Gaylord EL-BBC-CL Service Manual

Rev 02

Operation, Maintenance

& Installation Manual

“EL” Series Commercial

Kitchen Exhaust Ventilators

For

GAYLORD INDUSTRIE S

10900 SW Avery Street – Tualatin, Oregon 97062 USA

Email: info@gaylordventilation.com

www.gaylordventilation.com

Toll Free 800-547-9696 – Fax 5023-692-6048

All rights reserved. No part of this book may be reproduced, stored in a retrieval

system, or transmitted in any form by an electronic, mechanical, photocopying,

recording means or otherwise without prior written permission of Gaylord

Industries.

©Copyright 2013, Gaylord Industries

The manufacturer reserves the right to modify the materials and

specifications resulting from a continuing program of product

improvement or the availability of new materials

Additional Copies $25.00 Each

__________________________________________________________________________________Page iii

Page iv__________________________________________________________________________________

This Page Intentionally Left Blank

______________________________________________________________________________Page v

Table of Contents

Chapter 1 – Introduction

Introduction ……………………………………………………………………………………………………………………… 1-1

Model Description …………………………………………………………………………………………………………….. 1-2

Model Number Explanation ………………………………………………………………………………………………. 1-3

Chapter 2 – Operation and Maintenance

Turning on Exhaust Fan ………………………..………..................................................................... 2-1

Turning off Exhaust Fan ..………………….. .…….…………………………………………………………………….. 2-1

Grease Extraction …………….………………………………………………………………………………………………. 2-2

Maintenance and Cleaning Instructions ……………………………………………………………………………. 2-3

Inspection and Cleaning Required by Code ………………………………………………………………………. 2-4

Detergent for Cleaning …………………………………………………………………………………………………….. 2-5

Fire Protection …………………………………………………………………………………………………………………. 2-6

Chapter 3 - Troubleshooting

Troubleshooting ………………………………………………………………………………………………………………. 3-1

Chapter 4 – Testing and Repair

Measuring Airflow ................................................................................................................. 4-1

Make-Up Air Guidelines …………………………………………………………………………………………………… 4-5

Balancing Dampers …………………………………………………………………………………………………………… 4-7

Chapter 5 - Parts

Parts ...................................................................................................................................... 5-1

Chapter 6 – Wiring Diagrams

Wiring Diagrams …………………………………………………………………………………………………………….. 6-1

Appendices

Installation Requirements ………………………………………………………………………………………………. A-1

Post Installation Check List ……………………………………………………………………………………………… B-1

Page vi__________________________________________________________________________________

This Page Intentionally Left Blank

___________________________________________________________Chapter 1 – Introduction, Page 1-1

Introduction

About this Technical Manual

The purpose of this manual is to provide the Operator, Maintenance and Service personnel instructions for

operating, maintaining and troubleshooting the Gaylord Ventilator. This manual also includes information

and guidance to contractors for the initial installation of the Ventilator.

The manual is divided into chapters for easy reference to a particular subject. The pages in the chapters

are numbered with the chapter number then a dash and then the page number. So for example pages in

Chapter 2 are numbered 2-1, 2-2, 2-3 etc. Figures and Tables are numbered in a similar manor. For

example Figure 5-3-2 is on page 5-3 and is the second figure. Please keep your manual in a convenient

location for so it can be accessed easily.

If you have any questions or concerns with the installation, operation, maintenance or service of your

Gaylord Ventilator, please contact Gaylord Industries;

Web: www.gaylordventilation.com

E-mail: info@gaylordventilation.com

Main Phone: 503-691-2010 Toll Free: 800-547-9696

Safety

It is important that the operator read Chapter 2, Operation and Maintenance, before operating the

Ventilator for the first time. Particular attention should be given to all the Caution and Warning

statements.

