Date: 10-8-13

Rev 00

Demand Control Ventilation System

MODEL “DCV-AV” Series

Operators Manual

GAYLORD INDUSTRIE S

10900 SW Avery Street – Tualatin, Oregon 97062 USA

Email: info@gaylordventilation.com

www.gaylordventilation.com

Toll Free 800-547-9696 – Fax 5023-692-6048

All rights reserved. No part of this book may be reproduced, stored in a retrieval

system, or transmitted in any form by an electronic, mechanical, photocopying,

recording means or otherwise without prior written permission of Gaylord

Industries.

©Copyright 2013, Gaylord Industries

The manufacturer reserves the right to modify the materials and

specifications resulting from a continuing program of product

improvement or the availability of new materials

Additional Copies $25.00 Each

______________________________________ Page iii

Table of Contents

Chapter 1 – Introduction

About the Manual ……………………………………………………………………………………………………………….. 1-1

Safety ………………………………………………………………………………………………………………………………….. 1-1

System Overview……….…………………………..…………………………………………………………………………….. 1-2

How the AirVantage System Works ………………………………..……………………………………………………. 1-2

Chapter 2 – System Components

Overview …………………………………………………………………………………………………………………………….. 2-1

AirVantage Command Center………………………………………………………………………………………………. 2-2

Variable Frequency Drives ………………………………………………………………………………………………….. 2-3

Hood Control Enclosure ……………………………………………………………………………………………………… 2-3

Modulating Dampers ………………………………………………………………………………………………………….. 2-4

100% Fan Button ………………………………………………………………………………………………………………… 2-4

Resistance Temperature Detectors (RTDs)…………………………………………………………………………… 2-5

Chapter 3 – Operation

Overview ……………………………………………………………………………………………………………………………. 3-1

Starting the Exhaust Fan …..………………………………………………………………………….…………………….. 3-2

Turning on Ventilator Lights ……………………………………………………………………….……………………….. 3-5

100% Exhaust Override Button ………………………………...…………………………………………………………. 3-6

Turning Off the Exhaust Fan ……………………………………..…………………………….………………………….. 3-7

Setting Functions ………………………………………………..………………………………………………………………. 3-8

1. Setting Time, Date and Day …………………….……………………………………………………………….. 3-10

2. Scheduling Automatic Start and Start of Exhaust Fan ………………………………………………. 3-13

Yellow and Red Alerts …………………………………………………………………………………………………………. 3-16

1. Yellow Alerts …………………………………………………………………………………………………………… 3-17

2. Red Alerts ………………………………………………………………………………………………………………. 3-18

Fire Alert …………………………………………………………………………………………………………………………….. 3-19

Chapter 4 - Service

Gaylord Service Information ……………………………………………………………………………………………….. 4-1

Hood Cleaning Precautions …………………………………………………………………………………………………. 4-3

Exhaust Fan Service Precautions …………………………………………………………………………………………. 4-3

Chapter 5 – Energy Data

Retrieving Data From the Main Screen ………………………………..……………………………………………… 5-1

Retrieving Data From the Data Screen …………………………………………………………………………………. 5-2

Limited Warranty ……………………………………………………………………………………………. Inside Back Cover

Page iv________________________________________________________________________________

This Page Intentionally Left Blank

Chapter 1: Introduction, Page 1-1

About this Manual

The purpose of this manual is to provide the kitchen operator complete information for operating the

Gaylord AirVantage Demand Control Ventilation System Model DCV-AV Series in conjunction with Gaylord

Ventilators Model ELX and ELXC Series.

The manual is divided into chapters for easy reference to a particular subject. The pages in the chapters

are numbered with the Chapter number, then a dash, and then the Page number. So for example pages in

Chapter 2 are numbered 2-1, 2-2, 2-3 etc. Figures and Tables are numbered in a similar manner. For

example Figure 3-3-2 is on Page 3-3 and is the second figure. Please keep your manual in a convenient

location for so it can be accessed easily.

