Gaylord ELX-BBC Installation Manual

EFFECTIVE DATE 04-2010

THE GAYLORD INSTALLATION,

OPERATION & MAINTENANCE MANUAL

for

“ELX” SERIES HOODS

GAYLORD INDUSTRIES

10900 S.W. AVERY STREET • TUALATIN, OREGON 97062 U.S.A.

1-800-547-9696 • 503-691-2010 • FAX: 503-692-6048 • email: info@gaylordusa.com

“Undisputed World Leader in

Engineered Systems for

Commercial Kitchens”

tm

GAYLORD INDUSTRIES

World Headquarters: 10900 S.W. Avery Street • Tualatin, Oregon 97062 U.S.A.

To Our Customers. . .

Congratulations on your recent purchase of a Gaylord

kitchen exhaust hood system. We are proud to be able to

provide you with a quality product that incorporates the latest engineering concepts and is a result of over 50 years of

experience in the foodservice kitchen exhaust industry.

If you have other Gaylord equipment, such as a Gaylord

Utility Distribution System, GPC and CUV Controls, or Roof

Top Pollution Control Unit, etc., please refer to the corresponding supplementary equipment manuals.

If you have further questions, please call us toll free at

1-800-547-9696. We are more than happy to help.

Sincerely,

Gaylord Industries

PHONE: 503-691-2010 • 800-547-9696 • FAX: 503-692-6048 • email: gaylord@gaylordusa.com • www.gaylordusa.com

COMMERCIAL KITCHEN EXHAUST SYSTEMS • FIRE PROTECTION • UTILITY DISTRIBUTION • ROOF TOP UNITS • POLLUTION CONTROL

STREET ADDRESS: 10900 S.W. Avery Street, Tualatin, Oregon 97062 U.S.A.

TABLE OF CONTENTS

ELX VENTILATOR MODEL DESCRIPTION ........................................................... 1

PRINCIPLES OF OPERATION ............................................................................... 4

MAINTENANCE AND CLEANING INSTRUCTIONS ............................................... 5

UV START-UP PROCEDURES ............................................................................... 12

MEASURING AIRFLOW .......................................................................................... 13

TROUBLESHOOTING ........................................................................................... 15

PARTS LIST ............................................................................................................ 20

SCHEMATICS ......................................................................................................... 23

INSTALLATION REQUIREMENTS ......................................................................... 24

HOOD START-UP INSPECTION REPORT ..... ....................................................... 30

WARRANTY

ALL RIGHTS RESERVED. NO PART OF THIS BOOK MAY BE REPRODUCED, STORED

IN A RETRIEVAL SYSTEM, OR TRANSMITTED IN ANY FORM BY AN ELECTRIC, MECHANICAL, PHOTOCOPYING, RECORDING MEANS OR OTHERWISE WITHOUT PRIOR

WRITTEN PERMISSION OF GAYLORD INDUSTRIES COPYRIGHT 2010.

© Copyright 2010, Gaylord Industries

The manufacturer reserves the right to modify the materials and

specifications resulting from a continuing program of product

improvement or the availability of new materials.