Related Technical Manuals

1. EL Series Ventilators installed in the United States typically include a Gaylord Autostart Control. In

some instances Ventilators installed outside the United States will include an Autostart Control. To

determine if the Ventilator includes an Autostart Control refer to page 1-3 and the Nameplate

mounted on the Ventilator (Refer to Figure 4-4-1). The specific manual for this control is titled

Operation and Maintenance Manual for the Gaylord Autostart Control.

2. EL Series Ventilators may be used in combination with Gaylord ELX or ELXC Series Ventilators.

In this case the exhaust fan would be controlled by a Gaylord Command Center. The specific

manual for the Command Center is titled Operation, Maintenance and Installation Manual for the

Gaylord Command Center and Wash Control Cabinet. Use this manual for all exhaust fan start and

stop functions.

Operation and Maintenance Manuals may be downloaded from the Gaylord website:

www.gaylordventilation.com or be obtained by calling Gaylord Industries.

Chapter 1 – Introduction, Page 1-2___________________________________________________________

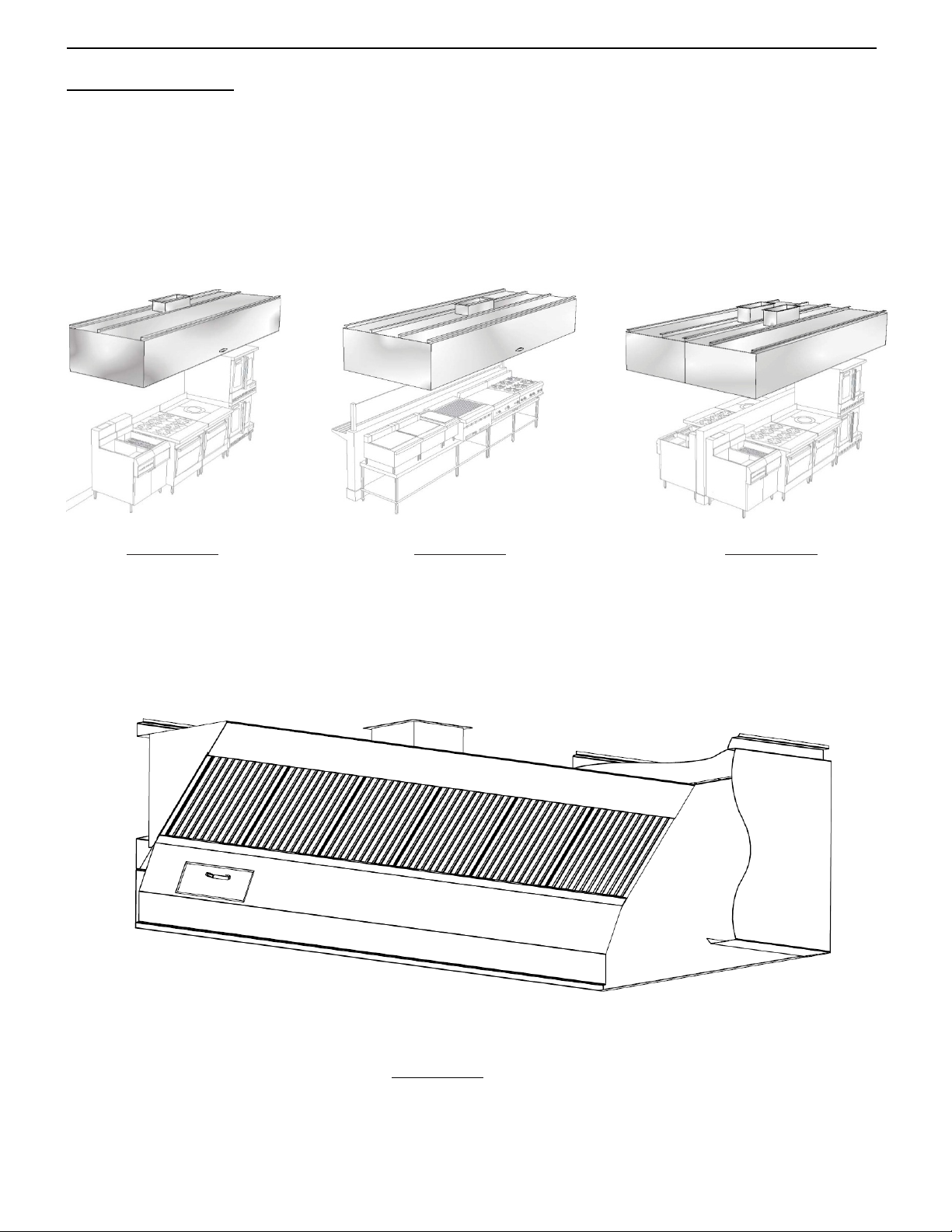

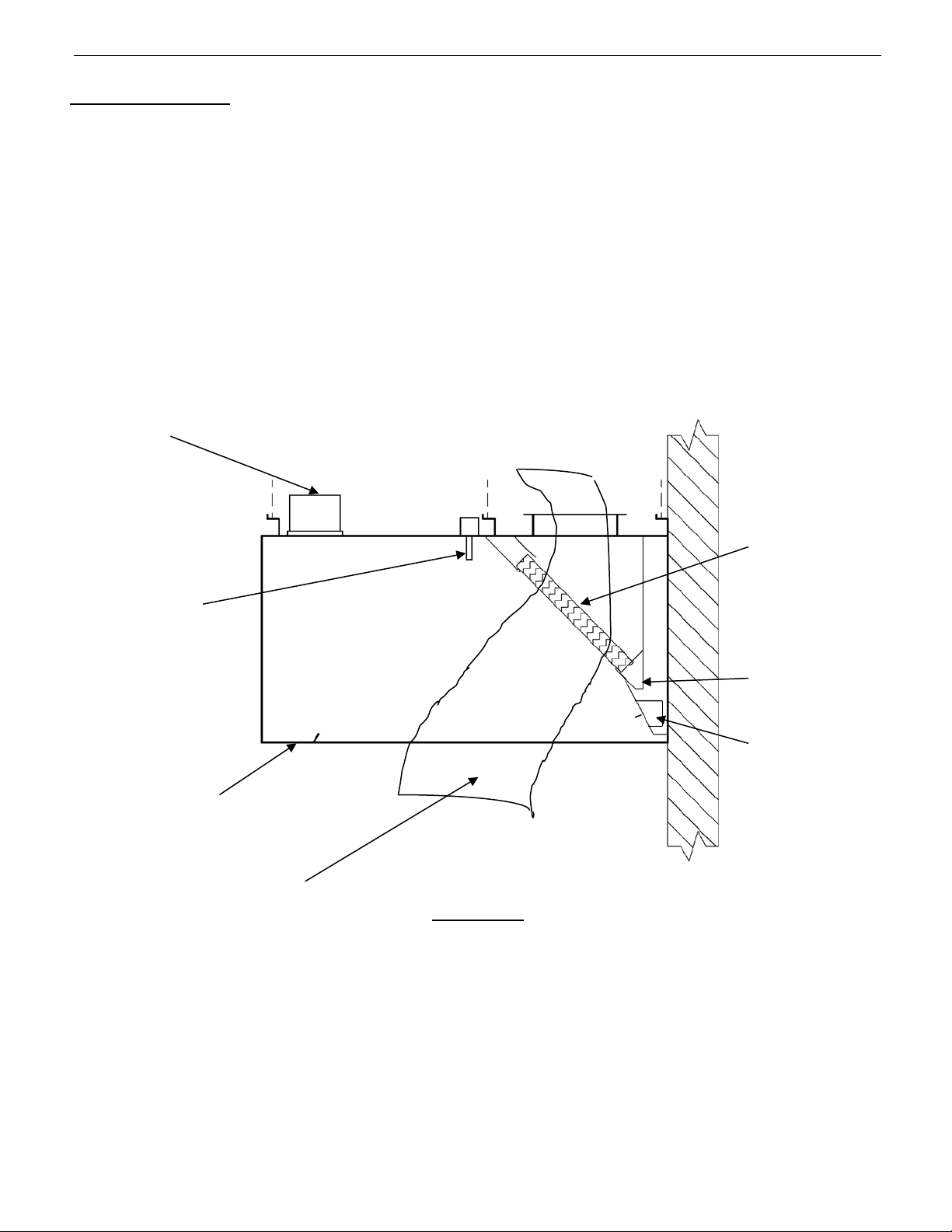

Figure 1-2-1

Figure 1-2-2

Figure 1-2-3

Figure 1-2-4

Model Description

Overview

The Gaylord Model EL Series Ventilator uses a Listed aluminum baffle filters as a standard or as an option

stainless steel filters, Gaylord XGS high efficiency Extractors, or spark arrester filters.

