Gaylord DCA Service Manual

Issue Date: 4-5-2016

Rev-01

Demand Control Autostart System

MODEL “DCA”

Technical Manual

GAYLORD INDUSTRIES

10900 SW Avery Street – Tualatin, Oregon 97062 USA

Email: info@gaylordventilation.com Toll Free 800-547-9696 – Fax 503-692-6048

www.gaylordventilation.com

All rights reserved. No part of this book may be reproduced, stored in a retrieval

system, or transmitted in any form by an electronic, mechanical, photocopying,

recording means or otherwise without prior written permission of Gaylord

Industries.

©Copyright 2015, Gaylord Industries

The manufacturer reserves the right to modify the materials and

specifications resulting from a continuing program of product

improvement or the availability of new materials

______________________________________ Page iii

Table of Contents

Chapter 1 – Introduction

About the Manual ……………………………………………………………………………………………………………….. 1-1

List of Abbreviations and Acronyms …………………………………………………………………………………….. 1-1

DCV System Overview …………………………..…………………………………………………………………………….. 1-2

Code Compliance ……………………………………….……………………………………………………………………….. 1-2

Chapter 2 – System Components

Overview …………………………………………………………………………………………………………………………….. 2-1

Resistance Temperature Detectors (RTDs)…………………………………………………………………………… 2-2

The DCA Control Box……………………………………………………………………………………………………………. 2-2

The Control Board ……………………………..………………………………………………………………………………… 2-3

Chapter 3 – Servicing the System

DCA Factory Settings ………………………………………………………………………….………………………………… 3-1

Accessing the Active Mode ………………………………………………………………………………….………………. 3-1

Accessing the Program Mode ………………………………………………………………………………………………. 3-1

Adjusting the Temperature Setpoint …………………………….……………………………………………………… 3-2

Adjusting the Shutdown Timer …………………………………………………………………………………………….. 3-2

DCA RTD Calibration …………………………………………………………………………………………………………….. 3-9

Chapter 4 – Wiring

Primary Control Box Wiring ….……………………………………………………………………………………………… 4-1

Secondary Control Box Wiring ………………………….…………………………………………………………………. 4-1

Chapter 5 –Replacement Parts

DCA Replacement Parts ….……………………………………………………………………………………………………. 5-1

Limited Warranty ……………………………………………………………………………………………. Inside Back Cover

Chapter 1: Introduction, Page 1-1

About this Manual

The purpose of this manual is to provide guidance for pre-installation assessment, installation,

programming, and commissioning information for the Gaylord Demand Control Autostart System Model

DCA. The manual also includes detailed information on adjustments to the system and a complete list of

replacement parts.

The manual is divided into chapters for easy reference to a particular subject. The pages in the chapters

are numbered with the Chapter number, then a dash, and then the Page number. So for example pages in

Chapter 2 are numbered 2-1, 2-2, 2-3 etc. Figures and Tables are numbered in a similar manner. For

example Figure 5-3-2 is on Page 5-3 and is the second figure. Please keep your manual in a convenient

location for so it can be accessed easily.

If you have any questions or concerns with the installation of the Gaylord Demand Control Ventilation

System, please contact Gaylord Industries.

Web: www.gaylordventilation.com

E-Mail: info@gaylordventilation.com

Main Phone: 503-691-2010

Toll Free: 800-547-9696

This manual and other Gaylord product manuals may be downloaded from the Gaylord website:

www.gaylordventilation.com or be obtained by calling Gaylord Industries.

List of Abbreviations and Acronyms

BMS Building Management System

CFM Cubic Feet per Minute (Air Volume)

CSA Certified Service Agency

DCA Demand Control Autostart

DCKV Demand Control Kitchen Ventilation

EF Exhaust Fan

FP Fire Protection (System)

FPM Feet Per Minute (Air Speed- Velocity)

HVAC Heating Ventilating Air Conditioning (unit)

IMC International Mechanical Code

MUA Makeup Air

NFPA National Fire Protection Association

RTD Resistance Temperature Detector

WG Water Gauge

Chapter 1: Introduction, Page 1-2____________________________________________________________

DCA System Overview

The Gaylord DCA system automatically starts and stops the kitchen exhaust based on the activity of the

cooking equipment. Heat generated by the cooking equipment is detected by hood mounted sensors.

Whenever the temperature setpoint is exceeded the fan will start. When the temperature drops below the

setpoint for 60 minutes (adj.), the fan will stop (note: external switching can override the fan on). The

Gaylord DCA system is designed to meet the requirements of IMC 2012 Section 507.2.1.1.

Each hood has a primary controller to interpret the sensor feedback and start/stop the fan. If the hood has

multiple sections then each additional section will have a secondary controller to read the sensors and

communicate data back to the primary controller.

The Gaylord DCA system may also be converted to a Demand Control Kitchen Ventilation (DCKV) system.

The control boards have additional parameters that are not used for DCA, but function for DCKV.

