GasGas Fse 450 2005 Owner's manual

MANUAL DEL USUARIO

MANUAL DEL USUARIO

SERVICE MANUAL

SERVICE MANUAL

MANUEL D’ENTRETIEN

MANUEL D’ENTRETIEN

LIBRETTO D´USO

LIBRETTO D´USO

USER MANUAL

USER MANUAL

ENGLISH

Foreword

GAS GAS thanks you for your confidence.

By choosing the new GAS GAS FSE / FSE SM 2005 you have just entered the great GAS GAS family and,

as a user of the number one off-road motorbike manufacturer, you deserve the distinguished treatment that

we wish to offer to you both in our after-sale relationship and in the explanations that we provide in this manual.

Our FSE / FSE SM 2005 is a bike conceived for highly competitive performance. In fact this bike is the fruit

of many years of competition and experimentation in these demanding disciplines; many great trial riders have

contributed their expertise and achievements to the essential da

exclusive motorcycles incorporating key features such as reliability, high performance and stability.

Congratulations for making, without a doubt, the right choice. With skill at the controls of this motorbike, an

adequate preparation and the corresponding essential servicing this GAS GAS will remain highly reliable and

you will be able to enjoy the most comfortable and rewarding motor sport.

Thank you for your confidence and welcome to GAS GAS motos SA.

ta we have used to create these high-quality,

-3-

IMPORTANT NOTICE

Read this manual carefully. This manual covers aspects that will

contribute to your security and to that of others, as well as guaranteeing

a correct conservation and maintenance of this GAS GAS motorcycle

you have just acquired.

All of the instructions to correctly handle and drive this motorcycle

are described in detail. Each message will be preceded by a symbol.

WARNING

This warning symbol identifies special instructions or procedures

that, if not correctly followed, could result in personal injury, or even

death.

CAUTION

Inadequate driving skill could cause problems to the environment

and conflict with other people. Responsible use of your motorcycle

will ensure that these problems and conflicts do not occur

TO PROTECT THE FUTURE OF YOUR SPORT, MAKE SURE

YOU USE YOUR BIKE LEGALLY, WITH CONCERN FOR THE

ENVIRONMENT, AND RESPECT THE RIGHTS OF OTHER

PEOPLE.

Motorcycle riding is a fantastic sport, and we hope you will enjoy it

to the fullest.

.

This caution symbol identifies special instructions or procedures

that, if not strictly observed, could result in damage to or destruction

of equipment.

NOTE

This symbol indicates points of particular interest for more

efficient and convenient operation.

OIL RECOMMENDED:

-4-

TABLE OF CONTENTS

Foreword.........................................................................................3

Important notice..............................................................................4

Table of contents ............................................................................5

General information ........................................................................6

Component locations......................................................................8

Side stand.....................................................................................10

Petrol ....................................................................10

Serial number and the qualification approval plate.......................11

Starting and stopping the engine .....................................12

Cold starting ............................................................13

Gear changes...........................................................13

Stopping the motorcycle...............................................14

Break-in .................................................................14

Maintenance chart .....................................................15

Battery...................................................................16

Cooling system .........................................................17

Spark plug.....................................................................................20

Air filter ..................................................................23

Accelerator cable.......................................................24

Clutch....................................................................25

Exhaust system ........................................................25

Chain guide .............................................................26

Tension adjustment ....................................................27

Handle bars.............................................................29

Brakes ...................................................................29

Steering .................................................................31

Steering lock............................................................32

Front forks...............................................................33

Rear suspension .......................................................36

Wheels ..................................................................38

Cleaning.................................................................39

Tighten bolts and nuts .................................................40

Tightening torque table ................................................41

Lubrication ..............................................................42

Engine oil................................................................43

Suspension adjustment................................................47

In competition...........................................................52

Storage ..................................................................53

Multi-function instructions ............................................53

Fault diagnosis .........................................................55

Electrical schemas .....................................................61

Guarantee manual .....................................................63

-5-

GENERAL INFORMATION

ENGINE

Engine 4 stroke, single-cylinder DOHC 4 valves, liquid cooled

Displacement in cubic centimetres 443 cc

Bore and stroke 95 x 62.6 mm.

Spark plug NGK CR8E or DENSO U24ESR-N

Fuel supply Magneti Marelli electronic injection

TRANSMISSION

Transmission type 6 speed

Clutch type Oil bath, multi-disk hydraulic action

Secondary transmission By chain

Gear ratio 1st 2.071(29/14)

2nd 1.625(26/16)

3rd 1.333(24/18)

4th 1.100(22/20)

5th 0.913(21/23)

6th 0.791(19/24)

Primary reduction ratio 2.85(57/20)

Final reduction ratio 3.692 (48/13)

Overall drive ratio 8.149(6th gear)

Transmission oil Capacity 1200 cc

Type 5W40 API SF or SG

CHASSIS

Type DELTABOX, semi double cradle chassis made from rectangular Cromoly tubes.

Aluminium rocker

Tyre sizes Front FSE - 90/90 x 21

FSE SM - 120/60 ZR17

Rear FSE - 140/80 x 18

FSE SM - 150/60 ZR17

-6-

Suspension Front Öhlins ø 48mm inverted fork.

Marzocchi ø 45mm inverted fork.

Rear Progressive system with single multi-adjustment ÖHLINS shock absorber.

Suspension stroke Front 295 mm.

Rear 320 mm.

Front suspension oil MARZOCCHI SAE 7.5

ÖHLINS SAE 5 - 7.5

Front fork oil level Marzocchi: 110 mm (compressed, without spring).

ÖHLINS: 110 mm (compressed, without spring).

BRAKES

Type Front / rear Disk brakes, NISSIN pump and simple / double callipers.

Effective disk diameter Front 260 mm

Rear 220 mm

DIMENSIONS

Overall height 1260 mm.

Overall length 2135 mm.

Overall width 810 mm.

Wheel base 1475 mm.

Minimum ground clearance 340 mm.

