Gas gas MOTOR FSE 450 2004 / 2005 WORKSHOP MANUAL

MANUAL DE TALLER /

MANUAL DE TALLER /

WORKSHOP MANUAL

WORKSHOP MANUAL

MOTOR FSE 450

MOTOR FSE 450

2004 / 2005

2004 / 2005

WORKSHOP MANUAL

WORKSHOP MANUAL

ENGINE FSE 450

ENGINE FSE 450

2004 / 2005

2004 / 2005

ENGLISH

Contents

Technical specifications................................................................4

Uninstalling and installing the engine in the chassis..................5

Engine dismounting................................................................15

Engine mounting...................................................................33

Replacement of the standard clutch with the ADLER

clutch APTC....................................................................................53

Inspection and maintenance

of the engine components.......................................................59

Periodic maintenance...............................................................91

MODEL FSE 400 / 450

ENGINE

Displacement in cubic centimetres

399 cc / 443 cc

Type

4 stroke DOHC 4 valves

No. of Cylinders

One

Cooling System

Water Cooled

Bore and stroke

90 x 62,6 mm / 95 x 62,6 mm

Injection

Fuel injection electronic system

Magneti Marelli

Ignition

Integrated in fuel injection electronic system

Clutch

Oil bath, multi-disk hydraulic action

Gear Box

6 speed

CHASSIS

Frame Type

DELTABOX, semi double cradle chassis made from rectangular

Cromoly tubes. Aluminium swing arm

Front Suspension

Inverted Marzocchi

Diameter 45 mm

Run 295 mm

Inverted Öhlins

Diameter 48 mm

Run 295 mm

Rear Suspension

Progressive system with Öhlins shock absorber

Run 320 mm

Front brake

Disk of 260 mm

Nissin Pump and simple / double Nissin calliper

Rear brake

Disk of 220 mm

Nissin Pump and simple / double Nissin calliper

Wheels

Rims D.I.D. Type U with tyres Michelin Comp3

Technical

Specifications

DIMENSIONS

Wheel base

1.475 mm

Seat Height

940 mm

Minimum ground clearance

340 mm

Fuel Tank Capacity

7.2 litres

4

Technical

Specifications

Un-installing and

installaing the engine

in the chassis

5

Un-installing the engine

Un-installing the engine in the chassis

Before dismounting the engine from the frame, wash it

with a steam washer.

The dismounting sequence is explained in the following

steps.

Dismount the seat and the frame covers.

Empty the engine oil.

Remove the engine plate.

!

B

C

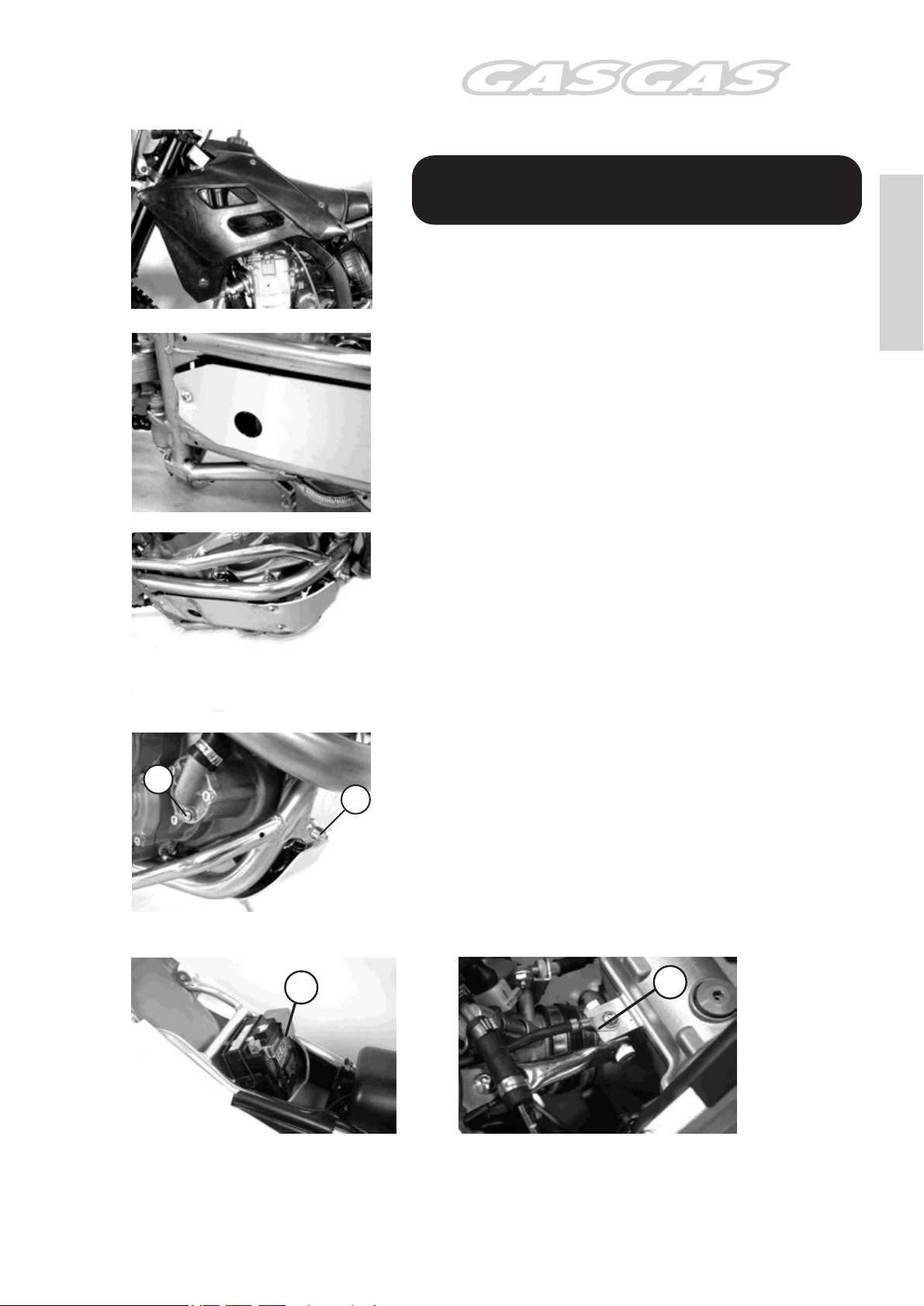

Empty the chassis (A) oil tank.

Empty the coolant of the engine (B).

A

Disconnect the wire (-) of the battery (C) and the engine

earth connection (D).

D

7

Un-installing the engine

E

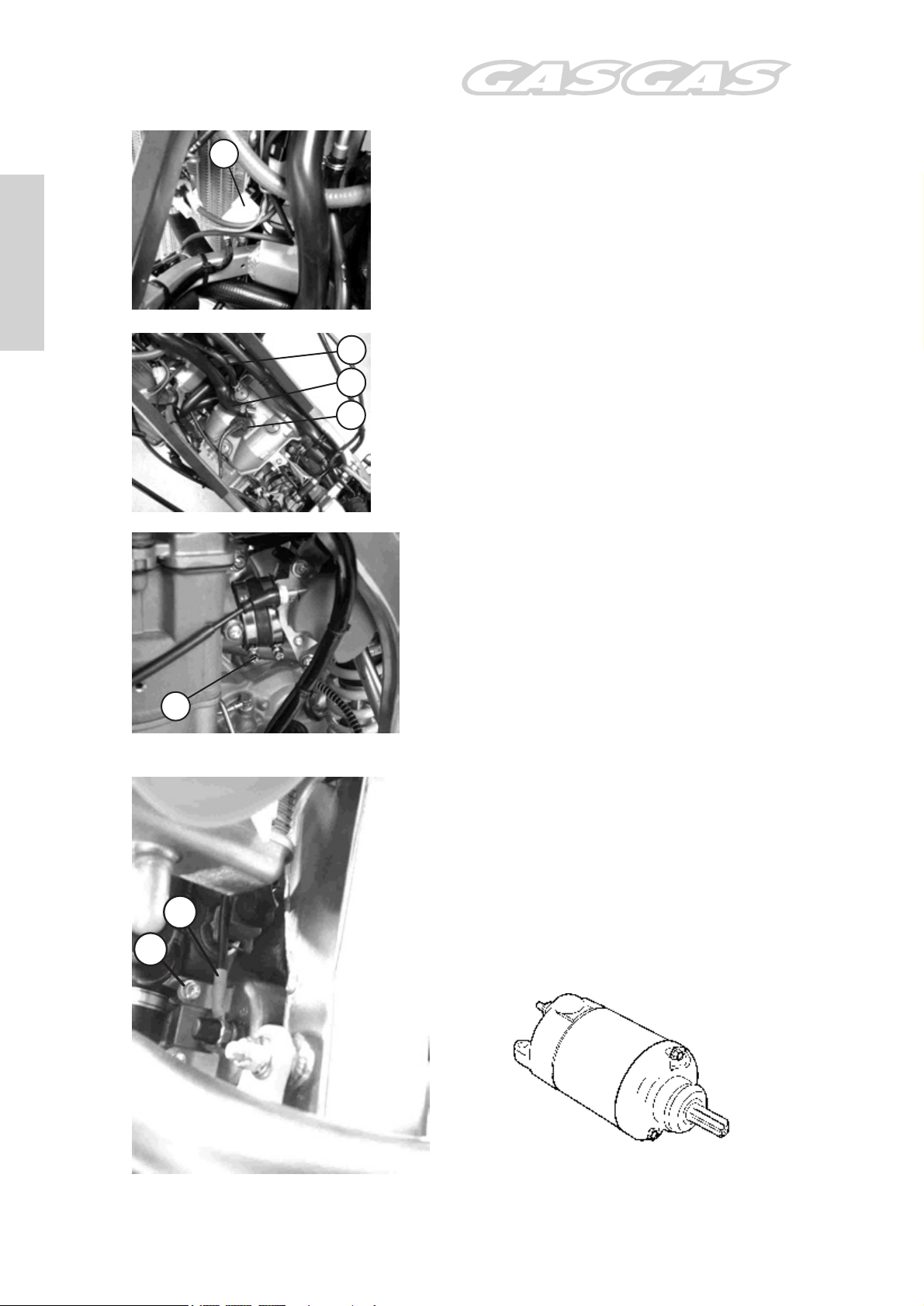

Disconnect the alternator clamp (E) and the phonic

wheel sensor wire.

