Page 1

g

Technical

Publications

2278812-100

Revision 0

GE Medical Systems

LOGIQ 200 and LOGIQ 200 PRO

Quality Assurance Manual

Copyright© 2000 by General Electric Company

Operating Documentation

Page 2

g

GE Medical Systems

GE Medical Systems: Telex: 3797371

P.O. Box 414, Milwaukee, Wisconsin 53201 U.S.A.

(Asia, Pacific, Latin America, North America)

GE Medical Systems—Europe: Telex: 695277

283 rue de la Miniére BP34

78533 BUC Cedex

Page 3

LOGIQ α200 or LOGIQ 200 PRO

Quality Assurance Testing Documents

TABLE of CONTENTS

TAB #1 ACR Accreditation Overview 3 pages

TAB #2 Probe ID List 1 Page

QA Testing - 2277615-100 16 Pages

TAB #3 Probe ID List 1 Page

Probe 3 2267008-100 4 Pages

Probe 4 2272728-100 4 Pages

Probe 5 2272729-100 4 Pages

Probe 6 2272730-100 4 Pages

Probe 7 2272732-100 4 Pages

Probe 8 2272733-100 4 Pages

Probe 9 2272735-100 4 Pages

TAB #4 QA Reference Manual - 2262684-100 30 Pages

Probe ID List 1 Page

TAB #5 System Display Format 2 Pages

TAB #6 Section 4 - Service Manuals 20 Pages

TAB #7 Section 2 - Service Manuals 75 Pages

TAB #8 Filling out the ACR Forms 5 Pages

TAB #9 ACR, Section G: Quality Control 3 Pages

ACR, Section H: Equipment Chart 1 Page

TAB #10 Inspection and Calibration Certificate 1 Page

Page 4

Page 5

GE ULTRASOUND QUALITY ASSURANCE

ACR ULTRASOUND ACCREDITATION PROGRAM

The ACR Ultrasound Accreditation Program evaluates qualifications of personnel, equipment,

image quality and quality control measures. It is believed that these are the primary factors

impacting the quality of patient ultrasound imaging.

The Ultrasound Accreditation Program is carried out through the mail (paper submission), with

random on site reviews performed as needed for validation or clarification.

PROGRAM GOALS

• Improvement in the quality of ultrasound performance.

• Provision of educational information by raising awareness of ultrasound issues.

• Recognition of ultrasound facilities which meet program objectives.

• Collection of national data about the practice of ultrasound.

DEFINITION OF AN ULTRASOUND FACILITY

• Ultrasound section within a hospital

• Ultrasound service offered in an outpatient setting, e.g., office, multispecialty clinic, or

imaging center

• Mobile ultrasound service

A separate application is required for each location of ultrasound practice.

ULTRASOUND ACCREDITATION PROCESS

The ultrasound accreditation process consists of three parts which must be completed

successfully in order to receive accreditation.

Application – requests credentials of physicians and sonographer personnel.

Quality Control Evaluation – requests information about ultrasound quality control.

Clinical Image Evaluation – requests specific types of normal ultrasound exams; plus normal and

abnormal exams for vascular accreditation.

QUALITY CONTROL EVALUATION

1. A quality assurance (QA) program should be in place for each scanner in the facility.

The quality assurance program must be directed by a medical physicist or by the supervising

radiologist or physician who may appoint an appropriate designee to oversee the program.

There must be program documentation which describes the goals of the quality assurance

program and the responsibilities involved.

The person responsible for the quality assurance program must work with the preventive

maintenance professional. Routine quality control testing must occur regularly; a minimum

requirement is semiannually. The same tests must be performed during each testing period so

that changes can be monitored over time and effective corrective action can be taken. Testing

results, corrective action, and the effects of corrective action must be documented and

maintained on site.

Page 6

GE ULTRASOUND QUALITY ASSURANCE

ACR ULTRASOUND ACCREDITATION PROGRAM

QUALITY CONTROL EVALUATION (continued)

The QA program must evaluate at least the following items in Gray-Scale Imaging Mode.

Specific QC data will be collected as part of the Full Application that is submitted in the second

phase of the accreditation process.

• System sensitivity and/or penetration capability.

• Image uniformity.

• Photography and other hard copy recording.

• Low contrast object detectability (optional).

• Assurance of electrical and mechanical safety.

In addition, it is recommended that users verify vertical and horizontal distance measurement

accuracy when a QA program is initiated for a scanner. It is not required that these factors be

reassessed during QC testing.

These items may be assessed using commercially available phantoms. At the present time,

there is no single phantom that is preferred; users should select a phantom from current

commercially available units.

2. Test Frequency

QA tests should be done at least semiannually for each scanner as part of the quality

assurance program for the site. Test results must be documented so that trends in equipment

performance can be identified and appropriate corrective action taken.

3. Transducers

On an ongoing basis, tests should be done using two probes commonly used with any

scanner employing more than one transducer. It is recommended that these be of different

scan formats such as one linear (or curvilinear) array and one sector (mechanical, phased or

vector).

4. Data to be Submitted for Accreditation

For each scanner, submit the QC Summary (Section G of the Full Application) which shows

the data acquired from one of the semiannual tests. The QC Summary should document

results from testing the transducer (which includes two probes with different formats). Data

should be taken from testing of the transducer which is used for the most frequently occurring

examination at the site.

Visit the ACR web site for more details:

http://www.acr.org/f-standards.html

Page 7

GE ULTRASOUND QUALITY ASSURANCE

ACR ULTRASOUND ACCREDITATION PROGRAM

HOW GE ULTRASOUND CAN HELP

The ACR Quality Control Evaluation and Program is where we can help our customers with GE

Quality Assurance Evaluations (PMs).

New QA procedures are being written and tested to ensure that we incorporate the items that are

required by the ACR. It may be a slightly new mindset for the Field Engineer as it will require a

little more documentation so that the customer maintains records necessary to determine

performance trends.

The new QA testing that can be offered by GE Ultrasound will consist of:

• System QA Procedure – A Job Card style document with checks, tests and space available to

attach hard copy images for archival.

• QA Reference Manual – A detailed explanation of each check and test in the procedure. The

FE can refer to this if necessary.

• ACR Quality Control, Section G &H – Electronic versions of the official ACR paper submittal

forms. We have permission from the ACR to reprint this part of the accreditation application.

How I envision this to work. All forms are electronic and will be on a CD:

• FE opens up System QA Procedure on field laptop.

• FE performs appropriate checks and tests in the System QA Procedure.

• FE makes necessary entries on the electronic form.

• FE makes required hard copy images.

• At the completion of the System QA Procedure, FE prints out the procedure, attaches the hard

copy images in the appropriate place on the printout.

• While the FE completed the System QA Procedure on the laptop, the ACR Quality Control –

Section G (and maybe H) forms are filled in automatically. The FE prints out the ACR forms

and signs them.

• The FE gets customer approval and leaves the completed System QA Procedure and ACR

forms with the customer, with instructions that Quality Control – Section G & H can be used to

submit for ACR approval with the remainder of the paper application required by the ACR.

• Customer should also be reminded that retention of records for performance trends is critical,

if not mandatory.

NOTE: One extra thing we could do (for all or warranty/contract customers) is provide a QC

binder with divider tabs. This would allow the customer to maintain records of preventative and

corrective maintenance for trending and audit purposes.