The EL Ventilators come in many different models, some of which are illustrated below. Your Ventilator

may appear slightly different as they may have been custom designed to fit the space and application.

Model EL Series

Wall mounted Canopy Style

MODEL EL-BBC-CL Series

Island Style for Single Island

Arrangement

MODEL EL-BB Series

Island Style for Double Island

Arrangements

Cut-away view of Canopy Style Ventilator

___________________________________________________________Chapter 1 – Introduction, Page 1-3

Series

Damper

Filter

Controls

Hood

Front Lip

Style

Canopy

Material

Model Number Explanation

Model Number Sequence

Gaylord Ventilator model numbers are made up of an alphabetic prefix followed by a series of alphabetic

and/or numeric suffixes to designate the style of ventilator and various options. Sequence of model

numbers is as follows.

1._____________ 2.______________ 3.______________ 4._____________ 5._____________ 6. _____________ 7. _____________ 8. ______________ 9. ______________

Type

Design

Option

Profile

Option

Type

Depth

(in)

Definition of Prefixes and Suffixes

1. Series

EL…...............…… Non-water-wash Ventilator with UL 1046 filters.

2. Damper Type

SD ........................... Listed Slide Gate Balancing Damper located at the duct collar (Standard).

ND .......................... No Damper.

GEBD ………………….. Gaylord Electric Balancing Damper.

GBD ……………………. Gaylord Balancing Damper.

3. Style

Blank ...................... Wall Mounted Canopy Ventilator.

