www.gastmfg.com

ISO 9001 & 14001 CERTIFIED

®Registered Trademark/™Trademark of Gast Manufacturing Inc., Copyright © 2003 Gast Manufacturing Inc. All Rights Reserved.

PART NO. 45-200 D170 Rev D-W

WARNING

PLEASE READ THIS MANUAL COMPLETELY BEFORE INSTALLING AND USING

THIS MOTOR. SAVE THIS MANUAL FOR FUTURE REFERENCE AND

KEEP IN THE VICINITY OF THE MOTOR.

AM SERIES LUBRICATED AIR MOTORS

OPERATION & MAINTENANCE MANUAL

Model 2AM Shown

Thank you for purchasing this Gast product. It is manufactured to the highest standards

using quality materials. This manual includes general safety instructions for operation under normal conditions and for

operation in hazardous conditions. Please follow all recommended maintenance, operational and safety instructions

General information

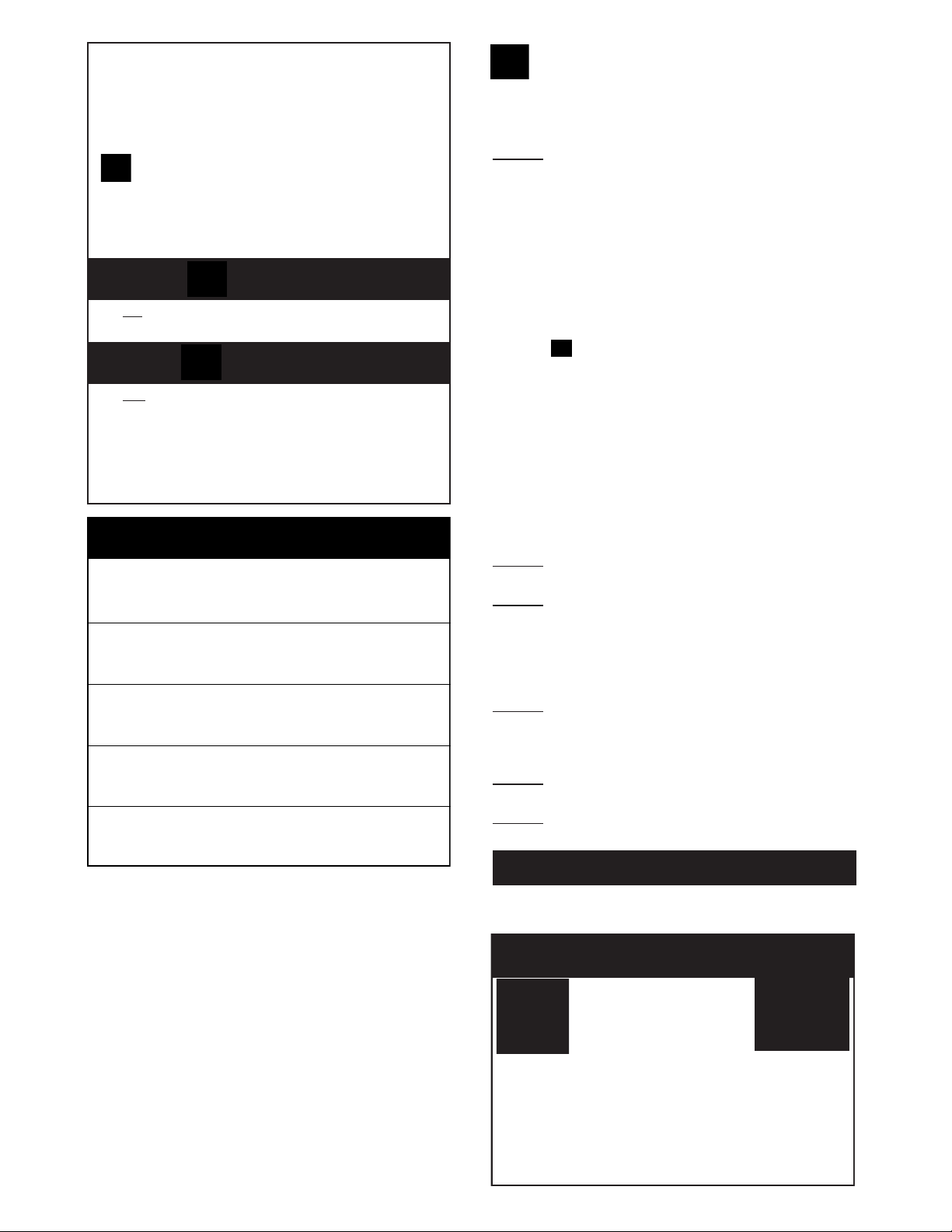

Operating Pressure Limits: Model Pressure

Model 4AM Shown

and you will receive years of trouble free service.

1AM 100 PSI / 7 bar

1 UP 80 PSI / 5.6 bar

2 AM 100 PSI / 7 bar

4 AM 100 PSI / 7 bar

6 AM 100 PSI / 7 bar

8 AM 100 PSI / 7 bar

16 AM 100 PSI / 7 bar

Model 6AM Shown

Model 16AM Shown

Product Use Criteria:

• Normal conditions: Operate at temperatures up to

250ºF (121ºC).

• Hazardous conditions: Operate at temperatures up to

104ºF (40ºC).

• Protect unit from dirt and moisture.

• Use ONLY compressed air to drive motor.

• Air lines connected to motor should be the same size or

the next size larger than the inlet port for efficient

output and speed control.

• Protect all surrounding items from exhaust air.

• Bearings are grease packed.

• Use Gast #AD220 or a detergent SAE#10 automotive

engine oil for lubricating.

• Motors are to be used in commercial installations only.

• This symbol appears on labels of air motors that

are designed for use in hazardous atmospheres.

These air motors comply with the applicable

standards and specifications and meet the

requirements of the guidelines of the EC directive

94/9EC (ATEX 100a). They are intended to be used in

