Page 1

HeatSeal® Sprint

TM

H925

Instruction Manual

Manuel d’instructions

Manual de instrucciones

To register this product go to www.gbc.com

Pour enregistrer ce produit, allez sur www.gbc.com

Para registrar este producto visite www.gbc.com

To register this product go to www.gbc.com

Pour enregistrer ce produit allez sur www.gbc.com

Para registrar este producto vaís en www.gbc.com

Page 2

2

3

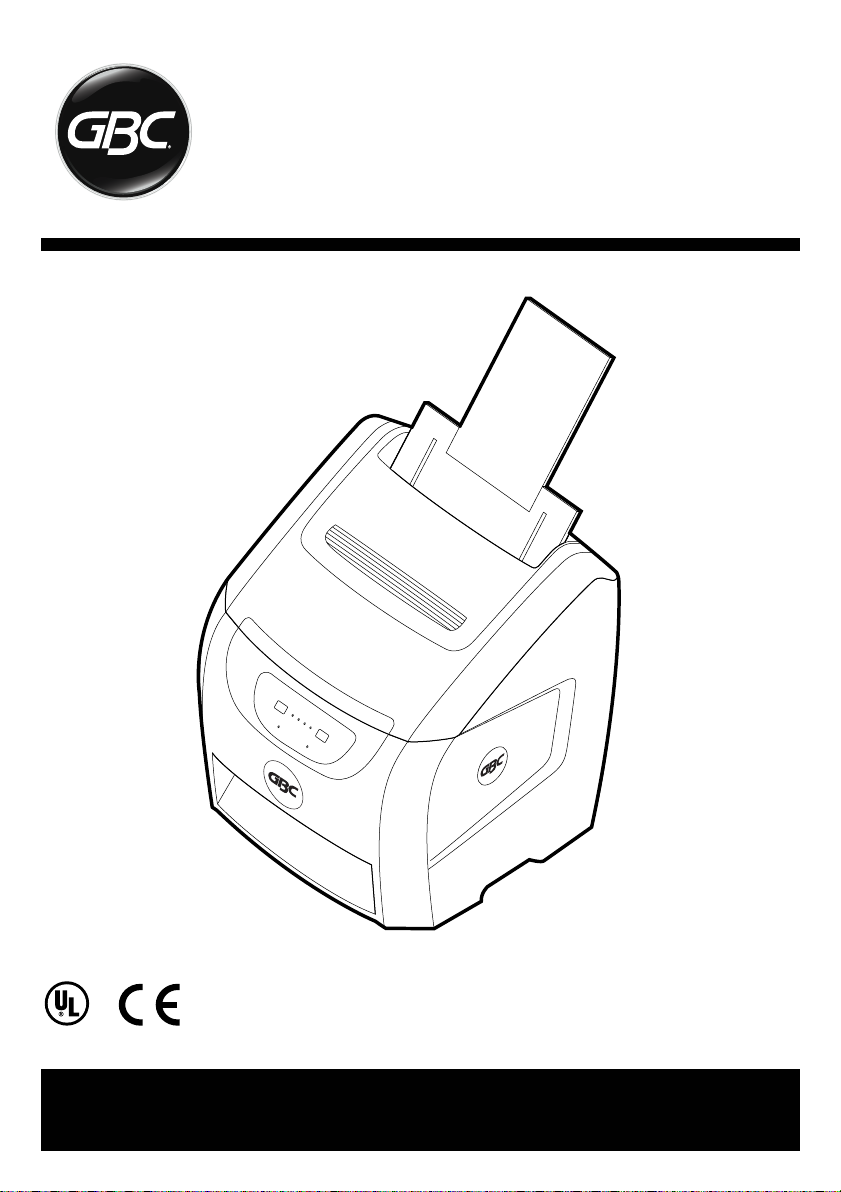

HeatSeal Sprint H925 - Description/

Description/Descripción

TM®

HeatSeal Sprint H925 - Safety

TM®

limenta

A

B

C

D

E

F

M

N

O

A) Feed Tray

Plateau d’alimentation

Bandeja de alimentación

B) Paper Side Guide

Guide latéral pour le papier

Guía lateral del papel

C) Top Cover

Couvercle supérieur

Tapa superior

D) Control Panel

Panneau de commande

Panel de control

E) Exit Tray

Plateau de sortie

Bandeja de salida

G

H

I

J

K

L

Start/Start/Inicio Stop/Stop/Interrupción

3 mil / 75 mic 5 mil / 125 mic

F) Power Button

Touche d’alimentation

Botón de encendido

G) 4 EZloadTM Levers

4 leviers de chargement EZload

4 palancas de carga EZload

K) Heat Shoe

Sabot chauffant

Zapata térmica

L) Film Roll

TM

Rouleau de pellicule

TM

Rollo de película

P) Alert (LED)

Voyant d’alerte (DEL)

LED “Alert” (Alerta)

Q) Low Film (LED)

Voyant de faible quantité

LED “Low Film” (Poca

H) Heat Button

Touche de chauffage

Botón “Heat” (de calentamiento)

M) Ready (LED)

Voyant d’état « Prêt » (DEL)

LED “Ready” (Lista)

R) Stop Button

Bouton d’arrêt

I) Feed Switch

Interrupteur d’alimentation

Interruptor “Feed” (de alimentación)

N) Power

Voyant d’alimentation

Encendido

Botón de Paro

S) Film Select Buttons

Touches de sélection de

J) Idler Bar Assembly

Assemblage de barre de transfert

Conjunto de barra intermediaria

O) Start Button

Touche de démarrage

Botón “Start” (Inicio)

Botones de selección de

P

Q

R

S

de pellicule (DEL)

película remanente)

pellicule

película

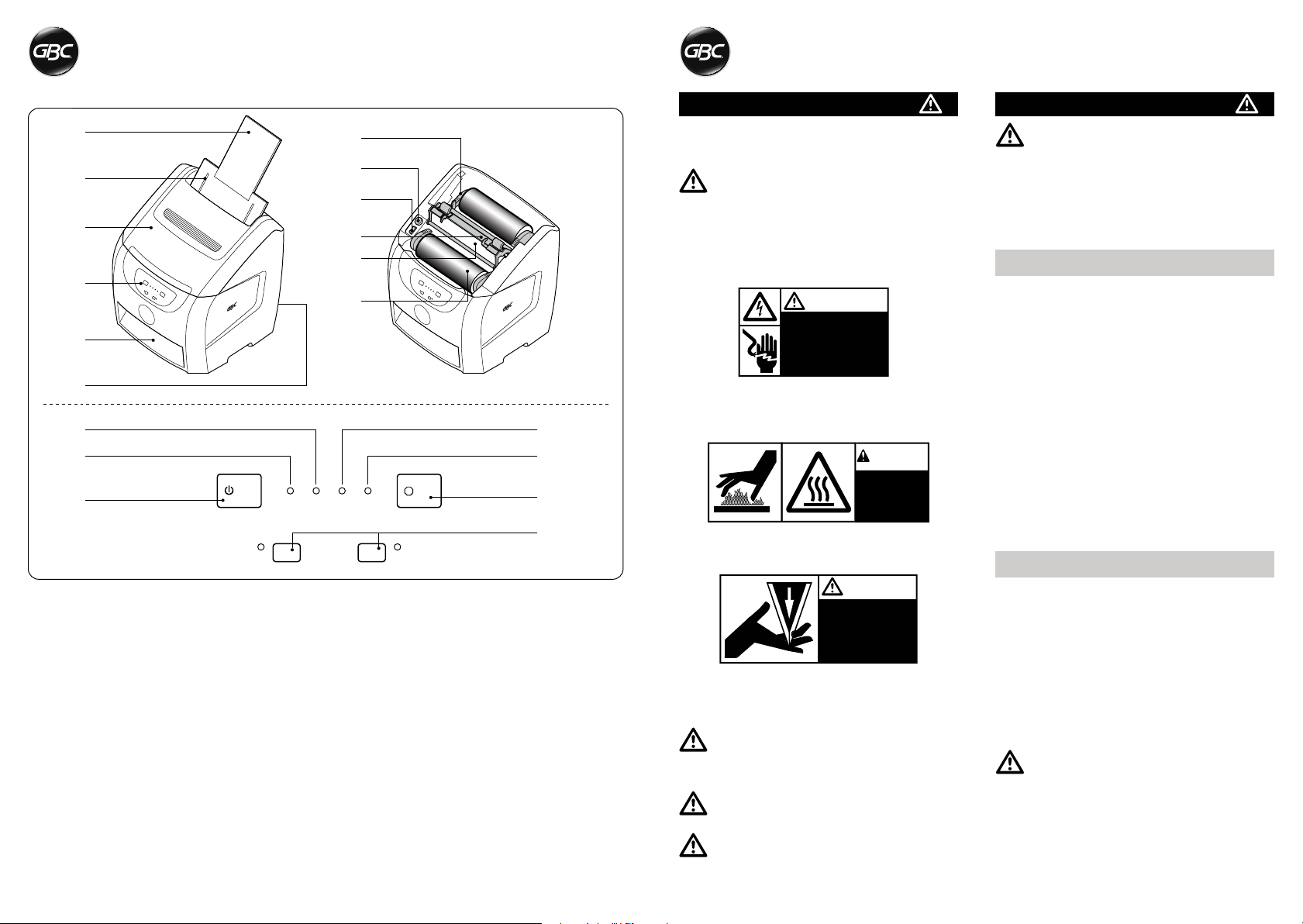

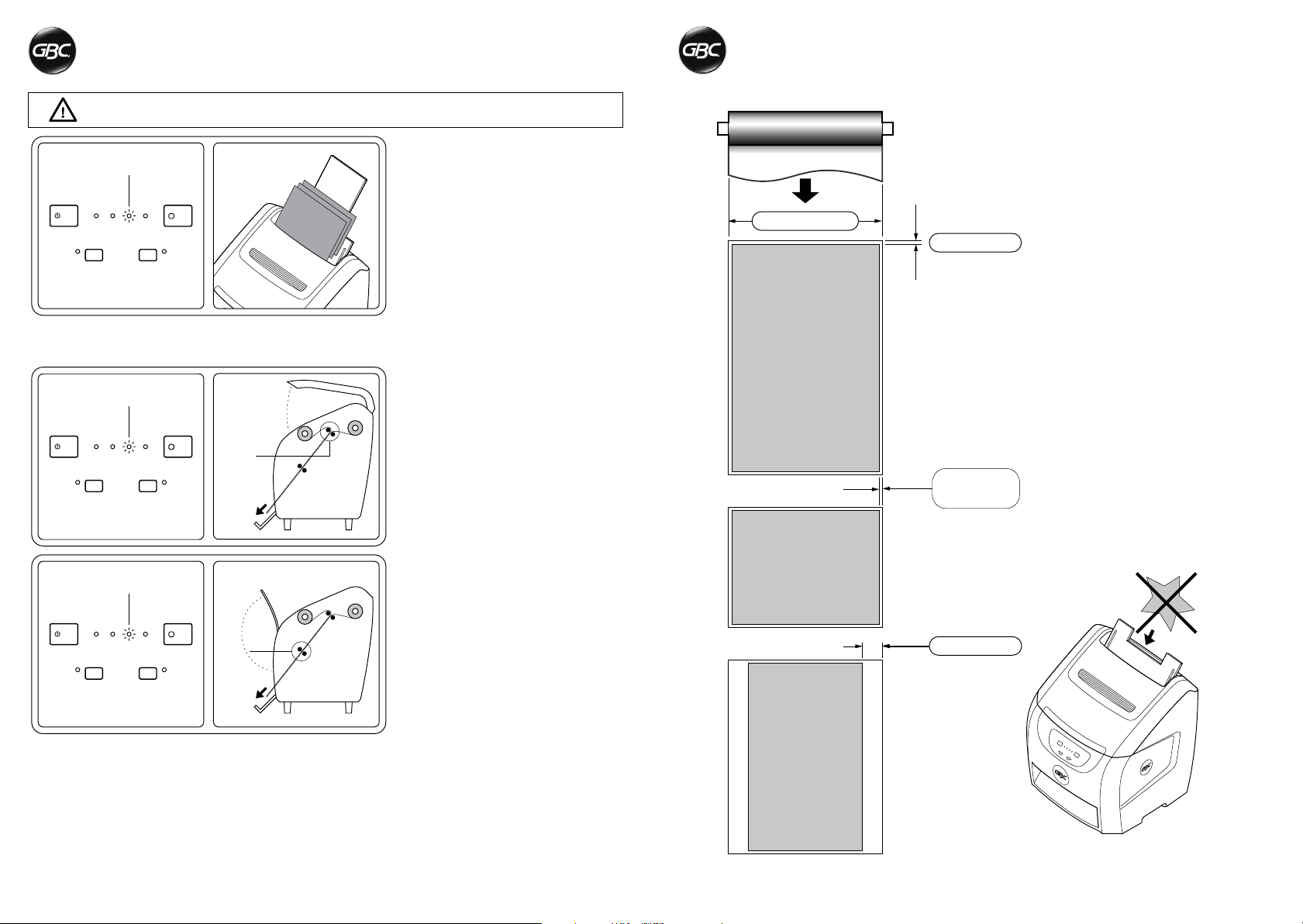

Important Safety Instructions Important Safeguards

YOUR SAFETY AS WELL AS THE SAFETY OF OTHERS IS IMPORTANT

TO GBC. IN THIS INSTRUCTION MANUAL AND ON THE PRODUCT ARE

IMPORTANT SAFETY MESSAGES. READ THESE MESSAGES CAREFULLY.

