Gaylord GDS User Manual

DUCT SUMP

MODEL GDS SERIES

GENERAL SPECIFICATION

Furnish one Model GDS - ______ x ______ x 24"L Duct Sump as manufactured by Gaylord Industries, Inc., Tualatin, Oregon. The sump shall be constructed of 16 gauge stainless steel and shall include 1" flanges at the inlet and outlet collars for welding to the duct system. All corners and seams shall be continuously welded. The duct sump shall include a stainless steel spray manifold with brass spray nozzles, a 1-1/2" drain with pre-flush line. The sump shall also include an access panel, with 1500°F gasketing,securedbyweldstudswithwingnutsforeasyremoval without tools. If the sump is larger than 36" wide, there shall be an access panel on each side. The access panel shall meet all requirementsofNFPA-96.Thesumpshallbeinterconnectedwith the water-wash ventilator control cabinet and wash simultaneously with the ventilator. (Note: If the system does not include a water-wash ventilator, a control cabinet must be specified.) Duct sump shall be approved by the City of Los Angeles Department of Building and Safety.

APPLICATION

The Gaylord Duct Sump is designed to be installed at the low point(s) of long horizontal duct runs to collect and drain off moisture, liquefied grease, etc. The International Mechanical Code (IMC), specifies that ducts must slope not less than 2% towards a hood or a grease reservoir (duct sump) and that duct runs over 75 ft. must slope not less than 8.3%. The installation of one or more duct sumps allows a 2% slope on duct runs exceeding 75 ft.by zig zagging the duct up and down as illustrated on the back of this specification sheet.

ESTABLISHING MODEL NUMBERS

The model number is determined by the size of the sump. Specify the model number as follows:

GDS - |

W x |

H x 24" L |

|

Width |

Height Length |

ITEM NO.

GENERAL DESCRIPTION

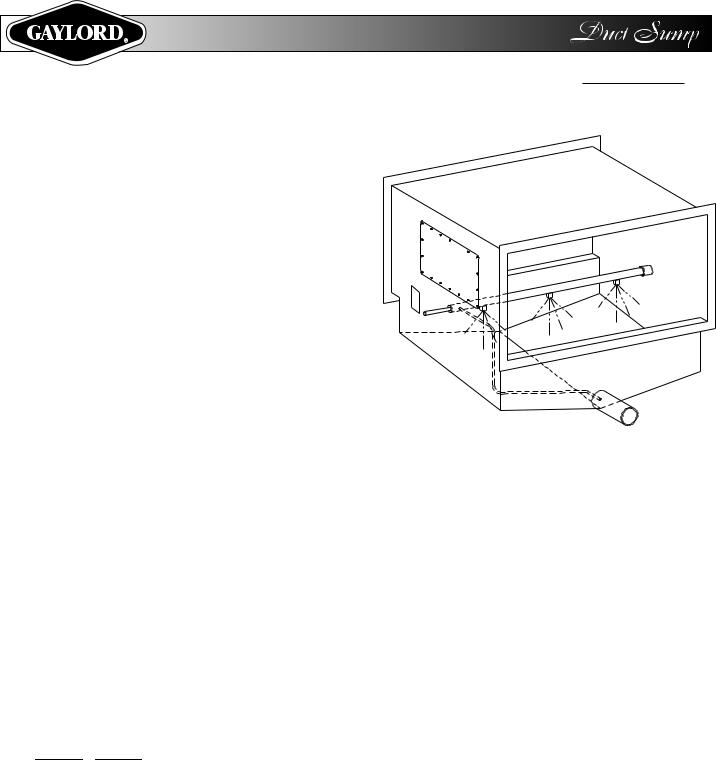

The Gaylord Duct Sump is constructed of 16 gauge stainless steel with all corners and seams continuously welded. It is equipped with a spray manifold, drain with pre-flush line and a removable access panel. The panel is removed without the use of tools and meets all requirements of NFPA-96. 1" flanges are provided at the inlet and outlet collars for welding to the duct system. Each duct sump is 24" long and is custom built to match the duct size required.

Typically, The Gaylord Duct Sump is provided in conjunction with a Gaylord Water-Wash Ventilator. The wash manifold of the duct sump would be interconnected to the hot water line coming from the ventilator control cabinet and therefore, the sump would be washed daily with hot detergent injected water simultaneously with the ventilator. An average wash cycle is 5 minutes. If the project is not utilizing a Gaylord Water-Wash Ventilator, then a Gaylord Control Cabinet, Model “GPC” Series must be provided. Refer to “GPC” Series Control Cabinet specification sheet for details.

TheGaylordDuctSump,Model“GDS”Seriesisapprovedbythe City of Los Angeles, Department of Building & Safety, Mechanical Testing Laboratories Research Report Number RR7657.

GAYLORD INDUSTRIES

10900 SW AVERY STREET • TUALATIN, OREGON 97062 U.S.A. PHONE: 800-547-9696 • FAX: 503-692-6048 • email: info@gaylordusa.com

Loading...

Loading...