Page 1

Rev.

Date

Description of Change

E

12/23/09

Update referenced publications and revision procedures

Updated referenced publications. Clarified periodic maintenance

instructions. Added new special inspection requirements.

Update referenced IM. Specify overbraid, bonding strap, foil, corrosion

Include GDC 74( ). TVS replace required after lightning.

Remove “FAA Approved” language. Update IM rev. Add additional

instructions for Mid-Continent standby attitude indicator installations.

Added GAD 43e. Removed reference to Pilot’s Guide. Revised lightning

strike inspection.

K

09/30/13

Added RVSM support for TBM700(850).

G600 PFD/MFD System

Instructions for Continued Airworthiness

as installed in

_____________________________

(Make and Model Airplane)

Reg. No.____________ S/N_______________

Dwg. Number:

190-00601-00 Rev. K

Garmin International, Inc.

1200 E. 151st Street

Olathe, Kansas 66062 USA

Record of Revision

F 12/16/10

G 03/21/11

H 08/31/11

J 10/12/12

inspections; periodic bonding test. Clarify TVS test. Foil check annual.

Page 2

1. INTRODUCTION ................................................................................................................... 3

1.1 Purpose ................................................................................................................. 3

1.2 Scope .................................................................................................................... 3

1.3 Document Control ................................................................................................. 3

1.4 Airworthiness Limitations Section ......................................................................... 3

1.5 Permission to Use Certain Documents ................................................................. 3

1.6 Definitions ............................................................................................................. 3

2. INSTRUCTIONS FOR CONTINUED AIRWORTHINESS .................................................... 4

2.1 Introduction ........................................................................................................... 4

2.2 Description of Alteration ........................................................................................ 4

2.3 Control, Operating Information ............................................................................. 4

2.4 Servicing Information ............................................................................................ 5

2.5 Periodic Maintenance Instructions ........................................................................ 6

2.6 Troubleshooting Information ................................................................................. 9

2.7 Removal and Replacement Information ............................................................... 9

2.8 Diagrams............................................................................................................... 9

2.9 Special Inspection Requirements ......................................................................... 9

2.10 Application of Protective Treatments .................................................................... 10

2.11 Data Relative to Structural Fastener s ................................................................... 10

2.12 Special Tools ........................................................................................................ 10

2.13 Additional Instructions ........................................................................................... 10

2.14 Overhaul Period .................................................................................................... 10

2.15 ICA Revision and Distribution ............................................................................... 10

2.16 Assistance............................................................................................................. 11

2.17 Implementation and Record Keeping ................................................................... 11

3. APPENDIX A ......................................................................................................................... 12

3.1 LRU Locations ...................................................................................................... 12

3.2 Wire Routing – Single-Engine .............................................................................. 13

3.3 Wire Routing – Twin-Engine ................................................................................. 14

G600 PFD/MFD System 190-00601-00 Rev. K

Instructions for Continued Airworthiness Page 2 of 14

Page 3

1. INTRODUCTION

1.1 Purpose

This document is designed for use by the installing agency of the Garmin G600 PFD/MFD System as

Instructions for Continued Airworthiness in response to Federal Aviation regulation (FAR) Part 23.1529,

and Part 23 Appendix G. This ICA includes information required by the operator to adequately maintain

the Garmin G600 system installed under Approved Model List (AML) STC.

1.2 Scope

This document identifies the Instruction for Continued Airworthiness for the modification of the aircraft for

installation of the Garmin G600 PFD/MFD System installed under Approved Model List (AML) STC.

1.3 Document Control

This document shall be released, archived, and controlled in accordance with the Garmin document

control system. When this document is revised, refer to Section 2.15 for information on how to gain FAA

acceptance or approval and how to notify customers of changes.

1.4 Airworthiness Limitations Section

There are no addition al Air wor thi nes s Lim itati ons as defined in 14 CFR § 23, Appendix G. G23.4 that

result from this modification. The Airworthiness Limitations section is FAA approved and specifies

maintenance required under §§43.16 and 91.403 of the Federal Aviation Regulations unless an

alternative program has been FAA approved.

