Gaylord CG3-UVi Service Manual

Rev 05

Technical Manual

Operation, Maintenance &

Installation

for

Model CG3-UVi Series

Ventilators

GAYLORD INDUSTRIE S

10900 SW Avery Street – Tualatin, Oregon 97062 USA

Email: info@gaylordventilation.com

www.gaylordventilation.com

Toll Free 800-547-9696 – Fax 503-692-6048

Page ii

All rights reserved. No part of this book may be reproduced, stored in a retrieval

system, or transmitted in any form by an electronic, mechanical, photocopying,

recording means or otherwise without prior written permission of Gaylord

Industries.

©Copyright 2014, Gaylord Industries

The manufacturer reserves the right to modify the materials and

specifications resulting from a continuing program of product

improvement or the availability of new materials

Page iii

Page iv

This Page Intentionally Left Blank

TABLE OF CONTENTS

Chapter 1 – Introduction Page

Introduction …………………………………………………………………………………………………………………….............. 1-1

Model Description ………………………………………………………………………………………………………………………… 1-2

Model Number Sequence …………………………………………………………………………………………………………….. 1-3

Explanation of Damper Options …………………………………………………………………………………………………… 1-5

Chapter 2 – Principles of Operation

Principle of Operation Overview …………..……………………………………………………………………………………… 2-1

Grease Extraction ………………………………….…………………………………………………………………………………….. 2-2

Optional Continuous Cold Water Mist ..……………………………………………………………………………………….. 2-4

Wash Cycle ………………………… ……………………………………………………………………………………………………….. 2-5

Internal Fire Mode ..……………………………………………………...………………………………………………………………. 2-8

Fire Extinguishing Systems ……………………………………………….……………………………………………………………. 2-9

Chapter 3 - Daily Operation

Starting the Exhaust and UV System ……………………………………………………………………………………………. 3-1

Turning Off the Exhaust Fan and Starting the Wash Cycle …………………………………………………………… 3-5

Recommend Detergent ………………………………………………………………………………………………………………… 3-8

Chapter 4 – Maintenance

Operator Preventive Maintenance ……………………………………………………………………………………………… 4-1

Preventive Maintenance Required by Code ………………………………………………………………………………… 4-2

UV System - Scheduled Preventive Maintenance ……………………………………………………………………….. 4-3

Chapter 5 - Troubleshooting

Troubleshooting ………………………………………………………………………………………………………………………….. 5-1

Chapter 6 – Testing and Repair

Measuring Airflow ............................................................................................................................ 6-1

Make-Up Air Guidelines ……………………………………………………………………………………………………………….. 6-5

Replacing UV Lamps …………………………………………………………………………………………………………………….. 6-7

Replacing UV Lamp Sockets ………………………………………………………………………………………………………….. 6-13

Replacing UV Ballast ……….……………………………………………………………………………………………………………. 6-19

Main Electrical Raceway Ventilation Fan ……………………………………………………………………………………… 6-30

UV Module Ventilation Fans …………………………………………………………………………………………………………. 6-32

High Temperature Shutdown Controller ……………………………………………………………………………………….. 6-36

Safety Interlock Pressure Switch ……………………………………………………………………………………………………. 6-37

UV Ventilation Control Board …………………………………………………………………………………………………………. 6-37

Replacing UV Module Access Door Gasket ……………………………………………………………………………………. 6-40

Replacing UV Module Plate Gasket ……………………………………………………………………………………………….. 6-41

Damper Motor ……………………………………………………………………………………………………………………………….. 6-42

Chapter 7 - Parts

Parts - Ventilator ............................................................................................................................... 7-1

Parts - UV Lamp Module ………………………………………………………………………………………………………………. 7-4

Parts – Main Electrical Raceway …………………………………………………………………………………………………… 7-5

Parts – Miscellaneous ……………………………………………………………………………………………………. 7-7

Chapter 8 – Wiring Diagrams

Wiring Diagrams ………………………………………………………………………………………………………………………….. 8-1

Page v

Page vi

Appendices

Sample Ventilator Nameplate ……………………………………………………………………………………………………… A-1

Installation Requirements ……………………………………………………………………………………………………………. B-1

Ventilator Start-Up Inspection and Tests – Overview …………………………………………………………………… C-1

Pre Start-Up Check List …………………………………………………………………………………………………………………. C-1

Start-Up Inspection and Tests Report Forms ………………………………………………………………………………… C-3

Limited Warranty ………………………………………………………………………………………................ Inside Back Cover

__________________________________________________________Chapter 1- Introduction, Page 1-1

About this Technical Manual

The purpose of this manual is to provide the Operator, Maintenance and Service personnel instructions

for operating, maintaining, troubleshooting and repairing the Gaylord Ventilator Model CG3-UVi Series.

Ventilators incorporating UV Systems, most maintenance and all repairs must be performed by a trained

and certified service company. This manual also includes information and guidance to contractors for

initial installation of the Ventilator.

The manual is divided into chapters for easy reference to a particular subject. The pages in the chapters

are numbered with the chapter number, then a dash, and then the page number. So for example pages

in Chapter 2 are numbered 2-1, 2-2, 2-3 etc. Figures and Tables are numbered in a similar manor. For

example Figure 5-3-2 is on page 5-3 and is the second figure. Please keep your manual in a convenient

location for so it can be accessed easily.

If you have any questions or concerns with the installation, operation, maintenance or service of your

Gaylord Ventilator, please contact Gaylord Industries;

Web: www.gaylordventilation.com

E-Mail: info@gaylordventilation.com

Main Phone: 503-691-2010

Toll Free: 800-547-9696

Safety

It is important that the operator read Chapter 2, Principle of Operation, and Chapter 3, Maintenance,

before operating the Ventilator for the first time. Particular attention should be given to all the Caution

and Warning statements.

Related Technical Manuals

CG3-UVi Series Ventilators are controlled by a Gaylord Command Center. The model number of the

Command Center is dictated by when the Ventilator was purchased. Typical models are C-6000 and C7000 Series. The model number of your Command Center can be found on the nameplate located on

the back of the electrical compartment door. All Installation Operation and Maintenance Manuals may

be downloaded from the Gaylord website: www.gaylordventilation.com or be obtained by calling

Gaylord Industries.

Chapter 1- Introduction, Page 1-2__________________________________________________________

Model Description Overview

The Gaylord Model CG3-UVi Series Ventilator is a high grease extraction efficiency Ventilator that

includes the additional feature of an Ultraviolet Light System that dramatically reduces grease

accumulation in the exhaust plenum, ductwork and exhaust fans. The Ventilator incorporates a hot

water Wash Cycle that automatically washes the accumulated grease and particles out of the Ventilator

and into the building drain system.

The CG3-UVi Ventilators come in many different models, Wall Mounted Canopy, Single Island Style, and

Double Island Style. All Gaylord Ventilators are custom designed to fit the space and application of your

facility.

__________________________________________________________Chapter 1- Introduction, Page 1-3

1._____

2._____

3._____

4._____

5.______

6._____

7._____

8. ______

9. _______

Series

Damper

Style

Low

Style of

Custom

Cold

Autostart

Front to

Inlet damper is fixed and no damper motor, and has fuse link activated fire

Model Number Sequence

The CG3-UVi Series model numbers are made up of an alphabetic prefix followed by a series of

alphabetic and/or numeric suffixes to designate the style of ventilator and various options. Sequence of

model numbers is as follows.

Type

Profile

Design

(Option)

Built in

Make-up

Air If

Applicable

Air If

Applicable

Water

Mist, If

Applicable

If

Applicable

Back

Dimension

of the

Ventilator

in Inches

Explanation of Prefixes and Suffixes

1. Series

CG3-UVi ……………… Water Wash Ventilator with ultraviolet light feature.

2. Damper Type

Blank Space …………. Electrically activated three position damper located at air inlet slot (Refer to

Figure 1-5-1).

FDD ……………………… Same as CG3-UVi except inlet damper is fixed and has a fuse link activated fire

damper located at the duct collar (Refer to Figure 1-6-1)

FDT ……………………….

FDL ….………………….. Same as CG3-UVi except a bracket (Fire Damper Lockout) has been added to

ND ………….…………… Same as CG3-UVi except inlet damper is fixed and has no fire damper (Refer to

3. Style

BDL ……………………... Wall mounted canopy.

BDL-BB ................. Island style for back-to-back cooking equipment using two extraction chambers

BBC ……………………… Island style for back-to-back cooking equipment using two extraction chambers

BDL-DS ………………… Island style for back-to-back cooking equipment using one extraction chamber

BDL-DS-CL …………… Island style for single line of cooking equipment.

4. Profile

LP ........................... Low Profile. Reduced height of front face of Ventilator and sloping end panels.

damper located at the duct collar with a thermostat to detect fire to send

notification (Refer to Figure 1-5-3)

prevent the damper from closing to the fire position (Refer to Figure 1-5-2)

Figure 1-6-2).

and two separate exhaust ducts.

with one common exhaust duct.

with two inlet slots. Has common exhaust duct.

Chapter 1- Introduction, Page 1-4__________________________________________________________

Definition of Prefixes and Suffixes – Cont.

5. Style of Built In Make-Up Air (If Applicable)

MAW ……………………. Front face make-up air using perforated stainless steel panels.

MAR ……………………… Front face make-up air using registers or grills.

MAI .......................... Internal short circuit make-up air.

MAW/MAI …………… Combination of MAW and MAI design.

MAR/MAI …………….. Combination of MAR and MAI Design.

6. Custom Air (If Applicable)

CA ………………...……… Additional baffles added to reduce the air volume over specific types of cooking

equipment.

7. Cold Water Mist (If Applicable)

CM ………………………… Addition of cold water manifold with spray nozzles at the air entry slot for

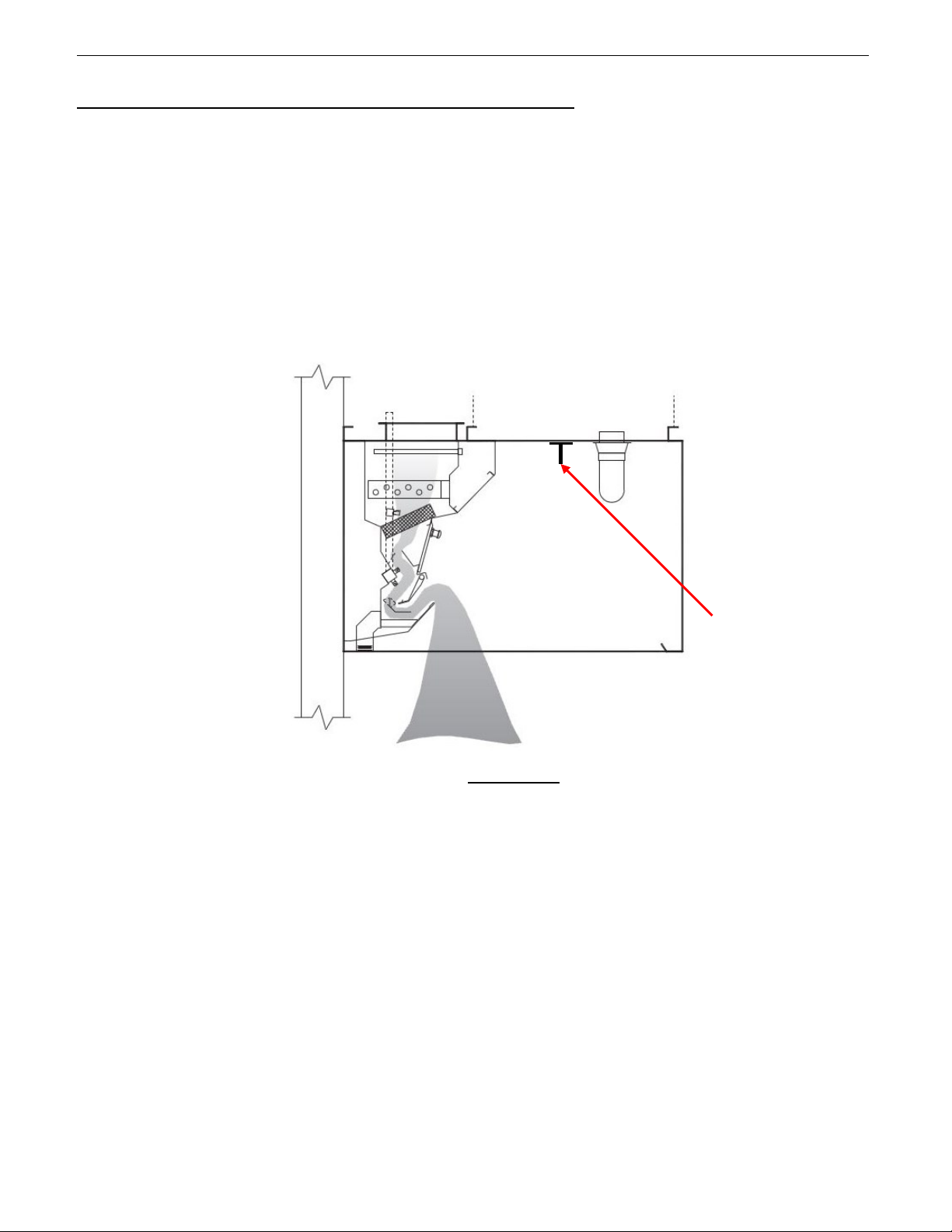

application over solid fuel burning cooking appliances (Refer to Figure 2-4-1).

