Page 1

NetworX NX-548E Receiver

A

Installation Instructions

466-2225B July 2006

Copyright © 2006, GE Security Inc.

Contents

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Internal mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

External mounting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

DIP switch settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Power up. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Testing and troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . 6

Programming settings table . . . . . . . . . . . . . . . . . . . . . . . . 7

Supported devices. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Introduction

The NX-548E Receiver adds wireless capabilities to the

NetworX line of control panels. Adding a receiver makes these

control panels compatible with NX wireless transmitters.

Only three wire connections are required for power and communication to the control panel.

WARNING: To avoid possible equipment damage

W

or personal injury, remove power from

the control panel before making any

wiring connections to the receiver.

Internal mounting

For internal mounting, mount the receiver inside the control

panel enclosure. Use the following installation guidelines:

• Leave at least 10 in. (25 cm) above the control panel for the

receiver’s antennas.

• Avoid areas that expose the receiver to moisture.

• Avoid areas with excessive metal or electrical wiring,

including furnaces and utility rooms.

To mount the receiver, do the following:

1. Remove the appropriate knockouts on the top of the control

panel enclosure for the antenna shrouds.

2. Assemble the antenna shrouds and fit the black O-rings to

the bottom of each shroud.

3. Insert the shrouds into the knockout holes (Figure 1).

4. Use the mounting screw provided to loosely install the edge

guide standoff in the lower mounting hole in the appropriate

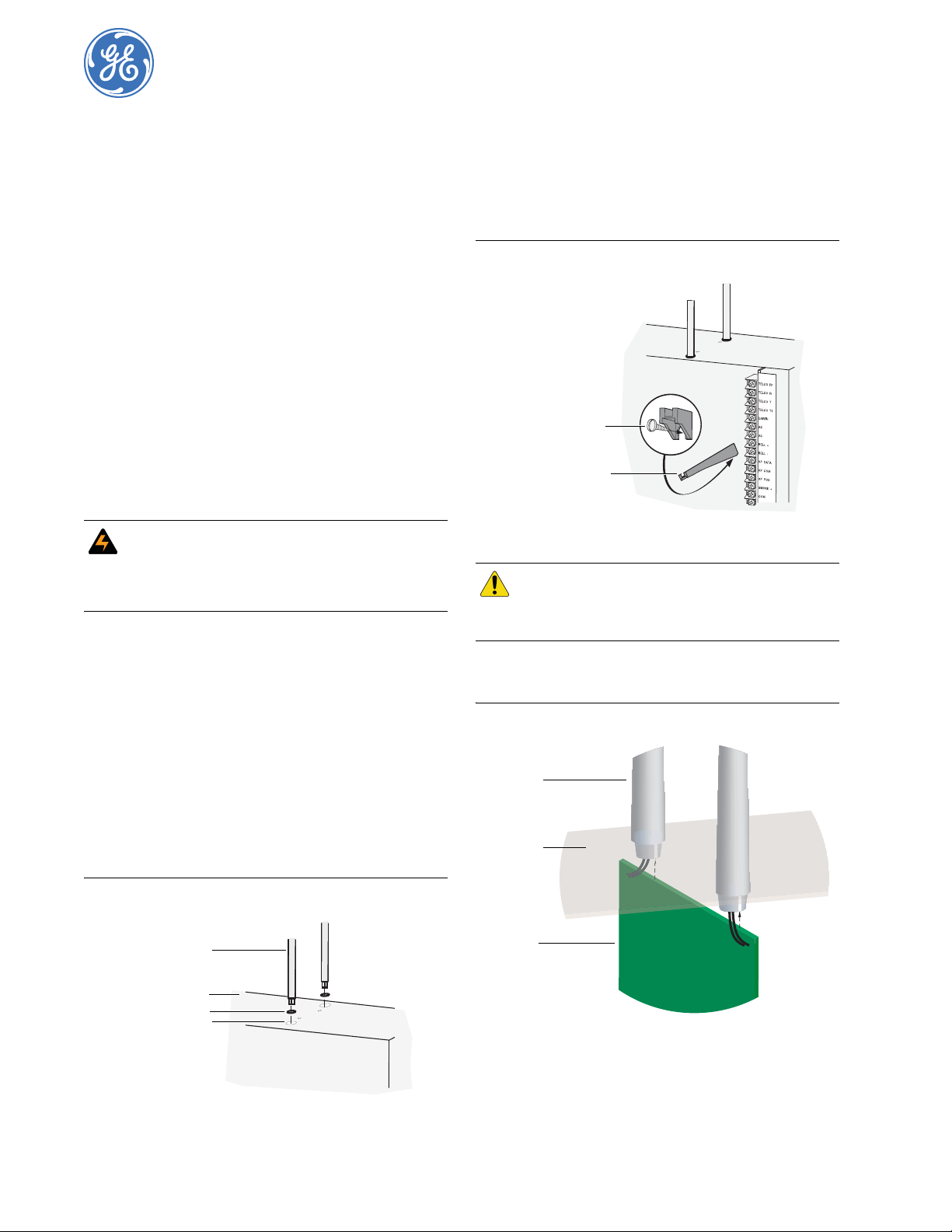

space to the left of the control panel (Figure 2). Do not

tighten the mounting screw down at this time.

Figure 2. Installing the edge guide standoff

Mounting screw

Edge guide standoff

CAUTION

5. Slide the printed circuit board into the antennae shroud

slots, after inserting wires into antennae shrouds (Figure 3).

Figure 3. Anntennae shrouds

Antennae

shrouds

Enclosure

You must be free of static electricity before

handling circuit boards. Touch a bare metal

surface or wear a grounding strap to

discharge yourself.

Figure 1. Installing the antenna shrouds

Antenna shroud

Enclosure top

O-ring

Knockout hole

Circuit

board

Page 2

NetworX NX-548E Receiver

2

Installation Instructions

6. Align the bottom of the circuit board in the edge guide

standoff and twist the standoff into place (Figure 4). Tighten

the mounting screw (Figure 2).

Figure 4. Installing the circuit board

Antenna shroud

Enclosure

Circuit board

Edge guide standoff

External mounting

This installation uses enclosure model NX-569 (600-1029-03).

The module comes as a kit that is assembled in the field. Use the

following installation guidelines:

• Allow at least 10 in. (25 cm) of clearance above the enclosure for the antennas.

• Use the wire length guidelines in Table 1.

Table 1. Wire lengths

Wire gauge (shielded or unshielded)

22 AWG (0.65 mm) 250 feet (76 m)

18 AWG (1.02 mm) 500 feet (152 m)

• Install the module in its own plastic enclosure. It should not

be installed inside the panel’s enclosure.

• Avoid m ounting locations that expose th e mod ule to moisture.