CL ........................... Island Ventilator for single line of cooking equipment using a single plenum

chamber.

BBC-CL .................... Island Style for single line of equipment using one plenum chamber with one

common exhaust duct.

BB .......................... Island Style for double line of equipment using two plenum chambers and two

separate exhaust ducts.

4. Front Lip Design (Front lower edge of the hood)

S ............................. Square front with 6" “Super Capture” lip (Standard).

Blank ...................... Facetted front design with 6 inch return flange (3 Break or greater 90° at front lip).

5. Canopy Profile

Blank ...................... Standard Profile - 30 inch or greater canopy height.

MP ......................... Medium Profile - 24 inch front height. Rear height range from 24” to 30” inches

tall.

LP ........................... Low Profile - 12 inch to 23 inch front height. Rear height range from 24” to 30”

tall.

6. Filter Option

AL ........................... Uses Aluminum Baffle filters (Standard).

SS ........................... Uses Stainless Steel Baffle Filters.

XGS ………………….. Uses 18” tall Gaylord XGS high efficiency Extractors.

SPB ......................... Uses a listed NFPA-96 accepted spark arresting baffle filter.

Chapter 1 – Introduction, Page 1-4___________________________________________________________

Definition of Prefixes and Suffixes – Cont.

7. (Controls) Automatic Start/Demand Control Option

Blank ...................... No Autostart - Does not have Autostart system.