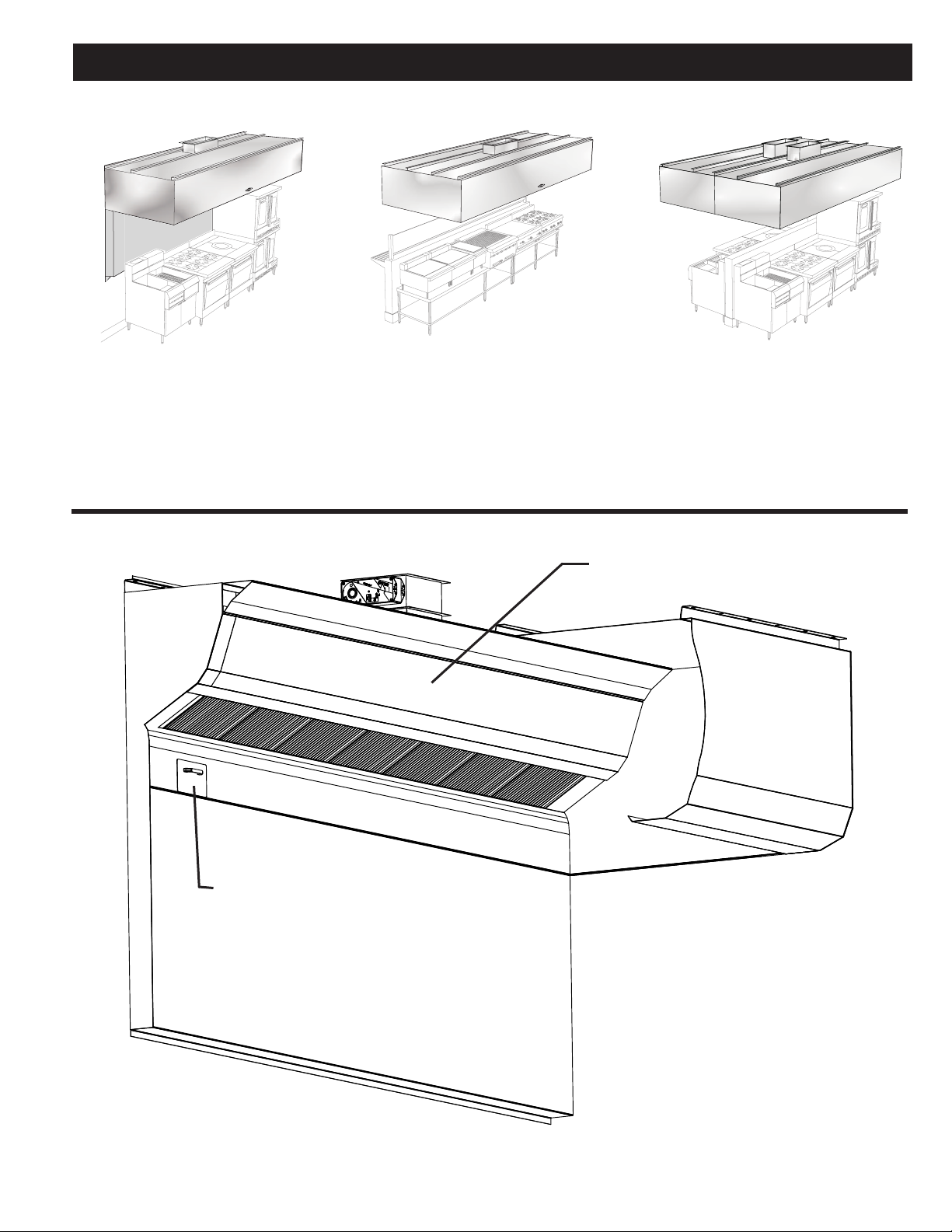

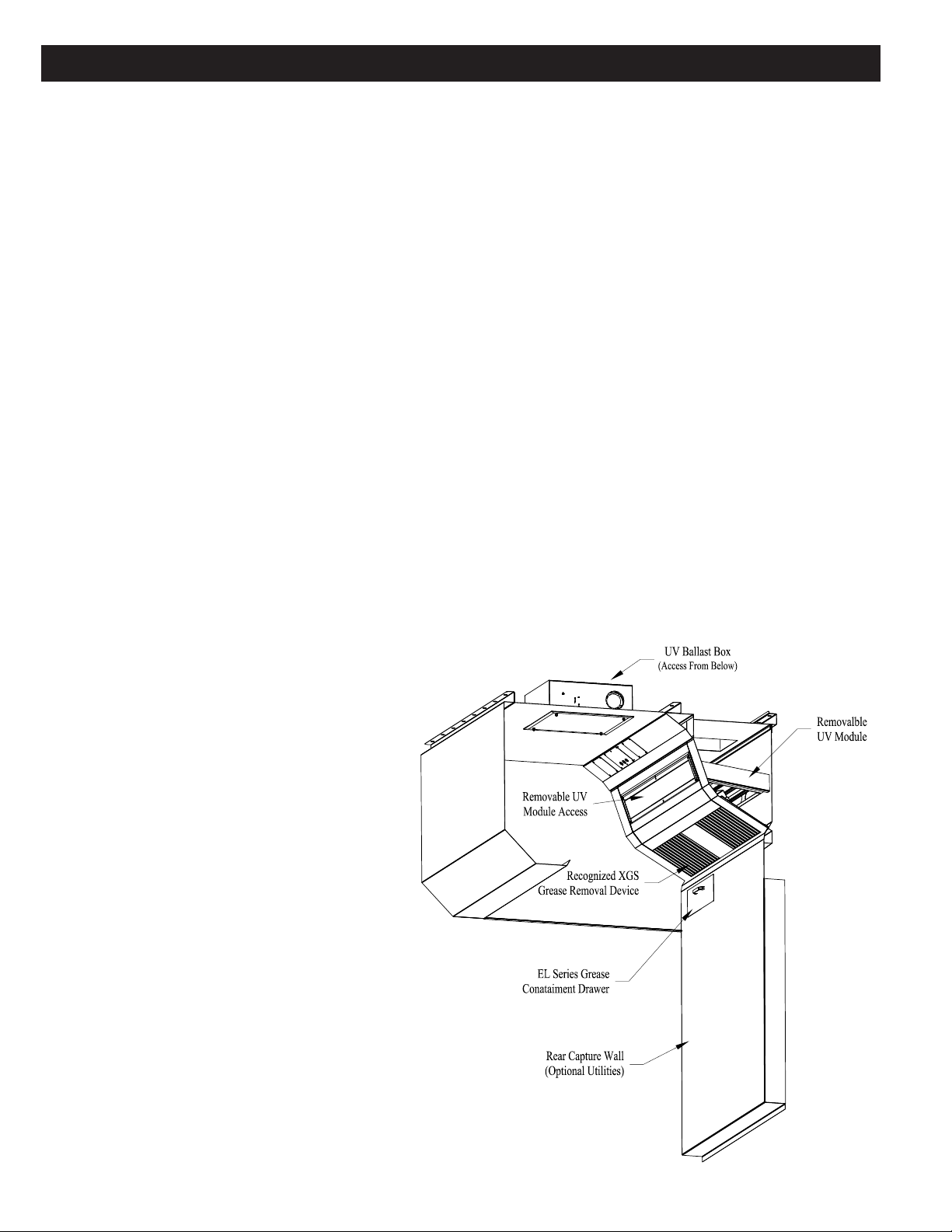

ELX SERIES VENTILATOR MODEL DESCRIPTION

MODEL “ELX”

APPLICATION - Wall mounted

canopy style.

MODEL “ELX-BBC”

APPLICATION - Used for cafeteria lines or

any other single line island arrangement.

FIGURE 1

Standard Ventilator Models

MODEL “ELX-BB”

APPLICATION - Used for typical island

style back to back cooking arrangement.

High Efficiency XGS Extractor

Will remove up to 4 times as much

grease as a Standard Baffle Filter

Enlarged Grease Cup to Collect

Captured Grease

(Regular Service May Be Required)

FIGURE 2

Model ELX Shown

1

Gaylord Ventilator model numbers are made up of an alphabetic prefix followed by a series of

alphabetic and/or numeric suffixes to designate the style of the ventilator and various options.