• Avoid areas with excessive metal or electrical wiring

including furnace and utility rooms. If unavoidable, mount

on or near metal with the antenna extending above the

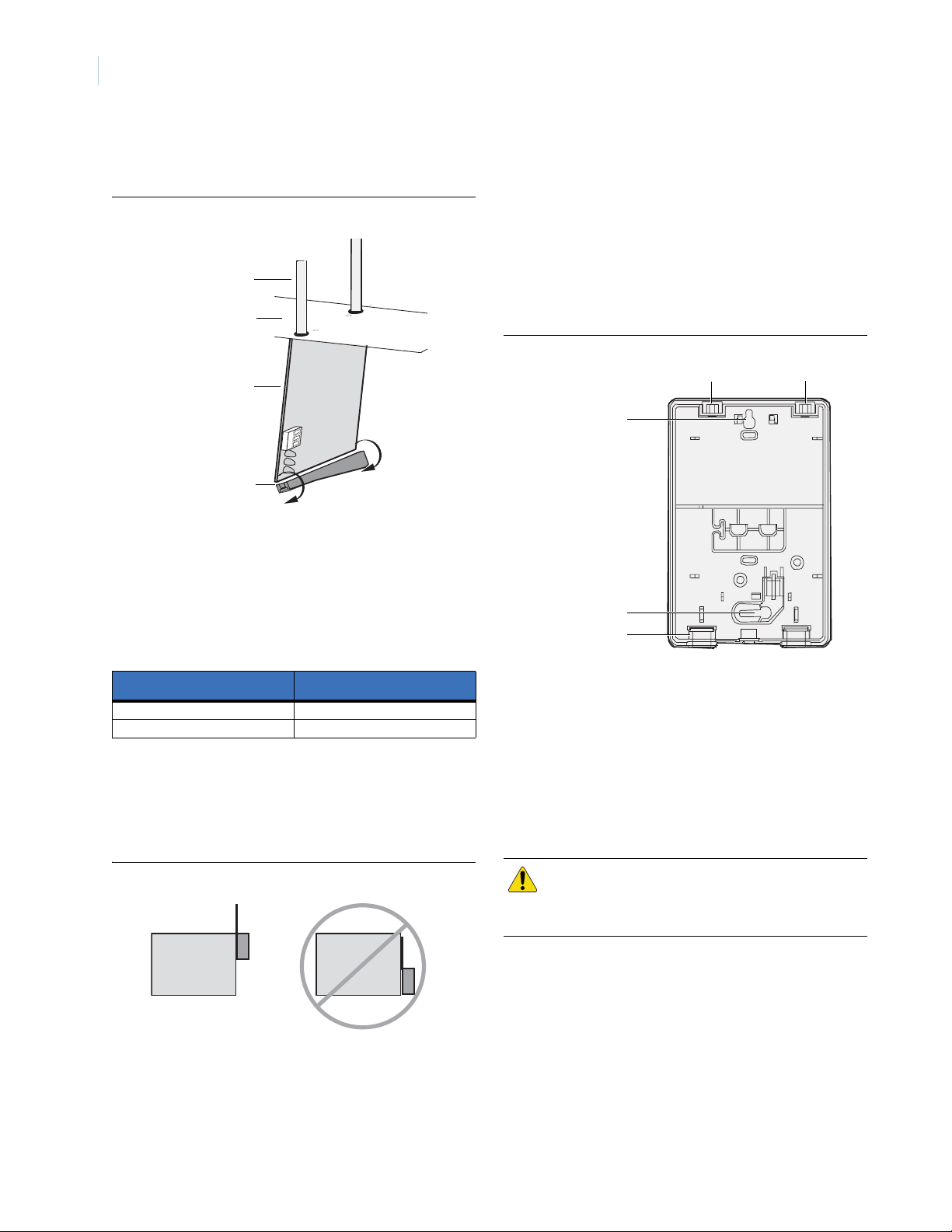

metallic surfaces as shown in Figure 5.

Maximum wire length between

module and panel

Mounting

The module can be mounted on any interior wall (protected from

the elements). To mount the module, do the following:

1. Remove the module back plate from the packaging.

2. Hold the base against the mounting surface and mark the

two mounting holes and the wire access hole as shown in

Figure 6. Remember to leave at least 10 in. (25 cm) above

the back plate for the antennas.

Note: The wire access hole is molded into the plastic so that

Figure 6. Back plate

3. Drill holes and insert the appropriate anchors (included).

4. Run a 3-conductor, 22 or 18 gauge (0.65 or 1.02 mm)

stranded wire cable from the module wire access hole location to the panel (Figure 6).

5. Secure the back plate to the wall with the pan head screws

provided.

6. To assemble the antenna shrouds, attach the proper number

of sections together, then attach the top cap.

7. Install each antenna shroud on top of the back plate.

8.

Remove the transceiver circuit board from the an tis ta tic bag.

you can access the wire, yet keep it hidden from the

back plate.

Antenna shroud locations

Mounting hole

Mounting hole

Wire access

Figure 5. Mounting on or near metal

Metal Metal

Tools and supplies needed

To complete the installation, you will need the following tools

and supplies:

• Screwdrivers;

• Drill with bits;

• Mounting screws and anchors (included); and

• 3-conductor, 22-gauge (0.65 mm) or larger, stranded wire.

CAUTION

You must be free of static electricity before

handling circuit boards. Wear a grounding

strap or touch a bare metal surface to

discharge static electricity.

Page 3

3

ON ECE

1 2 3 4

4

4

4

4

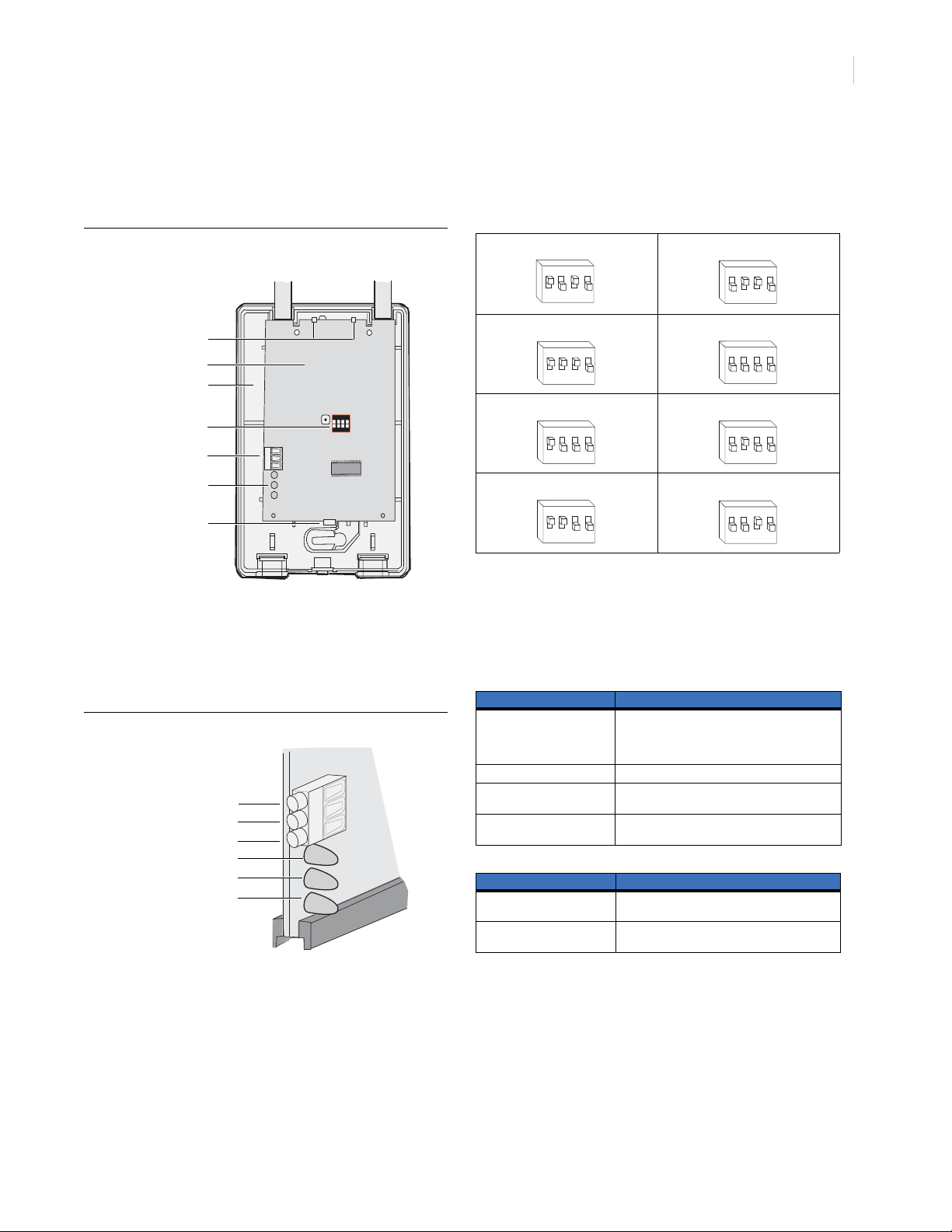

9. To install the circuit board onto the back plate (Figure 7),

insert the antennas into the antenna shrouds, then gently

slide the top of the circuit board under the two top latches,

and snap the circuit board in at the bottom latch to secure it

in place.

Figure 7. Circuit board and back plate

Antenna shrouds

Top latches

Circuit board

Back plate

DIP switches

ON ECE

1 2 3 4

Wiring terminals

LEDs

Bottom latch

Wiring

To wire the receiver, do the following:

1. Remove power (if applied) from the control panel.Use 22gauge, or larger, stranded wire to connect the +12, GND,

and DA TA terminals on the receiver (Figure 8) to the power,

common, and data terminals on the control panel.