zones 1 and 2 where explosive atmospheres are likely

to occur.

• Air supply, directional control valve and pressure regulator

should be selected based upon the air consumption

of the motor.

Your safety and the safety of others

WARNING

Injury Hazard

Wear eye protection when installing this product.

Install proper guards around output shaft as needed.

Air stream from product may contain solid or liquid

materials that can result in eye or skin damage.

Failure to follow these instructions can result in

serious injury or property damage.

CODE SYMBOLS

Hazard. Possible consequences: death or

severe injuries.

Hazardous situation. Possible

consequences: slight or mild injuries.

Dangerous situation. Possible

consequences: damage to the drive or the

environment.

Important instructions on protection

against explosion.

Application tips and useful

information.

is extremely important.

We have provided many important safety messages in

this manual and on your product. Always read and

obey all safety messages.

This is the safety alert symbol. This symbol

alerts you to hazards that can kill or hurt you and

others. The safety alert symbol and the words

“DANGER” and “WARNING” will precede all safety

messages. These words mean:

DANGER

You will

instructions.

be killed or seriously injured if you donʼt follow

WARNING

You can

instructions.

All safety messages will identify the hazard, tell you

how to reduce the chance of injury, and tell you what

can happen if the safety instructions are not followed.

be killed or seriously injured if you donʼt follow

Complete the following checklist prior to

starting installation in a hazardous area. All

actions must be completed in accordance with ATEX

100a.

Checklist for installation in hazardous areas:

Read air motor label to check that

motor has been designed for use

in a hazardous application:

• Hazardous zone

• Hazardous category

• Equipment group

• Temperature class

• Maximum surface temperatures

Example:

Model designation: 1UP-NRV-10

Year manufactured: 2003

Gast Mfg. Corp.