Page 8

Page 9

05/23/00 MAC

LOGIQ a200 and LOGIQ 200 PRO

ACR Accredited Quality Assurance Procedure

Probe ID List

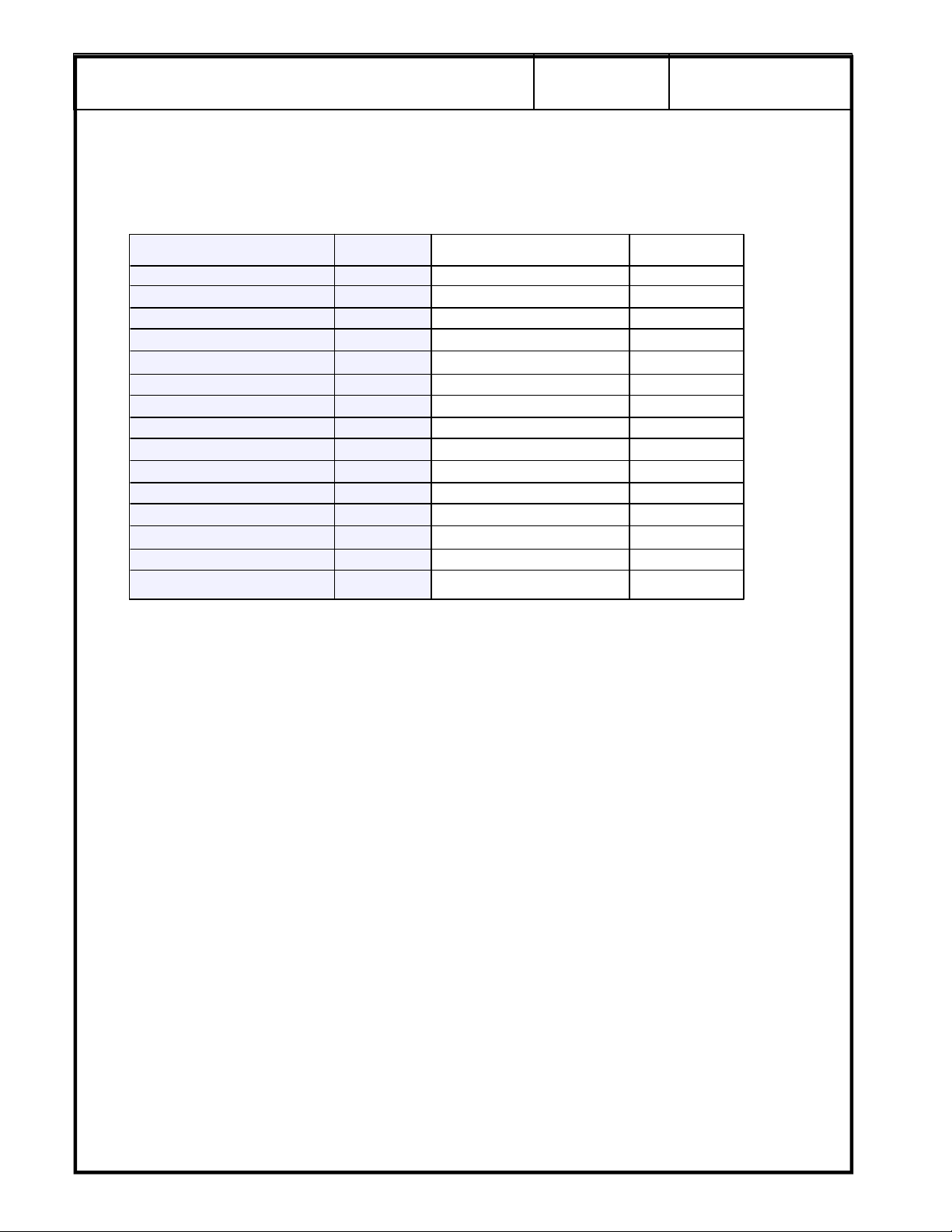

Name Model # Type Frequency Scan Format

CBF H460222CB Gen Purp 3-5 MHz Curved Linear

CAE H46022CA Gen Purp 5-7.5 MHz Curved Linear

MTZ H46022MT Endo Vag 5-7.5 MHz Curved Linear

CZB H45202CZ Superficial 5-7.5 MHz Curved Linear

CS H45222CS Gen Purp 3-5 MHz Curved Linear

ERB H45202ER Endorectal 5-7.5 MHz Curved Linear

3Cb H45202WB Gen Purp 3-5 MHz Curved Linear

LH H46022LH Superficial 7.5 MHz + Linear

LE H46022LE Gen Purp 5-7.5 MHz Linear

LI H46022LI Intraoperative 7.5 MHz + Linear

LT H46022LT Intraoperative 7.5 MHz + Linear

LB H46022LB Gen Purp 3-5 MHz Linear

LD H45202LD Intraoperative 3-5 MHz Linear

10L H45202LM Gen Purp 5-7.5 MHz Linear

SY H46022SY Gen Purp 3-5 MHz Phased Array

S317 H45202SD Gen Purp 3-5 MHz Phased Array

ATR H4061PR Endorectal 5-7.5 MHZ Curved Linear

Page 1 of 2

Page 10

05/23/00 MAC

Page 2 of 2

Page 11

g

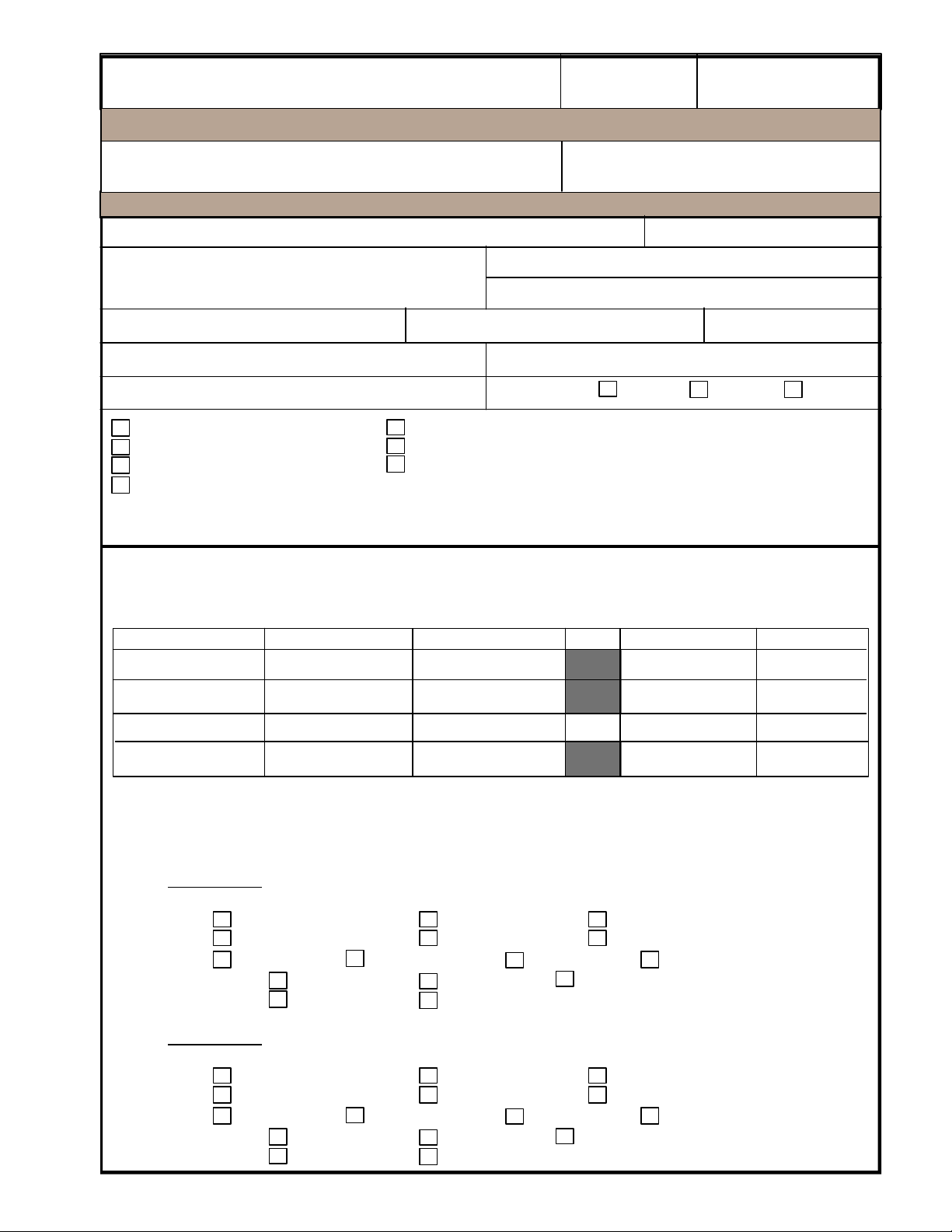

Samsung GE Medical Systems

LOGIQ a200

GE Medical Systems

1/16

2277615-100

REV 0

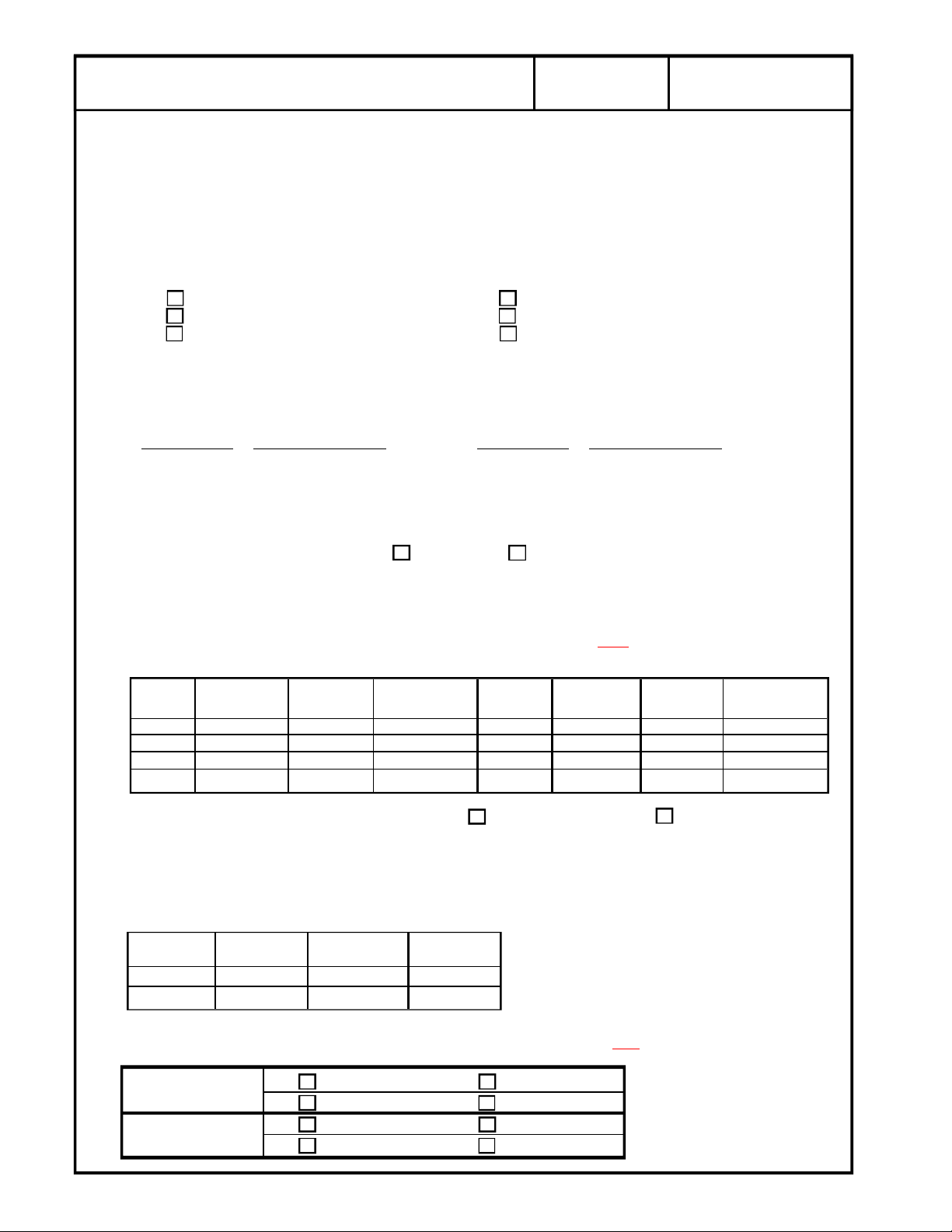

Purpose: Quality Assurance Testing

Customer Name:

Address: System Model:

System Serial #:

System ID #:

Purchase Order #:

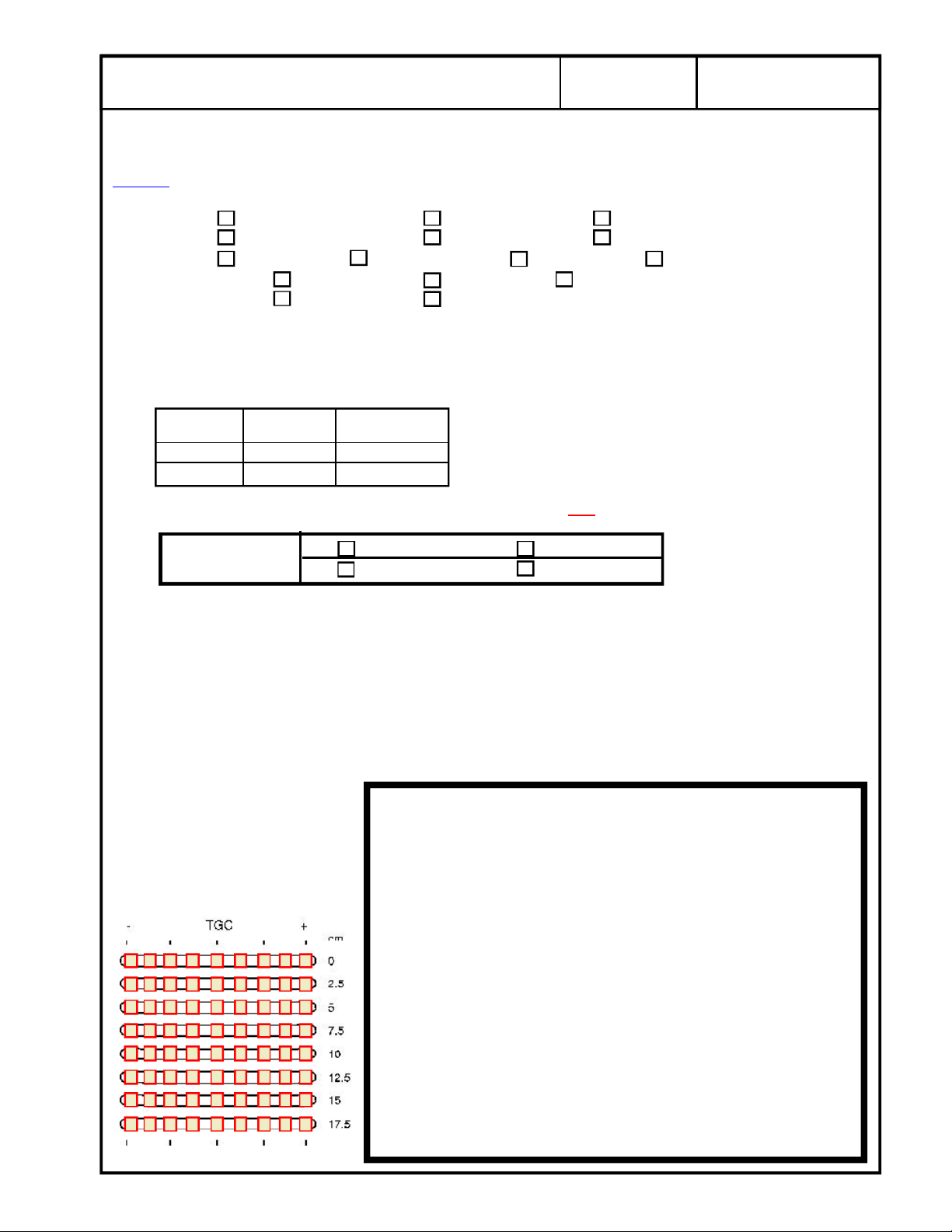

System Configuration

Video Cassette Recorder

Line Printer

Video Page Printer

Urological Therapy Guidance

Other ___________________________________

_________________________________________

Field Service Engineer: ____________________________________ Employee #: _______________

US Unit Manufacturer:

Dispatch #:

System Status: Warranty Contract Billable

Biopsy Guide

Spectral Doppler

Color

Configuration Notes:

Refer to the Ultrasound QA Reference

Manual 2262684-100 for details.

Survey Date:

Year of Mfg.:

TEST EQUIPMENT

NAME MANUFACTURER MODEL Atten. SERIAL # CAL DATE

Leakage Tester

Multimeter

Gray Scale Phantom

TRANSDUCERS TESTED

The two transducers used most frequently should be listed as transducer number 1 and 2. Use the

separate documents provided to document the remaining transducers.

Transducer 1

Model: ________________________ Serial Number: ______________________________

Type: General Purpose Superficial Intraoperative

Endorectal Endovaginal Other _____________________

Freq: 2-3.5 MHz 3-5 MHz 5-7.5 MHz 7.5 MHz and higher

Scan Format: Phased Array Linear Array Curved Linear Array

Transducer 2

Model: ________________________ Serial Number: ______________________________

Type: General Purpose Superficial Intraoperative

Endorectal Endovaginal Other _____________________

Freq: 2-3.5 MHz 3-5 MHz 5-7.5 MHz 7.5 MHz and higher

Scan Format: Phased Array Linear Array Curved Linear Array

Mechanical Other _____________________

Mechanical Other _____________________

Page 12

g

LINE VOLTAGE TEST

System OFF: ______________VAC__ System ON: ________________VAC__

LINE CURRENT TEST (optional)

System OFF: ______________Amps_ System ON: ________________Amps_

OUTLET WIRING TEST QA Reference Manual Section 3-3. If correct, proceed to the next step.

GROUND CONTINUITY

QA Reference Manual Section 3-4. Use the Dale 600 Tester. Resistance should be less than 0.2

Ohms. If greater than 0.2 Ohms, perform detailed chassis leakage tests and troubleshoot.

GE Medical Systems

Correct Wiring Open Ground Wire

Reversed Polarity Open Neutral Wire

Hot & Gnd Reversed Open Hot Wire

2/16

2277615-100

REV 0

TEST POINT

Console _______________ Probe Screw ______________(any side screw)

Caster _______________ Foot Switch ________________

Monitor _______________ Printer ________________

Ground Continuity Tests PASS FAIL

CHASSIS SOURCE LEAKAGE TEST

QA Reference Manual Section 3-5. Max allowable is 300 uA.

IMPORTANT: Be sure to pause the polarity reverse switch in the OFF

seconds before reversing polarity.

POWER POLARITY SWITCH CHASSIS GND POWER POLARITY SWITCH CHASSIS GND

ON NORM Closed ON REV Closed

ON NORM Open ON REV Open

OFF NORM Closed OFF REV Closed

OFF NORM Open OFF REV Open

Chassis Source Leakage Tests Summary PASS FAIL

TRANSDUCER LEAKAGE CURRENT TESTS

All readings in micro-amps. Maximum allowable leakage current is 100 uA for general purpose and

endocavitary or 50 uA for surgical probes. QA Reference Manual Section 3-9.

DALE 600 DALE 600

POLARITY GND SW PROBE 1 PROBE 2

NORM Closed

NORM Open

Resistance (ohms) TEST POINT Resistance (ohms)

GROUND CONSOLE GROUND CONSOLE

VCR ________________

position for a minimum of 10

Transducer Leakage Current Test Summary: Choose Pass or Fail and

Transducer 1 PASS FAIL

CHANGE NO CHANGE

Transducer 2 PASS FAIL

CHANGE NO CHANGE

Change or No Change

Page 13

g

PHYSICAL INSPECTION/CLEANING

Cleaned and inspected the console? YES NO

Cleaned and inspected foot switch? YES NO

All cords and cables intact (no frays, tears or splits)? YES NO

All transducers intact

All transducer connector pins straight and intact? YES NO

All transducer strain reliefs in good condition? YES NO

All transducers cleaned (after each use)? YES NO

Image monitors cleaned? YES NO

Cleaned and inspected all power supplies? YES NO

All fans and/or air filters cleaned? YES NO

Checked all cable connectors to ensure they are properly seated? YES NO

Checked all plug-in boards to ensure they are properly seated? YES NO

All wheel locks in working condition? YES NO

All wheels fastened securely? Do they rotate easily? YES NO

All "onboard" peripherals fastened securely

Cleaned thermal printer print head with cleaner paper? YES NO

GE Medical Systems

(no cracks, dents, scratches or delamination)? YES NO

to the ultrasound unit (VCRs, Cameras, Printers, etc....)? YES NO

3/16

VCR Inspected Cleaned

Printer Inspected Cleaned

Camera Inspected Cleaned

REV 0

2277615-100

Overall Electrical Safety and Cleanliness:

CHANGE NO CHANGE

All safety problems must be rectified before the system can be returned to service or before ACR

Accreditation submittal.