Figure 8. Receiver wiring connections and LEDs

+ 12 (to panel POS)

GND (to panel COM)

DATA (to panel DATA)

Green (power) LED

Red (data) LED

Red (not used) LED

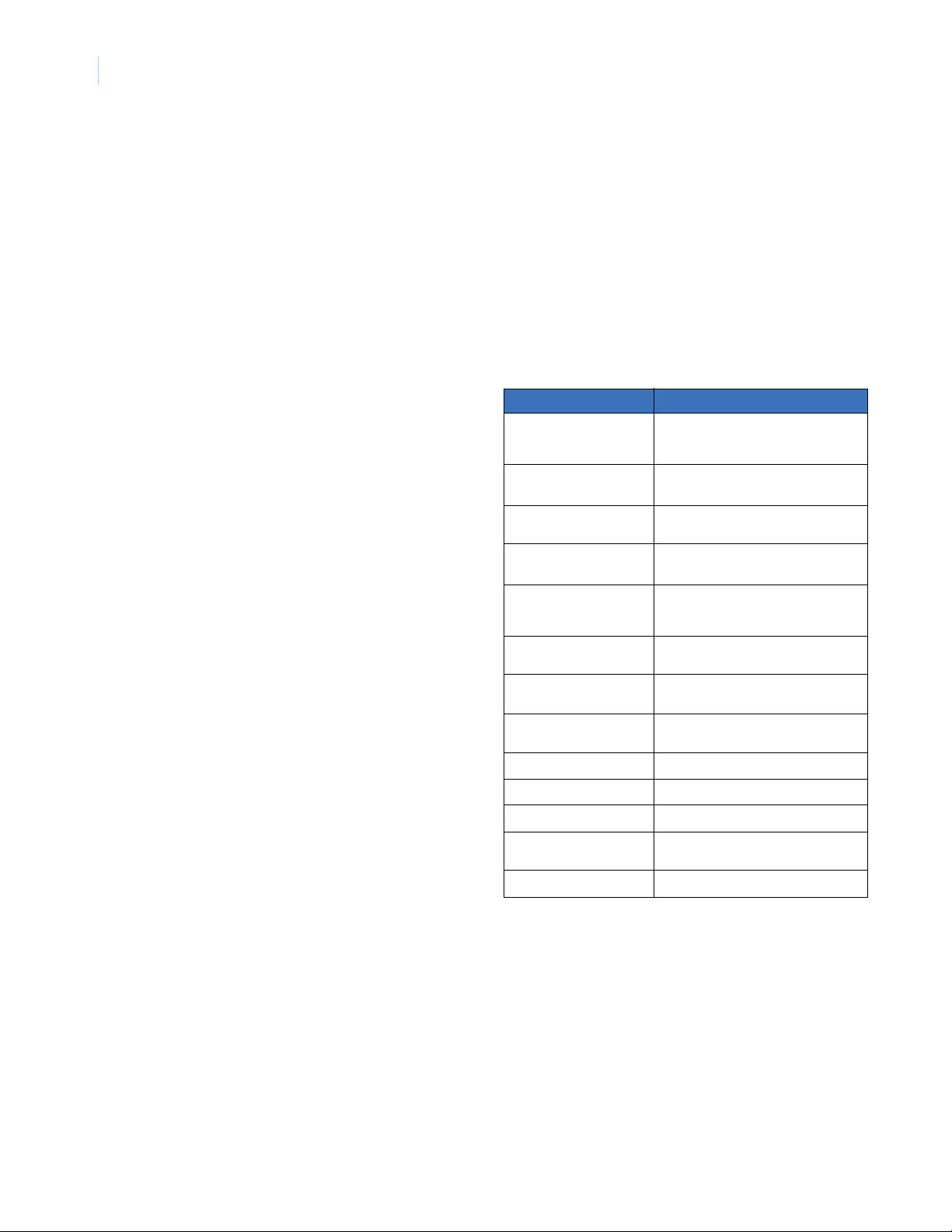

DIP switch settings

The DIP switches (Figure 7) on the circuit board are used to set

the receiver module number. Use Table 2 to set the DIP switches

to the desired module number.

Table 2. DIP switch settings

Module number 32 Module number 33

ON

EDG

43

12

Module number 34 Module number 35 (default)

ON

EDG

43

12

Module number 36 Module number 37

ON

EDG ON

3

1 2

Module number 38 Module number 39

ON

EDG

3

1 2

ON

12

ON

1 2

1 2

ON

12

EDG

43

EDG

3

EDG

3

EDG

43

Power up

When you apply power to the control panel, the green (power)

LED on the receiver (Figure 8) blinks for approximately 10

seconds. Table 3 describes the receiver status based on LED

conditions.The lower red LED at the bottom of the receiver

(Figure 8) may emit a dim glow, but is not used as an indicator.

Table 3. LED indications

Green (power) LED status Meaning

Power-up blinks LED blinks represent Product Version Number

Off No packets from sensors being received.

Short blink on Receiver received a valid packet from an

Long blink on Receiver received a valid packet from an

Red (data) LED status Meaning

Off No data communication with the control panel.

Short blink on Normal data communication with the control

(PVN). Long blink on is 1, short blink on is 0. PVN

is in binary, from most significant to least significant bit.

unknown sensor.

enrolled sensor.

Check wiring and power source.

panel.

Page 4

NetworX NX-548E Receiver

4

Installation Instructions

Programming

This section describes how to program the units.

Programming guidelines

Use the following programming guidelines:

• NX-4 and NX-6 control panels can have receivers added

with zones that overlap those contained in the control panel.

No hardware expanders can be used.

• NX-8 control panels can have expansion zones (hardwire or

wireless) set the same as those contained in the control

panel. To do this you mu st disable the onboard control panel

zones in panel location 37. All zone expansion modules

must not overlap any blocks of 8 zones.

• All other control panels can have wireless zones added to

any zone. If a hardwire input (on either the control panel or

hardwire expander) is also present on the same zone as an

enabled wireless zone, the wireless transmitter takes

priority.

Transmitter programming

When programming wireless transmitters into the receiver, you

can set various options and partitions for each transmitter. These

settings appear in segments of each programming location.

Use Table 5 on page 7 to record zone assignments and settings.

Be sure to circle where each zone resides:

RM. Receiver module

HE. Hardwire expander

P. Panel

This gives you all the programming information in one place to

facilitate the programming process.

Zone locations 1 to 192

Zone locations 1 to 192 are not numbered in Table 5 on page 7

since these locations vary depending on location 194, Receiver

zone bank setting.

Note: The default settings shown for segments 1 and 2 in the first

zone location apply to all zone locations.

Add transmitters

LCD touchpads will display instructions when accomplishing tasks.

To add transmitters, do the following:

1. Enter * 8 at the keypad. On LED touchpads, the five func-

tion lights start flashing.

2. Enter the program code (factory default is 9 7 1 3). On LED

touchpads, the service light flashes and the five function

lights change from flashing to on steady.

3. Enter the DIP switch setting module number and press #.

On LED touchpads, the Armed LED turns on, indicating the

control panel is waiting for a programming location entry.

4. For new installations, enter 9 1 0 # to load factory defaults

and clear any unwanted information in memory.

5. For new installations, set the receiver zone bank setting in

location 194 to determine the starting zone number for the

specific receiver . This applies only to NX-8E. This must be

set before learning sensors. For example, if location 194 is

set to 3, the first available location is 25. The total number

of available locations depends on the zone limits for both

the panel and receiver.

6. Enter 0 # to enter the sensor learning location. On LED

touchpads, the Ready LED turns on and the Armed LED

turns off.

7. Enter the zone number (1 through 192) and press *. Three

beeps from the keypad indicate an entry error . This occurs if

you enter a transmitter number that is not within the

receiver’s zone block or if the location already has a sensor

learned into it.

Note: If you change your mind about your entry, terminate

programming by entering 0 # 0 * and start over at

step 6.

8. Trip the desired transmitter (within 250 seconds) as

described

tion

Note: For specific instructions on tripping a transmitter,

Table 4. Tripping transmitters

Transmitter Action

Door/window, shock, glass

guard, freeze, UFT (Universal

Fire Transmitter)

Door/window with external

contact

Recessed door/window Activate tamper switch by removing circuit

Micro door/window and

Micro recessed door/window

SlimLine door/window Remove cover, then press the button on

PIR Activate tamper switch by removing back

Smoke detector without

tamper switch

Smoke detector with tamper

switch

Heat detector Press, then release the tamper switch.

Single button panic Press and hold the button.

Dual button panic Press and hold both buttons together.

