Gast 2D User Manual

2D SERIES MINIATURE PUMP

OPERATION and MAINTENANCE

INSTRUCTION MANUAL

KEEP THIS DOCUMENT FOR FUTURE REFERENCE

70-2300(Rev. A)

G445PL

This is the hazard alert symbol: When you

see this symbol be aware that personal injury or

property damage is possible. The hazard is

explained in the text following the symbol.

Read the information carefully

before proceeding.

The following is an explanation of the three

different types of hazards:

DANGER Severe personal injury or death

will occur if hazard is ignored.

WARNING Severe personal injury or death

can occur if hazard is ignored.

CAUTION Minor injury or property damage

can occur if hazard is ignored.

GENERAL SAFETY GUIDELINES

FOR THIS PRODUCT

WARNING

•Poor wiring can result in electric shock. Wiring

must conform to all required safety codes and be

installed by a qualified person. Refer to wiring

diagram on page 8.

•Always disconnect power source before servicing.

CAUTION

•Required ambient temperature is -10OF to 150OF.

Operation at temperatures outside this range, will

reduce the life of the pump.

Lower atmospheric pressure at high altitudes lowers performance. Consult a Gast distributor for details.

Never lubricate this oil-less pump. The sealed bearings are

grease-packed. Introducing petroleum based or hydrocarbon

products will reduce the service life of the diaphragm and valve.

Ensure that nothing will interfere with the movement of the

eccentric. While not dangerous, the eccentric must move freely

to allow the pump to operated properly.

MOUNTING

To reduce noise and vibration, use Velcro or a vibration-isolated

mounting surface.

PLUMBING

To prevent air flow restriction, use an elastic hose of the same

size as the hose port. These ports are not designed to support

plumbing.

FILTERS

Avoid unfiltered operation in an environment where there is

visible airborne particulate material. Use a suitable filter to

avoid ingesting dirt/metal or other foreign material into the

pump.

WIRING

Ensure that the supply voltage agrees with the pump operating

voltage. Remove power to the pump if the motor fails to start or

stops under load. Warming the pump to a minimum of -10 F in

extremely cold weather will ease starting and extend the life of

the pump.

OPERATION

General recommendations for operation:

Avoid operating the pump at temperatures less than -10oF or

greater than 150oF.

Draw through the pump only those substances which do not

react with PPS or EPDM (diaphragm and valve material).

•Do not block the flow of cooling air over the pump

in any way.

•This unit is designed to pump gases only.

Ingestion of dirt, metal, water, or petroleum-based

contaminants will reduce the life of the pump.

Avoid unfiltered operation in an environment where there is

visible airborne particulate matter.

Avoid ingesting dirt into the pump.

Following these basic recommendations will avoid damage to

the pump and may extend its operating life.

MAINTENANCE

Do not attempt to replace the connecting rod or motor bearings.

If after cleaning the unit and/or installing a new valve, the unit still

does not operate properly, contact your representative, or the

factory, or return the pump to an Authorized Service Facilities.

DC WIRING

RED/WHITE (

+)

Before attempting repair, determine if the pump has been

exposed to/or contains biological, toxic, or radioactive materials,

so that the repair personnel are not exposed to these items.

