Gaylord GX2-ND-BDL Service Manual

EFFECTIVE DATE 5-19-03

THE

GAYLORD VENTILATOR

TECHNICAL MANUAL

FOR THE GRAND “GX2-ND” SERIES

NON WATER-WASH VENTILATORS

GAYLORD INDUSTRIES

10900 S.W. AVERY STREET • P.O. BOX 1149 • TUALATIN, OREGON 97062-1149 U.S.A.

800-547-9696 • 503-691-2010 • FAX: 503-692-6048 • email: info@gaylordusa.com

“Undisputed World Leader in

Engineered Systems for

Commercial Kitchens”

tm

GAYLORD INDUSTRIES

World Headquarters: P.O . Bo x 1149 • T ualatin, Oregon 97062-1149 U .S .A.

To Our Customers. . .

Congratulations on your recent purchase of a Gaylord

kitchen exhaust hood system. W e are proud to be ab le

to provide you with a quality product that incorporates

the latest engineering concepts and is a result of over

50 years of experience in the foodservice kitchen

exhaust industry.

If you have other Gaylord equipment such as a Gaylord

Utility Distribution System, Quencher Fire Protection Sys-

tem, or Roof Top Air Handling Equipment, etc., please

refer to the corresponding supplementary equipment

manuals.

If you have further questions, please call us toll free at

1-800-547-9696 or email:info@gaylordusa.com. We are

more than happy to help.

Sincerely,

Gaylord Industries

PHONE: 503-691-2010 • 800-547-9696 • FAX: 503-692-6048 • email: gaylord@gaylordusa.com • www.gaylordusa.com

COMMERCIAL KITCHEN EXHAUST SYSTEMS • FIRE PROTECTION • UTILITY DISTRIBUTION • ROOF TOP UNITS • POLLUTION CONTROL

STREET ADDRESS: 10900 S.W. Avery Street, Tualatin, Oregon 97062-8549 U.S.A.

TABLE OF CONTENTS

“GX2-ND” SERIES PRINCIPLE OF OPERATION ................................................. 3

STANDARD MODELS ............................................................................................ 6

MAINTENANCE AND CLEANING INSTRUCTIONS.............................................. 7

TROUBLESHOOTING ........................................................................................... 8

MEASURING INLET SLOT VELOCITY ................................................................. 10

WIRING DIAGRAM ................................................................................................ 13

PARTS LIST ........................................................................................................... 14

START-UP INSPECTION REPORT ....................................................................... 15

WARRANTY................................................................................. Inside back cover

PATENT NUMBERS

U.S.A.: 4,266,529

4,281,635

4,356,870

CANADA: 1,139,151

1,155,366

GERMANY: 8,034,240

ALL RIGHTS RESERVED. NO PART OF THIS BOOK MAY BE REPRODUCED, STORED

IN A RETRIEVAL SYSTEM, OR TRANSMITTED IN ANY FORM BY AN ELECTRIC, MECHANICAL, PHOTOCOPYING, RECORDING MEANS OR O THERWISE WITHOUT PRIOR

WRITTEN PERMISSION OF GAYLORD INDUSTRIES, INC. COPYRIGHT 2003.

© Copyright 2003, Gaylord Industries

The manufacturer reserves the right to modify the materials and

specifications resulting from a continuing program of product improvement or the availability of new materials.

ADDITIONAL COPIES $10.00

“GX2-ND” SERIES PRINCIPLE OF OPERATION

The Gaylord “GX2-ND” Series Non Water-Wash Ventilator

offers simplicity, economy and performance that no other

ventilator can offer. The unique “extractor insert” gives a

grease extraction efficiency far superior to that of a typical

baffle filter. The Gaylord “GX2-ND” Series Ventilators are UL

Listed and meet all the requirements of NFPA #96 and the

International Mechanical Code.

EXHAUST FAN OPERATION

The exhaust fan is controlled by the Gaylord C-150 “Exhaust

Fan Start/Stop Switch”, an optional switch, or a standard wall

switch. The switch is usually located on a wall near the

ventilator. When the switch is flipped up to the on position,

the exhaust fan will come on.