H

Disconnect the spark plug pipe (F), the engine oil

vaporiser tube (G), the engine oil resevoir vent

hose (H).

G

F

Loosen the cylinder head injector tubing clamp (l).

I

Disconnect the starter motor connection wire (J).

Dismount the starter motor removing the screws

(K).

K

J

8

Un-installing the engine

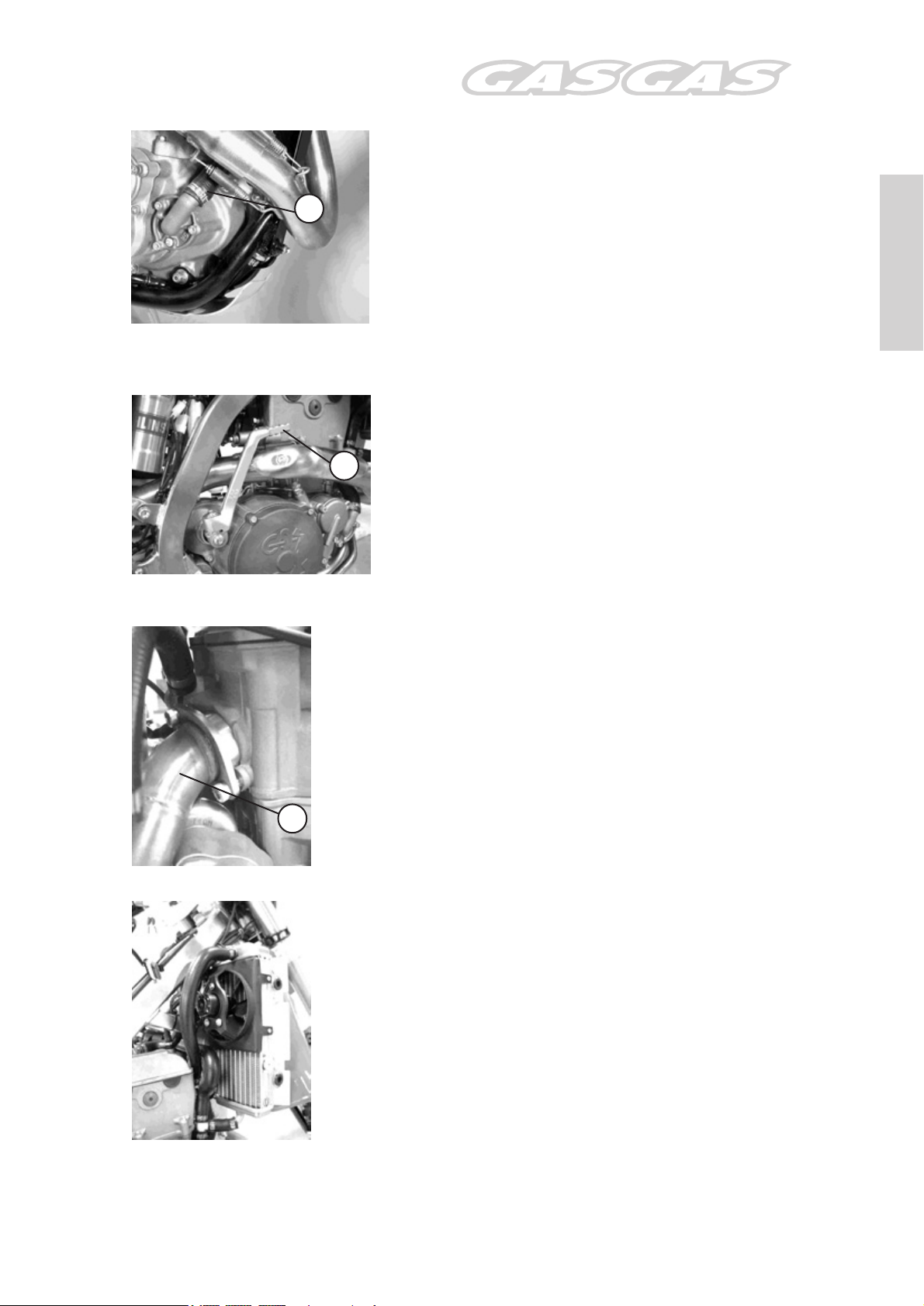

Dismount the water tube (L).

L

Remove the pedal starter lever (M).

M

N

Remove the exhaust collector (N).

Disconnect the 2 radiator tubes.

9

Un-installing the engine

P

Disconnect the engine oil tube (O) in the chassis tank.

O

Remove the gearshift lever (P).

S

R

Q

Remove the engine pinion protector (Q).

Remove the clutch cap (R).

De-tense the chain.

Remove the output pinion clip (S).

10

Un-installing the engine

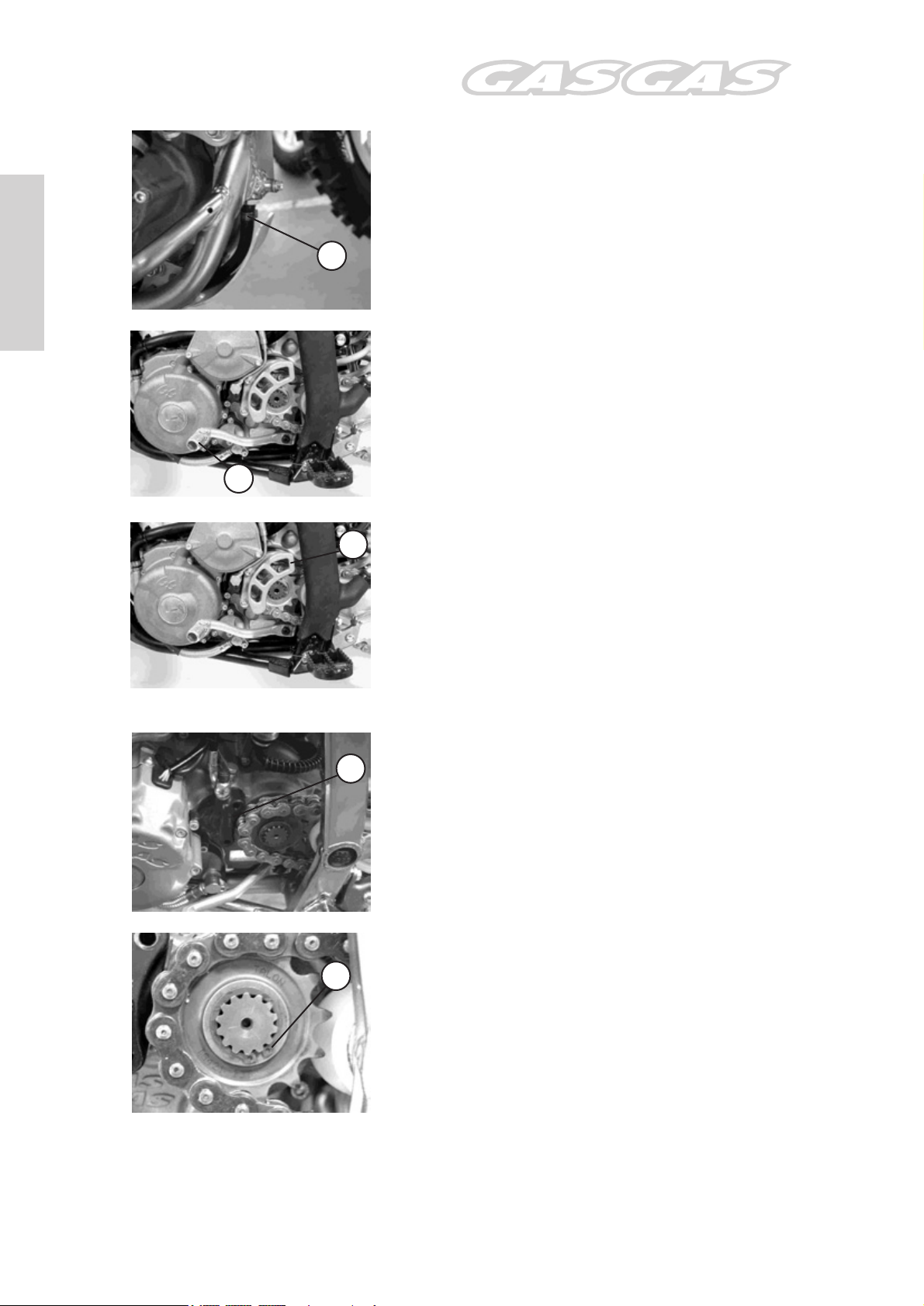

Remove the Engine pinion (T).

T

NOTE:

Observe which is the placement direction of the

said pinion.

Remove the carved bolts and the brake pedal.

Remove the motor from the frame.

11

Un-installing the engine

Installation of the engine in the chassis

Mount the engine in inverse order to de-installation

!