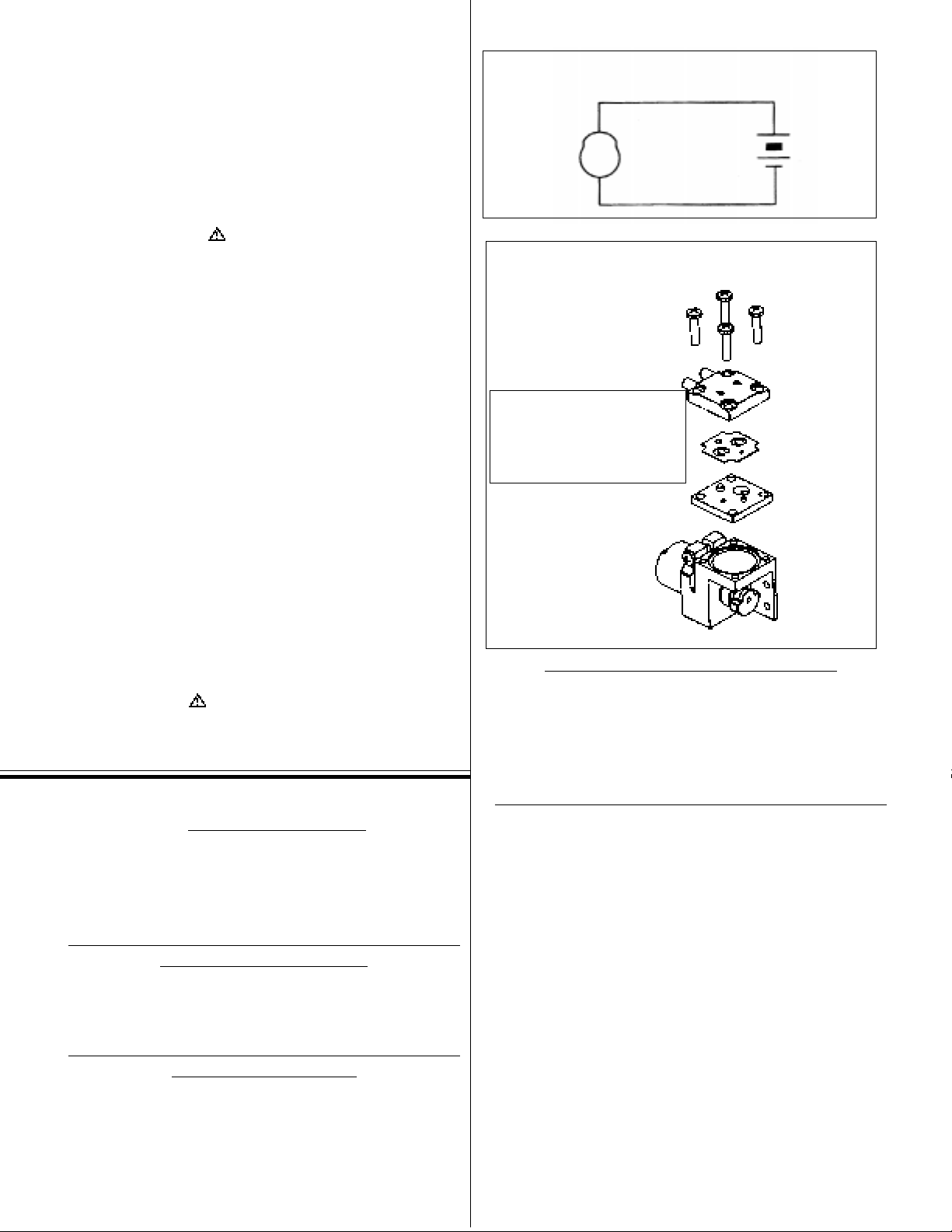

Follow these steps to replace the valve:

1) Disconnect pump from electrical power.

WARNING

Always disconnect power source before servicing. Failure to do

so can result in personal injury and/or property damage.

2) Vent all air lines to the pump to remove pressure.

3) Note the direction of the arrows so you can orient the pump

head correctly during reinstallation.

4) Remove the four corner head screws and remove the head,

valve, and valve plate.

5) Clean the pump head and valve plate using water-based

solvents.

6) Ensure the diaphragm is centered in the recessed area of the

bracket with no bends or folds.

7) Place the new valve on the valve plate so that the holes in the

valve fit over the correct pins in the valve plate.

8) Assemble the head by fitting the correct holes in the head

onto the pins in the valve plate.