THE SAFETY ALERT SYMBOL PRECEDES EACH SAFETY

MESSAGE IN THIS INSTRUCTION MANUAL.

ON THE PRODUCT YOU WILL FIND IMPORTANT SAFETY MESSAGES.

READ THESE MESSAGES AND INSTRUCTIONS CAREFULLY.

SAVE THESE INSTRUCTIONS FOR LATER USE.

THE FOLLOWING WARNINGS ARE FOUND ON THIS PRODUCT.

WARNING

Electrical shock hazard.

Do not open. No user

serviceable parts inside.

Refer servicing to qualified

service personnel.

This safety message means that you could be seriously hurt or killed

if you open the product and expose yourself to hazardous voltage.

CAUTION

Hot

surface.

Do not touch heat shoes until they have cooled.

WARNING: FOR YOUR PROTECTION, DO NOT CONNECT

THE LAMINATOR TO ELECTRICAL POWER OR ATTEMPT

TO OPERATE UNTIL YOU READ THESE INSTRUCTIONS

COMPLETELY. KEEP OPERATING INSTRUCTIONS IN A

CONVENIENT LOCATION FOR FUTURE REFERENCE. TO

GUARD AGAINST INJURY, THE FOLLOWING BASIC SAFETY

PRECAUTIONS MUST BE OBSERVED IN THE SET-UP AND

USE OF THE LAMINATOR.

General Safeguards

• Use this laminator only for its intended purposes as according

to the specifications outlined in the operating instructions.

• Keep hands, long hair, loose clothing and articles such as

necklaces or ties away from the front of the pull rollers to avoid

entanglement and entrapment.

• Avoid contact with the heat shoes during operation or shortly

after the laminator has been turned off. The heat shoes can reach

temperatures in excess of 300°F.

• Keep hands and ngers away from the path of the sharp lm

cutter blade located at the film exit.

• Place the laminator on a stable cart, stand or table capable of

supporting at least 110 lbs/50 kg. An unstable surface may cause

the laminator to fall resulting in serious bodily injury. Avoid quick

stops, excessive force and uneven floor surfaces when moving

the laminator on a cart or stand.

• Do not defeat or remove electrical and mechanical safety

equipment such as interlocks, shields and guards.

• Do not insert objects unsuitable for lamination.

• Do not expose laminator to liquids.

Electrical Safeguards

CAUTION

SHARP BLADE.

Keep hand and

fingers away.

This safety message means that you could cut yourself if you

are not careful.

WARNING: THE SAFETY ALERT SYMBOL PRECEDES EACH

SAFETY MESSAGE IN THIS INSTRUCTION MANUAL THIS

SYMBOL INDICATES A POTENTIAL PERSONAL SAFETY

HAZARD THAT COULD HURT YOU OR OTHERS.

WARNING: DO NOT ATTEMPT TO SERVICE OR REPAIR

THE LAMINATOR.

WARNING: DO NOT CONNECT THE LAMINATOR TO AN

ELECTRICAL SUPPLY OR ATTEMPT TO OPERATE THE

LAMINATOR UNTIL YOU HAVE COMPLETELY READ THESE

INSTRUCTIONS. MAINTAIN THESE INSTRUCTIONS IN A

CONVENIENT LOCATION FOR FUTURE REFERENCE.

• This laminator must be connected to a supply voltage correspon-

ding to the electrical rating as indicated on the serial plate located

on the rear of the machine.

• Unplug the laminator before moving it, or when it is not in use for

an extended period of time.

• Do not operate the laminator with a damaged power supply cord

or plug.

• Do not overload electrical outlets as this can result in re or shock.

• Do not alter the attachment plug. This plug is congured for the

appropriate electrical supply.

• The unit is intended for indoor use only.

CAUTION: The receptacle must be located near the equipment

and easily accessible. Do not use an extension cord.

• Disconnect the attachment plug from the receptacle to which it is

connected and keep the power supply cord in your possession

while moving the laminator.

• Do not operate the laminator with a damaged power supply

cord or attachment plug, upon occurrence of a malfunction, or

after laminator has been damaged. Contact an authorized GBC

service representative for assistance.

Page 3

4

5

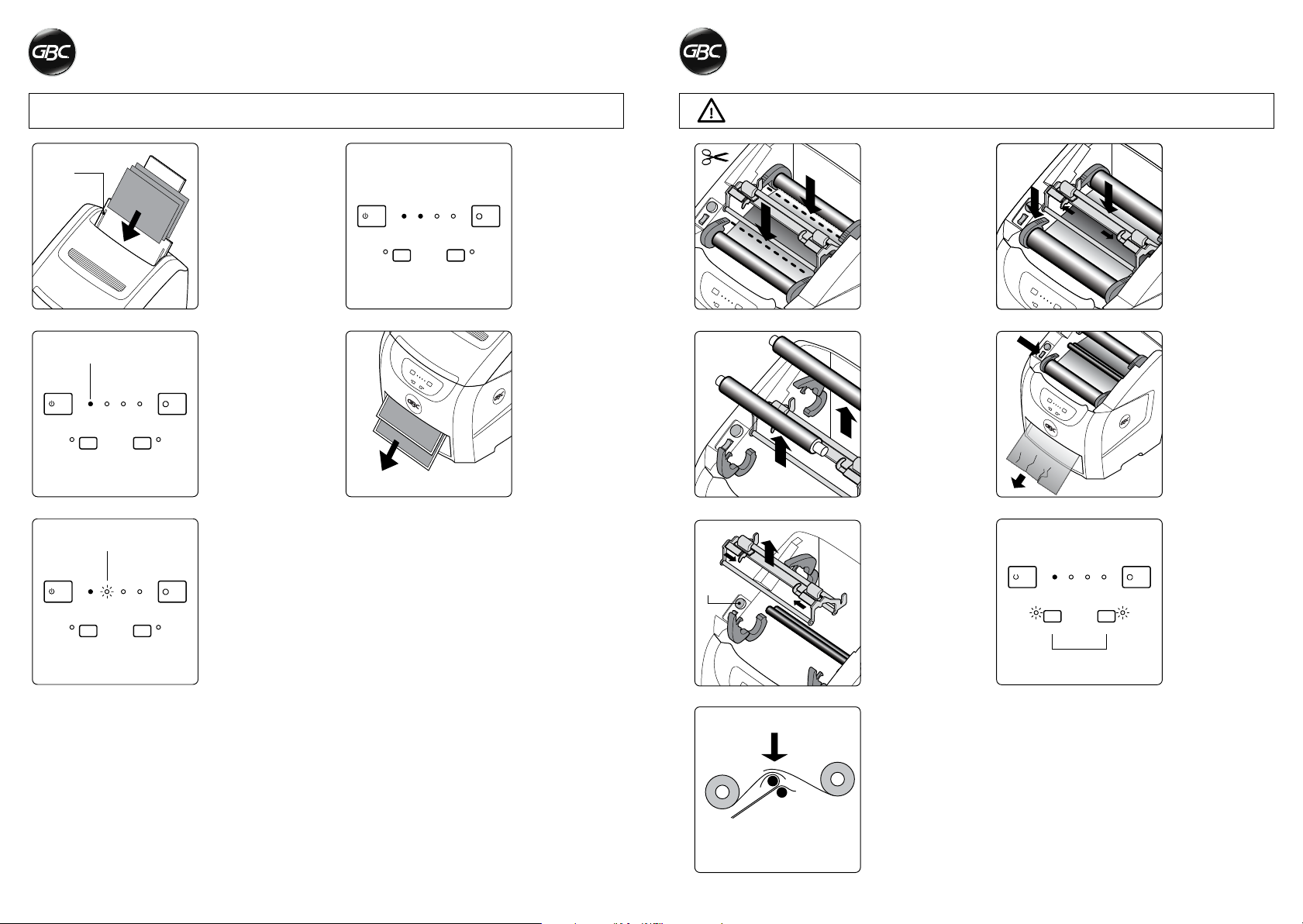

STEP 2

Open exit tray to

fully extended

position for normal

operation.

For longer paper or

banners close tray.

STEP 1

In back of machine,

turn on power.

Power light LED in

front control panel

lights up.

STEP 4

Adjust side guides

to fit document(s).

STEP 3

Insert and secure

feed tray into

position.

Side

Guides

Laminator comes pre-loaded with 3 mil/75 mic film, approximately 30ft/9m.

HeatSeal Sprint H925 - Setup

TM®

Tray

Service

HeatSeal Sprint H925 - Safety

TM®

Perform only the routine maintenance procedures referred to

in these instructions.

Do not attempt to service or repair the laminator.

Unplug the unit and contact an authorized GBC service representative

for any required repairs if one or more of the following has occurred:

• The power supply cord or attachment plug is damaged.

• Liquid has been spilled into the laminator.

• The laminator is malfunctioning after being mishandled.

• The laminator does not operate as described in these instructions.

WARNING: THIS IS NOT A TOY - DO NOT ALLOW CHILDREN

TO OPERATE THIS LAMINATOR!

Installation

• Shipping damage should be brought to the immediate attention of

the delivering carrier.

• Place the laminator on a stable at surface capable of supporting

110 lbs/50 kg. The surface should be at least 30" high to assure

comfortable positioning during operation. All four rubber feet should

be on the supporting surface.

• Connect power cord to an appropriate power source. Avoid

connecting other equipment to the same branch circuit to which

the laminator is connected as this may cause nuisance tripping

of the circuit breaker or blown fuses.

• Position laminator to allow documents to exit freely.

• If laminating letter/A4 size documents, open exit tray to fully

extended position. When laminating any media that is longer

than letter/A4 in the landscape orientation – the exit tray MUST be

folded back into the machine. Failure to do so will result in a jam

caused by the finished media not having enough room to clear the

rollers once laminated.

• Install this laminator where the ambient temperature is at least

72°F/22°C.

Caring for the H925 Laminator

The only maintenance required by the operator is to periodically clean the heat

shoes. This should only be done when changing film rolls, please see page 7

steps 1,2, & 3. The following procedure will help keep the heat shoes free of

adhesive that has been deposited along the edge of the laminating film.

CAUTION: THE FOLLOWING PROCEDURE IS PERFORMED

WHILE THE LAMINATOR IS HOT. USE EXTREME CAUTION.

WARNING: Do not apply cleaning fluids or solvents

to the rollers.

WARNING: Do not attempt to laminate adhesives

marked ‘Flammable’.

1

Preheat the laminator using the heat button.

Clean the top and bottom heat shoes with a soft cloth.

2

Follow the procedure on page 7, steps 4,5,6 and 7.

3

NOTE: Do not use metal scouring pads to clean the heat shoes!

WARNING: Do not laminate glitter and/or metallic items.

Damage to the rollers may result.

Page 4

6

7

STEP 1

Adjust side

guides and place

document(s) in

feeder.

Side

Guides

STEP 5

Laminated

document(s) will

stack in exit tray.

Lamination will

stop when job is

complete*.

Start Stop

3 mil / 75 mic 5 mil / 125 mic

STEP 2

Press start and

lamination will

begin after warm

up. (See page 13

for additional

information).

Start Stop

3 mil / 75 mic 5 mil / 125 mic

STEP 4

Machine ready,

lamination in

process.

(Power LED)

Start Stop

3 mil / 75 mic 5 mil / 125 mic

STEP 3

Ready LED

will flash during

process warmup.

At the beginning

of each job, first

output will be film

only as film aligns to

edge of document.

(Ready LED)

For optimal laminator performance, see “Tips” page 15.

HeatSeal Sprint H925 - Operation

TM®

*First output will be film only as film aligns to leading edge of document.

If possible, always load film before running completely out.