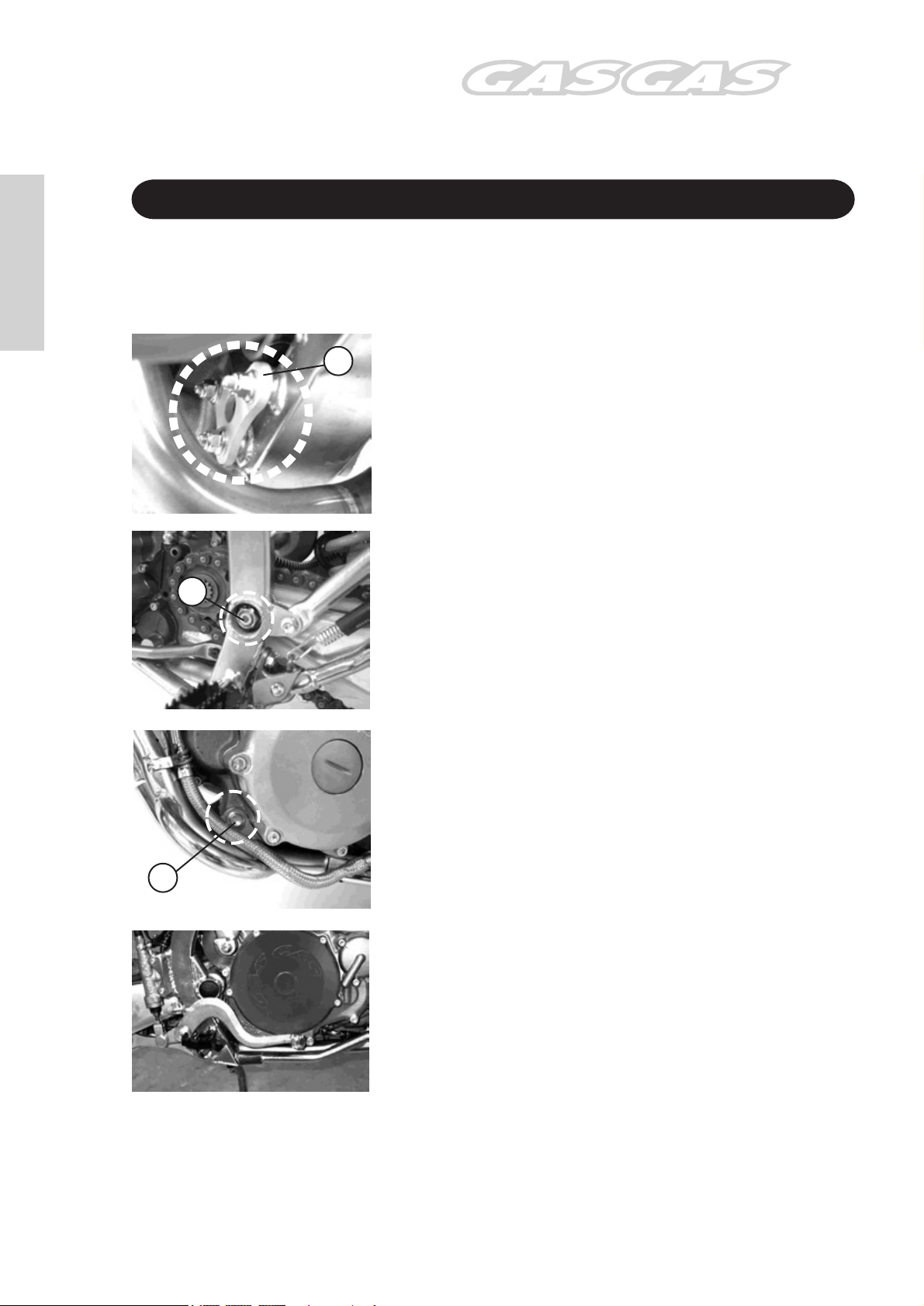

Fix the screws and engine fixing nuts.

A

NOTE:

In this phase, temporarily tighten the nuts.

The engine fixing nuts are self-locking.

Once removed they lose their self-locking

capability and are useless.

PRECAUTION

Replace the engine fixing nuts with new ones.

B

Hold the screw heads with a spanner and tighten

the engine fixing screws with the specified torque.

!

!

Element Nm Kgm

A 66 6,6

B 66 6,6

C 66 6,6

Length of the screws

(A): 108 mm

(B): 110 mm

(D): 103 mm

C

Fix the brake pedal screw with the specified torque.

Brake pedal screw: 29 Nm (2,9 Kg)

PRECAUTION

Replace the carved bolts with new ones.

12

Un-installing the engine

Mount the engine pinion.

NOTE:

Observe which is the placement direction before

the said pinion, to be able to achieve the same

direction of wear.

Place the engine pinion clip.

Connect the chassis tank tube.

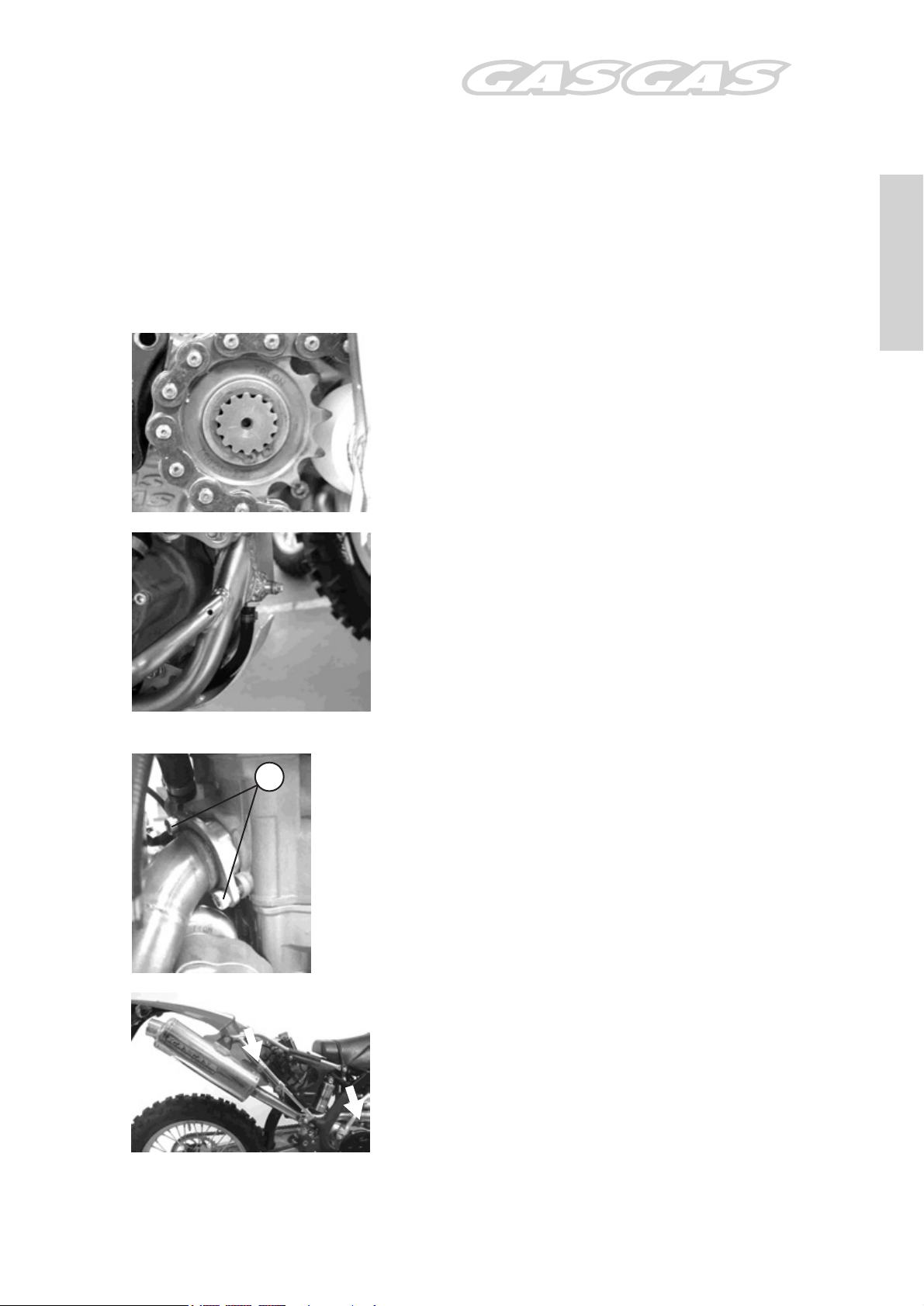

Fix the exhaust collector screw (1), with the specified

1

torque.

NOTE:

Apply component NURAL 29 in the exhaust system

joints.

13

Un-installing the engine

A

NOTE:

Apply LOCTITE 243 to the pedal starter lever screw.