AS ........................... Autostart - Ventilator has Autostart utilizing bi-metallic thermostats.

DCA ........................ Demand Autostart - Ventilator has Autostart utilizing RTD’s and a hood mount

circuit board.

DCV-F ..................... Demand Control Fan - Ventilator is equipped with RTD’s to connect to DCV-F

system.

8. Material Type

300 …………………... Indicates 300 Series Stainless construction.

400 …………………... Indicates 430 Series Stainless construction.

9. Hood Depth (Front to back dimension of Ventilator)

(##.###) .................. Value in inches to indicate the Ventilator depth.

______________________________________________Chapter 2 – Operation and Maintenance, Page 2-1

Turning On the Exhaust Fan

Caution: Always turn on the exhaust fan before turning on the cooking equipment.

Caution: The chemical fire extinguishing system may discharge if the exhaust fan is not on while the

cooking equipment is on or still hot.

Caution: Never operate your Ventilator without the Grease Filters in place. Refer to Figure 2-1-1.

To operate the exhaust fan flip the fan switch to the ON position. The switch is typically mounted on a wall

near the Ventilator or it may be mounted on the face of the Ventilator.

Note 1: The EL Series Ventilator may be equipped with a Gaylord Electric Balancing Damper, designated

“GEBD” in the Ventilator model number. The Ventilator model number can be found on the Ventilator

Nameplate (Refer to Figure 4-4-1 for a sample of the nameplate and to Page 4-7 for information on

Balancing Dampers). If the Ventilator includes this damper, when the fan is started the damper moves

from the closed to open position and it will take approximately 45 seconds for the exhaust to come up to

100%.

Note 2: Typically EL Series Ventilators installed in the United States are equipped with a Gaylord Autostart

Controller Model AS or DCA that automatically turns on the exhaust fan if the temperature at the sensors

mounted in the canopy exceeds 90°F. (Refer to Figure 2-2-1). In some instances Ventilators installed

outside the United States will include an Autostart Control. Inclusion of an Autostart Control is designated

by the suffix AS or DCA in the model number. The Ventilator model number can be found on the

Ventilator Nameplate (Refer page 4-4-1 for a sample of the Nameplate). Refer to the Operation,

Maintenance and Installation Manual for the Gaylord Command Center for complete information on the

Autostart Control.

Note 3: If Gaylord model ELX-UVi or ELXC Series Ventilators are connected to the same exhaust fan as an

EL Series, then the exhaust fan would be controlled by a Gaylord Command Center. The manual for the

Command Center is titled Operation, Maintenance and Installation Manual for the Gaylord Command

Center and Wash Control Cabinet. Refer to this manual for instructions for turning on and off the exhaust

fan.

Turning Off the Exhaust Fan

Caution: Always turn off the cooking equipment and allow cooling before turning off the exhaust fan.

The chemical fire extinguishing system may discharge if the cooking equipment is on or hot when the

exhaust fan is off.

At the end of the cooking day, turn off the cooking equipment and allow cooling before turning off the

exhaust fan. To turn off the exhaust fan flip the fan switch to the OFF position

Note 1: If the Ventilator includes a Gaylord Autostart Controller the exhaust fan will stay on if the

temperature at the duct collar is above 90°F. Once the temperature drops below 90°F., the fan will

continue to run for 20 to 60 minutes and then shut off.

Note 2: If the Ventilator is equipped with a Gaylord Electric Balancing Damper, designated GEBD, when

the fan is turned off the damper will move from the open to the closed position, and remain closed until

the exhaust fan is re-started. Closing the damper saves building energy by not allowing conditioned air

from drafting up the exhaust duct, or in cold climates prevents cold air from coming down the duct and

into the kitchen.