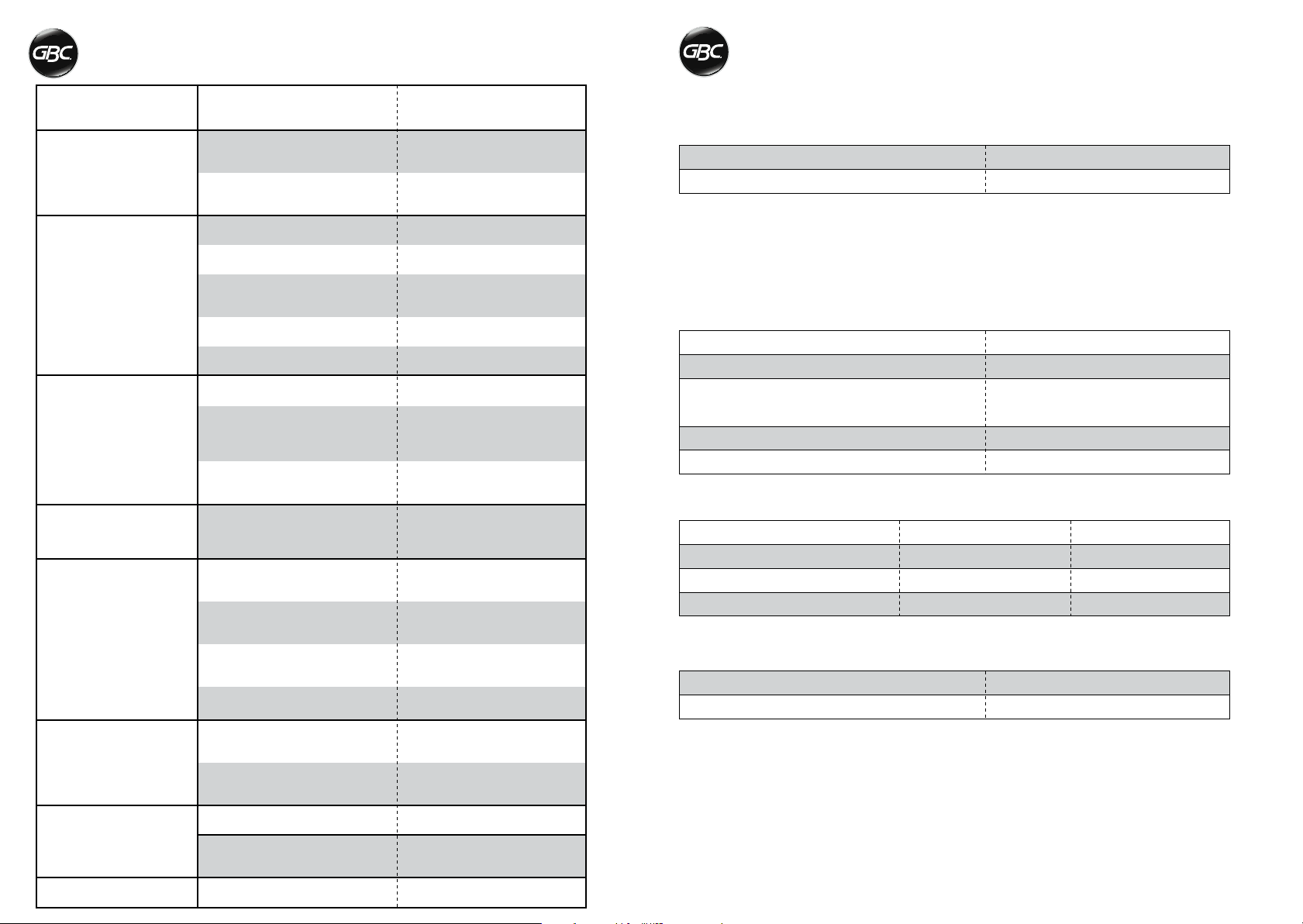

STEP 1

Cut laminating

film as indicated

in diagram at left.

If film is not

present see next

page.

STEP 4

Insert new film,

overlap film on

heat shoe.

Note: Match colors

of film core ends to

EZload levers.

STEP 5

Insert and lock

idler bar assembly,

then close 4

EZload levers.

STEP 6

Press feed switch

(forward) and

hold until

wrinkle-free

lamination.

Close top.

STEP 2

Open all 4 EZload

levers and

remove film.

STEP 3

Remove idler bar

assembly, then

press “Heat”

button. Ready

LED will flash

during warmup.

Heat

Button

Start Stop

3 mil / 75 mic 5 mil / 125 mic

STEP 7

Select film

thickness.

(Film Select)

HeatSeal Sprint H925 - Load Film

TM®

Page 5

8

9

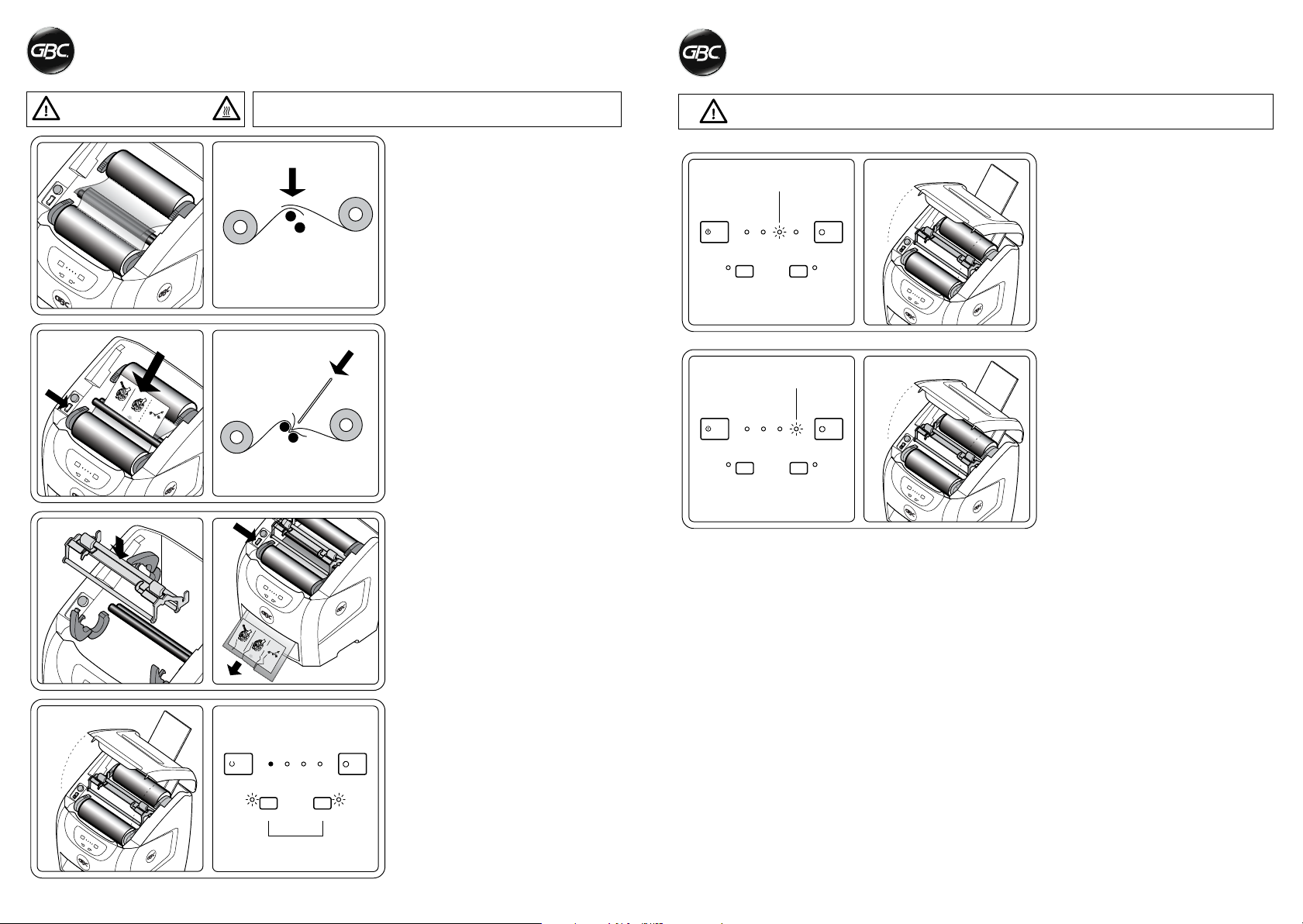

STEP 1

First, complete steps 2, 3 and 4

from “Load Film” page 7. Close 4

EZload levers.

STEP 2

Press Feed switch (forward) and

insert the threading card (supplied

with EZload film) as shown. Insert

card with slight force through film

rollers.

STEP 3

Insert idler bar assembly. Continue

pressing feed switch and wait for

clear, wrinkle-free lamination.

STEP 4

Close top cover, select film

thickness.

Start Stop

3 mil / 75 mic 5 mil / 125 mic

(Film Select)

Use instructions below to load new film if completely empty.Caution, hot surfaces.

HeatSeal Sprint H925 - Load Film from Empty

TM®

TOP COVER ALERT

Top cover is open. Close the cover

and resume lamination.

LOW FILM ALERT

Open top cover and load new

film rolls. Refer to “Load Film”,

pg. 7 and 8.

Start Stop

3 mil / 75 mic 5 mil / 125 mic

Start Stop

3 mil / 75 mic 5 mil / 125 mic

(Alert LED)

(Low Film LED)

Do not take machine apart - No user servicable parts.

HeatSeal Sprint H925 - Alert Indicators

TM®

Page 6

10

11

Do not take machine apart - no user servicable parts.

JAM ERROR

A) Open covers

B) Locate film jam

C) Press heat button

Use feed switch (forward/reverse)

to clear jam. It may be necessary

to cut and remove film. (Take care

not to damage rollers when

cutting film).

If cutting is required, use feed

switch (forward / reverse) to

re-feed film through machine.

Jam

Jam

FEED JAM ERROR

Remove document(s) and any debris

from feed tray. Fan documents and

adjust size guides. Turn main power

button, located on the back of

machine, off and on again.

Press “Start” to resume*.

Start Stop

3 mil / 75 mic 5 mil / 125 mic

Start Stop

3 mil / 75 mic 5 mil / 125 mic

Start Stop

3 mil / 75 mic 5 mil / 125 mic

(Alert LED)

(Alert LED)

(Alert LED)

HeatSeal Sprint H925 - Error Indicators

TM®

* For additional information to optimize performance see page 15.

Lamination Direction

If possible, always load documents

in landscape format. Top and

bottom film border is always

0.25”/ 6mm, and side film borders

will vary depending on document

size.

For recommended max document

length, see specifications, pg. 14.

For best lamination results, avoid

irregular shapes as shown below.

Menu Size / A3

11” x 17”

Letter Size / A4

11” x 8.5”

Legal Size

8.5” x 14”

11”

17”

(279 mm x 432 mm)

(432 mm)

(279 mm)

(279 mm x 216 mm)

(216 mm x 356 mm)

(356 mm)

(216 mm)

(216 mm)

(279 mm)

11”

8.5”

8.5”

14”

Letter=0.25”

A4=4 mm

0.25”(6.35 mm)

11.5” (292 mm)

1.5” (3.8 cm)