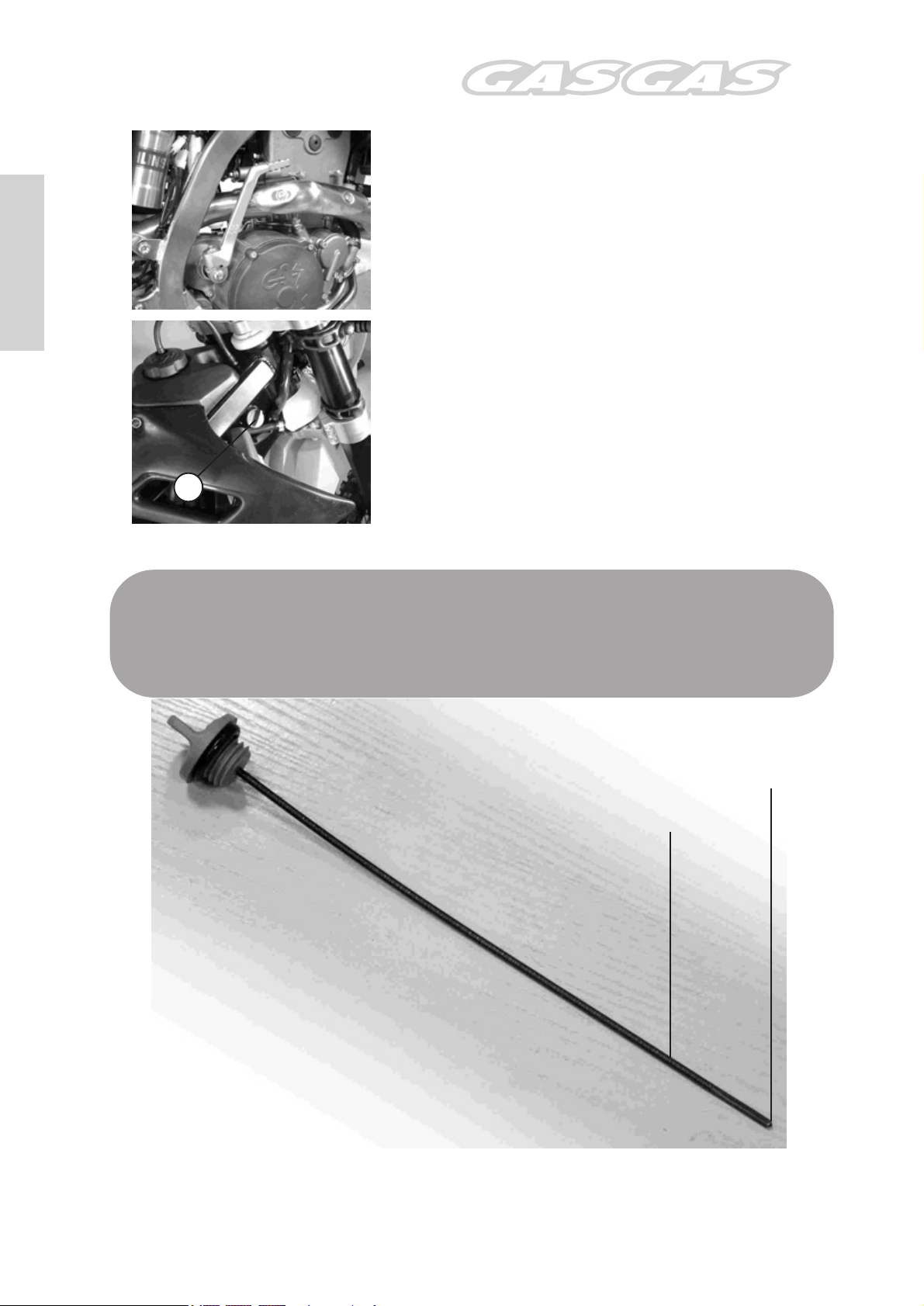

Fill 1.2 L of an engine oil classified SF or SG through the

API service and with a degree of viscosity SAE 10W-40

through the oil fill mouth in the frame (A) and check the

level.

DATA

Engine oil capacity

Change of oil: 1 L

Changing the oil and filter: 1.2 L

Engine general inspection: 1.2 L

!

3 min

Start the engine and leave it running some three

minutes at idle.

Stop the engine and wait three minutes;

immediately check the oil level via the rod.

Minimum level

Maximum level

14

Un-installing the engine

Dismounting

the engine

15

Dismounting the engine

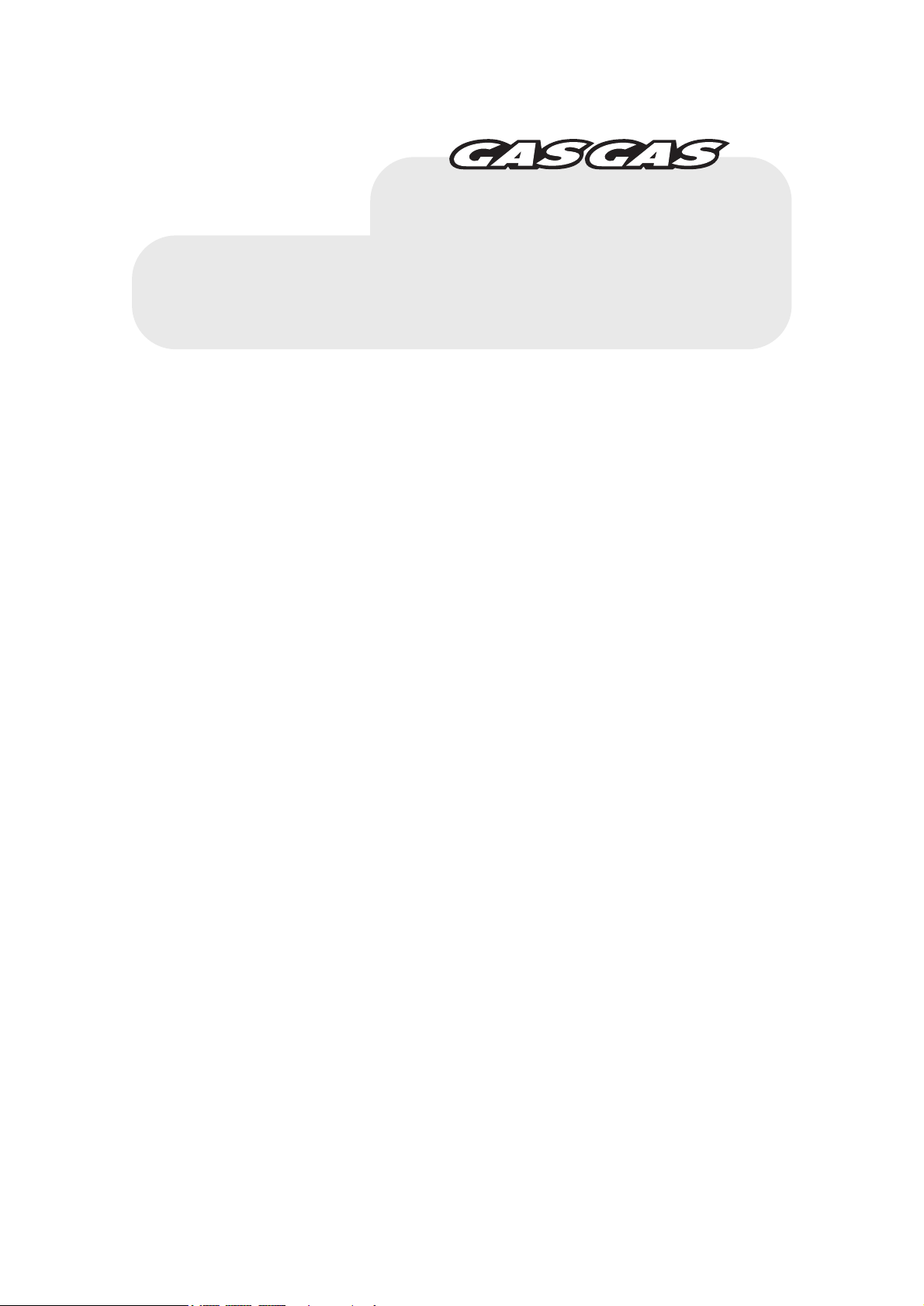

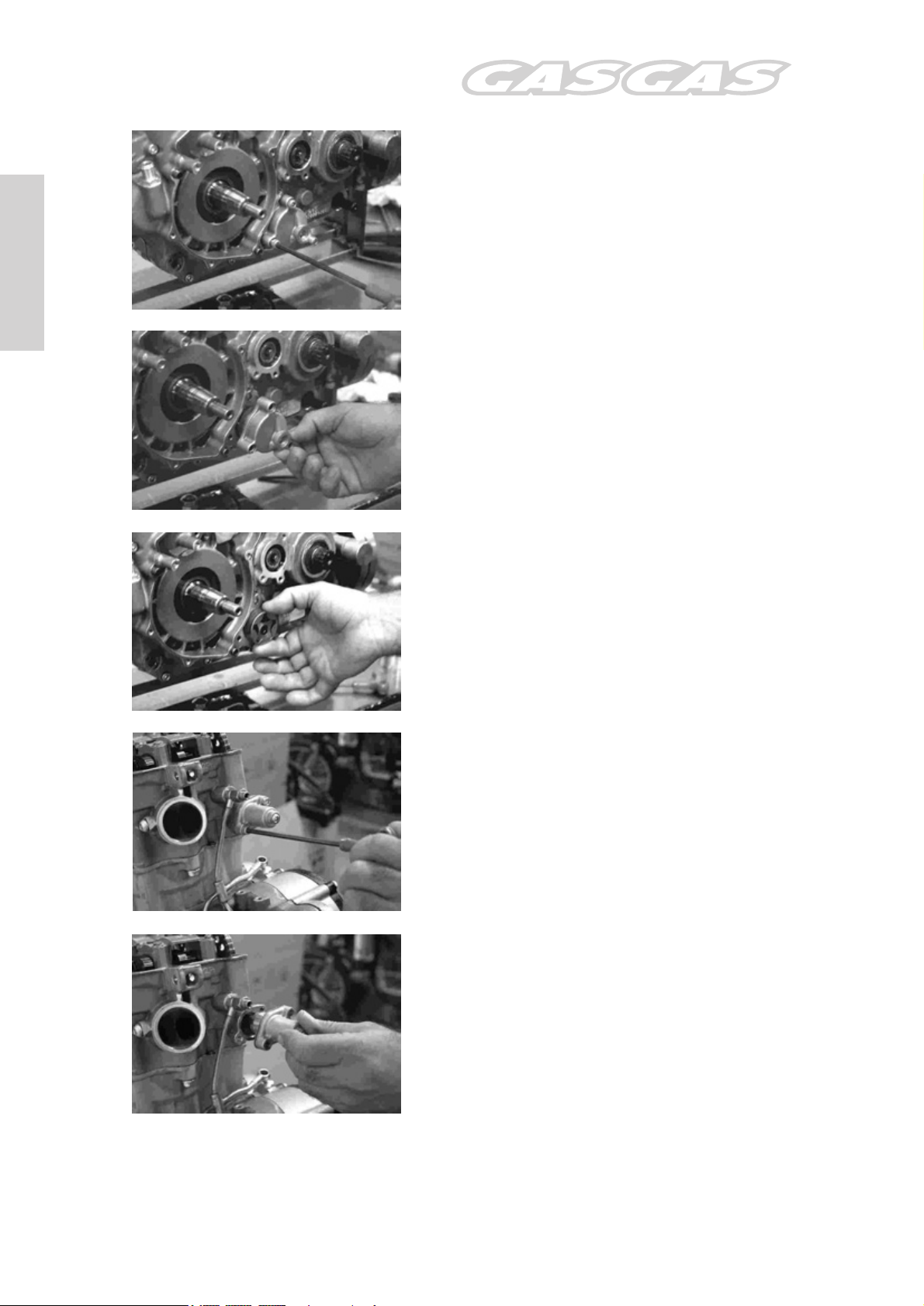

Loosen the 3 screws that hold the starter clutch

cover.