Sequence of model numbers is as follows.

1.______ 2.______ 3._______ 4._______ 5._________ 6.________ 7. _______

Series Damper Style Front lip Apron Design Canopy Front Spark

Type Design (If Applicable) Height Option Arrestor

Option (If Applicable)

Explanation of Prefixes and Suffixes

1.

Series

"

EL…………………….. Non water-wash ventilator with UL 1046 filters

ELX ........................... Non water-wash ventilator incorporating XGS Extractors

ELX-UV .................... Non water-wash ventilator incorporating XGS Extractors and UV Lamps

ELX-ENL……………. Non water-wash ventilator incorporating XGS18 Enlarged extractor.

Damper Type

2.

GBD.......................... Gaylord Balancing Damper. Has a mechanical balancing damper located at the duct collar

GFBD ....................... Gaylord Fire Balancing Damper. Has an electric, thermostatically activated Fire/Balancing

GEBD ....................... Gaylord Electric Balancing Damper. Has an electric balancing damper located at the duct collar

FDD…………….. ...... Weighted Fuse Link activated damper located at the duct collar. 280°F Fuse link standard.

ND ............................ No Damper

Style

3.

Blank ........................ Wall Mounted canopy style

CL ............................. Island style for single line

BBC-CL .................... Island style for single line

BBC ......................... Island style for double line

BB ........................... Island style for double line

Front Lip Design

4.

Blank......................... Facetted front design with 6 inch return flange. (3 Break or greater 90° at front lip)

C ............................... Chamfer (6 x 6) with 6 inch return flange

S ............................... Square front with 12" “Super Capture” lip

Apron Design Designation

5.

Blank ......................... Rear Wall to be added below hood

A ............................... Hood to have an Apron, which will terminate at the bottom lower edge of the canopy.

UW ............................ Utility Wall to be added below hood. Note: DCR-WM model Utility Distribution System to be

Canopy Front Height Option

6.

Blank......................... 30 inch

MP ............................ Medium Profile - 24 inch

LP ............................. Low Profile - 12 inch

Spark Arrestor

7.

SPA .......................... Uses “XGS-SPA” or “XGS18-SPA” Spark Arrestor Extractors – for solid fuel applications.

ENERGLINK"

(Standard)

damper located at the duct collar and back draft feature. 325°F Thermostat standard.

with back draft feature.

of cooking equipment using one extraction chamber (Light-Medium

Duty only)

of cooking equipment using one extraction chamber with one common

exhaust duct (Light-Extra Heavy Duty)

of cooking equipment using one extraction chamber. Has one

exhaust duct.

of cooking equipment using two extraction chambers. Has two

separate exhaust ducts.

(Front lower edge of the hood)

added as a separate piece of equipment.

or greater Canopy Height

Front height hoods. Extractors range from 24 to 30 inches tall.

Models containing UV are required to have 30 inch tall extractors.

to 23 inch front height. Extractors range from 24 to 30 inches tall.

(If Applicable – 700°F Applications only)

2

PRINCIPLES OF OPERATION

UL 710 Recognized XGS

Model Commercial Kitchen

Grease Extractor Must Always

be in Place to Protect Downstream

Ductwork

and IMC

or

UL 710 Recognized XGS

Model Commercial Kitchen

Grease Extractor

FAN OPERATION

To operate the exhaust fan turn on the fan switch that

is typically mounted on a wall near the hood. The “EL”

Series hood may be equipped with a fan, auto start

controller, and/or light switch mounted on the face of

the hood.

GREASE EXTRACTION

The Gaylord Industries Patent Pending “XGS” Extractor

Cartridge is designed to deliver the absolute optimum

in collection efficiency at the lowest possible pressure

drop. The units are ETL recognized as part of the “ELX”

Ventilator. They are constructed of corrosion resistant

stainless steel.