Fuel tank capacity 9.5 litres

Weight 119 Kg.

(Specifications subject to change without notification, also possibly not applicable in some countries).

-7-

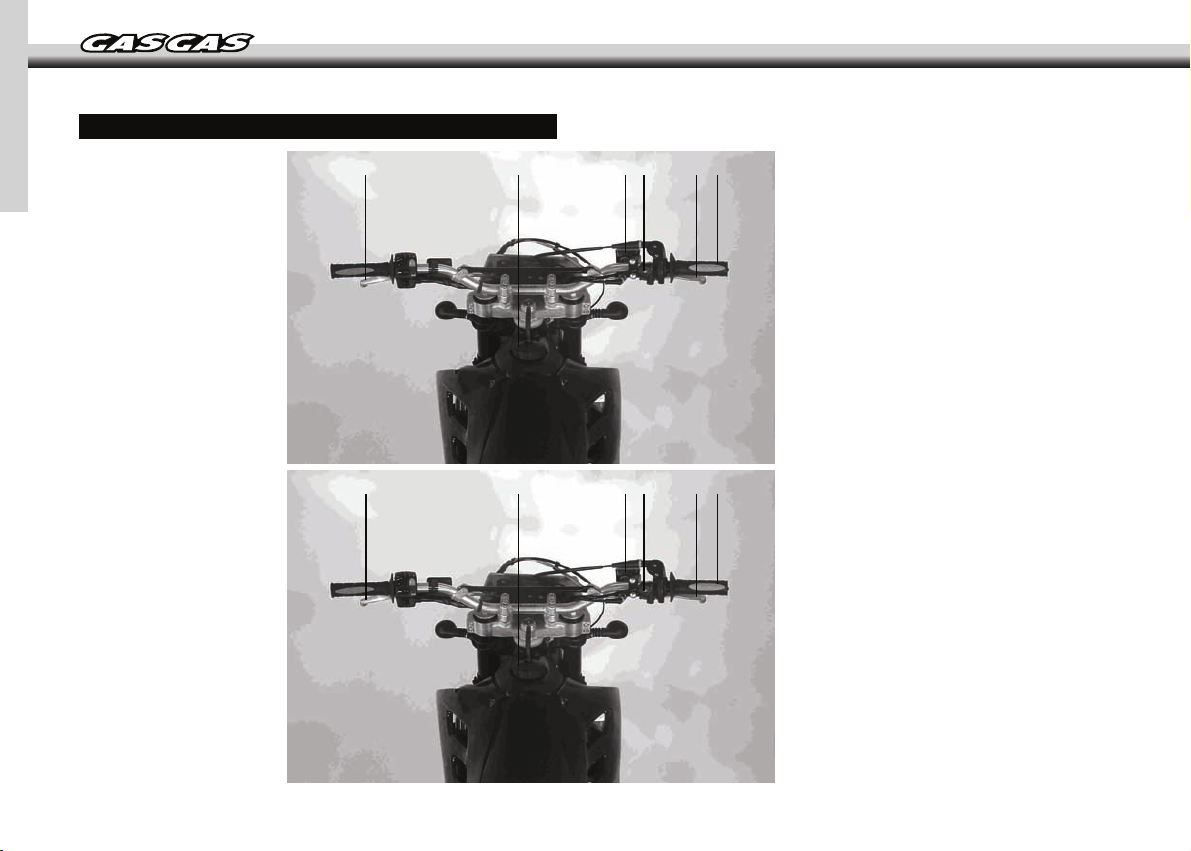

LOCATION OF COMPONENTS

GAS GAS FSE 450

GAS GAS FSE SM 450

1 3 4 2 65

1- Clutch handle

2- Engine start button

3- Fuel tank cap

4- Front brake fluid tank

5- Front brake handle

6- Throttle control

1 3 4 2 65

1- Clutch handle

2- Engine start button

3- Fuel tank cap

4- Front brake fluid tank

5- Front brake handle

6- Throttle control

-8-

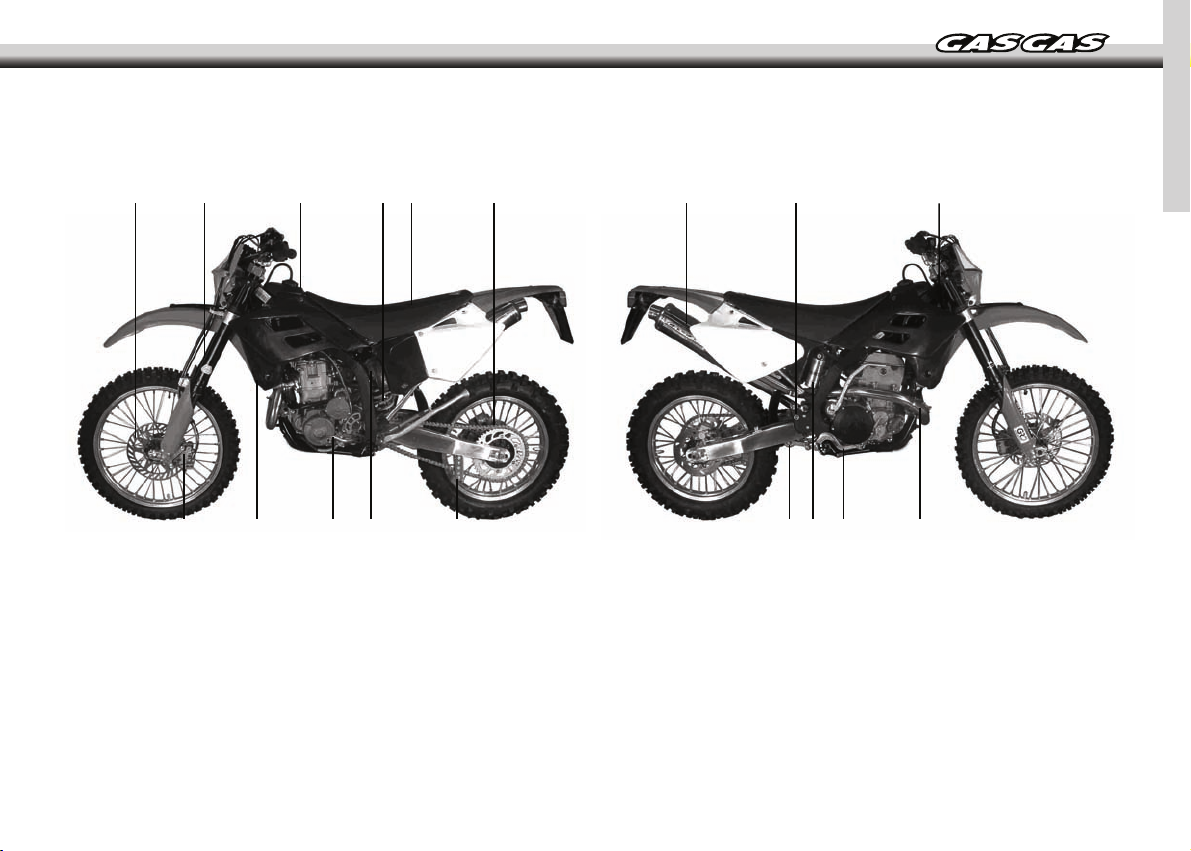

7

9

16

1112

18 19

14

23

13

8

10

15 17

7- Front suspension

8- Radiator

9- Fuel tank

10- Air filter

11- Seat

12- Front brake disk

13- Front brake callipers

14- Rear brake fluid tank

15- Shift pedal

-9-

2021 22

16- Rear shock absorber

17- Chain guide

18- Chain

19- Silencer

