap between optical

mounting and ballast for optimum

temperature control and thermal

management

• Slide-on mounting box adaptor with

3/4-in pendant and thru feed capability

for ease of installation and mounting.

• External wattage selection port for

selection of 250, 320, 350 & 400 watt

choices.

• Safety chain provisions

• Mogul base socket – E39 standard

• Shipped as components: Ballast, Optical

Magnapack available for ballast.

11

MOUNTING

CODE

XX

11= Pendant Slide on Box

15 = Prewire with Loop, Cord and Plug part “Power

Hook”. (Order Receptacle/Hook Box separately)

Discrete Voltages must be specied when ordering

cord & plug assemblies below:

31 = Prewired with Hook, 3 ft. (0.9 meters) #16/3 Cord

and NEMA PLUG

33 = Prewired with Loop, 3 ft. (0.9 meters) #16/3 Cord

and NEMA PLUG (Order Locking Receptacle

Separately, if required)

MODULAR PREWIRE

41 = ACS with 3 ft (.9 meter) cord & Hook

69 = ACS with 6 ft (1.8 meter) cord & Hook

43 = ACS with 3 ft (.9 meter) cord & Loop

70 = ACS with 6 ft (1.8 meter) cord & Loop

PLUG-N-GO

51 = Plug-N-Go with 3 ft. (0.9 meter) Cord & Hook

71 = Plug-N-Go with 6 ft. (1.8meter) Cord & Hook

53 = Plug-N-Go with 3 ft. (0.9 meter) Cord & Loop

72 = Plug-N-Go with 6 ft. (1.8 meter) Cord & Loop

Note: ACS = Flex 3+

Plug-N-Go = FSC Series

X

OPTIONS

X

Q = Automatic

switched quartz

S = Exclusionary

mogul base socket

for MH open xtures.

I-20/2008

Exclusionary base socket is available for use with Metal Halide lamps in open

xtures to comply with NEC 2005 regulations (GELS “S” Option).

Customer should consult or review local electrical codes for compliance.

All Electronic devices are susceptible to transient voltage spikes. For facilities

where the lighting circuits are not protected from transient voltage spikes

a (TVSS) Transient Voltage Surge Suppression system is recommended.

To protect the NuVation ballast a T VS protection system must be able to

suppress a 3000V ring wave as described in ANSI/IEEE C62.41 B1.

