Page 1

Document Information for:

5213326-100TPH

Type

Name

Revision

State

Drawing Print

5213326-100TPH

3

Release

ECO 2063269

Description

Originator

Basic Service Manual for LOGIQ Uno Console

501568001_praveen__kumar

File List

1. 5213326-100TPH_s2_r1.pdf

Approval Information

Person Action Date and Time

305018343_seshachala__bettadapura Approved 09/10/2008 12:58:08 PM GMT

305018956_sandesh__n Approved 09/11/2008 05:05:00 AM GMT

This page is generated automatically by the GEMS ePDM System

Printed documents are for Reference Only and may be out-of-date.

Check the database to ensure you have the correct revision.

State: RELEASE - Document is released and under formal Change Control. Changes are subject to the ECR/ECO Process.

See the GEHC Myworkshop System to determine the status of this document.

Approved Document - 5213326-100TPH_r3.pdf Page 1 of 252

Page 2

Technical

Publication

Direction 5213326-100

Revision 3

GE Healthcare

GE Healthcare

LOGIQ A3 Basic Service Manual

Operating Documentation

Copyright© 2007,2008 by General Electric Co.

State: RELEASE - Document is released and under formal Change Control. Changes are subject to the ECR/ECO Process.

See the GEHC Myworkshop System to determine the status of this document.

Approved Document - 5213326-100TPH_r3.pdf Page 2 of 252

Page 3

This page was intentionally left blank.

State: RELEASE - Document is released and under formal Change Control. Changes are subject to the ECR/ECO Process.

See the GEHC Myworkshop System to determine the status of this document.

Approved Document - 5213326-100TPH_r3.pdf Page 3 of 252

Page 4

GE HEALTHCARE

D

IRECTION 5213326-100, REVISION 3 LOGIQ™ A3 SERVICE MANUAL

Important Precautions

• THIS SERVICE MANUAL IS AVAILABLE IN ENGLISH ONLY.

• IF A CUSTOMER’S SERVICE PROVIDER REQUIRES A LANGUAGE OTHER THAN

ENGLISH, IT IS THE CUSTOMER’S RESPONSIBILITY TO PROVIDE

TRANSLATION SERVICES.

WARNING

AVERTISSEMENT

• DO NOT ATTEMPT TO SERVICE THE EQUIPMENT UNLESS THIS SERVICE

MANUAL HAS BEEN CONSULTED AND IS UNDERSTOOD.

• FAILURE TO HEED THIS WARNING MAY RESULT IN INJURY TO THE SERVICE

PROVIDER, OPERATOR OR PATIENT FROM ELECTRIC SHOCK, MECHANICAL

OR OTHER HAZARDS.

• CE MANUEL DE MAINTENANCE N’EST DISPONIBLE QU’EN ANGLAIS.

• SI LE PRESTATAIRE DE SERVICES DU CLIENT A BESOIN DE CE MANUEL DANS

UNE AUTRE LANGUE QUE L’ANGLAIS, IL INCOMBE AU CLIENT DE LE FAIRE

TRADUIRE.

• NE PAS TENTER D’INTERVENTION SUR LES ÉQUIPEMENTS TANT QUE LE

MANUEL DE MAINTENANCE N’A PAS ÉTÉ CONSULTÉ ET COMPRIS.

• LE NON-RESPECT DE CET AVERTISSEMENT PEUT ENTRAÎNER CHEZ LE

TECHNICIEN, L’OPÉRATEUR OU LE PATIENT DES BLESSURES DUES À DES

DANGERS ÉLECTRIQUES, MÉCANIQUES OU AUTRES.

WARNUNG

• DIESES KUNDENDIENST-HANDBUCH EXISTIERT NUR IN ENGLISCHER

SPRACHE.

• FALLS EIN FREMDER KUNDENDIENST EINE ANDERE SPRACHE BENÖTIGT, IST

ES AUFGABE DES KUNDEN, FÜR EINE ENTSPRECHENDE ÜBERSETZUNG ZU

SORGEN.

• WARTEN SIE DIESES GERÄT NUR, WENN SIE DIE ENTSPRECHENDEN

ANWEISUNGEN IM KUNDENDIENST-HANDBUCH GELESEN HABEN UND

NACHVOLLZIEHEN KÖNNEN.

• WIRD DIESE WARNUNG NICHT BEACHTET, SO KANN ES ZU VERLETZUNGEN

DES KUNDENDIENSTTECHNIKERS, DES BEDIENERS ODER DES PATIENTEN

DURCH ELEKTRISCHE SCHLÄGE, MECHANISCHE ODER SONSTIGE

GEFAHREN KOMMEN.

State: RELEASE - Document is released and under formal Change Control. Changes are subject to the ECR/ECO Process.

See the GEHC Myworkshop System to determine the status of this document.

Approved Document - 5213326-100TPH_r3.pdf Page 4 of 252

i

Page 5

GE HEALTHCARE

D

IRECTION 5213326-100, REVISION 3 LOGIQ™ A3 SERVICE MANUAL

• ESTE MANUAL DE SERVICIO SÓLO ESTÁ DISPONIBLE EN INGLÉS.

• SI ALGÚN PROVEEDOR DE SERVICIOS AJENO A GEMS SOLICITA UN IDIOMA

QUE NO SEA EL INGLÉS, LA TRADUCCIÓN ES RESPONSABILIDAD DEL

CLIENTE.

• NO SE DEBERÁ DAR SERVICIO TÉCNICO AL EQUIPO SIN HABER

AVISO

CONSULTADO Y COMPRENDIDO ESTE MANUAL DE SERVICIO.

• LA NO OBSERVANCIA DEL PRESENTE AVISO PUEDE DAR LUGAR A QUE EL

PROVEEDOR DE SERVICIOS, EL USUARIO O EL PACIENTE SUFRAN LESIONES

PROVOCADAS POR DESCARGAS ELÉCTRICAS, PROBLEMAS MECÁNICOS O

PELIGROS DE OTRA NATURALEZA.

• ESTE MANUAL DE ASSISTÊNCIA TÉCNICA SÓ SE ENCONTRA DISPONÍVEL EM

INGLÊS.

• SE QUALQUER OUTRO SERVIÇO DE ASSISTÊNCIA TÉCNICA, QUE NÃO A

GEMS, SOLICITAR ESTES MANUAIS NOUTRO IDIOMA, É DA

RESPONSABILIDADE DO CLIENTE FORNECER OS SERVIÇOS DE TRADUÇÃO.

ATENÇÃO

• NÃO TENTE REPARAR O EQUIPAMENTO SEM TER CONSULTADO E

COMPREENDIDO ESTE MANUAL DE ASSISTÊNCIA TÉCNICA.

• O NÃO CUMPRIMENTO DESTE AVISO PODE PÔR EM PERIGO A SEGURANÇA

DO TÉCNICO, OPERADOR OU PACIENTE DEVIDO A CHOQUES ELÉTRICOS,

MECÂNICOS OU OUTROS.

AVVERTENZA

HOIATUS

• IL PRESENTE MANUALE DI MANUTENZIONE È DISPONIBILE SOLTANTO IN

INGLESE.

• SE UN ADDETTO ALLA MANUTENZIONE ESTERNO ALLA GEMS RICHIEDE IL

MANUALE IN UNA LINGUA DIVERSA, IL CLIENTE È TENUTO A PROVVEDERE

DIRETTAMENTE ALLA TRADUZIONE.