20- Rear shock absorber gas tank

21- Tie rod and rocker suspension

22- Rear brake pedal

23- Engine oil rod

24- Exhaust bend

24

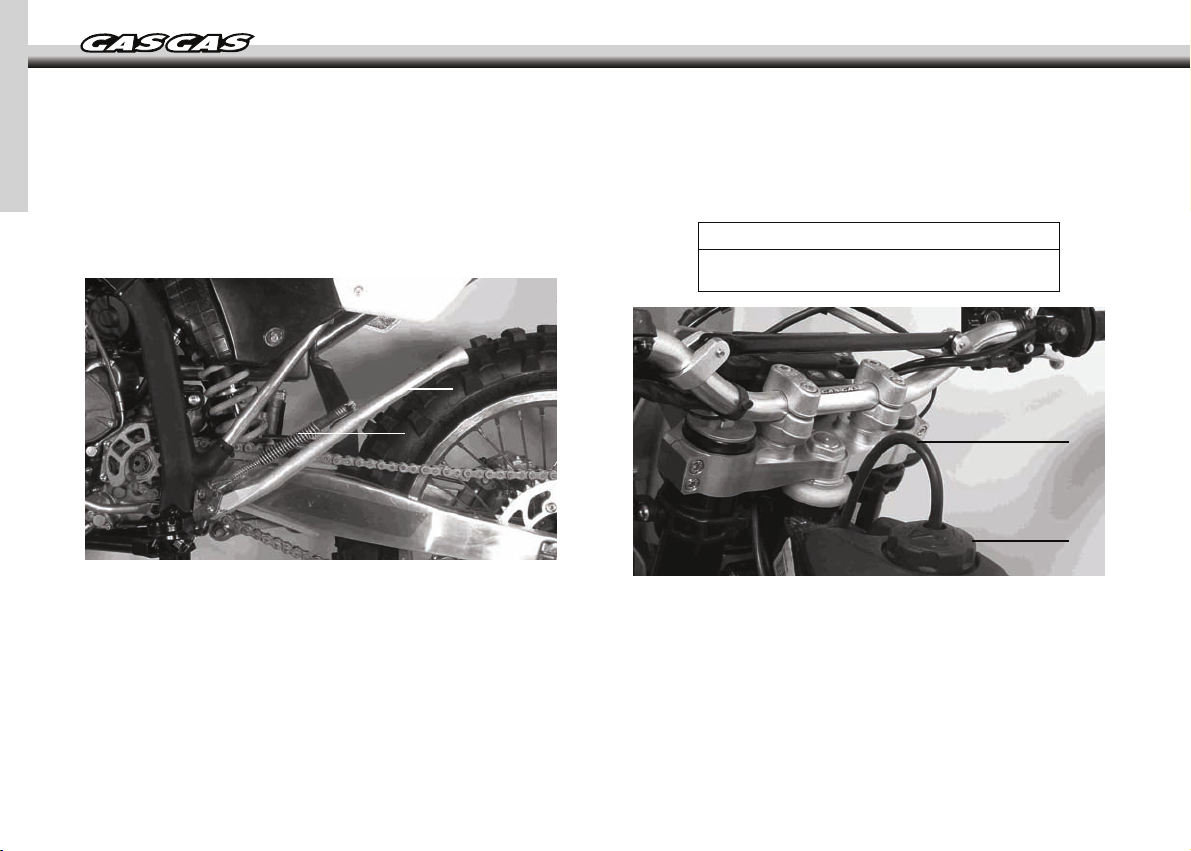

SIDE STAND

PETROL

To unfold the side stand

(B) then the stand is opened to vertical position.

The stand returns to its original position with the aid of the spring

(B).

(A) the securing strap must be released

(A)

(B)

(A). Side stand.

(B). Spring.

Do not start the engine or ride the motorcycle when the side

stand is down. Always engage the security strap before driving

the motorcycle.

NOTE

The GAS GAS FSE / SM FSE 450 has a four stroke engine and

requires 98 octane, unleaded petrol.

Fuel Tank Capacity

7.2L

(B)

(A)

(A). Fuel cap.

(B). Fuel vent hose.

To open the fuel cap

handle bar and rotate the fuel cap in an anti-clockwise direction.

To close the fuel cap, rotate it in a clockwise direction.