If you have any questions regarding the Gaylord AirVantage System, please contact Gaylord Industries.

Web: www.gaylordventilation.com

E-Mail: info@gaylordventilation.com

Main Phone: 503-691-2010

Toll Free: 800-547-9696

This manual and other Gaylord product manuals may be downloaded from the Gaylord website:

www.gaylordventilation.com or be obtained by calling Gaylord Industries.

Safety

Please read this manual in its entirety before operating the AirVantage system. Some portions of the

control circuitry operate on 120 volts. One of the following Warning statement precedes any instructions

or guidance where contact with 120 volts could occur:

Warning: 120 volt circuit. Opening the access door and working on this equipment may result in

electrical shock.

Warning: 120 volt circuit. This equipment can only be serviced by a Gaylord Certified Service Agency.

Accessing and working on this equipment may result in electrical shock.

Chapter 1: Introduction, Page 1-2____________________________________________________________

AirVantage System Overview

The Exhaust Fans of traditional kitchen exhaust systems are sized to exhaust the effluent produced by the

cooking appliances running at full load with the fan running at a constant speed throughout the cooking

day. Air removed from the kitchen space must be replaced by the use of a dedicated Makeup Air system,

and this air must be heated and cooled as required to maintain a comfortable kitchen. The energy to

operate the Exhaust Fan, heat and cool the Makeup Air for 10 to 18 hours a day at 100% capacity, wastes a

tremendous amount of energy. Just a 20% reduction in airflow volume can yield approximately 45-50% in

annual fan energy savings and a 20% reduction on heating and cooling costs.

The AirVantage Demand Control Ventilation System has been designed to reduce overall ventilation rates

by tying the cooking appliance’s sensible heat output to the required airflow rates. It monitors the sensible

heat produced by the cooking appliances, using Resistance Temperature Detectors (RTDs) mounted in the

Ventilator, to automatically increase or decrease the Exhaust Fan and Makeup Air units fan speeds, saving a

substantial amount of money each year on energy costs. If for example all the cooking appliances are not

in use, or they are turned down, the RTDs sense the lower temperature and the system automatically

decreases the Exhaust Fan speed, and reduces the amount of Makeup Air proportionally to a level required

to maintain optimum capture performance. As the appliance temperatures go up and cooking increases,

the Exhaust Fan and Makeup Air fan increase to a point as required to maintain optimum capture to

remove the smoke, grease, and heat. The AirVantage System can generate and overall savings of 10%-50%

and reduce fan energies from 25%-70%.