Comments: _____________________________________________________________________

_______________________________________________________________________________

_______________________________________________________________________________

_______________________________________________________________________________

_______________________________________________________________________________

_______________________________________________________________________________

_______________________________________________________________________________

_______________________________________________________________________________

_______________________________________________________________________________

_______________________________________________________________________________

_______________________________________________________________________________

_______________________________________________________________________________

_______________________________________________________________________________

Page 14

g

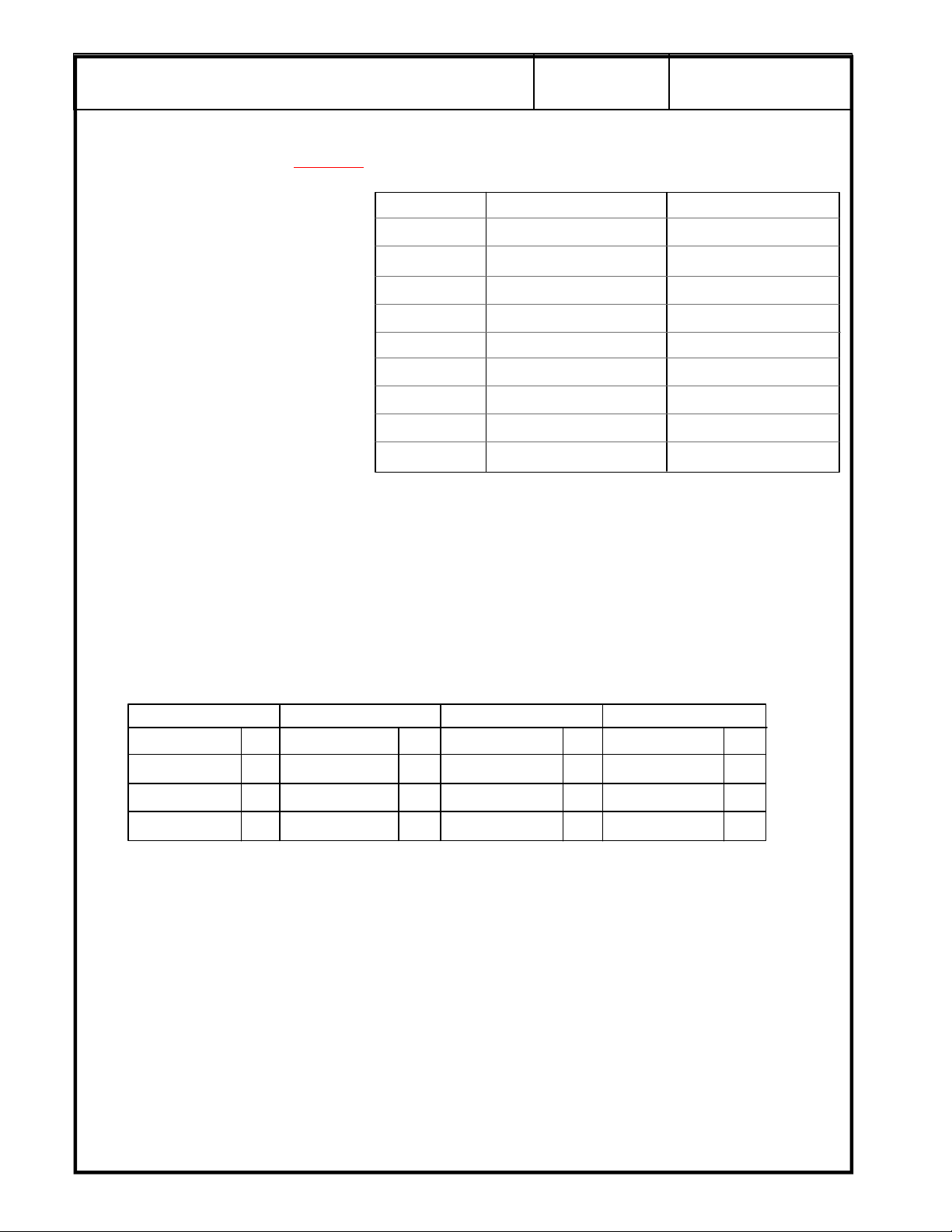

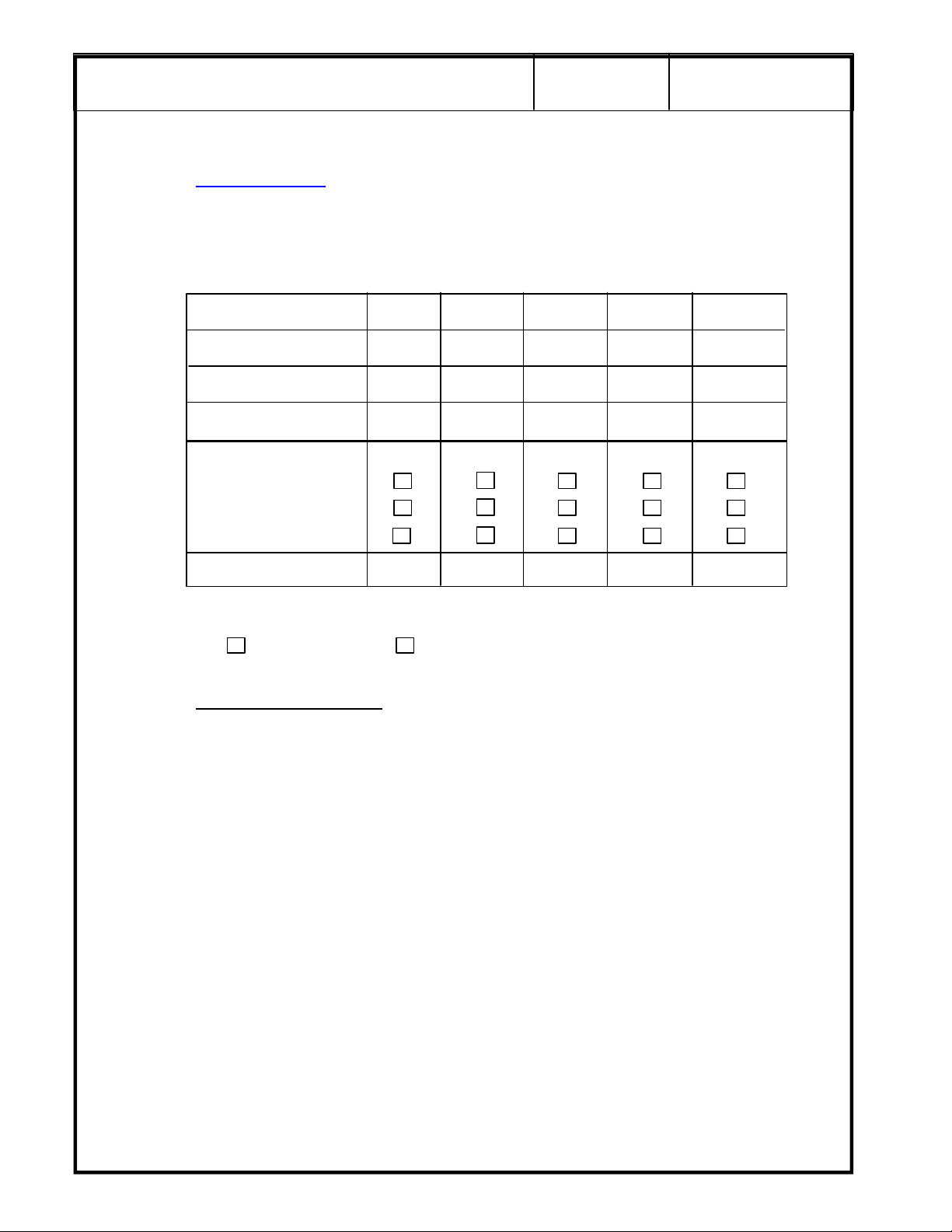

Power Supply Readings Refer to Chapter 4, Section 4-3 of the LOGIQ a200 or LOGIQ 200 PRO Service

Manuals for details on tolerances

Power Supplies available

depend on the type of system

serviced.

GE Medical Systems

, checking and adjusting of power supplies.

Supply Actual Reading Adjusted To

+5v Digital

-5v Digital

4/16

REV 0

2277615-100

Check only those that apply.

Mark all other entries N/A.

Reference is 0 voltage for the supply being measured.

Comments: ____________________________________________________________________

_______________________________________________________________________________

_______________________________________________________________________________

Functional Checks Refer to Chapter 4, Section 4-2 of the LOGIQ a200 or LOGIQ 200 PRO Service Manual.

General B-Mode B/M-Mode M-Mode

+5v Analog

-5 v Analog

+15

-15

+12v

-12v

HV

Foot Switch Focus Oper. Focus Oper. Focus Oper.

Record Key Gain Knob Gain Knob Gain Knob

Freeze Key TGC Pots TGC Pots TGC Pots

Printer Setting Dynamic Range Dynamic Range Dynamic Range

Comments: _____________________________________________________________________

_______________________________________________________________________________

_______________________________________________________________________________

NOTE: Refer to the LOGIQ a200 or LOGIQ 200 PRO User Manual for more information on system operation.

Page 15

g

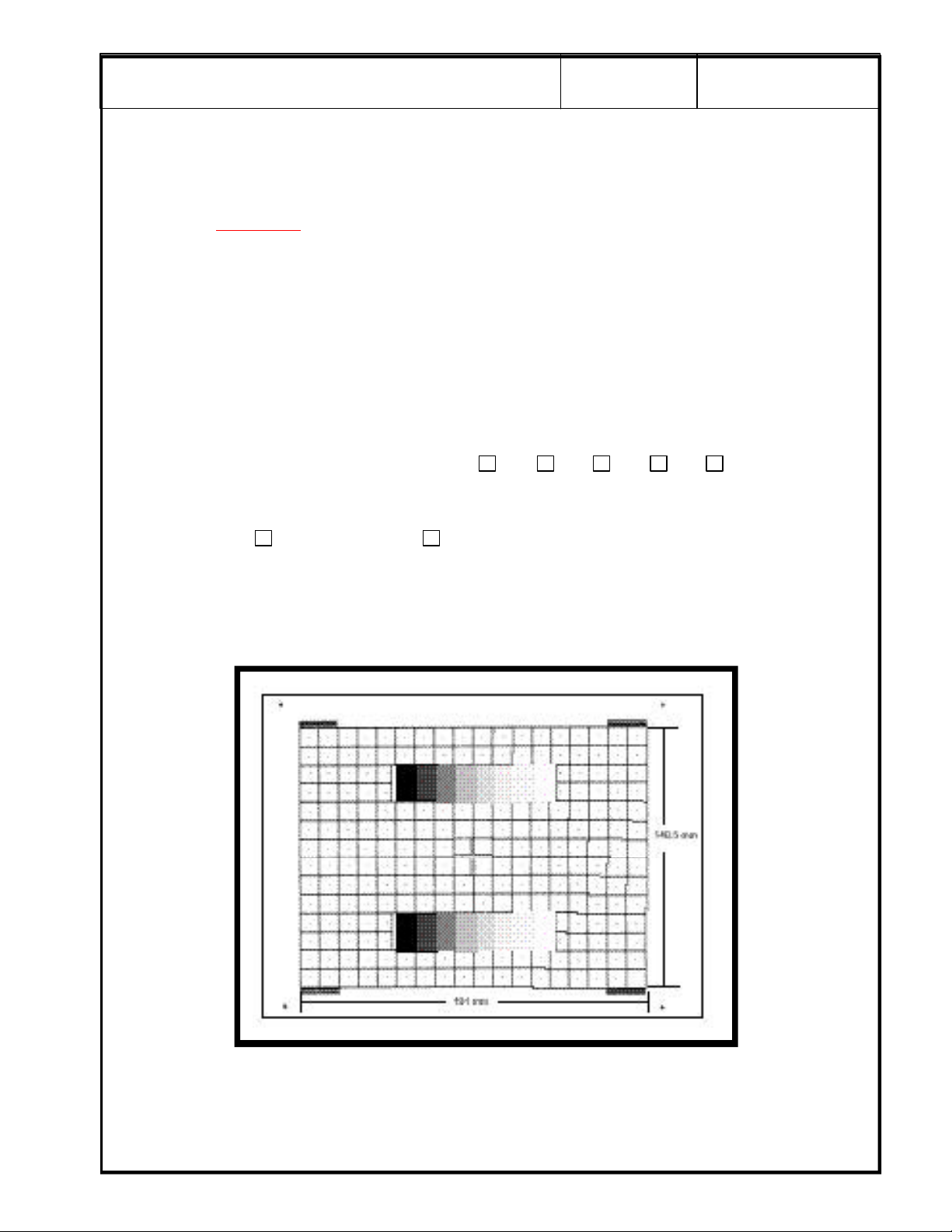

GRAY SCALE TEST

Refer toChapter 2, Section 2-3-2 in the LOGIQ a200 or LOGIQ 200PRO Proprietary manual for details on

entering the service software program, tests and control commands.

GE Medical Systems

5/16

2277615-100

REV 0

Select Monitor Test

The gray scale test is not intended to set up the camera, printer or peripherals to the test pattern. Ensure

that the monitor and photography are set up to the customer specifications.

Look at the gray bar test pattern on the left side of the viewing monitor.

Count the number of distinct gray bar steps on the viewing monitor. Then count the number of steps

visualized in the Gray bar on the hard copy image. Circle the number of steps, if any, that are missing on

the hard copy. Circle the number of steps, if any, that are missing on the hard copy.

Check the one box that applies:

Number of steps missing on the hard copy: 0 1 2 3 4+

Has the photography changed since the last QA Test?

NOTE: Press <CTRL><X> to exit the Monitor Test

from the Service Utility Menu

Change No Change (or First Test)

SECURE PAGE PRINT OF GRAY SCALE TEST HERE

Page 16

g

OVERVIEW

The following tests should be performed with each probe. Where indicated, a hard copy record should

be made and filed in order to assess performance trending during subsequent QA checks.

Refer to the QA Procedures Reference Manual for details in performing any tests.

GE Medical Systems

6/16

PERFORMANCE EVALUATION TESTS

2277615-100

REV 0

PHANTOM

.

Temperature __________________________

* Remember that phantom temperature may demonstrate errors in excess of 10% if you are establishing

a baseline or comparing to previous results.