(A), release the fuel vent hose (B) from the

-10-

RECOMMENDED FUEL

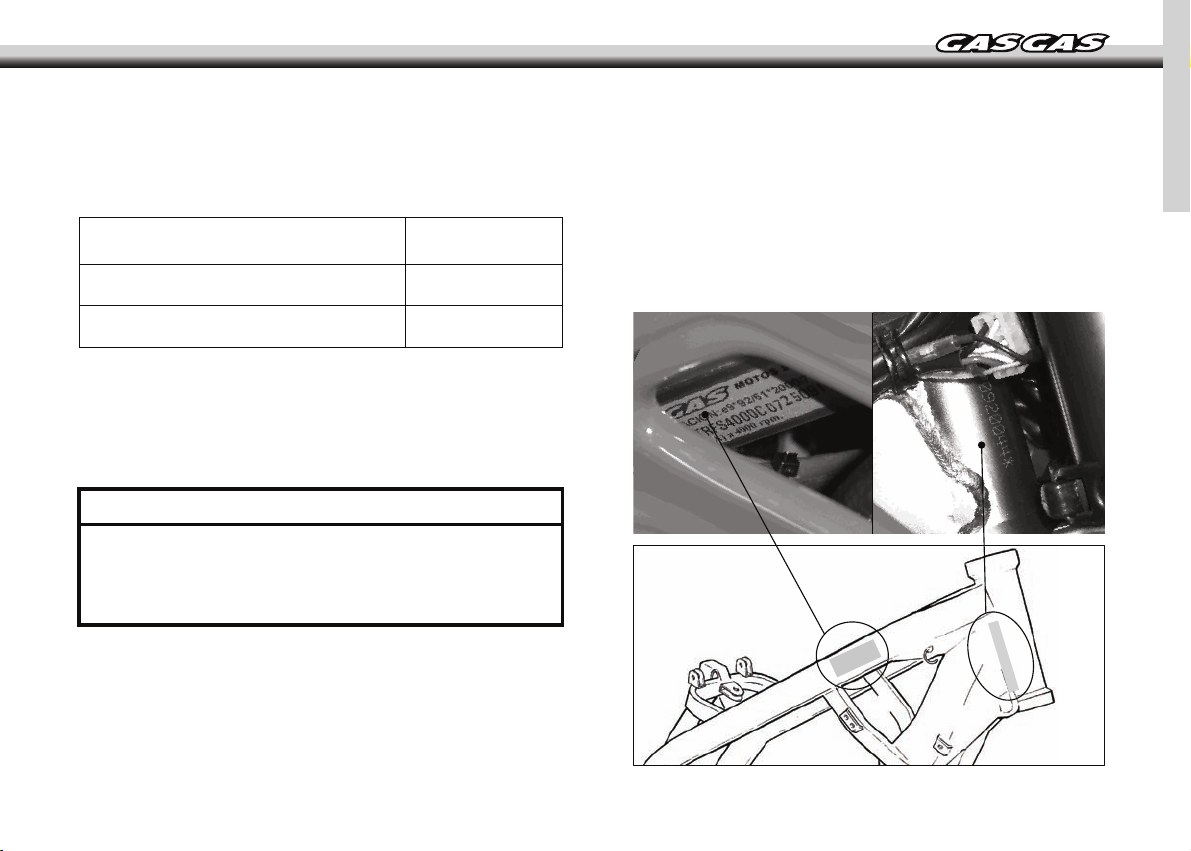

SERIAL NUMBER

Use lead-free petrol with an octane rating equal to or higher than

that shown in the table.

OCTANE RATING METHOD OCTANE

RATING

(MIN)

Antiknock Index (RON+MON)/2 90

Research Octane No. (RON) 98

NOTE

If knocking occurs, try a different brand of gasoline or higher octane

grade.

WARNING

Gasoline is extremely flammable and can be explosive under certain

conditions. Always stop the engine and do not smoke. Make sure

the area is well ventilated and free from any source of flame or

sparks; this includes any appliance with a pilot light.

Printed on the steering tube. Indicates the frame number with which

the motorcycle is registered.

Qualification approval plate

The motorcycle is fitted with its own corresponding qualification

approval plate with the serial number, also printed on the steering

tube and whose data also coincides with that in the documents.

-11-

STARTING THE ENGINE

Stopping the engine

- Ensure that the motorcycle is in neutral.

- Rotate the starter key clockwise (ON

electric circuits are active and the engine can start.

(A) position), in this way the

(A)

(B)

- Without using the throttle, press the electric start button (B).

- Change gear to neutral.

- After a slight acceleration, release the throttle completely and rotate

the ignition key anti-clockwise.

(D)

- The key should point left

circuits are inactive. The engine cannot start.

- The key may be extracted from the ignition.

Starting the engine while the key is being turned to the ON

position may cause a loss in battery power.

(D), this means that all of the electric

NOTE

-12-

COLD STARTING

The cold start function is responsible for aiding the engine start if

this is cold.

- There is no need to use the throttle, simply start the engine. Note

that the engine will start after a certain number of revolutions.

After some seconds, the engine will be at normal operation

temperature. The engine will reach its optimal temperature, in low

time and without causing damage.

NOTE

- If the engine is flooded then start with the throttle fully open.

- The motorcycle may be started in gear if the clutch is

disengaged.