Keyfobs Press and hold the lock and unlock buttons

Repeater Press, then release the tamper switch.

in

Table 4

. Listen for the

.

consult the transmitter’s manual.

Activate tamper switch by removing cover.

Activat e tamp er swi tch by remo ving c over.

Feature 4—Input option 1, must be on.

board until tamper switch is exposed.

Refer to the installation instructions for the

specific sensor for activation information.

the top of the sensor, or activate the

tamper switch by removing the cover.

plate from PIR.

Press and hold the test button.

Trip the tamper switch. Feature 4—Input

option 1, must be on.

together.

ding dong

for confirma-

9. To program remaining transmitte rs, repeat steps 6 to 8.

10. To exit program mode, press EXIT EXIT.

11. Confirm that the zone types and partition assignments are

set correctly in the control panel. Refer to the control panel

installation manual for instructions on how to set zone types

and partition assignments.

Note: When an 80-bit device is added, Feature 6 of Segment 1

(see Table 5 on page 7) is turned on. But when a 63-bit

device is added on a zone location that previously had an

80-bit device, make sure to turn off Feature 6 of Segment 1.

Page 5

5

Transmitter options

LCD touchpads will display instructions when accomplishing

tasks.

To program the transmitter and partition settings, do the

following:

1. Enter * 8 at the keypad. On LED touchpads, the five func-

tion lights start flashing.

2. Enter the program code (factory default is 9713). On LED

touchpads, the service light flashes and the five function

lights change from flashing to on steady.

3. Enter the DIP switch setting module number for the receiver

and press #. On LED touchpads, the Armed LED turns on to

indicate the control panel is waiting for a programming

location entry.

4. Enter the zone location number and press #. On LED touch-

pads, the Armed LED turns on and the Zone LEDs display

the binary data for the current settings.

5. Press the keypad button that corresponds to the feature

number you want changed. On LED touchpads, the lights

corresponding to the feature number will turn on or off

depending on the previous state. On LCD touchpads, the

feature number will turn on or off depending on the

previous state.

6. Press * to enter the changes and automatically advance to

segment 2.

Note: If you press # instead of * in step 6, it exits the zone

location and does not save changes to transmitter

options.

7. Press # to exit zone location. To continue programming

other zone locations, repeat steps 4 to7. To exit program

mode, press EXIT EXIT.

Door/window transmitter settings

Use the following guidelines when setting features 4 and 5 (see

Segment 1 in Table 5 on page 7) for door/window transmitters:

• Feature 4 - Input option 1. Turn on this feature to disable the

transmitter’s internal reed switches.

• Feature 5 - Input option 2. For transmitters that use a

normally open (N/O) external contact, leave this feature of f.

For transmitters that use a normally closed (N/C) external

contact, turn this feature on.

Wireless smoke detector settings

Use the following guideline when setting feature 4 (see Segment

1 in Table 5 on page 7) for wireless smoke detectors:

• Feature 4 - Input option 1. For detectors with tamper

switches, turn on this feature to enable the tamper feature.

Note: Feature 4 must be off (disabled) when using wireless smoke

detectors without tamper switches.

4-button keyfob settings

The control panel installation manual describes how keyfob

functions 1 and 2 can be used to control relays, outputs, or X-10

.

devices

Use the following guidelines when setting features 4 and 5 (see

Segment 1 in Table 5 on page 7) for 4-button keyfobs:

• Feature 4 - Input option 1. Turn on this feature to change the

Light button to keyfob function 1.

• Feature 5 - Input option 2. Turn on this feature to change the

Star button to keyfob function 2.

UFT settings

Use the following guidelines when setting features 4, 5 and 7

(see Segment 1 in Table 5 on page 7) for UFTs:

• Feature 4 - Input option 1. For UFTs, turn on this feature to

disable the transmitter’s primary reed.

• Feature 5 - Input option 2. For UFTs on this feature to

disable the transmitter’s secondary reed.

• Feature 7 - Input option 3. For UFTs that use a normally

open (NO) external contact, leave this feature off. For UFTs

that use a normally closed (NC) external contact, turn this

feature on.

Partition settings for keyfobs

LCD touchpads will display instructions when accomplishing tasks.

To program the transmitter and partition settings, do the following:

1. Enter * 8 at the keypad. On LED touchpads, the five func-

tion lights start flashing.

2. Enter the program code (factory default is 9 7 1 3). On LED

touchpads, the service light flashes and the five function

lights change from flashing to on steady.

3. Enter the DIP switch setting module number and press #.

On LED touchpads, the Armed LED turns on to indicate the

control panel is waiting for a programming location entry.

4. Enter the zone location number and press #. On LED touch-

pads, the Armed LED turns on and the Zone LEDs display

the binary data for the current settings. On LCD touchpads,

the display shows Segment 1 and its settings.

5. Press * to advance to Segment 2.

6. Press the keypad button that corresponds to the partition

number you want to change. On LED touchpads, lights that

turn off indicate the keyfob is active in tha t part ition. On

LCD touchpads, partition numbers that turn on indicate the

keyfob is active in that partition.

Note: These partition settings apply only to keyfobs.

Partition assignments for other types of transmitters

are made in the panel.

7. Press * to enter the changes. To continue programming

transmitter partition settings, repeat steps 4 to 8.

Note: If you press #, it does not save changes to the current

segment, but it does save changes to previous

segments.

8. To exit program mode, press EXIT EXIT.

Page 6

NetworX NX-548E Receiver

6

Installation Instructions

Transmitter supervision windows

LCD touchpads will display instructions when accomplishing tasks.

To change the transmitter supervision windows, do the following:

1. Enter * 8 at the keypad. On LED touchpads, the five func-

tion lights start flashing.

2. Enter the program code (factory default is 9 7 1 3).

3. Enter the DIP switch setting module number and press #.

On LED touchpads, the Armed LED turns on to indicate the

control panel is waiting for a programming location entry.

4. Enter 195 # to enter location 195, segment 1.

5. Enter the new normal supervision time (0 to 255 hours) and

press *. If you choose 0, the normal supervision window is

set to 256 hours.

CAUTION

6. Enter the new fire supervision time (0 to 255 hours) and

press *. If you choose 0, the fire supervision window is set

to 256 hours.

7. Enter the new short supervision time (up to 30 minutes).

The short supervision time prevents arming if a transmitter

has not checked in within the set time. This applies only to

specific countries outside the US. Check the control panel

installation manual to determine if this setting is available.

If you enter a number higher than 30 (the default value is

40), you disable the feature.

8. Press * to save any changes. The panel waits for the next

location entry.

Note: If you press #, it does not save changes to the current

9. To exit program mode, press EXIT EXIT.

Do not set the normal or fire supervision

windows to 1 hour. This causes false trouble

reports from all learned wireless transmitters.

segment, but it does save changes made in previous

segments.

Delete transmitters

LCD touchpads will display instructions when accomplishing tasks.

The following section describes how to delete transmitters from

the receiver.

Note: This procedure makes the receiver ignore a transmitter, but

does not remove the transmitter identification from the

receiver’s memory. The transmitter can be reactivated by

turning segment 1 on zone back on, or a new one can be

learned into the zone.

To delete transmitters, do the following:

1. Enter

* 8

at the keypad. On LED touchpads, the five function

lights start flashing.

2. Enter the program code (factory default is 9 7 1 3). On LED

touchpads, the service light flashes and the five function

lights change from flashing to on steady.

3. Enter the DIP switch setting module number and press #.

On LED touchpads, the Armed LED turns on, indicating the

control panel is waiting for a programming location entry.

4. Enter the zone location number to be deleted and press #.

On LED touchpads, the Armed LED turns on and the Zone

LEDs display the binary data for the current settings.

5. T o change transmitter feature 1 (enable sensor), press 1. On

LED touchpads, the 1 LED turns off to indicate the feature

change and the Ready LED flashes to indicate the change

request.

6. Enter * #. On LED touchpads, the Ready LED stops

flashing to indicate the new settings are stored in memory

and the system automatically exits from that location.

7. To continue deleting transmitters, repeat steps 4 to 6.

8. If you want to delete all transmitters and load factory

defaults, enter 9 1 0 #.

9. To exit program mode, press EXIT EXIT.

Testing and troubleshooting

Test all transmitters to verify programming and operation. Use

location 200 to troubleshoot transmitters mounted in marginal

signal strength locations or if the panel has a sensor lost trouble

condition. To troubleshoot the transmitters, do the following:

• Delete the transmitter and relearn it back into the receiver.