• SI PROCEDA ALLA MANUTENZIONE DELL’APPARECCHIATURA SOLO DOPO

AVER CONSULTATO IL PRESENTE MANUALE ED AVERNE COMPRESO IL

CONTENUTO.

• NON TENERE CONTO DELLA PRESENTE AVVERTENZA POTREBBE FAR

COMPIERE OPERAZIONI DA CUI DERIVINO LESIONI ALL’ADDETTO ALLA

MANUTENZIONE, ALL’UTILIZZATORE ED AL PAZIENTE PER FOLGORAZIONE

ELETTRICA, PER URTI MECCANICI OD ALTRI RISCHI.

• KÄESOLEV TEENINDUSJUHEND ON SAADAVAL AINULT INGLISE KEELES.

• KUI KLIENDITEENINDUSE OSUTAJA NÕUAB JUHENDIT INGLISE KEELEST

ERINEVAS KEELES, VASTUTAB KLIENT TÕLKETEENUSE OSUTAMISE EEST.

• ÄRGE ÜRITAGE SEADMEID TEENINDADA ENNE EELNEVALT KÄESOLEVA

TEENINDUSJUHENDIGA TUTVUMIST JA SELLEST ARU SAAMIST.

• KÄESOLEVA HOIATUSE EIRAMINE VÕIB PÕHJUSTADA TEENUSEOSUTAJA,

OPERAATORI VÕI PATSIENDI VIGASTAMIST ELEKTRILÖÖGI, MEHAANILISE

VÕI MUU OHU TAGAJÄRJEL.

ii -

State: RELEASE - Document is released and under formal Change Control. Changes are subject to the ECR/ECO Process.

See the GEHC Myworkshop System to determine the status of this document.

Approved Document - 5213326-100TPH_r3.pdf Page 5 of 252

Page 6

GE HEALTHCARE

D

IRECTION 5213326-100, REVISION 3 LOGIQ™ A3 SERVICE MANUAL

• TÄMÄ HUOLTO-OHJE ON SAATAVILLA VAIN ENGLANNIKSI.

• JOS ASIAKKAAN PALVELUNTARJOAJA VAATII MUUTA KUIN

ENGLANNINKIELISTÄ MATERIAALIA, TARVITTAVAN KÄÄNNÖKSEN

HANKKIMINEN ON ASIAKKAAN VASTUULLA.

• ÄLÄ YRITÄ KORJATA LAITTEISTOA ENNEN KUIN OLET VARMASTI LUKENUT

VAROITUS

JA YMMÄRTÄNYT TÄMÄN HUOLTO-OHJEEN.

• MIKÄLI TÄTÄ VAROITUSTA EI NOUDATETA, SEURAUKSENA VOI OLLA

PALVELUNTARJOAJAN, LAITTEISTON KÄYTTÄJÄN TAI POTILAAN

VAHINGOITTUMINEN SÄHKÖISKUN, MEKAANISEN VIAN TAI MUUN

VAARATILANTEEN VUOKSI.

• ΤΟ ΠΑΡΟΝ ΕΓΧΕΙΡΙ∆ΙΟ ΣΕΡΒΙΣ ∆ΙΑΤΙΘΕΤΑΙ ΣΤΑ ΑΓΓΛΙΚΑ ΜΟΝΟ.

• ΕΑΝ ΤΟ ΑΤΟΜΟ ΠΑΡΟΧΗΣ ΣΕΡΒΙΣ ΕΝΟΣ ΠΕΛΑΤΗ ΑΠΑΙΤΕΙ ΤΟ ΠΑΡΟΝ

ΕΓΧΕΙΡΙ∆ΙΟ ΣΕ ΓΛΩΣΣΑ ΕΚΤΟΣ ΤΩΝ ΑΓΓΛΙΚΩΝ, ΑΠΟΤΕΛΕΙ ΕΥΘΥΝΗ ΤΟΥ

ΠΕΛΑΤΗ ΝΑ ΠΑΡΕΧΕΙ ΥΠΗΡΕΣΙΕΣ ΜΕΤΑΦΡΑΣΗΣ.

• ΜΗΝ ΕΠΙΧΕΙΡΗΣΕΤΕ ΤΗΝ ΕΚΤΕΛΕΣΗ ΕΡΓΑΣΙΩΝ ΣΕΡΒΙΣ ΣΤΟΝ ΕΞΟΠΛΙΣΜΟ

ΠΡΟΕΙ∆ΟΠΟΙΗΣΗ

ΕΚΤΟΣ ΕΑΝ ΕΧΕΤΕ ΣΥΜΒΟΥΛΕΥΤΕΙ

ΚΑΙ ΕΧΕΤΕ ΚΑΤΑΝΟΗΣΕΙ ΤΟ ΠΑΡΟΝ

ΕΓΧΕΙΡΙ∆ΙΟ ΣΕΡΒΙΣ.

• ΕΑΝ ∆Ε ΛΑΒΕΤΕ ΥΠΟΨΗ ΤΗΝ ΠΡΟΕΙ∆ΟΠΟΙΗΣΗ ΑΥΤΗ, ΕΝ∆ΕΧΕΤΑΙ ΝΑ

ΠΡΟΚΛΗΘΕΙ ΤΡΑΥΜΑΤΙΣΜΟΣ ΣΤΟ ΑΤΟΜΟ ΠΑΡΟΧΗΣ ΣΕΡΒΙΣ, ΣΤΟ ΧΕΙΡΙΣΤΗ Ή

ΣΤΟΝ ΑΣΘΕΝΗ ΑΠΟ ΗΛΕΚΤΡΟΠΛΗΞΙΑ, ΜΗΧΑΝΙΚΟΥΣ Ή ΑΛΛΟΥΣ ΚΙΝ∆ΥΝΟΥΣ.

FIGYELMEZTETÉS

VIÐVÖRUN

• EZEN KARBANTARTÁSI KÉZIKÖNYV KIZÁRÓLAG ANGOL NYELVEN ÉRHETŐ

EL.

• HA A VEVŐ SZOLGÁLTATÓJA ANGOLTÓL ELTÉRŐ NYELVRE TART IGÉNYT,

AKKOR A VEVŐ FELELŐSSÉGE A FORDÍTÁS ELKÉSZÍTTETÉSE.

• NE PRÓBÁLJA ELKEZDENI HASZNÁLNI A BERENDEZÉST, AMÍG A

KARBANTARTÁSI KÉZIKÖNYVBEN LEÍRTAKAT NEM ÉRTELMEZTÉK.

• EZEN FIGYELMEZTETÉS FIGYELMEN KÍVÜL HAGYÁSA A SZOLGÁLTATÓ,

MŰKÖDTETŐ VAGY A BETEG ÁRAMÜTÉS, MECHANIKAI VAGY EGYÉB

VESZÉLYHELYZET MIATTI SÉRÜLÉSÉT EREDMÉNYEZHETI.

• ÞESSI ÞJÓNUSTUHANDBÓK ER EINGÖNGU FÁANLEG Á ENSKU.

• EF ÞJÓNUSTUAÐILI VIÐSKIPTAMANNS ÞARFNAST ANNARS TUNGUMÁLS EN

ENSKU, ER ÞAÐ Á ÁBYRGÐ VIÐSKIPTAMANNS AÐ ÚTVEGA ÞÝÐINGU.

• REYNIÐ EKKI AÐ ÞJÓNUSTA TÆKIÐ NEMA EFTIR AÐ HAFA SKOÐAÐ OG SKILIÐ

ÞESSA ÞJÓNUSTUHANDBÓK.