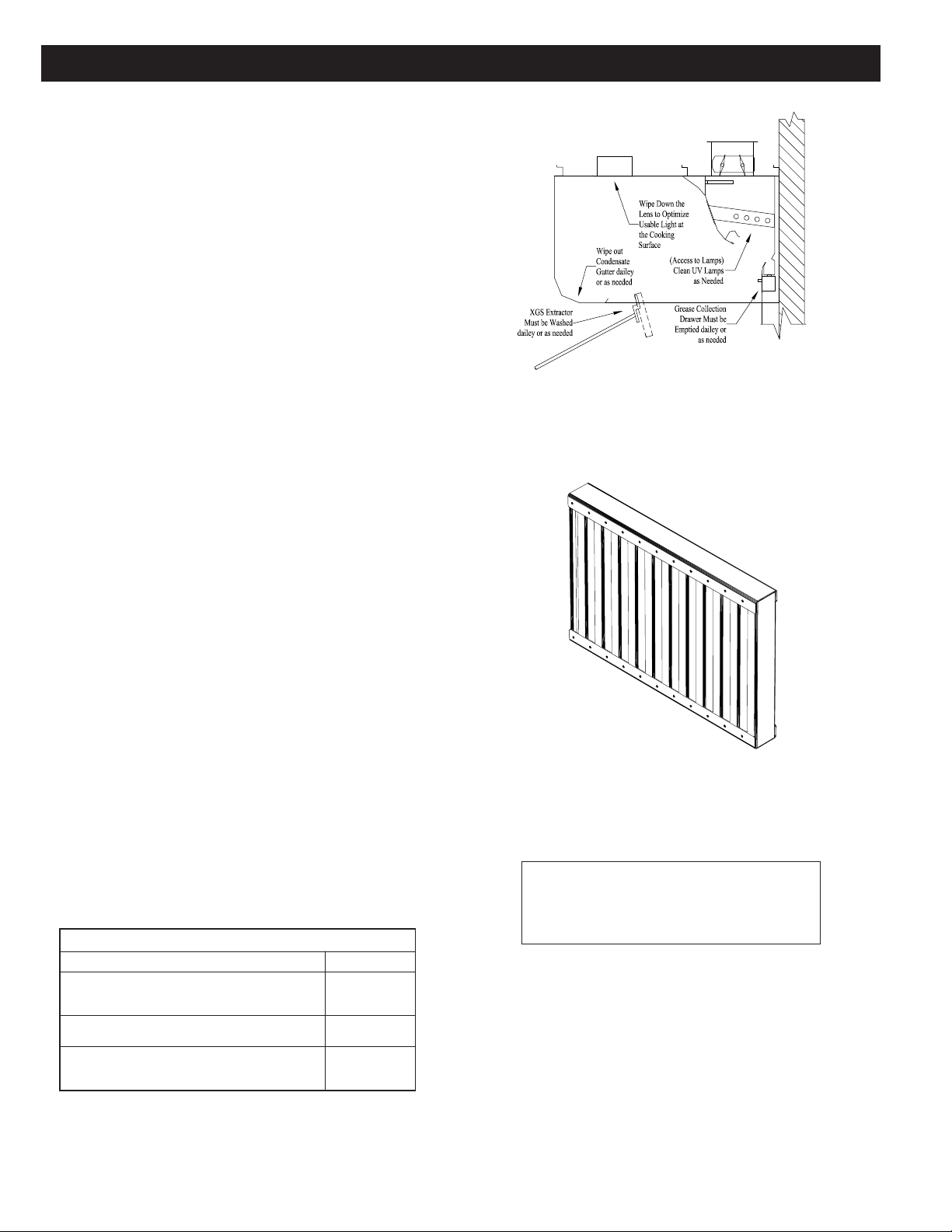

FIGURE 4

Grease Extraction

FIGURE 5

Cleaning

FIGURE 6

Fire Protection

3

PRINCIPLES OF OPERATION

UV LAMPS

Systems incorporating UV lamps will have the extra added benefit

of futher break down of grease, in some cases down to CO

and base minerals. The processes called “Photolytic Oxidation”, and

“Ozonolysis” are the drivers behind keeping your ducts clean and

free of containments for much greater durations over conventional

kitchen exhaust systems not utilizing the UVC technology. The

processes break down, and condition grease dramatically reducing

its ability to burn or in some cases even combust. For proper UV

operation, the hoods must be maintained in good working order.

UV lamps will accumulate a gray-brown dust on them that will have

to be periodically wiped off from below. Duct work will have to be

inspected in accordance with NFPA-96 or local guidelines, though

frequency of duct cleanings will be dramatically reduced.

Important Notice:

Extractors in place. The XGS Extractor is a light attenuation barrier

to remain in place at all times during the use of your UV system.

Never operate your ventilator without the XGS

, H2O,

2

CLEANING

At the end of the cooking day the fan is to be turned off and the

XGS Extractors are to be removed from the hood and cleaned. The

XGS Extractors can be washed either in a dishwasher or soaked

and rinsed off. Periodic scrubbing of the extractors may be necessary in lines servicing busy kitchens, or lines using sugary sauces

or bastings.

The UV lamps will develop a coating of dust, and sometimes debris

that will have to be wiped away to optimize the UVC Systems performance. The lamps should be inspected weekly after the filters

are removed. When necessary, the lamps can be cleaned from

below by carefully wiping the bulbs with a wet cloth using some

mild detergent. A maintenance rotation should be initiated at the

point of start up by a Gaylord Industries certified Service Agent to

address any maintenance, or repair issues that may be required.

FIRE PROTECTION

NFPA-96 and the IFC requires the use of Surface Fire Protection

(Duct, Plenum, Surface/Appliance) on all hoods. It is these systems

that are the first line of defense against equipment fires. Refer to

the fire extinguishing system owner’s manual for operation and

maintenance instructions for these systems.

The “ELX-GFBD” Series ventilator incorporates a fire / balancing damper installed in the duct collar to protect your ducts, fans,

and roof tops from the threat of fire in the event your primary fire

protection system fails to extinguish the fire. In the event of a fire

when the thermostat reaches it set point of 325°F, the power to the

damper will be cut allowing the dual blade damper to spring shut

sealing the duct entrance and keeping the fire contained in the

plenum, where it can be properly managed. Exhaust dampers are

an excellent way to reduce the threat of fire spreading to your roof

top and loaded grease ducts.

The hood may also be supplied without a fire damper, which would

be designated by either the suffix “ND” or “GBD” in the model number. “GBD” designates a balancing ONLY damper. Refer to the

nameplate on the hood for the exact model number designation.