HeatSeal Sprint H925 - Loading and

Document Orientation

TM®

Page 7

12

13

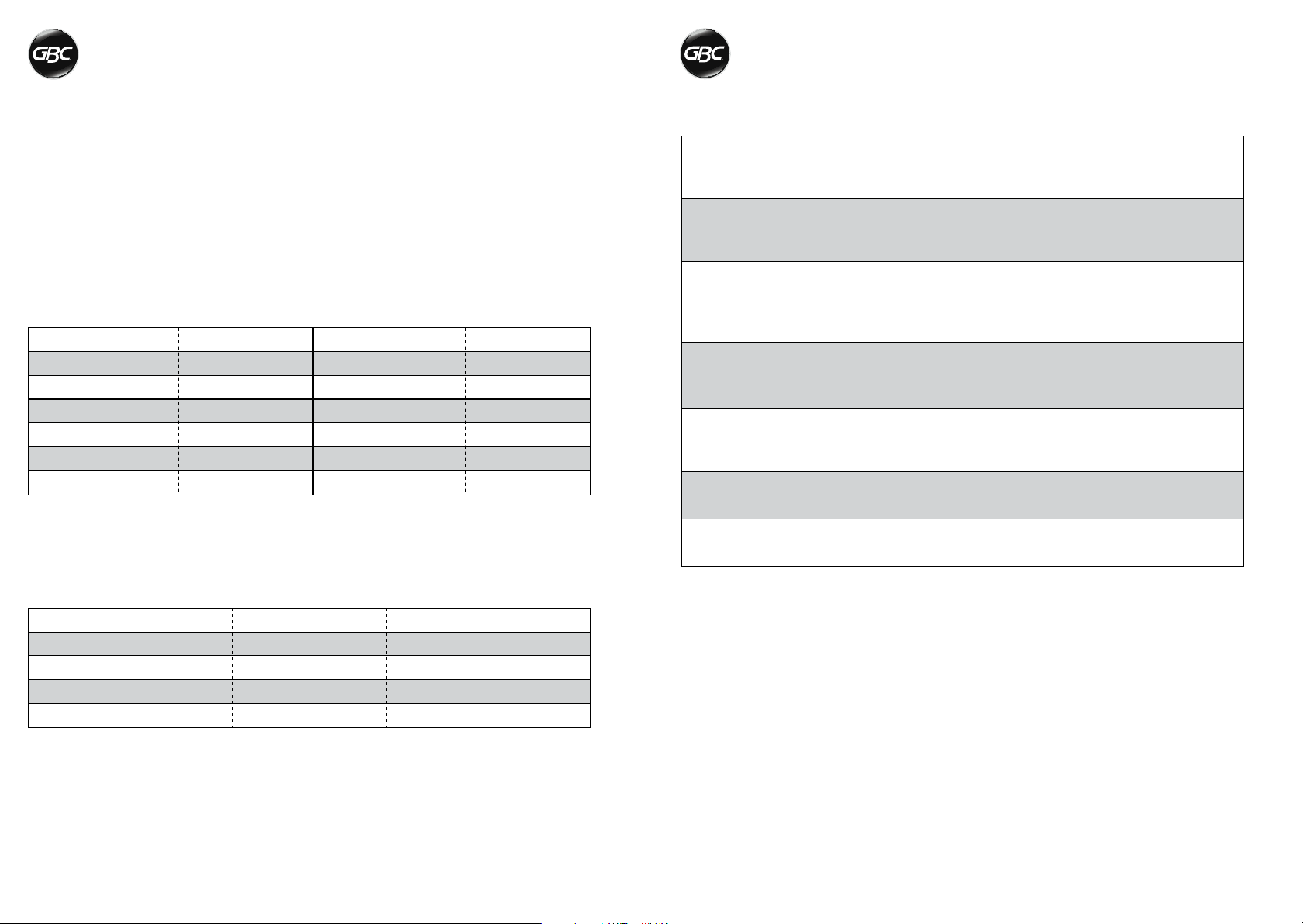

No power. Switch does

not illuminate when in

ON position.

Power cord is not plugged

into live power outlet

Circuit breaker has tripped

Plug into live outlet

Reset circuit breaker at

rear of machine

Machine does not

respond after

pressing standby

button

Faint lines across

the document

Cover is open Close cover

Ambient temperature is

below 72°F/22°C

Operate at ambient

temperatures at or

above 72°F/22°C

Feeder does not

feed document

Finished document

is skewed

Feeder picks multiple

documents

(add to existing)

Media not compatible

with feeder

Try different media

Print output not compatible

with feeder

Try different printer

Paper is not fully inserted

into feeder

Fully insert paper into

feeder

Sever paper curl Ensure paper is flat

Paper curl is excessive Ensure paper is flat

Static electricity on media,

or media is stuck together

Fan paper and replace

in feeder

Media is too smooth or slick Feed one at a time or

change media type

Paper side guides are not

adjusted squarely

Adjust paper side guides

to paper size

Cloudy lamination. Wavy

lamination. Unsatisfactory

adhesion to media.

Incorrect film settings,

insufficient heat

Verify and select correct

setting

Incorrect film setting Select correct film setting

EZload levers not closedWrinkles in document Close EZload levers

Low line voltage Ensure correct voltage

is available

No paper in feeder Insert paper

Main power switched off Turn on power

Low film Load new film

Idler bar assembly

not latched

Latch idler bar levers

SYMPTOMS POSSIBLE CAUSE CORRECTIVE ACTION

HeatSeal Sprint H925 - Troubleshooting

TM®

3 mil / 75 mic Max 2 minutes from cold

5 mil / 125 mic Max 2 minutes from cold

2. Speed

A) The machine throughput speed is 31” (787.4mm) per minute

B) Equivalent to 4 Letter or A4 documents per minute

C) 25 Letter or A4 sheets take approximately 7 minutes

6. Feeder capacity

A) Maximum of 25 sheets at 20 lbs - 75 gsm

7. Machine weight

A) In box 85 lbs - 38.6 kg

B) Out of box 70 lbs - 32 kg

9. Electrical Specifications

A) 120v @ 60Hz, 7.5A

B) 230v, @ 50Hz, 4A

C) 100v, @ 50Hz/60Hz, 8.5A

8. Dimensions (with exit tray open)

19” Wide x 31” High x 27” Deep

(483 mm Wide x 787 mm High x 686 mm Deep)

Max paper weight 80 lbs cover - 216 gsm

Min paper weight 20 lbs - 75 gsm

Max paper width

12” film, 11.6” - 295 mm

11.5” film, 11” - 279 mm

Min paper width 6” - 152 mm

Max paper length 48” - 1219 mm

3 . Paper sizes and weights

A4 paper (side border) 12” - 305 mm wide film

A4 paper (top & bottom border) 12” - 305 mm wide film

Letter paper (side border) 11.5” - 292 mm wide film

Letter paper (top & bottom border) 11.5” - 292 mm wide film

0.15” - 4 mm

0.25” - 6 mm

0.25” - 6 mm

0.25” - 6 mm

4 . Border sizes

3 mil / 75 mic

5 mil / 125 mic

Flexible

Semi Rigid

5. Film thickness

1. Warm-up time

Note: If machine is warm, the warm up times are reduced. Standby mode is

activated after 30 minutes of non-use. To resume, press “Start” button.

HeatSeal Sprint H925 - Specifications

TM®

Page 8

14

15

HeatSeal Sprint H925 - Lamination Tips

for Optimum Performance

TM®

Selection of media/paper requirements

The following is a guide to selecting the proper paper for this unit to perform at an optimum level.

Before laminating important or unique documents always run a test document through the

laminator using a similar media. If you find that your printed media is not compatible with the

H925, try a different media and/or a different print engine.

* Certain finishes (levels of gloss), weights and ink compositions may require the user to feed

single sheets into the laminator rather than stack loading.

Size & finish/weight

Size: The minimum width that can be fed through the H925 is 6” or 152 mm. Standard paper

sizes that will automatically feed into the laminator are as follows: (leading edge into machine

is indicated in bold)

Finish/weight: As stated above, even standard media can change from time to time due to

circumstances that cannot be controlled by GBC. It is always recommended that the user

experiment with the media prior to loading a full run into the feed tray. The media range that will

optimize performance of the feeder when stack loading is as follows*:

Type

Letter

Legal

Menu

Size

11” x 8.5”

8.5” x 14”

11” x 17”

Half-letter 8.5” x 5.5”

Executive 10.5” x 7.25”

Government legal 8.5” x 13

Type

Government letter

A4

A5

Size

10.5” x 8.5”

297 x 210 mm

210 x 148 mm

B5 250 x 176 mm

F4 210 x 330 mm

Media

Standard copy/bond paper

Cover stock

Index stock

Minimum Weight

20lb / 75gsm

28lb / 75gsm

42lb / 75gsm

Maximum Weight

53lb / 203gsm

80lb / 216gsm

110lb / 203gsm

Porous photo paper 20lb / 75gsm Up to 50lb / 200gsm

Media such as double sided printed output, designer papers, card stocks, cover stocks, high

gloss photo papers, glossy photo cards and others with specialized coatings should be fed into

the laminator one sheet at a time to avoid mis-feeding or jamming the feeder mechanism.

HeatSeal Sprint H925 - Lamination Tips

for Optimum Performance

TM®

IMPORTANT: When laminating any media that is longer than letter/A4 in the landscape orientation,

the exit tray MUST be folded back into the machine. Failure to do so will result in a jam caused by

the finished media not having enough room to clear the rollers once laminated.

The exit tray was designed to only stack letter/A4 and smaller media in the landscape orientation.

Capacity of this tray varies based on overall thickness of media and film mil used. GBC recommends

emptying the exit tray frequently.

Loading

Exit tray

Before loading prints, fan sheets on all four sides. This creates a small layer of air between the

sheets that will help the feeder mechanism by eliminating any blocking that may have occurred

while the sheets were drying or while in storage.

To maximize the film usage for letter/A4 stock, it is best to load the prints into the feeder tray

with landscape orientation. For legal/A3 stock, the media must be loaded with portrait

orientation.

If your document is severely curled, or warped, it may pose a feeding problems for the H925

feeder. To minimize this potential issue you can try to eliminate the curl by rolling the media

stack in reverse prior to loading the document. You may also try loading the document upside

down or backwards.

When loading a stack of prints, it is best to square off the bottom edge of the stack by lightly

tapping the entire stack on a flat surface. Loading the feeder tray with the bottom of the stack

squared will help eliminate mis-feeds.

Ensure the paper side guides on the document feed tray are properly spaced to rest against the

edges of the paper without compressing the stack. If paper side guides are not against the

media, sheets can skew during lamination.

Once media is loaded into the feeder tray, the lamination run must conclude before adding

more prints. DO NOT add more pages to the feed tray while lamination job is in process.

The film rolls will laminate more total pages per refill if the maximum width is utilized when

loading media into the feed tray.

Page 9

16

17

HeatSeal Sprint H925 - Lamination Tips

for Optimum Performance

TM®

Minimizing potential heat lines on media

Depending on the ambient temperature, media type and film thickness the HeatSeal Sprint H925

may produce a heat line on the initial 3 to 5 sheets of output. Follow the below recommendation

to minimize the likelihood of experiencing heat lines:

Recommended morning start-up routine:

Turn the main power switch to the “ON” position.

Additional tips:

Film thickness can make a difference and 1.7 mil film may produce more of a heat line than

3 mil or 5 mil films.

If your machine has not been used for several hours, it may be “cold” again and the morning

start-up routine is recommended to be repeated.

Media and inks can make a difference and darker images or glossy papers may produce more

of a heat line than other medias.

For best results, do not operate this machine in an environment with an ambient temperature

less than 72°F/22°C.

Operating at a lower than normal room temperature, prevents the nip rollers from reaching the proper laminating

temperature, resulting in faint heat lines across the finished sheet.

Load two or three sheets of plain paper into the feed tray.

Press the start button.

Test one single sheet of your special media.

Allow the machine to run the start-up sheets and stabilize its temperature for at least 5 minutes.

If required, repeat steps 4 and 5 again until the heat line is no longer visible.

HeatSeal Sprint H925 - Lamination Tips

for Optimum Performance

TM®

IMPORTANT: When laminating media that has been 3 hole punched, load that media in with the

holes down into the machine first. Failure to do so will result in mis-cut sheets due to the sensor

picking up a hole as the end of the page.

The composition and quality of any type of media/paper can change at any time. GBC cannot specify nor

guarantee the performance of any specific brand, type or manufacturer of media/paper. Even standard media

can change from time to time due to circumstances that cannot be controlled by GBC.

Successful lamination tips:

Prior to use, media should be allowed to acclimate at least 48 hours in the environment in which

it will be used. Optimum storage and operating environment is between 70°-80°F with 50%

relative humidity.

Upon completion of a lamination run, do not leave unlaminated media in the feeder tray.

Media should be removed and stored in a way that it is stacked flat and in the proper

environmental conditions.

Always ensure that the media has the straightest possible path into the laminator. If laminating

a longer length of media, it is not recommended that the media is draped over the back of the

feeder tray, as this may cause the feeder to not pick the sheets properly.

Allow ink on printed media to properly dry prior to lamination.

DO NOT load any type of media that is creased, folded or not square into the feeder as this

may cause the unit to jam.

Page 10

18

19

Service

Limited One (1) Year Warranty

ACCO Brands USA

300 Tower Parkway,

Lincolnshire, IL 60069-3640

(800) 541-0094

ACCO Brands Canada

5 Precidio Court

Brampton, ON L6S-6B7

(800) 263-1063

ACCO Mexicana

Neptuno #43, Colonia Nueva Industrial Vallejo

Delagacion Gustavo A. Madero, CP 07700

México, DF. (55) 1500-5578

ACCO Brands USA LLC, 300 Tower Parkway, Lincolnshire, IL 60069 (in Canada, ACCO Brands Canada Inc.,

5 Precidio Court, Brampton, ON L6S-6B7; and in Mexico, ACCO Mexicana, S.A. de C.V. Av. Circuito Industrial Norte

#6 Parque Industrial Lerma 52000, Lerma Edo. de México) (each, respectively, “ACCO Brands”) warrants to the

original purchaser that this ACCO Brands product is free from defects in workmanship and material under normal

use and service for 1 year limited warranty after purchase.

ACCO Brands’ obligation under this warranty is limited to replacement or repair, at ACCO Brands’ option, of any

warranted part found defective by ACCO Brands without charge for material or labor. Any replacement, at ACCO

Brands’ option, may be the same product or a substantially similar product that may contain remanufactured or

refurbished parts. This warranty shall be void in the following circumstances:

(i) if the product has been misused,

(ii) if the product has been damaged by negligence or accident, or

(iii) if the product has been altered by anyone other than ACCO Brands or ACCO Brands’ authorized agents.