1.5 Permission to Use Certain Documents

Permission is granted to any corporation or person applying for approval of a Garmin G600 system to

use and reference appropriate STC documents to accomplish the Instructions for Continued

Airworthiness and show compliance with STC engineering data. This permission does not construe

suitability of the documents. It is the responsibility of the applicant to determine the suitability of the

documents for the ICA.

1.6 Definitions

The following terminology is used within this document:

1) AC: Advisory Circular

2) ACO: Aircraft Certification Office

3) ADC: Air Data Computer

4) AEG: Aircraft Evaluation Group

5) AHRS: Attitude Heading Reference System

6) CFR: Code of Federal Regulations

7) FAA: Federal Aviation Administration

8) ICA: Instructions for Continued Airworthiness

9) MFD: Multi-Function Display

10) PFD: Primary Flight Display

11) PMI: Primary Manufacturing Inspector

12) RVSM: Reduced Ver t ical S eparation Minima

13) STC: Supplemental Type Certificate

14) TSO: Technic al Sta ndard O rder

15) TVS: Transient Voltage Suppressor

G600 PFD/MFD System 190-00601-00 Rev. K

Instructions for Continued Airworthiness Page 3 of 14

Page 4

2. INSTRUCTIONS FOR CONTI NUED AIRWORT HINES S

2.1 Introduction

Content, Scope, Purpose and Arrangement: This document identifies the Instructions for

Continued Airworthiness for the modification of the

aircraft by installation of the Garmin G600

PFD/MFD System.

Applicability: Applies to aircraft altered by installation of the

Garmin G600 PFD/MFD System.

Definition of Abbreviations: See Section 1.6

Precautions: None

Units of measurement: None

Referenced publications:

Retention: This document, or the information contained within,

Garmin 190-00601-06 Rev. L “G600 AML STC

Installation Manual” or later revisions

will be included in the aircraft’s permanent records.

2.2 Description of Alteration

The Garmin G600 PFD/MFD System is a combination of Garmin LRUs designed to provide both a PFD

and MFD in the primary field of view. The system consists of a GDU 620 display, GRS 77 AHRS, GDC

74( ) ADC, GMU 44 magnetometer, and GTP 59 outside air temperature probe. This modification may

also include a Garmin GAD 43/43e Adapter and/or Mid Continent Instruments attitude indicator (models

4300-4( ), or 4200-( ) with MD42 0). Installation of the Garmin G600 system, specific for the aircraft

installation, is documented in the G600 AML STC Installation Manual.

2.3 Control, Operating Information

The GDU 620, GRS 77, GMU 44, and GDC 74( ) are powered by an electrical bus which is normally

energized with battery, generator, or external power applied to the aircraft. The GAD 43/43e is typically

powered by an avionics bus which is normally controlled by the avionics bus power switch. The LRUs

do not have individual power switches and are powered when the bus is energized and the circuit

breakers are closed. The following circuit breakers provide power to the individual LRUs:

• PFD: GDU 620

• AHRS: GRS 77 #1 and GMU 44 #1

• ADC: GDC 74( )

• GAD: GAD 43/43e

In a dual G600 installation, the PFD, AHRS, and ADC circuit breakers are suffixed with the numbers 1

and 2 (i.e. PFD 1 and PFD 2). If an LRU is optionally powered from multiple circuit breakers, then the

circuit breakers will be suffixed with the letters A and B (i.e PFD 1A and PFD 1B).

The GDU 620 has a PFD and MFD display and front panel controls for performing all G600 normal and

configuration operations. Knobs at the lower left and right corners are used for selecting and entering

data on each screen. The function of the soft keys along the bottom of the display is depicted by the text

above the key. There are dedicated ENT, CLR, and MENU keys on the MFD side of the unit.