7. Autostart Option

Blank Space ............. Indicates the hood section does not have Autostart system as required by IMC.

AS ……………………..…. Indicates the hood section has Autostart conforming with the IMC requirement.

8. Front to Back Dimension

In Inches ………………. Indicates front to back dimension of the Ventilator, or the overall width of an

island style.

__________________________________________________________Chapter 1- Introduction, Page 1-5

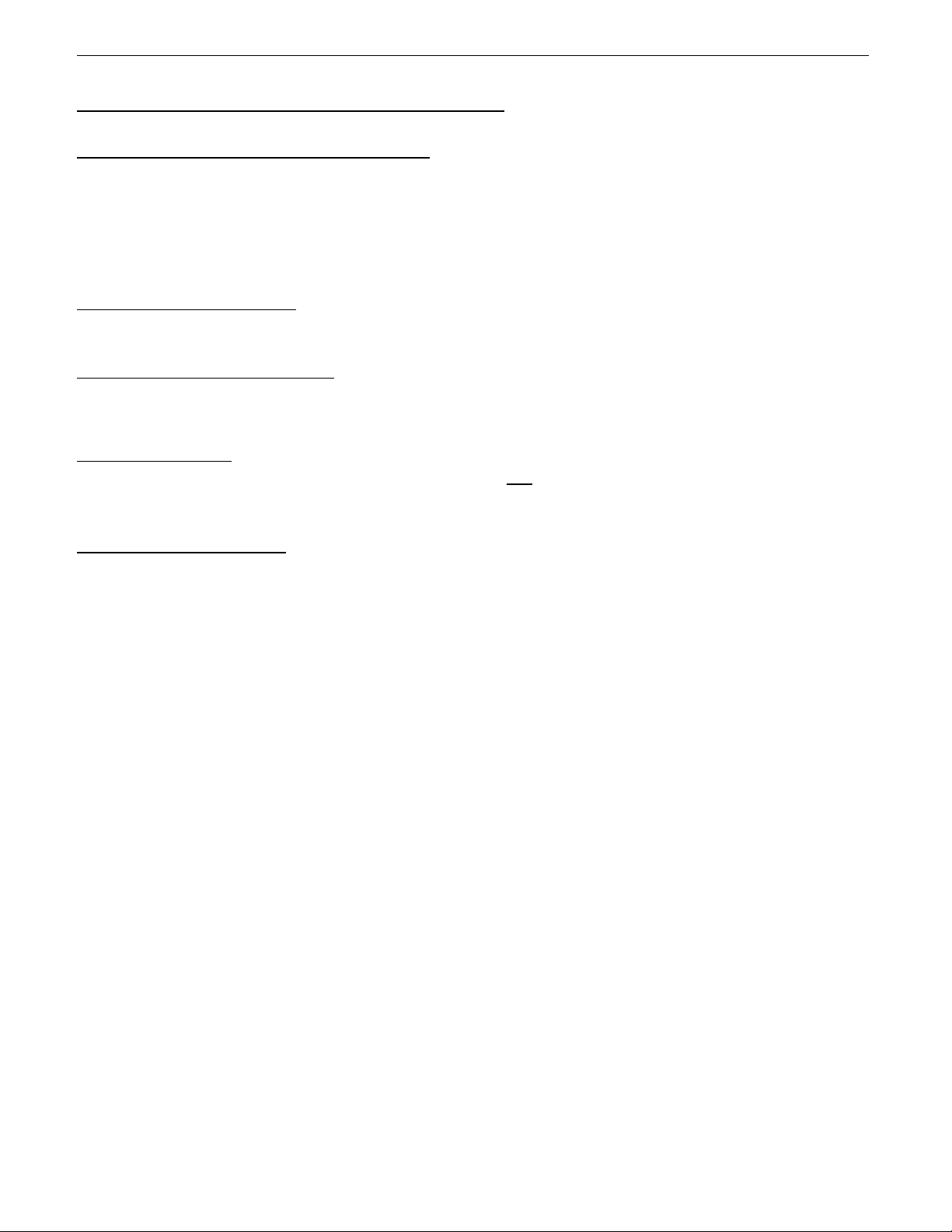

Figure 1-5-3

CG3-UVi-FDT

Figure 1-5-1

CG3-UVi

Figure 1-5-2

Explanation of Damper Options

1. CG3-UVi Ventilator – This is the standard Ventilator and

incorporates a damper at the air inlet slot that during a

wash mode closes forward by and electric motor to seal

off the inlet slot and opens to the exhaust position when

the exhaust fan is started. During a fire mode, that is

activated by a thermostat the damper closes backwards

to the fire position and stays closed until the thermostat

drops below its set point and then closes to the wash

position.

2. CG3-UVi-FDL Series – The FDL in the model number

stands for Fire Damper Lockout. This Ventilator

incorporates the same inlet damper as the CG3-UVi that

during a wash mode closes forward by and electric

motor to seal off the inlet slot and opens to the exhaust

position when the exhaust fan is started. The main

difference is the CG3-UVi-FDL has a Fire Damper

Lockout (FDL) bracket added that prevents the inlet

damper from closing to the fire position, so it does

NOT have a fire damper. This Ventilator does include a

thermostat to send a signal to fire alarm systems.

3. CG3-UVi-FDT Series – The FDT in the model number

stands for a fuse link Fire damper in the Duct collar

with a Thermostat. The fire damper is weighted and

when the fuse link reaches its melting point, the

damper closes. The thermostat sends a signal to the

fire alarm systems.

Section View

Section View

CG3-UVi-FDL

Section View

Chapter 1- Introduction, Page 1-6__________________________________________________________

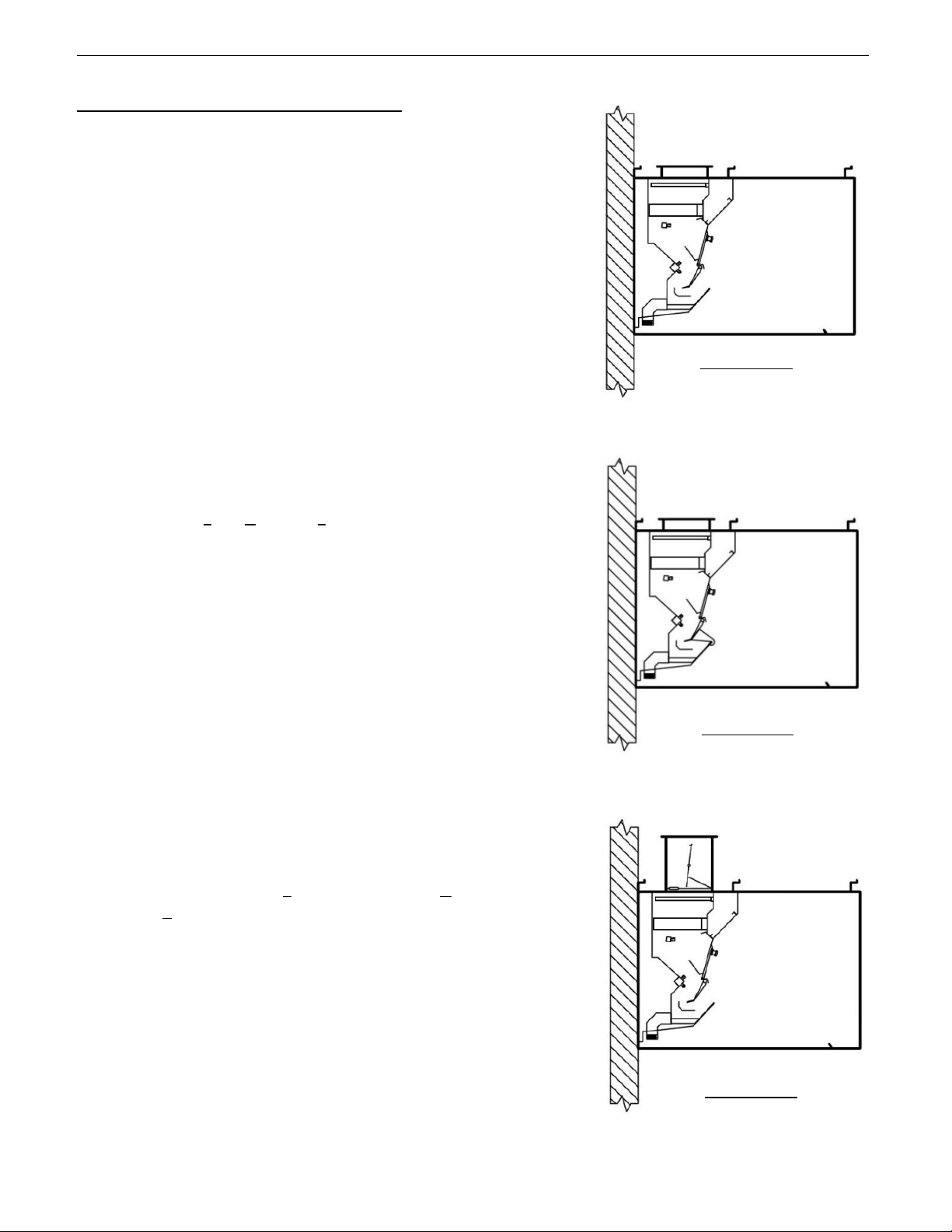

Figure 1-6-1

Figure 1-6-2

Explanation of Damper Options – Cont.

4. CG3-UVi-FDD Series – The FDD in the model number

stands for Fire Damper in the Duct collar. The fire

damper is weighted and when the fuse link reaches its

melting point, the damper closes. There is no

thermostat.

5. CG3-UVi-ND Series – The ND in the model number stands for

No Damper.