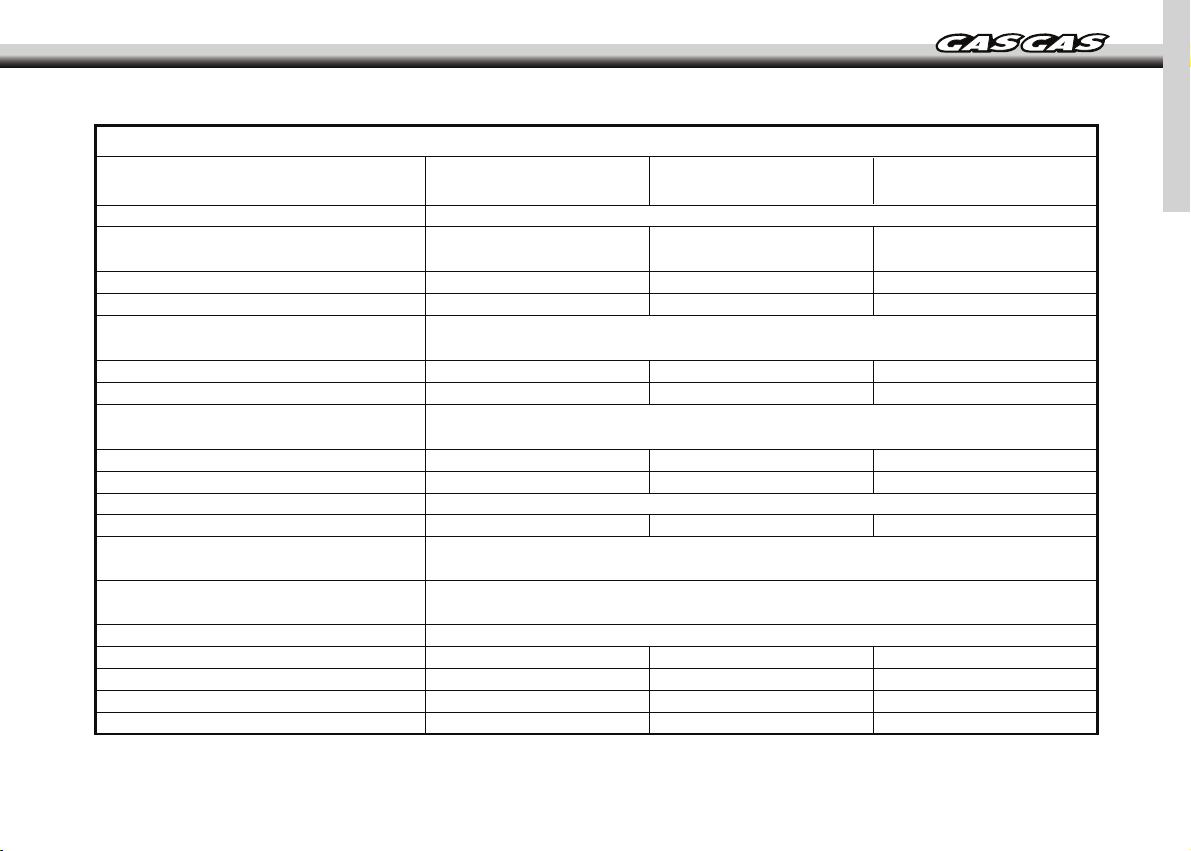

SHIFTING GEARS

The transmission is a 6 speed, return shift type meaning that to go

back to first gear from a higher gear, you must shift back through

the gears one by one.

To engage first gear from neutral, pull in the clutch lever and push

down on the shift pedal then release the pressure on the shift pedal

and gently release the clutch lever.

CAUTION

When changing gears, press firmly on the shift pedal to ensure

complete, positive shifting. Careless, incomplete shifts can cause

the transmission to jump out of gear and lead to engine damage.

(B)

-13-

(B). Shift pedal.

STOPPING THE MOTORCYCLE

For maximum deceleration, close the throttle (A) and apply both

front and rear brakes. Disengage the clutch as the motorcycle comes

to a stop. Independent use of the front or rear brake may be

advantageous under certain conditions.

Downshift progressively as speed is reduced to ensure good engine

response when you want to accelerate.

(A)

BREAK-IN

To obtain the proper operating clearances in the engine and

transmission that are necessary for smooth engine performance and

reliability, an initial break-in must be completed. For the first hour

or 100 Km of operation, run the engine at low rpm.

The slow speed necessary during the break-in period may cause

carbon to build up on the spark plug and soil it. If inspection

of the spark plug shows this to be the case, replace the standard

spark plug with a higher heat grade spark plug for the duration

of the break-in period.

Break-in following these steps:

1. Start the engine and let it run at idle until the engine is thoroughly

warmed up.

2. Stop and let the engine cool completely

3. Start the engine and ride for 10 minutes at

moderate speed. NEVER ACCELERATE FULLY.

4. Stop and let the engine cool completely. Check and

slack and spoke tightness and make a general inspection.

5. Start the engine and ride for 20 minutes at

moderate engine speed. NEVER ACCELERATE FULLY.

6. Stop and let the engine cool completely. Check and adjust (4).

7. Fit the inspected parts.

8. Fill the radiator up completely with cooling liquid. Before

starting the engine bleed the air from the cooling system.

9. Start the engine and ride for 30 minutes at moderate speed.

10. Stop and let the engine cool completely. Check and adjust (4).

11. After the break-in procedure has been properly carried out, the

motorcycle is ready for regular operation.

In any case, even an imprudent acceleration can cause engine

trouble, take special care and use the proper skills and techniques

required for correct driving of the motorcycle.

Following the break-in, fit a new standard spark plug.