• EF EKKI ER FARIÐ AÐ ÞESSARI VIÐVÖRUN GETUR ÞAÐ VALDIÐ MEIÐSLUM

ÞJÓNUSTUVEITANDA, STJÓRNANDA EÐA SJÚKLINGS VEGNA RAFLOSTS,

VÉLRÆNNAR EÐA ANNARRAR HÆTTU.

State: RELEASE - Document is released and under formal Change Control. Changes are subject to the ECR/ECO Process.

See the GEHC Myworkshop System to determine the status of this document.

Approved Document - 5213326-100TPH_r3.pdf Page 6 of 252

iii

Page 7

GE HEALTHCARE

D

IRECTION 5213326-100, REVISION 3 LOGIQ™ A3 SERVICE MANUAL

• TENTO SERVISNÍ NÁVOD EXISTUJE POUZE V ANGLICKÉM JAZYCE.

• V PŘÍPADĚ, ŽE POSKYTOVATEL SLUŽEB ZÁKAZNÍKŮM POTŘEBUJE NÁVOD V

JINÉM JAZYCE, JE ZAJIŠTĚNÍ PŘEKLADU DO ODPOVÍDAJÍCÍHO JAZYKA

ÚKOLEM ZÁKAZNÍKA.

• NEPROVÁDĚJTE ÚDRŽBU TOHOTO ZAŘÍZENÍ, ANIŽ BYSTE SI PŘEČETLI

VÝSTRAHA

TENTO SERVISNÍ NÁVOD A POCHOPILI JEHO OBSAH.

• V PŘÍPADĚ NEDODRŽOVÁNÍ TÉTO VÝSTRAHY MŮŽE DOJÍT ÚRAZU

ELEKTRICKÁM PROUDEM PRACOVNÍKA POSKYTOVATELE SLUŽEB,

OBSLUŽNÉHO PERSONÁLU NEBO PACIENTŮ VLIVEM ELEKTRICKÉHOP

PROUDU, RESPEKTIVE VLIVEM K RIZIKU MECHANICKÉHO POŠKOZENÍ NEBO

JINÉMU RIZIKU.

• DENNE SERVICEMANUAL FINDES KUN PÅ ENGELSK.

• HVIS EN KUNDES TEKNIKER HAR BRUG FOR ET ANDET SPROG END

ENGELSK, ER DET KUNDENS ANSVAR AT SØRGE FOR OVERSÆTTELSE.

• FORSØG IKKE AT SERVICERE UDSTYRET MEDMINDRE

ADVARSEL

DENNE SERVICEMANUAL ER BLEVET LÆST OG FORSTÅET.

• MANGLENDE OVERHOLDELSE AF DENNE ADVARSEL KAN MEDFØRE SKADE

PÅ GRUND AF ELEKTRISK, MEKANISK ELLER ANDEN FARE FOR TEKNIKEREN,

OPERATØREN ELLER PATIENTEN.

WAARSCHUWING

BRĪDINĀJUMS

• DEZE ONDERHOUDSHANDLEIDING IS ENKEL IN HET ENGELS

VERKRIJGBAAR.

• ALS HET ONDERHOUDSPERSONEEL EEN ANDERE TAAL VEREIST, DAN IS DE

KLANT VERANTWOORDELIJK VOOR DE VERTALING ERVAN.

• PROBEER DE APPARATUUR NIET TE ONDERHOUDEN VOORDAT DEZE

ONDERHOUDSHANDLEIDING WERD GERAADPLEEGD EN BEGREPEN IS.

• INDIEN DEZE WAARSCHUWING NIET WORDT OPGEVOLGD, ZOU HET

ONDERHOUDSPERSONEEL, DE OPERATOR OF EEN PATIËNT GEWOND

KUNNEN RAKEN ALS GEVOLG VAN EEN ELEKTRISCHE SCHOK,

MECHANISCHE OF ANDERE GEVAREN.

• ŠĪ APKALPES ROKASGRĀMATA IR PIEEJAMA TIKAI ANGĻU VALODĀ.

• JA KLIENTA APKALPES SNIEDZĒJAM NEPIECIEŠAMA INFORMĀCIJA CITĀ

VALODĀ, NEVIS ANGĻU, KLIENTA PIENĀKUMS IR NODROŠINĀT TULKOŠANU.

• NEVEICIET APRĪKOJUMA APKALPI BEZ APKALPES ROKASGRĀMATAS

IZLASĪŠANAS UN SAPRAŠANAS.

• ŠĪ BRĪDINĀJUMA NEIEVĒROŠANA VAR RADĪT ELEKTRISKĀ

S STRĀVAS

TRIECIENA, MEHĀNISKU VAI CITU RISKU IZRAISĪTU TRAUMU APKALPES

SNIEDZĒJAM, OPERATORAM VAI PACIENTAM.

iv -

State: RELEASE - Document is released and under formal Change Control. Changes are subject to the ECR/ECO Process.

See the GEHC Myworkshop System to determine the status of this document.

Approved Document - 5213326-100TPH_r3.pdf Page 7 of 252

Page 8

GE HEALTHCARE

D

IRECTION 5213326-100, REVISION 3 LOGIQ™ A3 SERVICE MANUAL

• ŠIS EKSPLOATAVIMO VADOVAS YRA IŠLEISTAS TIK ANGLŲ KALBA.

• JEI KLIENTO PASLAUGŲ TEIKĖJUI REIKIA VADOVO KITA KALBA – NE ANGLŲ,

VERTIMU PASIRŪPINTI TURI KLIENTAS.

• NEMĖGINKITE ATLIKTI ĮRANGOS TECHNINĖS PRIEŽIŪROS DARBŲ, NEBENT

ĮSPĖJIMAS

VADOVAUTUMĖTĖS ŠIUO EKSPLOATAVIMO VADOVU IR JĮ SUPRASTUMĖTE

• NEPAISANT ŠIO PERSPĖJIMO, PASLAUGŲ TEIKĖJAS, OPERATORIUS AR

PACIENTAS GALI BŪTI SUŽEISTAS DĖL ELEKTROS SMŪGIO, MECHANINIŲ AR

KITŲ PAVOJŲ.

• DENNE SERVICEHÅNDBOKEN FINNES BARE PÅ ENGELSK.

• HVIS KUNDENS SERVICELEVERANDØR TRENGER ET ANNET SPRÅK, ER DET

KUNDENS ANSVAR Å SØRGE FOR OVERSETTELSE.

• IKKE FORSØK Å REPARERE UTSTYRET UTEN AT DENNE

ADVARSEL

SERVICEHÅNDBOKEN ER LEST OG FORSTÅTT.

• MANGLENDE HENSYN TIL DENNE ADVARSELEN KAN FØRE TIL AT

SERVICELEVERANDØREN, OPERATØREN ELLER PASIENTEN SKADES PÅ

GRUNN AV ELEKTRISK STØT, MEKANISKE ELLER ANDRE FARER.

OSTRZEŻENIE

ATE NŢIE

• NINIEJSZY PODRĘCZNIK SERWISOWY DOSTĘPNY JEST JEDYNIE W JĘZYKU

ANGIELSKIM.