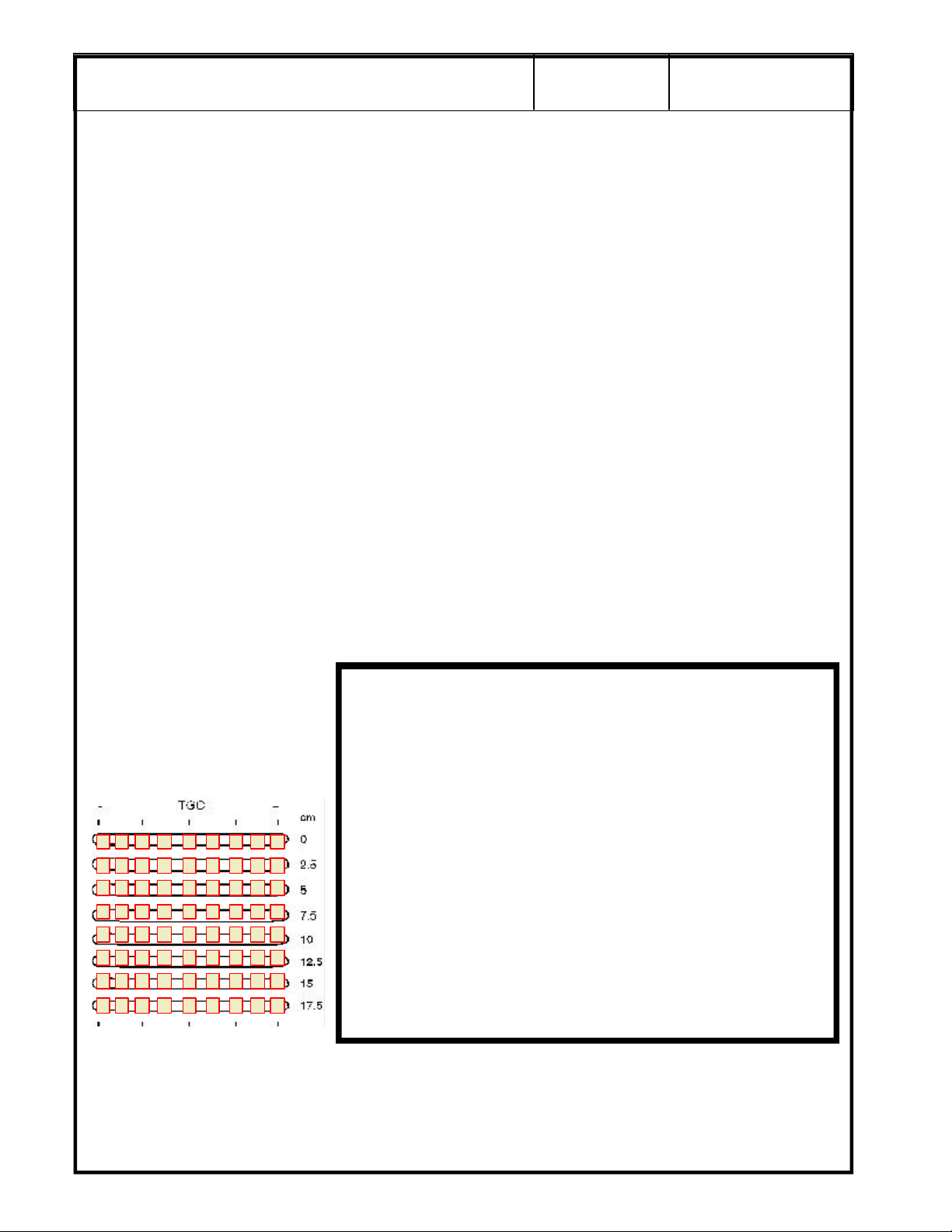

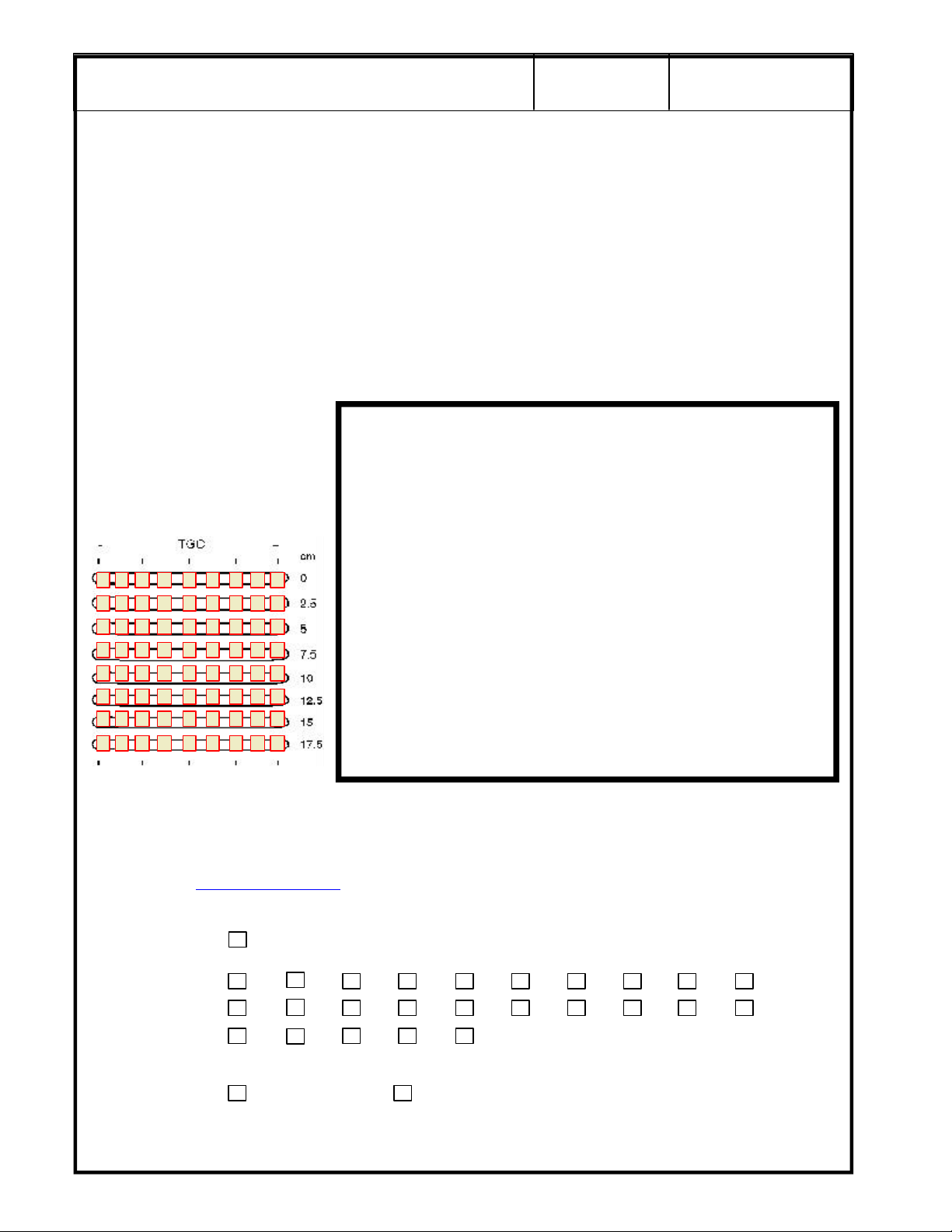

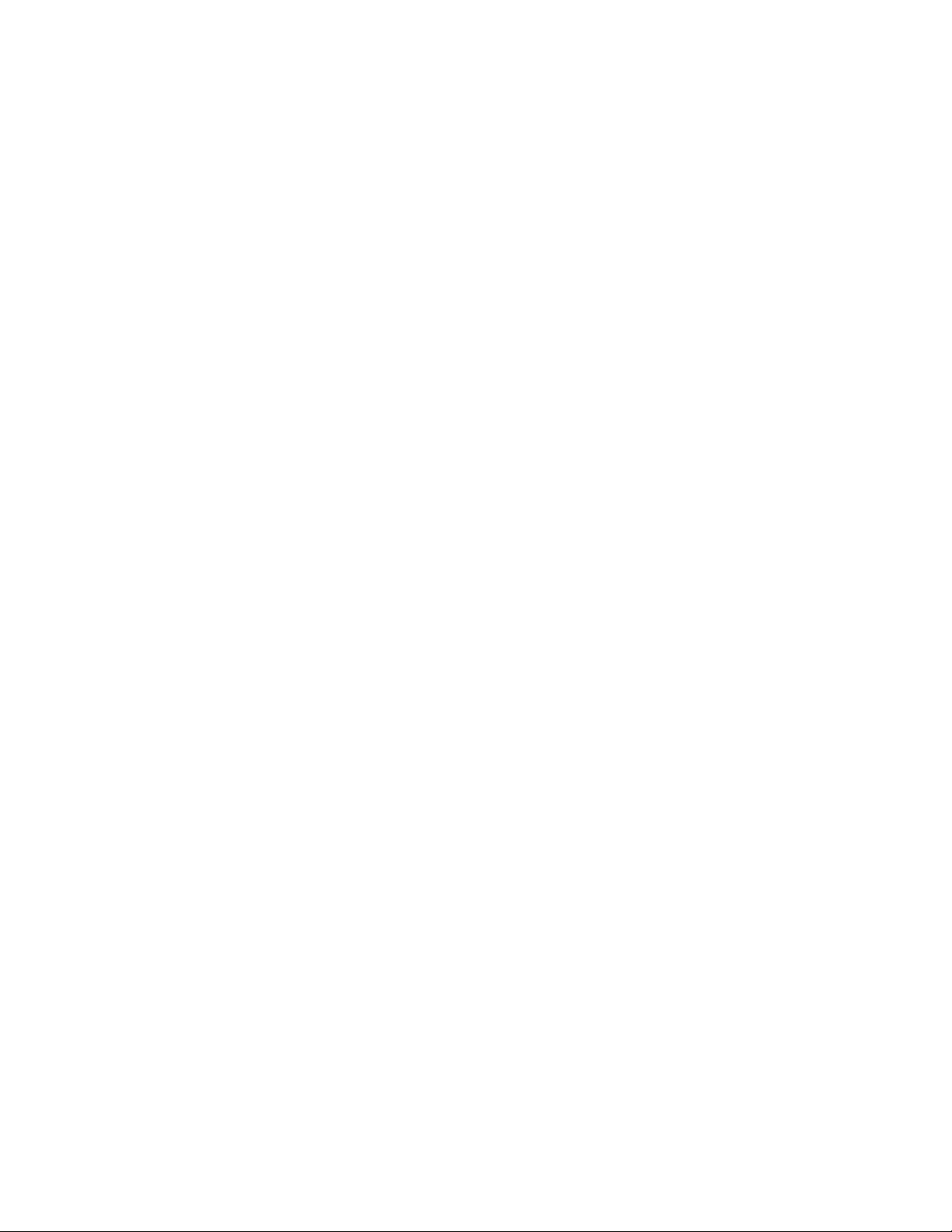

Probe 1:

For Probe 1, adjust the system settings to produce the best possible overall image of the phantom.

This scan will be used to assess penetration capabilities, image uniformity, measurement

accuracy, axial resolution, lateral resolution and contrast detectability.

Gain: ________________________ Focus : ________________________

Dynamic Range: ____________________

For scan repeatability during

the next QA check, place a

check mark in a box to

indicate the relative position of

each TCG control for the scan.

SECURE PAGE PRINT OF PROBE 1 SCAN

Page 17

g

Probe 1 (cont'd):

GE Medical Systems

7/16

2277615-100

REV 0

Penetration Capability

from the skin line to the point furthermost in depth where echoes disappear and record the depth

in centimeters. The maximum depth through which the echographic pattern can be visualized

is: Less than 3.0

3.0 3.5 4.0 4.5 5.0 5.5 6.0 6.5 7.0 7.5

8.0 8.5 9.0 9.5 10.0 10.5 11.0 11.5 12.0 12.5

13.0 13.5 14.0 15.0 116.0 or higher

Did system penetration change since the previous test?

Change No Change ( or First Test)

Image Uniformity

Change No Change (or First Test)

With your eye, evaluate the scan for image uniformity against the three indicators below:

The average brightness at the edge of the scan is the same as the average brightness in the

middle.

Agree Disagree, slight non-uniformity Disagree, major non-uniformity

There are no vertical or radially oriented shadows from array element dropout.

Agree Disagree, slight non-uniformity Disagree, major non-uniformity

. QA Reference Manual Section 4-2 Step 4. Use the calipers to measure

. Assess the image for uniformity from near field to far field.

There are no noticeable brightness transitions between focal zones.

Agree Disagree, slight non-uniformity Disagree, major non-uniformity

Measurement Accuracy

from the vertical pin closest to the skin line to the pin furthermost in depth. Do the same with

the horizontal row of pins.

Did the distance between the pins measured equal the e-caliper measurement?

Pass Fail

Change No Change (or First Test)

Lateral Resolution

how well the system/probe can display two targets side by side

of two targets on the same horizontal plane is the Lateral Resolution.

Note the Lateral Resolution measurement in mm : ________________________________

Axial Resolution

well the system/probe can display two targets above and below each other

distance of two targets on the same vertical plane is the Axial resolution.

. QA Reference Manual Section 4-2 Step 2. AXIAL resolution defines how

. QA Reference Manual Section 4-2 Step 3. Use the calipers to measure

. QA Reference Manual Section 4-2 Step 1. LATERAL resolution defines

. The smallest visible distance

. The smallest visible

Note the Axial Resolution measurement in mm : ________________________________

Page 18

g

NO

NO

NO

NO

NO

Probe 1 (cont'd):

GE Medical Systems

8/16

2277615-100

REV 0

Contrast Resolution

the phantom contrast targets in the current scan. The point is not how any ONE of the targets

look but how well defined they are from each other, and from the background material.

Record the following information for five of the contrast targets, if available in the phantom. If

they are not available, indicate with N/A:

Object Number 1 2 3 4 5

Object Depth

Object Size

Object Contrast *

Object Detectability

Complete

Partial

Not Seen

Changed for Worse Y/N

Overall Probe Low Contrast Detectability:

Change No Change (or First Test)

. (OPTIONAL) QA Reference Manual Section 4-2 Step 6 & 7. Evaluate

Notes for contrast resolution

Object Depth - is from the skin line to the center of the object.

Object Size - is the overall diameter of the object (all should be the same)

Object Contrast -

Use the Echo Level function by freezing the image. Press the Measurement

key three (3) times to assess the gray scale contrast level.

A 3 cm square box appears in the image area.

Position the box in the center of the contrast object.

Press Set.

Record the resulting number as the Object Contrast in the chart above.

Object Detectability - Check one box according to your evaluation of the object.

Changed for Worse Y/N - Enter a Y (yes) or N (no).

Document any system setting changes if they are different than the original scan on page 6.

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

:

Page 19

g

Probe 1 (cont'd):

GE Medical Systems

9/16

2277615-100

REV 0

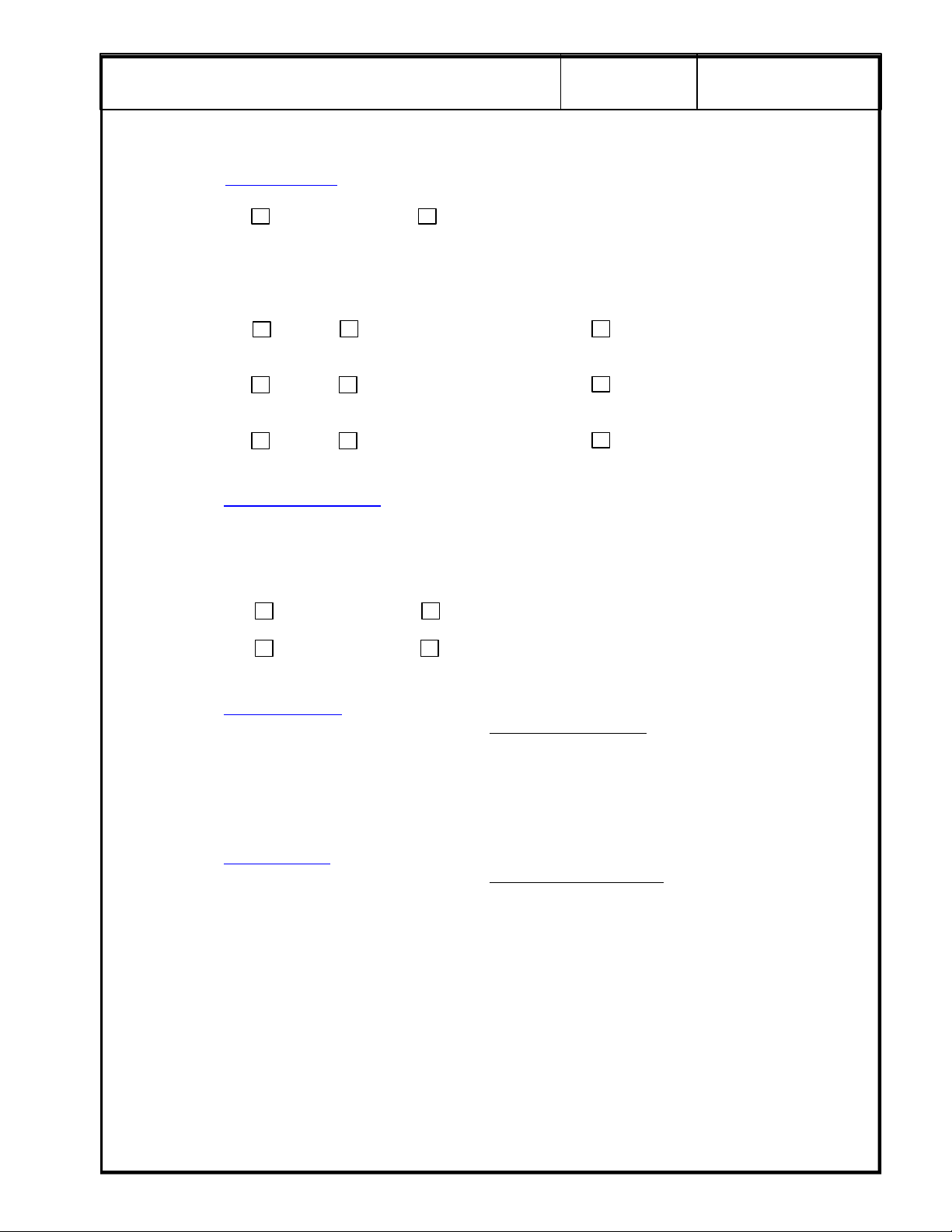

Noise Level

scanning conditions. Describe the lighting conditions for repeatability during the next QA check.