G600 PFD/MFD System 190-00601-00 Rev. K

Instructions for Continued Airworthiness Page 4 of 14

Page 5

Turning the PFD knob adjusts the values for the mode selected by the PFD bezel keys, such as,

Heading (HDG), Course (CRS), Altitude (ALT), Vertical Speed (V/S), and Barometric Setting (BARO).

The values are shown in a window to the left of the HSI. Pressing the PFD knob reverts to the default

value of the selected mode.

The Small (Inner) MFD Knob selects a specific page within a page group. Pressing the small MFD knob

turns the selection cursor ON and OFF. When the cursor is ON, data may be entered in the applicable

window by turning the small and large MFD knobs. In this case, the large MFD knob moves the cursor

on the page and the small MFD knob selects individual characters or values for the highlighted cursor

location. The Large (Outer) MFD Knob selects the MFD page group. When the cursor is ON, the large

MFD knob moves the cursor to highlight available fields.

The G600 system starts in normal mode when power is applied to the LRUs. After completing the selftest, the database confirmation page is displayed. Invalid or expired databases are displayed in yellow.

Press ENT to proceed to normal mode. Normal mode consists of a Primary Flight Display (PFD) on one

screen and a Multifunction Display (MFD) on the other screen. The AHRS alignment should complete

within one minute and attitude should be displayed on the PFD. System alerts are accessible via an

“ALERTS” softkey at the lower right of the MFD. During normal system operation with all aircraft

systems and avionics powered there should not be any red Xs or system alerts on the GDU 620.

To enter into Configuration Mode for the G600 system, verify that the GDU 620 is off and an Installer

Unlock Card is inserted in the SD card slot of the GDU 620. Apply power to the GDU 620 while holding

the ENT key. Release the ENT key when “INITIALIZING SYSTEM” appears in the upper left corner of

the display.

Refer to the G600 AML STC Installation Manual for further configuration instructions.

2.4 Servicing Information

None. In the event of system failure, troubleshoot the G600 system in accordance with Section 2.6

Troubleshooting Information.

If the Mid-Continent Instruments 4300-4XX Electric Attitude Indicator or MD420 battery pack is installed,

the battery or batteries may be charged by one of the following methods:

1. Keep the battery or batteries plugged into the Attitude Indicator or Battery Module. Apply power

to the aircraft and run the unit overnight (approx. 15 hours) at the rated voltage.

2. Float Charging: Disconnect the battery or batteries from the indicator or module. Connect the

battery or batteries to a constant voltage source (battery plug (pin 1) red wire = positive) of 20.4

to 20.6 VDC continuously. Float charging may take 24 hours or longer to charge a battery pack.

3. Routine Charging: Disconnect the battery or batteries from the indicator or module. Connect the

battery or batteries to a constant voltage source (battery plug pin 1 red wire = positive) of 21.6 to

22.1 VDC with a current limit of 0.1 ampere maximum. When the charging current drops to

approximately 5mA, the battery is fully charged and should be disconnected. Leaving 21.6 to

22.1 VDC charge voltage on the battery for an extended time will degrade its life. If continuous

maintenance of the charge is desired, refer to step 2, Float Charging.

****WARNING****

Battery out gassing and a rotten egg odor may occur due to

prolonged high rate overcharging and may result in battery

damage. The battery assembly must be replaced if

out gassing has occurred.

G600 PFD/MFD System 190-00601-00 Rev. K

Instructions for Continued Airworthiness Page 5 of 14

Page 6

4. The Mid-Continent Instruments Battery Charger/Tester P/N 36029 may be used. This Battery

Charger/Tester will apply an initial charge, per step 3 above, and then automatically switch to

maintain a float charge, per step 2 above, indefinitely after initial charging is complete.

2.5 Periodic Maintenance Instructions

All G600 system LRUs are designed to detect internal failures. A thorough self-test is executed

automatically upon application of power to the units, and built-in tests are continuously executed.

Detected errors are indicated on the GDU 620 display via failure annunciations.