Aftermarket conversion services are available through a Gaylord DCV-Retrofit Certified Service Agent

(CSA). CSAs can be found on the Gaylord website at http://gaylordventilation.com/Service_Agencies/.

Code Compliance

The DCA Series control is a recognized component to a UL 710 listed commercial kitchen hood, complying

with IMC 507.2.1.1 and the latest edition of NFPA 96. Additionally they are listed to ULC s646, UL 873, CSA

C22.2#24, and UL 508. Contact Gaylord Industries for additional information.

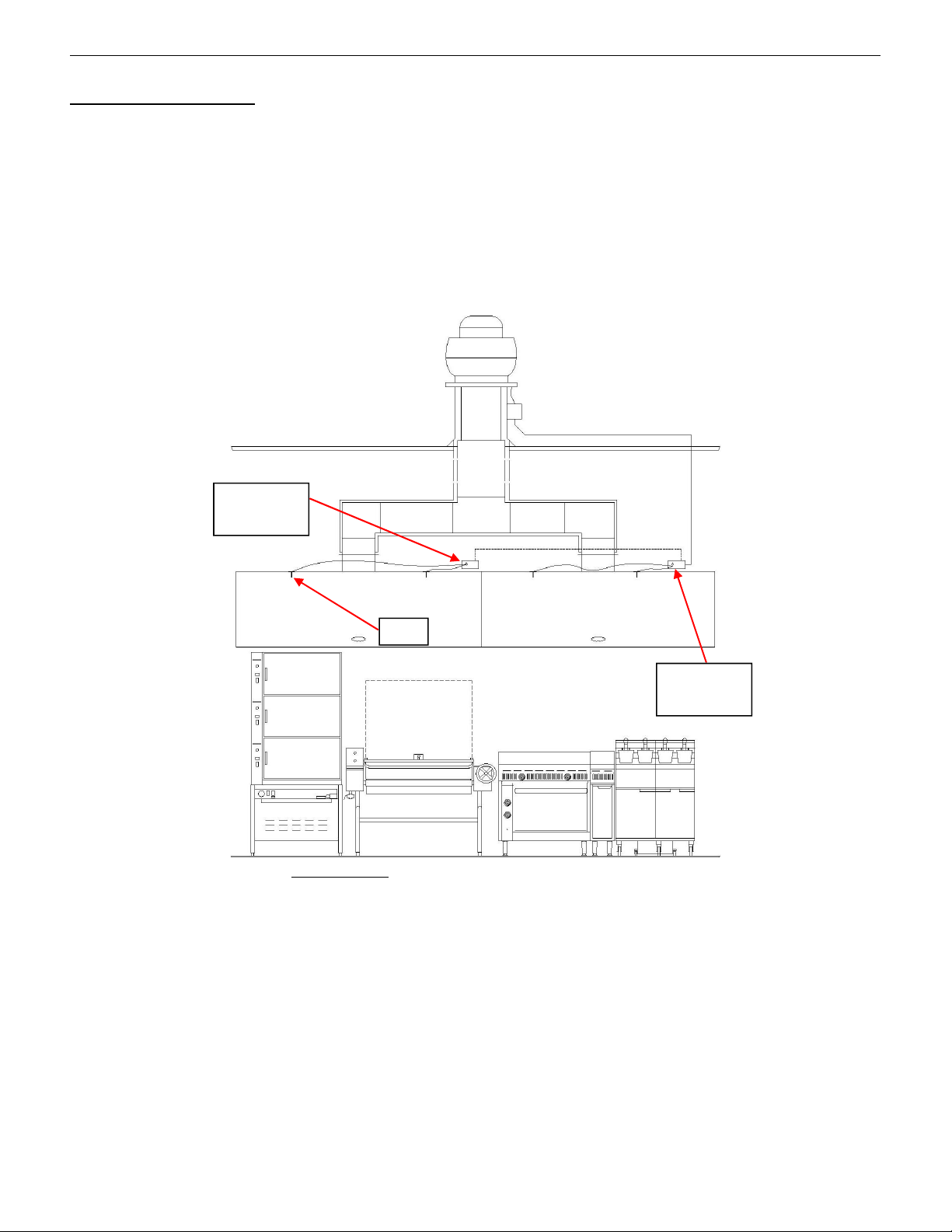

Chapter 2: System Components, Page 2-1

RTD

System Components

As illustrated in Figure 2-1-1 below the Gaylord DCA system is made up of canopy mounted RTDs and a

control box for each hood section. The primary control box provides 120V switching for the fan, while the

secondary control box communicates information about its section to the primary control box. Secondary

control boxes are only used on multi-section hoods. One primary control box can receive information from

up to five secondary control boxes. The quantity and location of the RTDs are determined by the type of

hood and the length. Each hood section can have from one to four RTDs mounted in the canopy.

Secondary

Control Box

Primary

Control Box

Figure 2-1-1: Components of Gaylord DCA System

Loading...

Loading...