___________________________________________________________________________________________________________

Adjust the system settings to produces a clean image.

Wipe all the gel from the probe face, and set the probe in its holder. With transmit power at a

fixed value, adjust the overall gain, until the far field image (beyond 3cm) begins to fill with noise.

Reduce the overall gain until the last of those noise “speckles” disappear.

Note the gain level on film and make a hard copy record of this test.

Gain: ________________________ Focus : ________________________

For scan repeatability during

the next QA check, place a

check mark in a box to

indicate the relative position of

each TCG control for the scan.

. QA Reference Manual Section 4-2 Step 5. Ensure that room lighting is set to normal

SECURE PAGE PRINT OF

PROBE 1 NOISE LEVEL

SCAN HERE

Page 20

g

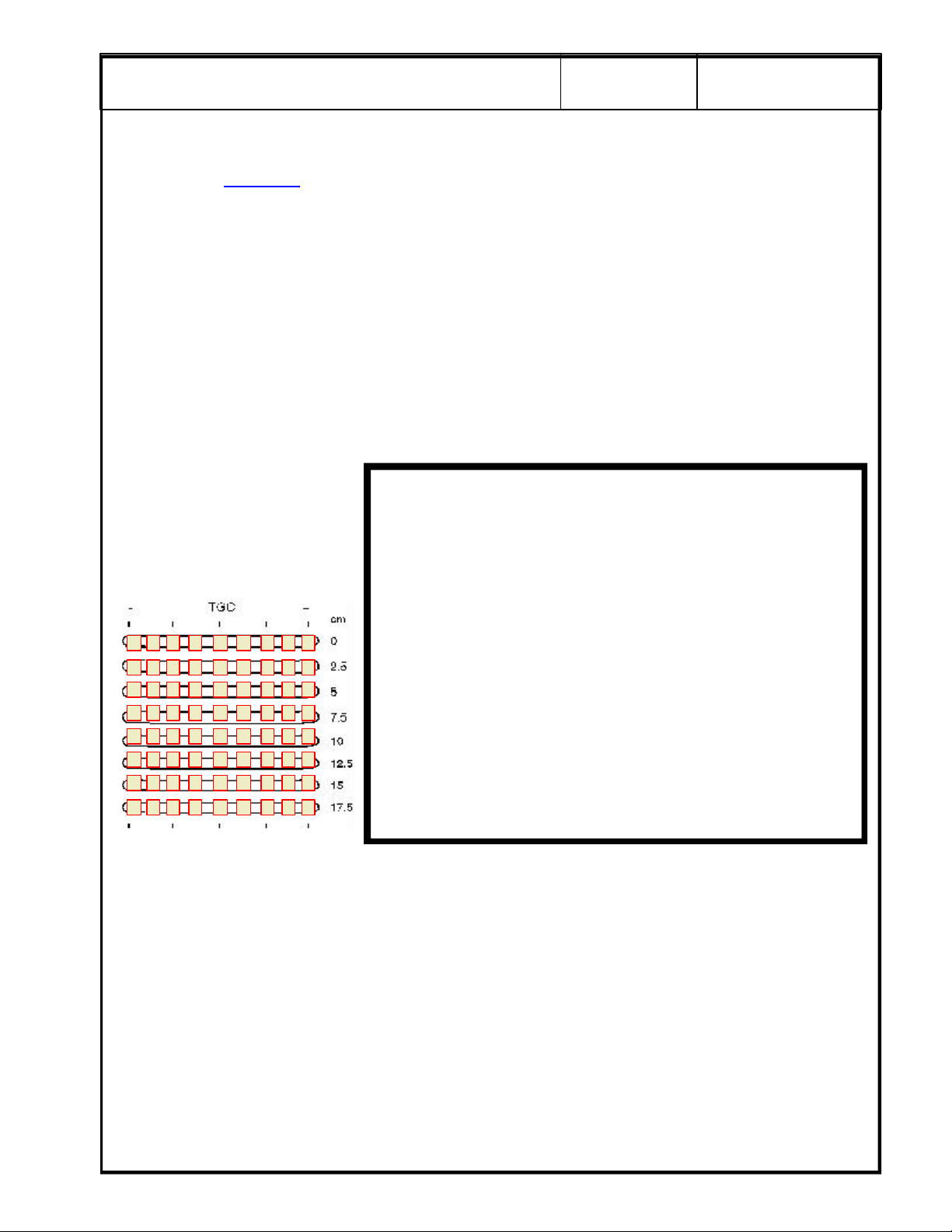

Probe 2:

For scan repeatability during

the next QA check, place a

check mark in a box to

indicate the relative position of

each TCG control for the scan.

GE Medical Systems

For Probe 2, adjust the system settings to produce the best possible overall image of the phantom.

This scan will be used to assess penetration capabilities, image uniformity, measurement

accuracy, axial resolution, lateral resolution and contrast detectability.

Gain: ________________________ Focus : ________________________

Dynamic Range: ____________________

10/16

2277615-100

REV 0

SECURE PAGE PRINT OF PROBE 2 SCAN

Penetration Capability

from the skin line to the point furthermost in depth where echoes disappear and record the depth

in centimeters. The maximum depth through which the echographic pattern can be visualized

is: Less than 3.0

3.0 3.5 4.0 4.5 5.0 5.5 6.0 6.5 7.0 7.5

. QA Reference Manual Section 4-2 Step 4. Use the calipers to measure

8.0 8.5 9.0 9.5 10.0 10.5 11.0 11.5 12.0 12.5

13.0 13.5 14.0 15.0 16.0 or higher

Did system penetration change since the previous test?

Change No Change ( or First Test)

Page 21

g

Probe 2 (cont'd):

GE Medical Systems

11/16

2277615-100

REV 0

Image Uniformity

Change No Change (or First Test)

With your eye, evaluate the scan for image uniformity against the three indicators below:

The average brightness at the edge of the scan is the same as the average brightness in the

middle.

Agree Disagree, slight non-uniformity Disagree, major non-uniformity

There are no vertical or radially oriented shadows from array element dropout.

Agree Disagree, slight non-uniformity Disagree, major non-uniformity

There are no noticeable brightness transitions between focal zones.

Agree Disagree, slight non-uniformity Disagree, major non-uniformity

Measurement Accuracy

from the vertical pin closest to the skin line to the pin furthermost in depth. Do the same with

the horizontal row of pins.

Did the distance between the pins measured equal the e-caliper measurement?

Pass Fail

. Assess the image for uniformity from near field to far field.

. QA Reference Manual Section 4-2 Step 3. Use the calipers to measure

Change No Change (or First Test)

Lateral Resolution

how well the system/probe can display two targets side by side

of two targets on the same horizontal plane is the Lateral Resolution.

Note the Lateral Resolution measurement in mm : ________________________________

Axial Resolution

the system/probe can display two targets above and below each other

of two targets on the same vertical plane is the Axial resolution.

Note the Axial Resolution measurement in mm : ________________________________

. QA Reference Manual Section 4-2 Step 1. LATERAL resolution defines

. The smallest visible distance

. QA Reference Manual Section 4-2 Step 2. AXIAL resolution defines how well

. The smallest visible distance

Page 22

g

NO

NO

NO

NO

NO

Probe 2 (cont'd):

GE Medical Systems

12/16

2277615-100

REV 0

Contrast Resolution

the phantom contrast targets in the current scan. The point is not how any ONE of the targets

look but how well defined they are from each other, and from the background material.

Record the following information for five of the contrast targets, if available in the phantom. If

they are not available, indicate with N/A:

Object Number 1 2 3 4 5

Object Depth

Object Size

Object Contrast *

Object Detectability

Complete

Partial

Not Seen

Changed for Worse Y/N

Overall Probe Low Contrast Detectability:

Change No Change (or First Test)

. (OPTIONAL) QA Reference Manual Section 4-2 Step 6 & 7. Evaluate

Notes for contrast resolution

Object Depth - is from the skin line to the center of the object.

Object Size - is the overalldiameter of the object (all should be the same)

Object Contrast -

Use the Echo Level function by freezing the image. Press the Measurement

key three (3) times to assess the gray scale contrast level.

A 3 cm square box appears in the image area.

Position the box in the center of the contrast object.

Press Set.

Record the resulting number as the Object Contrast in the chart above.

Object Detectability - Check one box according to your evaluation of the object.

Changed for Worse Y/N - Enter a Y (yes) or N (no).

Document any system setting changes if they are different than the original scan on page 6.

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

:

Page 23

g

Probe 2 (cont'd):

GE Medical Systems

13/16

2277615-100

REV 0

Noise Level

scanning conditions. Describe the lighting conditions for repeatability during the next QA check.

___________________________________________________________________________________________________________

Adjust the system settings to produces a clean image.

Wipe all the gel from the probe face, and set the probe in its holder. With transmit power at a

fixed value, adjust the overall gain, until the far field image (beyond 3cm) begins to fill with noise.

Reduce the overall gain until the last of those noise “speckles” disappear.

Note the gain level on film and make a hard copy record of this test.

Gain: ________________________ Focus : ________________________

For scan repeatability during

the next QA check, place a

check mark in a box to

indicate the relative position of

each TCG control for the scan.

. QA Reference Manual Section 4-2 Step 5. Ensure that room lighting is set to normal

Customer Acceptance and Sign-off

Assure covers and side panels are aligned and secure.

Reconnect any peripherals and interconnections removed during the QA Tests.

Return the system to it's original location, if moved.

Refer to the QA Reference Manual Section 2-15.

Gain Customer acceptance that the system is ready to return to service.

______________________________________________ _____________

Customer Signature Date

SECURE PAGE PRINT OF

PROBE 2 NOISE LEVEL

SCAN HERE

______________________________________________ _____________

Field Engineer Signature Date

Page 24

g

GE Medical Systems

14/16

REV 0

OPTIONAL DATA FOR THE LOGIQ α200 OR LOGIQ 200 PRO

2277615-100

The remainder of the checks are optional steps that can be accomplished by the field engineer or the customer.

While the following do not directly affect image quality, it may be good information to archive in the event that

the system would need to be restored after a catastrophic system failure.

LOGIQ 200 PRO

PRESETS

All system presets can be saved on a 128 Mbyte MOD through the SETUP>UTILITY Menu.

Press the SETUP MENU Key. Arrow down to USER UTILITY and press SET.

In the USER UTILITY Menu, ensure that a MOD has been formatted using Media Initialize.

Perform thye following procedures:

Preset Data Backup

OB User Table Backup

OB Trend Data Backup.

Label and date the MOD accordingly and have the customer store it in a safe place.

Preset data backed up at the request of the customer.

Customer chose not to back up preset data.

Page 25

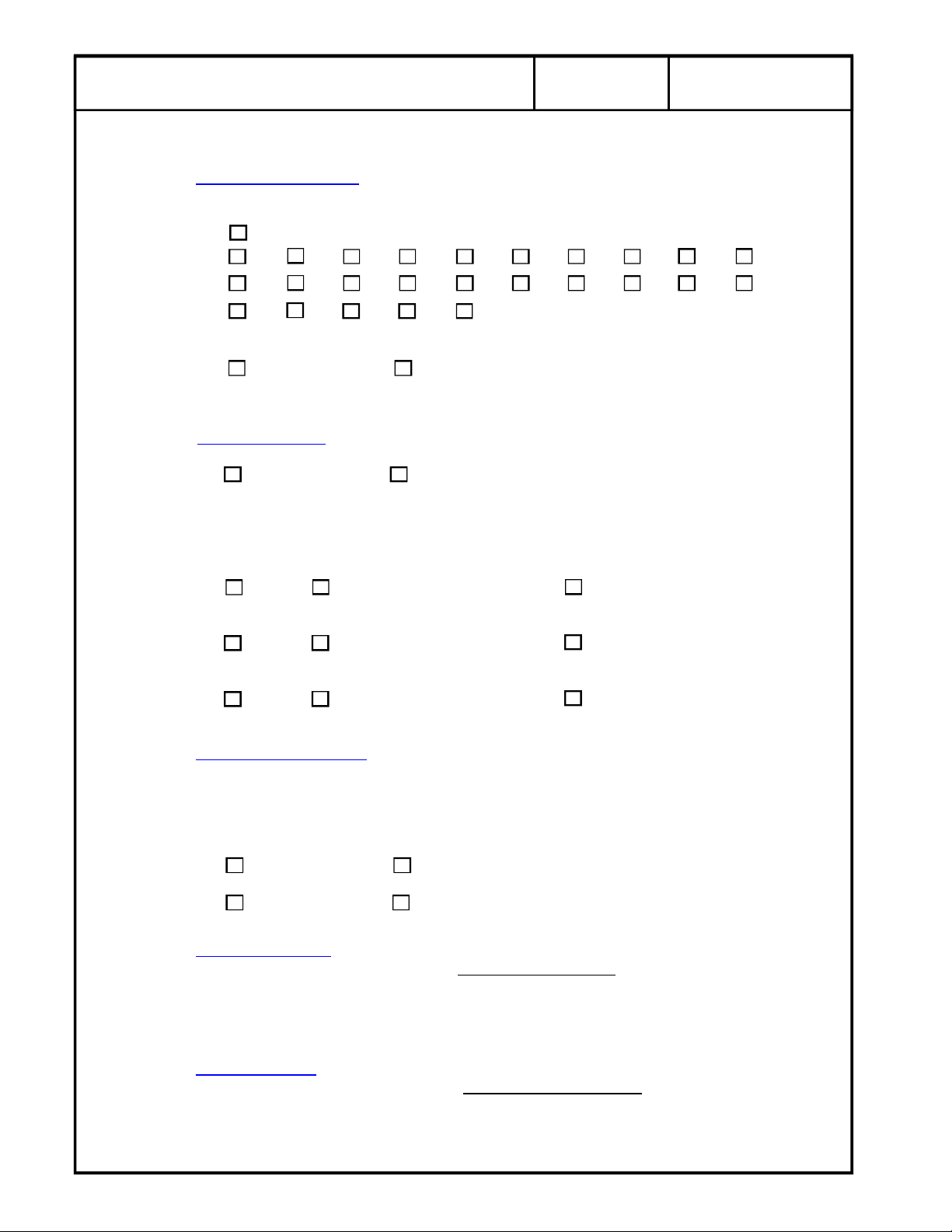

g

This process is more intensive than a LOGIQ 200 PRO. No device is available the save the presets

electronically. Each screen must be displayed on the monitor and a print taken of that display. The prints

can then be stored in a safe place for future reference.

Ask the customer which menus are important for them to archive in the rare case of a catastropic failure.

PRESETS

To go directly to the system setup parameters pages, press <CTRL><S>

Make prints of all System Setup Parameter pages.

