Gaylord ELX-UV-CL User Manual

MODEL “ELX-UV-CL”

HIGH EFFICIENCY EXTRACTOR VENTILATOR

GENERAL SPECIFICATIONS

Furnish Gaylord Ventilator Model “ELX-UV-CL-___________” as shown on

plans and in accordance with the following specications:

DESCRIPTION: The ventilator shall include a stationary grease collecting

gutter at the bottom of the grease extraction device, sloped to a drain at

one end to a 0.5 gallon built-in stainless steel grease drawer. The sloped

gutter shall be concealed by an apron which extends the full length of

the hood. Each ventilator shall contain two or more “XGS” Super High

Eciency Filtration Extractors. “XGS” Extractors shall utilize the “capture

and drain” principle.

The ventilator shall achieve its low air ow rates without the use of

internal motors, plenums, or jets. The ventilator shall also include a

“Super Capture”TM lip on the front panel for enhancement of smoke and

grease capture. The ventilator shall perform at airow rates as tested to

ASTM 1704-09 by the Architectural Energy CKV lab and published on the

Food Service Technology Center web site. The ventilator shall include an

“Autostart” controller and sensors to meet current IMC standards.

The ventilator shall include a static pressure port in each section to be

used in balancing the static pressure. Continuous front and rear mounting

brackets shall be provided to facilitate hanging from the overhead building

structure.

The ventilator shall include ultraviolet lamps mounted in modules located

in the plenum section. There shall be one or more UV modules, as dictated

by the ventilator length, and each module shall be on a slide track for easy

removal. Access to the UV modules shall be through tooled removable

UV module doors. A pressure switch shall be provided to monitor the

airow and prevent operation of the UV lamps if the tooled removable

UV module doors is opened, or if any “XGS” Extractor is removed, or if

the airow is inadequate. Mounted on the face of the plenum of each

ventilator section shall be indicating lights to monitor “UV System On”,

“UV Lamp Failure” and “UV Safety Interlock Activated”.

o Gaylord Balancing Damper (GBD - Standard Equipment)

The ventilator shall be equipped with an opposed blade balancing damper.

The damper shall be manually adjustable and accessible from below.

o G aylo rd Fir e B alanc in g Damp er (GFBD - O ptiona l)

The ventilator shall be equipped with an opposed blade balancing damper

that is controlled by an electrically driven actuator, and shall be activated

by fail-safe thermostat(s) located at each duct collar.

o Gaylo rd Elec tric B ala ncing Dam per (G EBD - O pti onal)

The ventilator shall be equipped with an opposed blade balancing

damper that is controlled by an electrically driven actuator located at

each duct collar.

o Fuse Link Damper (FDD - Optional)

The ventilator shall be equipped with a fuse link activated re damper

located at the duct collar.

o No Damper (ND - Optional)

ELX

SERIES

ITEM NO. _______________

APPLICATION

Used for cafeteria lines or single island arrangements when covering

light or medium duty cooking equipment. (Note: 345 CFM / Lineal Ft.

maxi¬mum exhaust volume.) Not to be used over heavy duty equipment,

including woks and gas or solid fuel char broilers.

CONSTRUCTION: The ventilator shall be of all stainless steel construction,

not less than 18 gauge, type 300 series. All exposed surfaces shall be a

number 4 nish. The use of aluminized steel, galvanized steel, or 430

stainless steel is not acceptable.

LIGHT FIXTURES: The ventilator shall be equipped with:

o Recessed LED

o Recessed uorescent

o 100 watt surface mounted incandescent

o 150 watt recessed incandescent

Light xtures shall be factory pre-wired to a single connection point.

Ventilators built in multiple sections shall be furnished with coiled ex

conduit for interconnecting sections.

ACCEPTANCE & APPROVALS: The ventilator shall be listed to UL

standard 710 and be ETL Sanitation listed. The ventilator shall comply

with all requirements of NFPA-96, IMC, UMC, BOCA and SBCCI mechanical

codes. The ventilator shall be capture tested to ASTM 1704-09. The “XGS”

Extractors shall be tested to ASTM 2519.

