Garmin SA01535Wi-D Airplane Flight Manual Supplement

© Copyright 2014

GARMIN Ltd. or its subsidiaries

All Rights Reserved

Except as expressly provided herein, no part of this manual may be reproduced, copied, transmitted,

disseminated, downloaded or stored in any storage medium, for any purpose without the express prior

written consent of GARMIN. GARMIN hereby grants permission to download a single copy of this manual

and of any revision to this manual onto a hard drive or other electronic storage medium to be viewed and

to print one copy of this manual or of any revision hereto, provided that such electronic or printed copy of

this manual or revision must contain the complete text of this copyright notice and provided further that any

unauthorized commercial distribution of this manual or any revision hereto is strictly prohibited.

GARMIN International, Inc.

1200 E. 151

st

Street

Olathe, KS 66062 USA

Telephone: 913-397-8200

www.garmin.com

Hawker Beechcraft 200, 200C, B200, B200C, 190-00915-02 Rev. 8

B200GT and B200CGT King Air

Page 2 of 179

GARMIN International, Inc

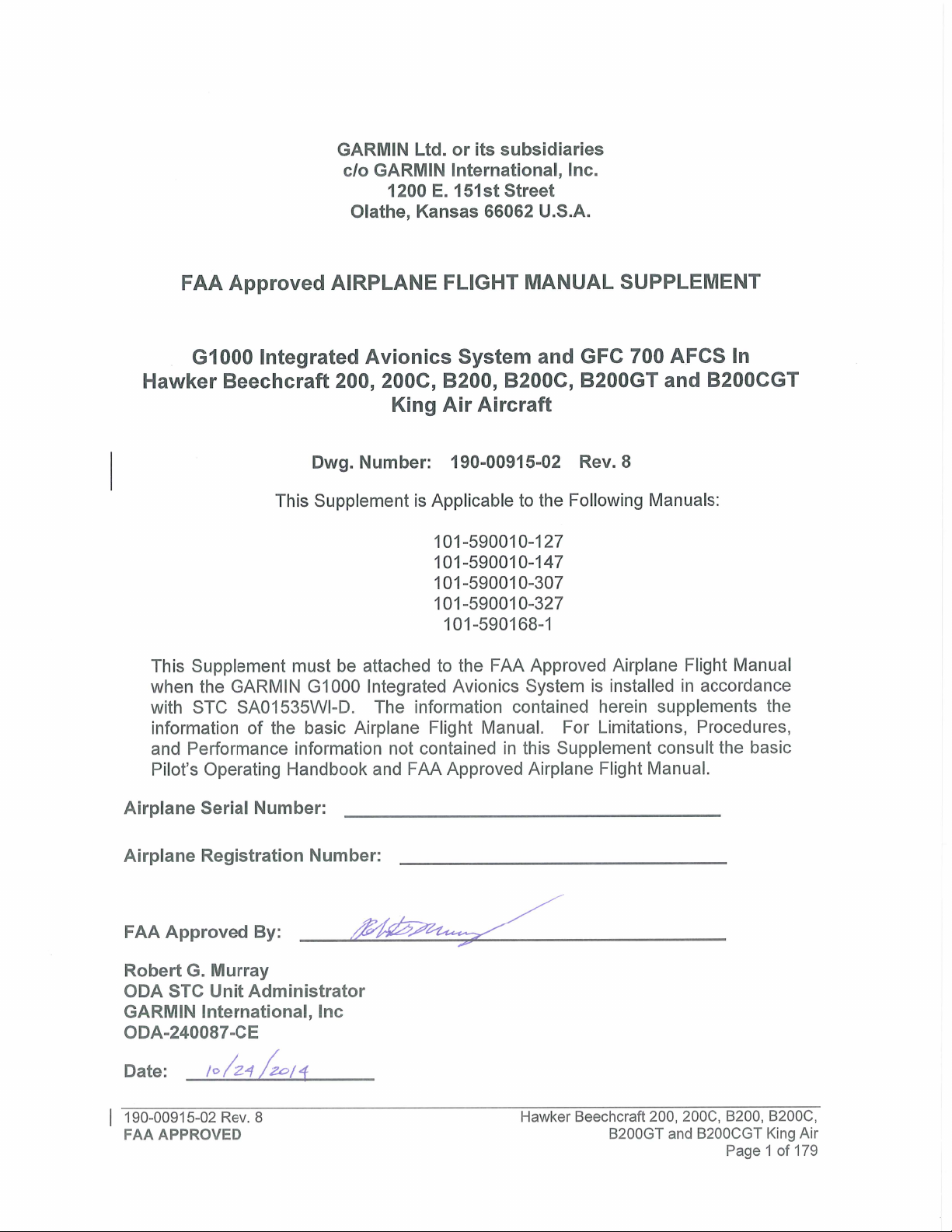

Log of Revisions

Pilot’s Operating Handbook and FAA Approved Airplane Flight Manual

Supplement for

G1000 Integrated Avionics System and GFC 700 AFCS In Hawker Beechcraft 200,

200C, B200 and B200C King Air Aircraft

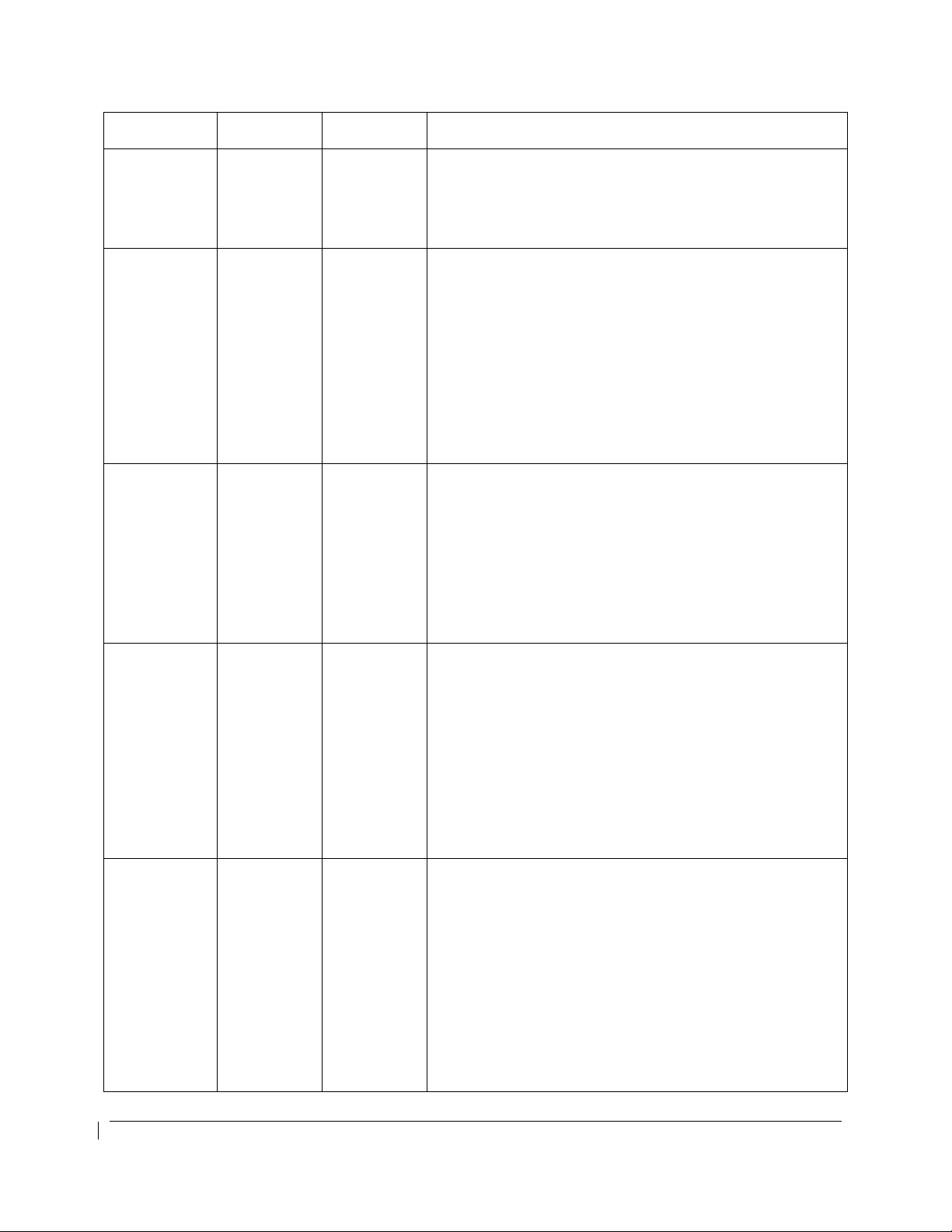

REV

NO.

PAGE

NO(S)

DESCRIPTION

DATE OF

APPROVAL

1 ALL Original Issue 3/14/2009

2 ALL Change 0985.00 to 0985.01 4/7/2009

3 ALL

4 ALL

Incorporate G1000 enhancement

and Class A TAWS information

Incorporate system software

0985.03 from 0985.02

12/14/2009

11/23/2010

Incorporate system software

5 ALL

0985.04 from 0985.03,

05/11/2012

miscellaneous editorial changes

FAA APPROVED

Robert G. Murray,

Lead DAS Administrator

GARMIN International, Inc.

DAS-240087-CE

Robert G. Murray,

ODA STC Unit

Administrator

GARMIN International, Inc.

ODA-240087-CE

Robert G. Murray,

ODA STC Unit

Administrator

GARMIN International, Inc.

ODA-240087-CE

Robert G. Murray,

ODA STC Unit

Administrator

GARMIN International, Inc.

ODA-240087-CE

Robert G. Murray,

ODA STC Unit

Administrator

GARMIN International, Inc.

ODA-240087-CE

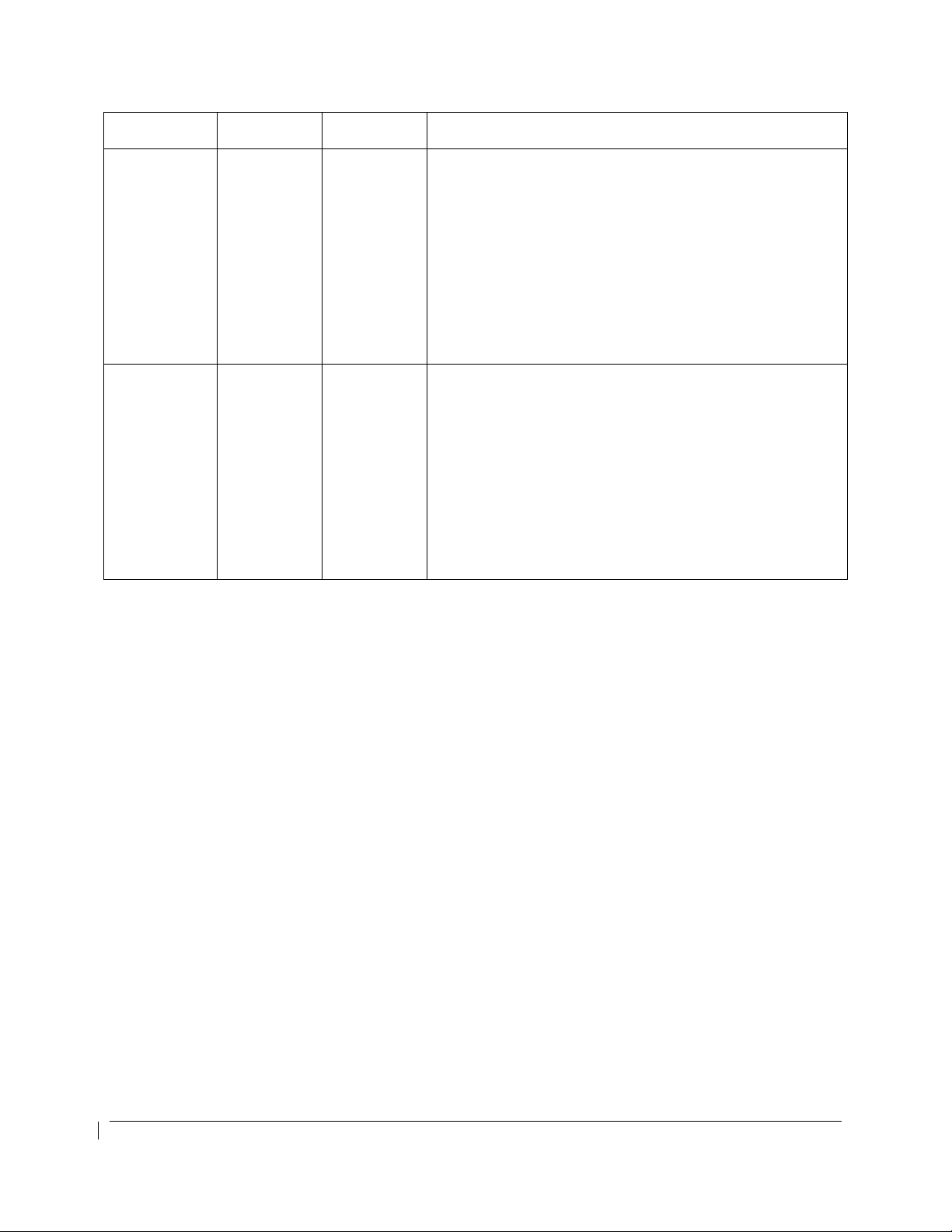

Incorporate system software

0985.06, revised AHRS areas of

operation, added a VNAV

6 ALL

limitation, revised system

temperature limitations, revised

TAWS database coverage areas,

11/16/2012

Robert G. Murray,

ODA STC Unit

Administrator

GARMIN International, Inc.