• Go to location 200 and check the signal strength. A signal of

6 or more indicates good signal strength, anything less

could cause periodic sensor lost trouble conditions.

• If signal strength is below the acceptable level, delete the

transmitter and rotate the mounting position (90, 180, or 270

degrees).

• Relearn the transmitter into the receiver and check loca tion

200 for signal strength.

• If rotating the mounting position does not improve signal

reception or is not practical, move the transmitter to

different locations near the desired mounting area.

• Delete and relearn the transmitter until an acceptable signal

level is attained, then mount the transmitter.

Page 7

7

Programming settings table

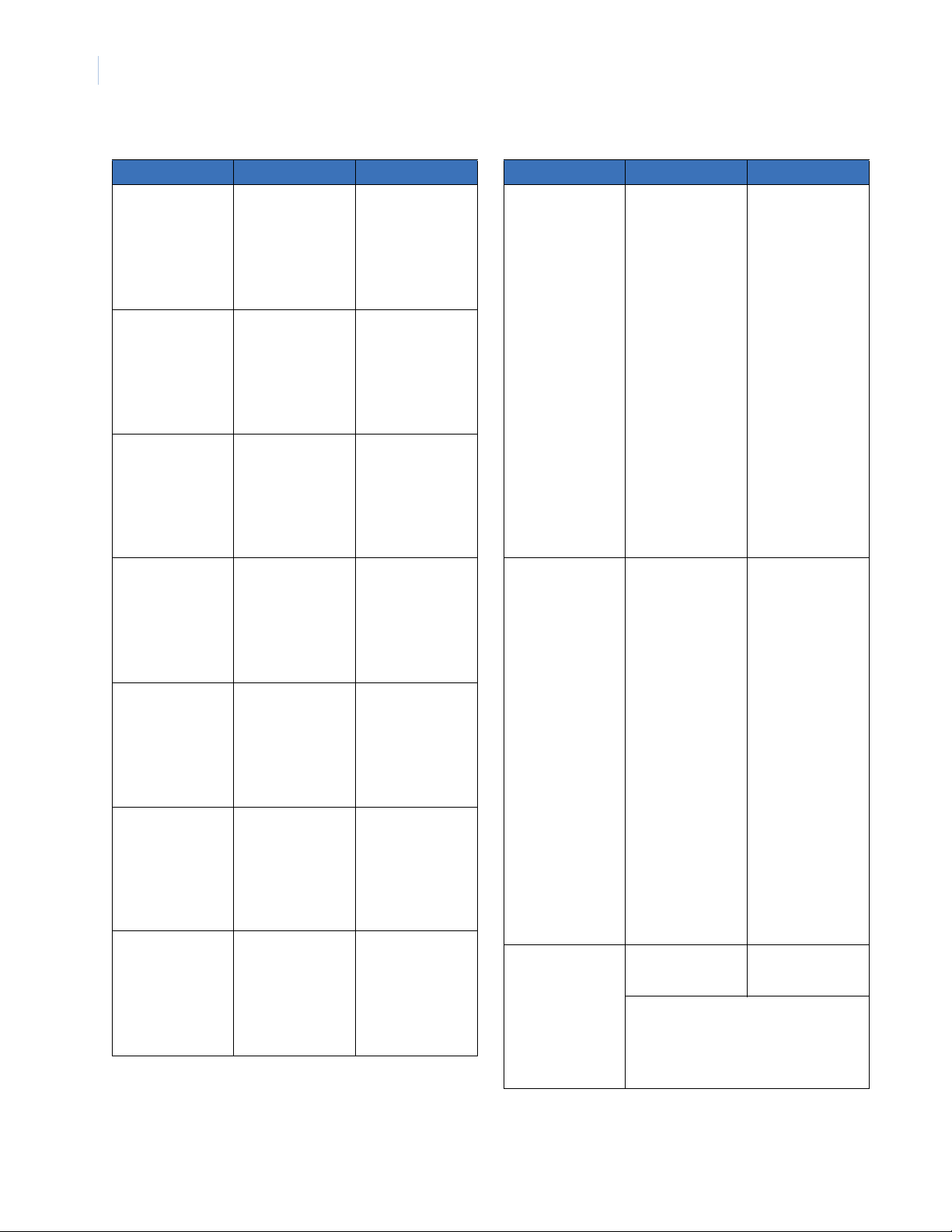

Table 5. Programming settings

Location Segment 1 Segment 2

0

(Transmitter to

program)

Zone _____

Assigned to module

#_____.

RM HE P

Zone _____

Assigned to module

#_____.

RM HE P

Zone _____

Assigned to module

#_____.

RM HE P

Zone _____

Assigned to module

#_____.

RM HE P

Zone _____

Assigned to module

#_____.

RM HE P

Zone _____

Assigned to module

#_____.

RM HE P

None None

1 - Enable sensor

(default = off)

2 - Supervised

(default = on)

3 - Fire supervision

(default = off)

4 - Input option 1

(default = off)

5 - Input option 2

(default = off)

6 - 80-bit device

(default = off)

7 - Input option 3

(default = off)

8 - Not used

1 - Enable sensor

2 - Supervised

3 - Fire supervision

4 - Input option 1

5 - Input option 2

6 - 80-bit device

7 - Input option 3

8 - Not used

1 - Enable sensor

2 - Supervised

3 - Fire supervision

4 - Input option 1

5 - Input option 2

6 - 80-bit device

7 - Input option 3

8 - Not used

1 - Enable sensor

2 - Supervised

3 - Fire supervision

4 - Input option 1

5 - Input option 2

6 - 80-bit device

7 - Input option 3

8 - Not used

1 - Enable sensor

2 - Supervised

3 - Fire supervision

4 - Input option 1

5 - Input option 2

6 - 80-bit device

7 - Input option 3

8 - Not used

1 - Enable sensor

2 - Supervised

3 - Fire supervision

4 - Input option 1

5 - Input option 2

6 - 80-bit device

7 - Input option 3

8 - Not used

Partition 1 keyfob

Partition 2 keyfob

Partition 3 keyfob

Partition 4 keyfob

Partition 5 keyfob

Partition 6 keyfob

Partition 7 keyfob

Partition 8 keyfob

Partition 1 keyfob

Partition 2 keyfob

Partition 3 keyfob

Partition 4 keyfob

Partition 5 keyfob

Partition 6 keyfob

Partition 7 keyfob

Partition 8 keyfob

Partition 1 keyfob

Partition 2 keyfob

Partition 3 keyfob

Partition 4 keyfob

Partition 5 keyfob

Partition 6 keyfob

Partition 7 keyfob

Partition 8 keyfob

Partition 1 keyfob

Partition 2 keyfob

Partition 3 keyfob

Partition 4 keyfob

Partition 5 keyfob

Partition 6 keyfob

Partition 7 keyfob

Partition 8 keyfob

Partition 1 keyfob

Partition 2 keyfob

Partition 3 keyfob

Partition 4 keyfob

Partition 5 keyfob

Partition 6 keyfob

Partition 7 keyfob

Partition 8 keyfob

Partition 1 keyfob

Partition 2 keyfob

Partition 3 keyfob

Partition 4 keyfob

Partition 5 keyfob

Partition 6 keyfob

Partition 7 keyfob

Partition 8 keyfob

(default = on)

(default = off)

(default = off)

(default = off)

(default = off)

(default = off)

(default = off)

(default = off)

Table 5. Programming settings (continued)

Location Segment 1 Segment 2

Zone _____

Assigned to module

#_____.

RM HE P

Zone _____

Assigned to module

#_____.

RM HE P

Zone _____

Assigned to module

#_____.

RM HE P

Zone _____

Assigned to module

#_____.

RM HE P

Zone _____

Assigned to module

#_____.

RM HE P

Zone _____

Assigned to module

#_____.

RM HE P

Zone _____

Assigned to module

#_____.