Remember: Some pages may require two or more prints due to each applications presets and then for

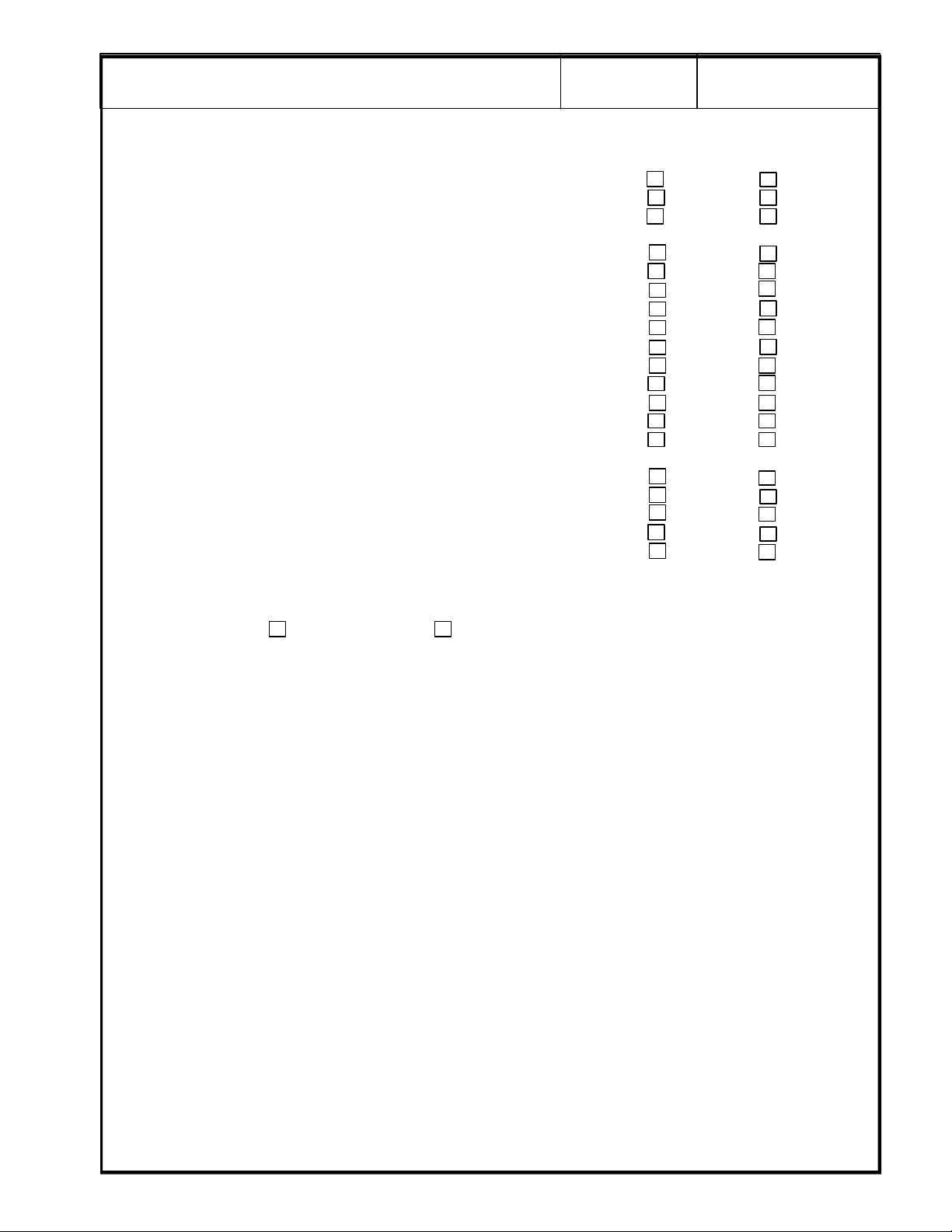

each probe attached. Use the following items as a check list of what menus were printed:

GE Medical Systems

LOGIQ α200

General System Setup

User OB Table Sub menu

Probe Parameter 1 Setup

Preset 1

Probe 1

Probe 2

Preset 2

Probe 1

Probe 2

Probe Parameter 2 Setup

Preset 1

Probe 1

Probe 2

Preset 2

Probe 1

Probe 2

Image Display and Application Setup

Preset 1

Preset 2

Body Pattern Setup

Preset 1

Preset 2

Comment Setup

Preset 1

Preset 2

Measurement Setup

Preset 1

Report Format Sub menu

A/N Assignment Sub menu

Cardiac Calc Sub menu

Preset 2

Report Format Sub menu

A/N Assignment Sub menu

Cardiac Calc Sub menu

Patient Entry Setup

Preset 1

Preset 2

15/16

2277615-100

REV 0

Page 26

g

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Diagnostics Refer toChapter 2, Section 2-3-2 in the LOGIQ a200 or LOGIQ 200PRO Proprietary manual for

details on entering the service software program, tests and control commands.

Caution: If you perform the over all System Test it will run for 21 minutes.

LOGIQ a200 Pass? LOGIQ 200 PRO Pass?

Beamformer Scan Test

HV TBF

ADC Linear/Convex Path

DSC/Front End Function Sector Path

B-Mode Function BPHV

B-Mode X-Y Memory MVP Hardware

B-Mode Cine B-Mode Function

M-Mode Function B-Mode Cine

MST M-Mode Function

System D-RAM MSTE

Keyboard Keyboard

PIOP PIOP

Monitor Monitor

Power Supply Power Supply

ROM Version

GE Medical Systems

16/16

REV 0

2277615-100

Comments: _____________________________________________________________________

_______________________________________________________________________________

_______________________________________________________________________________

Page 27

05/23/00 MAC

LOGIQ a200 and LOGIQ 200 PRO

ACR Accredited Quality Assurance Procedure

Probe ID List

Name Model # Type Frequency Scan Format

CBF H460222CB Gen Purp 3-5 MHz Curved Linear

CAE H46022CA Gen Purp 5-7.5 MHz Curved Linear

MTZ H46022MT Endo Vag 5-7.5 MHz Curved Linear

CZB H45202CZ Superficial 5-7.5 MHz Curved Linear

CS H45222CS Gen Purp 3-5 MHz Curved Linear

ERB H45202ER Endorectal 5-7.5 MHz Curved Linear

3Cb H45202WB Gen Purp 3-5 MHz Curved Linear

LH H46022LH Superficial 7.5 MHz + Linear

LE H46022LE Gen Purp 5-7.5 MHz Linear

LI H46022LI Intraoperative 7.5 MHz + Linear

LT H46022LT Intraoperative 7.5 MHz + Linear

LB H46022LB Gen Purp 3-5 MHz Linear

LD H45202LD Intraoperative 3-5 MHz Linear

10L H45202LM Gen Purp 5-7.5 MHz Linear

SY H46022SY Gen Purp 3-5 MHz Phased Array

S317 H45202SD Gen Purp 3-5 MHz Phased Array

ATR H4061PR Endorectal 5-7.5 MHZ Curved Linear

Page 1 of 2

Page 28

05/23/00 MAC

Page 2 of 2

Page 29

g

GE Medical Systems

PERFORMANCE EVALUATION

Probe 3

Model: ________________________ Serial Number: ______________________________

Type: General Purpose Superficial Intraoperative

Endorectal Endovaginal Other _____________________

Freq: 2-3.5 MHz 3-5 MHz 5-7.5 MHz 7.5 MHz and higher

Scan Format: Phased Array Linear Array Curved Linear Array

Mechanical Other _____________________

TRANSDUCER LEAKAGE CURRENT TESTS

All readings in micro-amps. Maximum allowable leakage current is 100 uA for general purpose and

endocavitary or 50 uA for surgical probes. QA Reference Manual Section 3-9.

DALE 600 DALE 600

POLARITY GND SW PROBE 3

NORM Closed

NORM Open

Leakage Current Test Summary: Choose Pass or Fail and Change or No Change

1/4

2267008-100

REV 0

Probe 3 PASS FAIL

CHANGE NO CHANGE

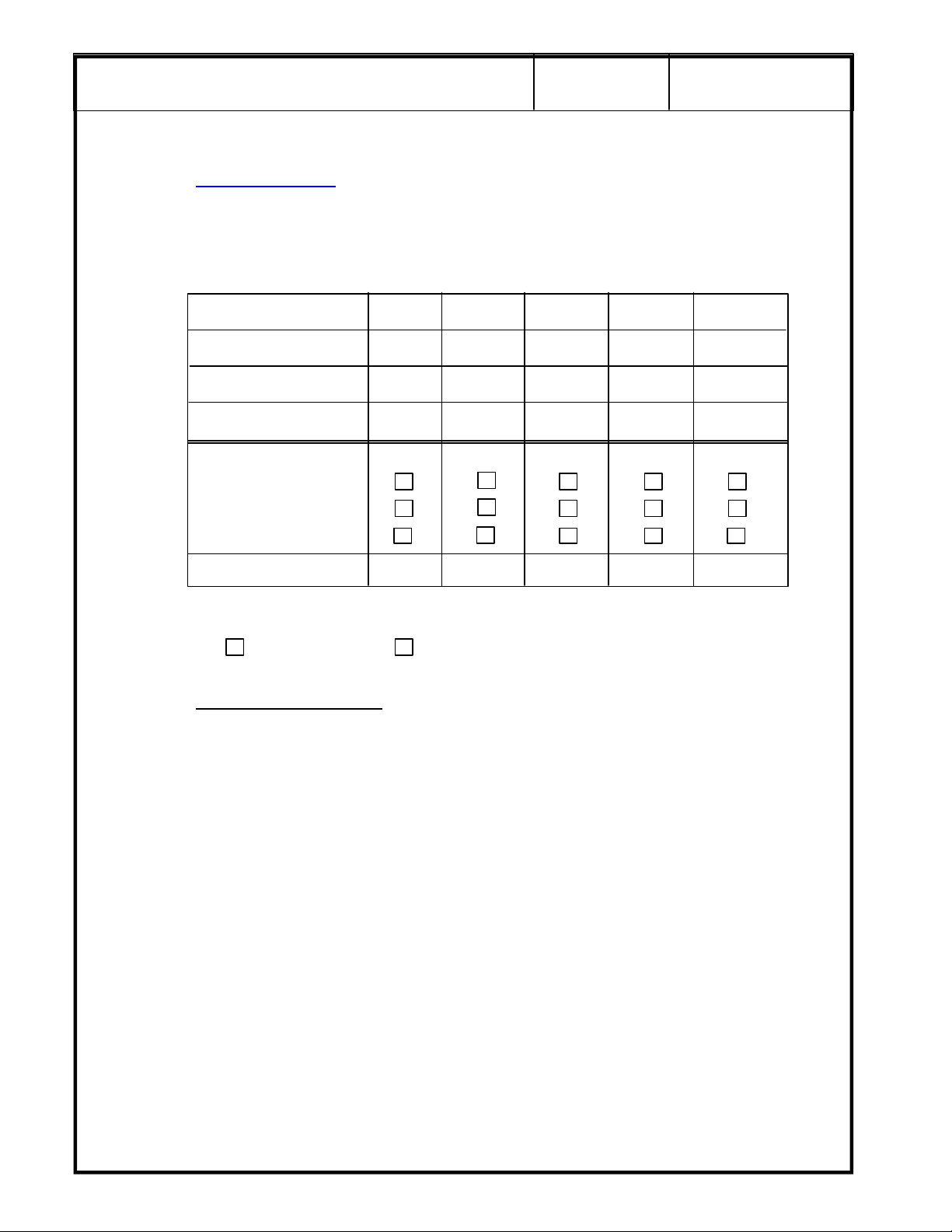

For Probe 3, adjust the system settings to produce the best possible overall image of the phantom. This

scan will be used to assess penetration capabilities, image uniformity, measurement accuracy, axial

resolution, lateral resolution and contrast detectability.

Gain: ________________________ Focus : ________________________

Dynamic Range: ____________________

For scan repeatability during

the next QA check, place a

check mark in a box to indicate

the relative position of each

TCG control for the scan.

SECURE PAGE PRINT OF PROBE SCAN

Page 30

g

Probe 3 (cont'd):

GE Medical Systems

Penetration Capability. QA Reference Manual Section 4-2 Step 4. Use the calipers to measure

from the skin line to the point furthermost in depth where echoes disappear and record the depth

in centimeters. The maximum depth through which the echographic pattern can be visualized is:

Less Than 3.0

3.0 3.5 4.0 4.5 5.0 5.5 6.0 6.5 7.0 7.5

8.0 8.5 9.0 9.5 10.0 10.5 11.0 11.5 12.0 12.5

13.0 13.5 14.0 15.0 16.0 or higher

Did system penetration change since the previous test?

Change No Change ( or First Test)

Image Uniformity. Assess the image for uniformity from near field to far field.

Change No Change (or First Test)

With your eye, evaluate the scan for image uniformity against the three indicators below:

2/4

2267008-100

REV 0

The average brightness at the edge of the scan is the same as the average brightness in the

middle.

Agree Disagree, slight non-uniformity Disagree, major non-uniformity

There are no vertical or radially oriented shadows from array element dropout.

Agree Disagree, slight non-uniformity Disagree, major non-uniformity

There are no noticeable brightness transitions between focal zones.

Agree Disagree, slight non-uniformity Disagree, major non-uniformity

Measurement Accuracy. QA Reference Manual Section 4-2 Step 3. Use the calipers to measure

from the vertical pin closest to the skin line to the pin furthermost in depth. Do the same with the

horizontal row of pins.

Did the distance between the pins measured equal the e-caliper measurement?

Pass Fail

Change No Change (or First Test)

Lateral Resolution. QA Reference Manual Section 4-2 Step 1. LATERAL resolution defines

how well the system/probe can display two targets side by side. The smallest visible distance of

two targets on the same horizontal plane is the Lateral Resolution.

Note the Lateral Resolution measurement in mm : ________________________________

Axial Resolution. QA Reference Manual Section 4-2 Step 2. AXIAL resolution defines how well

the system/probe can display two targets above and below each other. The smallest visible distance

of two targets on the same vertical plane is the Axial resolution.

Note the Axial Resolution measurement in mm : ________________________________

Page 31

g

NO

NO

NO

NO

NO

Probe 3 (cont'd):

GE Medical Systems

3/4

2267008-100

REV 0

Contrast Resolution

the phantom contrast targets in the current scan. The point is not how any ONE of the targets look

but how well defined they are from each other, and from the background material.

Record the following information for five of the contrast targets, if available in the phantom. If they

are not available, indicate with N/A:

Object Number 1 2 3 4 5

Object Depth

Object Size

Object Contrast *

Object Detectability

Complete

Partial

Not Seen

Changed for Worse Y/N

Overall Probe Low Contarst Detectability

Change No Change (or First Test)

. (OPTIONAL) QA Reference Manual Section 4-2 Step 6 & 7. Evaluate

Notes for contrast resolution

Object Depth - is from the skin line to the center of the object.

Object Size - is the overalldiameter of the object (all should be the same)

Object Contrast -

Use the Echo Level function by Freezing the image. Press the Measurement

key three (3) times to assess the gray scale contrast level.

A 3 cm square box appears in the image area.

Position the box in the center of the contrast object.

Press Set.

Record the resulting number as the Object Contrast in the chart above.

Object Detectability - Check one box according to your evaluation of the object.

Changed for Worse Y/N - Enter a Y (yes) or N (no).

Document any system setting changes if they are different than the original scan on page 6.

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

:

Page 32

g

Probe 3 (cont'd):

GE Medical Systems

Noise Level. QA Reference Manual Section 4-2 Step 5. Ensure that room lighting is set to normal

scanning conditions. Describe the lighting conditions for repeatability during the next QA check.

___________________________________________________________________________________________________________

Adjust the system settings to produces a clean image.

Wipe all the gel from the probe face, and set the probe in its holder. With transmit power at a fixed

value, adjust the overall gain, until the far field image (beyond 3cm) begins to fill with noise. Reduce

the overall gain until the last of those noise “speckles” disappear.

Note the gain level on film and make a hard copy record of this test.