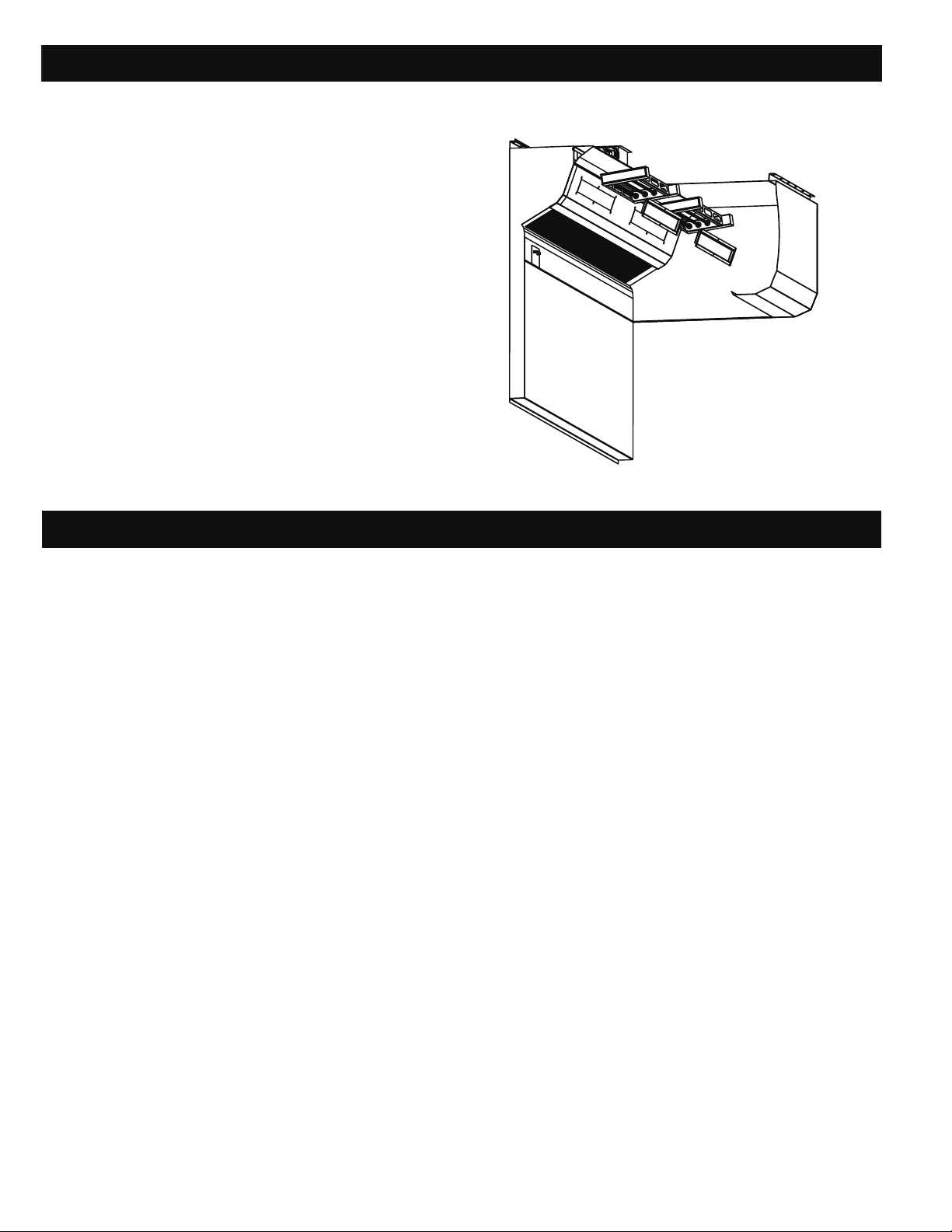

FIGURE 7

ELX-GFBD Model

4

MAINTENANCE AND CLEANING INSTRUCTIONS

ELUDEHCSNOITCEPSNIMETSYSTSUAHXE

snoitarepognikoocleufdilosgnivressmetsyS ylhtnoM

snoitarepognikoocemulov-hgihgnivressmetsyS

kowrogniliorbrahc,gnikoocruoh-42sahcus

gnikooc

ylretrauQ

gnikoocemulov-etaredomgnivressmetsyS

snoitarepo

yllaunna-imeS

,snoitarepognikoocemulov-wolgnivressmetsyS

lanosaes,spmacyad,sehcruhcsahcus

sretnecroinesro,sessenisub

yllaunnA

At the end of each cooking day, the exposed interior surfaces of the hood

should be wiped down and the grease cup emptied. During the course of

operation, grease particles are gradually collecting inside the XGS extractors. Daily, or at periodic intervals, depending on the type of cooking, the

XG extractors must be removed and cleaned. To clean, proceed as follows:

1. Remove extractors. CAUTION: Care should be taken when removing extractors, especially over fryers. It is recommended that the

cooking equipment be cooled down and the fryers be covered prior

to removing extractors. To remove, lift up slightly on extractors and

pull out at the bottom, then straight down.

2. Extractors may be cleaned either by using a dishwasher or by soaking in deep well sink using hot water with a degreasing detergent,

scrubbed and rinsed. Formula G-510 is highly recommended for

this application. For information contact:

20/10 Products

P.O. Box 7609

Salem, Oregon 97303

Phone: 800-286-2010

Fax: 503-363-4296

email: twentyten@juno.com

3. With extractors removed, wipe and clean the back wall and top of the

plenum area and the grease gutter with hot detergent water. NOTE: If

steam or hot water pressure wash is used for periodic cleaning of the

interior, remove the grease drawer and connect a hose to the gutter

drain and lead it to a floor sink or large bucket to drain off water.

4. When applicable, periodic cleaning of the UV lamps will be required.

After removing extractors for servicing, wipe the UV bulbs down with

a clean wet rag to remove any contaminants or grease that may have

collected on the lamps. Failure to maintain the cleanliness of the

lamps will reduce the UVC systems ability to reduce the build-up of

grease and debris on ducts and fans.

5. Replace extractors. Be sure to replace extractors with openings running vertical as shown in Fig. 9. Note: Arrow will designate “UP”.