II 2GD c +1Cº Ta +40Cº

Benton Harbor, MI USA

Telephone: 269.926.6171

* Legend:

II Equipment group II

2 Equipment category 2

G Gas atmospheres

D Dust atmospheres

c Constructional safety

+1CTa +40C* Max. surface temp. 275ºF/135ºC

Ambient range +1Cº to +40ºC (34ºF/104ºF)

Check the site environment for potentially

explosive oils, acids, gases, vapors or radiation

Check the ambient temperature of the site and

the ability to maintain proper ambient

temperature.

Ambient range:

Normal conditions: 34ºF/1ºC to 250ºF/121ºC

Hazardous conditions: 34ºF/1ºC to 104ºF/40ºC

Check the site to make sure that the air motor

will be adequately ventilated and that there is

no external heat input (e.g. couplings). The

cooling air may not exceed 104ºF/40ºC.

Check that products to be driven by the air

motor meet ATEX approval.

Check that the air motor is not damaged.

Improper environment, installation and operation can

result in severe personal injury and/or damage to

property.

Qualified personnel must perform all work to assemble,

install, operate, maintain and repair air motor.

Qualified personnel must follow:

• These instructions and the warning and information

labels on the motor.

• All other drive configuration documents, startup

instructions and circuit diagrams.

• The system specific legal regulations and

requirements.

• The current applicable national and regional

specifications regarding explosion protection,

safety and accident prevention.

2

INSTALLATION

Correct installation is your responsibility. Make sure you

have the proper installation conditions.

Mounting

WARNING

Injury Hazard

Air stream from product may contain solid or liquid

material that can result in eye or skin damage

Do Not use cumbustible gases to drive this motor.

Wear hearing protection. Sound level from motor

may exceed 85 db(A).

Failure to follow these instructions can result in eye

injury or other serious injury.

This product can be installed in any orientation. Mount

the motor to a solid metal base plate that is mounted to

a stable, rigid operating surface. Use shock mounts to

reduce noise and vibration. Install a pressure regulator

or simple shut-off valve to control motor.

Connection

Check the direction of the motor airflow. A single

rotation motor will operate properly only in one direction.

Single rotation motors require a sound absorber to be

connected to the air port. Remove the plastic shipping

plugs from the ports. Save plugs for future use during

shutdown.

Install a 5-micron filter in the air line before the

connection to the motor. Next install an air pressure

regulator to control motor speed and torque.

An automatic air line lubricator should be installed in the

air line as close as possible and no more than 18

inches (1/2 meter) from the air motor. Install the

lubricator level with or above the air motor so that the oil

mist will blow directly into or fall down into the motor.

Fill the oil reservoir to the proper level with Gast

#AD220 or SAE 10W high detergent or non-detergent

motor oil. For food processing applications, White Rex

425 food grade motor oil is FDA approved. Adjust

lubricator to feed 1 drop of oil for every 50 CFM of air

while the unit is running, or 1 drop of oil per continuous

minute of run time. Do Not overfeed oil or exhaust air

may become contaminated.

Clean the compressed air connection with low pressure

air to remove any dirt from the line before connecting to

the ports.

Use the proper sized fasteners. For the most efficient

output and control of speed, use air lines that are the

same size as the motor inlet port if the connection is

less than 7 feet (2 meters). For longer connections, use

the next pipe size larger than the motor intake port.

Connect lines to motor in the proper direction.

A reversible motor will work equally well in both

directions. Connect a 4-way valve with piping to both

air ports of motor to make reversing possible. Connect

the sound absorber on the exhaust air port or valve

connection.

Do not add any thrust to the end or side of the shaft

when making connections.

Do not use a hammer on the shaft or

connections.

Lubricating the drive shaft will make assembly

easier. Use a puller for removal of pulleys,

couplings and pinions on the motor shaft.

Check that the tension on the belt pulley matches the

manufacturerʼs specifications. Do not exceed the

maximum radial and axial forces on the shaft. If the

motor shaft is connected to the part to be driven without

a coupling, check that the radial offset and axial force

effect will not cause problems.

Use only belts with < 109electrical leakage

resistance to prevent static electrical problems.

Ground the motor.