For warranty execution, please call 1-800-541-0094 in the USA/1-800-268-3447 in Canada/1-800-759-6825 in

Mexico or go to www.gbc.com.

TO THE EXTENT ALLOWED BY APPLICABLE LAW, THIS WARRANTY IS IN LIEU OF ALL OTHER EXPRESSED

WARRANTIES. REPRESENTATIONS OR PROMISES INCONSISTENT WITH OR IN ADDITION TO THIS WARRANTY ARE

UNAUTHORIZED AND SHALL NOT BE BINDING ON ACCO BRANDS. TO THE EXTENT PERMITTED BY APPLICABLE

LAWS, ANY IMPLIED WARRANTIES (IF APPLICABLE) ARE LIMITED IN DURATION TO THE DURATION OF THIS

WARRANT. SOME STATES AND JURISDICTIONS DO NOT ALLOW LIMITATIONS ON HOW LONG AN IMPLIED

WARRANTY LASTS, SO THE ABOVE LIMITATION MAY NOT APPLY TO YOU. TO THE EXTENT PERMITTED BY

APPLICABLE LAW, IN NO EVENT SHALL ACCO BRANDS BE LIABLE FOR ANY SPECIAL, INCIDENTAL, PUNITIVE,

EXEMPLARY, CONSEQUENTIAL OR SIMILAR DAMAGES, WHETHER OR NOT FORSEEABLE. SOME STATES AND

JURISDICTIONS DO NOT ALLOW THE EXCLUSION OR LIMITATION OF SPECIAL, INCIDENTAL, PUNITIVE,

EXEMPLARY, CONSEQUENTIAL, OR SIMILAR DAMAGES, SO THE ABOVE EXCLUSION OR LIMITATION MAY NOT

APPLY TO YOU.

To the extent permitted by law, this warranty is not transferable and will automatically terminate if the original

product purchaser sells or otherwise disposes of the product.

This warranty gives you specific legal rights. Other rights, which vary from jurisdiction to jurisdiction, may exist.

In addition some jurisdictions do not allow (i) the exclusion of certain warranties, (ii) limitations on how long an

implied warranty lasts and/or (iii) the exclusion or limitation of certain types of costs and/or damages, so the

above limitations may not apply.

Purchase information

Register this product online at: www.gbc.com.

The model and serial numbers are recorded on the bottom of the machine.

Serial number:

Model number:

Purchase date:

Purchased from:

FCC CLASS B NOTICE

Note: This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to

part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference in a

residential installation. This equipment generates, uses and can radiate radio frequency energy and, if not installed and

used in accordance with the instructions, may cause harmful interference to radio communications. However, there is no

guarantee that interference will not occur in a particular installation. If this equipment does cause harmful interference to

radio or television reception, which can be determined by turning the equipment off and on, the user is encouraged to try

to correct the interference by one or more of the following measures:

Reorient or relocate the receiving antenna.•

Increase the separation between the equipment and receiver.•

Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.•

Consult the dealer or an experienced radio/TV technician for help.•

CANADA CLASS B NOTICE

This Class B digital apparatus complies with Canadian ICES-003

MODIFICATIONS

Any modifications made to this device may void the authority granted to the user by the FCC and/or by Industry Canada to

operate this equipment.

Made in China.

GBC and HeatSeal are registered trademarks of

General Binding Corporation.

ACCO is a registered trademark of ACCO Brands.

Copyright © 2010 ACCO Brands. All rights reserved.

Issue 2 July 2010

Page 11

20

21

Importantes instructions de sécurité Importantes mesures de protection

HeatSeal Sprint H925 - Sécurité

TM®

HeatSeal Sprint H925 - Sécurité

TM®

POUR GBC, VOTRE SÉCURITÉ ET CELLE DES AUTRES EST UNE

PRÉOCCUPATION DE PREMIER PLAN. CE MANUEL ET CE PRODUIT

COMPORTENT DES MESSAGES DE SÉCURITÉ IMPORTANTS. VEUILLEZ

LIRE CES MESSAGES ATTENTIVEMENT.

CHACUN DES MESSAGES DE SÉCURITÉ DE CE MANUEL

D’INSTRUCTIONS EST PRÉCÉDÉ D’UN SYMBOLE DE

MISE EN GARDE DE SÉCURITÉ.

D’IMPORTANTS MESSAGES DE SÉCURITÉ FIGURENT SUR CE

PRODUIT. VEUILLEZ LIRE ATTENTIVEMENT CES MESSAGES ET CES

INSTRUCTIONS. CONSERVER CES INSTRUCTIONS POUR UTILISATION

ULTÉRIEURE ÉVENTUELLE.

LES MISES EN GARDES SUIVANTES FIGURENT SUR CE PRODUIT.

DANGER

Risque de choc électrique. Ne

pas ouvrir. Ne contient aucune

pièce pouvant être réparée ou

remplacée par l’utilisateur. Ne

confier la réparation qu’à du

personnel qualifié.

Ce message de sécurité signifie que vous risquez de vous blesser

gravement ou d’être tué si vous ouvrez le produit et que vous vous

exposez à une tension extrêmement dangereuse

PRUDENCE

Surface

très

chaude.

Ne pas toucher les sabots chauffants avant qu’ils ne soient refroidis.

PRUDENCE

LAME

TRANCHANTE.

Tenir les mains et les

doigts à distance.

Ce message de sécurité signifie que vous risquez de vous couper si

vous n’êtes pas prudent.

MISE EN GARDE : CHACUN DES MESSAGES DE SÉCURITÉ

DE CE MANUEL D’INSTRUCTIONS EST PRÉCÉDÉ D’UN

SYMBOLE DE MISE EN GARDE DE SÉCURITÉ.

MISE EN GARDE : NE PAS ESSAYER DE PROCÉDER À

LA MAINTENANCE DE CETTE PLASTIFIEUSE OU DE LA

RÉPARER.

MISE EN GARDE : LIRE ENTIÈREMENT CES INSTRUCTIONS

AVANT DE RACCORDER CETTE PLASTIFIEUSE À UNE PRISE

ÉLECTRIQUE OU TENTER DE LA FAIRE FONCTIONNER.

CONSERVER CES INSTRUCTIONS À PORTÉE DE LA MAIN

AFIN DE POUVOIR LES CONSULTER ULTÉRIEUREMENT.

MISE EN GARDE : POUR VOTRE PROPRE SÉCURITÉ,

NE METTEZ PAS LA PLASTIFIEUSE SOUS TENSION

ET NE TENTEZ PAS DE LA FAIRE FONCTIONNER TANT

QUE VOUS N’AVEZ PAS LU ENTIÈREMENT CES

INSTRUCTIONS. CONSERVER CE MODE D’EMPLOI À

PORTÉE DE LA MAIN AFIN DE POUVOIR LE CONSULTER

ULTÉRIEUREMENT. AFIN D’ÉVITER TOUTE BLESSURE,

SUIVRE LES PRÉCAUTIONS DE SÉCURITÉ DE BASE

SUIVANTES DURANT L’INSTALLATION ET L’UTILISATION

DE CETTE PLASTIFIEUSE.

Mesures de protection générales

• N’utiliser cette plastieuse qu’aux ns prévues, conformément

aux spécifications indiquées dans le mode d’emploi.

• Éloigner les mains, cheveux longs, vêtements amples et tout

objet tel que colliers ou cravates de la partie frontale des rouleaux

d’entraînement afin d’éviter qu’ils ne se coincent ou s’emmêlent.

• Éviter tout contact avec les sabots chauffants lorsque la

plastifieuse est en marche ou peu après sa mise hors tension.

Les sabots chauffants peuvent atteindre des températures allant

jusqu’à 149 °C (300 °F).

• Tenir les mains et les doigts à distance du trajet emprunté par la

lame très tranchante du dispositif de coupe se trouvant à l’endroit

de sortie du film.

• Placez la plastieuse sur un chariot, une table ou un sup

port stable pouvant supporter un poids d’au moins 50 kg/110 lb.

Une surface instable pourrait causer la chute de la plastifieuse et

entraîner des blessures sérieuses. Évitez les arrêts brusques, la

force excessive et les surfaces de plancher inégales lorsque

vous déplacez la plastifieuse sur un chariot ou un support.

• Ne pas essayer de contourner ou d’enlever les dispositifs de

sécurité électriques et mécaniques tels que les systèmes de ver

rouillage, blindages et protections.

• Ne pas insérer d’objets ne convenant pas à la plastication.

• Ne pas exposer la plastieuse aux liquides.

Mesures de protection électrique

• Cette plastieuse doit être raccordée à une source d’alimentation

correspondant au voltage spécifié sur la plaque du numéro de

série située à l’arrière de l’appareil.

• Débrancher la plastieuse avant de le déplacer ou lorsqu’elle

n’est pas utilisé pendant une longue période de temps.

• Ne pas utiliser cette plastieuse avec un cordon d’alimentation

ou une fiche endommagé(e).

• Ne pas surcharger les prises électriques au-delà de leur capacité;

un incendie ou un choc électrique pourrait en résulter.

• Ne pas modier la che de l’appareil. Elle est conçue pour rece

voir l’alimentation électrique adéquate.

• L’appareil est conçu pour utilisation à l’intérieur uniquement.

PRUDENCE: La prise doit être située tout près de

l’équipement et être facile d’accès. Ne pas utiliser de rallonge.

• Débrancher la che de raccordement de la prise de courant à

laquelle elle est connectée et garder avec vous le cordon

d’alimentation lorsque vous déplacez la plastifieuse.

• Ne pas faire fonctionner la plastieuse à l’aide d’un cordon

d’alimentation ou d’une fiche de raccordement endommagé(e),

encas de défectuosité ou si elle est endommagée. Contacter un

représentant GBC agréé pour toute assistance.

Entretien

Effectuer uniquement les procédures de maintenance habituelles

dont il est fait mention dans les présentes instructions.

Ne pas essayer de procéder à l’entretien de cette

plastifieuse ou de la réparer vous-même.

Débrancher l’appareil et contacter le service technique agréé par GBC

pour toute réparation nécessaire si l’un des problèmes suivants se

produit :

• Le cordon ou la che de raccordement est endommagé(e).

• Un liquide s’est renversé dans la plastieuse.

• La plastieuse ne fonctionne pas correctement suite à une

manipulation inadéquate.

• La plastieuse ne fonctionne pas tel que décrit dans ces

instructions.

MISE EN GARDE : CECI N’EST PAS UN JOUET.NE PAS LAISSER UN ENFANT FAIRE FONCTIONNER

CETTE PLASTIFIEUSE!

Installation

• Tout dommage occasionné en cours d’expédition doit être immédiate

ment signalé au transporteur.

• Placez la plastieuse sur une surface plate et stable pouvant supporter

un poids de 50 kg/110 lb. La surface doit se trouver à une hauteur

d’au moins 76 cm (30 po) pour garantir le poids de 50 kg/110 lb. La

surface doit se trouver à une hauteur d’au moins 76 cm (30 po) pour

garantir un positionnement confortable pendant l’utilisation. Les quatre

pieds en caoutchouc doivent reposer sur la surface d’appui.

• Brancher l’appareil à une source d’alimentation adéquate.

Éviter de connecter tout autre équipement au circuit de branchement

auquel la plastifieuse est raccordée car cela risque de déclencher le

disjoncteur ou de brûler les fusibles.

Entretien de la plastifieuse H-925

La seule tâche d’entretien devant être exécutée par l’utilisateur est le

nettoyage périodique des sabots chauffants. Cette opération doit être

effectuée lors du changement des rouleaux (voir page 7, étapes 1, 2

et 3.) La procédure suivante permet d’éviter que la colle qui aurait pu

se fixer sur les bords du film de plastification ne se dépose sur les

sabots chauffants.

PRUDENCE : LA PROCÉDURE SUIVANTE EST EFFECTUÉE

ALORS QUE LA PLASTIFIEUSE EST CHAUDE. VEUILLEZ

USER DE LA PLUS GRANDE PRUDENCE.

MISE EN GARDE : Ne pas appliquer de liquides

nettoyants ou de solvants sur les rouleaux.

MISE EN GARDE : Ne pas essayer de plastifier

des adhésifs portant la mention « Inflammable ».

• Positionnez la plastieuse de façon à ce que les documents puissent

en sortir librement.

• Si vous plastiez des documents de format lettre/A4, ouvrez comp-

lètement le plateau de sortie. Lorsque vous plastifiez n’importe quel

média plus long que le format lettre/A4 et ce, dans l’orientation

paysage – le plateau de sortie DOIT être rabattu dans la machine.

Si vous ne respectez pas cette consigne, un blocage pourrait se

produire par manque d’espace pour libérer les rouleaux, une fois la

plastification terminée.

• Installez cette plastieuse dans un endroit où la température

ambiante est d’au moins 22 °C/72 °F.

1

Faites préchauffer la plastifieuse à l’aide du bouton de

préchauffage.