ENERGLINK DESIGN FEATURES

• Internal Canopy Radius

• Enhanced “XGS” Extractor Angle and Slot Spacing

• Faceted “Super Capture”™ Lip

OPTIONAL EQUIPMENT

1. “XGS” Spark Arrestor Extractors

2. Decorative Facings and Trim

3. Exhaust Fans, Supply Fans, & Roof Top Units

4. Fire Extinguisher Systems

5. Utility Distribution Systems

6. Pollution Control Systems

7. Demand Ventilation Controls

6 Watts / Ft. Min.

12 Watts / Ft. Min.

24 Watts / Ft. Min.

36 Watts / Ft. Min.

GAYLORD INDUSTRIES

10900 SW AVERY ST • TUALATIN, OREGON 97062 U.S.A.

PHONE: 800.547.9696 • FAX: 503.692.6048 • email: info@gaylordusa.com

www.gaylordusa.com

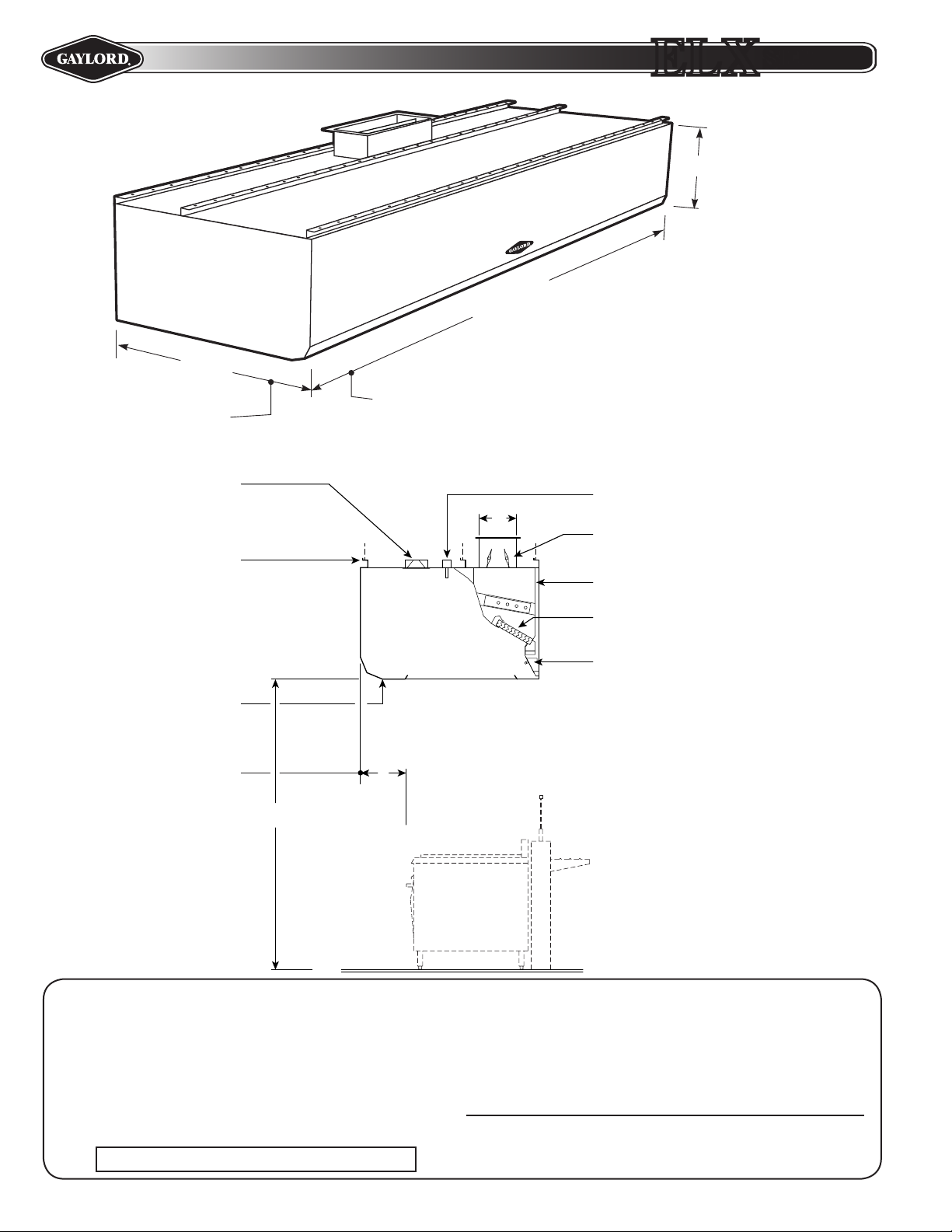

ELX

30” STANDARD

ALSO AVAILABLE

24” HIGH

*16’ -0” MAX. UNIT LENGTH.

FOR GREATER LENGTH, JOIN TWO OR MORE

SECTIONS TOGETHER. ALLOW 12” MIN.

OVERHANG AT EACH END.

48” MINIMUM.

DIMENSION VARIES

WITH DEPTH OF THE

EQUIPMENT.

SERIES

LIGHT FIXTURE

CONTINUOUS

HANGING BRACKET

SUPERCAPTURE™ LIP

NOTE: 18” OVERHANG

REQUIRED OVER

UPRIGHT BROILER

6’-8”

MTG. HT.

14”

MIN.

10”

OR 12”

“AUTOSTART” SENSOR

GAYLORD BALANCING DAMPER (LISTED)

1” MINIMUM AIR SPACE

(LISTED FOR REDUCED CLEARANCE TO

LIMITED COMBUSTIBLES)

“XGS” SUPER HIGH EFFICIENCY

FILTRATION EXTRACTOR

0.5 GALLON GREASE DRAWER

Mechanical Requirements

The amount of exhaust volume required is dependent upon the type of cooking

equipment and the type and volume of cooking. Contact factory for exhaust

volumes, duct sizes, and static pressures.

Electrical

o Provide a 120 volt 20 amp, o 220/240 volt, 50/60 Hz., Non-Interrupted

service to Gaylord CUV-1000 Control Cabinet, to be fused separately. Provide

a separate 220/240 volt, 50/60 Hz, 20 amp service for every 2 ventilator sections to power UV lamps. Ventilator lights to be on separate circuit, 120 volt

15 amp standard, 220/240 volt optional.

The manu facturer res erves the r ight to modif y the materi als and spe cifications resulting

Form No. ELX-UV-CL 0310-20196 © Copyright 2010, Gaylord Industries Litho USA

from a co ntinuing progr am of product improvement o r the availab ility of new materials

Ventilator Lengths

Maximum unit length 16’-0”. For greater lengths, join two or more sections together.

Check to ensure that there is adequate access into building and kitchen area.

Note: Ventilators manufactured outside North America; maximum unit length

*

10’-0”.

Hanging Weight

Ventilator Width 48” 54” 60”

Wt. / Lineal Ft. Lbs. 100 105 110

ENGINEERING DATA

Loading...

Loading...