How the AirVantage System Works – The Basics

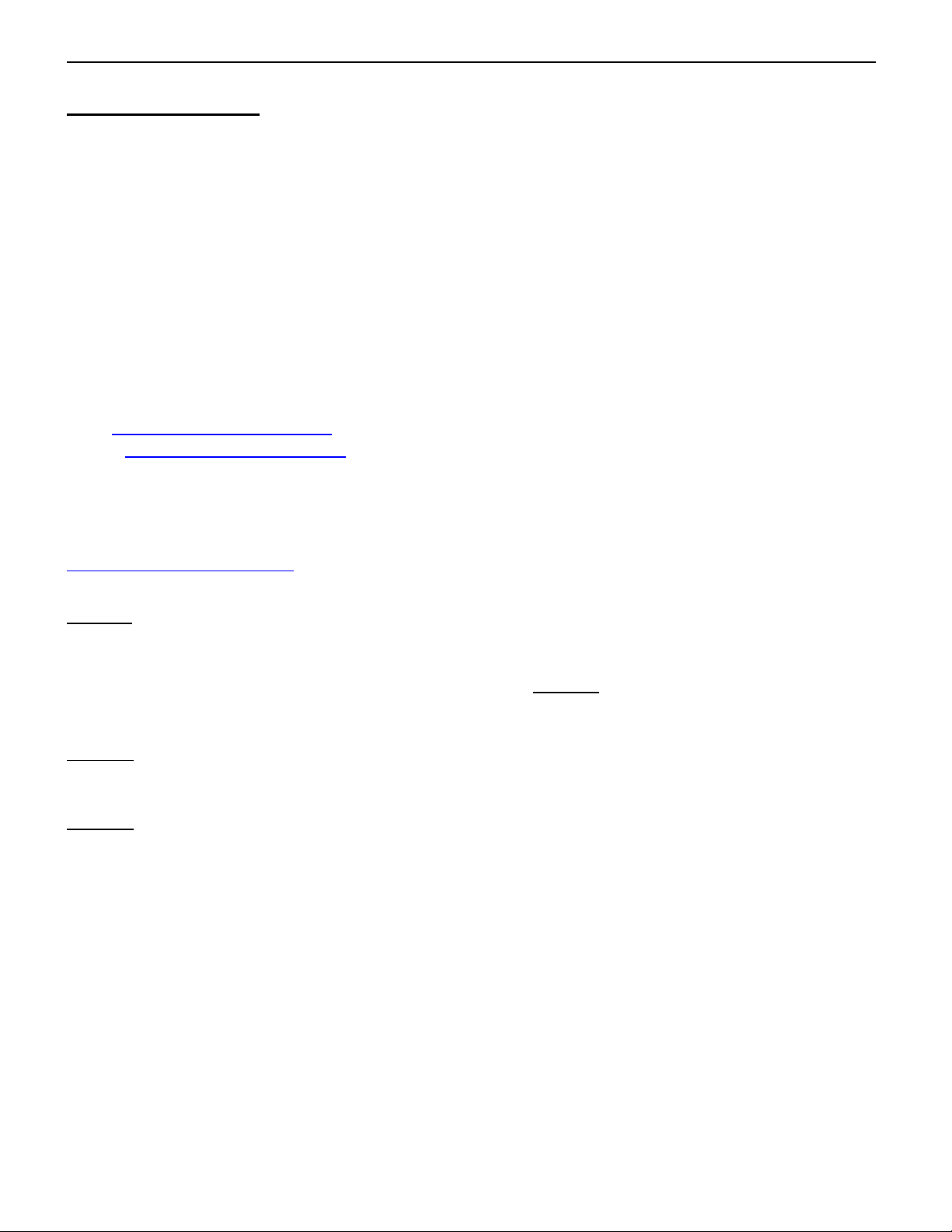

The AirVantage System is made up of six major components as illustrated in Figure 1-3-1 on the following

page. They are 1) Command Center, 2) Variable Frequency Drives (VFD’s), 3) Hood Control Enclosure (HCE),

4) Modulating Dampers, 5) 100% Fan Button, and 6) Resistance Temperature Detectors (RTDs). The

Command Center is mounted in the kitchen area. It houses the Touch Screen Controller that controls the

Start/Stop of the exhaust fan, Ventilator lights and all the other functions of the system. Two RTD’s are

mounted in each Ventilator section. There is one VFD for each Exhaust Fan and one for each Makeup Air

fan. The VFD’s can be mounted in a cabinet on the end of the Ventilator, as shown on Figure2-1-1, or

mounted remotely. The RTDs, DSC, VFDs and 100% Fan Button are connected to the Command Center with

low-voltage cables. The VFDs are programmed to operate between a minimum and maximum speed based

on a Low Cooking Load and a High Cooking Load. The Control Board within the DCV Control Cabinet is

programmed to correlate the temperature at each individual RTD to the heat generated by the cooking

appliance(s) with a High Cooking Load.

During a cooking day, as the sensible heat, created by the cooking appliances, increases or decreases, the

RTDs detect the change which is interpreted at the Command Center. A signal is then sent to the Balancing

Dampers and the VFDs to modulate the exhaust volume for that particular Ventilator section. To reduce

the risk smoke spillage, the system will respond to temperature changes of five degrees or more, up or

down, in any 40 second period by going to 100% for a five minute period.

____________________________________________________________Chapter 1: Introduction, Page 1-3

AirVantage System Overview – Cont.