ODA-240087-CE

miscellaneous editorial

corrections, repaginated

Incorporate system software

7 ALL

0985.07, revised AHRS areas of

operation to account for GRS

7800 installations

2/28/2014

Robert G. Murray,

ODA STC Unit

Administrator

GARMIN International, Inc.

ODA-240087-CE

190-00915-02 Rev. 8 Hawker Beechcraft 200, 200C, B200, B200C,

FAA APPROVED B200GT and B200CGT King Air

Page 3 of 179

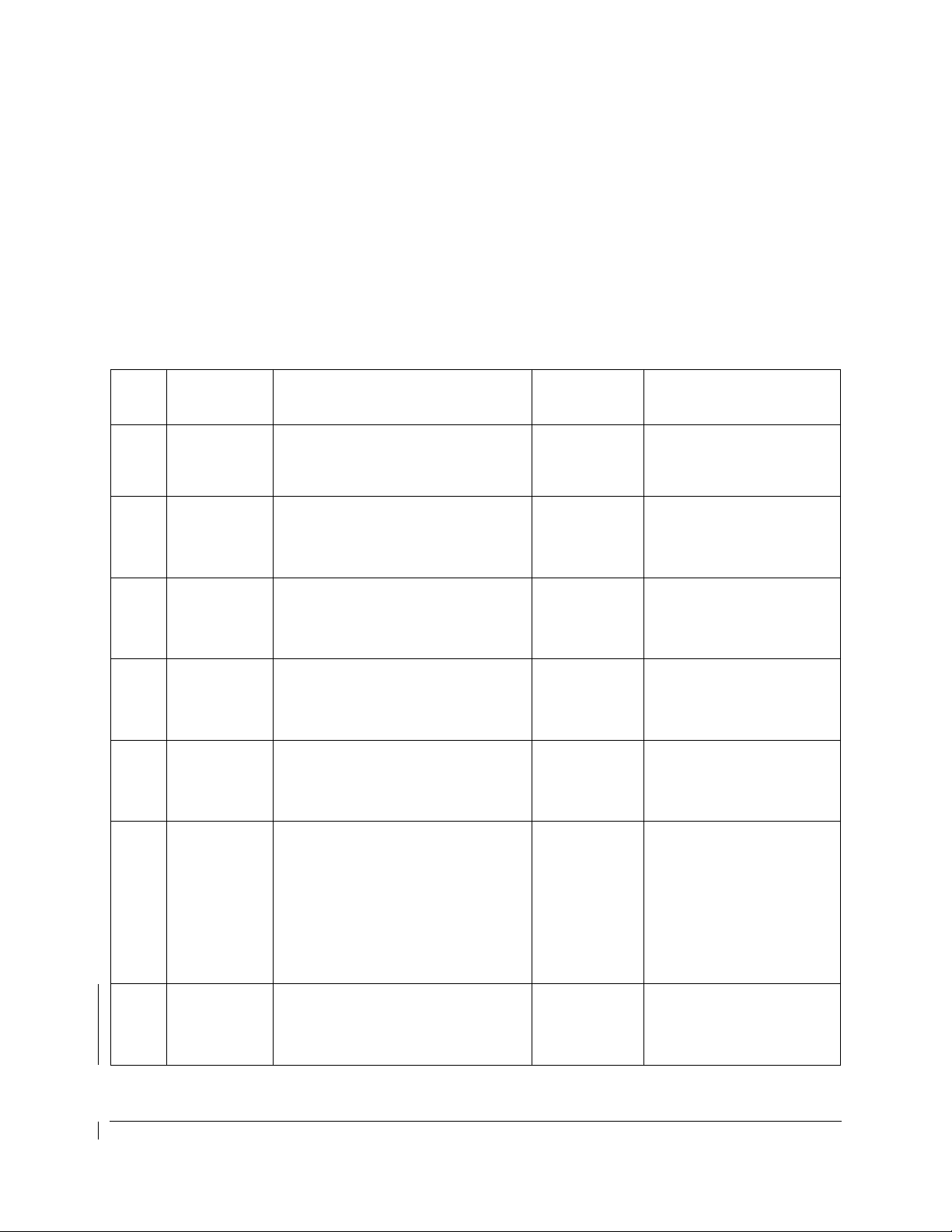

Log of Revisions

(Continued)

REV

NO.

8 ALL

PAGE

NO(S)

DESCRIPTION

Revised GRS 7800 AHRS areas

of operation

DATE OF

APPROVAL

See Cover See Cover

FAA APPROVED

Hawker Beechcraft 200, 200C, B200, B200C, 190-00915-02 Rev. 8

B200GT and B200CGT King Air

Page 4 of 179

Table of Contents

Section 1 - General ........................................................................................................ 7

Section 2 - Limitations ................................................................................................ 19

Section 3 - Emergency Procedures ........................................................................... 38

Section 3A - Abnormal Procedures ........................................................................... 53

Section 4 - Normal Procedures .................................................................................. 85

Section 5 – Performance .......................................................................................... 113

Section 6 - Weight and Balance ............................................................................... 115

Section 7 - Systems Description .............................................................................. 117

Section 8 – Handling, Service, and Maintenance ................................................... 169

190-00915-02 Rev. 8 Hawker Beechcraft 200, 200C, B200, B200C,

FAA APPROVED B200GT and B200CGT King Air

Page 5 of 179

This page intentionally left blank.

Hawker Beechcraft 200, 200C, B200, B200C, 190-00915-02 Rev. 8

B200GT and B200CGT King Air FAA APPROVED

Page 6 of 179

Section 1 - General

The information in this supplement is FAA-approved material and must be attached to the Pilot’s Operating

Handbook and FAA Approved Airplane Flight Manual (POH/AFM) when the airplane has been modified by

installation of the GARMIN G1000 Integrated Avionics System and GFC 700 Digital Automatic Flight

Guidance System in accordance with GARMIN International, Inc. approved data.

The information in this supplement supersedes or adds to the basic POH/AFM only as set forth below.

Users of the manual are advised to always refer to the supplement for possibly superseding information

and placarding applicable to operation of the airplane.

The GARMIN G1000 system installed in the Hawker Beechcraft 200, 200C, B200 and B200C King Air

Aircraft provides a fully integrated Display, Communications, Navigation and Flight Control system.

Functions provided by the G1000 system include: Primary Flight Information, Powerplant Monitoring,

Navigation, Communication, Traffic Surveillance, TAWS Class A or B, Weather Avoidance, and a

three-axis automatic flight control / flight director system with optional Electronic Stability & Protection.

Use of this supplement requires Garmin G1000 system software version 0985.07 or later to be installed in

the aircraft. Pilots are advised to carefully review the contents of this revision before operating the

airplane.

USE OF THE HANDBOOK

The following definitions apply to WARNINGS, CAUTIONS and NOTES found throughout the handbook:

WARNING

Operating procedures, techniques, etc., which could result in personal injury or loss of life if not

carefully followed.

CAUTION

Operating procedures, techniques, etc., which could result in damage to equipment if not

carefully followed.

NOTE

Operating procedures, techniques, etc., which is considered essential to emphasize.

190-00915-02 Rev. 8 Hawker Beechcraft 200, 200C, B200, B200C,

FAA APPROVED B200GT and B200CGT King Air

Page 7 of 179

OPERATIONAL APPROVALS

G1000 GNSS (GPS/SBAS) NAVIGATION SYSTEM EQUIPMENT

APPROVALS

The Garmin G1000 Integrated Avionics GNSS navigation system installed in this airplane is a GPS system

with a Satellite Based Augmentation System (SBAS) comprised of two TSO-C145a Class 3 approved

Garmin GIA 63Ws, TSO-C146a Class 3 approved Garmin GDU 104X and GDU 1500 Display Units,

GARMIN GA36 and GA37 antennas, and GPS software version 3.2 or later approved version. The

G1000 GNSS navigation system in this airplane is installed in accordance with AC 20-138C.

The Garmin G1000 Integrated Avionics GNSS navigation system as installed in this airplane complies with

the requirements of AC 20-138C and is approved for navigation using GPS and GPS/SBAS (within the

coverage of a Satellite Based Augmentation System signals complying with ICAO Annex 10) for IFR en

route, terminal area, non-precision approach, and approach procedures with vertical guidance operations.

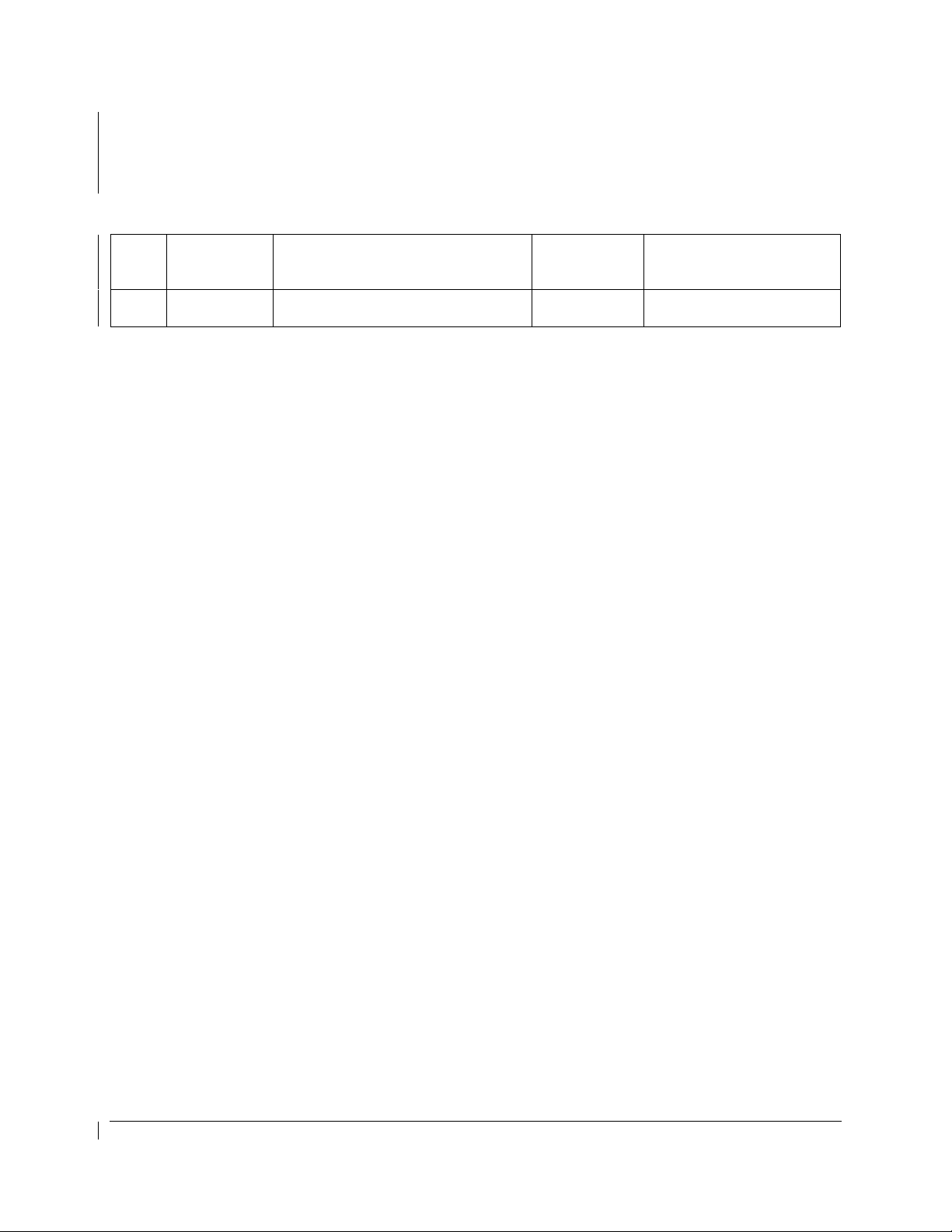

The Garmin G1000 Integrated Avionics GNSS navigation system as installed in this airplane complies with

the equipment, performance, and functional requirements to conduct RNAV and RNP operations in

accordance with the following table:

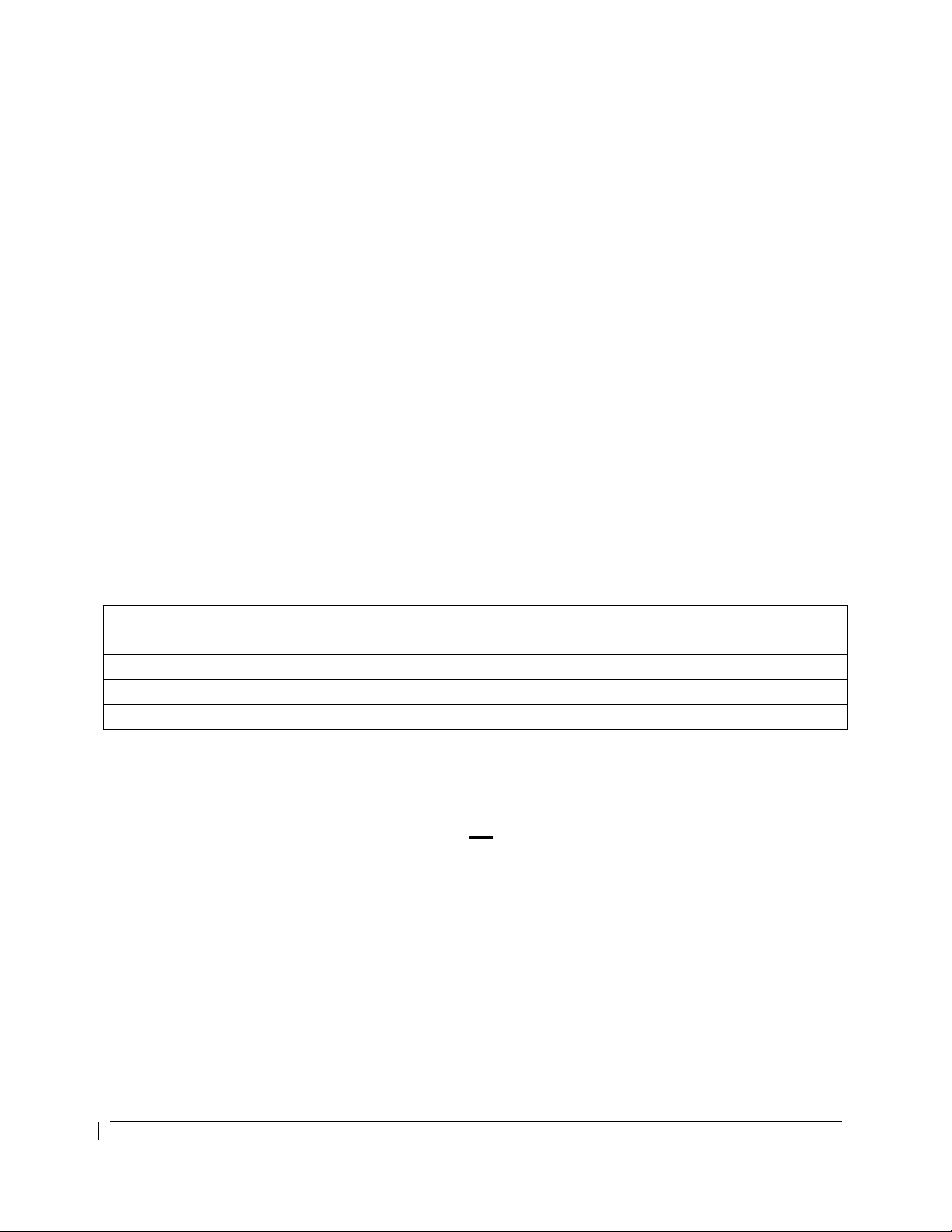

Specification

RNAV 10

(RNP 10)

(Oceanic)

B-RNAV/

RNAV 5

(Europe)

RNAV 2

RNAV 1

Reference

Documents

FAA Order

8400.12C

FAA AC

90-96A

CHG 1,

EASA AMC

20-4

FAA AC

90-100A

FAA AC

90-100A

ICAO Flight

Plan Code

GPS Class II navigation in oceanic and remote navigation

without reliance on other long-range navigation systems

when used in conjunction with the G1000 WFDE Prediction

program, part number 006-A0154-01 (010-G1000-00) or

A1

B2 This does not constitute an operational approval.

C2

D2

later approved version.

This does not constitute an operational approval. Part 91,

Part 91 subpart K, 121, 125, and 135 operators require

operational approval.

Includes RNAV Q and T routes.

In accordance with AC 90-100A, Part 91 operators (except

subpart K) following the aircraft and training guidance in

AC 90-100A are authorized to fly RNAV 2 and RNAV 1

procedures. Part 91 subpart K, 121, 125, 129, and 135

operators require operational approval.

Includes RNAV terminal departure and arrival procedures.

In accordance with AC 90-100A, Part 91 operators (except

subpart K) following the aircraft and training guidance in

AC 90-100A are authorized to fly RNAV 2 and RNAV 1

procedures. Part 91 subpart K, 121, 125, 129, and 135

operators require operational approval.

Notes

Hawker Beechcraft 200, 200C, B200, B200C, 190-00915-02 Rev. 8

B200GT and B200CGT King Air FAA APPROVED

Page 8 of 179

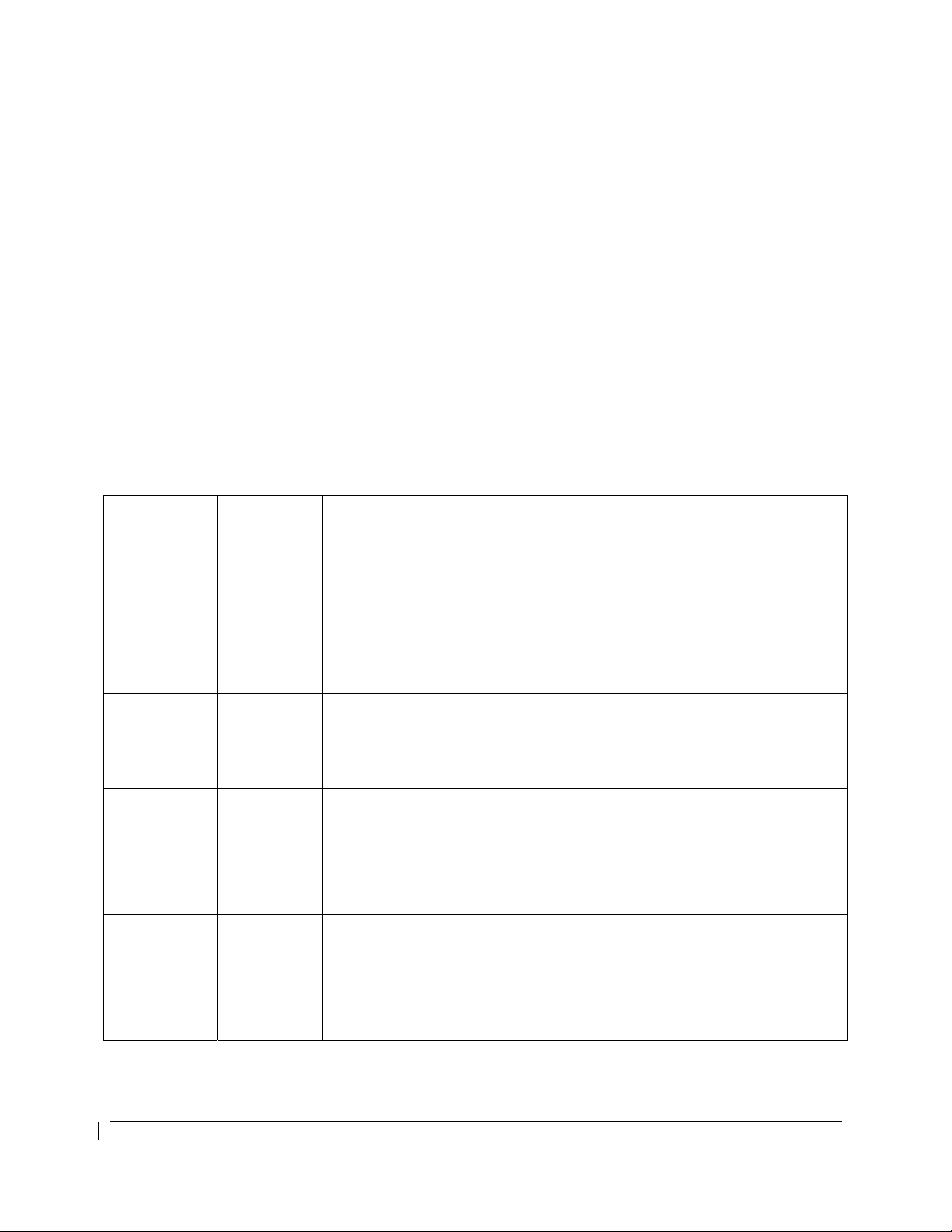

Specification

P-RNAV

(Europe)

RNP 4

(Oceanic)

RNP 1

RNP APCH

LNAV minima

RNP APCH

LNAV/VNAV

minima

Reference

Documents

FAA AC

90-96A

CHG 1,

JAA TGL 10

Rev 1

FAA Order

8400.33

FAA AC

90-105

FAA AC

90-105,

EASA AMC

20-27

FAA AC

90-105,

EASA AMC

20-27 with

CM-AS-002

ICAO Flight

Plan Code

Notes

D2 This does not constitute an operational approval.

Primary means of Class II navigation in oceanic and

remote navigation without reliance on other long-range

navigation systems when used in conjunction with the

G1000 WFDE Prediction program, part number

006-A0154-01 (010-G1000-00) or later approved version.

L1

Additional equipment may be required to obtain operational

approval to utilize RNP-4 performance.

This does not constitute an operational approval. Part 91,

Part 91 subpart K, 121, 125, and 135 operators require

operational approval.

Includes RNP terminal departure and arrival procedures.

For airplanes that have system software 0985.07 or later

installed, this includes procedures with RF (radius to fix)

legs.

O2

In accordance with AC 90-105, Part 91 operators (except

subpart K) following the aircraft and training guidance in

AC 90-105 are authorized to fly RNP 1 procedures. Part

91 subpart K, 121, 125, 129, and 135 operators require

operational approval.

Includes non-precision approaches based on conventional

navigation aids with “or GPS” in the title and area

navigation approaches titled “GPS”, “RNAV(GPS)”, and

“RNAV(GNSS)”. For airplanes with system software

0985.07 or later installed, this includes procedures with RF

S1

(radius to fix) legs.