Accessories

A muffler is shipped with the air motor (except 16AM)

but is not installed. Consult your Gast

Distributor/Representative for additional filter

recommendations. Install a moisture trap and 5 micron

filter in the air line ahead of motor.

Air consumption data at various speeds and pressures

are available from your Gast Distributor/Representative

or the factory.

OPERATION

Check all connections before starting motor. It is your

responsibility to operate this product at recommended

speeds, loads and room ambient temperatures. Do not

run the motor at high speeds with no load. This will

result in excessive internal heat that may cause motor

damage.

The starting torque is less than the running torque. The

starting torque will vary depending upon the position of

the vanes when stopped in relation to the air intake

port.

Use a pressure regulator and/or simple shut-off valve to

regulate the motor’s speed and torque. This will provide

the required power and will conserve air. Open the air

supply valve to the motor. Set the pressure or flow rate

to the required speed or torque. Adjust the lubricator to

feed one drop of oil for every 50-75 CFM (1.5-2 M

minute) of air moving through motor. Check the oil level

daily. The gear reducer does not need lubrication.

3

per

3

WARNING

Injury Hazard

Disconnect air supply and vent all air lines.

Wear eye protection when flushing this product.

Air stream from product may contain solid or liquid

material that can result in eye or skin damage.

Flush this product in a well ventilated area.

Do Not use kerosene or other combustible solvents

to flush this product.

Failure to follow these instructions can result in eye

injury or other serious injury.

Operate the motor for approximately 2 hours at

the maximum desired load. Measure the

surface temperature of the motor on the casting

opposite the pipe ports. The maximum surface

temperature listed on the motor is for normal

environmental and installation conditions. For most air

motors, the maximum surface temperature should not

exceed 266ºF/130ºC. Do not continue to operate the

motor if the measured surface temperature exceeds

temperature listed on the motor. If your measured

temperature does exceed listed value, consult with your

Gast Distributor/Representative for a recommendation.

MAINTENANCE

It is your responsibility to regularly inspect and make

necessary repairs to this product in order to maintain

proper operation.

Lubrication

Use Gast #AD220 or a detergent SAE #10 automotive

engine oil for lubricating. Lubricating is necessary to

prevent rust on all moving parts. Excessive moisture in

air line may cause rust or ice to form in the muffler

when air expands as it passes through the motor.

Install a moisture separator in the air line and an after

cooler between compressor and air receiver to help

prevent moisture problems.

Manual Lubrication

Shut the air motor down and oil after every 8 hours of

operation. Add 10-20 drops of oil to the air motor intake

port.

Automatic Lubrication

Adjust inline oiler to feed 1 drop of oil per minute for

high speed or continuous duty usage. Do Not overfeed

oil or exhaust air may become contaminated.

Check intake and exhaust filters after first 500 hours of

operation. Clean filters and determine how frequently

filters should be checked during future operation. This

one procedure will help assure the motor’s performance

and service life.

Flushing

Flushing this product to remove excessive dirt, foreign

particles, moisture or oil that occurs in the operating

environment will help to maintain proper vane

performance. Flush the motor if it is operating slowly or

inefficiently.

4

Use only Gast recommended Flushing Solvent. DO

NOT use kerosene or ANY other combustible solvents

to flush this product.

1. Disconnect air line and muffler.

2. Add flushing solvent directly into motor. If using

liquid solvent, pour several tablespoons directly

into the intake port. If using Gast recommended

spray solvent for 5-10 seconds into intake port.

3. Rotate the shaft by hand in both directions for a

few minutes.

4. You must wear eye protection for this step.

Cover exhaust with a cloth and reconnect the air

line.

5. Restart the motor at a low pressure of

approximately 10 PSI / 0.7 bar until there is no

trace of solvent in the exhaust air.

6. Listen for changes in the sound of the motor. If

motor sounds smooth, you are finished. If motor

does not sound like it is running smoothly,

installing a service kit will be required

(See “Service Kit Installation”).