2

Nettoyez les parties supérieure et inférieure des sabots

chauffants à l’aide d’un chiffon doux.

3

Suivez les instructions de la page 21, étapes 4, 5, 6 et 7.

REMARQUE: Ne pas utiliser de tampons de récurage métallique

pour nettoyer les sabots chauffants!

MISE EN GARDE: Ne plastifier aucun article scintillant ou

métallique. Cela risquerait d’endommager

les rouleaux.

Page 12

22

23

ÉTAPE 2

Ouvrez complètement le plateau de

sortie pour une

opération normale.

Fermez le plateau

si vous souhaitez

plastifier des

bannières ou

feuilles plus

longues.

ÉTAPE 1

Mettez l’appareil

en marche en

appuyant sur la

touche située à

l’arrière. Le voyant

DEL d’alimentation

s’allume alors sur

le panneau de

commande à

l’avant.

ÉTAPE 4

Réglez les guides

latéraux en fonction

du format des

documents.

ÉTAPE 3

Insérez le plateau

d’alimentation et

fixez-le en position.

La plastifieuse est fournie avec une pellicule de 3 mil/75 mic

préinstallée, faisant environ 9 m/30 pi de longueur.

Guides

latéraux

HeatSeal Sprint H925 - Préparation

TM®

Plateau

Pour bénéficier d’un niveau de performance optimal lors de l’utilisation de

votre plastifieuse, consultez la section « Conseils » à la page 15.

ÉTAPE 1

Réglez les guides

latéraux et placez

le(s) document(s)

dans le dispositif

d’alimentation.

Guides

latéraux

ÉTAPE 5

Les documents

plastifiés

s’empilent dans le

plateau de sortie.

La plastification

s’arrête lorsque

tous les

documents sont

plastifiés*.

Start Stop

3 mil / 75 mic 5 mil / 125 mic

ÉTAPE 2

Appuyez sur

la touche de

démarrage et

la plastification

commencera

après le

préchauffage.

Start Stop

3 mil / 75 mic 5 mil / 125 mic

ÉTAPE 4

L’appareil est prêt

et la plastification

est en cours.

(Voyant DEL d’alimentation)

Start Stop

3 mil / 75 mic 5 mil / 125 mic

ÉTAPE 3

Le voyant DEL

d’état « Prêt »

clignote pendant

la procédure de

préchauffage.

(Ready LED)

HeatSeal Sprint H925 - Fonctionnement

TM®

*La pellicule apparaît d’abord seule à la sortie car elle doit s’aligner à la bordure du document.

Page 13

24

25

ÉTAPE 1

Coupez la pellicule

de plastification tel

qu’indiqué dans le

schéma de gauche.

Si aucune pellicule

n’est présente,

consultez la page

suivante.

ÉTAPE 4

Insérez la nouvelle pellicule, puis

superposez les pellicules sur le sabot de

chauffage. Remarque : Faites correspondre les couleurs des extrémités du

rouleau de pellicule avec celles des

leviers de chargement EZload.

ÉTAPE 5

Insérez

l’assemblage de

barre de transfert et

verrouillez-le, puis

fermez les 4 leviers

de chargement

EZload.

ÉTAPE 6

Appuyez sur

l’interrupteur

d’alimentation

(vers l’avant) et

maintenez-le

enfoncé jusqu’à

ce que la pellicule

ne soit plus plissée.

Fermez le couvercle

supérieur.

ÉTAPE 2

Ouvrez les 4

leviers de

chargement

« EZ » et retirez

la pellicule.

Si possible, chargez toujours la pellicule avant que l’appareil ne soit

complètement vide.

ÉTAPE 3

Retirez

l’assemblage de

barre de transfert,

puis appuyez sur

la touche de

chauffage. Le

voyant DEL d’état

« Prêt » clignote

pendant le

préchauffage.

Touche de

chauffage

Start Stop

3 mil / 75 mic 5 mil / 125 mic

ÉTAPE 7

Sélectionnez

l’épaisseur de

pellicule.

(Sélection de pellicule)

HeatSeal Sprint H925 - Chargement de pellicule

TM®

ÉTAPE 1

Commencez par suivre les

étapes 2, 3 et 4 de la procédure

« Chargement de pellicule »

présentée à la page 7.

Fermez les 4 leviers EZload.

ÉTAPE 2

Appuyez sur l’interrupteur

d’alimentation (vers l’avant) et

insérez la carte d’enfilage (fournie

avec la pellicule EZload), tel

qu’illustré. Insérez la carte en la

forçant légèrement entre les

rouleaux de pellicule.

ÉTAPE 3

Insérez l’assemblage de barre de

transfert. Continuez d’appuyer sur

l’interrupteur d’alimentation

jusqu’à ce que la pellicule ne soit

plus plissée.

ÉTAPE 4

Fermez le couvercle supérieur,

puis sélectionnez l’épaisseur

de la pellicule.

Start Stop

3 mil / 75 mic 5 mil / 125 mic

(Film Select)

HeatSeal Sprint H925 - Chargement de pellicule

lorsque vide

TM®

Suivez les instructions ci-dessous pour charger la

nouvelle pellicule si l’appareil est complètement vide.

Attention,

surfaces chaudes.

Page 14

26

27

ALERTE DU COUVERCLE

SUPÉRIEUR

Le couvercle supérieur est

ouvert. Fermez-le et reprenez

la plastification.

Ne tentez pas de démonter cet appareil – Aucune pièce ne peut être

réparée par l’utilisateur.

ALERTE DE FAIBLE QUANTITÉ

DE PELLICULE

Ouvrez le couvercle supérieur et

chargez un nouveau rouleau de

pellicule. Reportez-vous à la section

« Chargement de pellicule » aux

pages 7 et 8.

Start Stop

3 mil / 75 mic 5 mil / 125 mic

Start Stop

3 mil / 75 mic 5 mil / 125 mic

(Voyant DEL d’alerte)

(Voyant DEL de faible

quantité de pellicule)

HeatSeal Sprint H925 - Voyants d’alerte

TM®

Ne tentez pas de démonter cet appareil – Aucune pièce ne peut être

réparée par l’utilisateur.

ERREUR DE BOURRAGE

A) Ouvrez les couvercles.

B) Localisez le bourrage

de pellicule.

C) Appuyez sur la touche

de chauffage.

Appuyez sur l’interrupteur

d’alimentation

(vers l’avant/arrière) pour

dégager le bourrage. Il peut être

nécessaire de couper la pellicule

pour la retirer. (Assurez-vous d

e ne pas endommager les

rouleaux lorsque vous coupez

la pellicule.) S’il est .nécessaire

de couper la pellicule, appuyez

sur l’interrupteur d’alimentation

(vers l’avant/arrière) pour

réalimenter la pellicule dans

l’appareil.

Bourrage

Bourrage

ERREUR DE BOURRAGE LORS

DE L’ALIMENTATION

Retirez le(s) document(s) et tous les

débris du plateau d’alimentation.

Éventez les documents et réglez les

guides en fonction du format. Utilisez la

touche d’alimentation principale (située

à l’arrière) pour éteindre l’appareil et le

remettre en marche. Appuyez sur la

touche de démarrage « Start » pour

reprendre la plastification*.

Start Stop

3 mil / 75 mic 5 mil / 125 mic

Start Stop

3 mil / 75 mic 5 mil / 125 mic

Start Stop

3 mil / 75 mic 5 mil / 125 mic

(Voyant DEL d’alerte)

(Voyant DEL d’alerte)

(Voyant DEL d’alerte)

HeatSeal Sprint H925 - Voyants d’erreur

TM®

*Pour des informations supplémentaires permettant d’optimiser le niveau de performance, consultez la page 15.

Page 15

28

29

Direction de la plastification

Si possible, chargez toujours les

documents à l’horizontale. Les

bordures de pellicule supérieure

et inférieure mesurent toujours

0,64 cm (0,25 po) et les bordures

latérales sont en fonction du

format de document.

Pour connaître la longueur de

document maximale, consultez les

spécifications à la page 14.

Pour obtenir de meilleurs résultats

lors de la plastification, évitez

d’insérer des documents de forme

irrégulière, comme celui illustré

ci-dessous.

Format menu

27,9 cm x 43,2 cm

(11 po x 17 po) A3

Format lettre

27,9 cm x 21,6 cm

(11 po x 8,5 po) A4

Grand format

21,6 cm x 35,6 cm

(8,5 po x 14 po)

6 mm (0,25 po)

6 mm (0,25 po)

29,2 cm (11,5 po)

3,8 cm (1,5 po)

11”

17”

8.5”

14”

(431 mm)

(279 mm)

(279 mm)

(216 mm)

11”

8.5”

(216 mm)

(355 mm)

HeatSeal Sprint H925 - Chargement et

orientation du document

TM®

HeatSeal Sprint H925 - Dépannage

TM®

Absence d’alimentation.

L’interrupteur ne s’allume

pas lorsqu’il est en

position MARCHE.

Le cordon d’alimentation n’est

pas branché à une prise de

courant active.

Le disjoncteur s’est déclenché.

Branchez-le à une prise de

courant active.

Réenclenchez le disjoncteur à

l’arrière de l’appareil.

L’appareil demeure

inactif lorsque vous

appuyez sur la touche

du mode de veille.

Présence de lignes pâles

sur le document.

Le couvercle est ouvert. Fermez le couvercle.

La température ambiante est

inférieure à 22 °C/72 °F.

Utilisez l’appareil à une température ambiante d’au moins

22 °C/72 °F.

Le dispositif

d’alimentation ne

fonctionne pas.

Le document est

plastifié de biais.

Le dispositif d’alimentation

insère plusieurs documents

(en les ajoutant à l’existant).

Le document n’est pas

compatible avec le dispositif

d’alimentation.

Essayez avec un document

différent.

L’imprimé n’est pas compatible

avec le dispositif d’alimentation.

Essayez une imprimante

différente.

Le papier n’est pas inséré

complètement dans le dispositif

d’alimentation.

Insérez-le complètement dans

le dispositif d’alimentation.

Le papier est très gondolé. Assurez-vous d’utiliser un

papier plat.

Le papier est extrêmement

gondolé.

Assurez-vous d’utiliser un

papier plat.

Présence d’électricité statique

sur le document, ou documents

collés ensemble.

Éventez le papier et réinsérezle dans le dispositif d’alimentation.

Les documents sont trop lisses. Insérez-les un à la fois ou

changez de type de document.

Les guides papier ne sont pas

centrés.

Ajustez les guides papier au

format du papier.

Platt

gondolée. Adhésion insatisfaisante au document.

Réglages de pellicule inappropriés, chaleur insuffisante.

Vérifiez et sélectionnez un

réglage approprié.

Le réglage de pellicule est

incorrect.

Sélectionnez le réglage de

pellicule approprié.

Les leviers EZload ne sont pas

fermés.

Le document est plissé.

Fermez les leviers EZload.

Tension de ligne faible Assurez-vous qu’une tension

appropriée est disponible.

Aucun papier n’est disponible. Insérez le papier.

L’appareil est éteint Mettez l’appareil en marche.

Il commence à manquer de pellicule. Chargez une nouvelle pellicule.

L’assemblage de barre de

transfert n’est pas verrouillé.

Verrouillez les leviers de la

barre de transfert.

SYMPTÔMES CAUSE POSSIBLE ACTION CORRECTRICE

Page 16

30

31

HeatSeal Sprint H925 - Spécifications

TM®

3 mil / 75 mic 2 minutes max. à partir de l’état froid

5 mil / 125 mic 2 minutes max. à partir de l’état froid

2. Vitesse

A) La vitesse d’exécution de l’appareil est de 1 000 mm (39 po) par minute

B) Cela équivaut à 4 documents de format lettre ou A4 par minute

C) La plastification de 25 feuilles de format lettre ou A4 prend environ 7 minutes

6. Capacité d’alimentation

A) Maximum de 25 feuilles à 20 lb – 75 g/m²

7. Poids de l’appareil

A) Dans l’emballage 85 lb – 38,7 kg

B) Hors de l’emballage 70 lb – 32 kg

9. Spécifications électriques

A) 120 V, 60 Hz, 7,5 A

B) 230 V, 50 Hz, 4 A

C) 100 V, 50 Hz/60 Hz, 8,5 A

8. Dimensions (avec le plateau de sortie ouvert)

19 po (largeur) x 31 po (hauteur) x 27 po (profondeur)

(483 mm x 787 mm x 686 mm)

Poids de papier maximal Couverture de 80 lb – 216 g/m²

Poids de papier minimal 20 lb - 75 g/m²

Largeur de papier maximale

Pellicule de 12”, 11.6” - 297 mm

Pellicule de 11,5”, 11” - 280 mm

Largeur de papier minimale 6” - 152 mm

Longueur de papier maximale 48” - 1220 mm

3 . Formats et poids du papier

Papier A4 (bordure latérale) 12” - 305 mm wide film

Papier A4 (bordures supérieure et inférieure) 12” - 305 mm wide film

Papier lettre (bordure latérale) 11.5” - 292 mm wide film

Papier lettre (bordures supérieure et inférieure) 11.5” - 292 mm wide film

0.15” - 4 mm

0.25” - 6 mm

0.25” - 6 mm

0.25” - 6 mm

4 . Tailles de bordure

3 mil / 75 mic

5 mil / 125 mic

Flexible

Semi Rigide

5. Épaisseur de pellicule

1. Temps de préchauffage

Remarque : Le temps de préchauffage est réduit lorsque l’appareil

est chaud. Le mode de veille est activé après 30 minutes d’inutilisation.