Typically the exhaust volume will modulate up and down throughout the day based on the use of the

cooking appliances. If ever needed, the 100% Fan Button, located on each Ventilator section, can be

pushed to ramp the exhaust volume up to 100% for that section. The 100% exhaust volume will run for 5

minutes and then revert back to the previous volume.

The AirVantage System also has a learning function that auto-calibrates the exhaust volume for each

Ventilator

Chapter 1: Introduction, Page 1-4____________________________________________________________

This Page Intentionally Left Blank

_____________________________________________________Chapter 2: System Components, Page 2-1

1. DCV-AV Command Center

1

Exhaust Fan

5 6 2

3

4

Figure 2-1-1

Typical Installation

System Components

The Gaylord AirVantage Demand Control Ventilation System is made up of several primary components.

Figure 2-1-1 illustrates a typical installation with the primary components identified.

2. Variable Frequency Drives shown mounted in

3. Hood Control Enclosure (HCE)

4. Modulating Dampers

5. 100% Fan Button

6. Resistance Temperature Detectors (RTD)

an optional Hood End Cabinet

Chapter 2: System Components, Page 2-2_____________________________________________________

Figure 2-2-1

Touch Screen

System Components – Cont.

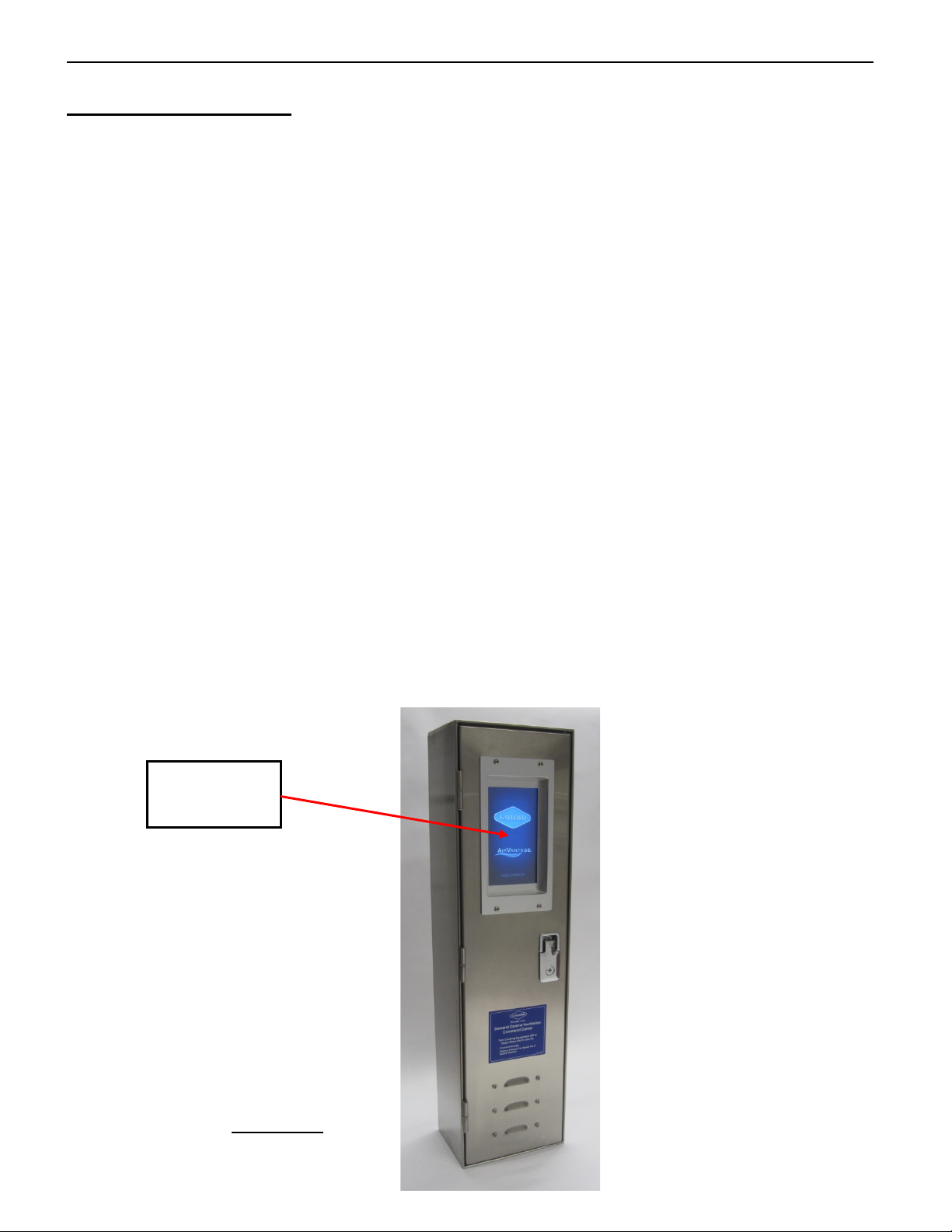

AirVantage Command Center

The Command Center, Figure 2-2-1, is a stainless steel cabinet that houses the Touch Screen Controller, and

electrical components for controlling the entire system. The Command Center is the heart of the system

and controls the Start and Stop functions of the Exhaust Fan and interfaces with the Variable Frequency

Drives (VFDs) controlling the exhaust and Makeup Air fans, the Hood Control Enclosure, Modulating

Dampers, 100% Fan Button and the Temperature Detectors (RTDs). It may also be connected with a

Building Management System (BMS). The DCV Command Center is typically located in the kitchen area in a

convenient location, within 60 feet of the Ventilator.

Warning: 120 volt circuit. Opening the access door and working on this equipment may result in

electrical shock.