Check that all external accessories such as relief valves

or gauges are attached and are not damaged before

operating product.

Cleaning sound absorber

1. Remove the sound absorber.

2. Clean the felt filter.

3. You must wear eye protection for this step.

Lubricate motor with 3-4 drops of oil.

4. Check the air compressor.

5. Listen for changes in the sound of the motor. If

motor sounds smooth, you are finished. If motor

does not sound like it running smoothly, installing

a service kit will be required (See “Service Kit

Installation”).

Shutdown

It is your responsibility to follow proper shutdown

procedures to prevent product damage.

1. Turn off air intake supply.

2. Disconnect air supply and vent all air lines.

3. Disconnect air lines.

4. Remove air motor from connecting machinery.

5. Remove the muffler.

6. Wear eye protection. Keep away

from air stream. Use clean, dry air

to remove condensation from the inlet port of the

motor.

7. Lubricate motor with a small amount of oil into the

intake port. Rotate shaft by hand several times to

distribute oil.

8. Plug or cap each port.

9. Coat output shaft with oil or grease.

10. Store motor in a dry environment.

Disposal (Please note current regulations)

Parts of the air motor or air powered gear motor,

shafts, cast iron or aluminum castings, gear

wheels as well as rolling contact bearings may be

recycled as scrap metal.

Estimated Ball Bearing Life of Lubricated Air Motors

Air Motor Model Shaft speed in RP Ball Bearing Life

hours L

1AM 10,000 28,000

1UP 6,000 14,000

2AM 3,000 30,000

4AM 3,000 14,000

6AM 3,000 6,500

8AM 2,500 8,000

16AM 2,000 15,000

Based on running pressure of 60 PSI and coupling connection to motor load. The direction,

magnitude and location of applied loads to the motor shaft will change expected bearing life.

Driving the motor with wet dirty compressed air can reduce expected bearing life. The above are

life estimates not warrantied minimum values.

SPUR & WORM GEAR REDUCERS - OPERATING AND MAINTENANCE INSTRUCTIONS

General Information:

The product nameplate specifies all information required

when ordering parts or requests for information. The

type of lubricant required for unit is also specified on the

nameplate.

10

Product Use Criteria:

• All worm gear reducers require that the air motor be

mounted so that the inlet and exhaust ports are at a

90º angle to the centerline of the reducer output shaft.

• Gear reducers are NOT self-locking. If a brake is

required for safety, as in the case of air pressure failure,

etc., contact your Gast Distributor/Representative.

• Some worm gear reducers may be shipped with a plug

in the top pipe plug. The plug must be removed and the

breather plug installed for proper operation.

• Check the oil level in spur gear reducers which have

been stored or not operated for a period of time.

• Gear motors require proper lubrication. Insufficient oil

level can cause loss of performance, damage or failure

of the gear reducer.