In accordance with AC 90-105, Part 91 operators (except

subpart K) following the aircraft and training guidance in

AC 90-105 are authorized to fly RNP APCH LNAV minima

procedures. Part 91 subpart K, 121, 125, 129, and 135

operators require operational approval.

Includes area navigation approaches titled “RNAV(GPS)”

and “RNAV(GNSS).” For airplanes with system software

0985.07 or later installed, this includes procedures with RF

(radius to fix) legs. Vertical guidance is based on

GPS/SBAS when within SBAS coverage and by baro

VNAV (system software 0985.07 or later) when outside

S2

SBAS coverage.

In accordance with AC 90-105, Part 91 operators (except

subpart K) following the aircraft and training guidance in

AC 90-105 are authorized to fly RNP APCH LNAV/VNAV

minima procedures. Part 91 subpart K, 121, 125, 129,

and 135 operators require operational approval.

190-00915-02 Rev. 8 Hawker Beechcraft 200, 200C, B200, B200C,

FAA APPROVED B200GT and B200CGT King Air

Page 9 of 179

Specification

RNP APCH

LP minima

RNP APCH

LPV minima

Garmin International holds an FAA Type 2 Letter of Acceptance (LOA) in accordance with AC 20-153 for

database integrity, quality, and database management practices for the Navigation database. Flight

crews and operators can view the LOA status at FlyGarmin.com then select” Type 2 LOA Status”.

Reference

Documents

FAA AC

90-107

FAA AC

90-107,

EASA AMC

20-28

ICAO Flight

Plan Code

N/A

N/A

Notes

For airplanes with system software 0985.07 or later

installed, this includes area navigation approaches titled

“RNAV(GPS)” and “RNAV(GNSS)” including procedures

with RF legs. LP minima are available only when within

SBAS coverage.

In accordance with AC 90-107, Part 91 operators (except

subpart K) following the operational considerations and

training guidance in AC 90-107 are authorized to fly RNP

APCH LP minima procedures. Part 91 subpart K, 121,

125, 133, 135, and 137 operators require operational

approval.

Includes area navigation approaches titled “RNAV(GPS)”

and “RNAV(GNSS).” For airplanes with system software

0985.07 or later installed, this includes procedures with RF

(radius to fix) legs. LPV minima are available only when

within SBAS coverage.

In accordance with AC 90-107, Part 91 operators (except

subpart K) following the operational considerations and

training guidance in AC 90-107 are authorized to fly RNP

APCH LPV minima procedures. Part 91 subpart K, 121,

125, 133, 135, and 137 operators require operational

approval.

Navigation information is referenced to the WGS-84 reference system.

Hawker Beechcraft 200, 200C, B200, B200C, 190-00915-02 Rev. 8

B200GT and B200CGT King Air FAA APPROVED

Page 10 of 179

ELECTRONIC FLIGHT BAG

The G1000 Integrated Avionics System as installed in this aircraft supports approval of AC 120-76A

Hardware Class 3, Software Type B Electronic Flight Bag (EFB) electronic aeronautical chart applications

when using current FliteChart or ChartView data. Additional operational approvals may be required.

Garmin International holds an FAA Type 2 Letter of Acceptance (LOA) in accordance with AC 20-153 for

database integrity, quality, and database management practices for the FliteChart database. Flight crews

and operators can view the LOA status by selecting the Type 2 LOA status quick link at

www.FlyGarmin.com.

For operations under 14 CFR Part 91, it is suggested that a secondary or back up source of aeronautical

information necessary for the flight be available to the pilot in the airplane. The secondary or backup

information may be either traditional paper-based material or displayed electronically. If the source of

aeronautical information is in electronic format, operators must determine non-interference with the G1000

system and existing aircraft systems for all flight phases.

REDUCED VERTICAL SEPARATION MINIMUMS (RVSM)

This airplane is approved as a group aircraft for operations in Reduced Vertical Separation Minimum

(RVSM) airspace when required equipment is maintained with the Hawker Beechcraft Super King Air 200

Series Maintenance Manual and Garmin’s G1000/GFC 700 System Maintenance Manual for the Hawker

Beechcraft Model 200/B200 Series King Air.

This does not constitute operational approval. Operational approval must be obtained in accordance with

the applicable operating rules.

190-00915-02 Rev. 8 Hawker Beechcraft 200, 200C, B200, B200C,

FAA APPROVED B200GT and B200CGT King Air

Page 11 of 179

ABBREVIATIONS AND TERMINOLOGY

The following glossary is applicable within the airplane flight manual supplement

AC Advisory Circular

ADC Air Data Computer

ADF Automatic Direction Finder

AFCS Automatic Flight Control System

AFM Airplane Flight Manual

AFMS Airplane Flight Manual Supplement

AGL Above Ground Level

Ah Amp hour

AHRS Attitude and Heading Reference System

ALT Altitude, or AFCS altitude hold mode, or ALT button on the GMC 710 AFCS

Mode Controller

ALTS AFCS altitude capture using the altitude in the altitude preselect window

ALTV AFCS altitude capture using the altitude from the VNAV profile vertical

constraint

AMMD Airport Moving Map Display

AP Autopilot

APR AFCS Approach mode, or APR button of GMC 710 AFCS mode controller

APTSIGNS Airport Signs (SVS softkey on the PFD)

APV Approach with Vertical Guidance

ATC Air Traffic Control

AUX Auxiliary

BANK Low-bank mode of the AFCS

BARO Barometric Setting

BAT Battery

BC Back Course

BRNAV Basic Area Navigation

BRT Bright

CB Circuit Breaker

CDI Course Deviation Indicator

CFR Code of Federal Regulations

CLR Clear

COM Communication radio

CRG Cockpit Reference Guide

CRS Course

Hawker Beechcraft 200, 200C, B200, B200C, 190-00915-02 Rev. 8

B200GT and B200CGT King Air FAA APPROVED

Page 12 of 179

CWS Control Wheel Steering

DA Decision Altitude

DC Direct Current

DG Directional Gyro

DH Decision Height

DL LTNG Connext Data Link Lightning

DME Distance Measuring Equipment

DN Down

DR Dead Reckoning

EC Error Correction

EFB Electronic Flight Bag

EIS Engine Indication System

ELEC Electrical

ENT Enter

ESP Electronic Stability and Protection

FAF Final Approach Fix

FD Flight Director

FLC AFCS Flight Level Change mode, or FLC button on the GMC 710 AFCS mode

controller

FLTA Forward Looking Terrain Awareness

FMS Flight Management System

FPM Flight Path Marker or Feet Per Minute

FSB Fasten Seat Belts

FSD Full Scale Deflection

ft Feet

ft-lbs Foot-Pounds

ft/min Feet/Minute

GA Go-around

GCU Garmin Control Unit

GDC Garmin Air Data Computer

GDL Garmin Data Link Radio

GDU Garmin Display Unit

GEA Garmin Engine/Airframe Unit

GEN Generator

GEO Geographic

GFC Garmin Flight Control

GIA Garmin Integrated Avionics Unit

190-00915-02 Rev. 8 Hawker Beechcraft 200, 200C, B200, B200C,

FAA APPROVED B200GT and B200CGT King Air

Page 13 of 179

GMA Garmin Audio Panel System

GMC Garmin Mode Control Unit

GP GPS Glide Path

GPS Global Positioning System

GPWS Ground Proximity Warning System

GRS Garmin Reference System (AHRS)

GS Glide Slope

GSR Garmin Iridium Satellite Radio

GTS Garmin Traffic System

GWX Garmin Weather Radar

HDG AFCS heading mode or the HDG button on the GMC 710 AFCS Mode

Controller

HITS Highway in the Sky

HPa Hectopascal

HSI Horizontal Situation Indicator

IAF Initial Approach Fix

IAP Instrument Approach Procedure

IAS Indicated Airspeed

ICAO International Civil Aviation Organization

IFR Instrument Flight Rules

ILS Instrument Landing System

IMC Instrument Meteorological Conditions

in-Hg inches of mercury

INH Inhibit

ITT Interstage Turbine Temperature

KIAS Knots Indicated Air Speed

Kt(s) Knot(s)

LCD Liquid Crystal Display

LDA Localizer Type Directional Aid

LNAV Lateral Navigation

LNAV + V Lateral Navigation with Advisory Vertical Guidance

LNAV/VNAV Lateral Navigation / Vertical Navigation

LOA Letter of Acceptance

LOC Localizer

LOI Loss of Integrity (GPS)

LP Localizer Performance

LPV Localizer Performance with Vertical Guidance

Hawker Beechcraft 200, 200C, B200, B200C, 190-00915-02 Rev. 8

B200GT and B200CGT King Air FAA APPROVED

Page 14 of 179

LRU Line Replaceable Unit

LTNG Lightning (XM Weather Product)

M Mach

MAP Missed Approach Point

MAXSPD Maximum Speed, AFCS Overspeed Protection mode

Mb Millibars

MDA barometric minimum descent altitude

MEL Minimum Equipment List

MFD Multi Function Display

MLS Microwave Landing System

M

Maximum operation limit speed in mach

MO

MINSPD Minimum Speed, AFCS Underspeed Protection mode

MNPS Minimum Navigational Performance Specifications

MSL Mean Sea Level

NAT North Atlantic Track

NAV Navigation, or AFCS navigation mode, or NAV button on the GMC710 AFCS

Mode Controller

NEXRAD Next Generation Radar (XM Weather Product)

NM Nautical Mile

NPA Non-precision Approaches

OAT Outside Air Temperature

OBS Omni Bearing Selector

ODP Obstacle Departure Procedure

OVR Override

P/N Part Number

PDA Premature Descent Alert

PFD Primary Flight Display

PFT Pre-Flight Test

PIT AFCS pitch mode

POH Pilot’s Operating Handbook

PRNAV Precision Area Navigation

PROC Procedure button on the GDU or GCU 477

PSI Pounds per Square Inch

PTCH Pitch

PWR Power

RA Radar Altimeter, or Radar Altitude, or TCAS II Resolution Advisory

RF Radius-to-Fix

190-00915-02 Rev. 8 Hawker Beechcraft 200, 200C, B200, B200C,

FAA APPROVED B200GT and B200CGT King Air

Page 15 of 179

RNAV Area Navigation

RNP Required Navigation Performance

ROL AFCS roll mode

RPM Revolutions per Minute

RVSM Reduced Vertical Separation Minimums

SBAS Satellite Based Augmentation System

SDF Simplified Directional Facility

SID Standard Instrument Departure

SPD Speed button on the GMC 710 AFCS Mode Controller. Toggles the FLC

speed between Mach and IAS references.

STAR Standard Terminal Arrival Route

STBY Standby

STC Supplemental Type Certificate

STD Standard

SUSP Suspend

SVS Synthetic Vision System

SW Software

SYN TERR Synthetic Terrain softkey

SYN VIS Synthetic Vision softkey

TA Traffic Advisory

TAWS Terrain Awareness and Warning System

TCAS Traffic Collision Avoidance System

TEMP Temperature

TIS Traffic Information System

TMR Timer

TO Take off

TOD Top of Descent

TSO Technical Standard Order

VAPP AFCS VOR Approach Mode

VCO Voice Call Out

Vdc Volts DC

VDI Vertical Deviation Indicator

VDP Visual Descent Point

VFR Visual Flight Rules

VHF Very High Frequency

VMC Visual Meteorological Conditions

VMI Vibro-meter Inc.

Hawker Beechcraft 200, 200C, B200, B200C, 190-00915-02 Rev. 8

B200GT and B200CGT King Air FAA APPROVED

Page 16 of 179

V

MO

Maximum operation limit speed in knots

VNAV Vertical Navigation

VNV Vertical Navigation button on the GMC 710 AFCS Mode Controller

VOR VHF Omni-directional Range

VPTH Vertical path

VS Vertical Speed

WAAS Wide Area Augmentation System

WFDE WAAS Fault Detection/Exclusion

WGS-84 World Geodetic System – 1984

WSHLD Windshield

XFR Transfer button on the GMC 710 AFCS Mode Controller

XM XM satellite system

XPDR Transponder

YD Yaw Damper

190-00915-02 Rev. 8 Hawker Beechcraft 200, 200C, B200, B200C,

FAA APPROVED B200GT and B200CGT King Air

Page 17 of 179

This page intentionally left blank.