IMPORTANT NOTE: In the event of a fire the thermostat must be replaced.

(Applicable to GFBD models only.)

NOTE: NEVER OPERATE THE HOOD

FIGURE 8

IF THE FILTERS ARE NOT IN PLACE.

INSPECTION AND CLEANING REQUIREMENTS

The 2008 edition of NFPA-96 (Standard for Ventilation Control and Fire

Protection of Commercial Cooking Operations) require that hoods, ducts

and exhaust fans be inspected by a properly trained, qualified and certified

company or person(s) in accordance with the following table.

Upon inspection, if found to be contaminated with deposits from greaseladen vapors, the entire exhaust system shall be cleaned by a properly

trained, qualified, and cer tified company or person(s) acceptable to the

authority having jurisdiction in accordance.

When a vent cleaning service is used, a certificate showing date of inspection or cleaning shall be maintained on the premises. After cleaning

is completed, the vent cleaning contractor shall place or display within

the kitchen area a label indicating the date cleaned and the name of the

servicing company. It shall also indicate areas not cleaned.

Facto r y tr a ined ser vi c e agenci e s ar e cer t ified by Gayl o r d

Industries to perform these inspections. For the name and phone number of your nearest agent, call 1-800-547-9696 or go online to visit our

website at www.gaylordusa.com.

FIGURE 9

NOTE: FILTERS MUST BE INSTALLED WITH

BAFFLES RUNNING VERTICAL AS SHOWN.

CAUTION: Care should be taken when removing

extractors, especially over fryers. It is recommended that the cooking equipment be cooled down and

the fryers be covered prior to removing filters.

5

UV PREVENTATIVE MAINTENANCE

CERTIFIED SERVICE AGENT MAINTENANCE WARNING!

Warning: Do NOT defeat any interlocks during cleaning and maintenance!

system inspection schedule described in NFPA-96 and on the previous

page in this tech manual. These tasks involve potential exposure to high

doses of UV light and live electrical components. There is risk of injury

to skin and eyes and in the case of electrical shock, injury or death! For

a list of CSAs go to www.gaylordusa.com and go to “Service Agencies”

for a list of companies nearest you.

1. Inspection of the Lamps and Ballasts

(Check the lamps for proper operation)

a. Turn on the fan at your CUV-1000

2. Inspect the Plenum (Around the UV lamps)

a. Turn off Exhaust fan at CUV-1000

controller. Look for green “UV System On”

light at your CUV-1000 controller. If the

b.

audible alarm sounds, refer to “UV Trouble-

shooting” on pages 17 - 18.

Confirm the green status light on each hood

section controlled by your CUV-1000

controller.

b. Remove the UV Module access cover.

(Philips head screwdriver required.)

c. Disconnect the UV Module power connector.

(Half turn required.)

d. Remove the UV Module from the ventilator.

(Caution! Care must be taken to keep the connector

from hitting the lamps while removing the module.)

e. Carefully inspect the UV access cover and

replace gasket as needed to ensure a good seal.

f. Clean the UV Module as needed with a mild

detergent, water and non-abrasive rag. Lamps

should be free of all grease and debris.

g. Reinstall the UV Module, being careful to not

hit the lamps. Re-secure the Module connector

and UV access door.