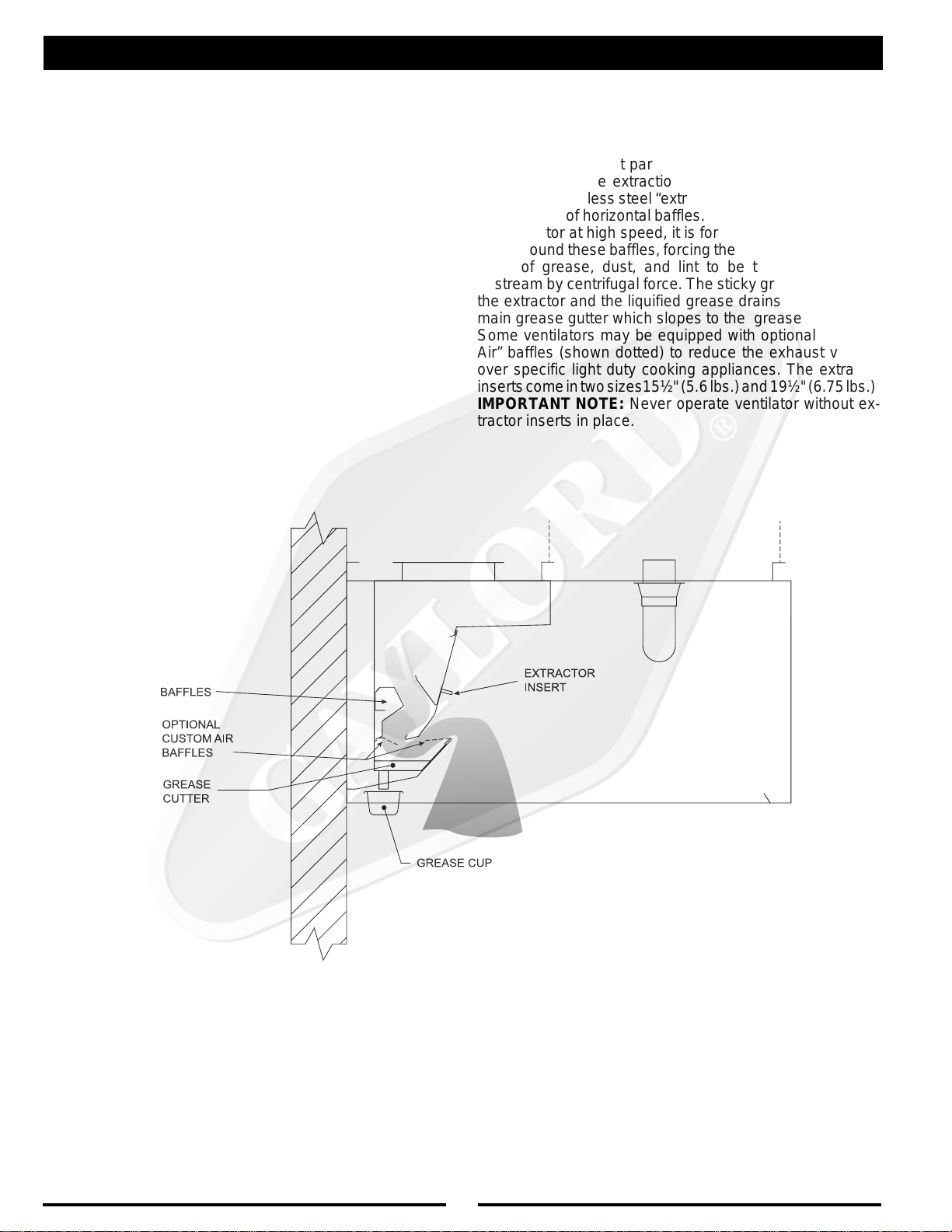

GREASE EXTRACTION

The Gaylord “GX2-ND” Series Ventilator extracts 90% of the

grease, dust, and lint particles from the airstream passing

through it. Grease extraction is accomplished by unique,

removable stainless steel “extractor inserts” which incorporate a series of horizontal baffles. As the air moves through

the extractor at high speed, it is forced to make a series of

turns around these baffles, forcing the heavier-than-air particles of grease, dust, and lint to be thrown out of the

airstream by centrifugal force. The sticky grease collects in

the extractor and the liquified grease drains down into the

main grease gutter which slopes to the grease cup. Note:

Some ventilators may be equipped with optional “Custom

Air” baffles (shown dotted) to reduce the exhaust volume

over specific light duty cooking appliances. The extractor

inserts come in two sizes15½" (5.6 lbs.) and 19½" (6.75 lbs.).