Pour reprendre l’utilisation, appuyez sur la touche de démarrage « Start ».

HeatSeal Sprint H925 - Conseils de plastification

pour des performances optimales

TM®

Exigences pour la sélection du document/papier

Cette section vous indique comment sélectionner un papier approprié pour optimiser le niveau de

performance de cet appareil.

Avant de plastifier des documents importants ou uniques, effectuez toujours un test en utilisant un

document similaire. Si votre document imprimé n’est pas compatible avec la H925, essayez un

document différent et/ou une imprimante différente.

* Avec certains finis (niveaux de lustre), poids et compositions d’encre, il peut être nécessaire que

l’utilisateur insère les feuilles une à la fois dans la plastifieuse, plutôt qu’en chargeant une pile.

Format et fini/poids

Format: La largeur minimale des documents pouvant être insérés dans la H925 est 15,2 cm ou 6 po.

Les formats de papier standard qui seront alimentés automatiquement dans la plastifieuse sont indiqués

ci-dessous : (la bordure insérée en premier dans l’appareil est indiquée en caractères gras)

Fini/poids: Tel qu’indiqué ci-dessus, mêmes les supports standard peuvent changer de temps à autre en

raison de circonstances qui sont hors du contrôle de GBC. Il est toujours recommandé que l’utilisateur

fasse des tests avec le média avant de passer complètement le document dans le plateau d’alimentation.

Voici les poids de support qui permettent d’optimiser le niveau de performance du dispositif d’alimentation

lors du chargement d’une pile*:

Type

Lettre

Grand format

Menu

Format

11” x 8.5”

8.5” x 14”

11” x 17”

Demi-letter 8.5” x 5.5”

Bureau 10.5” x 7.25”

Grand format

gouvernemental

8.5” x 13

Type

Lettre gouvernemental

A4

A5

Format

10.5” x 8.5”

297 x 210 mm

210 x 148 mm

B5 257 x 182 mm

F4 210 x 330 mm

Support

Papier bond/pour copie standard

Papier pour couverture

Papier pour index

Poids minimal

20 lb / 75 g/m²

28 lb / 75 g/m²

42 lb / 75 g/m²

Poids maximal

53 lb / 203 g/m²

80 lb / 216 g/m²

110 lb / 203 g/m²

Papier photo poreux 20 lb / 75 g/m² Jusqu’à 50 lb / 200 g/m²

Les supports tels que les imprimés recto verso, les papiers de dessinateur, les papiers cartonnés,

les papiers pour couverture, les papiers photo très lustrés, les cartes photo lustrées et les autres

papiers avec revêtements spéciaux doivent être insérés dans la plastifieuse une feuille à la fois pour

éviter de causer des problèmes d’alimentation ou bloquer le mécanisme du dispositif d’alimentation.

Page 17

32

33

HeatSeal Sprint H925 - Conseils de plastification

pour des performances optimales

TM®

IMPORTANT: Lorsque vous plastifiez n’importe quel média plus long que le format lettre/A4 et ce,

dans l’orientation paysage, le plateau de sortie DOIT être rabattu dans la machine. Le fait de ne pas

respecter cette consigne peut causer un bourrage car le document fini risque de manquer d’espace

pour passer entre les rouleaux après la plastification.

Le plateau de sortie est conçu pour des piles de format lettre/A4 et autre média plus petit dans

l’orientation paysage. La capacité de ce plateau varie en fonction de l’épaisseur générale du support

et de la pellicule utilisée. GBC recommande de vider fréquemment le plateau de sortie.

Chargement

Plateau de sortie

Avant de charger des imprimés, éventez les feuilles sur les quatre côtés. Ceci permet de créer

une fine couche d’air entre les feuilles pour aider le mécanisme du dispositif d’alimentation en

éliminant toute adhérence pouvant résulter du séchage ou de l’entreposage des feuilles.

Pour maximiser l'utilisation de pellicule lors de la plastification de papier lettre/A4, il est

préférable de charger les imprimés dans le plateau d’alimentation avec l’orientation horizontale.

Pour le papier grand format/A3, le support doit être chargé avec l’orientation verticale.

Si votre document est très gondolé ou courbé, il risque de causer des problèmes au dispositif

d’alimentation de la HS925. Pour éviter ce genre de problème, vous pouvez essayer d’éliminer

le gondolement en roulant la pile de supports en sens inverse avant de charger le document.

Vous pouvez également essayer de charger le document en sens inverse ou à l’envers..

Lors du chargement d’une pile d’imprimés, il est préférable d’égaliser sa bordure inférieure en

frappant légèrement toute la pile sur une surface plate. Le fait de charger la pile avec la bordure

inférieure égalisée dans le plateau d’alimentation aide à prévenir les problèmes d’alimentation.

Assurez-vous que les guides papier du plateau d’alimentation soient correctement espacés afin

que les bords des feuilles les frôlent et ainsi ne pas compresser la pile. Si les guides papier ne

frôlent pas le média, les feuilles pourraient s’insérer de travers pendant la plastification.

Une fois le support chargé dans le plateau d’alimentation, vous devez attendre que la procédure

de plastification se termine avant d’ajouter d’autres imprimés. N’AJOUTEZ pas des feuilles dans

le plateau d’alimentation pendant la période de plastification.

Les rouleaux de pellicule permettront de plastifier un plus grand nombre de pages par

recharge si vous respectez la largeur maximale lors du chargement du support dans le

dispositif d’alimentation

HeatSeal Sprint H925 - Conseils de plastification

pour des performances optimales

TM®

Pour éviter l’apparition de lignes de chaleur sur le support

Selon la température ambiante, le type de support et l’épaisseur de la pellicule, la HeatSeal

Sprint H925 peut produire une ligne de chaleur sur les 3-5 premières feuilles plastifiées.

Suivez les recommandations ci-dessous pour éviter de voir apparaître des lignes de chaleur:

Routine recommandée pour le démarrage en début de journée:

Réglez l’interrupteur d’alimentation principale sur la position « Marche ».

Conseils supplémentaires:

L’épaisseur de la pellicule peut faire une différence. La pellicule de 1,7 mil peut produire une

ligne de chaleur plus prononcée que les pellicules de 3 ou 5 mil.

Votre appareil peut refroidir lorsqu’il n’est pas utilisé pendant plusieurs heures. Il est alors

recommandé de répéter la routine de démarrage.

Les types de support et d’encre peuvent aussi faire une différence. Les images plus foncées ou

les papiers lustrés peuvent produire une ligne de chaleur plus prononcée que d’autres supports.

Pour de meilleurs résultats, n’utilisez pas cet appareil dans un environnement où la

température ambiante est inférieure à 22 °C/72 °F.

L’utilisation à une température inférieure à la température ambiante normale empêche les rouleaux de pression

d’atteindre une température de plastification convenable, causant ainsi l’apparition de lignes de chaleur pâles sur

les feuilles plastifiées.

Chargez deux ou trois feuilles de papier uni dans le plateau d’alimentation.

Appuyez sur la touche de démarrage.

Faites un essai avec une seule feuille de votre support spécial.

Avant de commencer la plastification, allouez à la machine au moins 5 minutes pour qu’elle

atteigne sa température.

Si nécessaire, répétez les étapes 4 et 5 jusqu’à ce que la ligne de chaleur ne soit plus visible.

Page 18

34

35

HeatSeal Sprint H925 - Conseils de plastification

pour des performances optimales

TM®

IMPORTANT: Lorsque vous plastifiez des supports avec 3 trous perforés, chargez-les en plaçant

le côté des trous en premier dans l’appareil. Le fait de ne pas respecter cette consigne risque de

causer des problèmes de coupure car le capteur pourrait identifier les trous comme étant la fin

d’une page.

La composition et la qualité de tous les types de support/papier peuvent changer à tout moment.

GBC ne peut pas spécifier ni garantir le niveau de performance d’une marque, d’un type ou d’un fabricant

de support/papier spécifique. Mêmes les supports standard peuvent changer de temps à autre en raison

de circonstances qui sont hors du contrôle de GBC.

Conseils pour une plastification réussie:

Avant l’utilisation, vous devez laisser le support s’acclimater pendant au moins 48 heures dans

l’environnement où il sera utilisé. La température d’entreposage et d’utilisation optimale est de

21 à 27 °C (70 à 80 °F), avec 50 % d’humidité relative.

Une fois la plastification terminée, ne laissez aucun support non plastifié dans le plateau

d’alimentation. Les supports doivent être retirés et rangés en pile dans des conditions

ambiantes appropriées.

Veillez toujours à faire passer le support de la façon la plus directe possible dans la plastifieuse.

Si vous plastifiez un support plus long, évitez de le déposer sur la partie arrière du plateau

d’alimentation car cela pourrait empêcher le dispositif d’alimentation de saisir les feuilles

correctement.

Laissez sécher l’encre des documents imprimés avant de les plastifier.

Ne chargez AUCUN type de support plissé, plié ou inégal dans le dispositif d’alimentation car

vous pourriez causer un bourrage dans l’appareil.

Entretien

Garantie limitée de un an (1)

ACCO Brands USA

300 Tower Parkway,

Lincolnshire, IL 60069-3640

(800) 541-0094

ACCO Brands Canada

5 Precidio Court

Brampton, ON L6S-6B7

(800) 263-1063

ACCO Mexicana

Neptuno #43, Colonia Nueva Industrial Vallejo

Delagacion Gustavo A. Madero, CP 07700

México, DF. (55) 1500-5578

ACCO Brands USA LLC, 300 Tower Parkway, Lincolnshire, IL 60069 (au Canada, ACCO Brands Canada Inc.,

5 Precidio Court, Brampton, ONTARIO L6S-6B7; et au Mexique, ACCO Mexicana, S.A. de C.V. Av. Circuito Industrial

Norte #6 Parque Industrial Lerma 52000, Lerma Edo. de México), (chacun, respectivement « ACCO Brands »)

garantit à l'acheteur original que ce produit ACCO Brands est libre de tout défaut de fabrication et de matériel

conditions normales d'utilisation et d'entretien pour 1 an de garantie limitée après achat.

L’obligation d'ACCO Brands envers cette garantie est limitée au remplacement ou à la réparation, au choix

d'ACCO Brands, dans le cas où, n’importe quelle pièce garantie serait trouvée défectueuse par ACCO Brands et

ce, sans frais de matériel ou de main-d’œuvre. ACCO Brands se réserve le droit de remplacer le produit

défectueux par un autre produit identique ou par son équivalent qui peut contenir des pièces réusinées ou

remises à neuf. La garantie sera nulle et non avenue dans les circonstances suivantes :

(i) si le produit a été utilisé abusivement,

(ii) si le produit a été endommagé par négligence ou accidentellement ou,

(iii) si le produit a été modifié par une personne autre qu'un employé ou un agent autorisé d'ACCO Brands.

Pour procéder à une demande de garantie, veuillez composer le 1-800-541-0094 aux É.-U. / 1-800-268-3447

au Canada/1-800-759-6825 au Mexique ou visitez le www.gbc.com.

DANS LA MESURE AUTORISÉE PAR LA LOI APPLICABLE, LA PRÉSENTE GARANTIE REMPLACE TOUTES LES

AUTRES GARANTIES EXPRESSES. TOUTES REPRÉSENTATIONS OU PROMESSES CONTRADICTOIRES AVEC, OU

AJOUTÉES À CETTE GARANTIE NE SONT PAS AUTORISÉES ET N’OBLIGENT ACCO BRANDS EN AUCUN CAS. DANS

LA MESURE AUTORISÉE PAR LES LOIS APPLICABLES, LA DURÉE DE TOUTE GARANTIE IMPLICITE (SI APPLICABLE)

SE LIMITE À LA DURÉE DE LA PRÉSENTE GARANTIE. CERTAINS ÉTATS ET CERTAINES JURIDICTIONS

N’AUTORISENT PAS LES LIMITATIONS PORTANT SUR LA DURÉE D’UNE GARANTIE IMPLICITE, DE SORTE QUE LES

LIMITATIONS CI-DESSUS PEUVENT NE PAS VOUS ÊTRE APPLICABLES. DANS LA MESURE AUTORISÉE PAR LA LOI

APPLICABLE, ACCO BRANDS NE SAURAIT, EN AUCUN CAS, ÊTRE TENU RESPONSABLE DE TOUS DOMMAGES

SPÉCIAUX, ACCESSOIRES, PUNITIFS, EXEMPLAIRES, CONSÉCUTIFS OU SIMILAIRES, QU’ILS SOIENT PRÉVISIBLES

OU NON. CERTAINS ÉTATS ET CERTAINES JURIDICTIONS NE PERMETTENT PAS L’EXCLUSION OU LA LIMITATION

DES DOMMAGES SPÉCIAUX, ACCESSOIRES, PUNITIFS, EXEMPLAIRES, CONSÉCUTIFS OU SIMILAIRES DE SORTE

QUE LES EXCLUSIONS OU LIMITATIONS CI-DESSUS PEUVENT NE PAS VOUS ÊTRE APPLICABLES.