Controller

Command Center

______________________________________________________Chapter 2: System Components, Page 2-3

on this

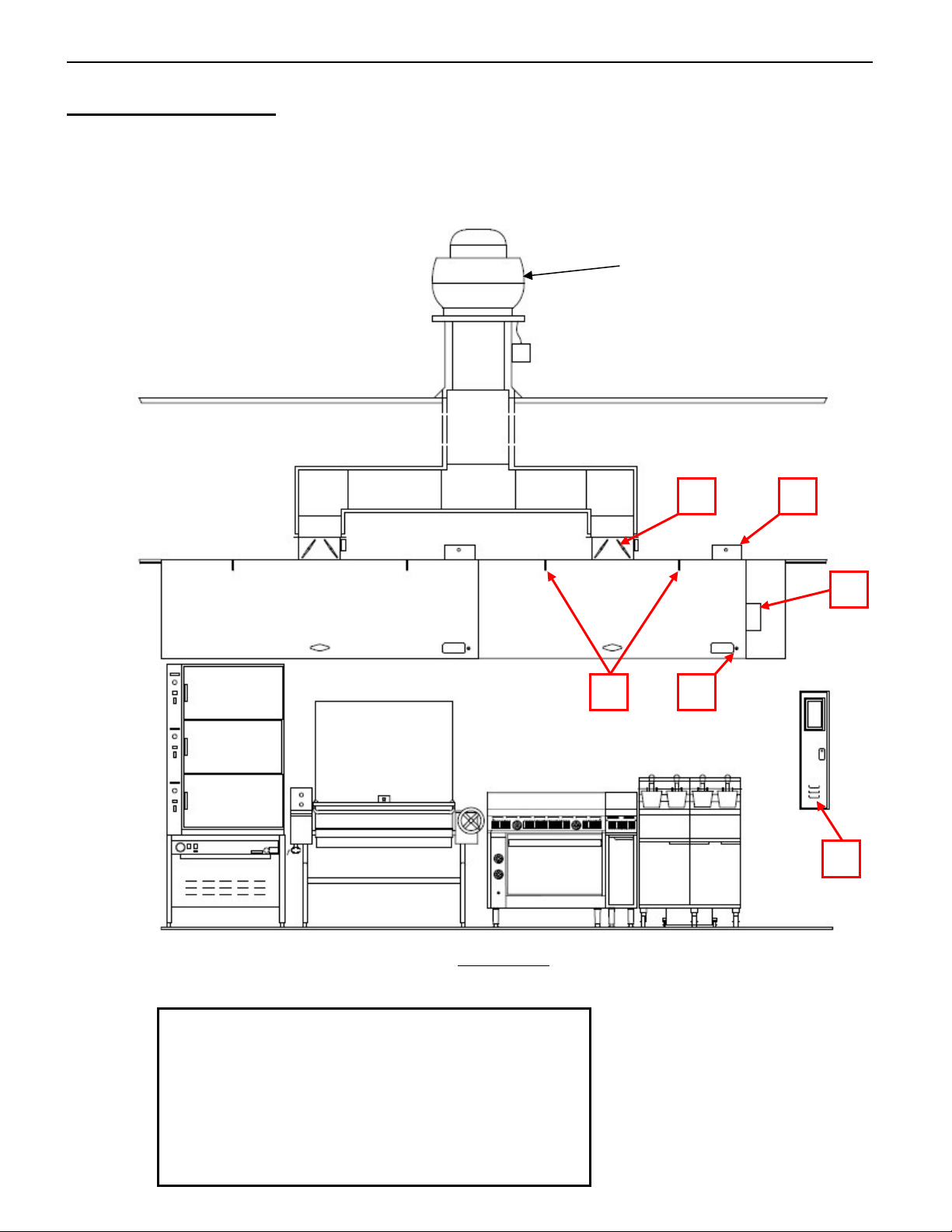

Figure 2-3-1

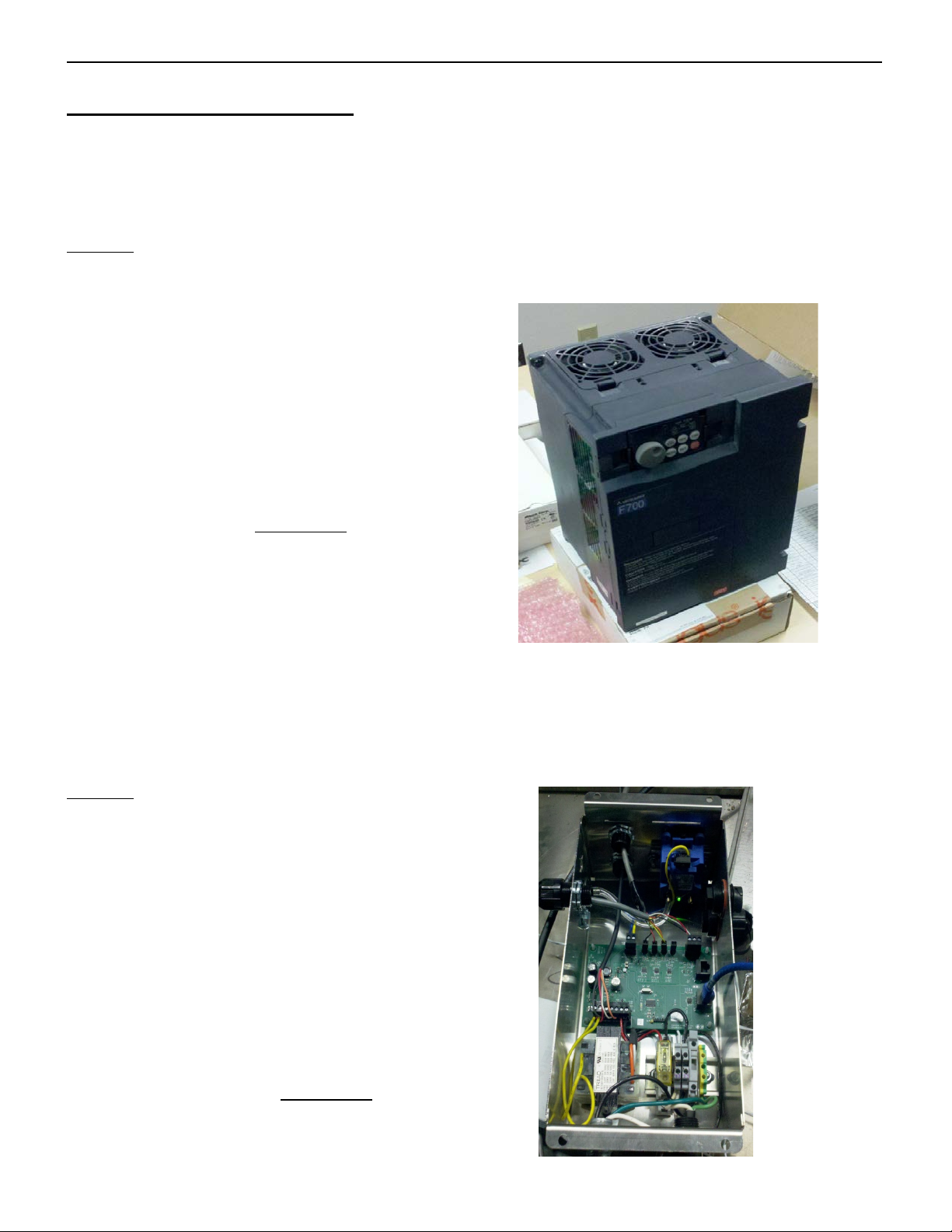

Figure 2-3-2

System Components – Cont.

Variable Frequency Drives (VFD)

One Variable Frequency Drive is required for each exhaust and Makeup Air fan. They are typically located

in proximity of the fans they serve but as an option can be mounted in a Hood End Cabinet. The VFD

controls the exhaust and makeup fan speeds and is interfaced with the Command Center.

Warning: 120 volt circuit. This equipment can only be serviced by a Gaylord Certified Service Agency.

Accessing and working on this equipment may result in electrical shock.