RM HE P

1 - Enable sensor

2 - Supervised

3 - Fire supervision

4 - Input option 1

5 - Input option 2

6 - 80-bit device

7 - Input option 3

8 - Not used

1 - Enable sensor

2 - Supervised

3 - Fire supervision

4 - Input option 1

5 - Input option 2

6 - 80-bit device

7 - Input option 3

8 - Not used

1 - Enable sensor

2 - Supervised

3 - Fire supervision

4 - Input option 1

5 - Input option 2

6 - 80-bit device

7 - Input option 3

8 - Not used

1 - Enable sensor

2 - Supervised

3 - Fire supervision

4 - Input option 1

5 - Input option 2

6 - 80-bit device

7 - Input option 3

8 - Not used

1 - Enable sensor

2 - Supervised

3 - Fire supervision

4 - Input option 1

5 - Input option 2

6 - 80-bit device

7 - Input option 3

8 - Not used

1 - Enable sensor

2 - Supervised

3 - Fire supervision

4 - Input option 1

5 - Input option 2

6 - 80-bit device

7 - Input option 3

8 - Not used

1 - Enable sensor

2 - Supervised

3 - Fire supervision

4 - Input option 1

5 - Input option 2

6 - 80-bit device

7 - Input option 3

8 - Not used

Partition 1 keyfob

Partition 2 keyfob

Partition 3 keyfob

Partition 4 keyfob

Partition 5 keyfob

Partition 6 keyfob

Partition 7 keyfob

Partition 8 keyfob

Partition 1 keyfob

Partition 2 keyfob

Partition 3 keyfob

Partition 4 keyfob

Partition 5 keyfob

Partition 6 keyfob

Partition 7 keyfob

Partition 8 keyfob

Partition 1 keyfob

Partition 2 keyfob

Partition 3 keyfob

Partition 4 keyfob

Partition 5 keyfob

Partition 6 keyfob

Partition 7 keyfob

Partition 8 keyfob

Partition 1 keyfob

Partition 2 keyfob

Partition 3 keyfob

Partition 4 keyfob

Partition 5 keyfob

Partition 6 keyfob

Partition 7 keyfob

Partition 8 keyfob

Partition 1 keyfob

Partition 2 keyfob

Partition 3 keyfob

Partition 4 keyfob

Partition 5 keyfob

Partition 6 keyfob

Partition 7 keyfob

Partition 8 keyfob

Partition 1 keyfob

Partition 2 keyfob

Partition 3 keyfob

Partition 4 keyfob

Partition 5 keyfob

Partition 6 keyfob

Partition 7 keyfob

Partition 8 keyfob

Partition 1 keyfob

Partition 2 keyfob

Partition 3 keyfob

Partition 4 keyfob

Partition 5 keyfob

Partition 6 keyfob

Partition 7 keyfob

Partition 8 keyfob

Page 8

NetworX NX-548E Receiver

8

Installation Instructions

Table 5. Programming settings (continued)

Location Segment 1 Segment 2

Zone _____

Assigned to module

#_____.

RM HE P

Zone _____

Assigned to module

#_____.

RM HE P

Zone _____

Assigned to module

#_____.

RM HE P

Zone _____

Assigned to module

#_____.

RM HE P

Zone _____

Assigned to module

#_____.

RM HE P

Zone _____

Assigned to module

#_____.

RM HE P

Zone _____

Assigned to module

#_____.

RM HE P

1 - Enable sensor

2 - Supervised

3 - Fire supervision

4 - Input option 1

5 - Input option 2

6 - 80-bit device

7 - Input option 3

8 - Not used

1 - Enable sensor

2 - Supervised

3 - Fire supervision

4 - Input option 1

5 - Input option 2

6 - 80-bit device

7 - Input option 3

8 - Not used

1 - Enable sensor

2 - Supervised

3 - Fire supervision

4 - Input option 1

5 - Input option 2

6 - 80-bit device

7 - Input option 3

8 - Not used

1 - Enable sensor

2 - Supervised

3 - Fire supervision

4 - Input option 1

5 - Input option 2

6 - 80-bit device

7 - Input option 3

8 - Not used

1 - Enable sensor

2 - Supervised

3 - Fire supervision

4 - Input option 1

5 - Input option 2

6 - 80-bit device

7 - Input option 3

8 - Not used

1 - Enable sensor

2 - Supervised

3 - Fire supervision

4 - Input option 1

5 - Input option 2

6 - 80-bit device

7 - Input option 3

8 - Not used

1 - Enable sensor

2 - Supervised

3 - Fire supervision

4 - Input option 1

5 - Input option 2

6 - 80-bit device

7 - Input option 3

8 - Not used

Partition 1 keyfob

Partition 2 keyfob

Partition 3 keyfob

Partition 4 keyfob

Partition 5 keyfob

Partition 6 keyfob

Partition 7 keyfob

Partition 8 keyfob

Partition 1 keyfob

Partition 2 keyfob

Partition 3 keyfob

Partition 4 keyfob

Partition 5 keyfob

Partition 6 keyfob

Partition 7 keyfob

Partition 8 keyfob

Partition 1 keyfob

Partition 2 keyfob

Partition 3 keyfob

Partition 4 keyfob

Partition 5 keyfob

Partition 6 keyfob

Partition 7 keyfob

Partition 8 keyfob

Partition 1 keyfob

Partition 2 keyfob

Partition 3 keyfob

Partition 4 keyfob

Partition 5 keyfob

Partition 6 keyfob

Partition 7 keyfob

Partition 8 keyfob

Partition 1 keyfob

Partition 2 keyfob

Partition 3 keyfob

Partition 4 keyfob

Partition 5 keyfob

Partition 6 keyfob

Partition 7 keyfob

Partition 8 keyfob

Partition 1 keyfob

Partition 2 keyfob

Partition 3 keyfob

Partition 4 keyfob

Partition 5 keyfob

Partition 6 keyfob

Partition 7 keyfob

Partition 8 keyfob

Partition 1 keyfob

Partition 2 keyfob

Partition 3 keyfob

Partition 4 keyfob

Partition 5 keyfob

Partition 6 keyfob

Partition 7 keyfob

Partition 8 keyfob

Table 5. Programming settings (continued)

Location Segment 1 Segment 2

Zone _____

Assigned to module

#_____.

RM HE P

Zone _____

Assigned to module

#_____.

RM HE P

Zone _____

Assigned to module

#_____.

RM HE P

Zone _____

Assigned to module

#_____.

RM HE P

Zone _____

Assigned to module

#_____.

RM HE P

Zone _____

Assigned to module

#_____.

RM HE P

Zone _____

Assigned to module

#_____.

RM HE P

1 - Enable sensor

2 - Supervised

3 - Fire supervision

4 - Input option 1

5 - Input option 2

6 - 80-bit device

7 - Input option 3

8 - Not used

1 - Enable sensor

2 - Supervised

3 - Fire supervision

4 - Input option 1

5 - Input option 2

6 - 80-bit device

7 - Input option 3

8 - Not used

1 - Enable sensor

2 - Supervised

3 - Fire supervision

4 - Input option 1

5 - Input option 2

6 - 80-bit device

7 - Input option 3

8 - Not used

1 - Enable sensor

2 - Supervised

3 - Fire supervision

4 - Input option 1

5 - Input option 2

6 - 80-bit device

7 - Input option 3

8 - Not used

1 - Enable sensor

2 - Supervised

3 - Fire supervision

4 - Input option 1

5 - Input option 2

6 - 80-bit device

7 - Input option 3

8 - Not used

1 - Enable sensor

2 - Supervised

3 - Fire supervision

4 - Input option 1

5 - Input option 2

6 - 80-bit device

7 - Input option 3

8 - Not used

1 - Enable sensor

2 - Supervised

3 - Fire supervision

4 - Input option 1

5 - Input option 2

6 - 80-bit device

7 - Input option 3

8 - Not used

Partition 1 keyfob

Partition 2 keyfob

Partition 3 keyfob

Partition 4 keyfob

Partition 5 keyfob

Partition 6 keyfob

Partition 7 keyfob

Partition 8 keyfob

Partition 1 keyfob

Partition 2 keyfob

Partition 3 keyfob

Partition 4 keyfob

Partition 5 keyfob

Partition 6 keyfob

Partition 7 keyfob

Partition 8 keyfob

Partition 1 keyfob

Partition 2 keyfob

Partition 3 keyfob

Partition 4 keyfob

Partition 5 keyfob

Partition 6 keyfob

Partition 7 keyfob

Partition 8 keyfob

Partition 1 keyfob

Partition 2 keyfob

Partition 3 keyfob

Partition 4 keyfob

Partition 5 keyfob

Partition 6 keyfob

Partition 7 keyfob

Partition 8 keyfob

Partition 1 keyfob

Partition 2 keyfob

Partition 3 keyfob

Partition 4 keyfob

Partition 5 keyfob

Partition 6 keyfob

Partition 7 keyfob

Partition 8 keyfob

Partition 1 keyfob

Partition 2 keyfob

Partition 3 keyfob

Partition 4 keyfob

Partition 5 keyfob

Partition 6 keyfob

Partition 7 keyfob

Partition 8 keyfob

Partition 1 keyfob

Partition 2 keyfob

Partition 3 keyfob

Partition 4 keyfob

Partition 5 keyfob

Partition 6 keyfob

Partition 7 keyfob

Partition 8 keyfob

Page 9

9

Table 5. Programming settings (continued)

Location Segment 1 Segment 2

Zone _____

Assigned to module

#_____.