Hawker Beechcraft 200, 200C, B200, B200C, 190-00915-02 Rev. 8

B200GT and B200CGT King Air FAA APPROVED

Page 18 of 179

Section 2 - Limitations

INTRODUCTION

The G1000 Cockpit Reference Guide for Hawker Beechcraft 200, 200C, B200 and B200C (CRG) must be

immediately available to the flight crew during all phases of flight. Use the G1000 Cockpit Reference

Guide for Hawker Beechcraft 200/B200 Series, GARMIN part number 190-00929-03, Revision A or later

revision when system software 0985.07 is installed.

The System Software Version number is displayed at the top right side of the MFD Power-up page.

AIRSPEED LIMITATIONS AND INDICATOR MARKINGS

No changes were made to the airplane’s airspeed limitations. The airspeed indicators on the Primary

Flight Displays (PFDs) and the standby airspeed indicator are marked in accordance with the airplane’s

POH/AFM.

A red low speed awareness band is marked on the PFDs in red from 20 – 75 KIAS. The low-speed

awareness band is suppressed while the airplane is on the ground. The low-speed awareness band

appears in flight two seconds after main gear liftoff.

The standby airspeed indicator is marked in accordance with the airspeed markings called out in the

airplane’s AFM/POH. The standby airspeed indicator is not marked with a low speed awareness band.

190-00915-02 Rev. 8 Hawker Beechcraft 200, 200C, B200, B200C,

FAA APPROVED B200GT and B200CGT King Air

Page 19 of 179

POWER PLANT LIMITATIONS AND INDICATOR MARKINGS

No changes were made to the airplane’s engine operating limits. The engine gauges are marked as

shown in the following tables. Refer to the latest Airplane Flight Manual or appropriate Airplane Flight

Manual Supplement for engine and propeller limitations.

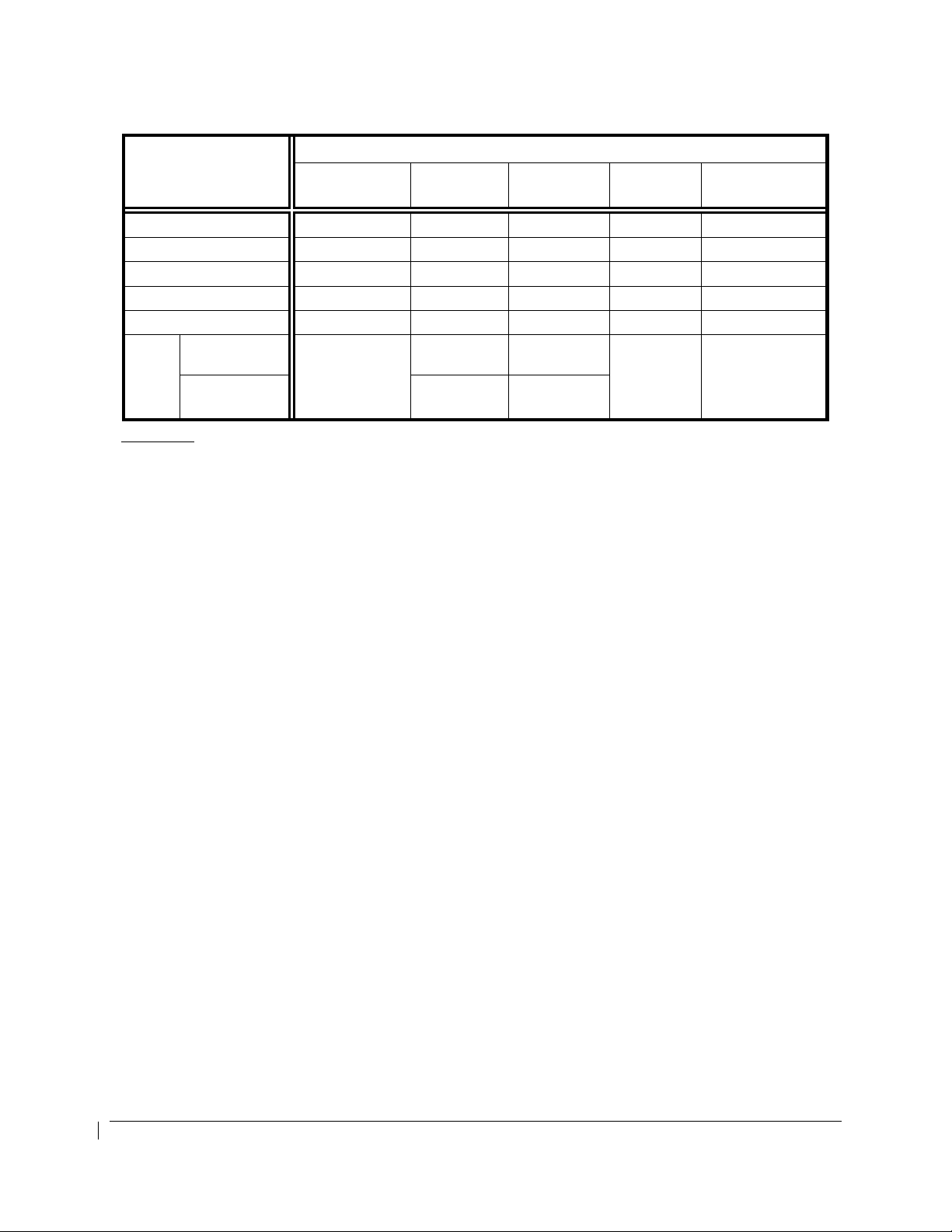

OPERATING

PARAMETER

Torque (ft-lbs) -- -- 0 to 2230 -- 2230 (1)

ITT (ºC) -- -- 400 to 750 -- 750 (2)

Prop N2 (rpm) -- -- (3) -- (3)

Gas Generator N1 (%) -- -- 52 to 101.5 -- 101.5 (4)

Oil Temp. (ºC) -40 (5) -40 to +10 (5) 10 to 99 (5) 99 to 104 (5) 99 (5)

Oil

Press.

(psi)

Less than

21,000’ MSL.

21,000’ MSL

and above

Red Arc/Radial

(Minimum Limit)

PT6A-41 ENGINES COLOR MARKINGS & RANGES

Yellow Arc

(Caution)

60 to 105 105 to 135

60

60 to 85 85 to 135

Green Arc

(Normal)

Yellow Arc

(Caution)

-- 135 (6)(7)

Red Arc/Radial

(Maximum

Limit)

Footnotes:

(1) The maximum transient torque value is 2750 ft-lb for up to 5 seconds. Within this transient

value, the torque indicator will display green digits and a white pointer. After 5 seconds, the digits

will flash alternating red and white background with a flashing red pointer for 5 seconds. After 5

seconds of flashing, the indication is steady white digits/red background and the pointer is red.

Above 2750 FT-LB, the indication immediately begins flashing for 5 seconds before displaying

steady white digits on a red background and a red pointer.

(2) A red diamond at 1000°C represents the upper transient limit for engine Starting Mode. Normally,

the ITT indicator will display green digits and a white pointer. Above 800°C, or when between

750°C and 800°C for more than 5 seconds, (or above 1000°C for more than 5 seconds in Starting

Mode), the digital indication will flash alternating red and white background with a flashing red

pointer for 5 seconds. After 5 seconds of flashing, the indication is steady white digits/red

background and the pointer is red.

(3) See PROPELLER TYPES AND INDICATOR MARKINGS table.

(4) The maximum transient N1 value is 102.6% for up to 10 seconds. Within this transient value, the

N1 indicator will display green digits and a white pointer. When between 101.5% and 102.6% for

more than 10 seconds, or when above 102.6%, the digital indication will flash alternating red and

white background with a flashing red pointer for 5 seconds. After 5 seconds of flashing, the

indication is steady white digits/red background and the pointer is red.

(5) Above 104°C, or between 99°C and 104°C for more than 5 minutes, the digital indication will flash

alternating red and white background with a flashing red pointer for 5 seconds. After 5 seconds

of flashing, the indication is steady white digits/red background and the pointer is red. Below 0°C

to -40°C, the digital indication will be black digits on a yellow background. Below -40°C, the

digital indication will be white digits on a red background.

(6) Above 135 PSI, or below 60 PSI and decreasing oil pressure, the digital indication will flash

alternating red and white background with a flashing red pointer for 5 seconds. After 5 seconds

of flashing, the indication is steady white digits/red background and the pointer is red.

(7) A red diamond at 200 psi represents the upper transient limit.

Hawker Beechcraft 200, 200C, B200, B200C, 190-00915-02 Rev. 8

B200GT and B200CGT King Air FAA APPROVED

Page 20 of 179

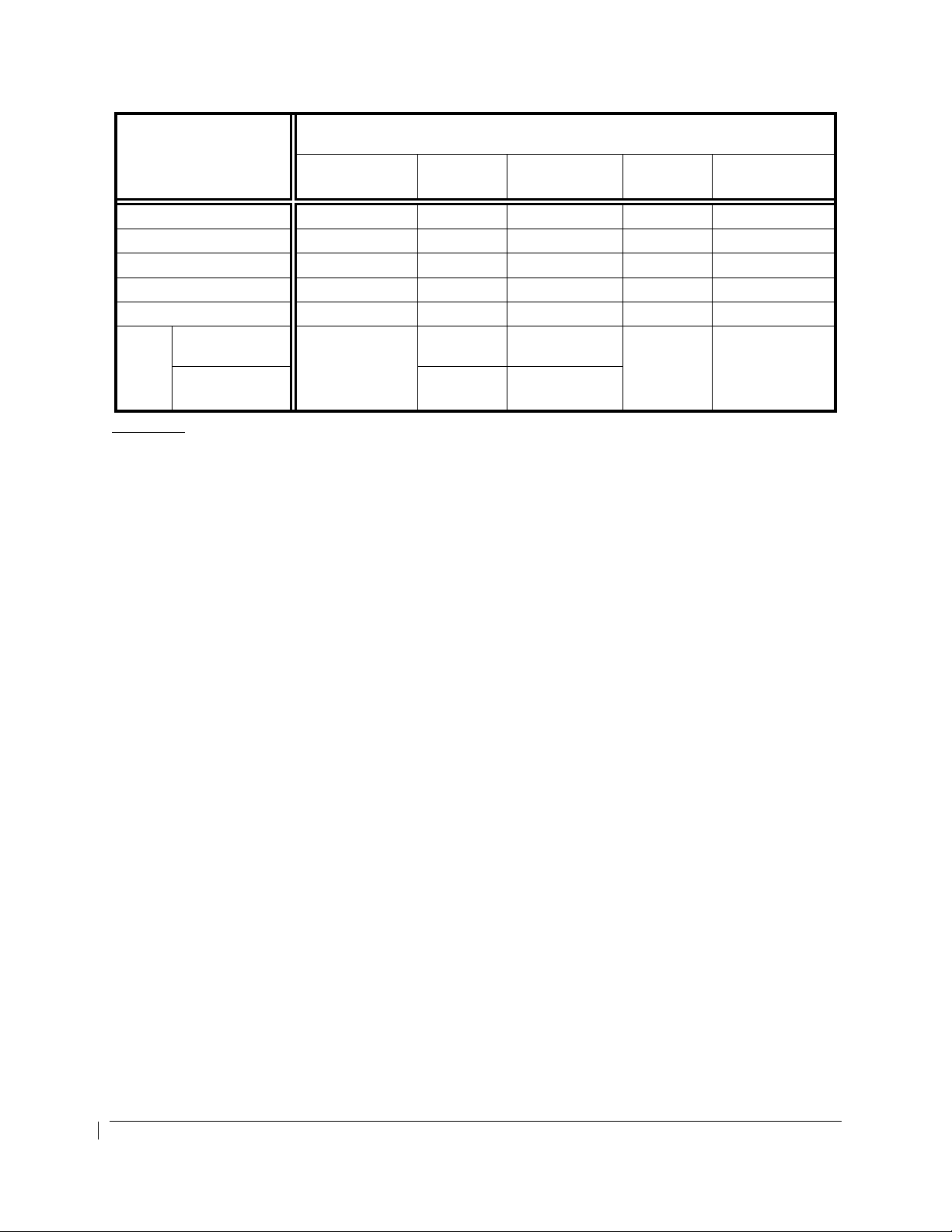

OPERATING

PARAMETER

Torque (ft-lbs) -- -- 0 to 2230 -- 2230 (1)

ITT (ºC) -- -- 400 to 800 -- 800 (2)

Prop N2 (rpm) -- -- (3) -- (3)

Gas Generator N1 (%) -- -- 61 to 101.5 -- 101.5 (4)

Oil Temp. (ºC) -40 (5) -40 to 0 (5) 0 to 99 (5) 99 to 104 99 (5)

Oil

Press.