Operation of the G600 system is not permitted unless an inspection as described in this section has

been completed within the preceding 12 calendar months. Conduct a visual inspection (look for signs of

wear, deterioration, or damage to wires, switches, backshells, connectors, overbraid, bonding straps or

foil) of the G600 system LRUs and wiring harnesses to ensur e insta ll ati on inte grity:

1. Inspect all units for security of attachment, including visual inspection of brackets and other

supporting structure attaching all units to the airframe.

2. Inspect all switches, knobs and buttons for legibility.

3. Visually inspect each unit’s wiring for chafing or wear at each termination.

4. Visually check for any signs of corrosion.

2.5.1 Transient Voltage Suppressors (non-metallic aircraft only) The GDU 620 #1, GRS 77 #1, GDC 74( ) #1, and GAD 43 (if installed) will have a TVS located at each

LRU. The electronic Mid Continent Instrument standby Attitude Indicator (if installed) will have a TVS

located at the indicator and at the attitude indicator power bus. These components must be tested every

24 calendar months in accordance with section 8.3.1 of the G600 AML STC Installation Manual.

2.5.2 Aluminum Foil Tape (non-metallic aircraft only) Any aluminum foil tape used in the G600 installation (see section 3.1 of this document) must be

inspected every 12 calendar months in accordance with section 8.3.2 of the G600 AML STC Installation

Manual.

2.5.3 GDU 620 – Display Unit Maintenance of the GDU 620 is ‘on condition’ only.

2.5.4 GRS 77 – Attitude, Heading Reference System (AHRS) The GRS 77 utilizes an Earth magnetic field model which is updated once every five years as part of the

Aviation Database maintained by the owner/operator. If the magnetic model is not up to date, the unit will

issue an alert upon startup indicating the model has expired. The model can be updated in accordance

with the database update section of the G600 AML STC Installation Manual.

Otherwise maintenance of the GRS 77 is ‘on condition’ only.

2.5.5 GMU 44 – Magnetometer Maintenance of the GMU 44 is ‘on condition’ only.

2.5.6 GDC 74( ) – Air Data Computer Test according to Title 14 CFR §§ 91.411 and 91.413 as well as 14 CFR §§ 43 Appendix E. See the

pitot-static checkout procedure in Section 5.8.2 of the G600 AML STC Installation Manual for the testing

procedure.

2.5.7 GTP 59 – OAT Probe Maintenance of the OAT Probe is ‘on condition’ only.

G600 PFD/MFD System 190-00601-00 Rev. K

Instructions for Continued Airworthiness Page 6 of 14

Page 7

2.5.8 GAD 43/43e – Adapter Maintenance of the GAD 43/43e is ‘on condition’ only.

2.5.9 Mid Continent Instruments Attitude Indicator Models 4300-4( ), or 4200-( ) with MD420 If a Mid Continent Instruments Attitude Indicator is installed as part of the G600 AML STC, the battery

pack must be tested by one of the following means:

1. Manual:

a. Disc onnec t the batt ery pack from the Attitude Indicator.

b. Ensure the battery pack is completely charged and at or near room temperature.

c. Connect the battery to a load of 90 ohms (rated for 10 watts) for 60 minutes while

monitoring the battery voltage level.

i. If the battery voltage is at or above 15.0 volts while under load at the end of the

60 minute test, the battery may be recharged in accordance with the Mid

Continent Instruments Installation Manual and re-installed in the aircraft.

ii. If the battery voltage is below 15.0 volts while under load at the end of the 60

minute test the battery must be replaced.

2. Automatic:

a. Use the Mid Continent Instruments Battery Charger/Tester P/N 36029 to test the battery.

i. If the time required for discharge is 60 minutes or greater, the battery may be

recharged in accordance with the Mid Continent Instruments Installation Manual

and re-installed in the aircraft.

ii. If the time required for discharge is less than 60 minutes, the battery must be

replaced.

****WARNING****

The battery may be permanently damaged if i t is left in a discharged state.

Recharge a discharged battery as soon as possible and

maintain with a float charge for maximum battery life.