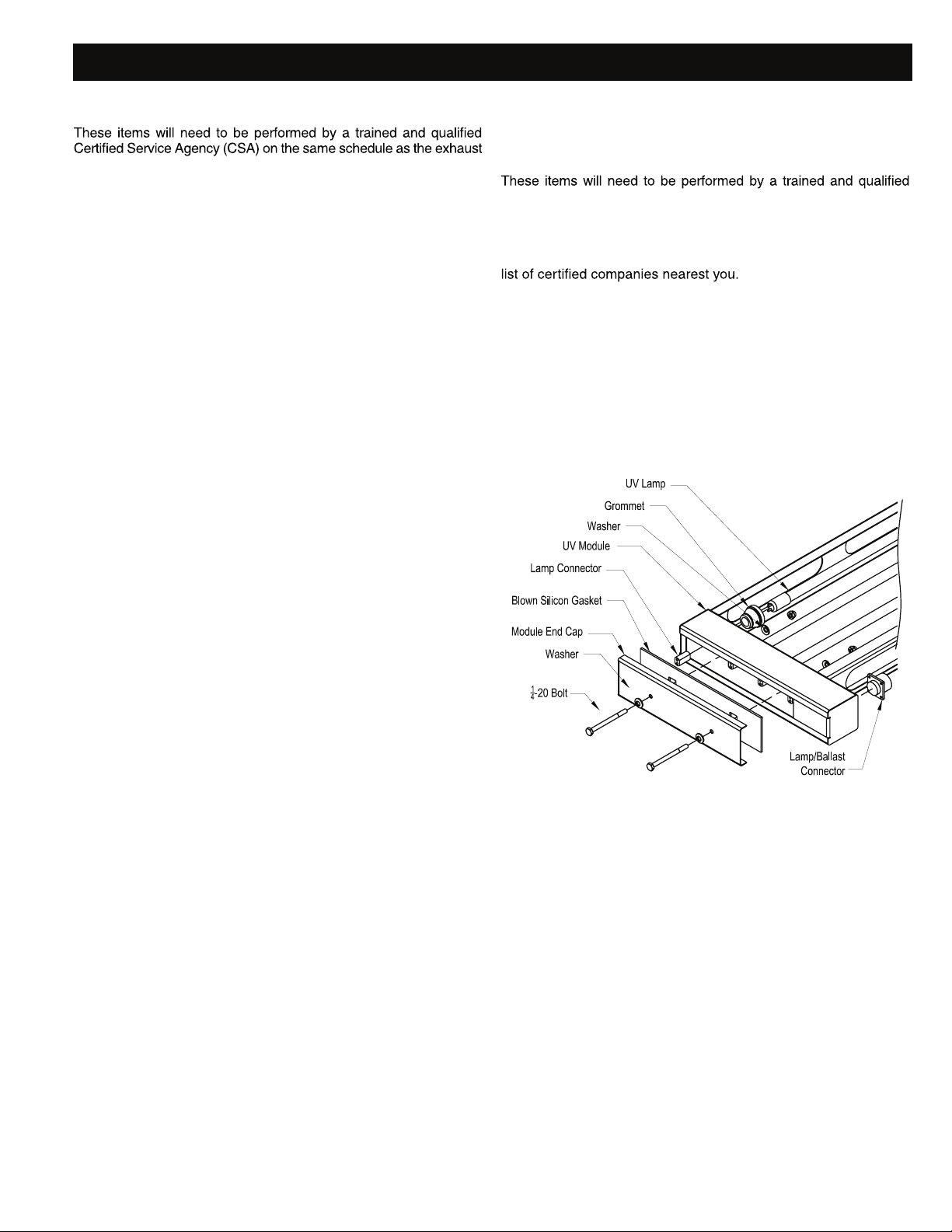

Replacing UV Lamps

Danger!

Certified Service Agency (CSA). These tasks involve potential

exposure to high doses of UV light and live electrical components.

There is a risk of serious injury to skin and eyes from UV light. There

is risk of shock, injury, and/or death from electrical. For a list of CSA’s

go to www.gaylordusa.com and go to the “Service Agencies” for a

Secure all power to the CUV-1000 control1.

Secure all circuits that provide power to the UV lamps2.

Open the UV Module Access door3.

Disconnect the UV module power connector4.

Remove the UV module from the ventilator 5.

Remove the bolts on the end of the UV module (2 total) 6.

that hold the end cap on. (see below)

3. Test the Safety Interlocks, (Pressure Switches)

a. Activate fan at CUV-1000, all Hood sections will

show the “UV System On” lamp activated at the

extractor.

b. Remove the XGS Extractor at the left side of the

hood. Lamps will deactivate. If lamps do not

activate, immediately shut down the CUV-1000

and go to “UV Troubleshooting” pages 17 - 18.

(Caution! Wear Polycarbonate Safety Glasses

when testing the UV Interlocks.)

c. Repeat the above steps for the right most XGS

Extractor and the center most Extractor. UV

System will deactivate accordingly, if not, shut

down, and refer to “UV Troubleshooting” pages

17 - 18.

4. Check all gaskets for damage

a. Replace any gaskets that are worn or damaged only

5. Check the Hour Meter

a. Record the hours

c. Determine when the 8000-hour life of the lamps will

with factory provided replacements.

b. Determine the approximate hours between inspection

intervals.

occur and inform the operator of the approximate date

when the lamps will need to be replaced.

FIGURE 11

Disconnect the lamp connector(s) on the UV lamp(s) to be 7.

replaced

Each lamp connector should be labeled from 1 to 4 •

Lamp #1 is at the Front of the ventilator when the UV •

module is installed

Lamp #4 is at the Back of the ventilator when the UV •

module is installed

Be sure to re-label the lamp connectors if necessary•

Lubricate the lamps around the grommets on each end of the 8.

UV lamp with a small amount of G-510 or similar detergent

Slide the UV lamp out one end, CAREFULLY!9.

Inspect the grommets around the lamps10.

Replace any grommets that show cracks, or any other •

damage

6

UV PREVENTATIVE MAINTENANCE CONTINUED

CERTIFIED SERVICE AGENT MAINTENANCE WARNING!

Warning: Do NOT defeat any interlocks during cleaning and maintenance!

11. Check all wires for damage

Replace any wires showing damage•

12. Lubricate each of the new UV lamp(s) before installing with a

small amount of G-510 or similar detergent

13. Re-connect the lamp connectors

Each lamp connector should be labeled from 1 to 4 •

Lamp #1 is at the Front of the ventilator when the UV •

Module is installed

Lamp #4 is at the Back of the ventilator when the UV •

Module is installed

14. Re-install the UV Module end cap and torque the bolts to

7-10 in-lbs.

15. Re-install the UV Module in the ventilator

16. Re-connect the UV Module power coNNECTOR

17. Tighten all quarter-turn screws holding the UV Module

cover to the ventilator

18. Check for proper operation of UV lamps & pressure

switches

FIGURE 12

SAFETY CONCERNS WITH UVC

As with many types of technology if it is not used properly and/or

proper precautions are not taken there is the potential for injury

or harm. This is especially true with UVC light due to the fact that

it does not physically hurt at the time of exposure. While UVC is

very effective at breaking down grease molecules, direct exposure

generated in these hoods is greater than that what results from

direct exposure to the sun. Under no circumstances is it acceptable

to view the lighted lamps without proper eye protection or expose

bare skin directly to the light. All interlocks and safety precautions

called for in this manual must be followed to avoid the potential for

harm to service personnel and/or operators. In addition, only trained

and authorized personnel may perform some maintenance See

previous page for details.

Personal Protective Equipment

Eye protection that prevents 100% of UVC being transmitted 1.

through the lens must be worn at all times when performing

service work on any ELX-UV that is energized and/or has

the potential to be energized and expose personnel to UVC

light.

Whenever service work is performed it is recommended that 2.

long sleeve pants and shirts be worn to minimize the potential

for inadvertent exposure of the skin to UVC.

