Garmin SMARTPUMP Installation Manual

SMARTPUMP

INSTALLATION INSTRUCTIONS

Important Safety Information

WARNING

See the Important Safety and Product Information guide in the product box for product warnings and other

important information.

You are responsible for the safe and prudent operation of your vessel. The autopilot is a tool that enhances

your capability to operate your boat. It does not relieve you of the responsibility of safely operating your boat.

Avoid navigational hazards and never leave the helm unattended.

Always be prepared to promptly regain manual control of your boat.

CAUTION

To avoid possible personal injury, always wear safety goggles, ear protection, and a dust mask when drilling,

cutting, or sanding.

NOTICE

To avoid damage to your boat, the autopilot system should be installed by a qualified marine installer. Specific

knowledge of marine steering and electrical systems is required for proper installation.

When drilling or cutting, always check what is on the opposite side of the surface to avoid damaging the vessel.

This pump is only for use with Garmin® autopilot systems. Attempting to use this pump with any other system

may damage the system, the pump, or the vessel.

This pump must not be installed with a steering system that has an unvented reservoir, because it will damage

the pump. Before installing the pump, you must verify that the vessel steering has a vented reservoir. Typically,

the vent hole is in the filler cap of the highest helm. If you are not clear as to whether the steering system is

vented, you should check with the manufacturer of the helm or the reservoir to verify.

The pump must be installed in a dry location, protected from water and the weather.

The SmartPump steers your boat by interacting with the hydraulic steering system, based on commands from

the autopilot system.

Autopilot Software Updates

After completing the autopilot installation, you should update the software before performing the configuration

process.

If you connected the autopilot system to a NMEA 2000® network with a Garmin chartplotter, you can update the

software using the chartplotter.

If you did not connect the autopilot system to a NMEA 2000 network with a Garmin chartplotter, you must use a

NMEA 2000 Network Updater (sold separately). Go to support.garmin.com for update information.

GUID-E8997D46-4304-4100-8790-5F1FB3DF637B v4April 2021

Tools Needed

• Safety glasses

• Drill and drill bits

• Wrenches

• Torque wrench (if configuring the pump for an unbalanced steering cylinder)

• Wire cutter/stripper

• Screwdrivers: Phillips and flat

• Cable ties

• Marine corrosion inhibitor spray

• Mounting screws: the pump kit includes mounting screws, but if the included screws are not appropriate for

the mounting surface, you must provide the correct types of screws

• Hydraulic system hardware (Hydraulic Considerations, page 3):

◦ Hydraulic hose, -4 [6 mm (1/4 in.) ID] or larger, with machine-crimped or field-replaceable fittings that have

a minimum rating of 1000 psi

◦ Hydraulic T-connectors

◦ Hydraulic shut-off valves

◦ Thread sealant, such as Loctite® 567

◦ Hydraulic bleeding equipment

◦ Hydraulic fluid

Mounting Considerations

NOTICE

The pump must be installed in a dry location, protected from water and the weather.

• Before you start the pump installation, you must identify the type of hydraulic steering system in your boat

and consult the hydraulic diagrams. Each boat is different, and you must consider the existing hydraulic

layout before deciding where to mount the pump (Hydraulic Considerations, page 3).

• Before you start the pump installation, you should verify that you have selected the appropriate pump for the

needs of your vessel. You can reference the autopilot compatibility guide on garmin.com.

• For installations with larger steering cylinders or those requiring higher fluid pressure, you should install the

pump as close to the cylinder as possible, so that preferably no more than 3 m (10 ft.) of hydraulic hose

connects the pump to the cylinder.

• You should mount the pump horizontally, if possible.

• If you cannot mount the pump horizontally, you must mount it vertically with the pump head connectors

facing up.

• You must mount the pump in a location to which you can extend the hydraulic steering lines of the boat.

• The pump has five hydraulic-connector fittings, although only three are used when installing the pump as

recommended. The pump-valve illustration provided in these instructions may be helpful when determining

the fitting layout that is best for your installation location (Pump Ports and Valves, page 4).

Mounting the Pump

Before you can mount the pump, you must select a location (Mounting Considerations, page 2) and determine

the correct mounting hardware (Tools Needed, page 2).

1 Hold the pump in the intended mounting location and mark the locations of the mounting holes on the

mounting surface, using the pump as a template.

2 Using a drill bit appropriate for the mounting surface and selected mounting hardware, drill the four holes

through the mounting surface.