NOTE

adjust chain

CAUTION

NOTE

-14-

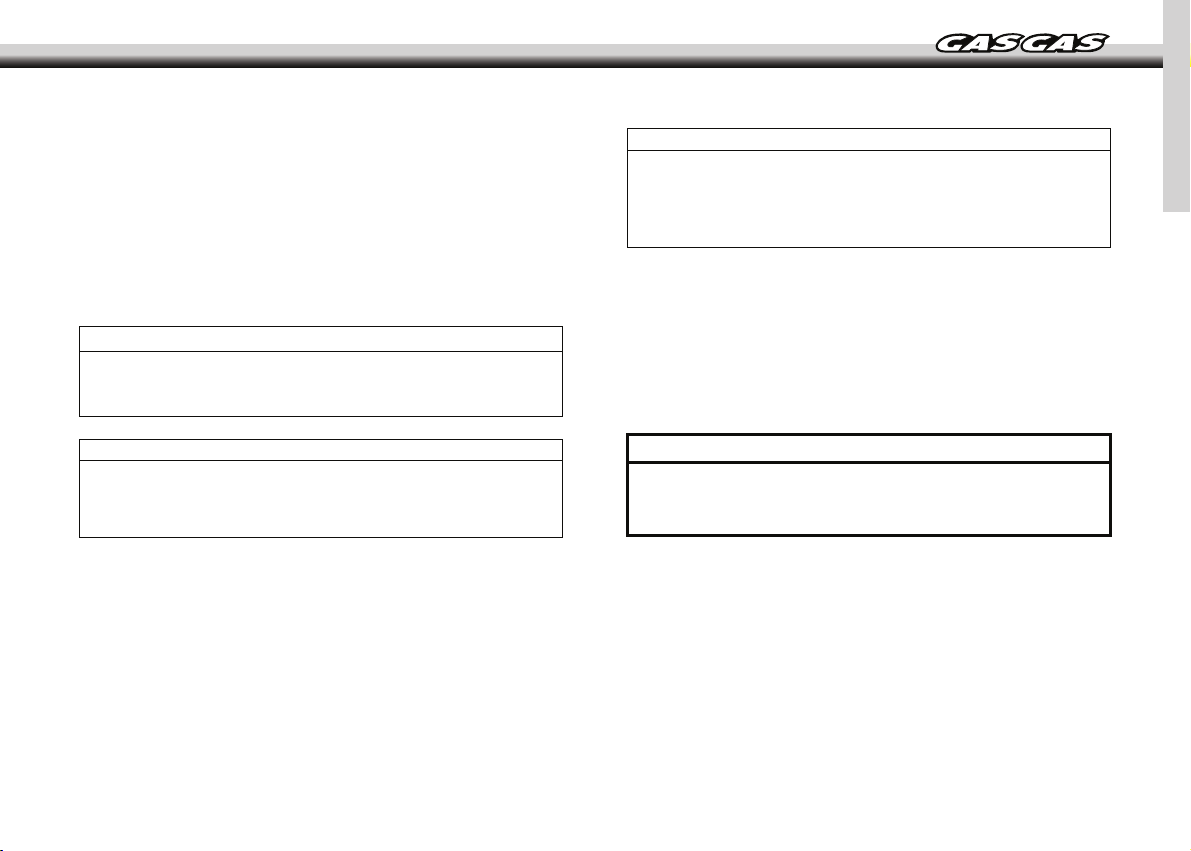

Article

Air filter

*Exhaust connectors and bolts

*Valve tolerances

Spark plug

Injection pump pipes

Engine oil and filter oil

*Engine oil pipes

Coolant

Radiator hoses

Clutch

Chain

*Brakes

Brake lines

Brake liquid

Tyres

*Steering assembly

*Front forks

*Rear suspension

*Chassis bolts and nuts

MAINTENANCE CHART

Period

First 5 hours

Period

Every 30 hours

Period

Every 60 hours

Inspect each time that the motorcycle has run or when necessary

T

I

I

T

I

I

T

I

R

I

*Revise every 4 years

R

I

-

R

I

I

R

I

I

Revise every 2 years

I

I

I

I

I

I

Clean, lubricate and inspect each time the motorcycle has run

I

I

I

I

I

I

*Revise every 4 years

I

I

I

*Revise every 2 years

Inspect tyres for damage and check the tyre pressure every time the motorcycle has run

I

I

I

T

-

-

-

T

I

I

I

T

NOTE: I = Inspect and clean, adjust, replace or lubricate if necessary; R = Replace, T = Tighten, C = Clean

-15-

BATTERY

This battery is maintenance free and checking the fluid level is not

required. It is advisable to check the charge of the battery periodically

To remove the battery, follow these steps:

(A)

3. Disconnect the terminals ensuring that they do not

enter into contact with metal parts then extract the

battery.

WARNING

Hydrogen gas produced by the battery may explode if exposed to

open flame or sparks.

Keep the area ventilated and free from naked flames.

The operating instructions for the battery are as follows:

1. Check the battery tension in open circuit status (disconnected).

(B)

(C)

1. Remove the screws (A) and remove the seat (B).

2. Release the rubber (C).

2. In case the battery's tension is below 12.60 V, or if the storage

period has exceeded 6 months, the battery has to be recharged

following the instructions in paragraph 3.

If the battery voltage is above 12.60 V, the battery can be

installed on the vehicle without having to recharge it.

3.1. Constant voltage charge mode.

- Constant voltage = 14.40 - 14.70V

- Initial charge current = 0.1 – 0.5 Cn

- Charge duration = 6 hours minimum / 24 hours maximum.

3.2. Constant power charge mode.

- Maximum charge current = 0.1 Cn

-16-

- Recommended charging duration = 5 - 8 hours.

- The product (charge current) X (charge duration) must be within

the range: 0.5 - 0.8 Cn.

Note

In case that a different mode of charging is used to those

established here, never exceed the maximum allowed currents

nor the maximum charge duration of 24 hours.

CAUTION

Not using the standard manner of charging may seriously shorten

the battery life.

Never exceed the standard charge.

Using a high pressure water source could damage the radiator fins

CAUTION

and render it ineffective.

Do not obstruct or deviate the radiator air intake by installing nonapproved accessories. Interfering with the radiator could cause

overheating and result in engine damage.

Coolant

This absorbs excessive heat from the engine and transfers it to the

air at the radiator. If the coolant level becomes low, the engine

overheats and may suffer severe damage. Check the coolant level

each day before riding the motorcycle. Replenish coolant if the level

is low.

Inverting the polarity of the battery terminals may cause battery

CAUTION

charge problems and cause damage to the battery system.

The red terminal is positive (+) and the black terminal is negative

(-).

THE COOLING SYSTEM

Radiator hose

Check the radiator hoses for cracks or deterioration, and connections

for leaks.