Within the preceding 12 calendar months, proper operation of the attitude instrument must be verified

with the following procedure:

1. Apply aircraft power to the unit and verify that the invalid flag is removed from view and the

STBY PWR indicator is not illuminated.

2. Remove aircraft power from the unit and verify that the invalid flag is not visible and the STBY

PWR indicator is flashing.

3. Press the STBY PWR button and verify that the invalid flag is not visible and the STBY PWR

indicator is not flashing.

4. Press the STBY PWR button a second time and verify that the invalid flag is displayed.

Otherwise maintenance of the Mid Continent Instruments attitude indicator is ‘on condition’ only.

2.5.10 Electrical Bonding Test G600 LRU electrical bonding must be tested every 2000 flight hours or ten (10) years, whichever is first.

During the test, any cables normally attached to the LRU must be disconnected from the LRU. If

measured resistance is greater than applicable values in the following table, bonding must be improved

to meet applicable requirements for a new installation in accordance with section 3.8 of the G600 AML

STC Installation Manual.

G600 PFD/MFD System 190-00601-00 Rev. K

Instructions for Continued Airworthiness Page 7 of 14

Page 8

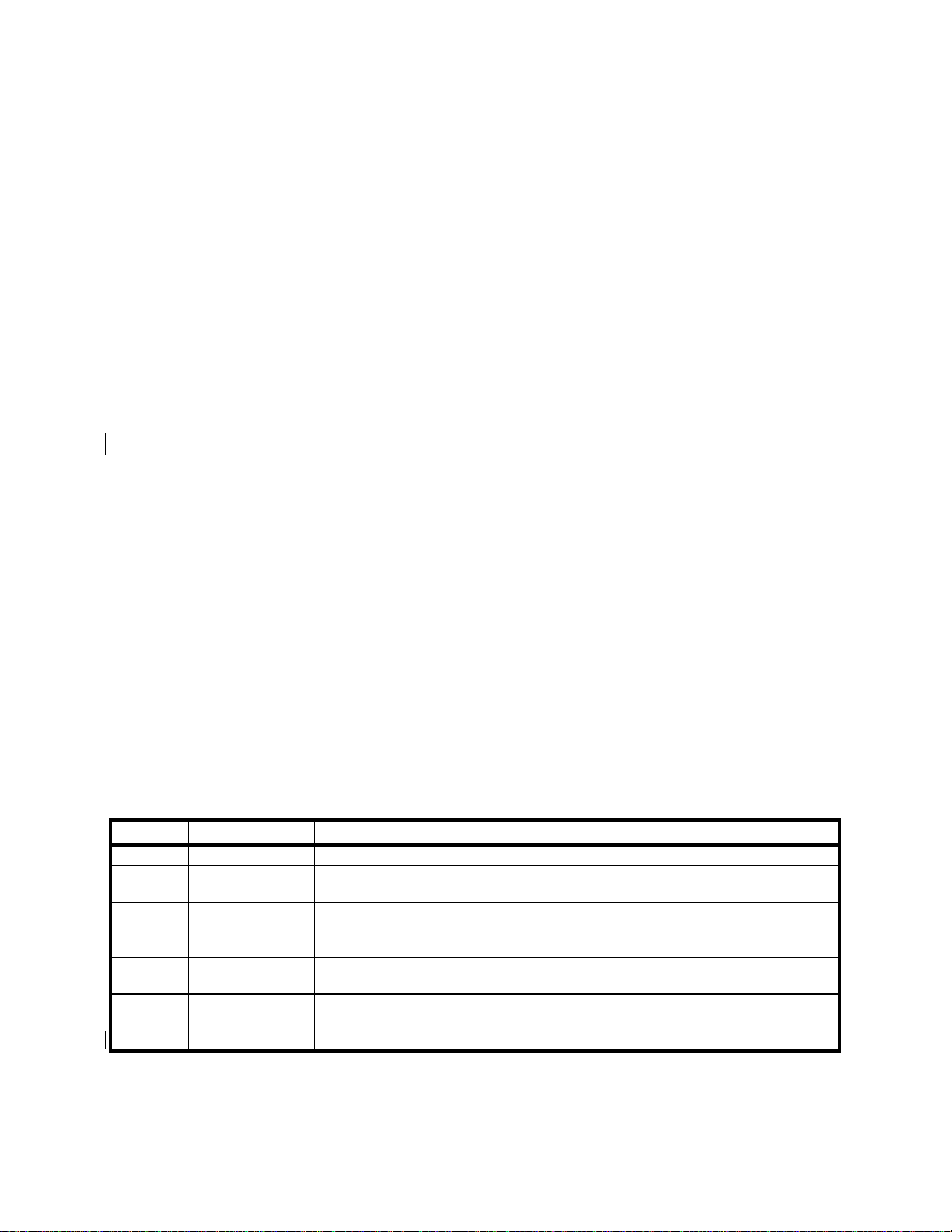

LRU Metallic Aircraft Non-Metallic Airc r a f t

GDU 620 – Displ a y Un it 40 mΩ (to instrument panel) 40 mΩ (to instrument panel)

GRS 77 – Attitude, Heading

Reference System (AHRS)

GMU 44 – Magnetometer 20 mΩ (to aircraft ground

GDC 74( ) – Air Data Computer 20 mΩ (to aircraft ground

GTP 59 – OAT Probe 5 mΩ (to aircraft skin) No bond check required since

GAD 43/43e – Adapter 20 mΩ (to aircraft ground

20 mΩ (to aircraft ground

plane)

plane)

plane)

plane)

20 mΩ (to instrument panel)

No bond check required since

the GMU is required to be

isolated from it’s mounting

location. Verify that there is

sufficient clearance around the

installation per section 2.5.11.5.3

of the G600 AML STC

Installation Manual

20 mΩ (to instrument panel)

the GTP is required to be

isolated from its mounting

location. Verify that there is

sufficient clearance around the

installation per section 2.5.11.7.2

of the G600 AML STC

Installation Manual