GE Lighting Solutions • 1-888-MY-GE-LED • www.gelightingsolutions.com

1 - 8 8 8 - 6 9 - 4 3 - 5 3 3

Page 2

OBE OMNIBEAM

NUVATION

™

400 LUMINAIRE

™

Electronic Ballast

High Bay, Open or Enclosed – Surface Mount Optical Series

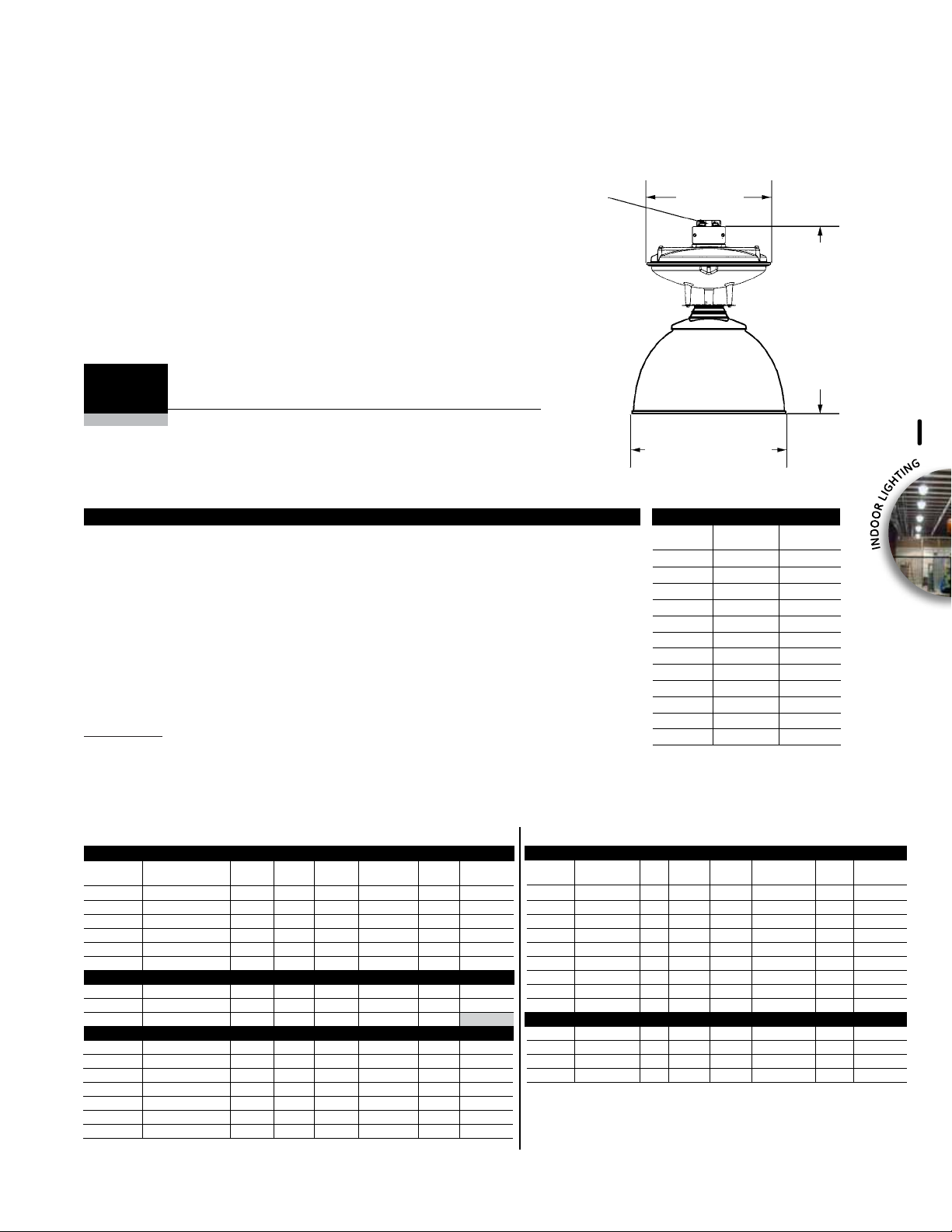

FIXTURE DIMENSIONS

3/4 in. NPSC

Thread

NOTES

See explanation on “Optical Flexibility” Page I-4. See References.

REFERENCES

See Page I-104 for start of Accessories.

See Page I-117 for Component Ordering Logic.

See Page I-129 for Explanation of Options and Other Terms Used.

DATA

Approximate Net Weight lbs kgs

Ballast and Optical 15-30 7-14

BALLAST DATA

* 13% Improvement in Pulse Start Metal Halide lamp lumen maintenance vs. magnetic.

* 6% improvement in Ceramic Metal Halide lamp lumen maintenance vs. magnetic.

* 50% lower ballast losses than typical CWA magnetic HID ballast.

* Lamp wattage regulation of +/-2% change for +/-10% change in line voltage.

* Ballast is rated for use with voltage range between 208 and 277 with +/-10% line voltage tolerance, 50/60 Hz, and will

automatically sense voltage within specied range.

* Ballast input current total harmonic distortion (THD) of less than 15% when operated at nominal line voltage.

* Ballast is thermally protected to shut o when operating temperatures are

above unacceptable levels for the ballast safe and reliable operation.

* Ballast has an end-of-lamp-life detection and shutdown circuit.

* The ballast shall have a minimum starting temperature of –20 degrees F

and maximum operating ambient of 55 degrees C..

* Ballast is capable of operating pulse start metal halide or ceramic metal halide lamp types.

* Five-Year Fixture Failure Warranty.

* Meets requirements of FCC rules and regulations, Title 47 CFR part 18 for nonconsumer equipment.

Dimming Ballast

* The ballast is supplied with a violet (+) and gray (-) wire for dimming control connections.

* Ballast dims to fty percent of rated lamp wattage.

* Dimming voltage is 0-10V where 10V is high wattage and 0 is fty percent of rated lamp wattage.

* Ballast operates the lamp at high wattage for 15 minutes at start up.