• JEŚLI FIRMA ŚWIADCZĄCA KLIENTOWI USłUGI SERWISOWE WYMAGA

UDOSTĘPNIENIA PODRĘCZNIKA W JĘZYKU INNYM NIŻ ANGIELSKI,

OBOWIĄZEK ZAPEWNIENIA STOSOWNEGO TłUMACZENIA SPOCZYWA NA

KLIENCIE.

• NIE PRÓBOWAĆ SERWISOWAĆ

NINIEJSZEGO SPRZĘTU BEZ UPRZEDNIEGO

ZAPOZNANIA SIĘ Z PODRĘCZNIKIEM SERWISOWYM.

• NIEZASTOSOWANIE SIĘ DO TEGO OSTRZEŻENIA MOżE GROZIĆ

OBRAŻENIAMI CIAłA SERWISANTA, OPERATORA LUB PACJENTA W WYNIKU

PORAŻENIA PRĄDEM, URAZU MECHANICZNEGO LUB INNEGO RODZAJU

ZAGROŻEŃ.

• ACEST MANUAL DE SERVICE ESTE DISPONIBIL NUMAI ÎN LIMBA ENGLEZĂ.

• DACĂ UN FURNIZOR DE SERVICII PENTRU CLIENŢI NECESITĂ O ALTĂ LIMBĂ

DECÂT CEA ENGLEZĂ, ESTE DE DATORIA CLIENTULUI SĂ FURNIZEZE O

TRADUCERE.

• NU ÎNCERCAŢI SĂ REPARAŢI ECHIPAMENTUL DECÂT ULTERIOR

CONSULTĂRII ŞI ÎNŢELEGERII ACESTUI MANUAL DE SERVICE.

• IGNORAREA ACESTUI AVERTISMENT AR PUTEA DUCE LA RĂNIREA

DEPANATORULUI, OPERATORULUI SAU PACIENTULUI ÎN URMA

PERICOLELOR DE ELECTROCUTARE, MECANICE SAU DE ALTĂ NATURĂ.

State: RELEASE - Document is released and under formal Change Control. Changes are subject to the ECR/ECO Process.

See the GEHC Myworkshop System to determine the status of this document.

Approved Document - 5213326-100TPH_r3.pdf Page 8 of 252

v

Page 9

GE HEALTHCARE

D

IRECTION 5213326-100, REVISION 3 LOGIQ™ A3 SERVICE MANUAL

• ДАННОЕ РУКОВОДСТВО ПО ОБСЛУЖИВАНИЮ ПРЕДОСТАВЛЯЕТСЯ

ТОЛЬКО НА АНГЛИЙСКОМ ЯЗЫКЕ.

• ЕСЛИ СЕРВИСНОМУ ПЕРСОНАЛУ КЛИЕНТА НЕОБХОДИМО РУКОВОДСТВО

НЕ НА АНГЛИЙСКОМ ЯЗЫКЕ, КЛИЕНТУ СЛЕДУЕТ САМОСТОЯТЕЛЬНО

ОБЕСПЕЧИТЬ ПЕРЕВОД.

ОСТОРОЖНО!

• ПЕРЕД ОБСЛУЖИВАНИЕМ ОБОРУДОВАНИЯ ОБЯЗАТЕЛЬНО ОБРАТИТЕСЬ

К ДАННОМУ РУКОВОДСТВУ И ПОЙМИТЕ ИЗЛОЖЕННЫЕ В НЕМ СВЕДЕНИЯ.

• НЕСОБЛЮДЕНИЕ УКАЗАННЫХ ТРЕБОВАНИЙ МОЖЕТ ПРИВЕСТИ К ТОМУ,

ЧТО СПЕЦИАЛИСТ ПО ТЕХОБСЛУЖИВАНИЮ

, ОПЕРАТОР ИЛИ ПАЦИЕНТ

ПОЛУЧАТ УДАР ЗЛЕКТРИЧЕСКИМ ТОКОМ, МЕХАНИЧЕСКУЮ ТРАВМУ ИЛИ

ДРУГОЕ ПОВРЕЖДЕНИЕ.

• TÁTO SERVISNÁ PRÍRUČKA JE K DISPOZÍCII LEN V ANGLIČTINE.

• AK ZÁKAZNÍKOV POSKYTOVATEĽ SLUŽIEB VYŽADUJE INÝ JAZYK AKO

ANGLIČTINU, POSKYTNUTIE PREKLADATEĽSKÝCH SLUŽIEB JE

ZODPOVEDNOSŤOU ZÁKAZNÍKA.

• NEPOKÚŠAJTE SA VYKONÁVAŤ SERVIS ZARIADENIA SKÔR, AKO SI

UPOZORNENIE

NEPREČÍTATE SERVISNÚ PRÍRUČKU A NEPOROZUMIETE JEJ.

• ZANEDBANIE TOHTO UPOZORNENIA MÔŽE VYÚSTIŤ DO ZRANENIA

POSKYTOVATEĽA SLUŽIEB, OBSLUHUJÚCEJ OSOBY ALEBO PACIENTA

ELEKTRICKÝM PRÚDOM, PRÍPADNE DO MECHANICKÉHO ALEBO INÉHO

NEBEZPEČENSTVA.

VAR NING

DİKKAT

• DEN HÄR SERVICEHANDBOKEN FINNS BARA TILLGÄNGLIG PÅ ENGELSKA.

• OM EN KUNDS SERVICETEKNIKER HAR BEHOV AV ETT ANNAT SPRÅK ÄN

ENGELSKA ANSVARAR KUNDEN FÖR ATT TILLHANDAHÅLLA

ÖVERSÄTTNINGSTJÄNSTER.

• FÖRSÖK INTE UTFÖRA SERVICE PÅ UTRUSTNINGEN OM DU INTE HAR LÄST

OCH FÖRSTÅR DEN HÄR SERVICEHANDBOKEN.

• OM DU INTE TAR HÄNSYN TILL DEN HÄR VARNINGEN KAN DET RESULTERA I

SKADOR PÅ SERVICETEKNIKERN, OPERATÖREN ELLER PATIENTEN TILL

FÖLJD AV ELEKTRISKA STÖTAR, MEKANISKA FAROR ELLER ANDRA FAROR.

• BU SERVİS KILAVUZU YALNIZCA İNGİLİZCE OLARAK SAĞLANMIŞTIR.

• EĞER MÜŞTERİ TEKNİSYENİ KILAVUZUN İNGİLİZCE DIŞINDAK

İ BİR DİLDE

OLMASINI İSTERSE, KILAVUZU TERCÜME ETTİRMEK MÜŞTERİNİN

SORUMLULUĞUNDADIR.

• SERVİS KILAVUZUNU OKUYUP ANLAMADAN EKİPMANLARA MÜDAHALE

ETMEYİNİZ.

• BU UYARININ GÖZ ARDI EDİLMESİ, ELEKTRİK ÇARPMASI YA DA MEKANİK

VEYA DİĞER TÜRDEN KAZALAR SONUCUNDA TEKNİSYENİN, OPERATÖRÜN

YA DA HASTANIN YARALANMASINA YOL AÇABİLİR.

vi -

State: RELEASE - Document is released and under formal Change Control. Changes are subject to the ECR/ECO Process.

See the GEHC Myworkshop System to determine the status of this document.

Approved Document - 5213326-100TPH_r3.pdf Page 9 of 252

Page 10

GE HEALTHCARE

D

IRECTION 5213326-100, REVISION 3 LOGIQ™ A3 SERVICE MANUAL

State: RELEASE - Document is released and under formal Change Control. Changes are subject to the ECR/ECO Process.