One of the 3 also holds the alternator cover.

Remove the starter clutch cover.

Extract the starter clutch.

Loosen the 2 screws that hold the starter motor.

Extract the starter motor.

NOTE:

The 2005 starter motor turns in the opposite

direction to that of 2004.

17

Dismounting the engine

A

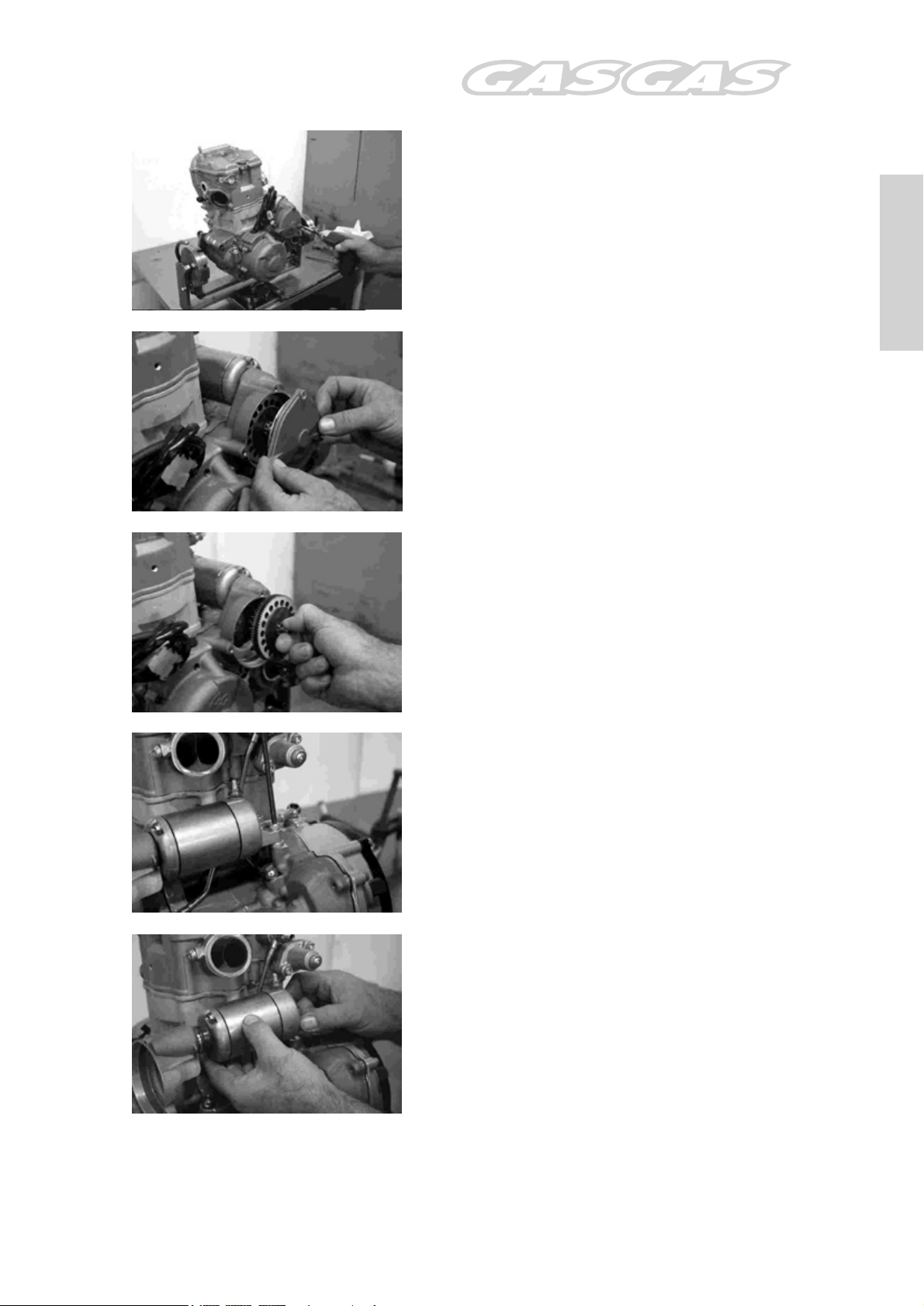

Loosen the 7 retaining screws that hold the

alternator cover.

One of them is located in the starter clutch cavity.

Remove the alternator cover.

Loosen the 2 screws that hold the position sensor

(Pick-Up) (A).

Remove the de-multiplier pinion (B).

Loosen and extract the spark plug.

18

Dismounting the engine

A

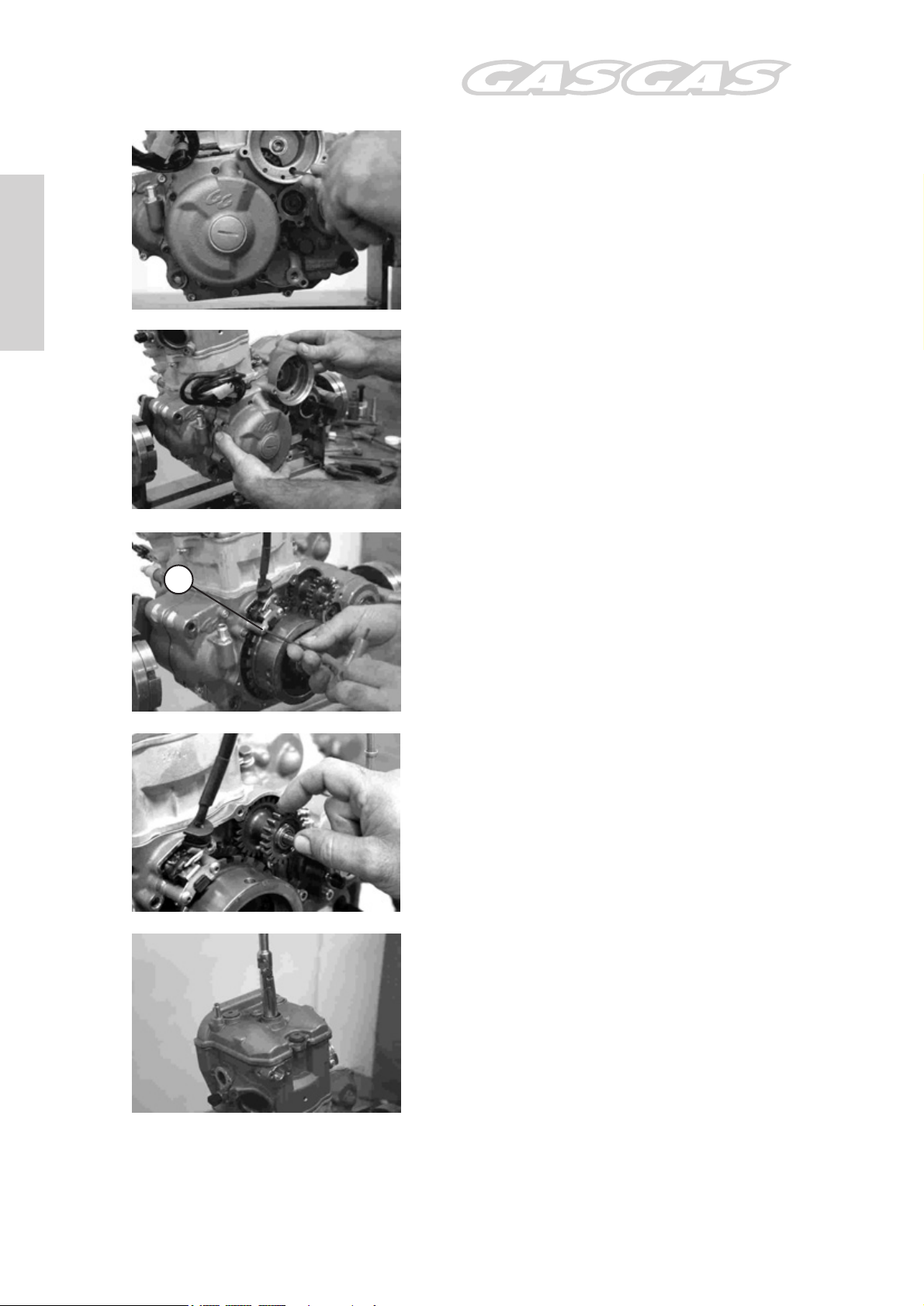

Loosen the crankshaft nut.

NOTE:

The nut loosens towards the right.

Turn the alternator rotor until placing the 7th tooth

(A) of the phonic wheel in the center of the position

sensor (Pick-Up) hole.

Loosen the 3 screws that hold the cylinder head

cover.

Remove the cylinder head cover.

With the help of the extractor (Ref:

MFS400134045), remove the alternator rotor.

