Page 1

GE Oil & Gas

Masoneilan* Products

78400/18400 Series LincolnLog

High-Pressure, Anti-Cavitation Control Valves

Integrated smart engineered

solutions for severe service

applications

*

• Long term reliability

• Longer service life

• Industry leading

technology

Page 2

LincolnLog Reliability

Valve Solutions

and Services

for the World’s

Tough Applications

Long-term Reliability

The Masoneilan LincolnLog valve from GE Oil & Gas offers longterm reliability in high-pressure, liquid-letdown, anti-cavitation

control valve applications. Engineering knowledge and

expertise has made us a leader in control valve applications

with products such as Flexible Better Fit severe-service

solutions. The LincolnLog valve is a control valve solution of

choice throughout the wide spectrum of severe-service liquidflow applications.

Proven Performance

The Masoneilan LincolnLog valve design has more than 20

years of proven field performance as the industry’s premier

high-pressure, liquid-letdown solution. The Masoneilan

LincolnLog is a reliable and robust anti-cavitation control

valve package with enhanced multi-stage and axial flow-trim

technology incorporated into a rugged valve design. Over the

years, the LincolnLog valve has successfully met the challenges

of thousands of severe-service applications around the globe.

Industries and Applications

UPSTREAM OIL and GAS

REFINING

• Pump Recirculation

• Produced Water Injection

• High Pressure Separator

• Rich Amine Service

• Cold High Pressure Separator Letdown

2 | GE Oil & Gas

POWER GENERATION

• Pump Recirculation

• Boiler Feedwater StartUp

• High Pressure Spraywater Control

Page 3

Innovative Solutions

Meeting Exacting Industry Specifications

The LincolnLog* valve is available in a variety of body

configurations, sizes, materials, ratings and trim types. The wide

variety of trim designs in the LincolnLog valve includes options

that offer up to a 150:1 turndown ratio, enabling response to a

wide range of process conditions. With a number of combinations

of forged or cast valve bodies, standard or exotic alloys, API or

ANSI-rated construction, and globe or angle configurations,

the LincolnLog valve meets or exceeds exacting industry

specifications such as corrosive service (NACE) and Pressure

Equipment Directive (PED) compliance.

