Gast ROA User Manual

OPERATION & MAINTENANCE

70-5200 G480PL (Rev.C)

Laboratory Rocking Piston

Vacuum Pump and Compressor

ROA Series

USER INSTRUCTIONS

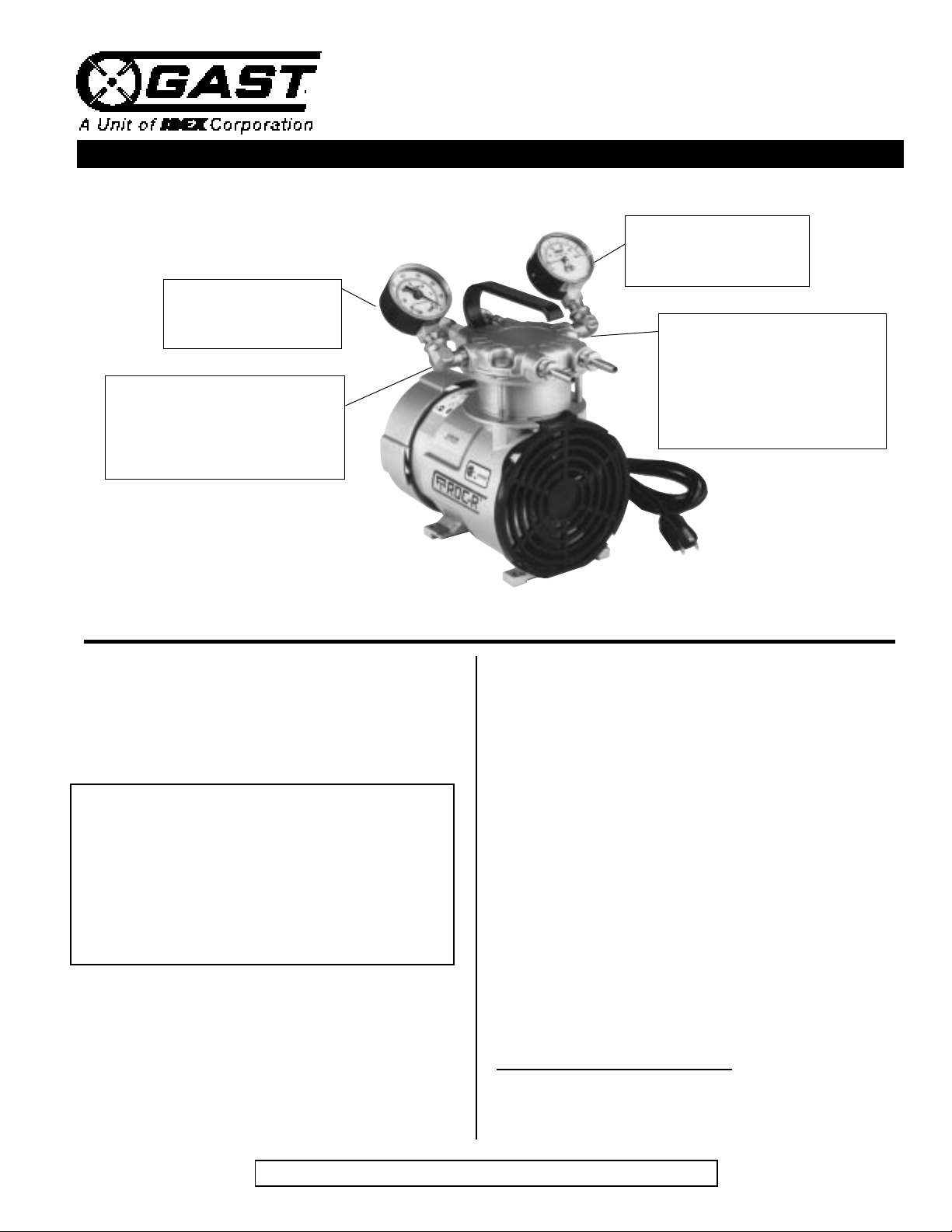

Pressure Gauge

The pressure gauge shows

the output pressure.

Pressure Regulator

Turn the regulator screw clockwise

to increase pressure (up to approximately 100 PSI max. with the screw

turned fully to the end stop).

Vacuum Gaug e

The vacuum gauge shows

the inlet vacuum.