19

Dismounting the engine

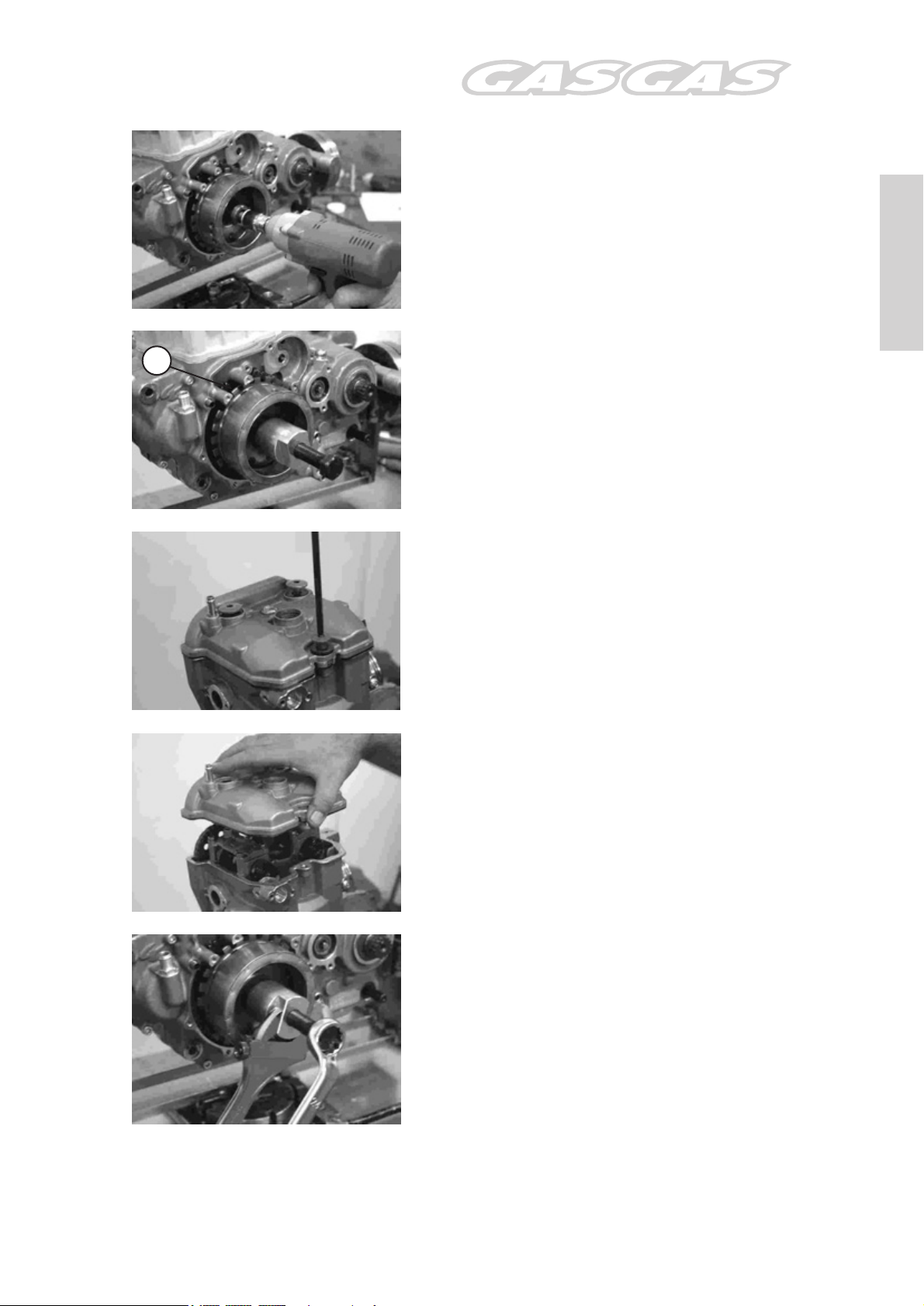

Loosen the 3 screws that hold the oil extractor

pump.

Remove the oil extractor pump cover.

Remove the oil extractor pump.

Loosen the 2 screws that hold the distributor chain

tensor.

Remove the distributor chain tensor.

20

Dismounting the engine

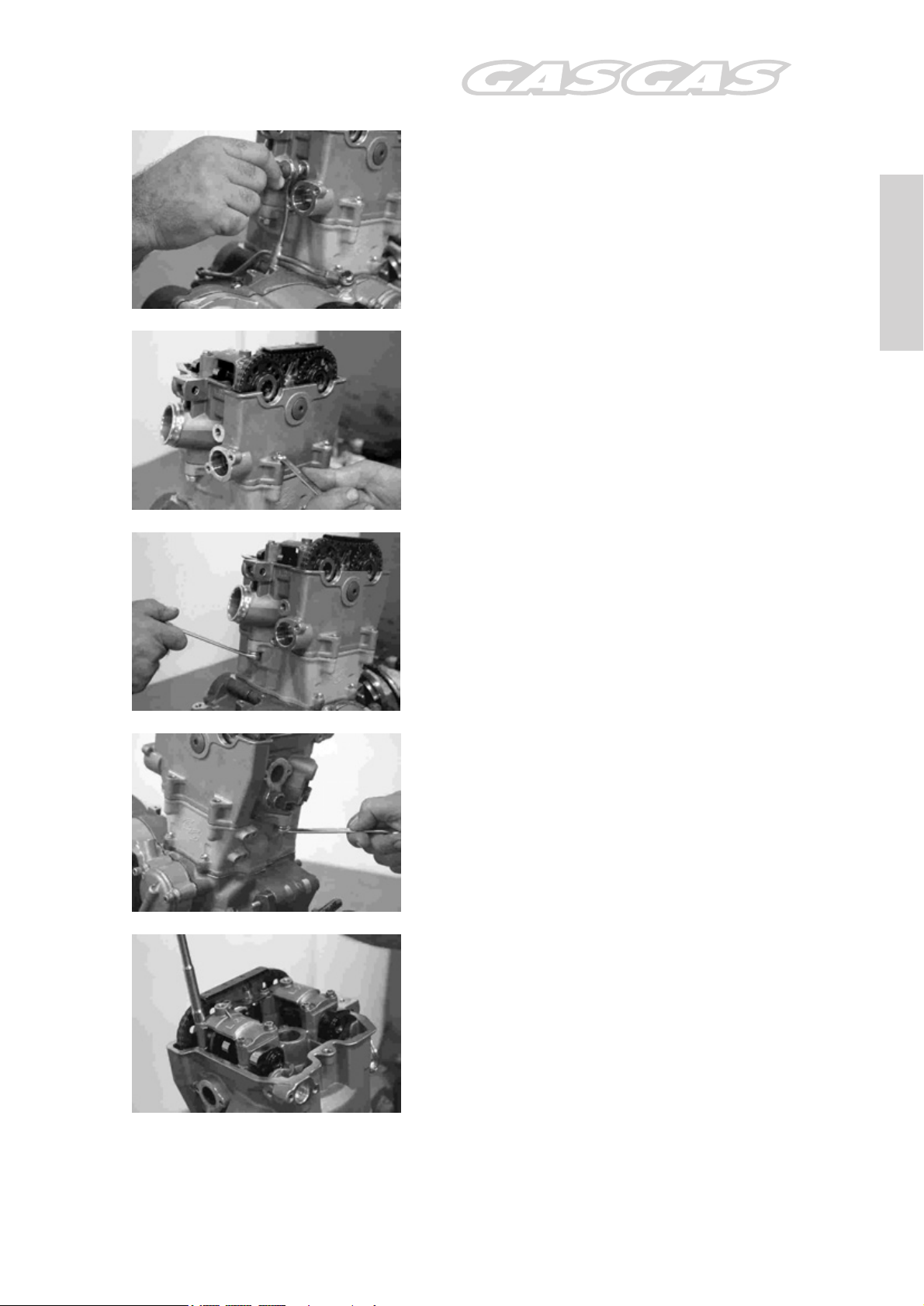

Remove the oil distributor.

Loosen the 2 lateral screws that hold the cylinder

head to the cylinder.

Loosen the rear screw that holds the cylinder to

the cylinder head.

Loosen the front screw that holds the cylinder to

the cylinder head.

Loosen the 8 screws of the covers of the 2

camshafts and the distribution chain skate.