Dans la mesure autorisée par la loi applicable, cette garantie n’est pas transférable et devient automatiquement

nulle si l’acheteur original du produit vend ou aliène de quelque autre manière le produit.

This warranty gives you specific legal rights. Other rights, which vary from jurisdiction to jurisdiction, may exist.

In addition some jurisdictions do not allow (i) the exclusion of certain warranties, (ii) limitations on how long an

implied warranty lasts and/or (iii) the exclusion or limitation of certain types of costs and/or damages, so the

above limitations may not apply.

Page 19

36

37

HeatSeal Sprint H925 - Seguridad

TM®

Information d’achat

Enregistrez ce produit en ligne à: www.gbc.com.

Les numéros de modèle et de série sont inscrits sous la machine.

Numéro de série:

Numéro de modèle:

Date d’achat:

Détaillant:

NOTICE, CLASSE B, FCC

Note: cet équipement a été testé et il est considéré comme conforme aux conditions restrictives relatives à un appareil

numérique de classe B, en vertu de la section 15 de la réglementation de la FCC. Ces conditions restrictives sont conçues

pour fournir une protection raisonnable contre les interférences nuisibles dans le cadre d’une installation résidentielle.

Cet équipement produit, utilise et émet une énergie de fréquence radio électrique et, s’il n’est pas installé et utilisé

conformément aux instructions, il est susceptible de produire des interférences nuisibles pour les communications radio.

Il n’est cependant aucunement garanti que des interférences ne se produiront pas dans une installation donnée. Si cet

équipement provoque effectivement des interférences indésirables au niveau de la réception radio ou télévision, ce qui

pourra être déterminé en éteignant l’appareil puis en le remettant en marche, l’utilisateur est encouragé à essayer de

corriger ces interférences par l’une ou plusieurs des mesures suivantes:

Réorienter ou repositionner l'antenne de réception;•

Augmenter l’espace entre l’équipement et le récepteur;•

Brancher l’équipement sur une prise d’un circuit différent de celui sur lequel le récepteur est branché;•

Demander conseil auprès du détaillant ou d’un technicien radio/TV expérimenté.•

AVIS CANADA, CLASSE B

Cet appareil mumérique de classe B est conforme à la norme NMB-003 du Canada.

MODIFICATIONS

Toutes modifications apportées à ce dispositif pourront annuler le droit accordé à l’utilisateur par le FCC et/ou par

Industrie Canada de faire fonctionner cet équipement.

Fait en Chine.

GBC et HeatSeal sont des marques de commerce enregistrées

de General Binding Corporation.

ACCO est une marque de commerce enregistrée d’ACCO Brands.

Droit d'auteur © 2010 ACCO Brands. Tous droits réservés.

Numéro 2 Juillet 2010

Instrucciones importantes para la seguridad Salvaguardas importantes

SU SEGURIDAD, ASÍ COMO LA SEGURIDAD DE LOS DEMÁS,ES DE

SUMA IMPORTANCIA PARA GBC. EN ESTE MANUAL DE INSTRUCCIONES Y EN EL PRODUCTO HAY MENSAJES IMPORTANTES SOBRE LA

SEGURIDAD. LÉALOS DETENIDAMENTE.

EN ESTE MANUAL DE INSTRUCCIONES, CADA MENSAJE

SOBRE LA SEGURIDAD ESTÁ PRECEDIDO POR EL

SÍMBOLO DE ALERTA.

ENCONTRARÁ EN EL PRODUCTO MENSAJES IMPORTANTES

SOBRE LA SEGURIDAD. LEA DETENIDAMENTE ESTOS MENSAJES

E INSTRUCCIONES. GUARDE ESTAS INSTRUCCIONES PARA USO

POSTERIOR.

SE INCLUYEN EN EL PRODUCTO LAS SIGUIENTES ADVERTENCIAS.

ADVERTENCIA

Riesgo de electrocución. No abra el

producto. No hay partes reparables

por el usuario en el interior del mismo.

Solicite el mantenimiento y las

reparaciones a personal de servicio

calificado.

Este mensaje sobre la seguridad significa que usted puede resultar

gravemente herido o morir si abre el producto y se expone a voltajes

peligrosos.

PRECAUCIÓN

Superficie

caliente.

No toque las zapatas térmicas hasta que se hayan enfriado.

PRECAUCIÓN

HOJA AFILADA.

Mantenga alejados

los dedos y la mano.

Este mensaje sobre la seguridad significa que si no es cuidadoso

puede lastimarse.

ADVERTENCIA: EN ESTE MANUAL DE INSTRUCCIONES, CADA

MENSAJE SOBRE LA SEGURIDAD ESTÁ PRECEDIDO POR EL

SÍMBOLO DE ALERTA. ESTE SÍMBOLO INDICA UN PELIGRO

POTENCIAL PARA LA SEGURIDAD PERSONAL QUE PODRÍA

CAUSARLE LESIONES A USTED O A OTRAS PERSONAS.

ADVERTENCIA: NO INTENTE EFECTUAR EL SERVICIO O

REPARAR LA PLASTIFICADORA.

ADVERTENCIA: NO CONECTE LA PLASTIFICADORA

AL SUMINISTRO ELÉCTRICO NI INTENTE HACERLA

FUNCIONAR HASTA QUE HAYA LEÍDO COMPLETAMENTE

ESTAS INSTRUCCIONES. GUÁRDELAS EN UN LUGAR

CONVENIENTE PARA REFERENCIA FUTURA.

ADVERTENCIA: PARA SU PROTECCIÓN, NO CONECTE

LA PLASTIFICADORA AL SUMINISTRO ELÉCTRICO NI

INTENTE HACERLA FUNCIONAR HASTA QUE LEA

COMPLETAMENTE ESTAS INSTRUCCIONES. GUARDE

LAS INSTRUCCIONES DE OPERACIÓN EN UN LUGAR

CONVENIENTE PARA REFERENCIA FUTURA. PARA

PROTEGERSE CONTRA LESIONES, CUANDO PREPARE

Y USE LA PLASTIFICADORA DEBE OBSERVAR LAS

SIGUIENTES PRECAUCIONES BÁSICAS DE SEGURIDAD.

Salvaguardas generales

Use esta plastificadora sólo para los fines para la que está •

diseñada, de acuerdo a las especificaciones incluidas en las

instrucciones de operación.

Mantenga las manos, el cabello largo, las prendas de vestir sueltas •

y los artículos como collares o corbatas lejos de la parte delantera

de los rodillos de tracción, a fin de evitar que se enreden y queden

atrapados.

Evite el contacto con las zapatas térmicas durante el funciona-•

miento o antes de que transcurra un tiempo suficiente después de

apagar la plastificadora. Las zapatas pueden alcanzar temperaturas

superiores a los 150°C (300°F).

Mantenga las manos y los dedos alejados del trayecto de la filosa •

hoja de corte de la película ubicada en la salida de esta última.

Coloque la plastificadora sobre un carro, soporte o mesa estable •

capaz de soportar 110 lb/50 kg como mínimo. Una superficie

inestable puede hacer que la plastificadora se caiga y produzca

graves lesiones. Evite las paradas repentinas, la fuerza excesiva y

los pisos de superficies desparejas cuando traslade la plastificadora

sobre un carro o soporte.

No anule ni desmonte los equipos de seguridad eléctrica y •

mecánica, tales como interbloqueos, defensas y protecciones.

No inserte objetos inadecuados para la plastificación.•

No exponga la plastificadora a líquidos.•

Salvaguardas eléctricas

Esta plastificadora se debe conectar a un suministro eléctrico •

correspondiente al voltaje especificado que se indica en la placa de

número de serie ubicada en la parte trasera de la máquina.

Desenchufe la plastificadora antes de moverla o cuando no se use •

durante un período prolongado.

No haga funcionar la plastificadora con un cordón de alimentación •

eléctrica o un enchufe dañado.

No sobrecargue los tomacorrientes porque puede ocasionar un •

incendio o descarga eléctrica.

No altere el enchufe. Este enchufe está configurado para el •

suministro eléctrico apropiado.

La unidad está diseñada para uso en interiores únicamente.•

PRECAUCIÓN: El receptáculo debe estar cerca del equipo y

fácilmente accesible. No use cables de prolongación.

Desconecte el enchufe del tomacorriente en el que está conectado •

y sostenga el cordón de alimentación eléctrica en su mano mientras

mueve la plastificadora.

No haga funcionar la plastificadora si el cordón de alimentación •

eléctrica o el enchufe están dañados, si se produce una falla o si

la máquina ha sufrido daños. Comuníquese con un representante

autorizado del servicio de GBC para solicitar asistencia.

Page 20

38

39

HeatSeal Sprint H925 - Seguridad

TM®

PASO 2

Abra la bandeja de

salida a la posición

completamente

extendida para

operación normal.

Para papeles más

largos o banderas,

cierre la bandeja.

PASO 1

Encienda la

máquina con

el botón de la

parte trasera

Se ilumina el LED

de encendido del

panel frontal de

control.

PASO 4

Ajuste las "guías

laterales" para

ajustarlas a los

documentos.

PASO 3

Inserte y sujete

la bandeja de

alimentación en

su posición.

La plastificadora viene precargada con aproximadamente

9 m (30 pies) de película de 3 milésimas/75 micrones.

Guías

laterales

HeatSeal Sprint H925 - Configuración

TM®

Bandeja

Servicio

Lleve a cabo únicamente los procedimientos de mantenimiento de

rutina que se explican en estas instrucciones.

No intente efectuar el servicio ni reparar la plastificadora

usted mismo.

Desenchufe la unidad y comuníquese con un representante autorizado

del servicio de GBC para solicitar cualquier reparación necesaria si ha

ocurrido uno o más de los siguientes problemas:

El cordón de alimentación eléctrica o el enchufe están dañados.•

Se derramó líquido dentro de la plastificadora.•

La plastificadora funciona mal después de haberse manejado •

incorrectamente.

La plastificadora no funciona como se describe en estas •

instrucciones.

ADVERTENCIA: ESTE PRODUCTO NO ES UN JUGUETE:

¡NO PERMITA QUE LOS NIÑOS HAGAN FUNCIONAR LA

PLASTIFICADORA!

Instalación

Los daños de transporte deben informarse inmediatamente al •

transportista que realiza la entrega.

Coloque la plastificadora sobre una superficie plana estable capaz de •

soportar 110 lb/50 kg. La superficie debe estar a 75 cm. (30 pulg.) de

altura como mínimo para asegurar las 110 lb/50 kg. La superficie debe

estar a 75 cm. (30 pulg.) de altura como mínimo para permitir que el

operador esté en una posición cómoda al usar la máquina. Las cuatro

patas de goma deben estar sobre la superficie de soporte.

Conecte el cordón de alimentación a un suministro eléctrico apropiado. •

Evite conectar otros equipos al mismo ramal de circuito al que está

conectada la plastificadora, puesto que puede ocasionarse el disparo

de desconexión del disyuntor o quemarse los fusibles.

Coloque la plastificadora para permitir que los documentos salgan •

libremente.

•

Si enmica documentos tamaño A4/carta, abrá la bandeja de salida •

hasta extender por completo su posición. Cuando enmique cual-

quier otra medida que sea mayor a carta/A4 en orientación horizontal la bandeja de salida deberá ser guardada (cerrada) hacia dentro

del equipo. De lo contrario resultaría un atascamiento causado

cuando los rodillos no tiene suficiente espacio para desalojar los

documentos una vez enmicados.

Instale la plastificadora donde la temperatura ambiente sea de •

72°F/22°C como mínimo.

Cuidado de la plastificadora H925

El único mantenimiento requerido por el operador es limpiar periódicamente

las zapatas térmicas. Esta limpieza debe realizarse cuando se cambian los

rollos de película, consulte la página 35, pasos 1, 2 y 3. El siguiente

procedimiento ayuda a mantener las zapatas térmicas libres del adhesivo