Section View

CG3-UVi-FDD

Section View

CG3-UVi-ND

__________________________________________________Chapter 2 - Principle of Operation, Page 2-1

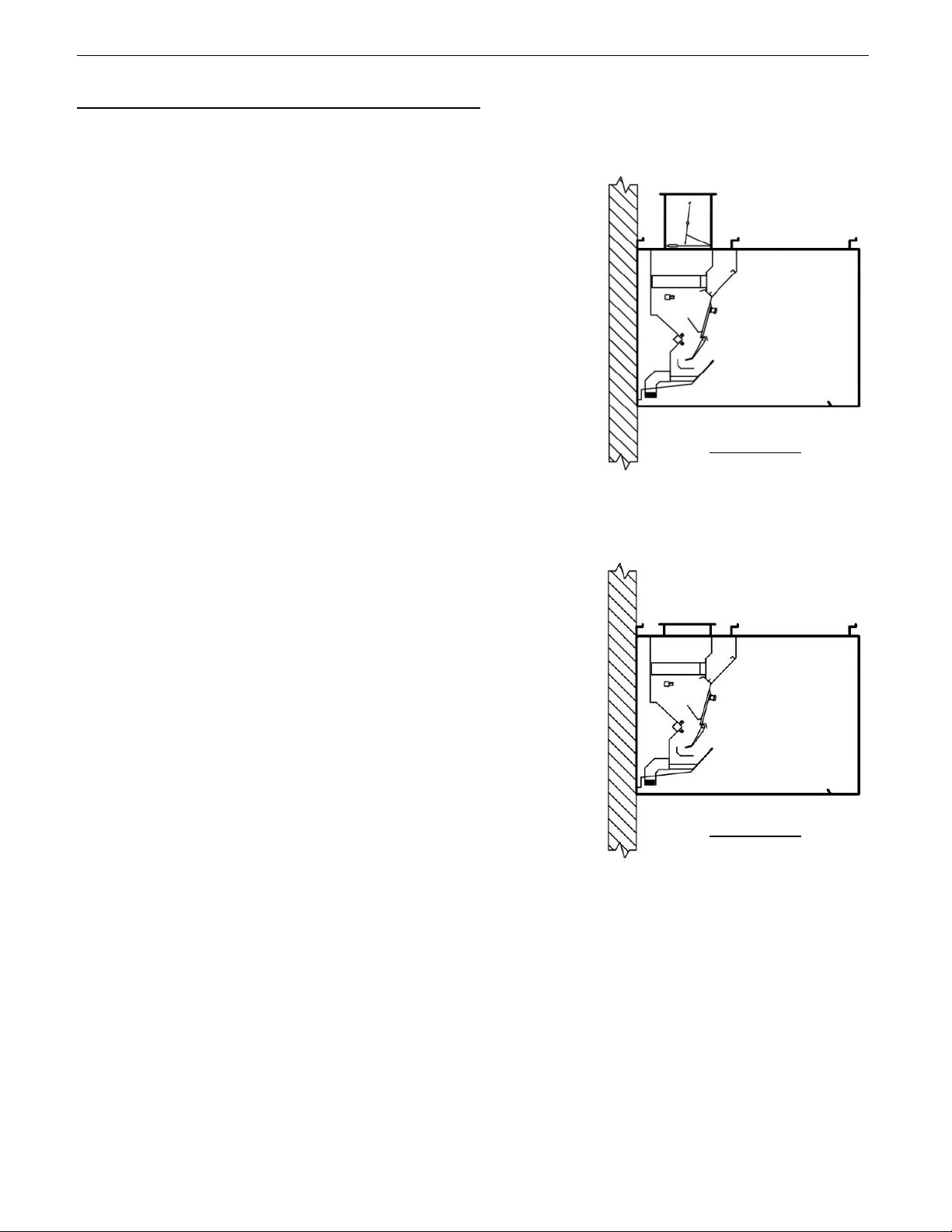

Figure 2-1-1

Figure 2-1-2

Principle of Operation Overview

The Gaylord Model CG3-UVi Series Ventilator is a high grease extraction efficiency Ventilator that

includes the additional feature of an Ultraviolet Light System that dramatically reduces grease

accumulation in the exhaust plenum, ductwork and exhaust fans. The Ventilator incorporates a hot

water Wash Cycle that automatically washes the accumulated grease and other particles out of the

Ventilator and into the building drain system. The standard CG3-UVi Ventilator has a full length fire

damper located at the air inlet slot, two models have a fire damper in the exhaust duct collar and one

model does not have a fire damper.

The operation of the exhaust fan and the Wash Cycle is controlled by the Gaylord Command Center

which is located on the face of the Wash Control Cabinet (Refer to Figure 2-1-1). All the plumbing

components, detergent pump and detergent tank are located inside the Wash Control Cabinet (Refer to

Figure 2-1-2 and Figure 2-7-2).

Typical Command Center

Typical Wash Control Cabinet

Chapter 2 - Principle of Operation, Page 2-2__________________________________________________

Grease Extraction

Overview

The Gaylord “CG3-UVi” Series Ventilator extracts up to 95% of the grease, dust and lint particles from

the airstream passing through it, when operated and maintained in accordance with design

specifications. This high rate of grease extraction is accomplished by the use of grease extraction

baffles, particulate separators and UV lamps. The following describes the function of each.

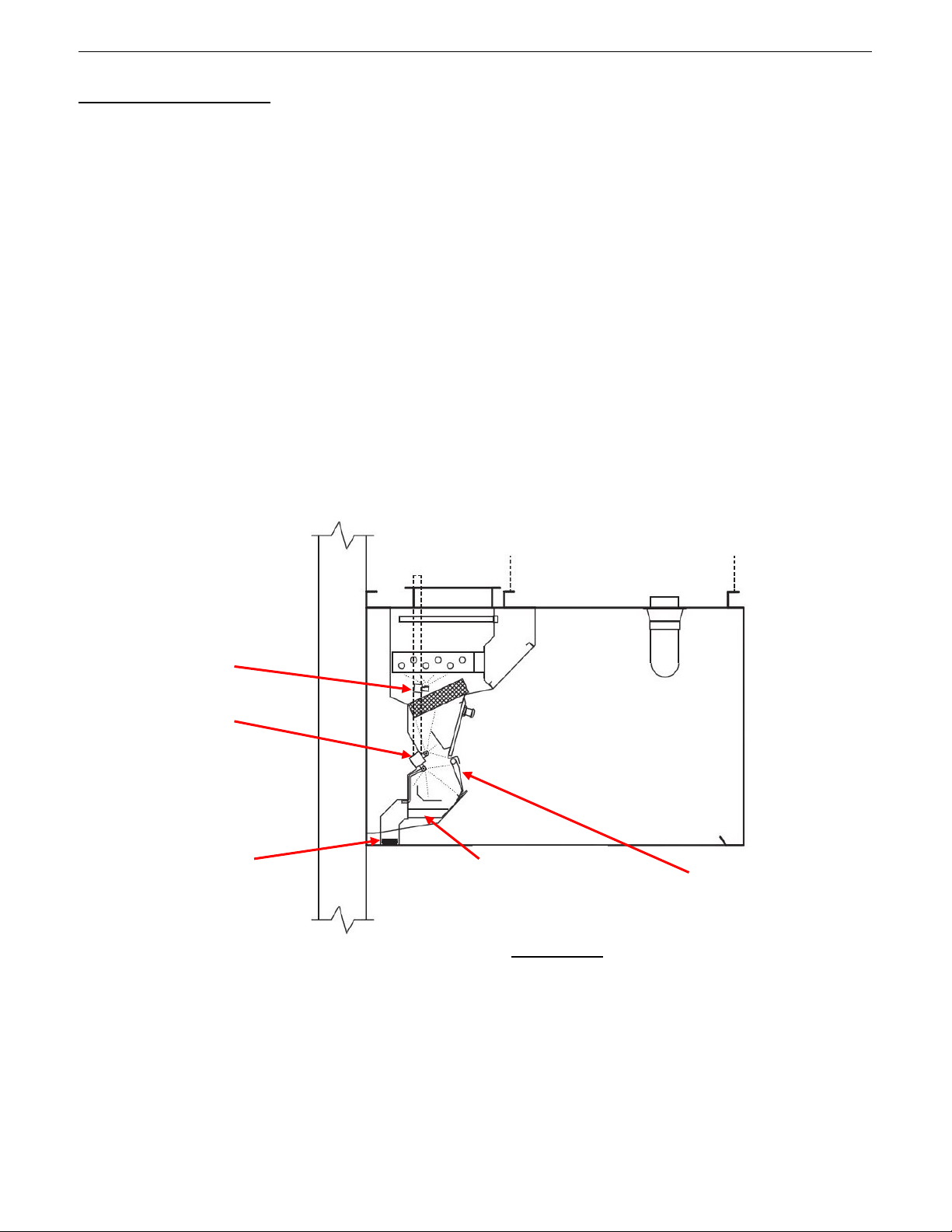

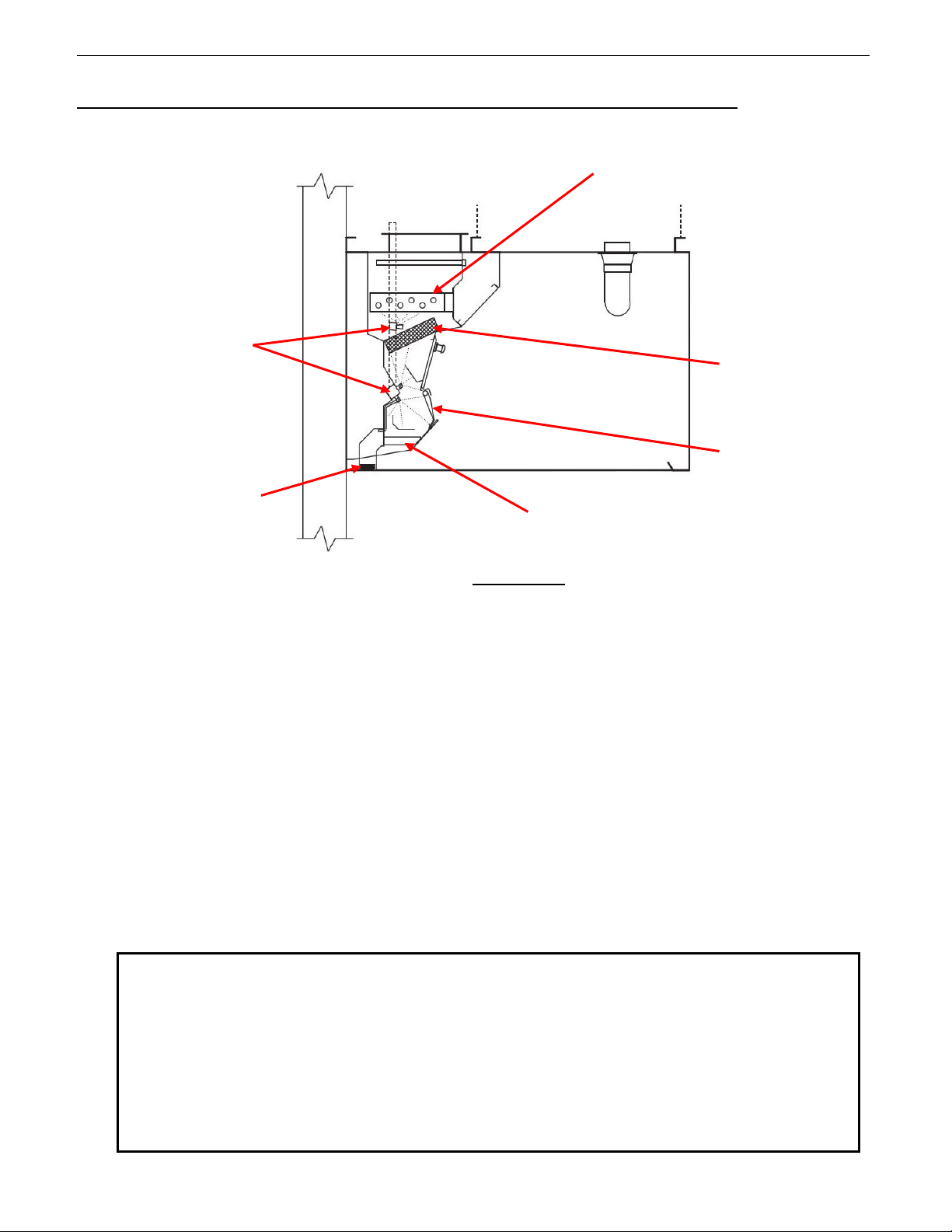

Grease Extraction Baffles

When the exhaust fan is started the hot, grease-laden air rising from the cooking surface merges with

the higher velocity air that wipes the front of the cooking equipment and extends, like an air blanket, from

the front edge of the cooking equipment to the air inlet slot of the

through the Ventilator’s extraction chamber at a high speed, it is forced to make a series of turns

around three baffles. As this high velocity air turns around each baffle, the

thrown out of the airstream by centrifugal force and collected on the baffles. The extracted grease,

dust and lint are collected in the interior of the ventilator, remaining out of the airstream until

removed daily by the wash cycle.