20 mΩ (to instrument panel)

Note: there are no applicable bonding requirements for the Mid Continent Instruments Attitude Indicator

Models 4300-4( ), or 4200-( ) with MD420.

2.5.11 TBM 700(850) RVSM Periodic Maintenance Maintain all RVSM equipment in accordance with the manufacturer’s maintenance and performance

requirements. The encoding altimeter must be checked as specified in the Socata Maintenance Manual

section 05-10-01, ATA 34. The RVSM critical areas must be inspected as specified in Socata

Maintenance Manual section 05-10-01, ATA Chapter 53.

The air data systems must be checked within the preceding 24 months as specified in the Socata

Maintenance Manual section 34-11-00 except the altitude displays and Altitude Alerter must be tested in

accordance with the G600 Installation Ma nua l sec tion P.3.2.1. Socata Maintenance Manual test

procedures may be adapted to complete all other air data system checks required in the G600

Installation Manual s ecti on 5.8.2 .

The autopilot altitude hold performance must be tested within the preceding 24 months in accordance

with the G600 Installation Manual section P.3.3.

G600 PFD/MFD System 190-00601-00 Rev. K

Instructions for Continued Airworthiness Page 8 of 14

Page 9

2.6 Troubleshooting Information

If error indications are displayed on the GDU 620 display unit, and/or the optional Mid Continent

Instruments standby attitude indicator, consult the Troubleshooting section contained in the G600 AML

STC Installation Manual. The ‘G600 System Post-Installation Checkout Log’ in the aircraft permanent

records includes the configuration information for the installation (see Section 5 in the G600 System

Installation Manual for a sample Log).

2.7 Removal and Replacement Information

If any G600 LRUs are removed and reinstalled, verify that the LRU unit power-up self -test sequence is

successfully completed and no failure messages are annunciated on the GDU 620 display. See the unit

replacement procedure in Section 3 of the G600 AML STC Installation Manual. Perform any additional

procedures that are required for each LRU, as specified in the following subsections. Any component

installed under this STC must be replaced by a component of the same model and part number or

defined equivalent component.