Chapter 2 – Operation and Maintenance, Page 2-2______________________________________________

Light Fixture

Autostart Sensor

Grease Laden Air

Listed Baffle

Extractors

Grease Gutter

Grease Drawer

Figure 2-2-1

Super Capture Lip

Grease Extraction

Grease is extracted by either Listed Grease Filters or by the use of Gaylord Model XGS Extractors. Grease

is removed from the exhaust air by centrifugal force as it passes through the filter. The hot grease laden

contaminated air rising from the cooking surface is drawn through the filters where a percentage of the

grease and other particulate are extracted from the airstream. The extracted liquid grease will drain down

the filters and into the Grease Gutter which then drains to the Grease Drawer. The sticky grease will

remain in the filters until cleaned.

The optional Gaylord Model XGS Extractor provides significantly higher grease extraction efficiency than

the Listed Grease Filters. The Extractors are ETL Recognized as part of the EL Ventilator. They are

constructed of corrosion resistant stainless steel.

Filters or

Gaylord XGS

Grease Extraction

______________________________________________Chapter 2 – Operation and Maintenance, Page 2-3

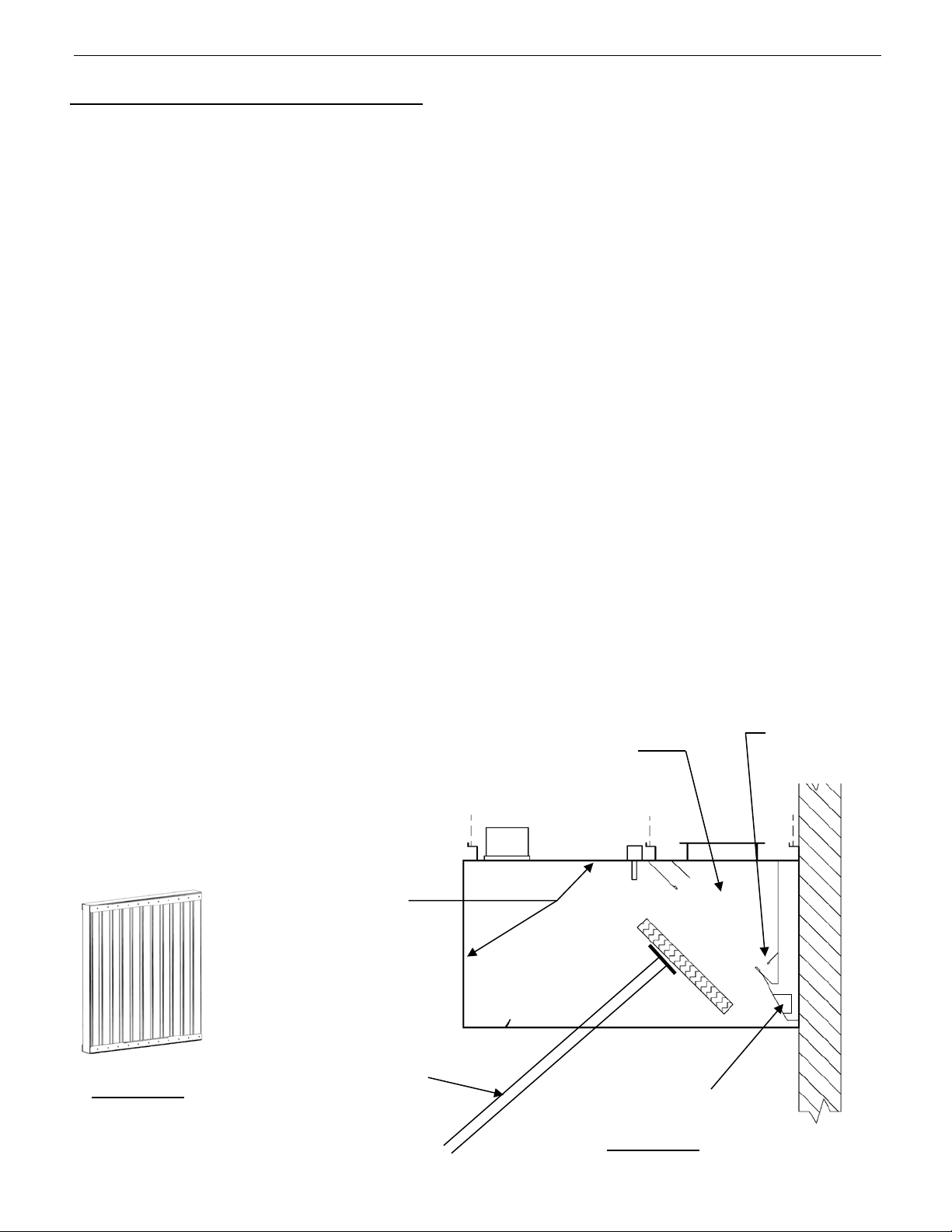

Figure 2-3-1

Filters or Extractors

Wipe interior

Figure 2-3-2

Filter / Extractor

Removable Tool

Inspect Plenum

Grease

Grease Drawer

Maintenance and Cleaning Instructions

Overview

To maintain the Gaylord Ventilator in good working order, and to keep the system operating at optimum

efficiency, preventive maintenance using the following schedule should be performed.

Daily Cleaning and Maintenance

At the end of the each cooking day, or at periodic intervals, depending upon the type of cooking, the filters