IMPORTANT NOTE: Never operate ventilator without ex-

tractor inserts in place.

GREASE EXTRACTION

FIG. 1

3

“GX2-ND” SERIES PRINCIPLE OF OPERATION

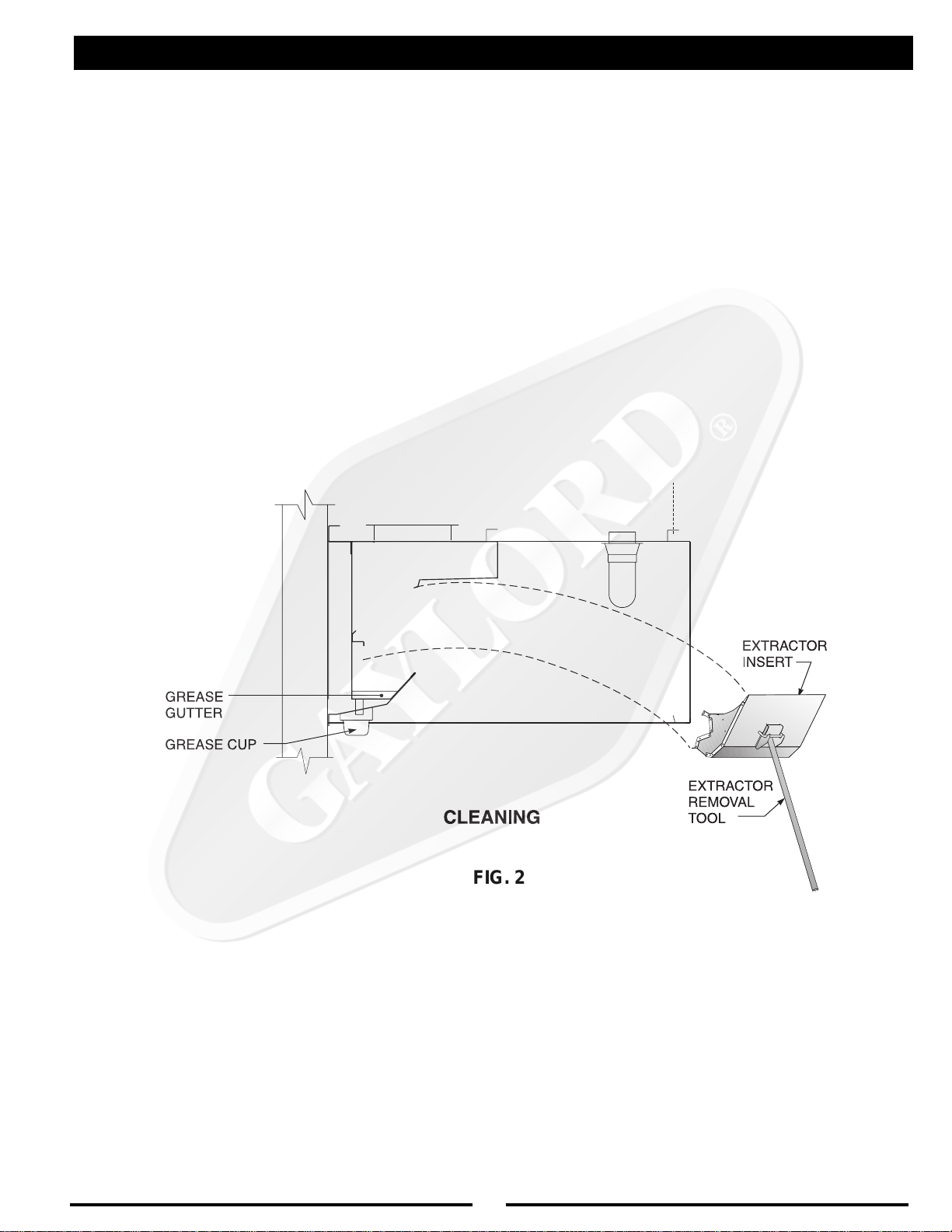

CLEANING

At the end of the cooking day the exhaust fan is turned off by

the “Exhaust Fan Start/ Stop Switch.” After the fan has been

turned off, the extractor inserts are removed and can be

washed either in a dishwasher or soaked and rinsed off. The

grease cup is also removed and emptied at this time. To ease

in the removal of the extractor inserts, an “Extractor Removal

Tool” is available which eliminates the need for kitchen

personnel to climb up on the cooking equipment, or up a

ladder.