If any work has been done on the aircraft that could affect the system wiring, antenna cable, or any

interconnected equipment, verify the G600 system unit power-up self-test sequence is successfully

completed and no failure messages are annunciated on the GDU 620 display.

Refer to the G600 AML STC Installation Manual (listed under reference documentation in Section 2.1 of

this document) for particular LRU removal/installation procedures and special handling precautions.

2.7.1 GAD 43e Adapter Replacement If the GAD 43e is used with an analog navigation receiver, the GAD 43e calibration specified in 5.5.11.3

of the G600 AML STC Installation Manual must be performed whenever the GAD 43e and/or the analog

navigation receiver is replaced.

2.7.2 TBM 700(850) RVSM Return to S ervice If the GDC 74B was removed or replaced, check the air data systems as specified in the Socata

Maintenance Manual section 34-11-00 except check the G600 altitude displa y in accordanc e with G600

Installation Manual section P.3.2.1.

If the co-pilot’s RVSM altimeter is removed or replaced, verify ADC 1/ADC 2 switch is operating normally

as specified in the G600 Installation Manual section P.3.1. Refer to the manufacturer’s instructions for

additional calibration and return service instructions. Check the air data systems as specified in the

Socata Maintenance Manual section 34-11-00 except check the co-pilot’s altitude display as specified in

the G600 Installation Manual section P.3.2.1.

If work was performed in the RVSM critical areas, including rear cargo door (if installed), static ports, and

fixation rivets, it must be checked as specified in Socata Maintenance Manual section 53-00-00.

2.8 Diagrams

Aircraft specific LRU locations and wire routing diagram are recorded during installation using the forms

in Appendix A of this document. Refer to the G600 AML STC Series Installation Manual (listed under

reference documentation in Section 2.1 of this document) for drawings applicable to this installation and

for instructions to complete the forms in Appendix A. Point to point wiring diagrams are in Appendix F of

the G600 AML STC Installation Manual. Refer to the G600 Post-Installation Checkout Log retained in the

aircraft permanent records for a list of the interfaced equipment and port configurations.

2.9 Special Inspection Requirements

After a suspected lightning strike, the following actions must be performed:

• Inspect the GTP 59 OAT for signs of lightning damage. Check the self-sealing washer

(P/N 212-00026-00) used on the probe tip outside of the aircraft for any evidence of melting or

G600 PFD/MFD System 190-00601-00 Rev. K

Instructions for Continued Airworthiness Page 9 of 14

Page 10

lack of seal. Replace washer if damaged. If there is evidence of lightning strike to the OAT or

any lightning damage, replace the GTP 59 OAT.

• Non-metallic aircraft must have all Transient Voltage Suppressors replaced in accordance with

section 8.3.1 of the G600 AML STC Installation Manual.

• Tube and fabric aircraft must replace the OAT bond strap (if installed) in accordance with section

8.3.3 of the G600 AML STC Installation Manual.

• Aircraft with a GMU mounted in the wingtip of metallic aircraft with non-metallic wingtip covers

must inspect the magnetometer installation in accordance with section 8.4.1 of the G600 AML

STC Installation Manual.

• Aircraft with an ARINC 708 weather radar interfaced to the GDU 620 must inspect the overbraid

to the weather radar in accordance with section 8.4.2 of the G600 AML STC Installation Manual.

• Aircraft with optional GDU 620 dual power bus diodes (see Installation Manual Figure F-2) must

perform a functional check of the diode isolation as follows:

o Power on Avionics #1 Bus and Avionics #2 Bus. Verify that all avionics are powered on.

o Power off Avionics #1 Bus only. Verify that both GDU 620 units remain powered on.

Verify that Avionics #1 Bus is unpowered.

o Power on Avionics #1 Bus and Power off Avionics #2 Bus only. Verify that both GDU

620 units remain powered on. Verify that Avionics #2 Bus is unpowered.