Baffle #1

Important Note: The following description of Baffle #1 is for the standard CG3-UVi series Ventilator.

For operation of Baffle #1 for series FDL, FDT, FDD, and ND refer to TableT-2-9-1).

This baffle, located at the air entrance of the ventilator, is a

the exhaust on mode as

2-6-1, and

pushed on the Command Center, the damper opens to the exhaust mode position 1 to become

is

the preliminary grease

back side of the damper which drains off liquefied

airstream.

Baffle #2

This baffle is located on the interior back wall of the ventilator

equipped with brass spray nozzles on 8" to 10" centers (Refer to Figure 2-3-1). During the wash

cycle, hot detergent water is released through the nozzles.

Baffle #3

This baffle is located on the back of the inspection doors (Refer to Figure 2-3-1). This baffle is also a

grease collecting gutter, collecting the grease extracted by the ventilator preventing the contaminants

from dropping back into the high velocity airstream.

Optional Custom Air Baffles

Some Ventilators may be equipped with optional Custom Air baffles, shown dotted, which reduces

the exhaust volume where the baffles occur (Refer to Figure 2-3-1).

Particulate Separator

Once the larger particles of grease have been captured through inertial impaction by the baffles, the

smaller particles will be arrested in the Particulate Separator using the principles of diffusion and inertial

impaction (Refer to Figure 2-3-1). These collected particles will be washed away each day by the

automatic wash.

position 3 is the fire mode as shown in Figure 2-8-1. When the "START FAN" button

shown in Figure 2 -3 - 1 , position 2 is the wash mode as shown in Figure

extraction baffle. There is a small sloped grease collecting gutter on the

grease, preventing it from re-entraining into the

V

entilator. As the air moves

larger

three position damper. Position 1 is

and is a stainless steel pipe,

particles of grease are

__________________________________________________Chapter 2 - Principle of Operation, Page 2-3

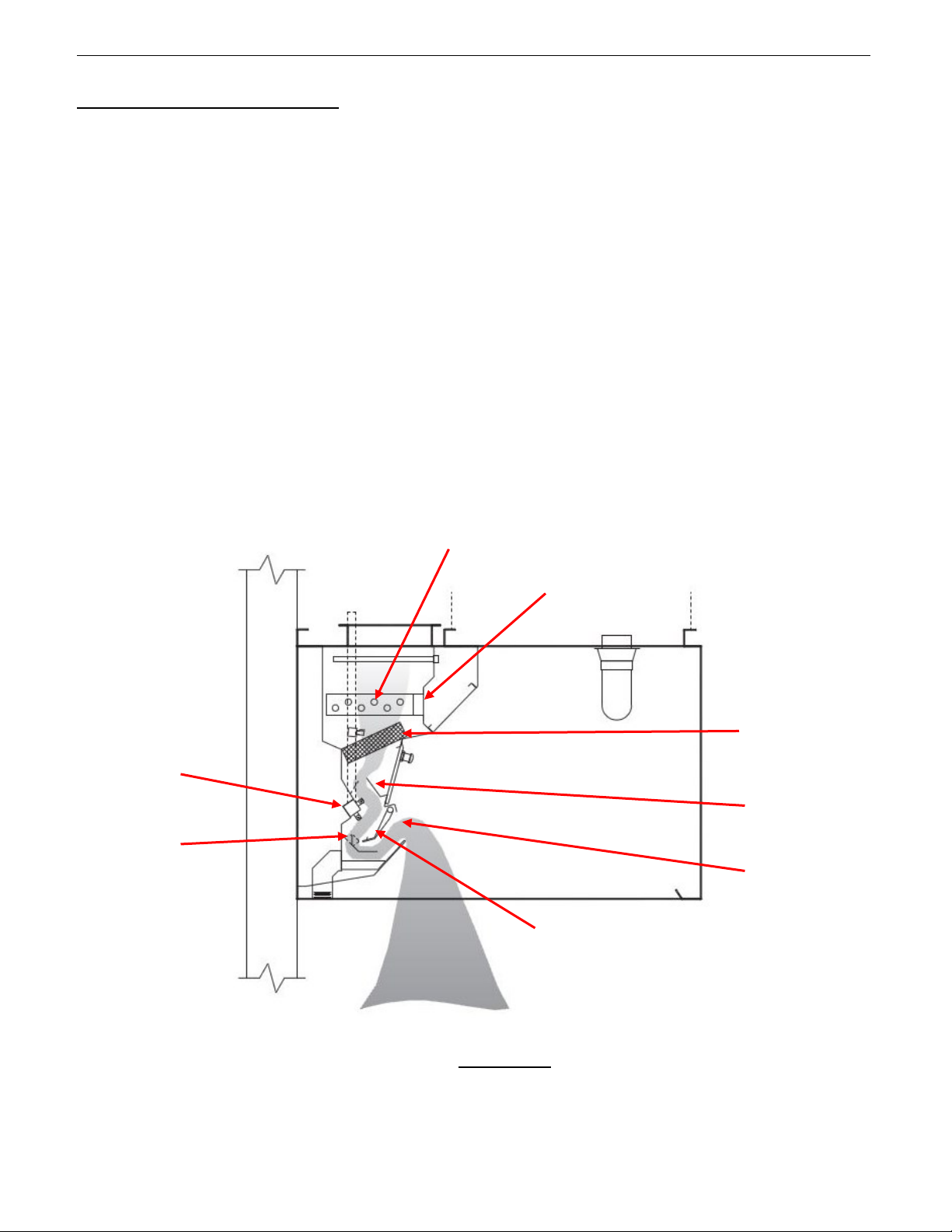

Figure 2-3-1

Grease Extraction Mode

Baffle #1

Baffle #3

Particulate

Baffle #2

Optional

Dotted

UV Module

UV Lamps

Air Inlet Slot

Grease Extraction – Cont.

UV Lamps

Once the baffles and particulate separator have collected the grease particles larger than 1 micron, the

UV lamps will break down the remaining grease particles by direct exposure to 254nm light and by the

Ozone, Hydroxyl Radicals and Anionic oxygen created by the 187nm UV light and oxidizing the grease into

a light gray dust. The Ozone will carry down the ductwork and continue to break down the grease

particulate and odor molecules keeping the ductwork much cleaner. The byproducts of this process are

CO2, H20 and the base minerals from the grease and particulate matter coming off of the cooking

surface. The light gray dust that collects on the lamps is washed away each day during the Wash Cycle.

UV Systems are used to remove a high percentage of grease that the baffles and particulate separator

cannot remove, offering many benefits to the owner/operator.

The UV Lamps are mounted in an UVi Module which slide into a track downstream of the Particulate

Separator (refer to Figure 2-3-1). The ballasts are mounted in the front portion of the module and other

electronics are mounted in the electrical raceway (Refer to Figure 6-7-1 and 6-15-1). The Command

Center monitors and displays text indicating the status of the UV System, and Safety Interlocks. Refer to

your Command Center Tech Manual for specific text displayed.

Separator

Custom Air

Baffle Shown

Chapter 2 - Principle of Operation, Page 2-4__________________________________________________

Figure 2-4-1

Cold Water Mist Nozzles

Grease Extraction – Cont.

UV Lamps – Cont.

For proper UV operation, the Ventilators must be maintained in good working order. The UV system

must be inspected periodically and the lamps replaced as necessary. The Ventilator, ductwork and

exhaust fan must be inspected in accordance with NFPA-96 or local guidelines, though frequency of duct

cleanings should be significantly reduced. Refer to Chapter 4 for maintenance details.

UV Safety

Caution: Exposure to UV light is harmful to skin and eyes.

The CG3-UVi Series Ventilator is equipped with panels and Safety Interlocks to protect operators from

direct exposure to UV light. All safety precautions called for in this manual must be followed to avoid the

potential for harm to operators or service personnel. Refer to Page 4-3 for complete description of

safety precautions.

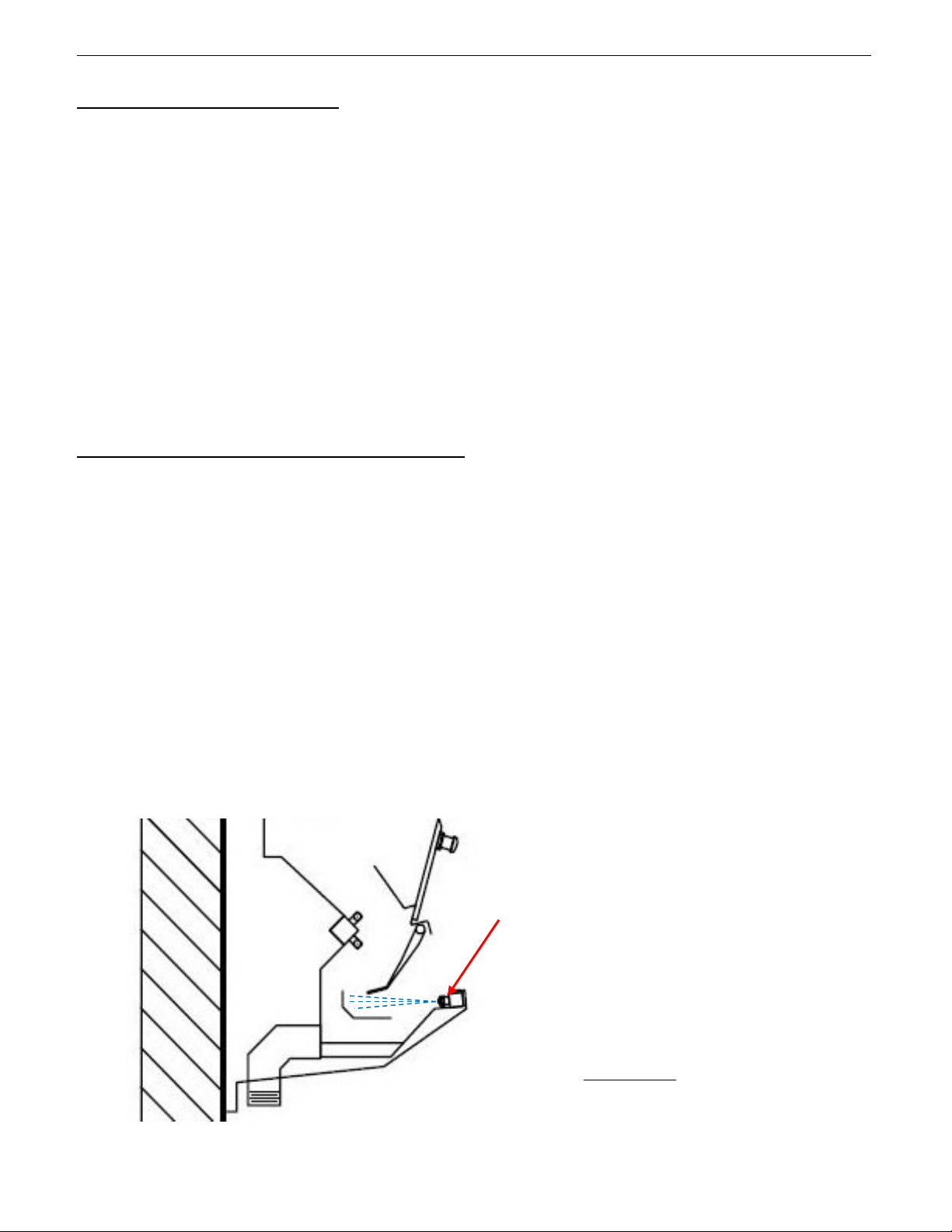

Optional Continuous Cold Water Mist

Overview

Some ventilators may be equipped with optional continuous cold water mist. NFPA-96 requires that all

hoods used over solid fuel burning appliances be equipped with a “spark arrester” to knock down any

embers, created by the burning of solid fuel, to reduce the possibility of embers or sparks being drawn

up into the exhaust duct and fan where it could ignite collected grease. Continuous cold water mist is

one of the acceptable spark arresters.