FIG. 2

4

“GX2-ND” SERIES PRINCIPLE OF OPERATION

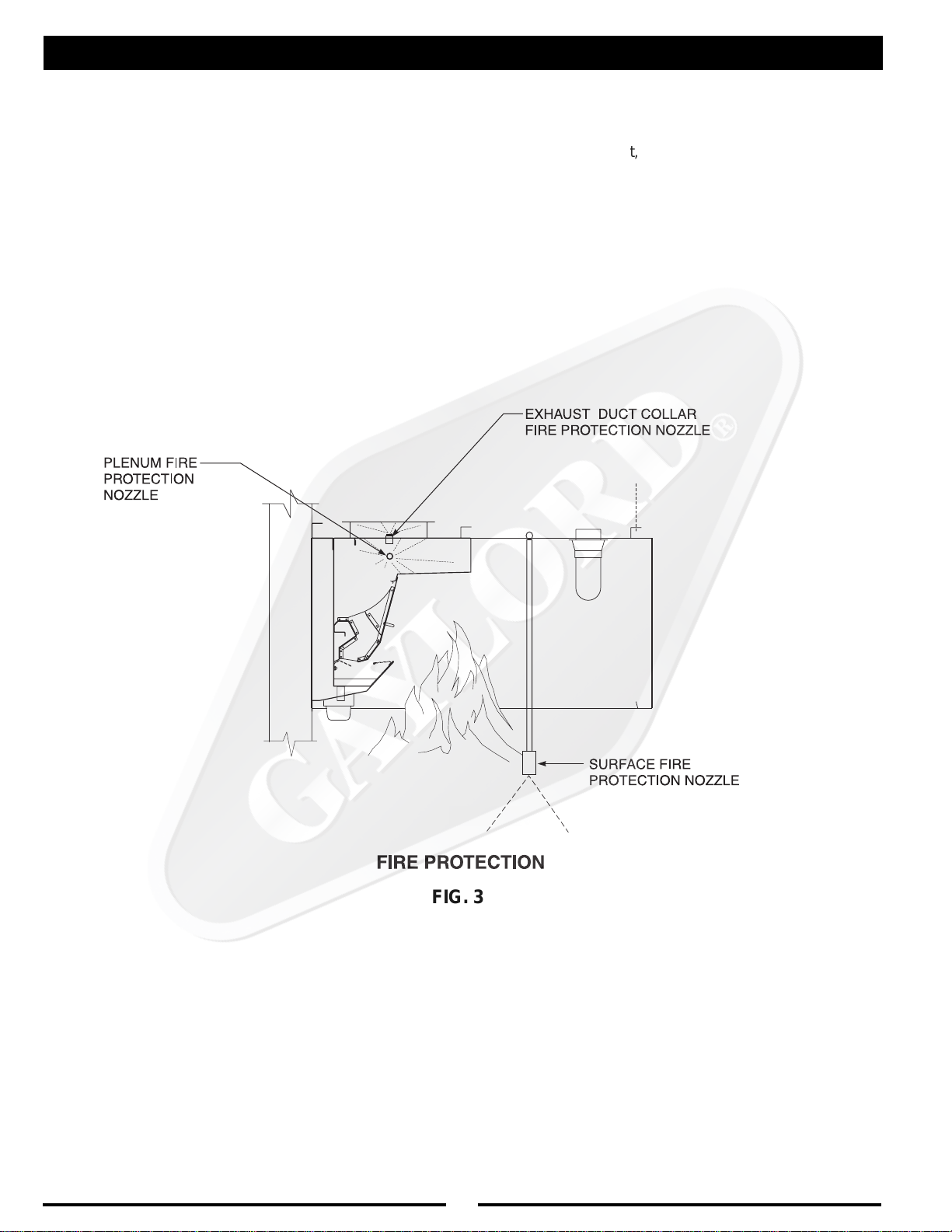

FIRE PROTECTION

NFPA #96 requires the use of surface, duct and plenum

protection on all hoods. It is these systems that are the first

line of defense against equipment fires.

Surface, duct collar and plenum fire protection utilizing The

Gaylord Quencher System, or other fire protection systems

currently on the market, can be factory installed as an option.

FIG. 3

5

Loading...

Loading...