If the Mid-Continent Standby Attitude Indicator (if installed) has not been operated for more than 3

months, charge each battery pack using one of the methods described in Section 2.4.

2.10 Application of Protective Treatments

None, N/A.

2.11 Data Relative to Structural Fasteners

Data relative to structural fasteners, such as type, torque, and installation requirements can be found in

Section 3 of the G600 AML STC Installation Manual.

2.12 Special Tools

For electrical bonding testing, a milli-ohm meter is required.

No special tools are required for system checkout. See G600 AML STC Installation Manual listed in

reference documentation in Section 2.1 of this document.

2.13 Additional Instructions

None

2.14 Overhaul Period

The system does not require overhaul at a specific time period. Power on self-test and continuous BIT

will monitor the health of the G600 system. If any LRU indicates an internal failure, the unit may be

removed and replaced. See the troubleshooting section contained in the G600 AML STC Installation

Manual, listed under reference documentation in paragraph 2.1 of this document.

2.15 ICA Revision and Distribution

To revise this ICA, a request must be submitted to the ACO or ODA along with the revised ICA. The

ACO or ODA will obtain AEG acceptance, and approve any revision to the Airworthiness Limitations in

Section 1.4. After FAA acceptance/approval, Garmin will release the revised ICA for customer use, and

provide any required notification of the revision.

G600 PFD/MFD System 190-00601-00 Rev. K

Instructions for Continued Airworthiness Page 10 of 14

Page 11

The latest revision of this document will be available on the Garmin website (www.garmin.com). A

Garmin Service Bulletin, describing ICA revision, will be sent to dealers if revision is determined to be

significant.

2.16 Assistance

Flight Standards Inspectors or the certificate holder’s PMI have the required resources to respond to

questions regarding this ICA. In addition, the customer may refer questions regarding this equipment and

its installation to the manufacturer, Garmin. Garmin customer assistance may be contacted during

normal business hours via telephone 913-397-8200 or email from the Garmin web site at

www.garmin.com.

2.17 Implementation and Record Keeping

Modification of an aircraft by this Supplemental Type Certificate obligates the aircraft operator to include

the maintenance information provided by this document in the operator’s aircraft maintenance manual

and/or the operator’s aircraft scheduled maintenance program.

G600 PFD/MFD System 190-00601-00 Rev. K

Instructions for Continued Airworthiness Page 11 of 14

Page 12

GDU 620 #2

only)

GRS 77 #2

only)

GDC 74( ) #2

only)

GMU 44 #2

only)

GTP 59 #2

only)

3. APPENDIX A

3.1 LRU Locations

The following table describes the locations of the G600 LRUs:

LRU

GDU 620 #1

GRS 77 #1

GDC 74( ) #1

GMU 44 #1

GTP 59 #1

LRU

included in

this

installation?

Yes

Yes

Yes

Yes

Yes

Aluminum

foil tape

used for

grounding?

N/A

Yes No

Yes No

N/A

N/A

GAD 43/43e Yes No Yes No

MCI 4300-4 ( ) Yes No N/A

MCI 4200-( ) Yes No N/A

MCI MD420 Yes No N/A

(dual installations

Yes No N/A

Description of Location

(dual installations

(dual installations

(dual installations

(dual installations

Yes No N/A

Yes No N/A

Yes No N/A

Yes No N/A

G600 PFD/MFD System 190-00601-00 Rev. K

Instructions for Continued Airworthiness Page 12 of 14

Page 13

3.2 Wire Routing – Single-Engine

The following diagram depicts the wire routing for the G600 LRUs throughout the aircraft structure for a

single-engine aircraft:

G600 PFD/MFD System 190-00601-00 Rev. K

Instructions for Continued Airworthiness Page 13 of 14

Page 14

3.3 Wire Routing – Twin-Engine

The following diagram depicts the wire routing for the G600 LRUs throughout the aircraft structure for a

twin-engine aircraf t:

G600 PFD/MFD System 190-00601-00 Rev. K

Instructions for Continued Airworthiness Page 14 of 14

Loading...

Loading...