Continuous cold water mist ventilators incorporate a water manifold with spray nozzles, located at

the lower edge of the air inlet slot (Refer to Figure 2-4-1). When the exhaust fan is started, the

solenoid valve in the cold water loop in the Wash Control Cabinet opens (Refer to Figure 2-5-1), turning

on the mist nozzles which remain on as long as the exhaust fan is on. The nozzles produce a very fine mist

and are located so

that the entire air stream passes through the mist.

Optional Cold Water Mist

__________________________________________________Chapter 2 - Principle of Operation, Page 2-5

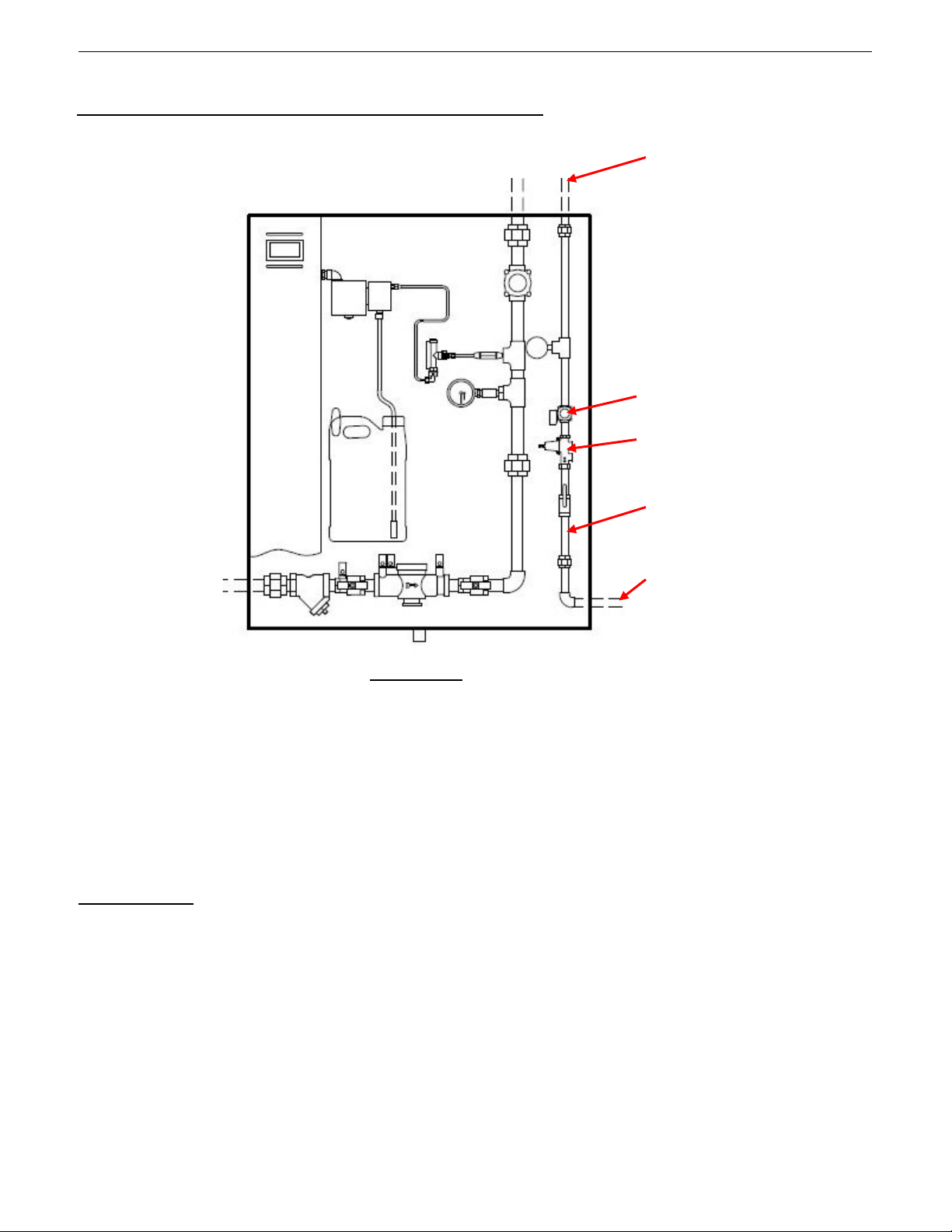

Figure 2-5-1

With Continuous Cold Water Mist Loop

Cold Water Loop

Cold Water Line to

Ventilator

Cold Water Inlet

Solenoid Valve

Pressure Regulator

Optional Continuous Cold Water Mist – Cont.

Engineering Notes

1. Water pressure: The optimal water flow pressure of the nozzle is 40 psi. There is a pressure

regulator and pressure gauge in the plumbing loop to accomplish this pressure.

2. Water Consumption: .66 GPH per lineal ft. of Ventilator at 40 psi.

Typical Wash Control Cabinet

Wash Cycle

The wash system is comprised of two wash manifolds with spray nozzles are located on 8" to 10" centers

(Refer to Figure 2-6-1). The wash cycle is activated each time the exhaust fan is shut off by pushing the

START WASH button on the Command Center or automatically at a specific time as programmed in the

Command Center (Refer to Figure 2-7-1). When activated the UV lamps shut off, the exhaust and

supply fans shut off, the electric damper motor is energized and the damper begins closing forward

to the wash position, and once closed the hot water wash sprays come on (Refer to Figure 2-6-1).

Chapter 2 - Principle of Operation, Page 2-6__________________________________________________

Wash Manifold

Wash Manifold

Pre-Flushed Drain

Sloping Gutter

Figure 2-6-1

Damper Closed to

Wash Cycle – Cont.

The detergent pump, detergent tank, solenoid valve and other plumbing components are located in the

Wash Control Cabinet (Refer to Figure 2-7-1). This hot detergent water washes the day’s grease, dust

and lint accumulation from the baffles, the Particulate Separator, and gray dust from the UV Lamps,

flushing it down to the main gutter which slopes to a pre-flushed drain which leads to the building

drain system. At the end of the wash cycle, the water automatically shuts off, and the interior of the

Ventilator is clean and ready for the next day’s operations. The damper remains in the wash position

until the exhaust fan is restarted. This is to prevent conditioned air from going up the exhaust system

during off hours.

The length of the wash cycle may be set between 3 minutes and 9 minutes. The length of time is

dependent upon the type of cooking equipment being used. Typical settings are 3 minutes for lightduty equipment, 5 minutes for medium-duty equipment, and 9 minutes for heavy-duty equipment.

However, adequate cleaning is dependent upon water pressure, water temperature, daily grease

accumulation, the length of the wash cycle, frequency of wash cycle and the type of detergent being

used. It may be necessary to increase the wash time to achieve proper cleaning. Refer to your Command

Center Technical Manual for instructions on programming wash times.

Engineering Notes

1. Hot Water Pressure: 40 PSI Min. – 80 PSI Max.

2. Hot Water Temperature: 140° Min. - 180° Max.

3. Water Consumption: 1.14 GPM/ lineal ft. of Ventilator at 40 PSI Average

1.67 GPM/ lineal ft. of Ventilator at 80 PSI Average

Wash Mode

Wash Position

__________________________________________________Chapter 2 - Principle of Operation, Page 2-7

Outlet to Ventilator

Detergent Pump

Figure 2-7-1

Detergent

Pressure

Detergent

Backflow

Command Center

Hot Water Inlet

Figure 2-7-2

Line Strainer

Wash Cycle – Cont.

Command Center

Electronic Boards

Injection Point

/Temperature

Gauge

Container

Preventer

Typical Wash Control Cabinet With Electrical

and Plumbing Doors Open

Chapter 2 - Principle of Operation, Page 2-8__________________________________________________

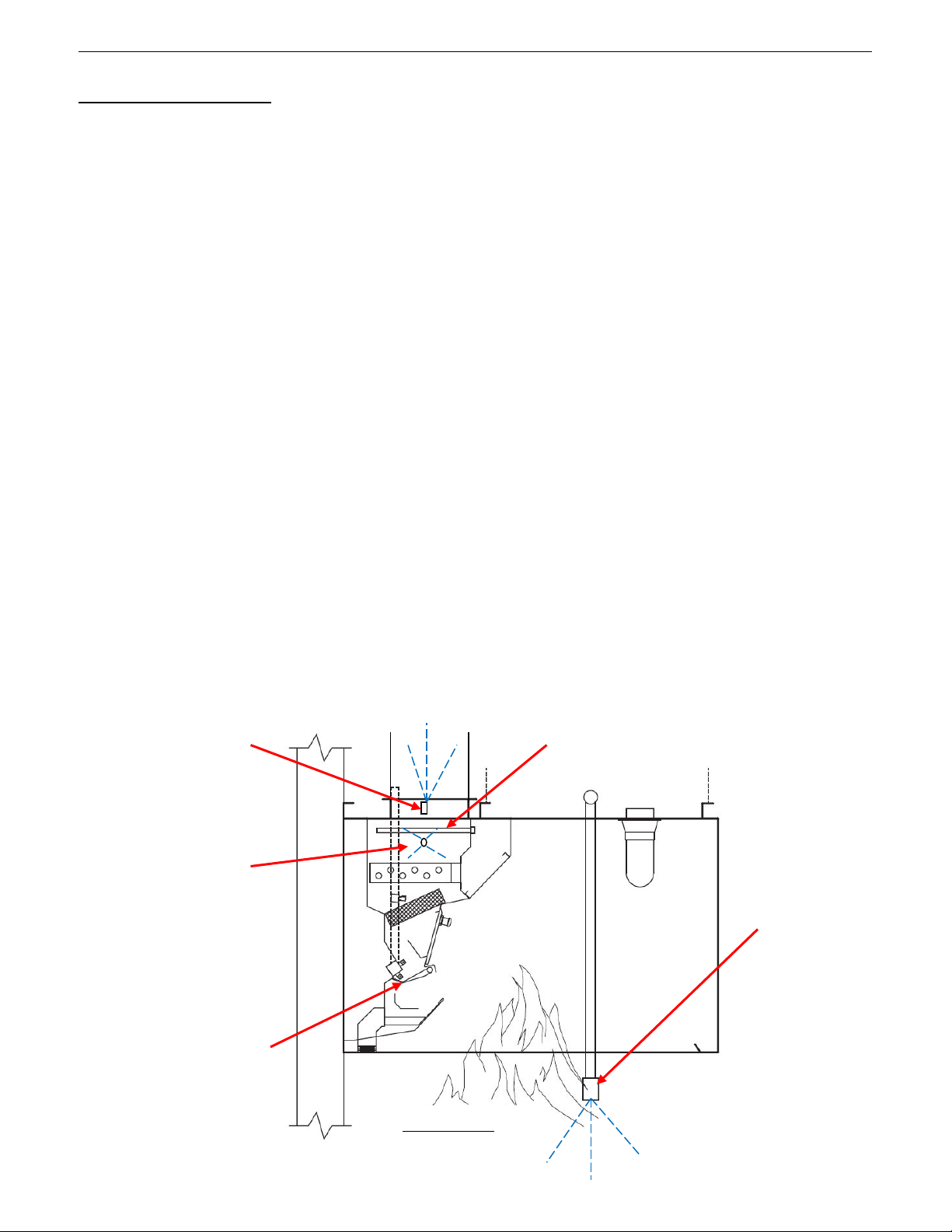

Baffle #1 Closed to

Figure 2-8-1

Fire Mode

Fire

Fire Extinguishing

Fire Extinguishing

Fire Thermostat

Internal Fire Mode

Important Note: The following description of the Internal Fire Mode is for the standard CG3-UVi series

Ventilator only. Refer to Table T-2-9-1 for a description of the Internal Fire Mode for series FDL, FDT,

FDD, and ND.