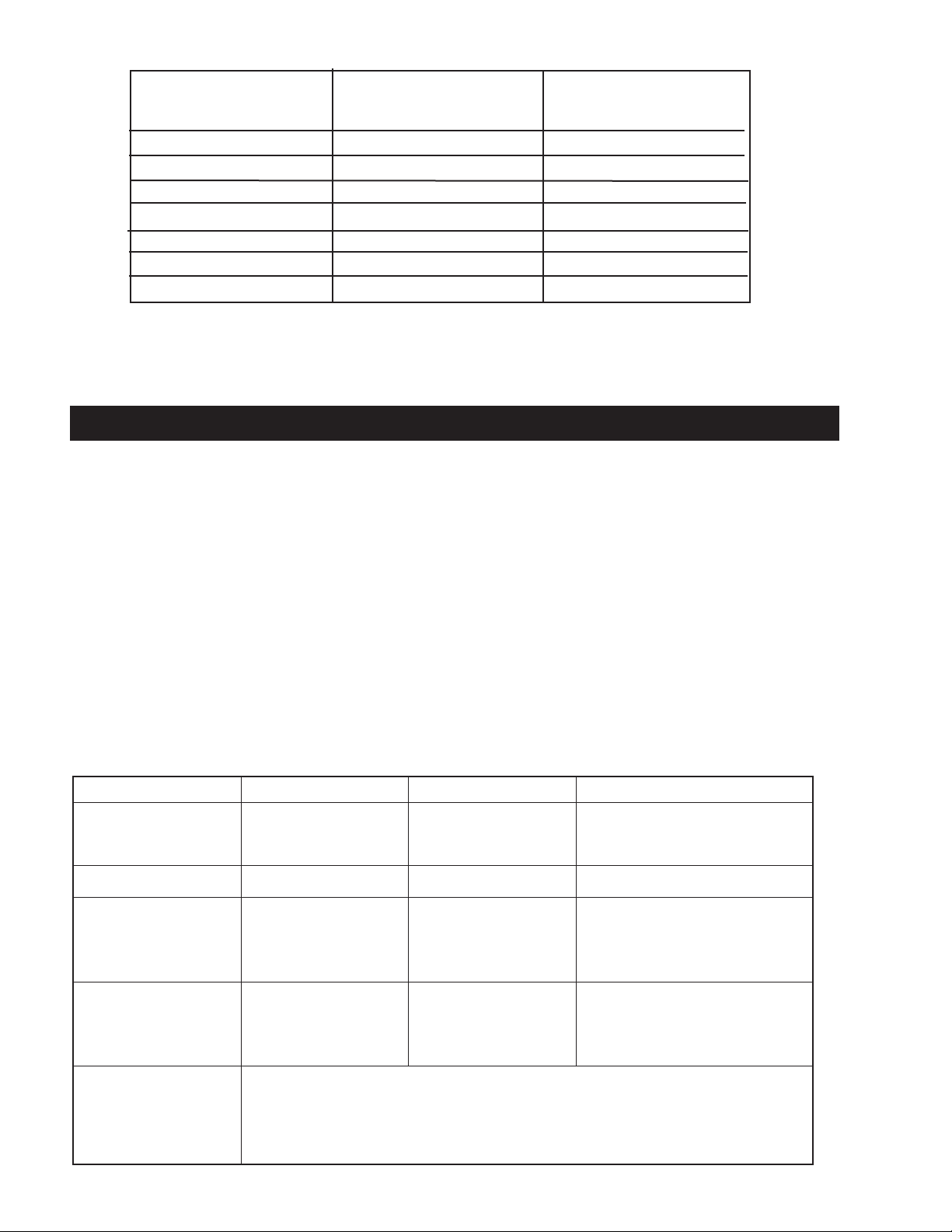

Spur Gear Reducer Specifications

Model GR11 GR20 GR25

Speed Range 33.3 to 400 RPM 30 to 300 RPM 20 to 200 RPM

(Reducer Output Shaft)

Gear Reduction 15:1 10:1 15:1

Maximum Allowable 100 lbs/45,4 kg 200 lbs/90,8 kg @300 250 lbs/113,5 kg at 200

End Thrust With RPM to 800 lbs/363,2 kg RPM to 800 lbs/363,2 kg

Zero Overhung Load. at 30 RPM at 20 RPM

(Reducer Output Shaft)

Maximum Allowable 100 lbs/45,4 kg at 333 200 lbs/90,8 kg at 300 200 lbs/90,8 kg at 200

Overhung Load With RPM to 200 lbs/90,8 kg RPM to 600 lbs/272,4 kg RPM to 600 lbs/272,4 kg

Zero End Thrust. at 33.3 RPM at 30 RPM at 20 RPM

(Reducer Output Shaft)

Lubrication Use a 300 ssu at 100˚F/38˚C turbine quality lubricant – Gast #AG292A, Gulf

Harmony 53, Shell Tellus 33, Socony DTE heavy medium or Humble Nuto 53.

For horizontal operation, remove both plugs and add oil to top hole until

other hole overflows.

For vertical operation, fill to overflow point of upper most hole.

5

Loading...

Loading...