* Ballast operates lamp at high wattage for fteen minutes after operating in dim mode for twenty-four hours.

15.00 in. Dia.

(381mm)

Fixture Height

V2 - 27.08 in.

(688mm)

E2 - 27.38 in.

(695mm)

P2 - 29.23 in.

(742mm)

V6- 28.22 in.

(717mm)

E6- 28.52 in.

(724mm)

V2 - 22.18 in. Dia. (563mm)

E2 - 22.50 in. Dia. (572mm)

P2 - 22.50 in. Dia. (572mm)

V6 - 25.56 in. Dia. (649mm)

E6 - 25.88 in. Dia. (657mm)

INPUT WATTAGE TABLE

Lamp Line Input

Wattage Voltage Watts

400 277 428

400 240 432

400 208 435

350 277 377

350 240 380

350 208 383

320 277 346

320 240 347

320 208 349

250 277 276

250 240 272

250 208 271

PHOTOMETRIC SELECTION TABLE

V2 OPTICAL - Open 22in. Reector

Light Max Spacing Socket Photometric Optical Photometry

Wattage Source Temp Criteria Position Curve Code Code

250

MH,P 55 1.3 A 452450 V2 AA

250

MH,P 55 1.5 G 452451 V2 AG

250

MH(Coated),P 55 1.3 A 452456 V2 AA

250

MH(Coated),P 55 1.5 F 452455 V2 AF

320, 350, 400

320, 350, 400

V6 OPTICAL - Open and Ventilated 26in. Reector

320, 350, 400

320, 350, 400

320, 350, 400

P2 OPTICAL - Enclosed 22in. with Acrylic prismatic conical lens

250 MH,P 40** 1.1 A 452441 P2 AA

250 MH,P 40** 1.5 H 452442 P2 AH

250 MH(Coated),P 40** 1.1 A 452446 P2 AA

250 MH(Coated),P 40** 1.5 G 452445 P2 AG

320* MH, P 40** 1.6 A 452454 P2 AA

320* MH(Coated),P 40** 1.5 A 452459 P2 AA

320, 350, 400

*320 watt is ED28 Pulse Start MH

**Contact Factory for 55C availability

MH, P 55 1.6 A 452460 V2 AA

MH(Coated),P 55 1.6 A 452463 V2 AA

MH,P 55 1.6 B 178906 V6 AB

MH(Coated),P 55 1.7 C 178976 V6 AC

MH(Coated),P 55 1.6 B 178975 V6 AB

MH(Coated),P 40** 1.8 A 452464 P2 AA

GE Lighting Solutions • 1-888-MY-GE-LED • www.gelightingsolutions.com

1 - 8 8 8 - 6 9 - 4 3 - 5 3 3

PHOTOMETRIC SELECTION TABLE

E2 OPTICAL - Enclosed 22in. with at clear Acrylic lens

Light Max Spacing Socket Photometric Optical

Wattage Source Temp Criteria Position Curve Code Code

250 MH,P 40** 1.0 E 452439 E2 AE

250 MH,P 40** 1.4 H 452440 E2 AH

250 MH(Coated),P 40** 1.0 D 452443 E2 AD

250 MH(Coated),P 40** 1.4 H 452444 E2 AH

320* MH,P 40** 1.3 A 452452 E2 AA

320* MH,P 40** 1.5 G 452453 E2 AG

320* MH(Coated),P 40** 1.3 H 452466 E2 AH

350, 400 MH,P 40** 1.9 A 452462 E2 AA

350, 400 MH(Coated),P 40** 1.6 A 452465 E2 AA

E6 OPTICAL - Enclosed 26in. with at clear Acrylic lens

350,400 MH,P 55 1.6 B 179849 E6 AB

350,400 MH,P 55 1.8 D 179851 E6 AD

350,400 MH(Coated),P 55 1.6 D 179852 E6 AD

350,400 MH(Coated),P 55 1.9 H 179853 E6 AH

*320 watt is ED28 Pulse Start MH

**Contact Factory for 55C availability

® Registered Trademark of General Electric Company

TM

Trademark of General Electric Company

Data subject to change without notice

Photometry

2008/I-21

Loading...

Loading...