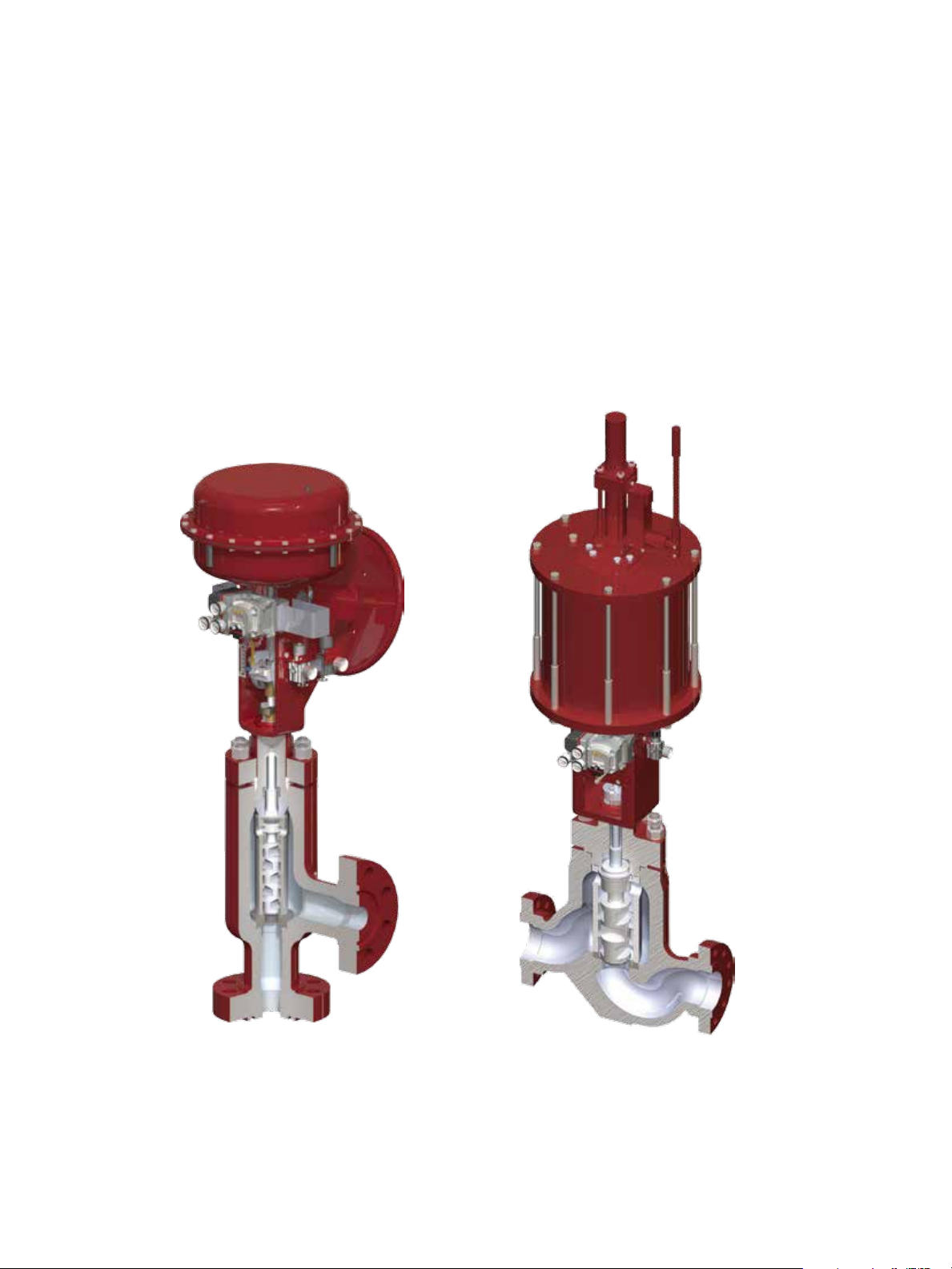

78400 Series

Angle Style LincolnLog

18400 Series

Globe Style LincolnLog

78400/18400 Series LincolnLog High Pressure, Anti-Cavitation Control Valves | 3

Page 4

Reliability in Performance

Reliable, Long Term Performance

The leading cause of poor control valve performance and

premature failure in high-pressure, liquid-letdown service

is cavitation. Some liquid applications cavitate so severely

that the valve can experience diminished performance or

even mechanical failure within hours of commissioning. The

multistage design of the LincolnLog valve reduces cavitation

by directing the fluid through a series of three-dimensional,

high-impedance pressure-reduction areas, or stages. This

highly tortuous flow path helps prevent cavitation by managing

the pressure reduction and fluid velocity through every stage,

promoting repeatable performance during the valve’s life.

The LincolnLog valve offers reliable, long-term performance

in the most extreme applications such as inaccessible

high-pressure, liquid-letdown, wellhead-injection valves.

The LincolnLog anti-cavitation control valve can be custom

engineered with as many as 10 stages of pressure reduction

for applications with extreme pressure drops in excess of 8000

psi (550 Bar). These valves control the pressure drop

in multiple stages for confident operation in remote

locations such as offshore platforms. Furthermore,

a flexible range of staging ratios is available to

customize the pressure drop for a wide variety of

fluids and conditions.

Multi-Stage, Axial Flow Technology

High trim velocity can intensify cavitation damage inside the

control valve. This damage is common in many single-stage

valve designs, which take the full pressure drop across a single

region within the trim. This single region is typically the leading edge of the plug and seat — an area that experiences the

highest velocity. Consequently, it receives the most severe and

excessive damage.

Similarly, many radial trim designs, such as drilled- hole cages

and stacked disks, often experience the same fate under

extreme pressure drops. Unlike the axial flow design of the

LincolnLog valve, many radial designs throttle the pressure

drop at the innermost radial stage adjacent to the plug-seating

surface. When this radial trim is only partially open, the outermost stages are oversized, essentially becoming inactive and

voiding any intended staging. In this case, the full pressure

drop is taken across the final stage, resulting in high energy

release right at the controlling and seating surface of the plug.