3 Secure the pump to the mounting surface using the selected mounting hardware.

2

Hydraulic Considerations

NOTICE

This pump must not be installed with a steering system that has an unvented reservoir, because it will damage

the pump. Before installing the pump, you must verify that the vessel steering has a vented reservoir. Typically,

the vent hole is in the filler cap of the highest helm. If you are not clear as to whether the steering system is

vented, you should check with the manufacturer of the helm or the reservoir to verify.

Do not attempt to use the autopilot to steer the boat until you bleed all air from each part of the hydraulic

system.

When adding hydraulic line to the system, use only hose that is -4 [6 mm (1/4 in.) ID] or larger with machinecrimped or field-replaceable fittings that have a minimum rating of 1000 lbf/in² (6,895 kPa).

You must not use thread seal tape, such as Teflon® tape, or thread putty on any hydraulic fitting in this system.

Small debris from thread seal tape or thread putty can enter the hydraulic system, become stuck in valves, and

render the autopilot or steering system inoperable. Using thread seal tape or thread putty on any hydraulic

fitting in this system voids your warranty.

Use caution when applying liquid thread sealant to avoid damage to the hydraulic system or to the autopilot

system.

Before you connect the pump to the hydraulic lines, you should consult the hydraulic-layout diagrams to help

determine how to best install the pump in the hydraulic system of the boat (Hydraulic Layouts, page 4).

When planning the hydraulic layout and making all hydraulic connections, consider the following:

• The pump must be reconfigured if the boat is equipped with an unbalanced steering cylinder (Configuring the

Pump for an Unbalanced Cylinder, page 11).

• The size and thread types for the hydraulic ports on the pump are listed in the specifications (Port and Fitting

Specifications, page 12).

• You must use -4 [6 mm (1/4 in.) ID] or larger hoses for all hydraulic connections, including the return line.

• For installations with larger steering cylinders or those requiring higher fluid pressure, you should install the

pump as close to the cylinder as possible, so that preferably no more than 3 m (10 ft.) of hydraulic hose

connects the pump to the cylinder.

• You should use T-connectors (not included) to connect the hydraulic lines to the pump.

• You should install shut-off valves (not included) in the hydraulic lines between the pump manifold and Tconnectors to allow for easy pump isolation and removal.

• For hydraulic fittings with an O-ring, such as ORB and ORFS fittings, you should not use thread sealant.

• For hydraulic fittings without an O-ring, you should use a liquid thread sealant, such as Loctite 567.

• When using liquid thread sealant, you must follow the instructions regarding the cure time, for example,

Loctite 567 cures after four hours. If the thread sealant is not properly cured per the manufacturer's

instructions, the high pressure in the hydraulic lines may push the sealant out of the threads and create a

leak.

• When disconnecting a connector sealed with liquid sealant, you must take care to keep any slivers or other

debris from the cured sealant from entering the hydraulic system.