21

Dismounting the engine

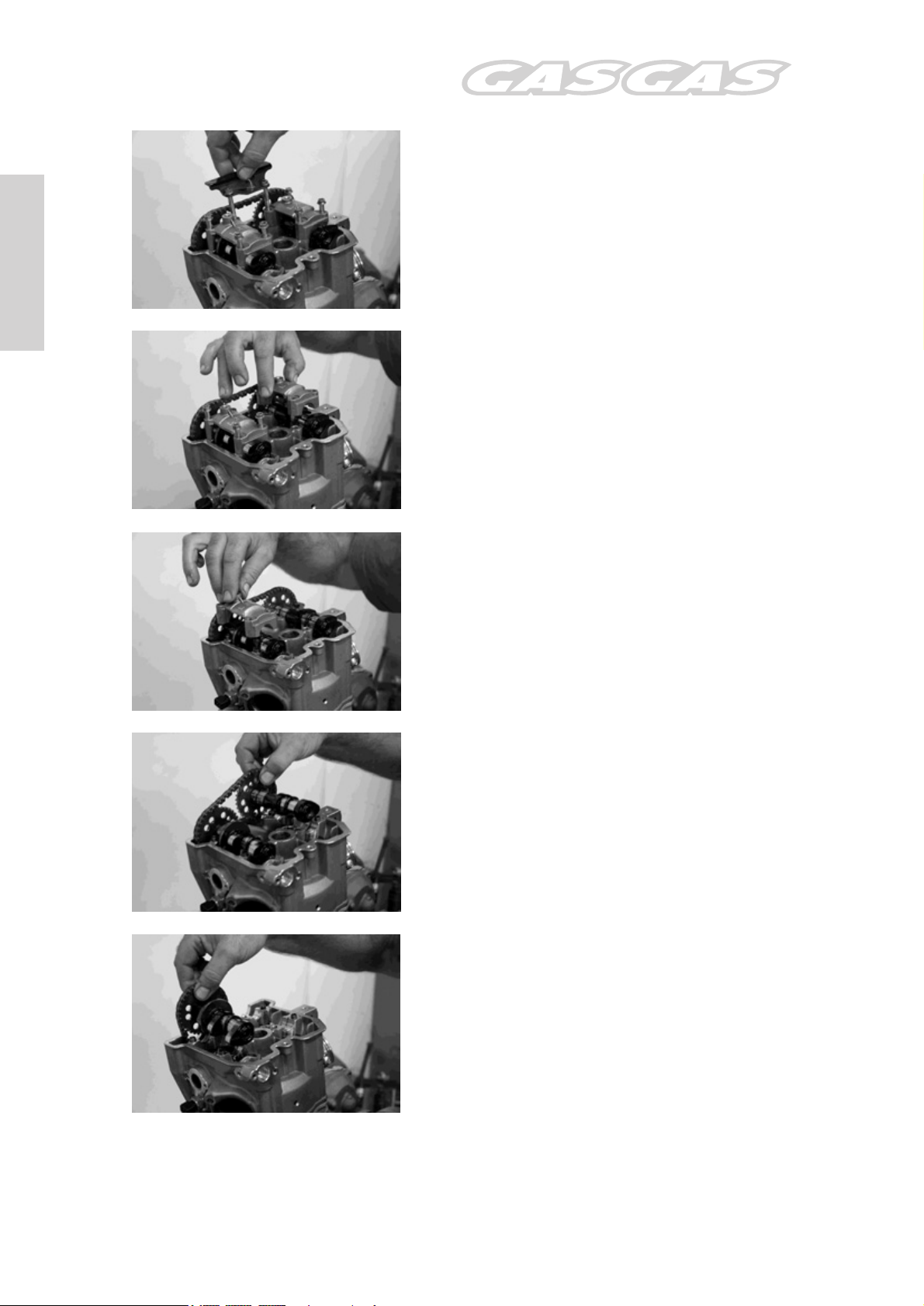

Remove the distributor chain upper skate.

Remove the intake camshaft cover.

Remove the exhaust camshaft cover.

Remove the intake camshaft.

Remove the exhaust camshaft.

22

Dismounting the engine

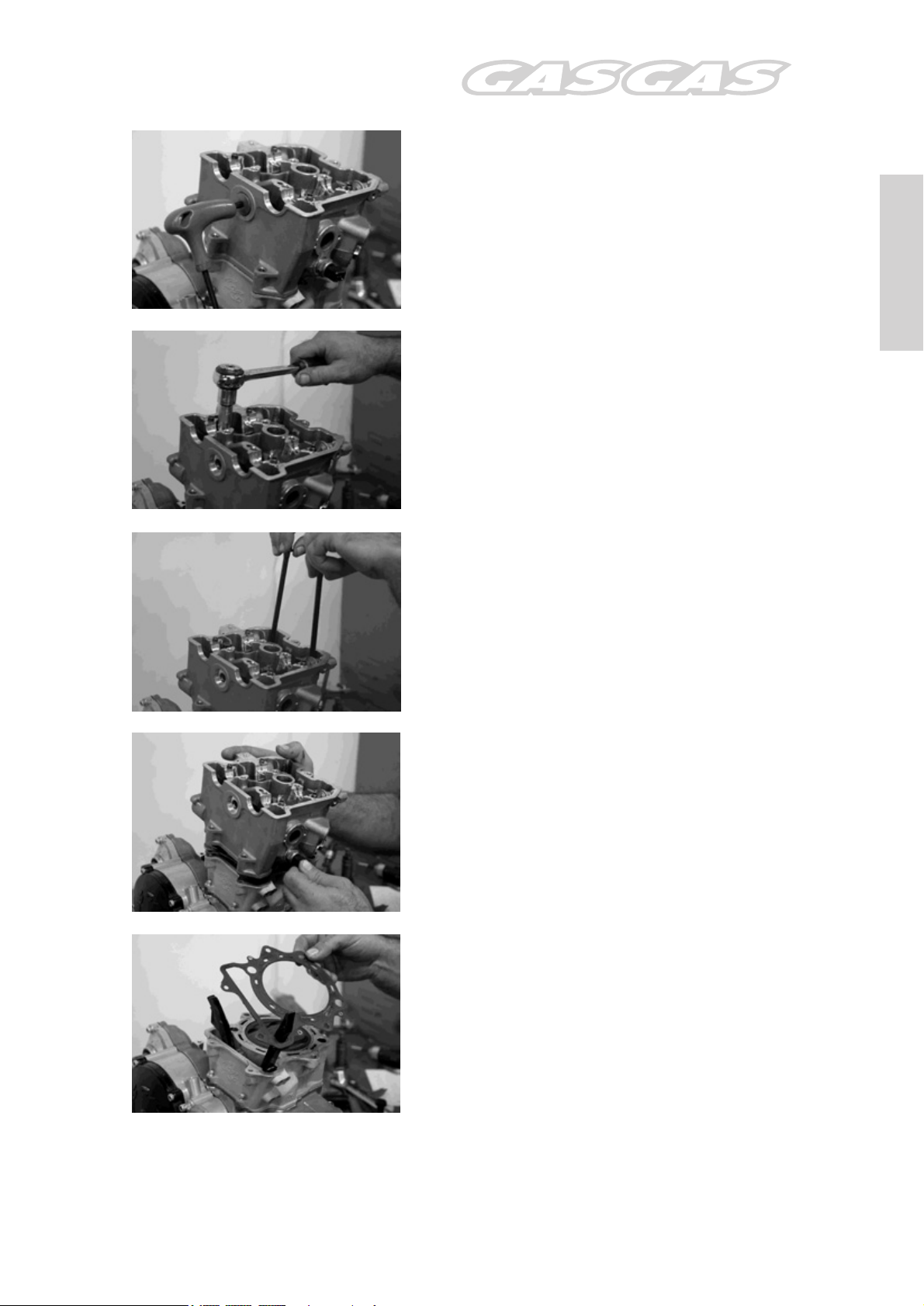

Loosen and remove cylinder head lateral screw.

Loosen the 4 locking screws that hold the cylinder

head.

Remove the 4 screws.

Remove the cylinder head.

Remove the cylinder head gasket.

23

Dismounting the engine

Remove the distributor chain front skate.

Loosen the 2 screws that hold the cylinder to the

engine housing.

Hold the distributor chain and remove the cylinder.

Remove one of the clips that hold the piston

casing and push to remove it.

Remove the cylinder gasket.

24

Dismounting the engine

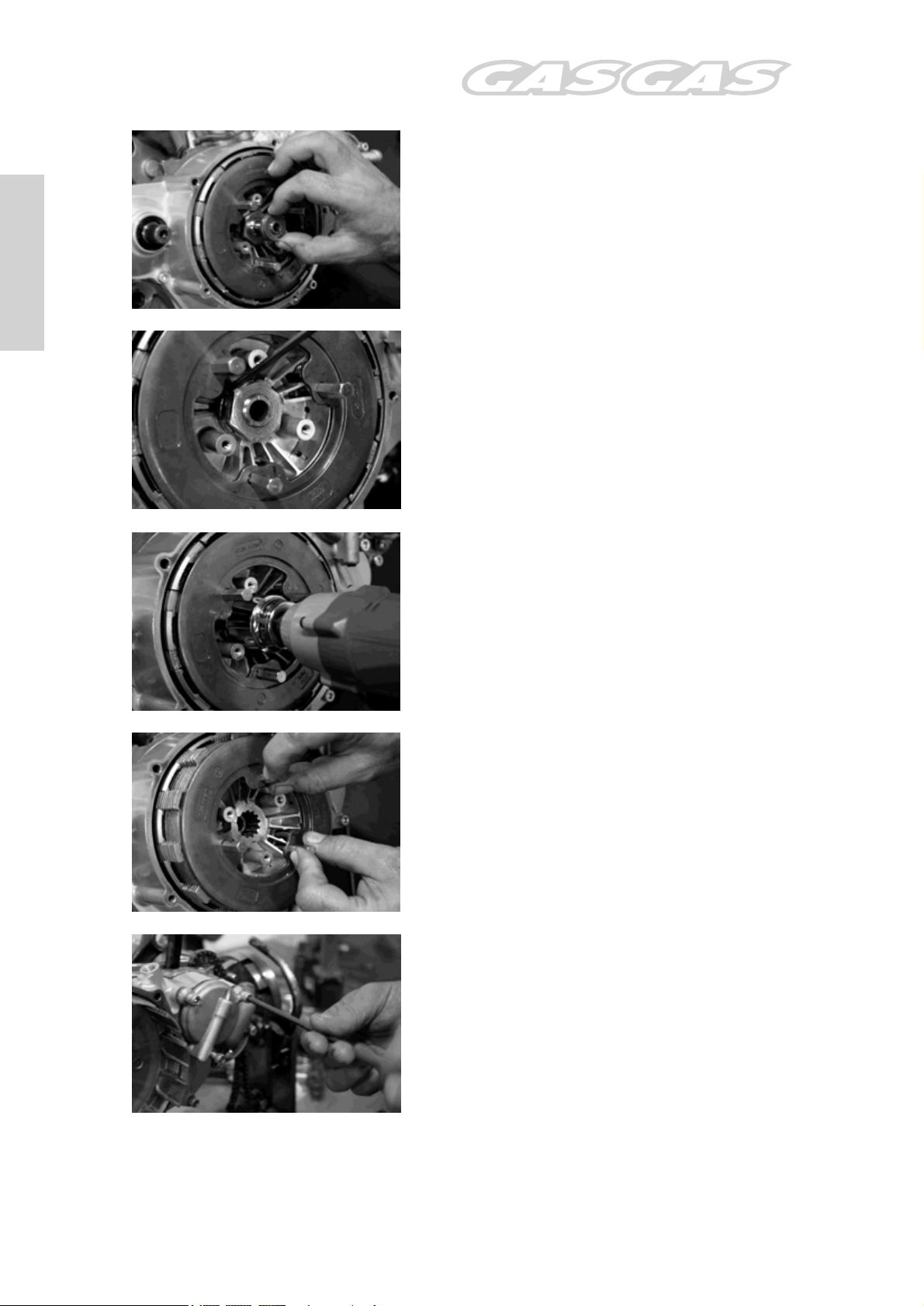

Loosen the 5 screws that hold the cover of the

clutch disks.