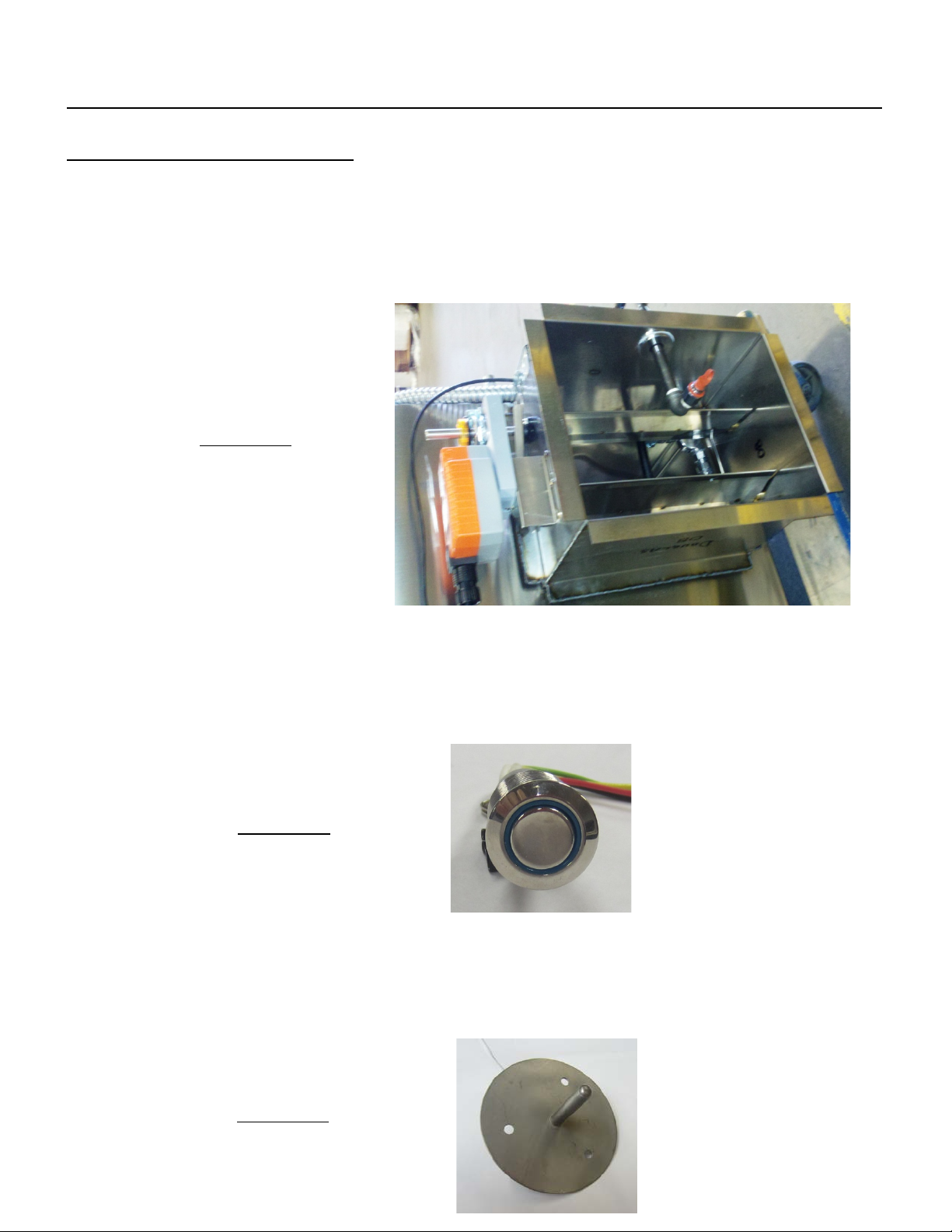

Hood Control Enclosure (HCE)

A Hood Control Enclosure box is mounted on the top of each Ventilator section. It is accessed through an

access panel in the top of the Ventilator canopy. The Hood Control

Enclosure interfaces the Command Center with the Modulating

Dampers and Ventilator light fixtures.

Warning: 120 volt circuit. This equipment can only be serviced by a

Gaylord Certified Service Agency. Accessing and working

equipment may result in electrical shock.

Typical Variable Frequency Drive (VFD)

Hood Control Enclosure

Figure 2-4-1

Figure 2-4-3

Figure 2-4-2

Chapter 2: System Components, Page 2-4______________________________________________________

System Components – Cont.

Modulating Dampers

A set of Modulating Dampers are mounted in the exhaust duct collar of each Ventilator section. The

dampers move, by and electric motor, to increase or decrease the exhaust rate based on a signal from the

Temperature Detectors.

100% Fan Button

One 100% Fan Button is mounted on the face of each Ventilator section. Pushing this button will increase

the exhaust rate of that Ventilator section for 5 minutes and then revert back to the original exhaust rate.

Temperature Detectors (RTD)

Two RTD’s are mounted in each Ventilator section as illustrated in Figure 2-1-1. The RTD’s read sensible

heat from the cooking appliances reacting to an increase or decrease of the thermal plume generated from

the appliance.

Modulating Dampers

100% Fan Button

Temperature Detectors

_____________________________________________________________Chapter 3: Operation, Page_3-1

Figure 3-1-1

Touch Screen

Operating the System

All functions of the system are controlled by the Command Center (Refer to Figure 3-1-1). The Touch

Screen Controller is used by the operator to initiate the following functions:

• Start and Stop the Exhaust Fan.

• Turn on and off the Ventilator lights.

• Program the date, time of day and the day.

• Program a scheduled Start and Stop of the Exhaust Fan.

• View Exhaust Fan speed in percentage.

• View year to date energy savings.

• View Kilowatt (KW) reduction.

• View other energy data for specific Ventilator sections.

The Touch Screen Controller has many other functions for set up and service of the system that are only

accessible by a Gaylord Certified Service Agency.

For instructions on operating the system proceed to the next page.

Controller

Command Center

Loading...

Loading...