RM HE P

Zone _____

Assigned to module

#_____.

RM HE P

Zone _____

Assigned to module

#_____.

RM HE P

Zone _____

Assigned to module

#_____.

RM HE P

Zone _____

Assigned to module

#_____.

RM HE P

Zone _____

Assigned to module

#_____.

RM HE P

Zone _____

Assigned to module

#_____.

RM HE P

1 - Enable sensor

2 - Supervised

3 - Fire supervision

4 - Input option 1

5 - Input option 2

6 - 80-bit device

7 - Input option 3

8 - Not used

1 - Enable sensor

2 - Supervised

3 - Fire supervision

4 - Input option 1

5 - Input option 2

6 - 80-bit device

7 - Input option 3

8 - Not used

1 - Enable sensor

2 - Supervised

3 - Fire supervision

4 - Input option 1

5 - Input option 2

6 - 80-bit device

7 - Input option 3

8 - Not used

1 - Enable sensor

2 - Supervised

3 - Fire supervision

4 - Input option 1

5 - Input option 2

6 - 80-bit device

7 - Input option 3

8 - Not used

1 - Enable sensor

2 - Supervised

3 - Fire supervision

4 - Input option 1

5 - Input option 2

6 - 80-bit device

7 - Input option 3

8 - Not used

1 - Enable sensor

2 - Supervised

3 - Fire supervision

4 - Input option 1

5 - Input option 2

6 - 80-bit device

7 - Input option 3

8 - Not used

1 - Enable sensor

2 - Supervised

3 - Fire supervision

4 - Input option 1

5 - Input option 2

6 - 80-bit device

7 - Input option 3

8 - Not used

Partition 1 keyfob

Partition 2 keyfob

Partition 3 keyfob

Partition 4 keyfob

Partition 5 keyfob

Partition 6 keyfob

Partition 7 keyfob

Partition 8 keyfob

Partition 1 keyfob

Partition 2 keyfob

Partition 3 keyfob

Partition 4 keyfob

Partition 5 keyfob

Partition 6 keyfob

Partition 7 keyfob

Partition 8 keyfob

Partition 1 keyfob

Partition 2 keyfob

Partition 3 keyfob

Partition 4 keyfob

Partition 5 keyfob

Partition 6 keyfob

Partition 7 keyfob

Partition 8 keyfob

Partition 1 keyfob

Partition 2 keyfob

Partition 3 keyfob

Partition 4 keyfob

Partition 5 keyfob

Partition 6 keyfob

Partition 7 keyfob

Partition 8 keyfob

Partition 1 keyfob

Partition 2 keyfob

Partition 3 keyfob

Partition 4 keyfob

Partition 5 keyfob

Partition 6 keyfob

Partition 7 keyfob

Partition 8 keyfob

Partition 1 keyfob

Partition 2 keyfob

Partition 3 keyfob

Partition 4 keyfob

Partition 5 keyfob

Partition 6 keyfob

Partition 7 keyfob

Partition 8 keyfob

Partition 1 keyfob

Partition 2 keyfob

Partition 3 keyfob

Partition 4 keyfob

Partition 5 keyfob

Partition 6 keyfob

Partition 7 keyfob

Partition 8 keyfob

Table 5. Programming settings (continued)

Location Segment 1 Segment 2

Zone _____

Assigned to module

#_____.

RM HE P

Zone _____

Assigned to module

#_____.

RM HE P

Zone _____

Assigned to module

#_____.

RM HE P

Zone _____

Assigned to module

#_____.

RM HE P

Zone _____

Assigned to module

#_____.

RM HE P

Zone _____

Assigned to module

#_____.

RM HE P

Zone _____

Assigned to module

#_____.

RM HE P

1 - Enable sensor

2 - Supervised

3 - Fire supervision

4 - Input option 1

5 - Input option 2

6 - 80-bit device

7 - Input option 3

8 - Not used

1 - Enable sensor

2 - Supervised

3 - Fire supervision

4 - Input option 1

5 - Input option 2

6 - 80-bit device

7 - Input option 3

8 - Not used

1 - Enable sensor

2 - Supervised

3 - Fire supervision

4 - Input option 1

5 - Input option 2

6 - 80-bit device

7 - Input option 3

8 - Not used

1 - Enable sensor

2 - Supervised

3 - Fire supervision

4 - Input option 1

5 - Input option 2

6 - 80-bit device

7 - Input option 3

8 - Not used

1 - Enable sensor

2 - Supervised

3 - Fire supervision

4 - Input option 1

5 - Input option 2

6 - 80-bit device

7 - Input option 3

8 - Not used

1 - Enable sensor

2 - Supervised

3 - Fire supervision

4 - Input option 1

5 - Input option 2

6 - 80-bit device

7 - Input option 3

8 - Not used

1 - Enable sensor

2 - Supervised

3 - Fire supervision

4 - Input option 1

5 - Input option 2

6 - 80-bit device

7 - Input option 3

8 - Not used

Partition 1 keyfob

Partition 2 keyfob

Partition 3 keyfob

Partition 4 keyfob

Partition 5 keyfob

Partition 6 keyfob

Partition 7 keyfob

Partition 8 keyfob

Partition 1 keyfob

Partition 2 keyfob

Partition 3 keyfob

Partition 4 keyfob

Partition 5 keyfob

Partition 6 keyfob

Partition 7 keyfob

Partition 8 keyfob

Partition 1 keyfob

Partition 2 keyfob

Partition 3 keyfob

Partition 4 keyfob

Partition 5 keyfob

Partition 6 keyfob

Partition 7 keyfob

Partition 8 keyfob

Partition 1 keyfob

Partition 2 keyfob

Partition 3 keyfob

Partition 4 keyfob

Partition 5 keyfob

Partition 6 keyfob

Partition 7 keyfob

Partition 8 keyfob

Partition 1 keyfob

Partition 2 keyfob

Partition 3 keyfob

Partition 4 keyfob

Partition 5 keyfob

Partition 6 keyfob

Partition 7 keyfob

Partition 8 keyfob

Partition 1 keyfob

Partition 2 keyfob

Partition 3 keyfob

Partition 4 keyfob

Partition 5 keyfob

Partition 6 keyfob

Partition 7 keyfob

Partition 8 keyfob

Partition 1 keyfob

Partition 2 keyfob

Partition 3 keyfob

Partition 4 keyfob

Partition 5 keyfob

Partition 6 keyfob

Partition 7 keyfob

Partition 8 keyfob

Page 10

NetworX NX-548E Receiver

10

Installation Instructions

Table 5. Programming settings (continued)

Location Segment 1 Segment 2

Zone _____

Assigned to module

#_____.

RM HE P

Zone _____

Assigned to module

#_____.

RM HE P

Zone _____

Assigned to module

#_____.

RM HE P

Zone _____

Assigned to module

#_____.

RM HE P

Zone _____

Assigned to module

#_____.

RM HE P

Zone _____

Assigned to module

#_____.

RM HE P

Zone _____

Assigned to module

#_____.