Radiator

Check the radiator fins for obstruction by insects or mud. Clean off

any obstructions with a stream of low-pressure water.

WARNING

To avoid burns, do not remove the radiator cap or try to change the

coolant when the engine is still hot.

Wait for it to cool down.

Anti-freeze liquid information

To protect the cooling system aluminium parts (engine and radiator)

from rust and corrosion, the use of corrosion and rust inhibitor

chemicals in the coolant is essential. If coolant containing corrosion

and rust inhibitor chemicals is not used, over a period of time, the

radiator will rust. This will block the cooling hoses.

-17-

Use of incorrect coolant solutions will cause severe engine and

CAUTION

cooling system damage.

Use coolant containing corrosion inhibitors made specifically for

aluminium engines and radiators in accordance with the instructions

of the manufacturer.

WARNING

Coolant chemicals are harmful to the human body. Follow coolant

manufacturer warnings and coolant handing instructions.

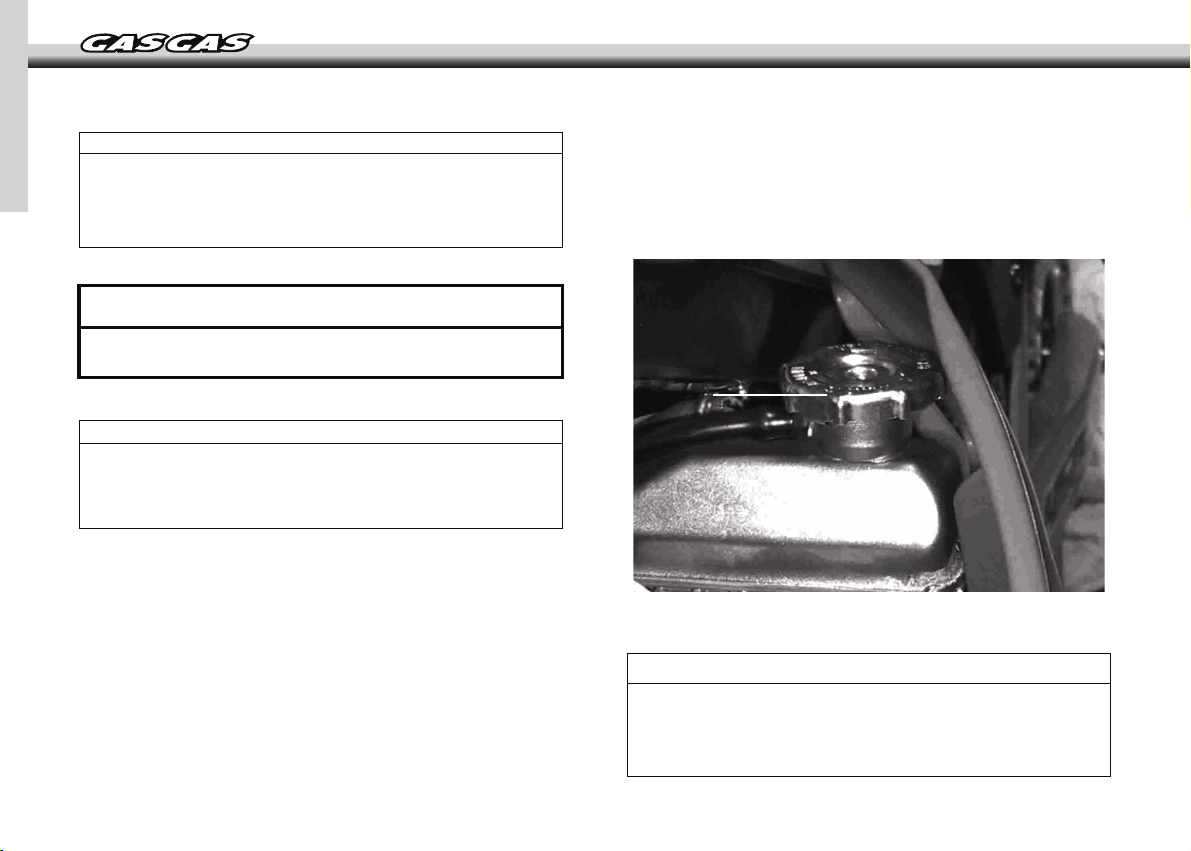

Coolant Level

- Situate the motorcycle so that it is perpendicular to the ground.

- Remove the radiator cap in two stages.

wise and wait for a few seconds. Then push and turn it further in the

same direction to remove the cap.

First turn the cap anti-clock

(A)

Soft or distilled water must be used with the inhibitor chemicals and

the antifreeze in the cooling system.

If normal water is used in the system, it the cooling system tubes

may become blocked.

If the lowest ambient temperature encountered falls below the freezing

point of water, protect the cooling system against freezing.

Use a permanent type of anti-freeze (soft water and ethylene glycol

plus corrosion and rust inhibitor chemicals

and radiators) in the cooling system.

For the coolant mixture ratio under extreme conditions, choose the

mixture ratio listed on the container for the lowest ambient temperature.

CAUTION

for aluminium engines

(A). Radiator Cap.

CAUTION

Permanent types of antifreeze on the market have anticorrosion and

anti-rust properties. When diluted excessively these lose their

antifreeze and anticorrosion properties. These must be diluted in

accordance with the instructions of manufacturer.

-18-

Check the level when the engine is cold.

NOTE

(1). Coolant level.

(2). Filler opening.

Changing the coolant

-

The coolant should be changed periodically to ensure long engine life.

- Wait for the engine to cool completely.

- Situate the motorcycle so that it is perpendicular to the ground.

- Remove the radiator cap.

- Place a container under the coolant drain plug, and drain the coolant

from the radiator and engine by removing the drain plug at the bottom

of the water pump cover. Immediately wipe or wash off any coolant

that spills on the frame, engine, or wheels.

If the coolant level is low, add the correct amount of coolant through

the filler opening.

Recommended liquid

Permanent type of antifreeze (distilled water and ethylene glycol)

with corrosion and rust inhibitor chemicals for aluminium engines

and radiators).