or XGS Extractors must be removed and cleaned. Caution: Before removing the filters/Extractors check to

see that the exhaust fan is shut off and the cooking equipment is cool. To remove the filters/Extractors

and clean proceed as follows:

1. Remove filters/Extractors: Caution: Care should be taken when removing the filters/Extractors,

especially over fryers. It is recommended that the cooking equipment be cooled down and the fryers

be covered prior to removing. They may be removed by hand or by use of an optional Filter/Extractor

Removal Tool (Refer to Figure 2-3-2). To remove, lift up slightly on the Filter/Extractor and pull out

from the bottom, then straight down.

2. The Filter/Extractor may be cleaned either by using a dishwasher or by soaking in a deep well sink using

hot water with a degreasing detergent, scrubbed and rinsed. Gaylord Formula G-510EF detergent is

highly recommended for this application. Refer to Page 2-5 for details.

3. With the filters/Extractors removed inspect the back wall and the underside of the exhaust plenum. If

necessary clean with hot detergent water.

4. Wipe and clean the Grease Gutter.

5. Remove and empty the Grease Drawer and replace.

6. Replace the filters or Extractors. Important Note: Filters and Extractors must be installed with the

openings running vertical as shown in Figure 2-3-1. Gaylord XGS Extractors have an arrow stamped on

the face designating “UP”.

7. Wipe the interior surfaces of the hood as required.

must be installed with

openings running

vertical as shown below

Typical Filter or

Gaylord Extractor

Gutter

and Grease Gutter

- clean if necessary

surfaces as

Cleaning

Chapter 2 – Operation and Maintenance, Page 2-4______________________________________________