(psi)

Less than

21,000’ MSL.

21,000’ MSL

and above

Red Arc/Radial

(Minimum Limit)

PT6A-42 ENGINES COLOR MARKINGS & RANGES

Yellow Arc

(Caution)

60 to 100 100 to 135

60

60 to 85 85 to 135

Green Arc

(Normal)

Yellow Arc

(Caution)

-- 135 (6)(7)

Red Arc/Radial

(Maximum Limit)

Footnotes:

(1) The maximum transient torque value is 2750 ft-lb for up to 5 seconds. Within this transient

value, the torque indicator will display green digits and a white pointer. After 5 seconds, the digits

will flash alternating red and white background with a flashing red pointer for 5 seconds. After 5

seconds of flashing, the indication is steady white digits/red background and the pointer is red.

Above 2750 FT-LB, the indication immediately begins flashing for 5 seconds before displaying

steady white digits on a red background and a red pointer.

(2) A red diamond at 1000°C represents the upper transient limit for engine Starting Mode. The

lower Normal Mode transient limit is 850°C. Within this transient value, the ITT indicator will

display green digits and a white pointer. After 20 seconds between 800

°

C and 850°C (or above

1000°C for more than 5 seconds in Starting Mode), the digital indication will flash alternating red

and white background with a flashing red pointer for 5 seconds. After 5 seconds of flashing, the

indication is steady white digits/red background and the pointer is red. In Normal Mode while

above 850

°

C, the indication immediately begins flashing for 5 seconds before displaying steady

white digits on a red background and a red pointer.

(3) See PROPELLER TYPES AND INDICATOR MARKINGS table.

(4) The maximum transient N1 value is 102.6% for up to 10 seconds. Within this transient value, the

N1 indicator will display green digits and a white pointer. When between 101.5% and 102.6% for

more than 10 seconds, or when above 102.6%, the digital indication will flash alternating red and

white background with a flashing red pointer for 5 seconds. After 5 seconds of flashing, the

indication is steady white digits/red background and the pointer is red.

(5) Above 104°C, or between 99°C and 104°C for more than 10 minutes, the digital indication will

flash alternating red and white background with a flashing red pointer for 5 seconds. After 5

seconds of flashing, the indication is steady white digits/red background and the pointer is red.

Below 0°C to -40°C, the digital indication will be black digits on a yellow background. Below

-40°C, the digital indication will be white digits on a red background.

(6) Above 135 PSI, or below 60 PSI and decreasing oil pressure, the digital indication will flash

alternating red and white background with a flashing red pointer for 5 seconds. After 5 seconds

of flashing, the indication is steady white digits/red background and the pointer is red.

(7) A red diamond at 200 psi represents the upper transient limit.

190-00915-02 Rev. 8 Hawker Beechcraft 200, 200C, B200, B200C,

FAA APPROVED B200GT and B200CGT King Air

Page 21 of 179

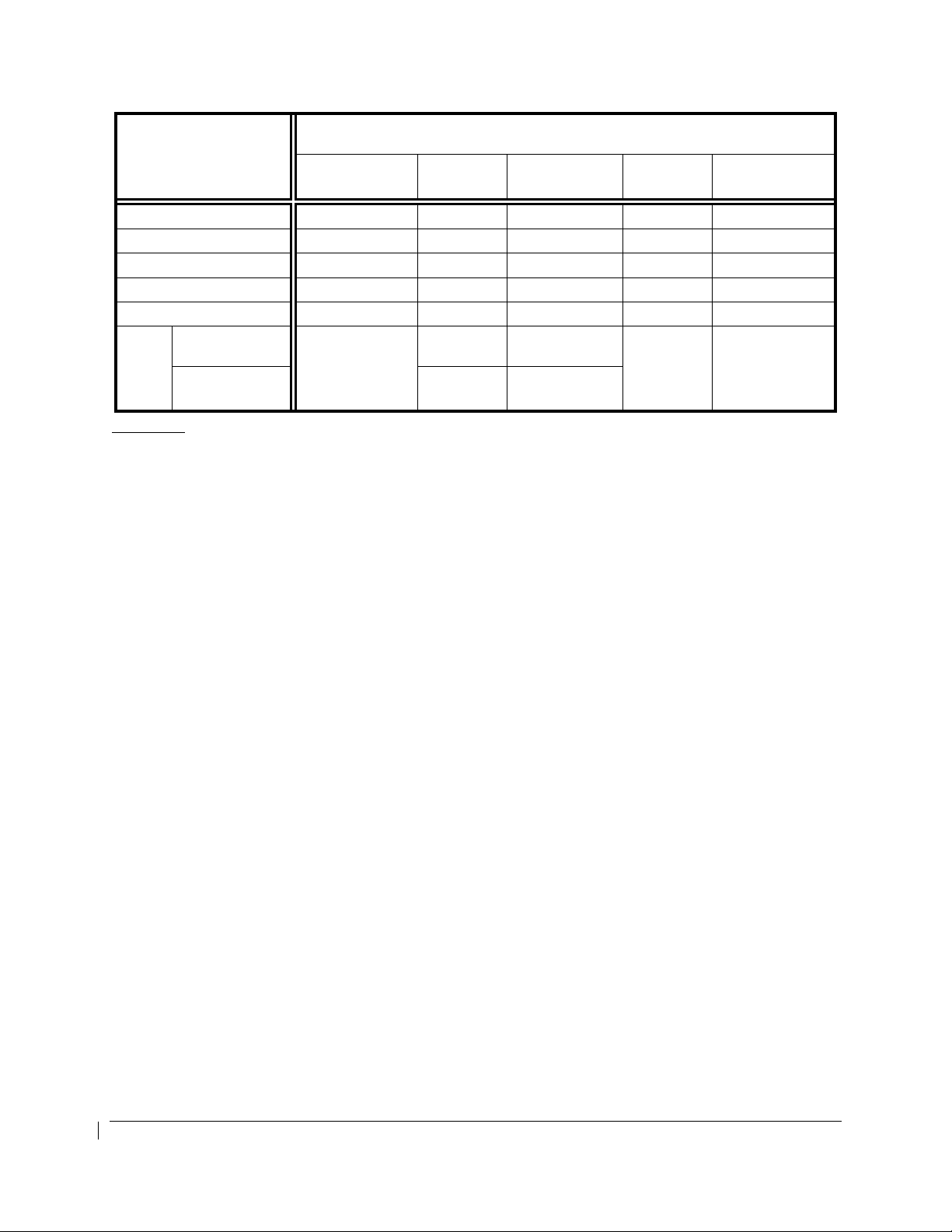

OPERATING

PARAMETER

Torque (ft-lbs) -- -- 0 to 2230 -- 2230 (1)

ITT (ºC) -- -- 400 to 820 -- 820 (2)

Prop N2 (rpm) -- -- (3) -- (3)

Gas Generator N1 (%) -- -- 61 to 104 -- 104 (4)

Oil Temp. (ºC) -40 (5) -40 to 0 (5) 0 to 110 (5) -- 110 (5)

Oil

Press.

(psi)

Less than

21,000’ MSL.

21,000’ MSL and

above

Red Arc/Radial

(Minimum Limit)

PT6A-52 ENGINES COLOR MARKINGS & RANGES

Yellow Arc

(Caution)

60 to 90 90 to 135

60

60 to 85 85 to 135

Green Arc

(Normal)

Yellow Arc

(Caution)

-- 135 (6)(7)

Red Arc/Radial

(Maximum Limit)

Footnotes:

(1) The maximum transient torque value is 2750 ft-lb for up to 5 seconds. Within this transient

value, the torque indicator will display green digits and a white pointer. After 5 seconds, the digits

will flash alternating red and white background with a flashing red pointer for 5 seconds. After 5

seconds of flashing, the indication is steady white digits/red background and the pointer is red.

Above 2750 FT-LB, the indication immediately begins flashing for 5 seconds before displaying

steady white digits on a red background and a red pointer.

(2) A red diamond at 1000°C represents the upper transient limit for engine Starting Mode. The

lower Normal Mode transient limit is 850°C. Within this transient value, the ITT indicator will

display green digits and a white pointer. After 20 seconds between 820

°

C and 850°C (or above

1000°C for more than 5 seconds in Starting Mode), the ITT digital indication will flash alternating

red and white background with a flashing red pointer for 5 seconds. After 5 seconds of flashing,

the indication is steady white digits/red background and the pointer is red. In Normal Mode while

above 850

°

C, the indication immediately begins flashing for 5 seconds before displaying steady

white digits on a red background and a red pointer.

(3) See PROPELLER TYPES AND INDICATOR MARKINGS table.

(4) Above 104%, the digital indication will flash alternating red and white background with a flashing

red pointer for 5 seconds. After 5 seconds of flashing, the indication is steady white digits/red

background and the pointer is red

(5) Above 110°C, the digital indication will flash alternating red and white background with a

flashing red pointer for 5 seconds. After 5 seconds of flashing, the indication is steady white

digits/red background and the pointer is red. Below 0°C to -40°C, the digital indication will be

black digits on a yellow background. Below -40°C, the digital indication will be white digits on a

red background.

(6) Above 135 PSI, or below 60 PSI and decreasing oil pressure, the digital indication will flash

alternating red and white background with a flashing red pointer for 5 seconds. After 5 seconds

of flashing, the indication is steady white digits/red background and the pointer is red.

(7) A red diamond at 200 psi represents the upper transient limit.

Hawker Beechcraft 200, 200C, B200, B200C, 190-00915-02 Rev. 8

B200GT and B200CGT King Air FAA APPROVED

Page 22 of 179

OPERATING

PARAMETER

Torque (ft-lbs) -- -- 0 to 2230 -- 2230 (1)

ITT (ºC) -- -- 400 to 800 -- 800 (2)

Prop N2 (rpm) -- -- (3) -- (3)

Gas Generator N1 (%) -- -- 61 to 104 -- 104 (4)

Oil Temp. (ºC) -40 (5) -40 to 0 (5) 0 to 110 (5) -- 110 (5)

Oil

Press.

(psi)

Less than

21,000’ MSL.

21,000’ MSL and

above

Red Arc/Radial

(Minimum Limit)

PT6A-61 ENGINES COLOR MARKINGS & RANGES

Yellow Arc

(Caution)

60 to 90 90 to 135

60

60 to 85 85 to 135

Green Arc

(Normal)

Yellow Arc

(Caution)

-- 135 (6)(7)

Red Arc/Radial

(Maximum Limit)

Footnotes:

(1) The maximum transient torque value is 2750 ft-lb for up to 5 seconds. Within this transient

value, the torque indicator will display green digits and a white pointer. After 5 seconds, the digits

will flash alternating red and white background with a flashing red pointer for 5 seconds. After 5

seconds of flashing, the indication is steady white digits/red background and the pointer is red.

Above 2750 FT-LB, the indication immediately begins flashing for 5 seconds before displaying

steady white digits on a red background and a red pointer.

(2) A red diamond at 1000°C represents the upper transient limit for engine Starting Mode. The

lower Normal Mode transient limit is 850°C. Within this transient value, the ITT indicator will

display green digits and a white pointer. After 20 seconds between 800

°

C and 850°C (or above

1000°C for more than 5 seconds in Starting Mode), the ITT digital indication will flash alternating

red and white background with a flashing red pointer for 5 seconds. After 5 seconds of flashing,

the indication is steady white digits/red background and the pointer is red. In Normal Mode while

above 850

°

C, the indication immediately begins flashing for 5 seconds before displaying steady

white digits on a red background and a red pointer.