RM HE P

1 - Enable sensor

2 - Supervised

3 - Fire supervision

4 - Input option 1

5 - Input option 2

6 - 80-bit device

7 - Input option 3

8 - Not used

1 - Enable sensor

2 - Supervised

3 - Fire supervision

4 - Input option 1

5 - Input option 2

6 - 80-bit device

7 - Input option 3

8 - Not used

1 - Enable sensor

2 - Supervised

3 - Fire supervision

4 - Input option 1

5 - Input option 2

6 - 80-bit device

7 - Input option 3

8 - Not used

1 - Enable sensor

2 - Supervised

3 - Fire supervision

4 - Input option 1

5 - Input option 2

6 - 80-bit device

7 - Input option 3

8 - Not used

1 - Enable sensor

2 - Supervised

3 - Fire supervision

4 - Input option 1

5 - Input option 2

6 - 80-bit device

7 - Input option 3

8 - Not used

1 - Enable sensor

2 - Supervised

3 - Fire supervision

4 - Input option 1

5 - Input option 2

6 - 80-bit device

7 - Input option 3

8 - Not used

1 - Enable sensor

2 - Supervised

3 - Fire supervision

4 - Input option 1

5 - Input option 2

6 - 80-bit device

7 - Input option 3

8 - Not used

Partition 1 keyfob

Partition 2 keyfob

Partition 3 keyfob

Partition 4 keyfob

Partition 5 keyfob

Partition 6 keyfob

Partition 7 keyfob

Partition 8 keyfob

Partition 1 keyfob

Partition 2 keyfob

Partition 3 keyfob

Partition 4 keyfob

Partition 5 keyfob

Partition 6 keyfob

Partition 7 keyfob

Partition 8 keyfob

Partition 1 keyfob

Partition 2 keyfob

Partition 3 keyfob

Partition 4 keyfob

Partition 5 keyfob

Partition 6 keyfob

Partition 7 keyfob

Partition 8 keyfob

Partition 1 keyfob

Partition 2 keyfob

Partition 3 keyfob

Partition 4 keyfob

Partition 5 keyfob

Partition 6 keyfob

Partition 7 keyfob

Partition 8 keyfob

Partition 1 keyfob

Partition 2 keyfob

Partition 3 keyfob

Partition 4 keyfob

Partition 5 keyfob

Partition 6 keyfob

Partition 7 keyfob

Partition 8 keyfob

Partition 1 keyfob

Partition 2 keyfob

Partition 3 keyfob

Partition 4 keyfob

Partition 5 keyfob

Partition 6 keyfob

Partition 7 keyfob

Partition 8 keyfob

Partition 1 keyfob

Partition 2 keyfob

Partition 3 keyfob

Partition 4 keyfob

Partition 5 keyfob

Partition 6 keyfob

Partition 7 keyfob

Partition 8 keyfob

Table 5. Programming settings (continued)

Location Segment 1 Segment 2

193

Receiver options (all

defaults off)

194

Receiver zone bank

setting (default = 0),

set this before

learning any sensors.

Applies only to NX8E.

195

Supervision Windows

1 - Enable jam detect

2 - Enable auto

advance to next

zone number

3 - Keyfob user ID (off

= all keyfobs

report as user 99;

on = keyfob

reports as

learned zone #)

4 - Enable antenna

tamper (only

selectable on

international

versions; reports

as box tamper)

5 - Enable case

tamper

6 - Keyfob disarming

(0 = keyfob

disarm normal; 1

= disarm only

during entry or

partial arm)

7 - Enable wall tamper

(reports as box

tamper)

8 - Not used

Starting zone

numbers by bank

setting:

0 = 1

1 = 9

2 = 17

3 = 25

4 = 33

5 = 41

6 = 49

7 = 57

8 = 65

9 = 73

10 = 81

11 = 89

12 = 97

13 = 105

14 = 113

15 = 121

16 = 129

17 = 137

18 = 145

19 = 153

20 = 161

21 = 169

22 = 177

23 = 185

Normal ______hours.

(0 to 255 hours;

default = 24 hours)

Segment 3:

Short supervision time _____minutes (1 to 30

minutes, default = 40 minutes - disabled)

Do not change Segment 3 setting unless

required. See step 7 under Transmitter supervi-

sion windows on page 6.

None

Fire ______hours.

(0 to 255 hours;

default = 4 hours)

Page 11

11

Table 5. Programming settings (continued)

Location Segment 1 Segment 2

200

Number of rounds

received from last

transmitter learned

See Testing and trou-

bleshooting on page 6.

None None

Supported devices

For 80-bit devices, Feature 6 must be on for Segment 1 on zone

location. For 63-bit devices, Feature 6 must be off for Segment 1

on zone location.

80-bit devices

• 60-849-02-95 ESL Smoke Detector

• 60-917-95 Universal Fire Transmitter

• 60-832-95R 2 Button Keychain Touchpad *

63-bit devices

• NX-450 (60-670-95R) SAW Door/Window Sensor, White

• NX-451 (60-670-11-95R) SAW Door/Window Sensor, Brown

• NX-452 (60-499-10-319.5) SlimLine Door/Window Sensor ,

White

• NX-453 (60-499-11-319.5) SlimLine Door/W indow Sensor ,

Brown

• NX-458 (60-751-95) Recessed Micro Door/Window Sensor

• 60-741-11-95 Rececessed Micro Door/Window

Sensor, Brown

• NX-470 (60-659-95R) 4-Button Keychain Touchpad

• NX-474 (60-906-95) Micro Multi-Purpose Crystal Panic Button

• NX-475 (60-578-10-95) Water-Resistant Pendant Panic Sensor

• NX-480 (60-639-95) Indoor SAW PIR Motion Sensor

• 60-639-95R-OD Outdoor SAW PIR Motion

• 60-639-02-95R SAW PIR Mothion w/1.5v

• NX-487 (60-834-95) Adjustable Dual Technology Sound Sensor

• NX-490 (60-506-319.5) Wireless Smoke Sensor

• NX-491NT (60-848-02-95) ESL 560 Series Wireless

Smoke Sensor

• NX-495 (60-460-319.5) Rate-of-Rise Heat Sensor

• NX-650 (60-362-10-319.5) Standard Door/W indow Sensor,

White

• NX-651 (60-362-11-319.5) Standard Door/Window Sensor,

Brown

• NX-652 (60-641-95) Long Life Door/Window Sensor, White

• NX-653 (60-641-11-95) Long Life Door/Window Sensor,

Brown

• NX-454 (60-688-95) Micro Door/Window Sensor, White*

• NX-455 (60-688-11-95) Micro Door/Window Sensor, Brown*

• NX-481 (60-807-95R) Indoor SAW PIR Motion Sensor*

• NX-482 (60-880-95) AP750W PIR Motion Sensor*

• NX-488 (60-873-95) ShatterP ro Crystal Glass Break Sensor*

• NX-497 (60-652-95) Crystal Carbon Monoxide Sensor*

• NX-656 (60-462-10-319.5) Glass Guard Crystal Sensor, White*

• NX-657 (60-462-11-319.5) Glass Guard Crystal Sensor,

Brown *

• NX-658 (60-742-95R) Crystal Freeze Sensor*

• NX-667 (60-886-95) Crystal Learn Mode Shock Sensor,

White*

• NX-668 (60-886-11-95) Crystal Learn Mode Shock Sensor,

Brown*

• NX-695 (60-744-95R) SAW Water Sensor*

• NX-706 (80-922) Repeater Kit 319.5*

• NX-707 (80-922-1) Repeater Kit 319.5 *

• 60-511-01-95 Learn Mode DS924 PIR Motion Sensor*

• 60-511-01-95 DS924I Pet Immune PIR*

• 60-452-10-319.5 Learn Mode Pendant Panic*

• 60-457-10-319.5 Learn Mode Double Button Panic *

• 60-458-10-319.5 Learn Mode Single Button Panic*

* These devices are not listed, investigated, or verified by UL.

Page 12

NetworX NX-548E Receiver

12

Installation Instructions

Specifications FCC compliance

Compatibility NX-4, NX-6, NX-8, NX-8E control panels

Frequency 319.5 MHz

Wireless range 1,000 feet (304 m)

Required power 12.0 VDC (provided by panel)

Current draw 55 mA maximum

Operating temperature 32 to 120°F (0 to 49°C)

Storage temperature -30 to 140°F (-34 to 60°C)

Max. relative humidity 85% noncondensing

Dimensions 4.65 x 3.20 inches (11.8 x 8.1 cm)

Listings

UL

CUL

UL 985, UL 1023

ORD-C1023-1974, ULC-S545-02

This device complies with part 15 of the FCC rules. Operation is subject to the

following conditions:

1. This device may not cause harmful interference.

2. This device must accept any interference received, including interference

that may cause undesired operation.

Changes or modifications not expressly approved by the party responsible for

compliance could void the user’s authority to operate the equipment.

Toll-free: 888.437.3287 (US, including Alaska and Hawaii; Puerto Rico; Canada).

Outside the toll-free area: Contact your local dealer.

Technical support

www.gesecurity.com

Loading...

Loading...