Automatic internal fire protection is accomplished by the action of the thermostat(s), which are located

at the point where the ductwork joins the ventilator (Refer to Figure 2-8-1). When the temperature of

the conveying airstream, which must pass over the thermostats, reaches 250°F, the system is activated,

and the following occurs:

1. Baffle #1 begins closing back to the fire position, position #3, stopping the combustion supporting

natural draft through the ventilator and creating a fire barrier to contain the fire in the kitchen (Refer

to Figure 2-8-1).

2. The UV lamps shut off.

3. The exhaust fan serving the ventilator is shut off. The supply fan is also shut off.

4. A fire signal is sent from the Command Center to the build fire alarm system (if wired).

5. The display on the Command Center will indicate a fire. Important Note: Refer to your Command

Center Technical Manual for specific text displayed during a Fire Mode.

6. Upon cooling of the thermostat below 250°F, a 2 minute Cool Down Cycle begins and Baffle #1

moves to the exhaust position. Important Note: Refer to your Command Center Technical Manual

for specific text displayed during a Cool Down Cycle.

7. At the end of the Cool Down Cycle the damper closes to the wash position. Important Note: Refer to

your Command Center Tech Manual for specific text displayed upon completion of a Cool Down

Cycle.

8. The exhaust fan can now be restarted.

Important Note: The water sprays do not come on during a Fire Mode

System Duct

Nozzle

System Plenum

Nozzle

the Closed Position

Extinguishing

System

Appliance

Nozzle

__________________________________________________Chapter 2 - Principle of Operation, Page 2-9

Signal sent to

(if wired)

CG3-UVi

Closes to Fire

Position

None

Yes

CG3-UVi-FDL

Baffle Fixed

None

Yes

CG3-UVi-FDT

Baffle Fixed

Closes if fuse link reaches

activation temp

Yes

CG3-UVi-FDD

Baffle Fixed

Closes if fuse link reaches

activation temp

No Thermostat

CG3-UVi-ND

Baffle Fixed

None

No Thermostat

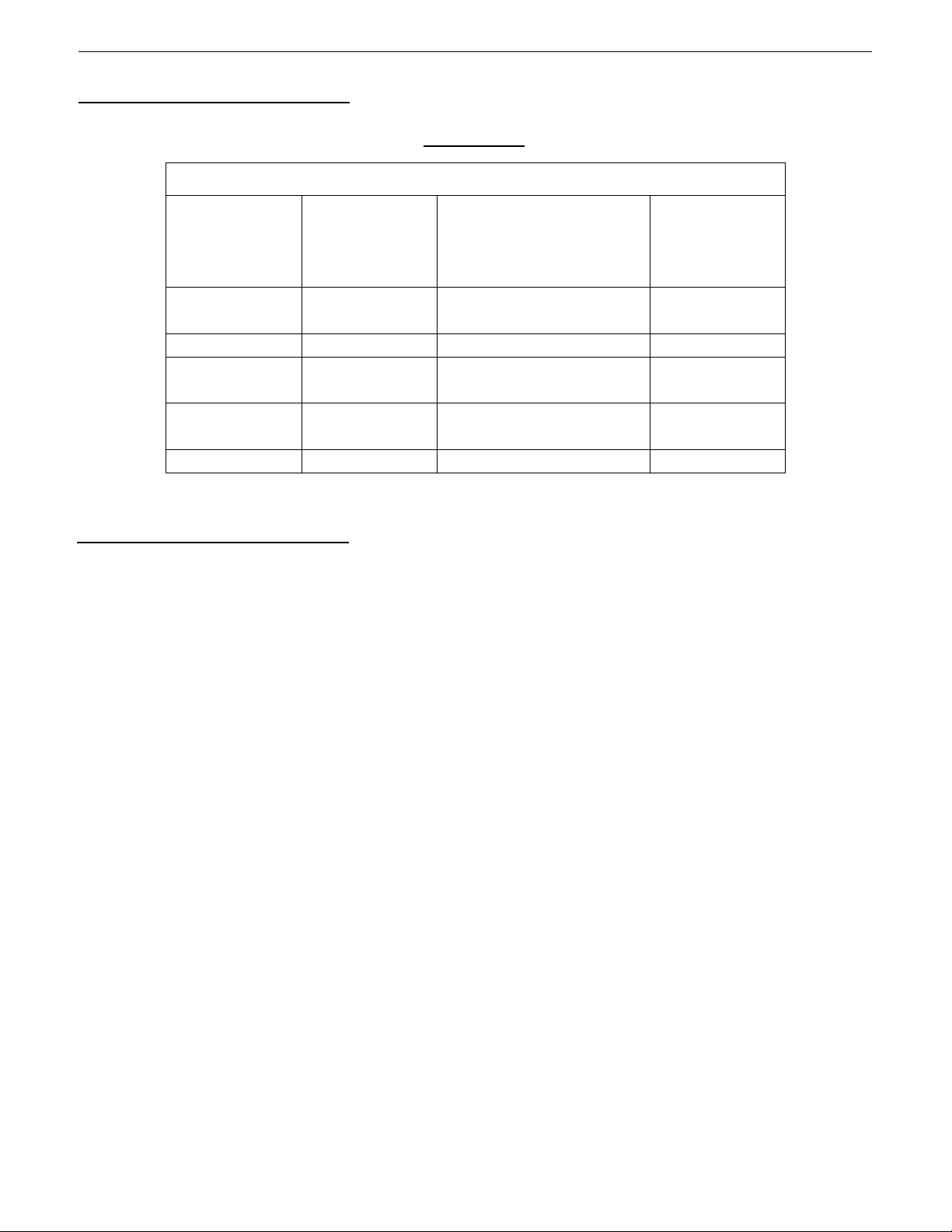

Table T-2-9-1

Internal Fire Mode – Cont.

Series Baffle #1 Duct Collar Damper

Internal Fire Mode (Thermostat Activated)

building fire

alarm system

Fire Extinguishing Systems

The National Fire Protection Association Standard 96 (NFPA-96) and the International Fire Code (IFC)

requires the use of a Fire Extinguishing System to cover the cooking surfaces, Ventilator exhaust plenums

(the area behind the grease extractors), and the exhaust duct (Refer to Figure 2-8-1). Upon activation of

the Fire Extinguishing System the follow will occur:

1. Fire extinguishing agent will discharge through the cooking equipment nozzles, the plenum nozzles

and the duct nozzle(s).

2. The protected cooking equipment and possibly other cooking equipment will shut off. Refer to the

above referenced codes for specific equipment that must shut off.

3. If the Fire Extinguishing System is wired to a building fire alarm system the alarm will activate.

4. If the Fire Extinguishing System is wired to a building management system it will notify of a fire

condition.

5. The Fire Extinguishing System should be wired to the Gaylord Command Center. If wired the

following will occur:

a) If the exhaust and supply fan were on the exhaust fan would stay on and the supply fan would

b) If the Ventilator Wash Cycle was on it would shut off.

6. After discharge, the Fire Extinguishing System must be recharged and certified by a fire system

contractor before the cooking equipment can be turned back on.

For Operation and Maintenance of the Fire Extinguishing System, refer to the system manufacture’s

Owner’s Manual.

Important: NFPA-96 requires inspection and certification of Fire Extinguishing Systems every 6 months.

shut off. It the exhaust and supply fans were off, the exhaust fan would come on and the supply

fan would stay off.

Chapter 2 - Principle of Operation, Page 2-10_________________________________________________

This Page Intentionally Left Blank

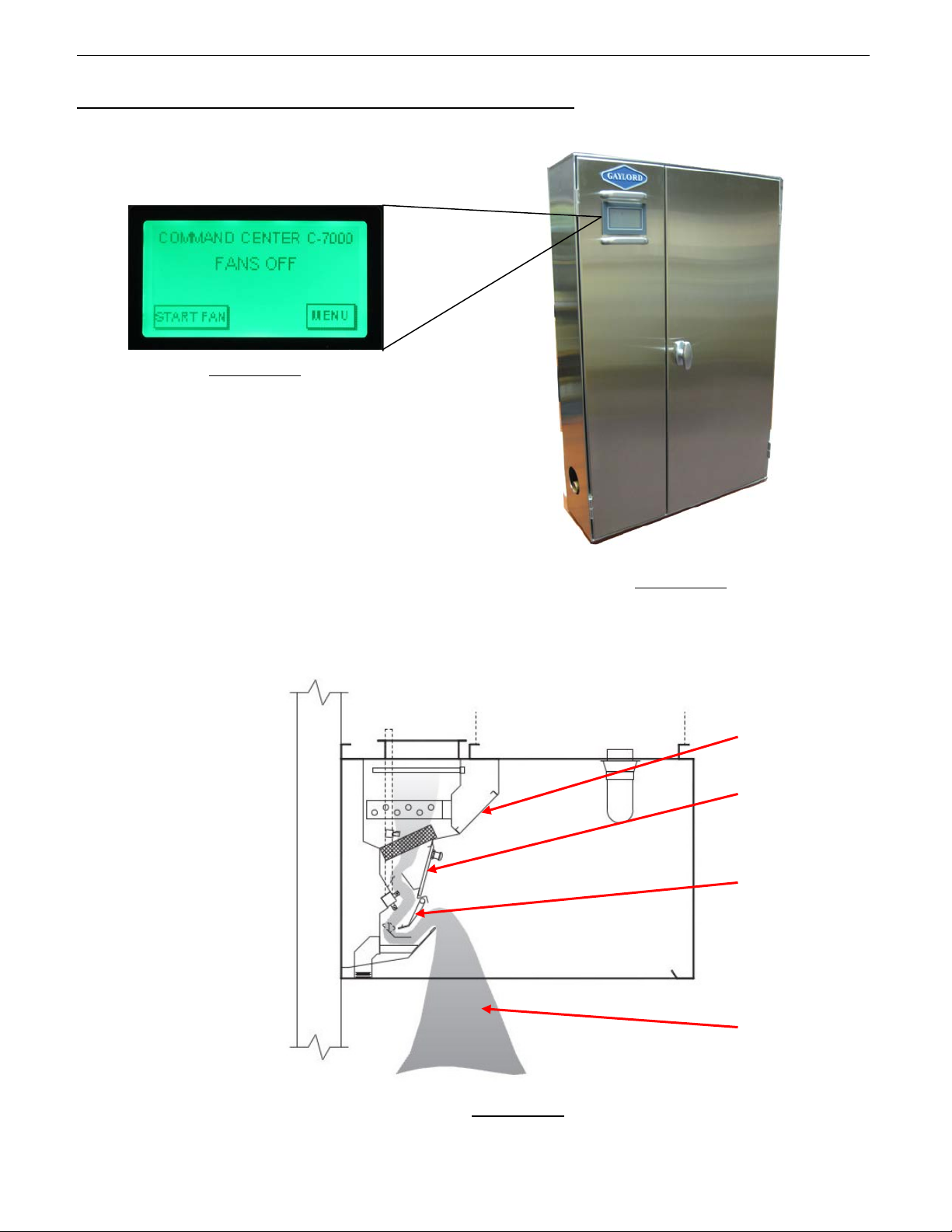

_______________________________________________________Chapter 3 - Daily Operation, Page 3-1

Starting the Exhaust Fan and UV System

Caution: Exposure to UV light is harmful to skin and eyes.