(3) See PROPELLER TYPES AND INDICATOR MARKINGS table.

(4) Above 104%, the digital N1 indication will flash alternating red and white background with a

flashing red pointer for 5 seconds. After 5 seconds of flashing, the indication is steady white

digits/red background and the pointer is red

(5) Above 110°C, the digital N1 indication will flash alternating red and white background with a

flashing red pointer for 5 seconds. After 5 seconds of flashing, the indication is steady white

digits/red background and the pointer is red. Below 0°C to -40°C, the digital indication will be

black digits on a yellow background. Below -40°C, the digital indication will be white digits on a

red background.

(6) Above 135 PSI, or below 60 PSI and decreasing oil pressure, the digital indication will flash

alternating red and white background with a flashing red pointer for 5 seconds. After 5 seconds

of flashing, the indication is steady white digits/red background and the pointer is red.

(7) A red diamond at 200 psi represents the upper transient limit.

190-00915-02 Rev. 8 Hawker Beechcraft 200, 200C, B200, B200C,

FAA APPROVED B200GT and B200CGT King Air

Page 23 of 179

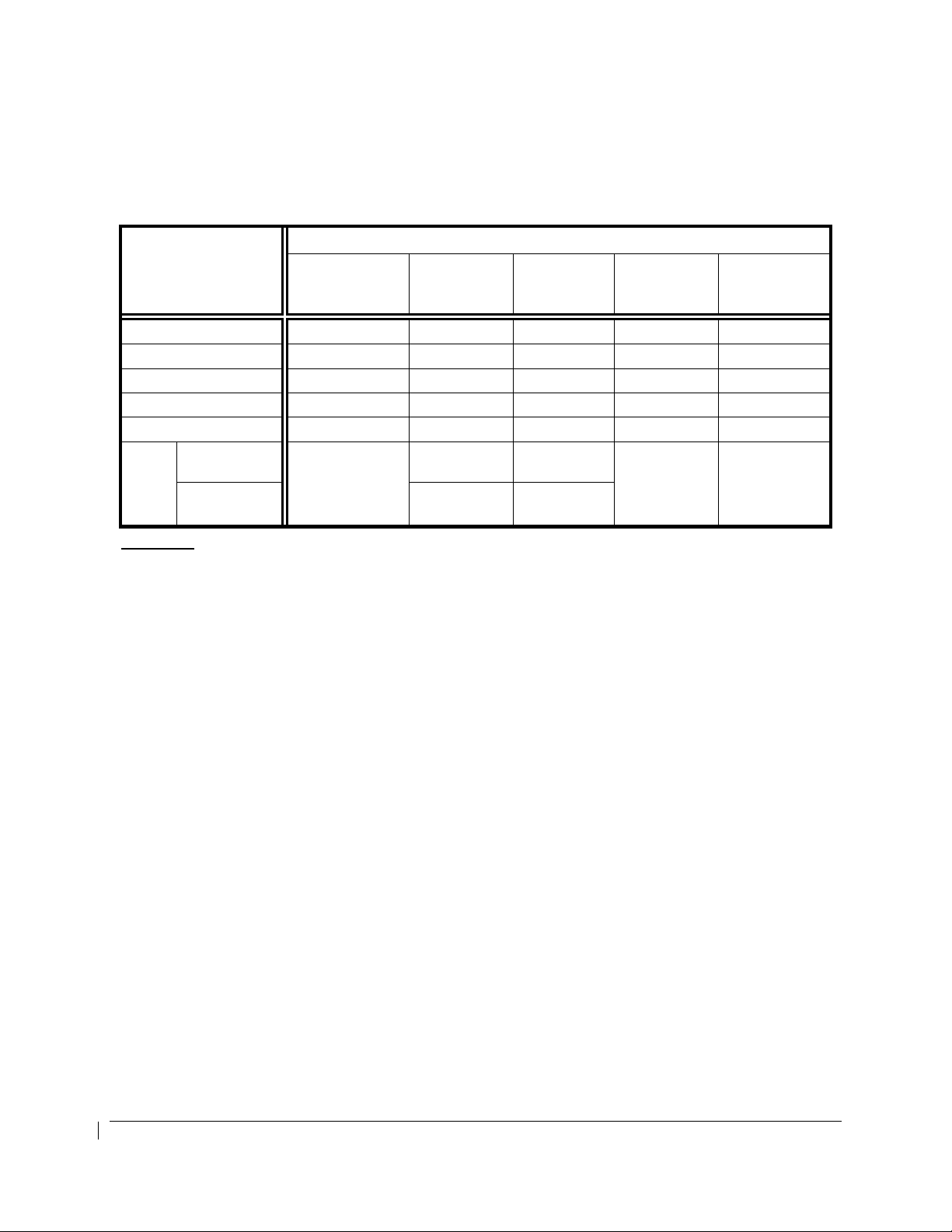

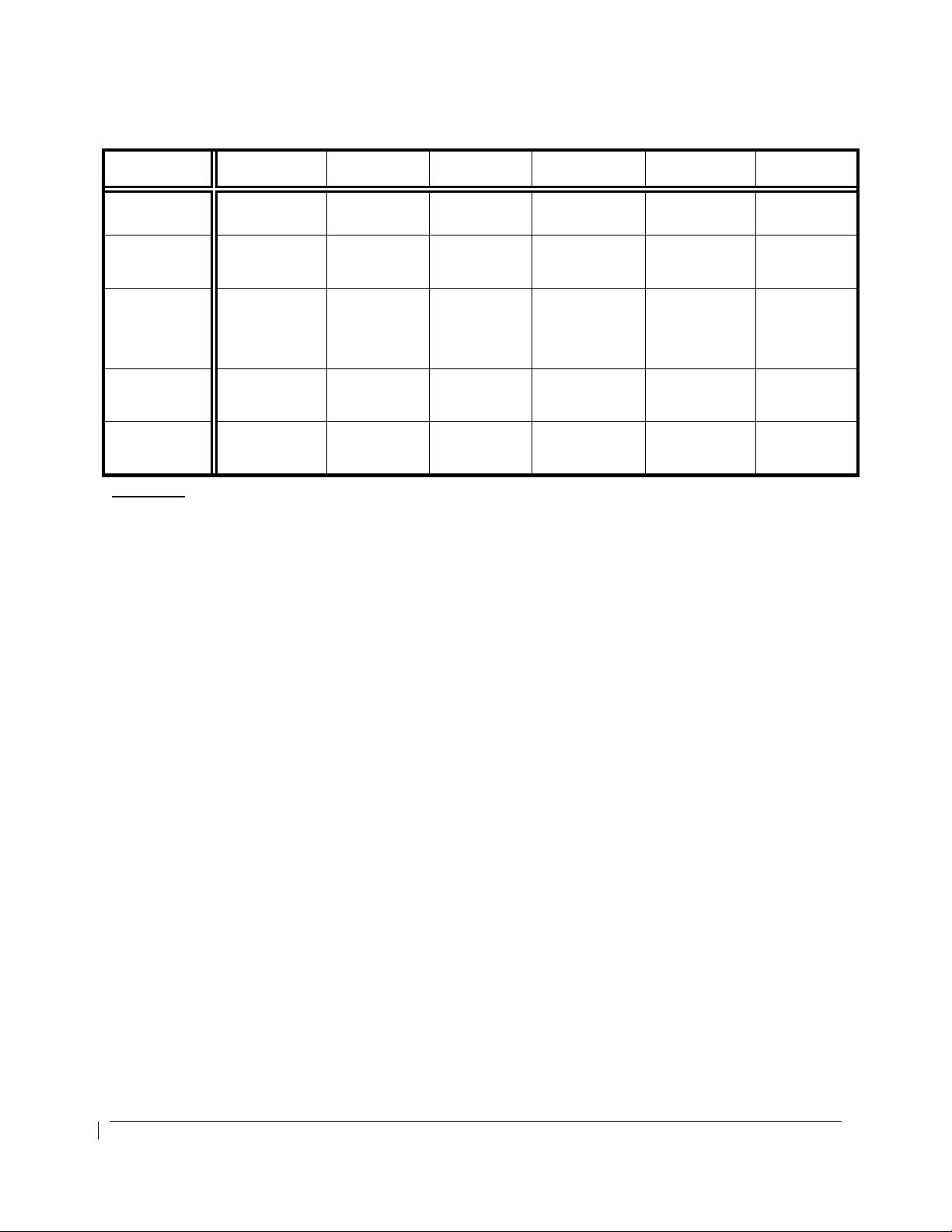

PROPELLER TYPES AND INDICATOR MARKINGS

Manufacturer Hartzell Hartzell Hartzell Hartzell McCauley McCauley

Hub

Blades T10178()-3R

Normal

Operating

Range – RPM

(Green Arc)

Maximum Limit

– RPM (Red

Radial)

Transient Limit

- RPM

HC-B3TN-3G

or -3N

1600-2000 1150-2000 1180-2000 1180-2000 1600-2000 1100-2000

2000 2000 2000 2000 2000 2000

2200 (1) 2200 (2) 2200 (2) 2200 (1) 2200 (1) 2200 (1)

HC-D4N-3A HC-E4N-3G HC–E4N-3A 3GFR34C702

D9383K

Or

D9515K

D9390SK-1R NC9208K 100LA-2 94LA-0

4HFR34C771

4HFR34C754

Footnotes:

(1) This value is time limited to 5 seconds. Within the transient value, the torque indicator will display

green digits and a white pointer. After 5 seconds, the digits will flash alternating red and white

background with a flashing red pointer for 5 seconds. After 5 seconds of flashing, the indication

is steady white digits/red background and the pointer is red. Above 2200 RPM, the indication

immediately begins flashing for 5 seconds before displaying steady white digits on a red

background and a red pointer.

(2) This value is time limited to 20 seconds. Within the transient value, the torque indicator will

display green digits and a white pointer. After 20 seconds, the digits will flash alternating red and

white background with a flashing red pointer for 5 seconds. After 5 seconds of flashing, the

indication is steady white digits/red background and the pointer is red. Above 2200 RPM, the

indication immediately begins flashing for 5 seconds before displaying steady white digits on a red

background and a red pointer.

Hawker Beechcraft 200, 200C, B200, B200C, 190-00915-02 Rev. 8

B200GT and B200CGT King Air FAA APPROVED

Page 24 of 179

MANEUVER LIMITS

No changes have been made to the airplane’s maneuver limits. The Hawker Beechcraft Super King Air

200, 200C, B200 and B200C are Normal Category airplanes. Acrobatic maneuvers, including spins, are

prohibited.

RVSM OPERATIONS

RVSM operations are prohibited if the static ports are damaged or surface irregularities are found within

the RVSM critical region.

The pilot and copilot PFDs must display on-side ADC information during RVSM operations.

G1000 INTEGRATED AVIONICS SYSTEM

Tuning of the COM and NAV radios using the GCU477 controller must be done from the Left seat pilot’s

station and only referencing the pilot’s PFD.

Required flight crewmembers must wear and use headsets when the overhead cockpit speaker audio is

selected OFF.

Do not take off unless all display units are installed and operational.

Do not take off with any display in reversionary mode.

Do not take off with any of the following messages displayed in the ALERTS window:

GPS1 FAIL and GPS2 FAIL simultaneously PFD1 SERVICE

GPS NAV LOST PFD2 SERVICE

GIA1 SERVICE GMA1 SERVICE

GIA2 SERVICE GMA2 SERVICE

MFD SERVICE GEO LIMITS

The G1000 system must be turned on and operated for at least 30 minutes before takeoff if ground outside

air temperature is -40°C (-40°F) or below.

The following temperature limitations apply only to aircraft with G1000 systems installed per Garmin

drawing 005-00421-00 Revision 15 or previous and not

• Do not takeoff if the PFD1 FAN FAIL, PFD2 FAN FAIL or MFD FAN FAIL is displayed in the ALERTS

window AND the Outside Air Temperature is greater than 41°C (106°F) AND cabin air conditioning is

inoperative.