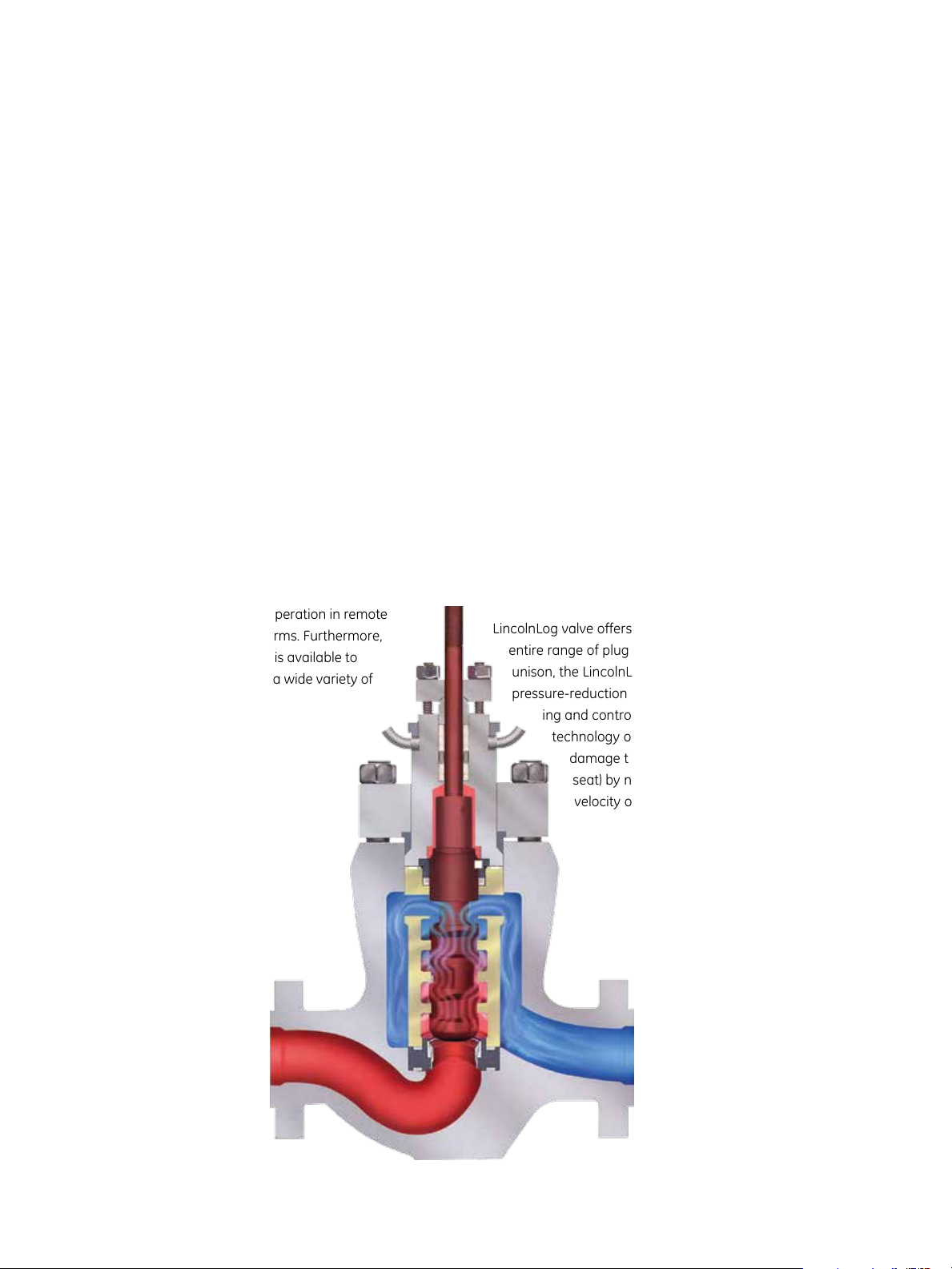

In contrast, the axial flow design of the GE Oil & Gas;s

LincolnLog valve offers reliable performance throughout the

entire range of plug travel. By throttling at all stages in

unison, the LincolnLog valve reduces short-circuiting of any

pressure-reduction stage, decreasing wear along the lead-

ing and controlling edge of the plug. The axial flow

technology of the LincolnLog valve helps eliminate

damage to any controlling surface (plug, cage or

seat) by not exposing any one stage to excessive

velocity or the full pressure drop.

4 | GE Oil & Gas

Axial Flow Technology

Page 5

Reliability in Service Life

Reliable Installed Life

The LincolnLog valve is repeatedly applied in some of the most

severe liquid service applications because of its robust design.

Some of the most challenging control valve applications

require the LincolnLog valve’s ability to reduce cavitation while

withstanding direct impingement from metal, sand or other

abrasive particles traveling within the process fluid.