Gain: ________________________ Focus : ________________________

4/4

2267008-100

REV 0

For scan repeatability during

the next QA check, place a

check mark in a box to indicate

the relative position of each

TCG control for the scan.

SECURE PAGE PRINT OF

PROBE NOISE LEVEL

SCAN HERE

Page 33

g

GE Medical Systems

PERFORMANCE EVALUATION

Probe 4

Model: ________________________ Serial Number: ______________________________

Type: General Purpose Superficial Intraoperative

Endorectal Endovaginal Other _____________________

Freq: 2-3.5 MHz 3-5 MHz 5-7.5 MHz 7.5 MHz and higher

Scan Format: Phased Array Linear Array Curved Linear Array

Mechanical Other _____________________

TRANSDUCER LEAKAGE CURRENT TESTS

All readings in micro-amps. Maximum allowable leakage current is 100 uA for general purpose and

endocavitary or 50 uA for surgical probes. QA Reference Manual Section 3-9.

DALE 600 DALE 600

POLARITY GND SW PROBE 3

NORM Closed

NORM Open

1/4

2272728-100

REV 0

Leakage Current Test Summary: Choose Pass or Fail and

Probe 4 PASS FAIL

CHANGE NO CHANGE

For Probe 3, adjust the system settings to produce the best possible overall image of the phantom. This

scan will be used to assess penetration capabilities, image uniformity, measurement accuracy, axial

resolution, lateral resolution and contrast detectability.

Gain: ________________________ Focus : ________________________

Dynamic Range: ____________________

For scan repeatability during

the next QA check, place a

check mark in a box to indicate

the relative position of each

TCG control for the scan.

SECURE PAGE PRINT OF PROBE SCAN

Change or No Change

Page 34

g

Probe 4 (cont'd):

GE Medical Systems

2/4

2272728-100

REV 0

Penetration Capability

from the skin line to the point furthermost in depth where echoes disappear and record the depth

in centimeters. The maximum depth through which the echographic pattern can be visualized is:

Less Than 3.0

3.0 3.5 4.0 4.5 5.0 5.5 6.0 6.5 7.0 7.5

8.0 8.5 9.0 9.5 10.0 10.5 11.0 11.5 12.0 12.5

13.0 13.5 14.0 15.0 16.0 or higher

Did system penetration change since the previous test?

Change No Change ( or First Test)

Image Uniformity

Change No Change (or First Test)

With your eye, evaluate the scan for image uniformity against the three indicators below:

The average brightness at the edge of the scan is the same as the average brightness in the

middle.

Agree Disagree, slight non-uniformity Disagree, major non-uniformity

There are no vertical or radially oriented shadows from array element dropout.

Agree Disagree, slight non-uniformity Disagree, major non-uniformity

. QA Reference Manual Section 4-2 Step 4. Use the calipers to measure

. Assess the image for uniformity from near field to far field.

There are no noticeable brightness transitions between focal zones.

Agree Disagree, slight non-uniformity Disagree, major non-uniformity

Measurement Accuracy. QA Reference Manual Section 4-2 Step 3. Use the calipers to measure

from the vertical pin closest to the skin line to the pin furthermost in depth. Do the same with the

horizontal row of pins.

Did the distance between the pins measured equal the e-caliper measurement?

Pass Fail

Change No Change (or First Test)

Lateral Resolution

how well the system/probe can display two targets side by side

two targets on the same horizontal plane is the Lateral Resolution.

Note the Lateral Resolution measurement in mm : ________________________________

Axial Resolution

the system/probe can display two targets above and below each other

of two targets on the same vertical plane is the Axial resolution.

. QA Reference Manual Section 4-2 Step 1. LATERAL resolution defines

. The smallest visible distance of

. QA Reference Manual Section 4-2 Step 2. AXIAL resolution defines how well

. The smallest visible distance

Note the Axial Resolution measurement in mm : ________________________________

Page 35

g

NO

NO

NO

NO

NO

Probe 4 (cont'd):

GE Medical Systems

3/4

2272728-100

REV 0

Contrast Resolution

the phantom contrast targets in the current scan. The point is not how any ONE of the targets look

but how well defined they are from each other, and from the background material.

Record the following information for five of the contrast targets, if available in the phantom. If they

are not available, indicate with N/A:

Object Number 1 2 3 4 5

Object Depth

Object Size

Object Contrast *

Object Detectability

Complete

Partial

Not Seen

Changed for Worse Y/N

Overall Probe Low Contarst Detectability

Change No Change (or First Test)

. (OPTIONAL) QA Reference Manual Section 4-2 Step 6 & 7. Evaluate

Notes for contrast resolution

Object Depth - is from the skin line to the center of the object.

Object Size - is the overalldiameter of the object (all should be the same)

Object Contrast -

Use the Echo Level function by Freezing the image. Press the Measurement

key three (3) times to assess the gray scale contrast level.

A 3 cm square box appears in the image area.

Position the box in the center of the contrast object.

Press Set.

Record the resulting number as the Object Contrast in the chart above.

Object Detectability - Check one box according to your evaluation of the object.

Changed for Worse Y/N - Enter a Y (yes) or N (no).

Document any system setting changes if they are different than the original scan on page 6.

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

:

Page 36

g

Probe 4 (cont'd):

GE Medical Systems

4/4

2272728-100

REV 0

Noise Level

scanning conditions. Describe the lighting conditions for repeatability during the next QA check.

___________________________________________________________________________________________________________

Adjust the system settings to produces a clean image.

Wipe all the gel from the probe face, and set the probe in its holder. With transmit power at a fixed

value, adjust the overall gain, until the far field image (beyond 3cm) begins to fill with noise. Reduce

the overall gain until the last of those noise “speckles” disappear.

Note the gain level on film and make a hard copy record of this test.

Gain: ________________________ Focus : ________________________

For scan repeatability during

the next QA check, place a

check mark in a box to indicate

the relative position of each

TCG control for the scan.

. QA Reference Manual Section 4-2 Step 5. Ensure that room lighting is set to normal

SECURE PAGE PRINT OF

PROBE NOISE LEVEL

SCAN HERE

Page 37

g

GE Medical Systems

PERFORMANCE EVALUATION

Probe 5

Model: ________________________ Serial Number: ______________________________

Type: General Purpose Superficial Intraoperative

Endorectal Endovaginal Other _____________________

Freq: 2-3.5 MHz 3-5 MHz 5-7.5 MHz 7.5 MHz and higher

Scan Format: Phased Array Linear Array Curved Linear Array

Mechanical Other _____________________

TRANSDUCER LEAKAGE CURRENT TESTS

All readings in micro-amps. Maximum allowable leakage current is 100 uA for general purpose and

endocavitary or 50 uA for surgical probes. QA Reference Manual Section 3-9.

DALE 600 DALE 600

POLARITY GND SW PROBE 3

NORM Closed

NORM Open

1/4

2272729-100

REV 0

Leakage Current Test Summary: Choose Pass or Fail and

Probe 5 PASS FAIL

CHANGE NO CHANGE

For Probe 3, adjust the system settings to produce the best possible overall image of the phantom. This

scan will be used to assess penetration capabilities, image uniformity, measurement accuracy, axial

resolution, lateral resolution and contrast detectability.

Gain: ________________________ Focus : ________________________

Dynamic Range: ____________________

For scan repeatability during

the next QA check, place a

check mark in a box to indicate

the relative position of each

TCG control for the scan.

SECURE PAGE PRINT OF PROBE SCAN

Change or No Change

Page 38

g

Probe 5 (cont'd):

GE Medical Systems

2/4

2272729-100

REV 0

Penetration Capability

from the skin line to the point furthermost in depth where echoes disappear and record the depth

in centimeters. The maximum depth through which the echographic pattern can be visualized is:

Less Than 3.0

3.0 3.5 4.0 4.5 5.0 5.5 6.0 6.5 7.0 7.5

8.0 8.5 9.0 9.5 10.0 10.5 11.0 11.5 12.0 12.5

13.0 13.5 14.0 15.0 16.0 or higher

Did system penetration change since the previous test?

Change No Change ( or First Test)

Image Uniformity

Change No Change (or First Test)

With your eye, evaluate the scan for image uniformity against the three indicators below:

The average brightness at the edge of the scan is the same as the average brightness in the

middle.

Agree Disagree, slight non-uniformity Disagree, major non-uniformity

There are no vertical or radially oriented shadows from array element dropout.

Agree Disagree, slight non-uniformity Disagree, major non-uniformity

. QA Reference Manual Section 4-2 Step 4. Use the calipers to measure

. Assess the image for uniformity from near field to far field.

There are no noticeable brightness transitions between focal zones.

Agree Disagree, slight non-uniformity Disagree, major non-uniformity

Measurement Accuracy. QA Reference Manual Section 4-2 Step 3. Use the calipers to measure

from the vertical pin closest to the skin line to the pin furthermost in depth. Do the same with the

horizontal row of pins.

Did the distance between the pins measured equal the e-caliper measurement?

Pass Fail

Change No Change (or First Test)

Lateral Resolution

how well the system/probe can display two targets side by side

two targets on the same horizontal plane is the Lateral Resolution.

Note the Lateral Resolution measurement in mm : ________________________________

Axial Resolution

the system/probe can display two targets above and below each other

of two targets on the same vertical plane is the Axial resolution.

. QA Reference Manual Section 4-2 Step 1. LATERAL resolution defines

. The smallest visible distance of

. QA Reference Manual Section 4-2 Step 2. AXIAL resolution defines how well

. The smallest visible distance

Note the Axial Resolution measurement in mm : ________________________________

Page 39

g

NO

NO

NO

NO

NO

Probe 5 (cont'd):

GE Medical Systems

3/4

2272729-100

REV 0

Contrast Resolution

the phantom contrast targets in the current scan. The point is not how any ONE of the targets look

but how well defined they are from each other, and from the background material.

Record the following information for five of the contrast targets, if available in the phantom. If they

are not available, indicate with N/A:

Object Number 1 2 3 4 5

Object Depth

Object Size

Object Contrast *

Object Detectability

Complete

Partial

Not Seen

Changed for Worse Y/N

Overall Probe Low Contarst Detectability

Change No Change (or First Test)

. (OPTIONAL) QA Reference Manual Section 4-2 Step 6 & 7. Evaluate

Notes for contrast resolution

Object Depth - is from the skin line to the center of the object.

Object Size - is the overalldiameter of the object (all should be the same)

Object Contrast -

Use the Echo Level function by Freezing the image. Press the Measurement

key three (3) times to assess the gray scale contrast level.

A 3 cm square box appears in the image area.

Position the box in the center of the contrast object.

Press Set.

Record the resulting number as the Object Contrast in the chart above.

Object Detectability - Check one box according to your evaluation of the object.

Changed for Worse Y/N - Enter a Y (yes) or N (no).

Document any system setting changes if they are different than the original scan on page 6.

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

:

Page 40

g

Probe 5 (cont'd):

GE Medical Systems

4/4

2272728-100

REV 0

Noise Level

scanning conditions. Describe the lighting conditions for repeatability during the next QA check.

___________________________________________________________________________________________________________

Adjust the system settings to produces a clean image.

Wipe all the gel from the probe face, and set the probe in its holder. With transmit power at a fixed

value, adjust the overall gain, until the far field image (beyond 3cm) begins to fill with noise. Reduce

the overall gain until the last of those noise “speckles” disappear.

Note the gain level on film and make a hard copy record of this test.

Gain: ________________________ Focus : ________________________

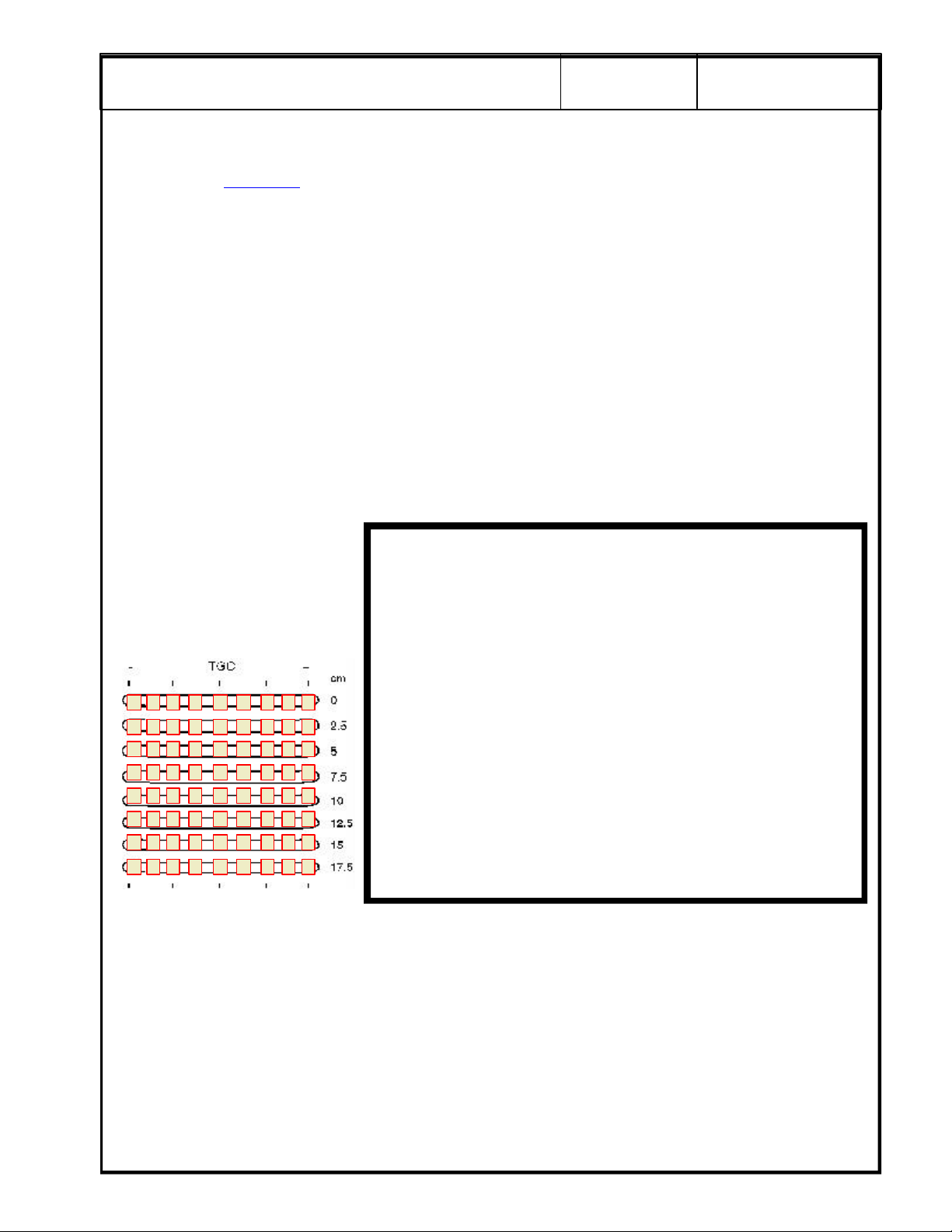

For scan repeatability during

the next QA check, place a

check mark in a box to indicate

the relative position of each

TCG control for the scan.