The CG3-UVi Ventilator is equipped with panels and Safety Interlocks to protect operators from direct

exposure to UV light. All safety precautions called for in this manual must be followed to avoid the

potential for harm to operators or service personnel. Refer to Page 4-3 for complete description of

safety precautions.

Caution: Always turn on the exhaust fan before turning on the cooking equipment.

Caution: The chemical fire extinguishing system may discharge if the exhaust fan is not on while the

cooking equipment is on or still hot.

Caution: Never operate the Ventilator with the UV Module Access Doors or the Extractor Inspection

Doors open (Refer to Figure 2-3-1).

Operation of the exhaust fan and UV Lamps is controlled by the Gaylord Command Center located on the

Wash Control Cabinet (Refer to Figure 3-2-1). To start the exhaust fan and turn on the UV Lamps push

the START FAN button on the Command Center. The Command Center may be programmed to

automatically start the exhaust fan at a specific time. Refer to the Technical Manual for your specific

Gaylord Command Center for complete operating instructions of the Command Center.

When the START FAN button is pushed the following occurs:

1. Baffle #1 begins opening from the wash position to the exhaust position (Refer to Figure 2-6-1

and 3-2-3). Note: Baffle #1 only opens on Models CG3-UVi and CG3-UVi-FDL Series. Baffle #1 is

fixed on Models CG3-UVi-FDT, CG3-UVi-FDD and CG3-UVi-ND Series. The Ventilator model

number can be found on the Ventilator Nameplate (Refer to Appendix “A” for a sample of the

Nameplate). Refer to page 1-3 for a complete explanation of model numbers.

Important Note: Refer to your Command Center Technical Manual for specific text displayed

while the baffle #1 is opening.

2. The supply fan comes on.

3. After baffle #1 fully opens (elapsed time approximately

(Refer to Figure 3-3-1). Important Note: Refer to your Command Center Technical Manual for

specific text displayed after baffle #1 opens.

4. Once the exhaust fan reaches operating speed, the UV

Status Light on each Ventilator section will come on (Refer to Figure 3-4-1). The Ventilator is

now in the operational exhaust mode. Important Note: Refer to your Command Center

Technical Manual for specific text displayed when the Ventilator is in the operational exhaust

mode.

45 seconds), the exhaust fan comes on

lamps will come on and the green UV

Chapter 3 - Daily Operation, Page 3-2_______________________________________________________

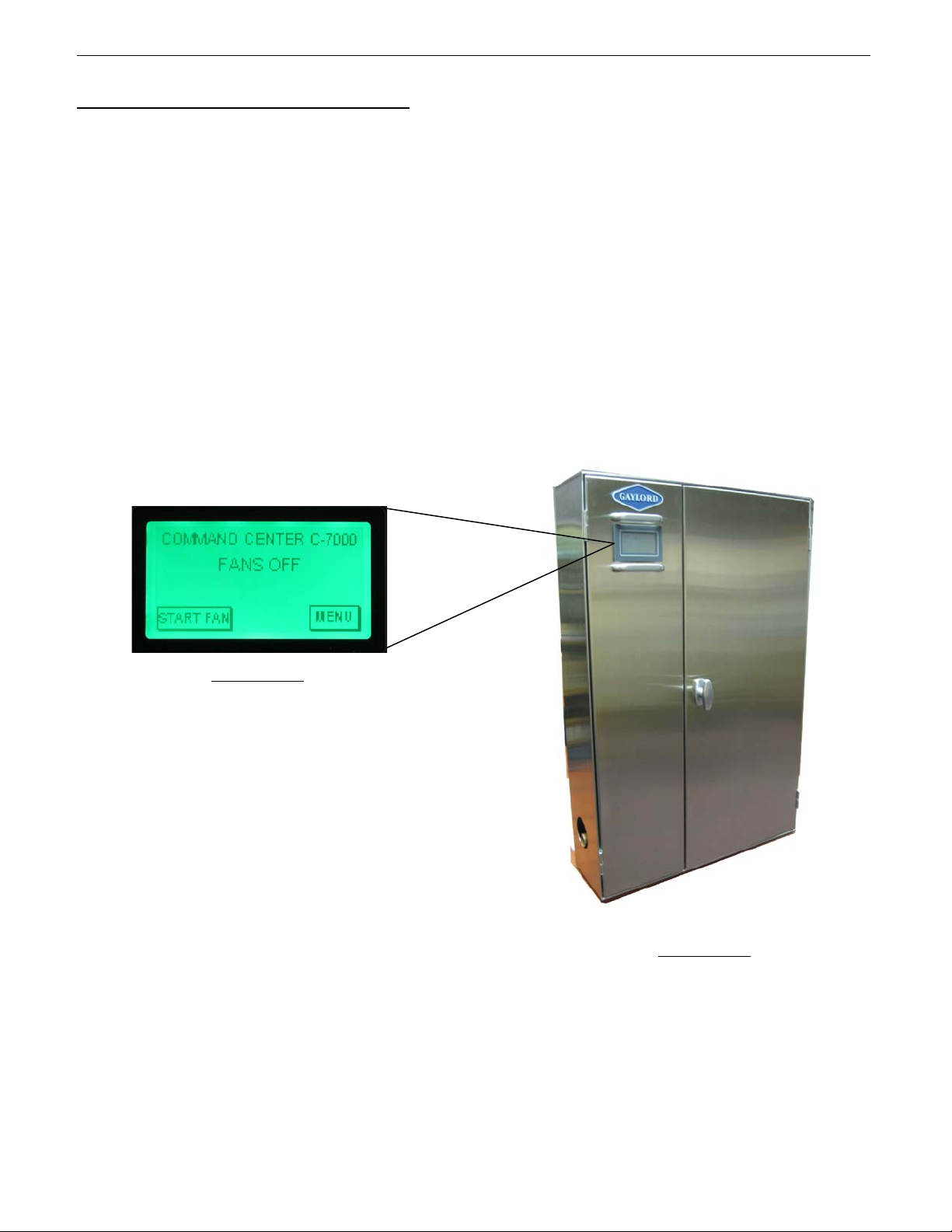

Figure 3-2-1

Typical Command Center

Figure 3-2-2

Exhaust Air

Baffle #1 in

Figure 3-2-3

UV Module

Extractor

Doors

Starting the Exhaust Fan and UVi System – Cont.

Typical Wash Control Cabinet

Access Doors

Inspection

Exhaust Position

Exhaust Mode

_______________________________________________________Chapter 3 - Daily Operation, Page 3-3

One Or More

Figure 3-3-1

Starting the Exhaust Fan and UVi System – Cont.

Note 1: Typically CG3-UVi Series Ventilators installed in the United States are equipped with a Gaylord

Autostart Controller that automatically turns on the exhaust fan if the temperature at the sensors

mounted in the canopy exceeds 90°F. (Refer to Figure 3-3-1). In some instances Ventilators installed

outside the United States will include an Autostart Control. Inclusion of an Autostart Control is

designated by the suffix “AS” in the model number. The Ventilator model number can be found on the

Ventilator Nameplate (Refer to Appendix “A” for a sample of the Nameplate). Refer to your Command

Center Technical Manual for complete information on the Autostart Control.

Note 2: The UV Lamps will not come on unless all the Extractor Inspection Doors and UV Module Access

Doors are closed as shown in Figure 3-2-3.

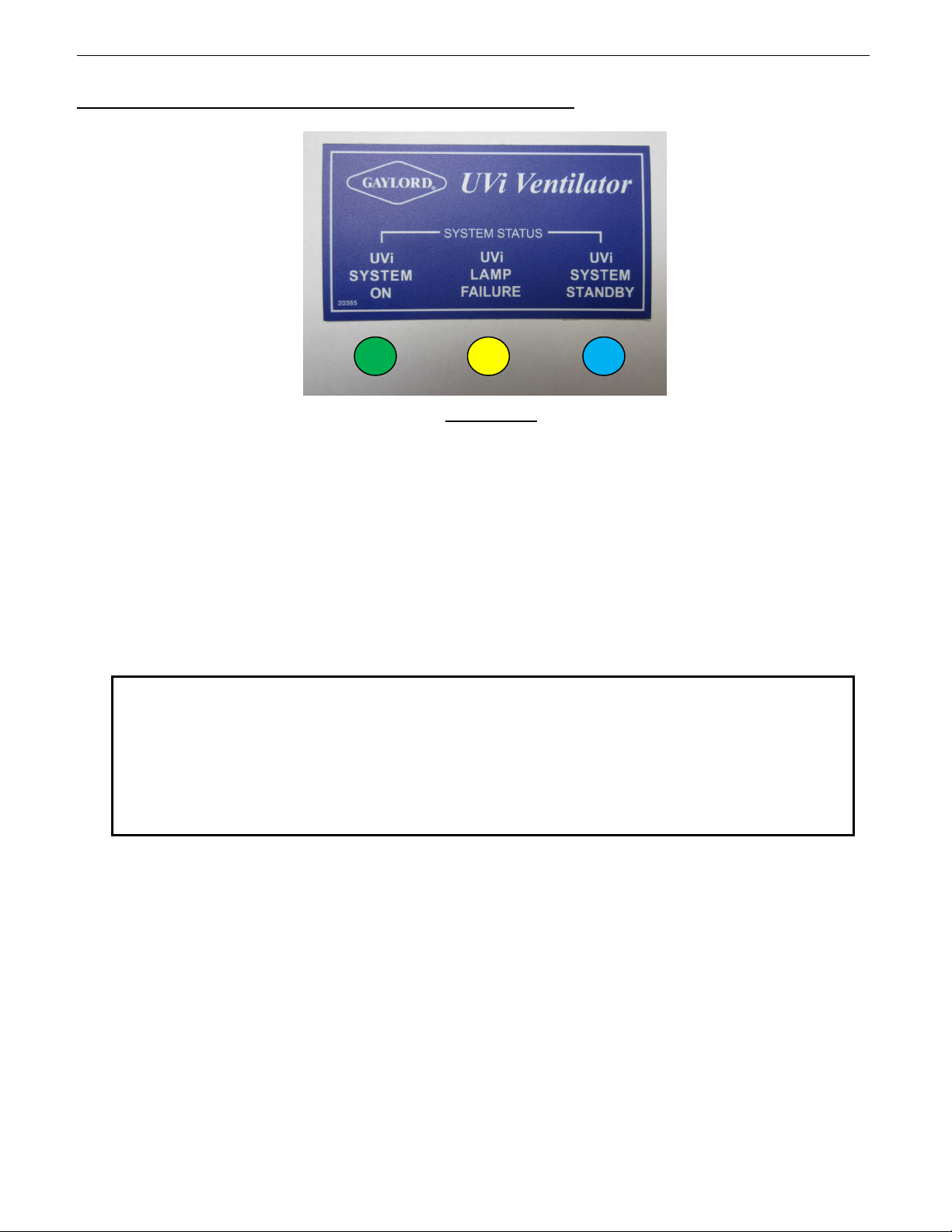

UV Status Lights

Each Ventilator section contains a bank of UV Status Lights to monitor the UV System (Refer to Figure 34-1). There are three colored lights, Green, Yellow and Blue. They indicate the system status as follows:

1. Green On: The UV system is operating properly.

2. Yellow On: One or more UV Lamps are not operating. If the yellow is on, less UV is being generated;

3. Blue On: One or more Extractors Inspection Doors or UV Module Access Doors are not closed or

Autostart Sensors

Depending Upon

Length of Ventilator

Ventilator Showing Autostart Sensor

however it does not prevent the operation of the Ventilator or indicate an unsafe condition.

latched properly. During this condition the UV System is not operating.