Vacuum Regulator

Turn the regulator screw clockwise

to increase vacuum (up to approximately 25” Hg max. with the screw

turned fully to the end stop).

Note: Maximum pressure and vacuum

cannot be produced at the same time.

This is the hazard alert symbol: m When you see

this symbol, be aware that personal injury or property

damage is possible. The hazard is explained in the

text following the symbol. Read the information

carefully before proceeding.

The following is an explanation of the three

different types of hazards:

m DANGER Severe personal injury or death

will occur if hazard is ignored.

m WARNING Severe personal injury or death

can occur if hazard is ignored.

m CAUTION Minor injury or property damage

can occur if hazard is ignored.

GENERAL INFORMATION

This pump is designed to be used for the purpose of

pumping air. The pump should not be used for the

pumping of fluids, particles, solids or any combustible substances likely to cause explosions.

m DANGER Do not pump flammable or explosive

gases or operate the unit in an atmosphere containing them.

m CAUTION The pump is designed for pumping air.

Do not allow corrosive gases or

particulate material to enter the pump.

Water, oil-based contaminants, or

other liquids must be filtered out.

m CAUTION Normal ambient temperature should

not exceed 400 C (1040 F). For

operation at higher temperatures,

consult the factory.

m WARNING Exhaust air temperature can be-

come very hot. Keep away from air

stream.

Performance is reduced by low atmospheric pressure found

at high altitudes. Consult a Gast distributor for details.

Never lubricate this oil-less pump. Most components are

made of aluminum and the valves are stainless steel.

KEEP THIS DOCUMENT FOR FUTURE REFERENCE

INSTALLATION

m WARNING To avoid risk of electrocution do not

use this product in an area where it

could come in contact with water or

other liquids. If exposed to the elements, it must be weather protected.

m CAUTION Do not block the flow of cooling air

over the pump in any way.

Mounting the Pump

m CAUTION Remove the plastic plugs in the

intake and exhaust ports before

operating unit.

The pump may be installed in any orientation as long as

the flow of cool, ambient air over the pump is not

blocked. To reduce noise and vibration, use shock mounts

and affix to a stable, rigid operating surface.

Plumbing

To prevent air flow restriction, use pipe and fittings that

are the same size or larger than the threaded ports of the

pump. NOTE: Be sure to connect the intake and exhaust

plumbing to the correct inlet and outlet ports.

Accessories

Filters and mufflers are supplied on some models. Check

periodically and replace when necessary. Consult a Gast

Representative for filter recommendations. For best

results, install relief valves and gauges at the inlet or

outlet, or both, to monitor performance.

Relief Valve

m WARNING Do not touch relief valve as it becomes

very hot during operation and will burn

skin on contact. Wait until unit has

been turned off and allowed to cool

before touching it.

A safety relief valve is provided on standard

compressors and is preset at factory. Do not exceed

or adjust safety relief to pressures other than those

preset at factory.