See the GEHC Myworkshop System to determine the status of this document.

vii

Approved Document - 5213326-100TPH_r3.pdf Page 10 of 252

Page 11

GE HEALTHCARE

D

IRECTION 5213326-100, REVISION 3 LOGIQ™ A3 SERVICE MANUAL

DAMAGE IN TRANSPORTATION

All packages should be closely examined at time of delivery. If damage is apparent write “Damage In

Shipment” on ALL copies of the freight or express bill BEFORE delivery is accepted or “signed for” by

a GE representative or hospital receiving agent. Whether noted or concealed, damage MUST be

reported to the carrier immediately upon discovery, or in any event, within 14 days after receipt, and the

contents and containers held for inspection by the carrier. A transportation company will not pay a claim

for damage if an inspection is not requested within this 14 day period.

CERTIFIED ELECTRICAL CONTRACTOR STATEMENT - FOR USA ONLY

All electrical Installations that are preliminary to position ing of the equipment at the site prepared for the

equipment shall be performed by licensed electrical contractors. Othe r conn ections between pieces o f

electrical equipment, calibrations and testing sha ll be performed by q ualified GE Healthcare person nel.

In performing all electrical work on these products, GE will use its own specially trained field engineers.

All of GE’s electrical work on these products will comply with the requirements of the applicable

electrical codes.

The purchaser of GE equipment shall only utilize qualified personnel (i.e., GE’s field engineers,

personnel of third-party service companies with equivalent training, or licensed electricians) to perform

electrical servicing on the equipment.

OMISSIONS & ERRORS

If there are any omissions, errors or suggestions for improving this documentation, please contact the

GE Healthcare Global Documentation Group with specific information listing the system type, manual

title, part number, revision number, page number and suggestion details. Mail the information to:

Service Documentation, 9900 Innovation Drive (RP-2123), Wauwatosa, WI 53226, USA.

GE Healthcare employees should use the iTrak System to report all documentation errors or omissions.

SERVICE SAFETY CONSIDERATIONS

DANGER

DANGEROUS VOLTAGES, CAPABLE OF CAUSING DEATH, ARE PRESENT IN

THIS EQUIPMENT. USE EXTREME CAUTION WHEN HANDLING, TESTING AND

ADJUSTING.

WARNINGWARNING

Use all Personal Protection Equipment (PPE) such as gloves, safety shoes, safety

glasses, and kneeling pad, to reduce the risk of injury.

For a complete review of all safety requirements, see the Chapter 1, Safety Considerations section of

the LOGIQ™ A3 Basic Service Manual (5213326-100).

viii -

State: RELEASE - Document is released and under formal Change Control. Changes are subject to the ECR/ECO Process.

See the GEHC Myworkshop System to determine the status of this document.

Approved Document - 5213326-100TPH_r3.pdf Page 11 of 252

Page 12

GE HEALTHCARE

D

IRECTION 5213326-100, REVISION 3 LOGIQ™ A3 SERVICE MANUAL

LEGAL NOTES

The contents of this publication may not be copied or duplicated in any form, in whole or in part, without

prior written permission of GE Healthcare.

GE Healthcare may revise this publication from time to time without written notice.

TRADEMARKS

All products and their name brands are trademarks of their respective holders.

COPYRIGHTS

All Material Copyright© 2007,2008 by General Electric Company Inc. All Rights Reserved

State: RELEASE - Document is released and under formal Change Control. Changes are subject to the ECR/ECO Process.

See the GEHC Myworkshop System to determine the status of this document.

Approved Document - 5213326-100TPH_r3.pdf Page 12 of 252

ix

Page 13

GE HEALTHCARE

D

IRECTION 5213326-100, REVISION 3 LOGIQ™ A3 SERVICE MANUAL

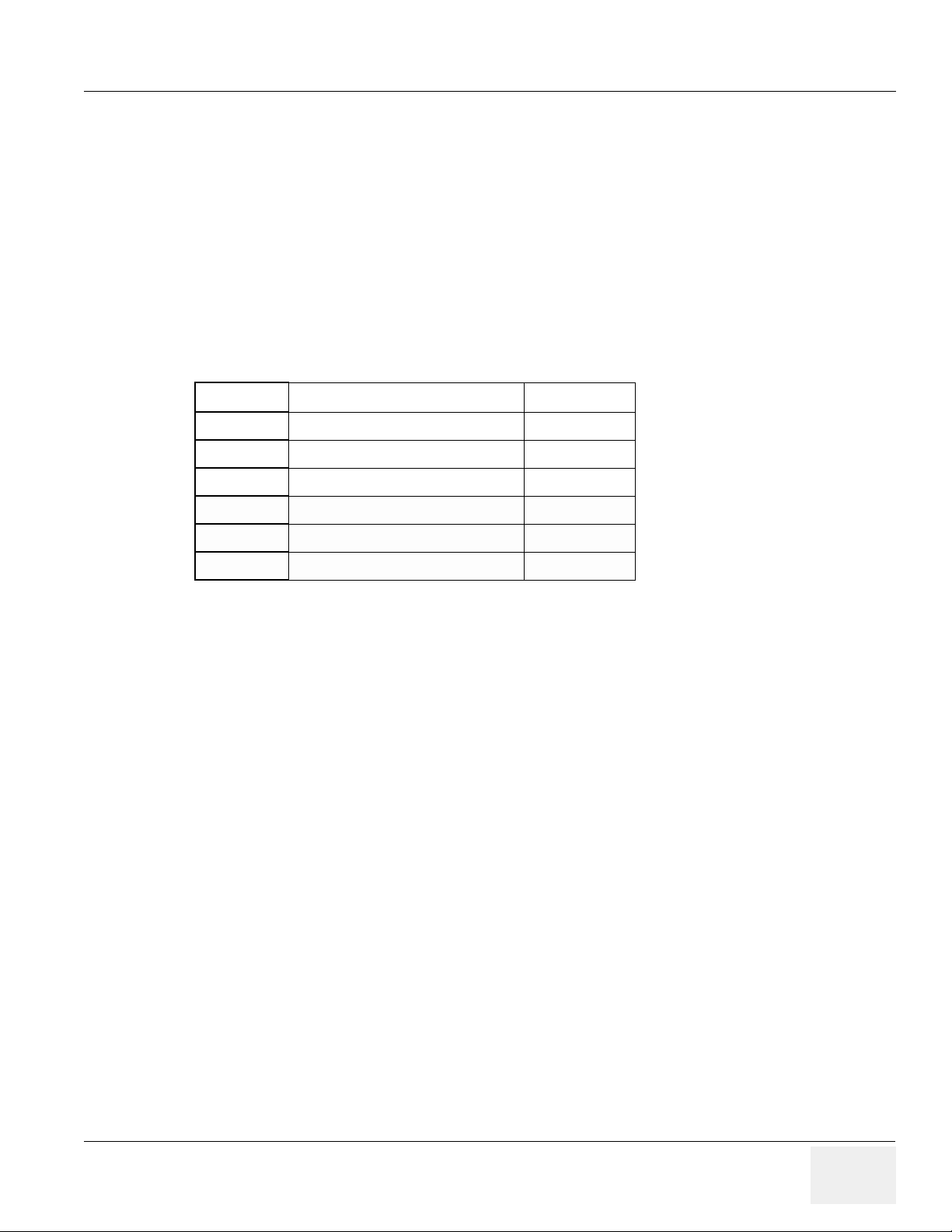

Revision History

Revision Date Reason for change

1 05 Aug 2007 Initial Release

2 28 Jan 2008 Revised to add a section on Service Diagnostics

Added sections on: Troubleshooting guide and Netowrk Connectivity

3 25 Aug 2008

FRU replacement procedures updated with functional checkout procedure and

debrief guidelines.