• Do not takeoff if GIA1 FAN FAIL or GIA2 FAN FAIL is displayed in the ALERTS window AND the

Outside Air Temperature is greater than 42°C (107°F).

• Ground operation of the G1000 system is limited to 18 minutes when the Outside Air Temperature is

greater than 47°C (116°F) AND cabin air conditioning is inoperative.

modified by Garmin service bulletin No. 1375:

.

190-00915-02 Rev. 8 Hawker Beechcraft 200, 200C, B200, B200C,

FAA APPROVED B200GT and B200CGT King Air

Page 25 of 179

For airplanes with system software 0985.06 or earlier, use of VNAV is prohibited during the intermediate

segment of an approach that includes a teardrop course reversal. VNAV will become ‘Unavailable’ at the

beginning of the teardrop segment of the course reversal.

Use of VNAV is prohibited with course changes greater than 90°.

The barometric altimeter must be used as the primary altitude reference for all baro VNAV operations,

including instrument approach procedure step-down fixes. Use of baro VNAV to a DA is not authorized

with a remote altimeter setting. A current altimeter setting for the landing airport is required. When

using remote altimeter minima, the baro VNAV function may be used to the published LNAV MDA.

When a flight is predicated on flying a RNP approach with an RF leg at the destination and/or alternate, the

pilot must determine that the AFCS is operational. At a minimum, the flight director must be displayed

and utilized when conducting procedures containing Radius-to-Fix (RF) segments.

For airplanes with 0985.07 system software, Vector-to-Final transitions are prohibited for the following

approaches:

• CYSB VOR/DME Rwy 12

• NZTH GPS 330

• TTPP ILS Rwy 10

The fuel quantity, fuel required, fuel remaining, and gross weight estimate functions of the G1000 are

supplemental information only and must be verified by the flight crew.

Do not use SafeTaxi or Chartview functions as the basis for ground maneuvering. SafeTaxi and

Chartview functions do not comply with the requirements of AC 20-159 and are not qualified to be used as

an airport moving map display (AMMD). SafeTaxi and Chartview are to be used by the flight crew to

orient themselves on the airport surface to improve pilot situational awareness during ground operations.

The use of the colors red and amber within the checklist function has not been evaluated or approved by

this STC. Use of the colors red and/or amber within user created checklists may require separate

evaluation and approval by the FAA.

Hawker Beechcraft 200, 200C, B200, B200C, 190-00915-02 Rev. 8

B200GT and B200CGT King Air FAA APPROVED

Page 26 of 179

G1000 GNSS (GPS/SBAS) NAVIGATION SYSTEM LIMITATIONS

NOTE

Limitations are in bolded text for this section only.

The flight crew must confirm at system initialization that the Navigation database is current.

The Navigation database is expected to be current for the duration of the flight. If the AIRAC c ycle will

change during flight, the flight crew must ensure the accuracy of navigation data, including

suitability of navigation facilities used to define the routes and procedures for flight. If an

amended chart affecting navigation data is published for the procedure, the database must not be

used to conduct the procedure.

GPS/SBAS based IFR enroute, oceanic, and terminal navigation is prohibited unless the flight crew

verifies and uses a valid, compatible, and current Navigation database or verifies each waypoint

for accuracy by reference to current approved data.

Discrepancies that invalidate a procedure must be reported to Garmin International. The affected

procedure is prohibited from being flown using data from the Navigation database until a new

Navigation database is installed in the aircraft and verified that the discrepancy has been

corrected. Navigation database discrepancies can be reported at FlyGarmin.com then select “Aviation

Data Error Report”. Flight crew and operators can view Navigation data base alerts at FlyGarmin.com

then select “NavData Alerts”.

For flight planning purposes, in areas where SBAS coverage is not available, the flight crew must

check RAIM availability. Within the United States, RAIM availability can be determined via the

following:

• Using G1000 WFDE Prediction program, part number 006-A0154-01 (010-G1000-00) or later

approved version with GARMIN GA36 and GA37 antennas selected.

• Via the FAA’s en route and terminal RAIM prediction website: www.raimprediction.net.

• Contacting a Flight Service Station (not DUATS) to obtain non-precision approach RAIM.

Within Europe, RAIM availability can be determined using the G1000 WFDE Prediction program or

Europe’s AUGER GPS RAIM Prediction Tool at http://augur.ecacnav.com/augur/app/home. For other

areas, use the G1000 WFDE Prediction program. This requirement is not necessary if SBAS coverage is

confirmed to be available along the entire route of flight. The route planning and WFDE prediction

program may be downloaded from the GARMIN G1000 website on the internet. For information on using

the WFDE Prediction Program, refer to GARMIN WAAS FDE Prediction Program, part number

190-00643-01, ‘WFDE Prediction Program Instructions’.

For flight planning purposes, operations within the U.S. National Airspace System on RNP and

RNAV procedures when SBAS signals are not available, the availability of GPS integrity RAIM shall

be confirmed for the intended route of flight. In the event of a predicted continuous loss of RAIM of

more than five minutes for any part of the intended route of flight, the flight should be delayed, canceled, or

re-routed on a track where RAIM requirements can be met.

For flight planning purposes for operations within European B-RNAV and P-RNAV airspace, if

more than one satellite is scheduled to be out of service, then the availability of GPS integrity RAIM

shall be confirmed for the intended flight (route and time). In the event of a predicted continuous loss

of RAIM of more than five minutes for any part of the intended flight, the flight should be delayed, canceled,

or re-routed on a track where RAIM requirements can be met.

190-00915-02 Rev. 8 Hawker Beechcraft 200, 200C, B200, B200C,

FAA APPROVED B200GT and B200CGT King Air

Page 27 of 179

For flight planning purposes, operations where the route requires Class II navigation the aircraft’s

operator or flight crew must use the Garmin WFDE Prediction program to demonstrate that there

are no outages on the specified route that would prevent the G1000 from providing primary means

of Class II navigation in oceanic and remote areas of operation that requires (RNP-10 or RNP-4)

capability. If the Garmin WFDE Prediction program indicates fault exclusion (FDE) is unavailable for

more than 34 minutes in accordance with FAA Order 8400.12C for RNP-10 requirements, or 25 minutes in

accordance with FAA Order 8400.33 for RNP-4 requirements, then the operation must be rescheduled

when FDE is available.

Both GIA 63W GPS/SBAS receivers must be operating and providing GPS navigation guidance to

their respective PFD for operations requiring RNP-4 performance.

North Atlantic (NAT) Minimum Navigational Performance Specifications (MNPS) Airspace operations per

AC 91-49 and AC 120-33 require both GIA 63W GPS/SBAS receivers to be operating and receiving

usable signals except for routes requiring only one Long Range Navigation sensor. Each display computes

an independent navigation solution based on the on-side GPS sensor. However, either display will

automatically revert to the cross-side sensor if the on-side sensor fails or if the cross-side sensor is

determined to be more accurate. A “BOTH ON GPS1” or “BOTH ON GPS2” message does not necessarily

mean that one GPS has failed. Refer to the MFD AUX-GPS STATUS page to determine the state of the

unused GPS.

Manual entry of waypoints using latitude/longitude or place/bearing is prohibited. Whenever

possible, RNP and RNAV routes including Standard Instrument Departures (SIDs) and Obstacle

Departure Procedures (ODPs), Standard Terminal Arrival (STAR), and en route RNAV “Q” and RNAV “T”

routes should be loaded into the flight plan from the database in their entirety, rather than loading route

waypoints from the database into the flight plan individually. Selecting and inserting individual named

fixes from the database is permitted, provided all fixes along the published route to be flown are inserted.

“GPS”, “or GPS”, “RNAV(GPS)”, or “RNAV(GNSS)” instrument approaches using the G1000

System are prohibited unless the flight crew verifies and uses the current Navigation database.

GPS based instrument approaches must be flown in accordance with an approved instrument

approach procedure that is loaded from the Navigation database.

Not all published Instrument Approach Procedures (IAP) are in the Navigation database. Flight crew

planning on flying an RNAV instrument approach must ensure that the Navigation database

contains the planned RNAV Instrument Approach Procedure and that approach procedure must b e

loaded from the Navigation database into the FMS flight plan by its name.

IFR non-precision approach approval using the GPS/SBAS sensor is limited to published

approaches within the U.S. National Airspace System. Approaches to airports in other airspace are

not approved unless authorized by the appropriate governing authority.

When operating under instrument flight rules, flight plan selection of any required alternate airport may be

based on an RNAV approach. For airplanes with system software 0985.06 or earlier, alternate airport

selection must be based upon an LNAV approach or an available ground-based approach for which the

aircraft is equipped to fly.

For airplanes that have system software 0985.07 or later installed, alternate airport selection may based

upon LNAV, LNAV/VNAV (when baro-VNAV is used), or other available ground-based approaches for

which the aircraft is equipped to fly. Alternate planning may include the use of an LNAV MDA(h) for

circling or LNAV/VNAV DA(h) when baro-VNAV is active.

The navigation equipment required to join and fly an instrument approach procedure is indicated by the

title of the procedure and notes on the IAP chart. Use of the GARMIN G1000 GPS/SBAS receivers to

provide navigation guidance during the final approach segment of an ILS, LOC, LOC-BC, LDA,

Hawker Beechcraft 200, 200C, B200, B200C, 190-00915-02 Rev. 8

B200GT and B200CGT King Air FAA APPROVED

Page 28 of 179

SDF, MLS or any other type of approach not approved for “or GPS” navigation is prohibited.

When using the G1000 VOR/LOC/GS receivers to fly the final approach segment, VOR/LOC/GS

navigation data must be selected and presented on the CDI of the pilot flying.

For airplanes that have system software 0985.07 or later installed, all VNAV altitude constraints must be

manually entered by the flight crew. The system will not auto-nominate VNAV altitude constraints.

Navigation information is referenced to WGS-84 reference system, and should only be used where the

Aeronautical Information Publication (including electronic data and aeronautical charts) conform to

WGS-84 or equivalent.

190-00915-02 Rev. 8 Hawker Beechcraft 200, 200C, B200, B200C,

FAA APPROVED B200GT and B200CGT King Air

Page 29 of 179

AHRS AREAS OF OPERATION

For airplanes that have GRS 77 AHRS installed:

Flight operations with the G1000 Integrated Avionics installed are prohibited in the following regions due to

unsuitability of the magnetic fields near the Earth’s poles:

1. North of 72° North latitude at all longitudes

2. South of 70° South latitude at all longitudes

3. North of 65° North latitude between longitude 75° W and 120° W (Northern Canada)

4. North of 70° North latitude between longitude 70° W and 128° W (Northern Canada)

5. North of 70° North latitude between longitude 85° E and 114° E (Northern Russia)

6. South of 55° South latitude between longitude 120° E and 165° E (Region south of Australia and

New Zealand)

NOTE

The Garmin G1000 system is not designed for use as a polar navigator and operation outside the

approved operating area is prohibited. The GRS-77 AHRS internally monitors the magnetic field

and will display a GEO LIMITS system message when the magnetic field becomes unsuitable for

AHRS operation. When the AHRS can no longer reliably compute heading, heading information

will be removed from the HSI.

For airplanes that have GRS 7800 AHRS installed:

Flight operations in the following regions require heading to be in DG FREE Mode when using system

software version 0985.07:

1. North of 72° North latitude at all longitudes

2. North of 65° North latitude between longitude 75° W and 120° W (Northern Canada)

3. North of 70° North latitude between longitude 70° W and 128° W (Northern Canada)

4. North of 70° North latitude between longitude 85° E and 114° E (Northern Russia)

Flight operations with the G1000 Integrated Avionics installed are prohibited in the following regions due to

unsuitability of the magnetic fields near the Earth’s poles:

1. North of 84° North latitude at all longitudes

2. South of 70° South latitude at all longitudes

3. South of 55° South latitude between longitude 120° E and 165° E (Region south of Australia and

New Zealand)

NOTE

The Garmin G1000 system is not designed for use as a polar navigator and operation outside the

approved operating area is prohibited.

Hawker Beechcraft 200, 200C, B200, B200C, 190-00915-02 Rev. 8

B200GT and B200CGT King Air FAA APPROVED

Page 30 of 179

Loading...

Loading...