Remove the cover of the clutch disks.

Screw the centering tools into place (supplied

together with the tools for the motorbike) and

tighten them to 10 Nm.

NOTE:

This operation is mandatory to ensure the

correct dismounting of the clutch.

Remove the 3 screws, the 3 washers and the 3

springs that hold the clutch unit.

Remove the clutch press cover.

25

Dismounting the engine

Remove the clutch pusher.

Open the washer lug.

Loosen the fixing bolt, blocking the clutch bell

turn with the tool Ref. MFS4504500220.

Remove the clutch unit.

Loosen the 3 screws that hold the oil filter cover.

26

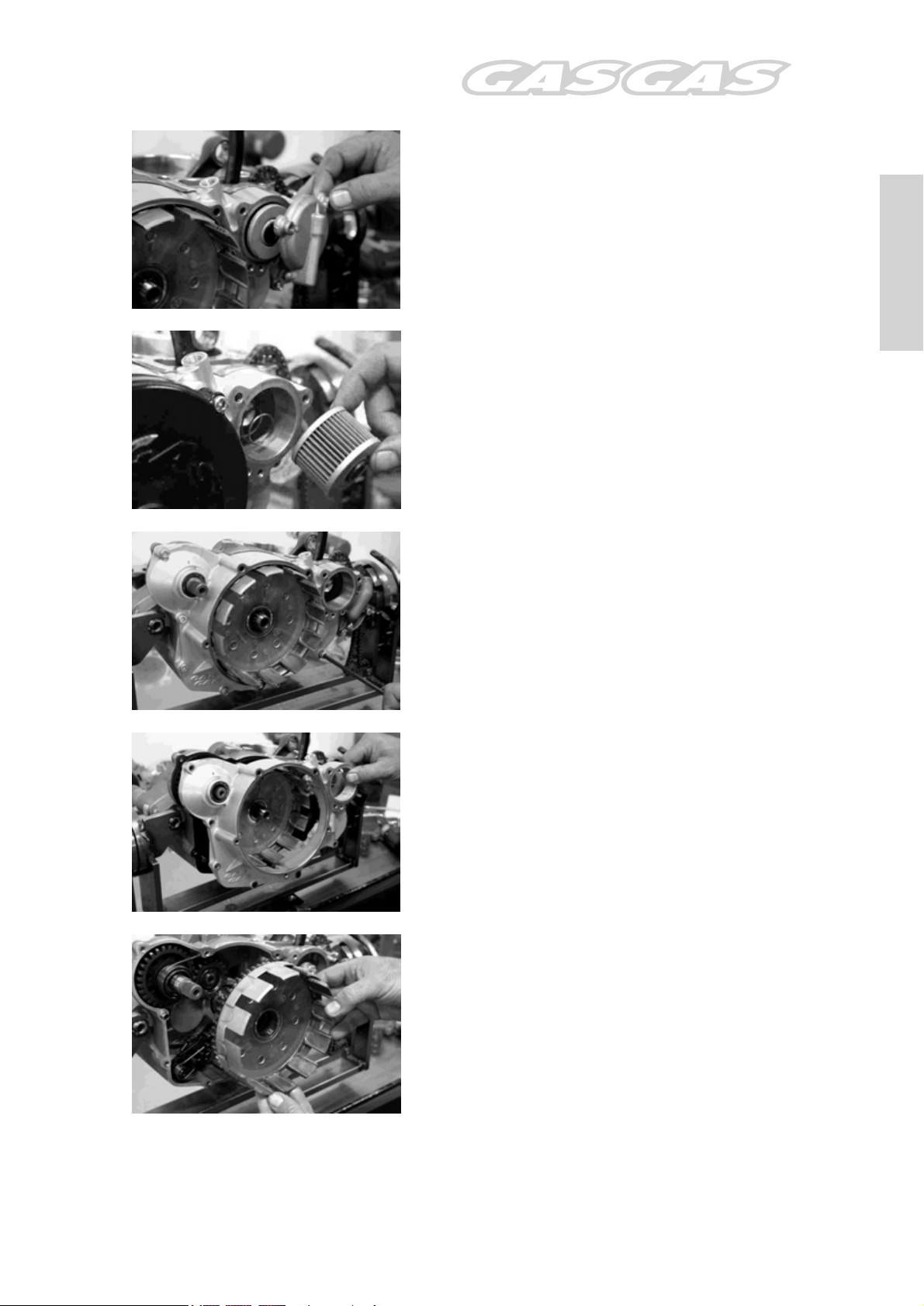

Dismounting the engine

Remove the oil filter cover.

Remove the oil filter and the spring.

Loosen the screws that hold the clutch casing.

Remove the clutch casing.

Remove the clutch bell.

27

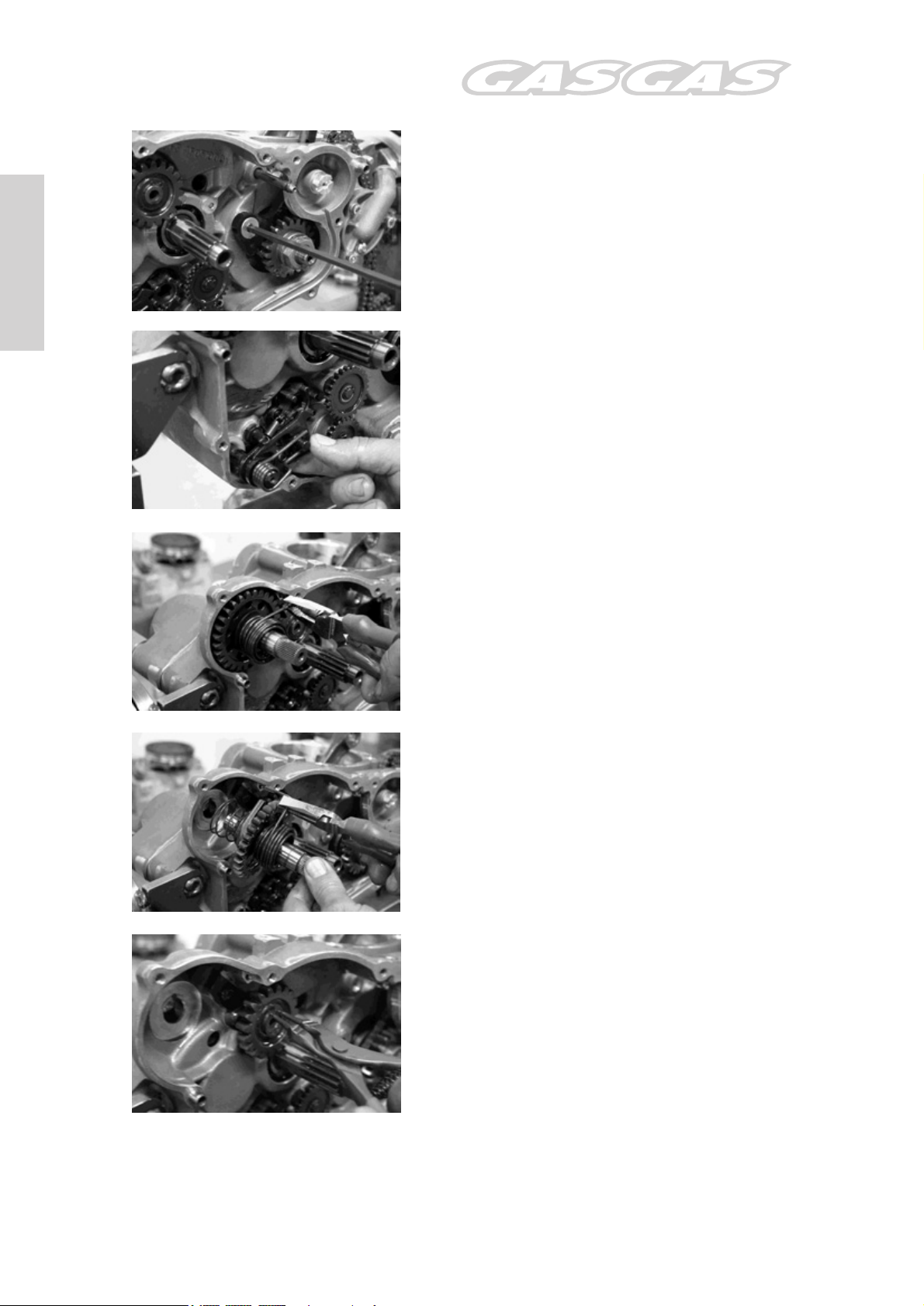

Dismounting the engine

Loosen the screw that holds the distributor chain

tensor skate and remove it.

Remove the gear selector axle.

Remove the gear pedal axle spring.

Remove the gear pedal axle unit.

Remove the starter intermediate pinion clip.

28

Dismounting the engine

Loading...

Loading...