3

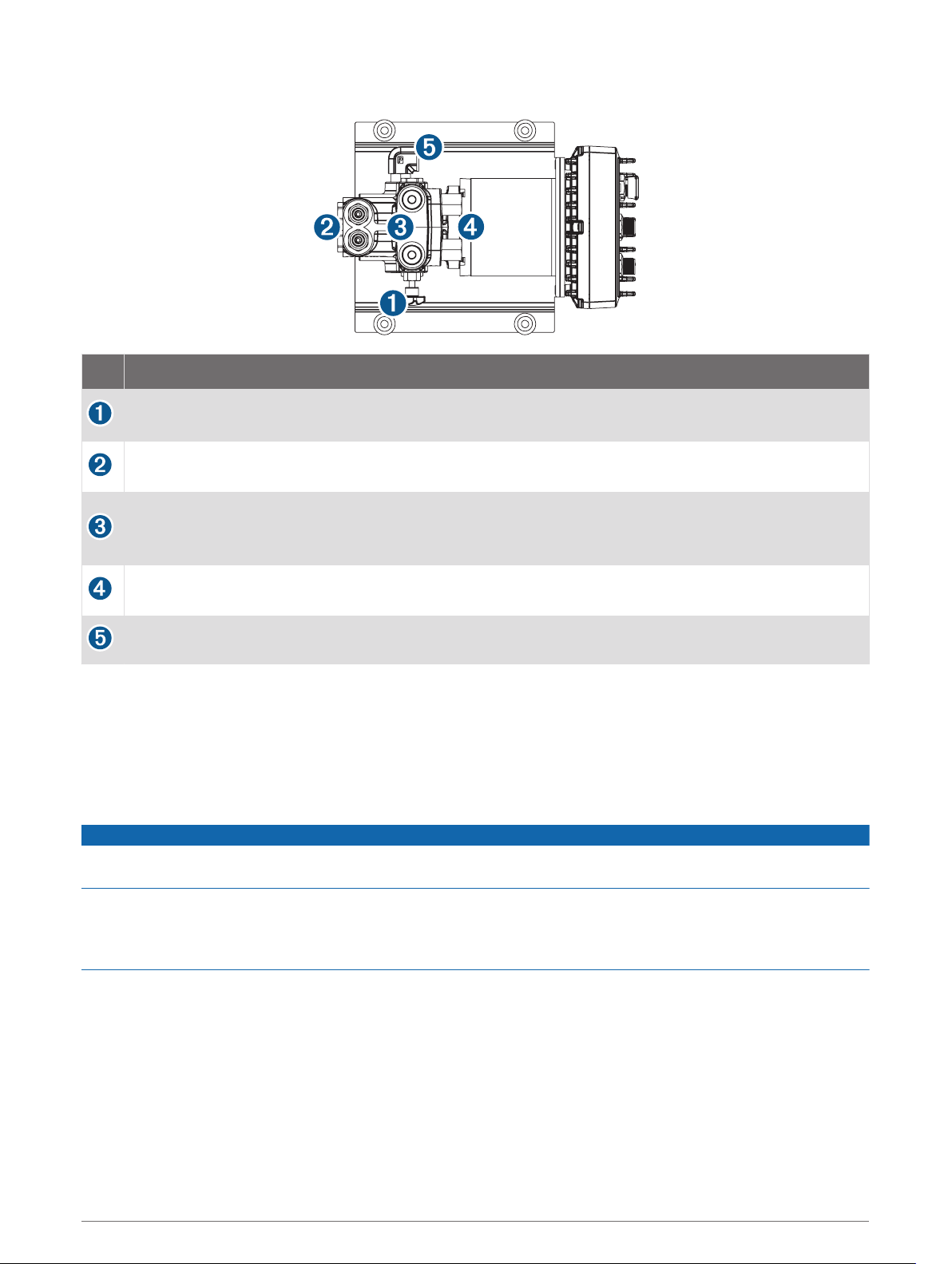

Pump Ports and Valves

Item Description

Bypass valve. Used for hydraulic bleeding only, and must remain fully tightened during normal

operation.

Check valves. Must be reconfigured if the boat is equipped with an unbalanced cylinder (Configuring the

Pump for an Unbalanced Cylinder, page 11).

H1 and H2 ports. These are the recommended ports for connecting the pump to the helm and cylinder.

The recommended installation method uses a shut-off valve and a T-connector to split each connector

on the pump for the helm and cylinder connections (Hydraulic Layouts, page 4).

C1 and C2 ports. These ports may be used instead of the H1 and H2 ports if they are more appropriate

for your installation location.

Return line port. Connects to the return port on the helm through a shut-off valve (recommended).

NOTE: The recommended installation method uses shut-off valves and T-connectors to connect the pump to

the helm and cylinder, so the pump can be removed for service while the boat retains normal steering. You can

install the pump using all five ports (connecting H1 and H2 to the helm and C1 and C2 to the cylinder), but this

type of installation is not recommended because it does not allow you to operate the steering system if you

must remove the pump for service.

Hydraulic Layouts

NOTICE

If the steering system in your boat does not match any of the hydraulic layouts in this manual and you are

unsure how to install the pump, contact Garmin Product Support.

This pump must not be installed with a steering system that has an unvented reservoir, because it will damage

the pump. Before installing the pump, you must verify that the vessel steering has a vented reservoir. Typically,

the vent hole is in the filler cap of the highest helm. If you are not clear as to whether the steering system is

vented, you should check with the manufacturer of the helm or the reservoir to verify.

Before you start the pump installation, identify the type of hydraulic steering system in your boat. Each boat is

different, and you must consider certain aspects of the existing hydraulic layout before deciding where to

mount the pump.

Before you start the pump installation, you should throughly review the hydraulic considerations for important

information on hydraulic hose and fitting types, installation methods, and thread-sealant information (Hydraulic

Considerations, page 3).

4

Loading...

Loading...