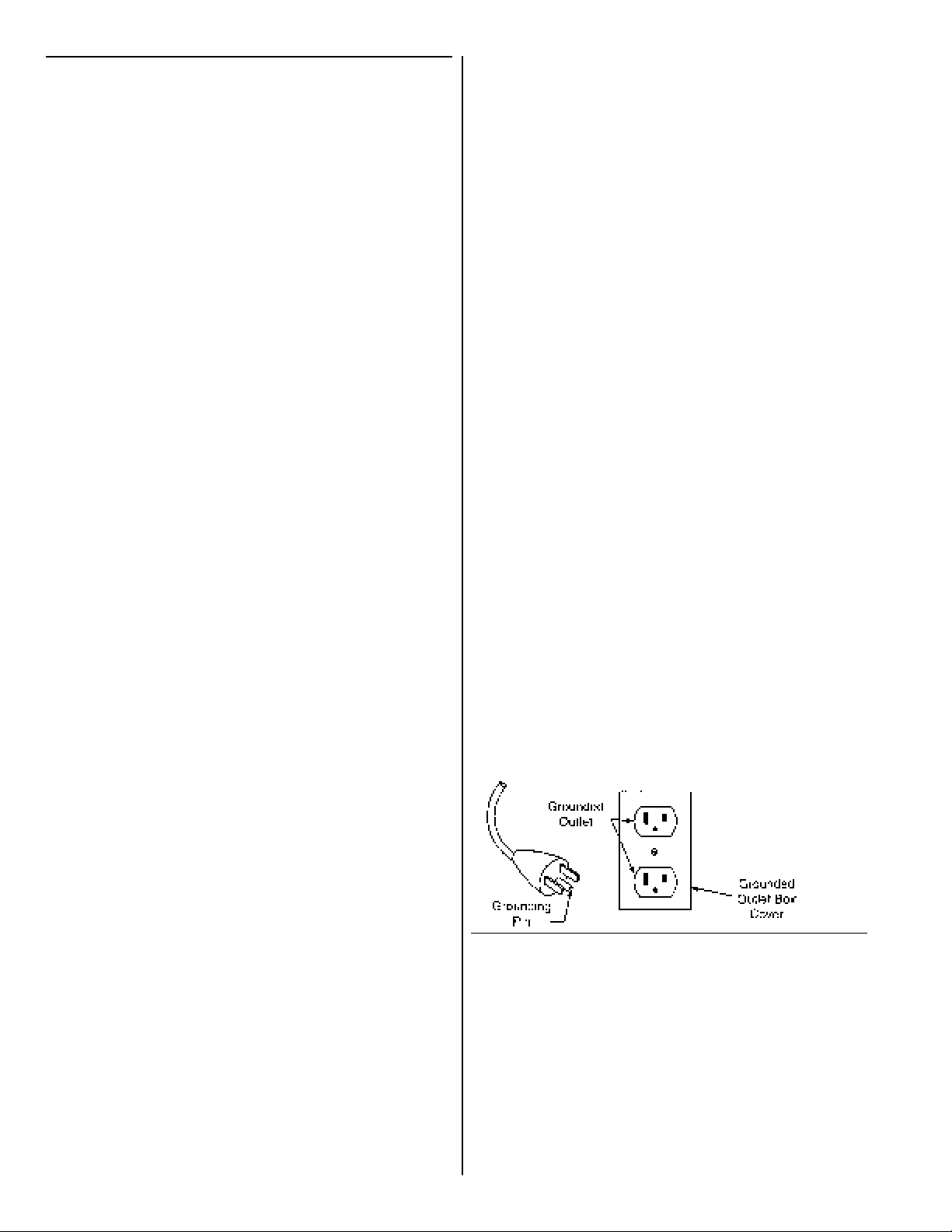

Grounding Instructions

Check with a qualified electrician or serviceman if

the grounding instructions are not completely understood, or if in doubt as to whether the product is

properly grounded. Do not modify the plug provided; if it will not fit the outlet, have the proper

outlet installed by a qualified electrician.

For All Grounded, Cord-connected Products:

This product should be grounded. In the event of an

electrical short circuit, grounding reduces the risk of

electric shock by providing an escape wire for the electric

current. Some units are equipped with a cord having a

grounding wire with an appropriate grounding plug. The

plug must be plugged into an outlet that is properly

installed and grounded in accordance with all local codes

and ordinances.

m DANGER Improper installation of the ground-

ing plug can result in a risk of electric

shock.

If repair or replacement of the cord or plug is necessary,

do not connect the grounding wire to either flat blade

terminal. The wire with insulation having an outer

surface that is green, with or without yellow stripes, is the

grounding wire.

For A Grounded, Cord-connected Product Rated

Less Than 15 Amperes And Intended For Use On A

Nominal 120v, Or 220-240 Volt Supply Circuit:

This product is for use on a nominal 120v, or 220240 volt circuit, and has a grounding plug. Make

sure that the product is connected to an outlet having

the same configuration as the plug. No adapter

should be used with the product.

m WARNING Do not unscrew relief valve head

entirely off while unit is operating.

Ejecting valve parts could cause

severe injury.

Wiring

m WARNING Incorrect wiring can result in electric

shock. Wiring must conform to all

required safety codes and be

installed by a qualified person.

m WARNING All power to the motor must

be de-energized and disconnected

when servicing.

OPERATION

mWARNING Solid or liquid material exiting the

unit can cause eye or skin damage.

Keep away from air stream.

mWARNING Always disconnect the power before

servicing. The motor may be ther

mally protected and will restart

automatically when it cools if the

thermal protection switch is tripped.

Loading...

Loading...