List of Effected Pages

Pages Revision Pages Revision Pages Revision

Title Page 3

Important Precautions

(pages i to X)

Table of Contents

(pages TOC1 to TOC6)

Chapter 1 - Introduction

(pages 1-1 to 1-18)

Chapter2-Preinstallation

(pages 2-1 to 2-8)

Chapter3-Installation

(pages 3-1 to 3-24)

3

3

3

3

Chapter4-Functional checks

(pages 4-1 to 4-14)

Chapter5-Components And

functions

(pages 5-1 to 5-12)

Chapter6-Scan Adjustments

(pages 6-1 to 6-2)

Chapter7-Trouble Shooting and

Diagnostics

(pages 7-1 to 7-2)

3

3

3

3 index 3

3 Rear Cover 3

Chapter8-Replacement

Proceduresn

(pages 8-1 to 8-28)

Chapter9-Renewalparts

(pages 9-1 to 9-8)

Chapter10-Care & maintenance

(pages 10-1 to 10-30)

3

3

3

x -

State: RELEASE - Document is released and under formal Change Control. Changes are subject to the ECR/ECO Process.

See the GEHC Myworkshop System to determine the status of this document.

Approved Document - 5213326-100TPH_r3.pdf Page 13 of 252

Page 14

GE HEALTHCARE

DIRECTION 5213326-100, REVISION 3 LOGIQ™ A3 SERVICE MANUAL

Table Of Contents

CHAPTER 1

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 1

Purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 1

Table Of Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 1

Purpose of Service Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 1

Typical Users of the Basic Service Manual . . . . . . . . . . . . . . . . . . . . . . . . 1 - 2

Purpose of Operator Manual(s) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 2

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 2

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 2

Important Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 3

Conventions Used in Book . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 3

Standard Hazard Icons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 4

Product Icons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 5

Safety Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 7

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 7

Human Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 7

Mechanical Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 7

Electrical Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 8

Returning/Shipping Probes and Repair Parts . . . . . . . . . . . . . . . . . . . . . . . 1 - 8

Warning Label Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 9

Dangerous Procedure Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 17

EMC, EMI, and ESD. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 17

Electromagnetic Compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 17

Electrostatic Discharge (ESD) Prevention . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 17

CE Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 17

Customer Assistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 18

Contact Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 18

System Manufacturer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 19

State: RELEASE - Document is released and under formal Change Control. Changes are subject to the ECR/ECO Process.

See the GEHC Myworkshop System to determine the status of this document.

Approved Document - 5213326-100TPH_r3.pdf Page 14 of 252

Table Of Contents TOC - 1

Page 15

GE HEALTHCARE

DIRECTION 5213326-100, REVISION 3 LOGIQ™ A3 SERVICE MANUAL

CHAPTER 2

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 1

Purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 1

Table Of Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 1

General Console Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 2

Console Environmental Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 2

Cooling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 2

Lighting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 2

Electrical Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 3

Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 3

Inrush Current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 3

Site Circuit Breaker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 3

Site Power Outlets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 3

Unit Power Plug . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 4

Power Stability Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 4

EMI Limitations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 4

Probes Environmental Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 5

Time and Manpower Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 5

Facility Needs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 6

Purchaser Responsibilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 6

Required Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 6

Desirable Ultrasound Room Facilities . . . . . . . . . . . . . . . . . . . . . . . . 2 - 7

Minimal Floor Plan Suggestion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 8

TOC - 2 -

State: RELEASE - Document is released and under formal Change Control. Changes are subject to the ECR/ECO Process.

See the GEHC Myworkshop System to determine the status of this document.

Approved Document - 5213326-100TPH_r3.pdf Page 15 of 252

Page 16

GE HEALTHCARE

DIRECTION 5213326-100, REVISION 3 LOGIQ™ A3 SERVICE MANUAL

CHAPTER 3

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 1

Purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 1

Table Of Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 1

Average Installation Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 2

Installation Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 2

Receiving and Unpacking LOGIQ A3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 3

Safety Reminders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 9

Moving into Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 10

Adjusting System Clock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 10

Product Locator Installation Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 10

Preparing for Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 11

Verify Customer Order . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 11

Physical Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 11

Systems Voltage Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 11

Video Formats . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 11

EMI Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 11

Checking the Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 11

Completing the Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 12

System Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 12

Physical Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 12

Weight with Monitor and without Peripherals . . . . . . . . . . . . . . . . . . 3 - 13

Acoustic Noise Output: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 13

Electrical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 13

Probe (Transducer) Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 13

Power On / Off Process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 14

Scanner Power On . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 14

System Boot Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 15

Power Off/ Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 16

System Power Down . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 16

Scanner Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 17

System Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 18

System Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 18

System Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 18

Network Connectivity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 19

Storage And Operation Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 23

Optional Peripherals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 23

Optional Peripherals/Peripheral Connection . . . . . . . . . . . . . . . . . . . . . . . . 3 - 23

Approved peripherals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 23

Connecting Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 24

Power Consumption of Optional Peripherals . . . . . . . . . . . . . . . . . 3 - 24

Available Probes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 25

Peripherals/Accessories Connector Panel . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 25

Paper work . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 29

State: RELEASE - Document is released and under formal Change Control. Changes are subject to the ECR/ECO Process.

See the GEHC Myworkshop System to determine the status of this document.

Approved Document - 5213326-100TPH_r3.pdf Page 16 of 252

Table Of Contents TOC - 3

Page 17

GE HEALTHCARE

DIRECTION 5213326-100, REVISION 3 LOGIQ™ A3 SERVICE MANUAL

Product Locator Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 29

GE Cares Sticker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 30

User Manual(s) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 30

TOC - 4 -

State: RELEASE - Document is released and under formal Change Control. Changes are subject to the ECR/ECO Process.

See the GEHC Myworkshop System to determine the status of this document.

Approved Document - 5213326-100TPH_r3.pdf Page 17 of 252

Page 18

GE HEALTHCARE

DIRECTION 5213326-100, REVISION 3 LOGIQ™ A3 SERVICE MANUAL

CHAPTER 4

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 1

Purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 1

Table Of Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 1

Required Equipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 1

General Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 2

Power On/Boot Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 2

Adjusting the Display Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 2

Brightness and Contrast . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 2

Lockout/Tagout Requirements (For USA/Europe Only) . . . . . . . . . . . . . . . 4 - 2

Functional Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 3

Basic Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 3

Alpha Numeric Keyboard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 3

Keyboard Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 3

B Mode Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 4

Preparations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 4

B Mode OP Panel Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 5

M Mode Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 6

Preparations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 6

M Mode OP Panel Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 7

M Mode Top and Sub menu Controls . . . . . . . . . . . . . . . . . . . . . . . 4 - 7

Measurement and Multi Image Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 8

Performing B Mode Measurements Checks . . . . . . . . . . . . . . . . . . 4 - 8

Basic Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 9

Distance and Tissue Depth Measurements . . . . . . . . . . . . . . . . . . . 4 - 9

Circumference/Area (Ellipse) Measurement . . . . . . . . . . . . . . . . . . 4 - 9

Report Pages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 9

Probe/Connectors Usage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 10

Connecting a probe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 10

Activating the probe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 10

Disconnecting the probe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 10

Using Cine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 11

Activating CINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 11

Image Management (QG) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 11

CF Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 11

Software Configuration Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 11

Peripheral Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 11

Presets Backup/Restore Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 12

Presets Backup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 12

Presets Restore . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 12

Safety Issues . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 13

Probe/Connectors Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 13

Power Supply Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 13

Site Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 14

State: RELEASE - Document is released and under formal Change Control. Changes are subject to the ECR/ECO Process.