NOTE

Initially a permanent type of antifreeze is installed in the cooling

system by the manufacturer. This is green in colour, containing

50 % ethylene glycol with a freezing point of –35°C.

Total quantity

Mix antifreeze and distilled water 1:1 (distilled water 50%, antifreeze

50%).

(A)

(B)

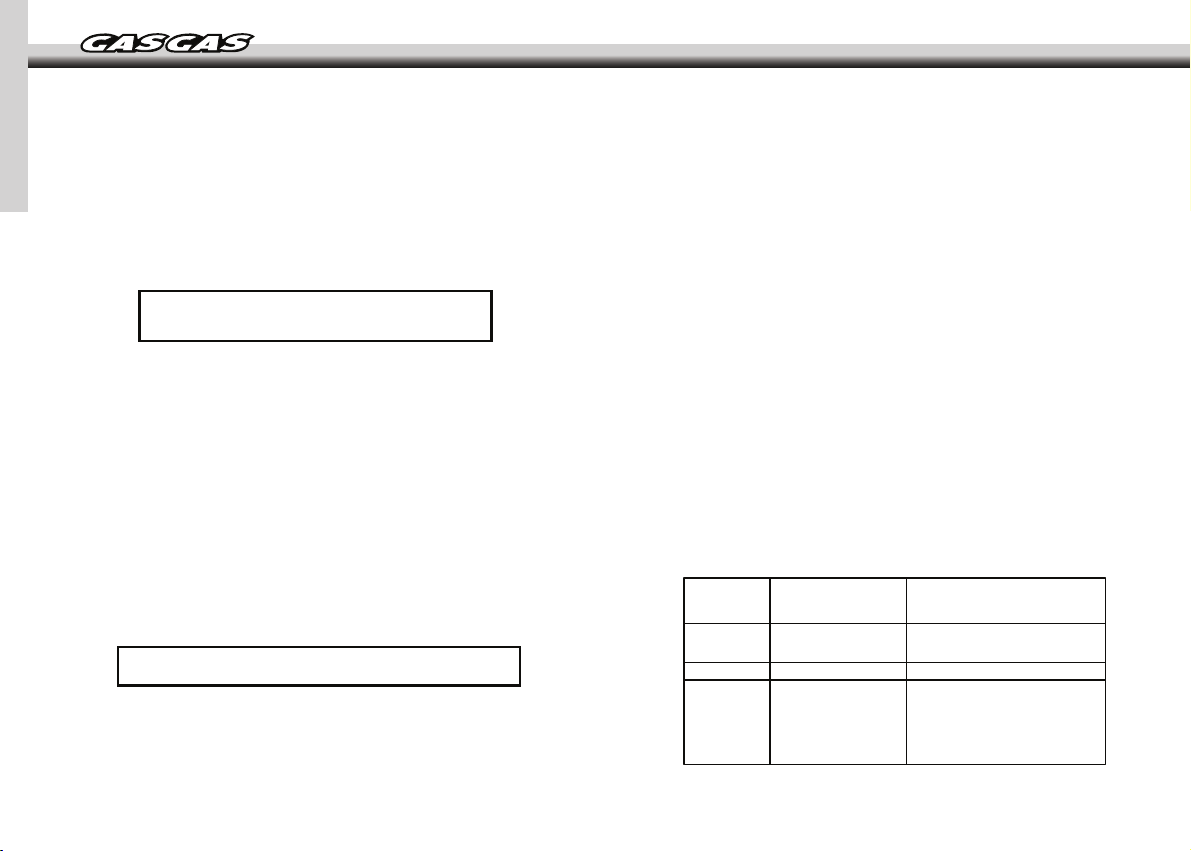

(A). Water pump cover.

(B). Coolant drain Plug.

WARNING

If coolant gets on the tyres this will make them slippery and could

result in an accident.

-19-

-Inspection of the coolant. If white cotton-like patches appear in the

liquid then this means that the aluminium elements of the cooling

system are corroded. If the liquid is brown then this means that the

steal or iron parts of the system are oxidized. In either case clean

out the system.

- Check the cooling system for damage, loose joints, or leaks.

- Install the water pump cover drain plug and cylinder drain plug with

the specified torque shown in the table. Always replace seals with

new ones.

between electrodes using a gauge and adjust in case that it is not

correct by bending the outer electrode. If the spark plug electrodes

are oxidised, damaged or the insulation is broken then replace the

plug.

NOTE

Inspect every 30 hours. Replace every 60 hours.

Bolt torques:

Water pump plug: 9 Nm.

-

Fill the radiator up to the edge and install the radiator cap.

- Check the cooling system for leaks.

- Start the engine, warm up the engine, and then stop it.

- Check the coolant level after the engine cools down. Add

coolant up to the bottom of the radiator filler neck.

SPARK PLUG

The standard spark plug is shown in the table and is tightened to

11 Nm.

Standard spark plug

NGK CR8 E or DENSO U24ESR-N 0.7-0.8 mm.

The spark plug should be taken out periodically to check the electrode

gap. If the plug is oily or has carbon build up on it the clean it with

a sand blaster. Following abrasive particle cleaning, the spark plug

should be cleaned with a wire brush or similar. Measure the distance

To find the correct heat grade spark plug is being used, take it out

and examine the insulation around the electrode. If the ceramic is

light brown, the spark plug is correctly matched to engine temperature.

If the ceramic is white, the plug should be replaced with the next

coldest plug. If the ceramic is black, the plug should be replaced

with the next hottest plug.

NOTE

If the engine output decreases, replace the spark plug to regain

performance.

Spark plug maintenance

NGK

CR7E

DENSO

U22ESR-N

COMMENTS

If the standard spark plug

is wet then replace it.

CR8E

CR9E

U24ESR-N

U27ESR-N

Standard

If the standard spark plug

looks

glassy or has a white

colour, replace it(

-20-

Loading...

Loading...