For applications such as wellhead chokes and reclaimed oil

processing, the LincolnLog valve reduces particle impact

damage by minimizing the trim velocity through its highimpedance tortuous flow path. Additionally, hardened materials

such as 440C stainless steel and solid tungsten carbide are

successfully incorporated into the trim design to further

withstand erosive attack. For these applications, the LincolnLog

valve offers a reliable and long-lasting solution by combining

hardened materials with a low velocity, multi-stage, anticavitation design.

Vibration is also a cause of premature valve- trim part failure –

specifically, the valve plug and stem. Vibration can be process

induced or can be caused by the throttling effects of very highpressure, liquid-flow streams. The LincolnLog valve features

oversized stem and guiding areas to overcome premature

failure due to vibration. The oversized stem is mated to the

plug with a unique male-female coupling configuration that

positively aligns the plug and stem. This reduces fatigue failure

due to vibration caused by trim misalignment. Secure guiding

extends across the full length of the valve plug, as continuous

plug guides are present in each of the staged reduction areas.

Multi-Stage Trim Comparison for 4 & 6 Stage Trim

Axial Flow Technology:

3-D Multi-Stage Pressure Reduction

78400/18400 Series LincolnLog High Pressure, Anti-Cavitation Control Valves | 5

Page 6

Reliability in Control

Reliable Valve Control

The axial flow technology of the LincolnLog valve offers

a smooth control characteristic across the entire range

of operation. Each pressure reduction stage is throttling

simultaneously across the plug, thus avoiding the stair-stepped

control response that is commonly found in valves with radial

flow designs. The smooth and continuous throttling control of

the LincolnLog valve is achieved by the notches, or stages, in

the plug design. The unique notched design coupled with the

staged liner and cage enables the LincolnLog valve to control

process conditions over an extremely large range of operation

— in some applications up to a 150:1 turndown ratio.

As an added feature, the enlarged flow passages of the axial

flow design help protect the trim from clogging with pipeline

debris. This inherent “debris- tolerant” feature offers the benefit

of uninterrupted service and repeatable control, which helps set

the LincolnLog valve apart from the competition. Applications

such as Pump Recirculation rely on this technology to promote

continuous flow passing through the pump, helping to prevent

burn-out or overheating of this critical piece of equipment.

The LincolnLog valve can be applied in this service as flow will

continue to recirculate with no risk of interruption resulting

from blocked flow passages.

Axial Flow Technology: Smooth Control Through

Continuously Active Stages

GE Oil & Gas’s smart instrumentation including the SVIII AP

(HART® digital positioner) and the FVP (FOUNDATION Fieldbus™

Positioner) allow for greater sensitivity and increased control

accuracy. Our digital positioners also increase the repeatability

and reliability of the control valve assembly, allowing for the

precise control enabled by 1/10,000th of an inch plug travel

resolution. Both positioners are available in single- or doubleacting configurations.

SVI II AP Digital Positioner

Trash Tolerant Design:

Large Flow Passages Prevent Clogging

FVP Foundation Fieldbus Positioner/Controller

6 | GE Oil & Gas

Page 7

Reliability in Service Life

Reliable Installed Life

Many valve applications result in poor shutoff or excessive seat

leakage after short-term use because the seating area also

serves as the primary control element. Designs that throttle

the flow near the seating surfaces often experience high fluid

velocity in this region and direct the pressure drop across

the leading edge of the plug and seat. Once early signs of

erosion or wire drawing develop on the seating surface, quick

deterioration of valve shutoff performance follows as a result

of the high pressure drop condition.

The Masoneilan LincolnLog valve is configured to maintain

long-term shutoff by separating the two functions of shutoff

and control into separate areas within the trim. As the plug lifts

off the seat, fluid begins to fill the first plug chamber until the

valve is approximately 15 percent open. With continued travel,

the downstream stages begin to open and the fluid is throttled

using the remaining trim stages. Thus, the seating surfaces

are never used for throttling at low flow, which commonly

produces erosion damage in radial flow designs. This seat

protection feature is critical for process startup valves since

they are typically used to throttle high upstream pressure

down to near vacuum conditions for downstream deaerators

or condensers at low plant loads.

Trim Surface Overlap with Valve in

Closed Position

Seat Protection Feature

Larger Flow Area at Seat Region

with Valve in Open Position

Tight Shutoff Designs

Shutoff performance consistent with ANSI/FCI Classes IV, V, and

VI, as well as MSS-SP-61, is available with the LincolnLog valve.

For temperatures up to 600 °F (316 °C), we offer a TFE-inserted,

soft-seat design for tight shutoff. This soft seat is protected by

a sliding metal collar that shields the TFE from direct exposure

to the flow stream and erosive particles when the valve is

open.