See the GEHC Myworkshop System to determine the status of this document.

Approved Document - 5213326-100TPH_r3.pdf Page 18 of 252

Table Of Contents TOC - 5

Page 19

GE HEALTHCARE

DIRECTION 5213326-100, REVISION 3 LOGIQ™ A3 SERVICE MANUAL

CHAPTER 5

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 1

Purpose of Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 1

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 1

System Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 1

Types of Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 2

Block Diagrams and Theory. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 3

Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 3

Front End . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 4

Transmit/Receive PCB (TxRx) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 4

Probe Interface PCB(Connector Board) . . . . . . . . . . . . . . . . . . . . . . 5 - 5

Back End Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 6

System On Module(SOM) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 6

Master Control Board(MST) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 6

Power Supply(LV/HVPS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 8

Rear Panel Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 9

Keyboard Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 10

Main PCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 10

TGC_PCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 10

LCD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 11

Brightness adjustment: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 12

Circuit Boards Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 12

ON/OFF Signal Flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 13

TOC - 6 -

State: RELEASE - Document is released and under formal Change Control. Changes are subject to the ECR/ECO Process.

See the GEHC Myworkshop System to determine the status of this document.

Approved Document - 5213326-100TPH_r3.pdf Page 19 of 252

Page 20

GE HEALTHCARE

DIRECTION 5213326-100, REVISION 3 LOGIQ™ A3 SERVICE MANUAL

CHAPTER 6

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 1

Purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 1

Table Of Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 1

Regulatory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 1

Monitor Adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 2

State: RELEASE - Document is released and under formal Change Control. Changes are subject to the ECR/ECO Process.

See the GEHC Myworkshop System to determine the status of this document.

Approved Document - 5213326-100TPH_r3.pdf Page 20 of 252

Table Of Contents TOC - 7

Page 21

GE HEALTHCARE

DIRECTION 5213326-100, REVISION 3 LOGIQ™ A3 SERVICE MANUAL

CHAPTER 7

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 1

Purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 1

Table Of Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 1

LED Descriptions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 1

TxRx Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 1

MST Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 3

BackPlane Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 4

Connector Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 5

Rear Panel BoardService Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 6

Voltage Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 7

MST Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 7

Troubleshooting Tips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 8

Troubleshooting Guide. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 9

Probe not getting recognized . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 9

No Ultrasound Image . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 10

No Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 11

System does not Boot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 12

System does not switch ON . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 13

Unable to Print on the Printers (UPD897/Deskjet) . . . . . . . . . . . . . . . . . . . . 7 - 14

No Keyboard response . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 15

No Image on External Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 16

Peripheral Power on Top Panel absent . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 17

Unable to Archive and Backup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 18

TGC malfunction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 19

Gain malfunction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 20

Trackball malfunction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 21

Service Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 22

TOC - 8 -

State: RELEASE - Document is released and under formal Change Control. Changes are subject to the ECR/ECO Process.

See the GEHC Myworkshop System to determine the status of this document.

Approved Document - 5213326-100TPH_r3.pdf Page 21 of 252

Page 22

GE HEALTHCARE

DIRECTION 5213326-100, REVISION 3 LOGIQ™ A3 SERVICE MANUAL

CHAPTER 8

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 1

Purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 1

Returning/Shipping Probes and Repair Parts . . . . . . . . . . . . . . . . . . . . . . . 8 - 1

LCD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 2

LCD ASSEMBLY(FRU P/N # 5271538) . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 2

Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 2

Needed Manpower . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 2

Preparations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 2

Removal procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 2

Mounting Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 3

Functional Checkout Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 3

LCD Arm Cover Set (FRU P/N # 5270335) . . . . . . . . . . . . . . . . . . . . . . . . 8 - 4

Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 4

Needed Manpower . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 4

Preparations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 4

Removal procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 4

Functional Checkout Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 5

Handle A3 Console (FRU P/N # 5168365) . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 6

Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 6

Needed Manpower . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 6

Preparations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 6

Removal procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 6

Functional Checkout Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 6

Monitor Holder Assembly(FRU P/N # 5308054) . . . . . . . . . . . . . . . . . . . . . 8 - 7

Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 7

Needed Manpower . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 7

Preparations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 7

Removal procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 7

Functional Checkout Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 8

Keyboard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 9

Keyboard Assembly (FRU P/N # 5168531) . . . . . . . . . . . . . . . . . . . . . . . . 8 - 9

Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 9

Needed Manpower . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 9

Preparations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 9

Removal Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 9

Replace Keyboard Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 10

Functional Checkout Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 11

TGC PWA FRU Assy (FRU P/N # 5266629) . . . . . . . . . . . . . . . . . . . . . . . 8 - 12

Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 12

Needed Manpower . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 12

Preparations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 12

Removal procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 12

Functional Checkout Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 13

Alpha Numeric Keyboard with cables (FRU P/N # 5181790) . . . . . . . . . . . 8 - 14

Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 14

State: RELEASE - Document is released and under formal Change Control. Changes are subject to the ECR/ECO Process.

See the GEHC Myworkshop System to determine the status of this document.

Table Of Contents TOC - 9

Approved Document - 5213326-100TPH_r3.pdf Page 22 of 252

Page 23

GE HEALTHCARE

DIRECTION 5213326-100, REVISION 3 LOGIQ™ A3 SERVICE MANUAL

Needed Manpower . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 14

Preparations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 14

Removal procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 14

Functional Checkout Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 14

Optical Trackball Assy (FRU P/N # 5262338) . . . . . . . . . . . . . . . . . . . . . . . 8 - 15

Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 15

Needed Manpower . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 15

Preparations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 15

Removal procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 15

Functional Checkout Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 15

Encoder Set (FRU P/N # 5262796) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 16

Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 16

Needed Manpower . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 16

Preparations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 16

Removal procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 16

Functional Checkout Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 17

CA3-Keyboard Interface Cable (FRU P/N # 5192650) . . . . . . . . . . . . . . . . 8 - 18

Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 18

Needed Manpower . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 18

Preparations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 18

Removal procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 18

Functional Checkout Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 21

Keyboard Cover Set (FRU P/N # 5262766) . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 22

Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 22

Needed Manpower . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 22

Preparations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 22

Removal procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 22

Functional Checkout Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 23

Keyboard Knob Set (FRU P/N # 5263937) . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 24

Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 24

Needed Manpower . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 24

Preparations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 24

Removal procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 24

Functional Checkout Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 25

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Mechani-

cals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 26

RH Side Cover (FRU No. 5265162) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 26

Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 26

Needed Manpower . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 26

Preparations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 26

Removal Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 26

Functional Checkout Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 26

LH Side Cover (FRU No. 5267220) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 27

Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 27

Needed Manpower . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 27

Preparations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 27

TOC - 10 -

State: RELEASE - Document is released and under formal Change Control. Changes are subject to the ECR/ECO Process.

See the GEHC Myworkshop System to determine the status of this document.