Safety Interlocks

This product comes equipped with redundant pressure switches to

ensure the Exhaust Fan is running, and that every filter is in place.

All of the switches must be working and/or adjusted properly in

CVU fo tnuoma ehT .seye dna niks ot lufmrah si stnuoma egral ot

order for the system to operate properly.

7

OPTIONAL FIRE / BALANCING DAMPER GBD SERIES

Gaylord System Balancing (GBD)

The ELX Serie s Venti lator will optionally come with a Gaylor d

Industries Listed balancing damper. The options available are the

GBD-IS (balancing only damper), GEBD (electrical balancing damper), and the GFBD (fire balancing damper). The GBD-IS is set

from below and performs the task of raising or lowering the exhaust

airflow to any section that it is installed on. The GFBD is a fire / balancing damper that will close upon the thermostat reaching its set

point. The thermostat for the XG series ventilator is set to 325°F,

and must be factory installed. The balancing of the GFBD and GEBD

is done by way of a potentiometer found in the UV electrical box (see

Figure 19) or in another dedicated electrical box, accessed from

inside the canopy. (See Figures 4 & 8). The GFBD is intended to

close upon the deactivation of the exhaust fan every night. The

feature is intended to eliminate cool air from drafting down the exhaust ducts, and entering the kitchen.

For further details on the Gaylord Industries commercial kitchen

exhaust dampers, please consult the GBD technical manual.

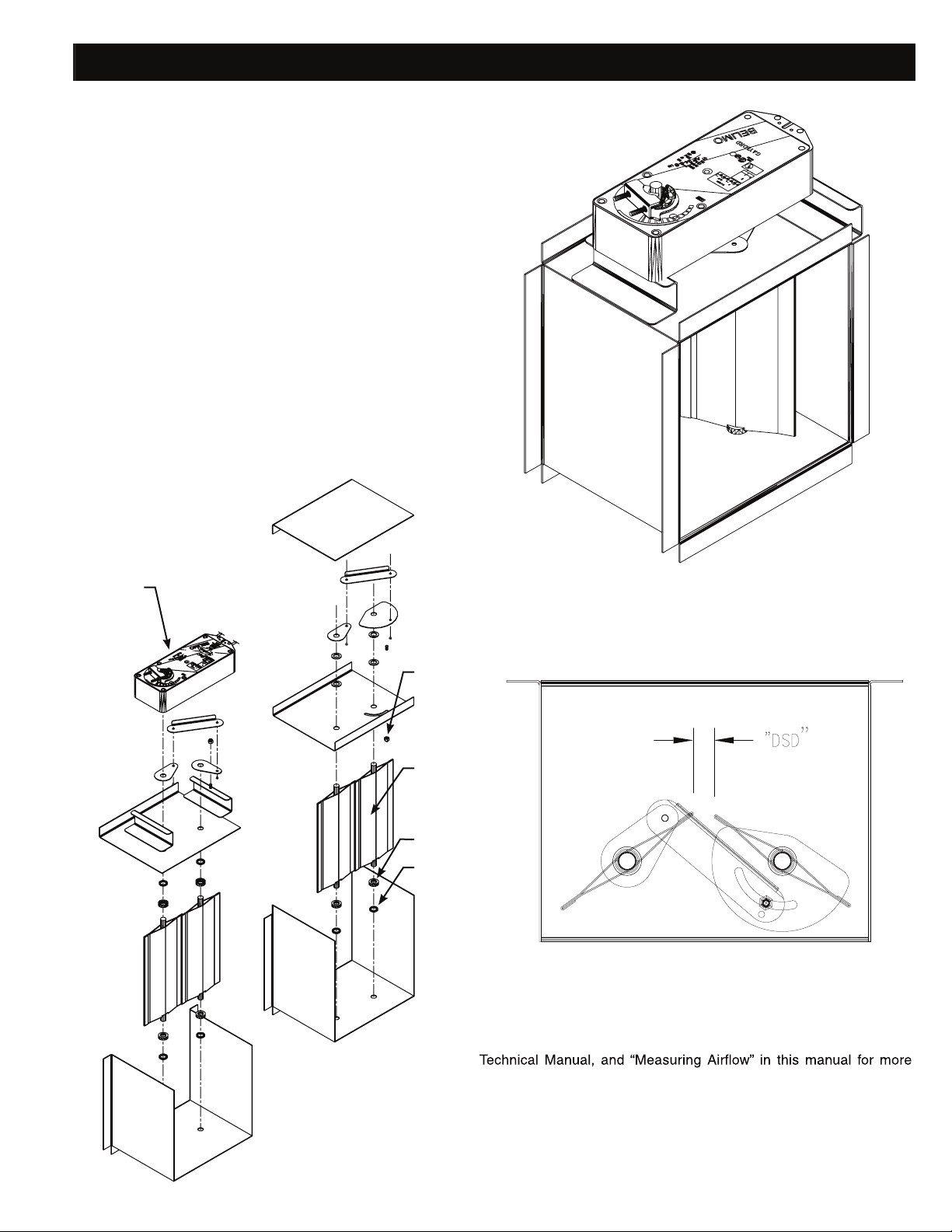

Damper Motor

GFBD Commercial Fire / Balancing Damper

FIGURE 14

Self Locking

Fastener

Damper Blade

Brass Support

Ring

Oil Seal

FIGURE 15

GBD “DSD” Damper Set Dimension

The adjustment of both systems relies on the internal dimension between

the two blades. Called the “DSD”. The manipulation of that distance will

accomplish your air balancing needs. See Figure 15, above, the GBD

FIGURE 13

details.

8

Loading...

Loading...