M

BLACK

Exploded Vie w and

Parts Ordering Information

Replacement Parts

Head Screws..............SCR1022

Head/Cover.................HDC1007

Valve...........................VLV1009

Valve Plate..................VPL1007

+

Head Screws

Head/Cover

V alve

Valve Plate

9) Place the entire head, valve, and valve plate assembly on top

of the bracket, by aligning the four holes and orienting the ports

in your desired position.

10) Torque the head screws to 17 to 21 in-oz. into the body.

CAUTION

Do not over-tighten head screw(s). To do so can risk stripping

the plastic threads.

TROUBLESHOOTING GUIDE

SYMPTOM: WON’T START

Possible Cause:

-Electrical Connection

-Wrong/Low Voltage

-Pressure/Vacuum on Head

Point to Check:

-Ensure electrical

power is supplied

and inspect

-Inspect relief valve

Remedy:

-Check plug or wire

connection

-Apply proper voltage

-Reset or replace

relief valve

SYMPTOM: EXCESSIVE NOISE

Possible Cause:

-Wrong V oltage

-Hose or plumbing leak

Point to Check:

-Inspect power supply

-Inspect hoses for

cracks

Remedy:

-Apply proper voltage

-Replace hose

SYMPTOM: OVERHEATING

Possible Cause:

-Dirty Filter

-Low or High Voltage

-Dirty Valves

Point to Check:

-Inspect Filter

-Inspect Power Supply

-Remove Head and

inspect valve

Remedy:

-Replace Filter

-Apply proper voltage

-Clean/Replace V alve

SYMPTOM: LOW PRESSURE/LOW VACUUM

Possible Cause:

-Dirty Filter

-Low voltage

-Damaged/Contaminated

Diaphragm

-Dirty Valve

AUTHORIZED SERVICE FACILITIES

Gast Mfg. Inc.

2550 Meadowbrook Rd

Benton Harbor, MI 49022

TEL: 269-926-6171

FAX: 269-927-5727

www.gastmfg.com

Air Oil Products

301 30th Street

Auburn WA 98002

Ph: 253/735-5449

Ph: 1-800-282-2672

Fax: 253/735-5496

www.air-oilproducts.com

Wainbee Limited

215 Brunswick Blvd.

Pointe Claire, Quebec

Canada H9R 4R7

Ph: 514-697-8810

Fax: 514-697-3070

www.wainbee.ca

Point to Check:

-Inspect filter

-Inspect power supply

-Remove Head & Valve

Plate and inspect

Diaphragm

-Remove Head and

inspect V alve

Gast Mfg. Inc.

505 W ashington Ave.

Carlstadt, NJ 07072

TEL: 201-933-8484

FAX: 201-933-5545

www.gastmfg.com

Hydraulic & Pneumatic Sales

11100 Park Charlotte Blvd

Charlotte, NC 28273

Ph: 704/588-3234

Fax: 704/588-1569

www.hpsales.com

Wainbee Limited

5789 Coopers Ave.

Mississauga, Ontario

Canada L4Z 3S6

Ph: 416-213-7202

Fax: 416-213-7207

www.wainbee.ca

-Replace Filter

-Supply proper

electrical power

-Send unit to an

Authorized Service

Facility

-Clean/Replace V alve

Remedy:

Brenner Fiedler & Assoc.

13824 Bentley Place

Cerritos, CA 90701

TEL: 800-843-5558

TEL: 310-404-2721

FAX: 310-404-7975

www.brenner-fiedler.com

Gast Mfg. Co. Ltd.

Beech House, Knaves

Beech

Business Centre, Loudwater

High Wycombe, Bucks

HP 10 9SD England

Ph: 44 628 532600

Fax: 44 628 532470

www.gastltd.com

NOTE: General Correspondence

should be sent to-Gast Mfg. Inc./

A Unit of IDEX Corp.,

P.O. Box 97,

Benton Harbor, MI 49023-0097

Ph: 269/926-6171

Fax: 269/925-8288

www.gastmfg.com

Loading...

Loading...