Approved Document - 5213326-100TPH_r3.pdf Page 23 of 252

Page 24

GE HEALTHCARE

DIRECTION 5213326-100, REVISION 3 LOGIQ™ A3 SERVICE MANUAL

Removal Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 27

Functional Checkout Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 27

Rear Cover (FRU No. 5269718) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 28

Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 28

Needed Manpower . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 28

Preparations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 28

Removal Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 28

Functional Checkout Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 28

Front Cover (FRU No. 5271834) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 29

Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 29

Needed Manpower . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 29

Preparations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 29

Removal Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 29

Functional Checkout Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 29

Top Cover (FRU P/N # 5168637) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 30

Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 30

Needed Manpower . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 30

Preparations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 30

Removal Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 30

Functional Checkout Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 30

Rear Arm Cover Set (FRU P/N # 5263051) . . . . . . . . . . . . . . . . . . . . . . . . 8 - 31

Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 31

Needed Manpower . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 31

Preparations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 31

Removal Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 31

Functional Checkout Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 31

LH Arm Cover Front with GE Logo (FRU P/N # 5263193) /

RH Arm cover Front with Labels (FRU # 5263420) . . . . . . . . . . . . . . . . . . 8 - 32

Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 32

Needed Manpower . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 32

Preparations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 32

Removal Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 32

Functional Checkout Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 34

Front Bumper (FRU No. 5168362) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 35

Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 35

Needed Manpower . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 35

Preparations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 35

Removal Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 35

Functional Checkout Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 35

Castor Wheel Front (FRU P/N # 5265433) /

Castor Wheel Rear (FRU P/N # 5264222) . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 36

Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 36

Needed Manpower . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 36

Preparations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 36

Removal Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 36

Functional Checkout Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 37

State: RELEASE - Document is released and under formal Change Control. Changes are subject to the ECR/ECO Process.

See the GEHC Myworkshop System to determine the status of this document.

Approved Document - 5213326-100TPH_r3.pdf Page 24 of 252

Table Of Contents TOC - 11

Page 25

GE HEALTHCARE

DIRECTION 5213326-100, REVISION 3 LOGIQ™ A3 SERVICE MANUAL

Right EMI Cover (Part of EMI Cover Assy FRU P/N # 5264421) . . . . . . . . . 8 - 38

Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 38

Needed Manpower . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 38

Preparations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 38

Removal Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 38

Left EMI Cover(Part of EMI Cover Assy FRU P/N # 5264421) . . . . . . . . . . 8 - 39

Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 39

Needed Manpower . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 39

Preparations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 39

Removal Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 39

Card Cage EMI Cover (Part of EMI Cover Assy FRU P/N # 5264421) . . . . 8 - 40

Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 40

Needed Manpower . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 40

Preparations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 40

Removal Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 40

Conn-EMI-Cover-Assy (Part of EMI Cover Assy FRU P/N # 5264421) . . . . 8 - 41

Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 41

Needed Manpower . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 41

Preparations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 41

Removal Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 41

Functional Checkout Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 41

Fan Assy (FRU No. 5215345) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 42

Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 42

Needed Manpower . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 42

Preparations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 42

Removal Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 42

Functional Checkout Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 43

I/O Interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 44

Rear Panel Assy (FRU No. 5196446) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 44

Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 44

Needed Manpower . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 44

Preparations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 44

Removal Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 44

Functional Checkout Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 45

Front Panel (FRU P/N # 5192657 for 100-110V /

P/N # 5196449 for 220-240V ) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 46

Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 46

Needed Manpower . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 46

Preparations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 46

Removal Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 46

Functional Checkout Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 47

CA9-Transformer to Front Panel and power supply cable assy

(FRU P/N # 5192656) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 48

Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 48

Needed Manpower . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 48

Preparations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 48

TOC - 12 -

State: RELEASE - Document is released and under formal Change Control. Changes are subject to the ECR/ECO Process.

See the GEHC Myworkshop System to determine the status of this document.

Approved Document - 5213326-100TPH_r3.pdf Page 25 of 252

Page 26

GE HEALTHCARE

DIRECTION 5213326-100, REVISION 3 LOGIQ™ A3 SERVICE MANUAL

Removal Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 48

Functional Checkout Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 53

CA4-USB Cable Assy (FRU P/N # 5192651) . . . . . . . . . . . . . . . . . . . . . . . 8 - 54

Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 54

Needed Manpower . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 54

Preparations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 54

Removal Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 54

Functional Checkout Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 57

PCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 58

PCB Boards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 58

Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 58

Needed Manpower . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 58

Preparations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 58

Removal Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 58

Functional Checkout Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 59

Connector Board Assy (FRU No. 5193606) . . . . . . . . . . . . . . . . . . . . . . . . 8 - 60

Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 60

Needed Manpower . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 60

Preparations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 60

Removal Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 60

Functional Checkout Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 61

Back Plane Board (FRU No. 5183676) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 62

Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 62

Needed Manpower . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 62

Preparations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 62

Removal Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 62

Functional Checkout Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 63

Power Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 64

Transformer Assembly (FRU No. 5196448) . . . . . . . . . . . . . . . . . . . . . . . . 8 - 64

Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 64

Needed Manpower . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 64

Preparations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 64

Removal Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 64

Functional Checkout Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 65

Power Entry Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 66

Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 66

Needed Manpower . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 66

Preparations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 66

Removal Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 66

Functional Checkout Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 67

State: RELEASE - Document is released and under formal Change Control. Changes are subject to the ECR/ECO Process.

See the GEHC Myworkshop System to determine the status of this document.

Approved Document - 5213326-100TPH_r3.pdf Page 26 of 252

Table Of Contents TOC - 13

Page 27

GE HEALTHCARE

DIRECTION 5213326-100, REVISION 3 LOGIQ™ A3 SERVICE MANUAL

CHAPTER 9

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 - 1

Purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 - 1

Table Of Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 - 1

List of Abbreviations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 - 1

Operator Console Assy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 - 2

LOGIQ A3 Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 - 3

TOC - 14 -

State: RELEASE - Document is released and under formal Change Control. Changes are subject to the ECR/ECO Process.

See the GEHC Myworkshop System to determine the status of this document.

Approved Document - 5213326-100TPH_r3.pdf Page 27 of 252

Page 28

GE HEALTHCARE

DIRECTION 5213326-100, REVISION 3 LOGIQ™ A3 SERVICE MANUAL

CHAPTER 10

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 1

Periodic Maintenance Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 1

Purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 1

Table Of Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 1

Why do Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 2

Keeping Records . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 2

Quality Assurance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 2

Periodic Maintenance Schedule. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 2

How often should care & maintenance tasks be performed? . . . . . . . . . . . 10 - 2

Tools Required. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 4

Standard GE Tool Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 4

Special Tools, Supplies and Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 6

Specific Requirements for Care & Maintenance . . . . . . . . . . . . . . . 10 - 6

System Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 7

Preliminary Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 7

Functional Checks (See Also Chapter 4) . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 8

System Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 8

Peripheral/Option Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 8

Input Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 8

Mains Cable Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 8

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 9

General Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 9

Air Filter Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 9

Physical Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 10

Diagnostic Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 11

View the Logs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 11

Probe Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 11

Probe Related Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 11

Basic Probe Care . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 11

Basic Probe Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 11

Electrical Safety Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 12

Safety Test Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 12

GEMS Leakage Current Limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 13

Outlet Test - Wiring Arrangement - USA & Canada . . . . . . . . . . . . . . . . . . 10 - 14

Grounding Continuity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 15

Meter Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 15

Dale 600 - Ground Continuity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 16

Chassis Leakage Current Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 17

Definition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 17

Generic Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 17

Dale 600 Meter Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 18

Data Sheet for Chassis Source Leakage Current . . . . . . . . . . . . . . 10 - 19