Maintaining long-term shutoff is critical in high-pressure

liquid service, as high-pressure differential leakage may lead

to wire drawing, cavitation, or flashing damage to the valve,

downstream piping, or other equipment.

Protected Soft Seat: Class VI Shutoff Design

78400/18400 Series LincolnLog High Pressure, Anti-Cavitation Control Valves | 7

Page 8

Features and Benefits

High

Performance

Actuation

4

8

10

9

6

7

5

1

3

11

18400 Series

Globe Style LincolnLog with Metal Seat

12

2

Angle Style LincolnLog with Soft Seat

78400 Series

8 | GE Oil & Gas

SVI II AP Digital Positioner

Page 9

FEATURE ADVANTAGE

END USER

BENEFIT

Protected Soft Seat Long-term, Reliable Class VI Shutoff Prevents Loss of Product

1

Revenue Enhancement

Trim Overlap

2

SVI II AP Positioner or

3

Masoneilan FVP

High Performance Actuation Trim Stability and Control Reliability Repeatable Process Control

4

Forged or Cast Angle &

5

Globe Configurations

Robust Plug/Stem

6

Connection

Multi-Stage Trim Cavitation Elimination Longer Installed Trim Life

7

Compact Metal Seal Design Reduces Bolting Torque Requirements Ease of Maintenance

8

Continuous Plug Guiding Eliminates Vibration Induced Damage Minimizes Downtime

9

Protects Seating Area from High

Velocity Flow, Maintaining Shutoff

Optimized Control Performance Precise Process Control

Flexible Installation Flexible Installation

Trim Durability Longer Installed Trim Life

Prevents Loss of Product

Cost Reduction

Risk Mitigation

10

11

12

High Resistance Tortuous

Flow Path

Axial Flow Technology Trim Stability and Seat Protection Reduces Trim Wear

Large Flow Passages Flow Entrained Particulate Tolerance Minimizes Downtime

Provides Flow Energy Management Minimizes Valve Damage

78400/18400 Series LincolnLog High Pressure, Anti-Cavitation Control Valves | 9

Page 10

Specifications

■ Flow Direction

standard: flow-to-open

optional: flow-to-close

■ Body

type: cast or forged globe style (18400 Series)

cast or forged angle style (78400 Series)

sizes: 1” to 12” (DN 25 to DN 300)

ratings: ANSI Class 600 to 4500

(ISO PN 100 to 400)

API 5000 & 10000

end connections: RF, RTJ, socket weld,

butt weld, threaded,

print flanges (forgings)

■ Bonnet

type: bolted

standard

extension

■ Body and Bonnet

materials: carbon steel

316 stainless steel

chrome-moly

others on request

■ Trim

plug type: multi-step axial flow

(3, 4, 6, 8 and 10 stages)

seat type: quick change

integral with plug liner (1” & 1.5” sizes)

metal seat

protected soft seat

guide: continuous top guided (liner acts as primary guide)

CV ratio: up to 150:1

flow characteristics: modified linear

materials: standard, NACE, cryogenic

■ Actuator

type: spring-diaphragm

spring-return cylinder

double-acting cylinder

electrohydraulic (such as REXA)

handwheel: optional

■ Positioner

type: SVI II AP - HART® (single or double-acting)

FVP - Foundation Fieldbus® (single or double-acting)

others

Optional designs are also available, such as larger sizes, higher pressure ratings, special materials, or additional trim stages as required. Consult

factory for design details and specifications.

10 | GE Oil & Gas

Page 11

Providing industry-leading

knowledge and technology

Integrated Smart-engineered

Technology

Make the most of the LincolnLog control valve’s

operational benefits with GE Oil & Gas’s leading

microprocessor-based field instrumentation

technology. Award-winning HART communicating

SVI* and FVP* digital positioners help improve your

asset’s effectiveness, resulting in higher returns on

investment. By using patented tuning algorithms

that optimize valve control performance, our digital

positioners deliver improved process yields and

lower maintenance cost.

Flexibility is built into each of GE Oil & Gas’s digital

instrumentation offerings. SVI II and FVP mount on

any control valve actuator and interface effectively

with HART and Foundation Fieldbus distributed

control schemes, respectively (since SVI is only Hart

and FVP is only FF).