Chapter 3 - Daily Operation, Page 3-4_______________________________________________________

Important Note:

for complete instructions on programming wash times. If you do not have a Technical

Manual for your Command Center, obtain the model number from the nameplate on the

Figure 3-4-1

Starting the Exhaust Fan and UVi System – Cont.

In addition to the Status Lights on the Ventilator, the Gaylord Command Center displays text indicating

the similar message as the Status Lights. Refer to your Command Center Technical Manual for specific

text displayed.

Note: If either the Yellow or Red light are on refer the Troubleshooting section of this manual beginning

on page 5-1 for corrective action.

The Command Center illustrated in this manual may not represent the model of Command

Center you have. Refer to the Technical Manual for your specific model of Command Center

Command Center and contact Gaylord Industries. Refer to page 1-1 for contact information.

UVi Status Lights

_______________________________________________________Chapter 3 - Daily Operation, Page 3-5

Turning Off the Exhaust Fan and Starting the Wash Cycle

Caution: Always turn off the cooking equipment and allow to cool before turning off the exhaust fan.

The chemical fire extinguishing system may discharge if the cooking equipment is on or hot when the

exhaust fan is off.

To turn off the exhaust fan and UV Lamps and start the Wash Cycle push the START WASH button on the

Gaylord Command Center (Refer to Figure 3-2-1). If the Command Center is programmed to

fan automatically, then the stop button does not need to be pushed.

When the START WASH button is pushed the following occurs:

1. The exhaust and supply fans shut off.

2. The UV lamps shut off and the green UV System Status Light will shut off.

3. Baffle #1 begins closing forward to the wash position

approximately 45 seconds. Note: Baffle #1 only move to the wash position on Models CG3-UVi

and CG3-UVi-FDL Series. Baffle #1 is fixed on Models CG3-UVi-FDT, CG3-UVi-FDD and CG3-UViND. Refer to pages 1-5 and 1-6 for complete explanation. Important Note: Refer to your

Command Center Technical Manual for specific text displayed while the baffle #1 is moving to

the wash position.

4. After baffle #1 closes to the wash position, the Wash Cycle comes on spraying hot,

detergent injected water, through the spray nozzles washing away the day’s grease, dust

lint accumulation from the baffles, the particulate separator, and gray dust from the UV

and

Module, flushing it

drain system (Refer to Figure 3-6-1). The Wash

programmed in the

equipment, 4 minutes for light /medium duty equipment, 5 minutes for mediumequipment, 7 minutes for heavy-duty equipment and 9 minutes for extra heavy duty

equipment. Important Note: Refer to your Command Center Technical Manual for specific text

displayed while the Ventilator is in a Wash Cycle.

5. Upon completion of the Wash Cycle, the baffle #1 stays in the

exhaust fan is re-started. Closing the baffle saves building energy by not allowing conditioned air

from drafting up the exhaust duct, or in cold climates prevents cold air from coming down the

duct and into the kitchen.

Note 1: If the Ventilator is equipped with a Gaylord Autostart Controller, the exhaust fan will stay on if

the temperature at the sensor mounted in the canopy exceeds 90°F. (Refer to Figure 3-3-1). Once the

temperature drops below 90°F., the fan will continue to run for 15 minutes and then shut off.

Note 2: The Command Center control may be programmed to automatically turn off the exhaust fan at a

specific time. Refer to your Command Center Technical Manual for complete operating instructions.

down to the main gutter which slopes to drain that leads to the building

Command Center. The typical wash times are 3 minutes for light-duty

(Refer to Figure 3-6-1). This action takes

Cycle stays on for the length of time

closed wash position until the

stop the

duty

Chapter 3 - Daily Operation, Page 3-6_______________________________________________________

Important Note:

grease extraction baffles, particulate separator and UV Lamps. The Command Center

to the Technical Manual for your specific model of Command Center for complete

instructions on programming wash times. If you do not have a Technical Manual for your

Sloping Gutter

UV Module

Wash Manifolds

Particulate

Baffle #1 In the

Drain To Building

Figure 3-6-1

Turning Off the Exhaust Fan and Starting the Wash Cycle – Cont.

With Spray Nozzles

Drain System

Wash Cycle

Length of Wash

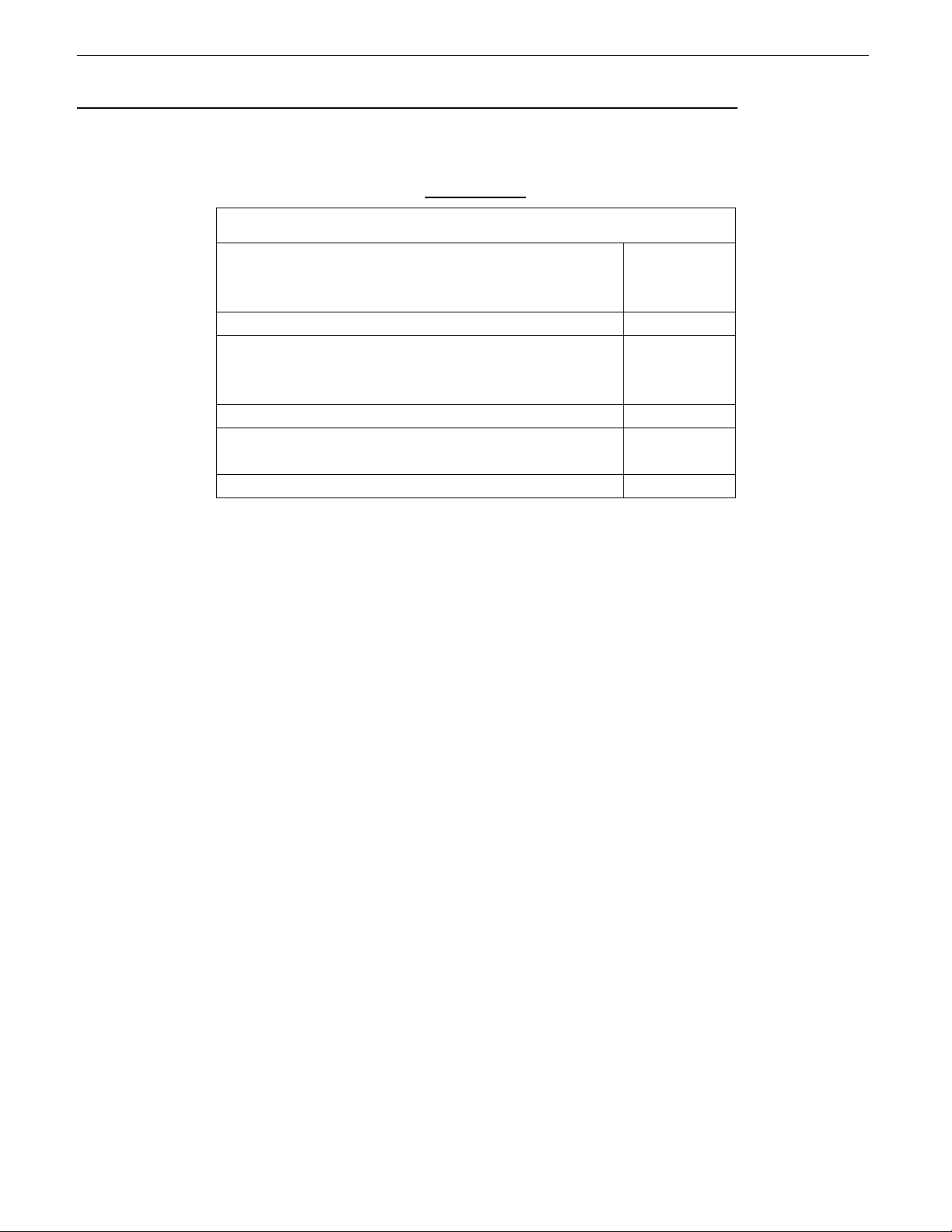

The length of the Wash Cycle is primarily determined by the type of cooking equipment involved; Light

Duty, Light/Medium, Medium Duty, Heavy Duty, and Extra Heavy Duty as shown Table T-3-7-1.. The

factory recommended wash times are shown on table T-3-7-1 however the length of the Wash Cycle to

adequately clean the Ventilator may vary depending on the following:

1. Actual amount of cooking within the hours of fan operation.

2. Type of food product being cooked.

3. Water pressure. Required pressure is 40 psi Min. to 80 psi Max.

4. Water temperature. Required temperature is 140 degrees F. Min. to 180 degrees F. Max.

5. Type of detergent. Refer to page 3-8 for recommend detergent.

6. Ratio of detergent to water.

Separator

Wash Position

The wash cycle may be programmed for different times as needed to adequately clean the

illustrated in this manual may not represent the model of Command Center you have. Refer

Command Center, obtain the model number from the nameplate on the Command Center

and contact Gaylord Industries. Refer to page 1-1 for contact information.

_______________________________________________________Chapter 3 - Daily Operation, Page 3-7

Length of

Wash Cycle

(in min.)

Light Duty – Ovens, steamers and kettles

3

Light/ Medium Duty – braising pans, tilting skillets,

open burner ranges, hot top ranges, and

conveyor ovens.

Medium Duty – griddles and grooved griddles.

5

Heavy Duty – gas and electric char broilers, upright

broilers, woks and conveyor broilers.

Extra Heavy Duty – solid fuel broilers

9

Table T-3-7-1

Turning Off the Exhaust Fan and Starting the Wash Cycle – Cont.

Minimum Factory Recommended Wash Cycle Times

Type of Cooking Equipment

fryers,

4

7

Chapter 3 - Daily Operation, Page 3-8_______________________________________________________

Recommended Detergent

Overview

FORMULA G-510EF is the only cleaner recommended by Gaylord Industries for use in the wash down

system of The Gaylord Ventilator. FORMULA G-510EF is a concentrated colloid cleaner specially

formulated to remove the daily accumulation of grease inside the Ventilator without damaging the

rubber and synthetic parts of the solenoid valves and the detergent pumping system. FORMULA G510EF is safe for kitchen personnel and has a variety of uses.

FORMULA G-510EF Safety

FORMULA G-510EF is registered with the U.S. EPA’s Design for the Environment Program (DfE) which

seeks to promote the use of institutional cleaners and maintenance products with improved

environmental and human health characteristics.

FORMULA G-510EF for the Ventilator Wash System

Pour FORMULA G-510EF directly into the detergent tank located inside the Wash Control Cabinet (Refer

to Figure 2-11-2). The detergent pump injects the detergent into the Main Feed Line where it dilutes

with the hot water at the proper ratio (Refer to Figure 2-11-2).

FORMULA G-510EF for Cleaning the Ventilator Exterior

Mix one part FORMULA G-510EF to twenty parts water in hand spray bottle. Spray on, let stand for a few

minutes and wipe off.

FORMULA G-510EF for Other Cleaning Jobs

The colloidal action of FORMULA G-510EF makes it a cleaner especially well-suited for use in kitchens.

The colloids break up dirt and grease into millions of tiny particles that constantly repel each other.

These particles cannot recombine or redeposit on a surface and are, therefore, easily washed away.

FORMULA G-510EF contains no harsh chemicals, yet offers outstanding performance on the toughest

cleaning jobs.

Use a mixture of one part FORMULA G-510EF to twenty parts water for:

- VINYL/PLASTIC/WALLS...Removes dirt, grease, food deposits and fingerprints.

- REFRIGERATORS...Removes dirt, spilled milk, blood, mildew and objectionable odors.

- RESTROOMS...Add a disinfectant to clean all fixtures, walls, floors, etc.

Use a mixture of one part FORMULA G-510EF to five parts water for extremely heavy grease build-up,

such as on the floor and on equipment around deep-fryers. Spray on, let set for a few minutes and rinse

or wipe off. For extremely soiled areas, gentle agitation, followed by a soaking period, will result in more

thorough cleaning. DON’T be afraid to experiment with FORMULA G-510EF because it contains no

phosphates, nitrates, enzymes, sulfates, suffocates or silicates.

Loading...

Loading...