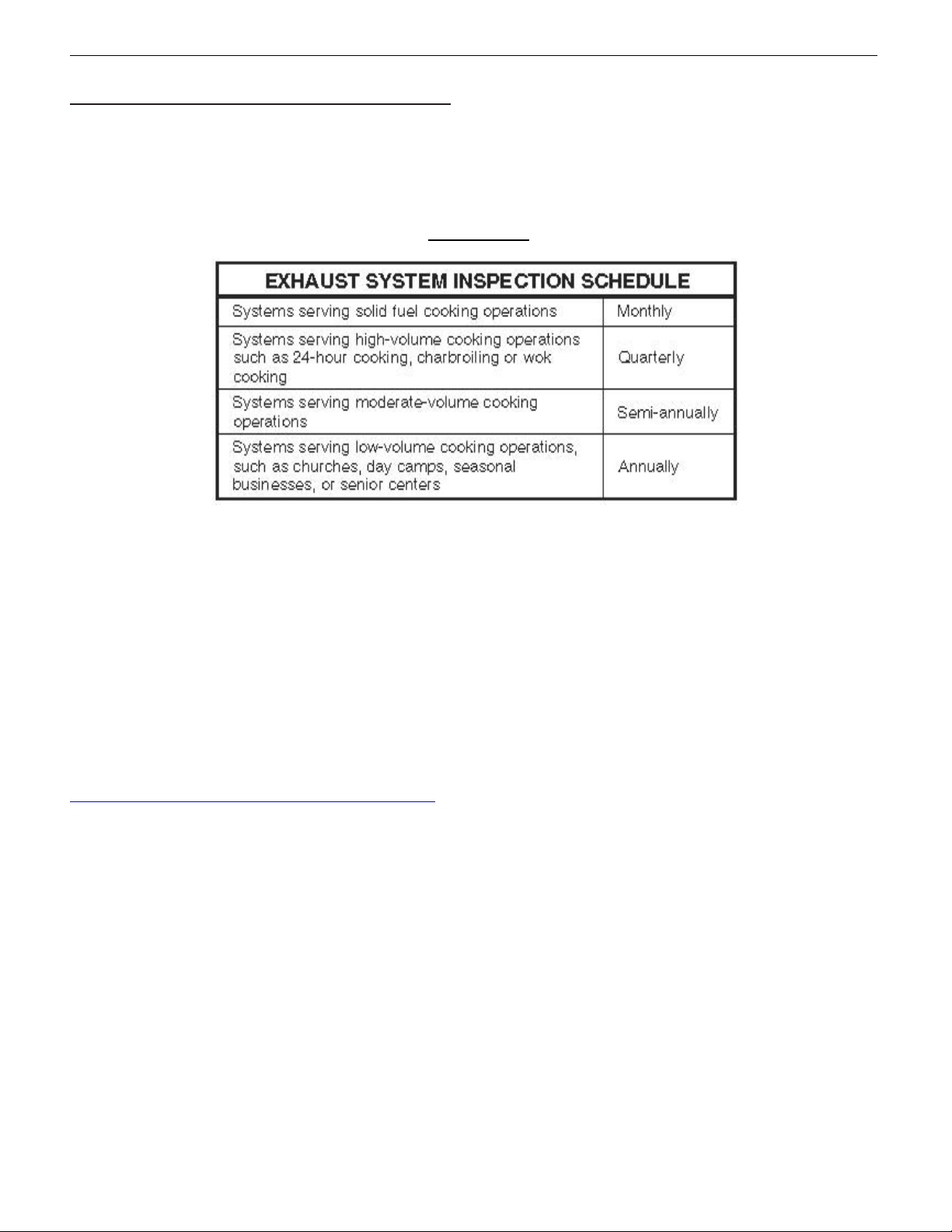

Table T-2-4-1

Inspection and Cleaning Required by Code

NFPA-96 (Standard for Ventilation Control and Fire Protection of Commercial Cooking Operations) require

that hoods, ducts and exhaust fans be inspected by a properly trained, qualified and certified company or

person(s) in accordance with the following table.

NFPA-96 states “Upon inspection, if found to be contaminated with deposits from grease-laden vapors,

the entire exhaust system shall be cleaned by a properly trained, qualified, and certified company or

person(s) acceptable to the authority having jurisdiction”.

“When a vent cleaning service is used, a certificate showing date of inspection or cleaning shall be

maintained on the premises. After cleaning is completed, the vent cleaning contractor shall place or

display within the kitchen area a label indicating the date cleaned and the name of the servicing company.

It shall also indicate areas not cleaned”.

Factory trained service agencies are certified by Gaylord Industries to perform these inspections. For the

name and phone number of your nearest agent, call 1-800-547-9696 or go to;

www.gaylordventilation.com/Service_Agencies/.

Loading...

Loading...