You can further increase flexibility and functionality

with GE’s smart instrument companion software

such as ValVue*, a tool that monitors realtime device status. In addition, ValvKeep* valve

database management and AMS Snap-on™ asset

management software provide a comprehensive

view into valve asset maintenance history and

performance trends. These software support

tools, in conjunction with the advanced diagnostic

capabilities of smart devices, help significantly

reduce operating costs.

Flexible Solutions for a Wide

Range of Applications

GE Oil & Gas provides a wide range of control valves

and services, supported by a global, integrated

network of manufacturing, sales and service offices.

Our broad portfolio of products includes general

service and severe service control valves, actuators,

pressure regulators and valve-mounted smart

instrumentation and accessories. GE Oil & Gas has

the expertise, experience and technology to deliver

the best-fit solution for virtually every process

control application. Masoneilan designs from GE

Oil & Gas include industry-leading products such

as the Camflex* rotary control valve, LincolnLog*

liquid letdown control valve, butterfly valves and

customized solutions including T-Ball parallel plate

technology and patented V-LOG* labyrinth trim

technology.

78400/18400 Series LincolnLog High Pressure, Anti-Cavitation Control Valves | 11

Page 12

DIRECT SALES OFFICE LOCATIONS

AUSTRALIA

Brisbane

Phone: +61-7-3001-4319

Fax: +61-7-3001-4399

Perth

Phone: +61-8-6595-7018

Fax: +61-8-6595-7299

Melbourne

Phone: +61-3-8807-6002

Fax: +61-3-8807-6577

BELGIUM

Phone: +32-2-344-0970

Fax: +32-2-344-1123

BRAZIL

Phone: +55-11-2146-3600

Fax: +55-11-2146-3610

CHINA

Phone: +86-10-8486-4515

Fax: +86-10-8486-5305

FRANCE

Courbevoie

Phone: +33-1-4904-9000

Fax: +33-1-4904-9010

GERMANY

Ratingen

Phone: +49-2102-108-0

Fax: +49-2102-108-111

INDIA

Mumbai

Phone: +91-22-8354790

Fax: +91-22-8354791

New Delhi

Phone: +91-11-2-6164175

Fax: +91-11-5-1659635

ITALY

Phone: +39-081-7892-111

Fax: +39-081-7892-208

JAPAN

Chiba

Phone: +81-43-297-9222

Fax: +81-43-299-1115

KOREA

Phone: +82-2-2274-0748

Fax: +82-2-2274-0794

MALAYSIA

Phone: +60-3-2161-0322

Fax: +60-3-2163-6312

MEXICO

Phone: +52-5-310-9863

Fax: +52-5-310-5584

THE NETHERLANDS

Phone: +0031-15-3808666

Fax: +0031-18-1641438

RUSSIA

Veliky Novgorod

Phone: +7-8162-55-7898

Fax: +7-8162-55-7921

Moscow

Phone: +7 495-585-1276

Fax: +7 495-585-1279

SAUDI ARABIA

Phone: +966-3-341-0278

Fax: +966-3-341-7624

SINGAPORE

Phone: +65-6861-6100

Fax: +65-6861-7172

SOUTH AFRICA

Phone: +27-11-452-1550

Fax: +27-11-452-6542

SOUTH & CENTRAL

AMERICA AND THE CARIBBEAN

Phone: +55-12-2134-1201

Fax: +55-12-2134-1238

SPAIN

Phone: +34-93-652-6430

Fax: +34-93-652-6444

UNITED ARAB EMIRATES

Phone: +971-4-8991-777

Fax: +971-4-8991-778

UNITED KINGDOM

Wooburn Green

Phone: +44-1628-536300

Fax: +44-1628-536319

UNITED STATES

Massachusetts

Phone: +1-508-586-4600

Fax: +1-508-427-8971

Corpus Christi, Texas

Phone: +1-361-881-8182

Fax: +1-361-881-8246

Deer Park, Texas

Phone: +1-281-884-1000

Fax: +1-281-884-1010

Houston, Texas

Phone: +1-281-671-1640

Fax: +1-281-671-1735

* Masoneil an, LincolnLo g, SVI, FVP, V-LOG, Lo- dB, Camflex, T-Ba ll, ValVue, ValvKee p, and

SteamForm a re registered t rademarks o f the General Ele ctric Comp any.

Other company names and product names used in this document are the registered trademarks

or trademarks of their respective owners.

© 2013 General El ectric Comp any. All rights r eserved.

GEA19508 04/2013

[Former ly Masoneila n BP78400 03/11]

Loading...

Loading...