. QA Reference Manual Section 4-2 Step 5. Ensure that room lighting is set to normal

SECURE PAGE PRINT OF

PROBE NOISE LEVEL

SCAN HERE

Page 41

g

GE Medical Systems

PERFORMANCE EVALUATION

Probe 6

Model: ________________________ Serial Number: ______________________________

Type: General Purpose Superficial Intraoperative

Endorectal Endovaginal Other _____________________

Freq: 2-3.5 MHz 3-5 MHz 5-7.5 MHz 7.5 MHz and higher

Scan Format: Phased Array Linear Array Curved Linear Array

Mechanical Other _____________________

TRANSDUCER LEAKAGE CURRENT TESTS

All readings in micro-amps. Maximum allowable leakage current is 100 uA for general purpose and

endocavitary or 50 uA for surgical probes. QA Reference Manual Section 3-9.

DALE 600 DALE 600

POLARITY GND SW PROBE 3

NORM Closed

NORM Open

1/4

2272730-100

REV 0

Leakage Current Test Summary: Choose Pass or Fail and

Probe 6 PASS FAIL

CHANGE NO CHANGE

For Probe 3, adjust the system settings to produce the best possible overall image of the phantom. This

scan will be used to assess penetration capabilities, image uniformity, measurement accuracy, axial

resolution, lateral resolution and contrast detectability.

Gain: ________________________ Focus : ________________________

Dynamic Range: ____________________

For scan repeatability during

the next QA check, place a

check mark in a box to indicate

the relative position of each

TCG control for the scan.

SECURE PAGE PRINT OF PROBE SCAN

Change or No Change

Page 42

g

Probe 6 (cont'd):

GE Medical Systems

2/4

2272730-100

REV 0

Penetration Capability

from the skin line to the point furthermost in depth where echoes disappear and record the depth

in centimeters. The maximum depth through which the echographic pattern can be visualized is:

Less Than 3.0

3.0 3.5 4.0 4.5 5.0 5.5 6.0 6.5 7.0 7.5

8.0 8.5 9.0 9.5 10.0 10.5 11.0 11.5 12.0 12.5

13.0 13.5 14.0 15.0 16.0 or higher

Did system penetration change since the previous test?

Change No Change ( or First Test)

Image Uniformity

Change No Change (or First Test)

With your eye, evaluate the scan for image uniformity against the three indicators below:

The average brightness at the edge of the scan is the same as the average brightness in the

middle.

Agree Disagree, slight non-uniformity Disagree, major non-uniformity

There are no vertical or radially oriented shadows from array element dropout.

Agree Disagree, slight non-uniformity Disagree, major non-uniformity

. QA Reference Manual Section 4-2 Step 4. Use the calipers to measure

. Assess the image for uniformity from near field to far field.

There are no noticeable brightness transitions between focal zones.

Agree Disagree, slight non-uniformity Disagree, major non-uniformity

Measurement Accuracy. QA Reference Manual Section 4-2 Step 3. Use the calipers to measure

from the vertical pin closest to the skin line to the pin furthermost in depth. Do the same with the

horizontal row of pins.

Did the distance between the pins measured equal the e-caliper measurement?

Pass Fail

Change No Change (or First Test)

Lateral Resolution

how well the system/probe can display two targets side by side

two targets on the same horizontal plane is the Lateral Resolution.

Note the Lateral Resolution measurement in mm : ________________________________

Axial Resolution

the system/probe can display two targets above and below each other

of two targets on the same vertical plane is the Axial resolution.

. QA Reference Manual Section 4-2 Step 1. LATERAL resolution defines

. The smallest visible distance of

. QA Reference Manual Section 4-2 Step 2. AXIAL resolution defines how well

. The smallest visible distance

Note the Axial Resolution measurement in mm : ________________________________

Page 43

g

NO

NO

NO

NO

NO

Probe 6 (cont'd):

GE Medical Systems

3/4

2272730-100

REV 0

Contrast Resolution

the phantom contrast targets in the current scan. The point is not how any ONE of the targets look

but how well defined they are from each other, and from the background material.

Record the following information for five of the contrast targets, if available in the phantom. If they

are not available, indicate with N/A:

Object Number 1 2 3 4 5

Object Depth

Object Size

Object Contrast *

Object Detectability

Complete

Partial

Not Seen

Changed for Worse Y/N

Overall Probe Low Contarst Detectability

Change No Change (or First Test)

. (OPTIONAL) QA Reference Manual Section 4-2 Step 6 & 7. Evaluate

Notes for contrast resolution

Object Depth - is from the skin line to the center of the object.

Object Size - is the overalldiameter of the object (all should be the same)

Object Contrast -

Use the Echo Level function by Freezing the image. Press the Measurement

key three (3) times to assess the gray scale contrast level.

A 3 cm square box appears in the image area.

Position the box in the center of the contrast object.

Press Set.

Record the resulting number as the Object Contrast in the chart above.

Object Detectability - Check one box according to your evaluation of the object.

Changed for Worse Y/N - Enter a Y (yes) or N (no).

Document any system setting changes if they are different than the original scan on page 6.

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

:

Page 44

g

Probe 6 (cont'd):

GE Medical Systems

4/4

2272730-100

REV 0

Noise Level

scanning conditions. Describe the lighting conditions for repeatability during the next QA check.

___________________________________________________________________________________________________________

Adjust the system settings to produces a clean image.

Wipe all the gel from the probe face, and set the probe in its holder. With transmit power at a fixed

value, adjust the overall gain, until the far field image (beyond 3cm) begins to fill with noise. Reduce

the overall gain until the last of those noise “speckles” disappear.

Note the gain level on film and make a hard copy record of this test.

Gain: ________________________ Focus : ________________________

For scan repeatability during

the next QA check, place a

check mark in a box to indicate

the relative position of each

TCG control for the scan.

. QA Reference Manual Section 4-2 Step 5. Ensure that room lighting is set to normal

SECURE PAGE PRINT OF

PROBE NOISE LEVEL

SCAN HERE

Page 45

g

GE Medical Systems

PERFORMANCE EVALUATION

Probe 7

Model: ________________________ Serial Number: ______________________________

Type: General Purpose Superficial Intraoperative

Endorectal Endovaginal Other _____________________

Freq: 2-3.5 MHz 3-5 MHz 5-7.5 MHz 7.5 MHz and higher

Scan Format: Phased Array Linear Array Curved Linear Array

Mechanical Other _____________________

TRANSDUCER LEAKAGE CURRENT TESTS

All readings in micro-amps. Maximum allowable leakage current is 100 uA for general purpose and

endocavitary or 50 uA for surgical probes. QA Reference Manual Section 3-9.

DALE 600 DALE 600

POLARITY GND SW PROBE 3

NORM Closed

NORM Open

1/4

2272732-100

REV 0

Leakage Current Test Summary: Choose Pass or Fail and

Probe 7 PASS FAIL

CHANGE NO CHANGE

For Probe 3, adjust the system settings to produce the best possible overall image of the phantom. This

scan will be used to assess penetration capabilities, image uniformity, measurement accuracy, axial

resolution, lateral resolution and contrast detectability.

Gain: ________________________ Focus : ________________________

Dynamic Range: ____________________

For scan repeatability during

the next QA check, place a

check mark in a box to indicate

the relative position of each

TCG control for the scan.

SECURE PAGE PRINT OF PROBE SCAN

Change or No Change

Page 46

g

Probe 7 (cont' d):

GE Medical Systems

2/4

2272732-100

REV 0

Penetration Capability

from the skin line to the point furthermost in depth where echoes disappear and record the depth

in centimeters. The maximum depth through which the echographic pattern can be visualized is:

Less Than 3.0

3.0 3.5 4.0 4.5 5.0 5.5 6.0 6.5 7.0 7.5

8.0 8.5 9.0 9.5 10.0 10.5 11.0 11.5 12.0 12.5

13.0 13.5 14.0 15.0 16.0 or higher

Did system penetration change since the previous test?

Change No Change ( or First Test)

Image Uniformity

Change No Change (or First Test)

With your eye, evaluate the scan for image uniformity against the three indicators below:

The average brightness at the edge of the scan is the same as the average brightness in the

middle.

Agree Disagree, slight non-uniformity Disagree, major non-uniformity

There are no vertical or radially oriented shadows from array element dropout.

Agree Disagree, slight non-uniformity Disagree, major non-uniformity

. QA Reference Manual Section 4-2 Step 4. Use the calipers to measure

. Assess the image for uniformity from near field to far field.

There are no noticeable brightness transitions between focal zones.

Agree Disagree, slight non-uniformity Disagree, major non-uniformity

Measurement Accuracy. QA Reference Manual Section 4-2 Step 3. Use the calipers to measure

from the vertical pin closest to the skin line to the pin furthermost in depth. Do the same with the

horizontal row of pins.

Did the distance between the pins measured equal the e-caliper measurement?

Pass Fail

Change No Change (or First Test)

Lateral Resolution

how well the system/probe can display two targets side by side

two targets on the same horizontal plane is the Lateral Resolution.

Note the Lateral Resolution measurement in mm : ________________________________

Axial Resolution

the system/probe can display two targets above and below each other

of two targets on the same vertical plane is the Axial resolution.

. QA Reference Manual Section 4-2 Step 1. LATERAL resolution defines

. The smallest visible distance of

. QA Reference Manual Section 4-2 Step 2. AXIAL resolution defines how well

. The smallest visible distance

Note the Axial Resolution measurement in mm : ________________________________

Page 47

g

NO

NO

NO

NO

NO

Probe 7 (cont' d):

GE Medical Systems

3/4

2272732-100

REV 0

Contrast Resolution

the phantom contrast targets in the current scan. The point is not how any ONE of the targets look

but how well defined they are from each other, and from the background material.

Record the following information for five of the contrast targets, if available in the phantom. If they

are not available, indicate with N/A:

Object Number 1 2 3 4 5

Object Depth

Object Size

Object Contrast *

Object Detectability

Complete

Partial

Not Seen

Changed for Worse Y/N

Overall Probe Low Contarst Detectability

Change No Change (or First Test)

. (OPTIONAL) QA Reference Manual Section 4-2 Step 6 & 7. Evaluate

Notes for contrast resolution

Object Depth - is from the skin line to the center of the object.

Object Size - is the overalldiameter of the object (all should be the same)

Object Contrast -

Use the Echo Level function by Freezing the image. Press the Measurement

key three (3) times to assess the gray scale contrast level.

A 3 cm square box appears in the image area.

Position the box in the center of the contrast object.

Press Set.

Record the resulting number as the Object Contrast in the chart above.

Object Detectability - Check one box according to your evaluation of the object.

Changed for Worse Y/N - Enter a Y (yes) or N (no).

Document any system setting changes if they are different than the original scan on page 6.

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

:

Page 48

g

Probe 7 (cont' d):

GE Medical Systems

4/4

2272732-100

REV 0

Noise Level

scanning conditions. Describe the lighting conditions for repeatability during the next QA check.

___________________________________________________________________________________________________________

Adjust the system settings to produces a clean image.

Wipe all the gel from the probe face, and set the probe in its holder. With transmit power at a fixed

value, adjust the overall gain, until the far field image (beyond 3cm) begins to fill with noise. Reduce

the overall gain until the last of those noise “speckles” disappear.

Note the gain level on film and make a hard copy record of this test.

Gain: ________________________ Focus : ________________________

For scan repeatability during

the next QA check, place a

check mark in a box to indicate

the relative position of each

TCG control for the scan.

. QA Reference Manual Section 4-2 Step 5. Ensure that room lighting is set to normal

SECURE PAGE PRINT OF

PROBE NOISE LEVEL

SCAN HERE

Page 49

g

GE Medical Systems

PERFORMANCE EVALUATION

Probe 8

Model: ________________________ Serial Number: ______________________________

Type: General Purpose Superficial Intraoperative

Endorectal Endovaginal Other _____________________

Freq: 2-3.5 MHz 3-5 MHz 5-7.5 MHz 7.5 MHz and higher

Scan Format: Phased Array Linear Array Curved Linear Array

Mechanical Other _____________________

TRANSDUCER LEAKAGE CURRENT TESTS

All readings in micro-amps. Maximum allowable leakage current is 100 uA for general purpose and

endocavitary or 50 uA for surgical probes. QA Reference Manual Section 3-9.

DALE 600 DALE 600

POLARITY GND SW PROBE 3

NORM Closed

NORM Open

1/4

2272733-100

REV 0

Leakage Current Test Summary: Choose Pass or Fail and

Probe 8 PASS FAIL

CHANGE NO CHANGE

For Probe 3, adjust the system settings to produce the best possible overall image of the phantom. This

scan will be used to assess penetration capabilities, image uniformity, measurement accuracy, axial

resolution, lateral resolution and contrast detectability.

Gain: ________________________ Focus : ________________________

Dynamic Range: ____________________

For scan repeatability during

the next QA check, place a

check mark in a box to indicate

the relative position of each

TCG control for the scan.

SECURE PAGE PRINT OF PROBE SCAN

Change or No Change

Page 50

g

Probe 8 (cont' d):

GE Medical Systems

2/4

2272733-100

REV 0

Penetration Capability

from the skin line to the point furthermost in depth where echoes disappear and record the depth

in centimeters. The maximum depth through which the echographic pattern can be visualized is:

Less Than 3.0

3.0 3.5 4.0 4.5 5.0 5.5 6.0 6.5 7.0 7.5

8.0 8.5 9.0 9.5 10.0 10.5 11.0 11.5 12.0 12.5

13.0 13.5 14.0 15.0 16.0 or higher

Did system penetration change since the previous test?

Change No Change ( or First Test)

Image Uniformity

Change No Change (or First Test)

With your eye, evaluate the scan for image uniformity against the three indicators below:

The average brightness at the edge of the scan is the same as the average brightness in the

middle.

Agree Disagree, slight non-uniformity Disagree, major non-uniformity

There are no vertical or radially oriented shadows from array element dropout.

Agree Disagree, slight non-uniformity Disagree, major non-uniformity

. QA Reference Manual Section 4-2 Step 4. Use the calipers to measure

. Assess the image for uniformity from near field to far field.

There are no noticeable brightness transitions between focal zones.

Agree Disagree, slight non-uniformity Disagree, major non-uniformity

Measurement Accuracy. QA Reference Manual Section 4-2 Step 3. Use the calipers to measure

from the vertical pin closest to the skin line to the pin furthermost in depth. Do the same with the

horizontal row of pins.

Did the distance between the pins measured equal the e-caliper measurement?

Pass Fail

Change No Change (or First Test)

Lateral Resolution

how well the system/probe can display two targets side by side

two targets on the same horizontal plane is the Lateral Resolution.

Note the Lateral Resolution measurement in mm : ________________________________

Axial Resolution

the system/probe can display two targets above and below each other

of two targets on the same vertical plane is the Axial resolution.

. QA Reference Manual Section 4-2 Step 1. LATERAL resolution defines

. The smallest visible distance of

. QA Reference Manual Section 4-2 Step 2. AXIAL resolution defines how well

. The smallest visible distance

Note the Axial Resolution measurement in mm : ________________________________

Page 51

g

NO

NO

NO

NO

NO

Probe 8 (cont' d):

GE Medical Systems

3/4

2272733-100

REV 0

Contrast Resolution

the phantom contrast targets in the current scan. The point is not how any ONE of the targets look

but how well defined they are from each other, and from the background material.

Record the following information for five of the contrast targets, if available in the phantom. If they

are not available, indicate with N/A:

Object Number 1 2 3 4 5

Object Depth

Object Size

Object Contrast *

Object Detectability

Complete

Partial

Not Seen

Changed for Worse Y/N

Overall Probe Low Contarst Detectability

Change No Change (or First Test)