Garmin GT50M-THP, GT50M-TM, GT51M-TH, GT51M-THP, GT41-TM Installation Instructions

...

Thru-Hull Transducer

Installation Instructions

Important Safety Information

WARNING

See the Important Safety and Product Information guide in the

product box for product warnings and other important

information.

The device must be installed with at least one of the included

anti-rotation bolts. Failure to do so could result in the device

rotating while the boat is moving and could cause damage to

your vessel.

You are responsible for the safe and prudent operation of your

vessel. Sonar is a tool that enhances your awareness of the

water beneath your boat. It does not relieve you of the

responsibility of observing the water around your boat as you

navigate.

CAUTION

Failure to install and maintain this equipment in accordance with

these instructions could result in damage or injury.

Always wear safety goggles, ear protection, and a dust mask

when drilling, cutting, or sanding.

NOTICE

When drilling or cutting, always check what is on the opposite

side of the surface.

This equipment should be installed by a qualified marine

installer.

To obtain the best performance and to avoid damage to your

boat, you must install the Garmin® transducer according to these

instructions.

Read all installation instructions before proceeding with the

installation. If you experience difficulty during the installation,

contact Garmin Product Support.

Registering Your Device

Help us better support you by completing our online registration

today.

• Go to http://my.garmin.com.

• Keep the original sales receipt, or a photocopy, in a safe

place.

Contacting Garmin Product Support

• Go to www.garmin.com/support for in-country support

information.

• In the USA, call 913-397-8200 or 1-800-800-1020.

• In the UK, call 0808 238 0000.

• In Europe, call +44 (0) 870 850 1241.

Loading the New Software on a Memory Card

You must copy the software update to a memory card.

Insert a memory card into the card slot on the computer.

1

Go to www.garmin.com/support/software/marine.html.

2

Select Download next to “Garmin Marine Network with SD

3

card”.

Read and agree to the terms.

4

Select Download.

5

If necessary, select Run or save and open the file.

6

If necessary, select the drive associated with the memory

7

card, and select Next > Finish.

Updating the Device Software

Before you can update the software, you must obtain a

software-update memory card or load the latest software onto a

memory card.

Turn on the chartplotter.

1

After the home screen appears, insert the memory card into

2

the card slot.

NOTE: In order for the software update instructions to

appear, the device must be fully booted before the card is

inserted.

Follow the on-screen instructions.

3

Wait several minutes while the software update process

4

completes.

The device returns to normal operation after the software

update process is complete.

Remove the memory card.

5

NOTE: If the memory card is removed before the device

restarts fully, the software update is not complete.

Tools Needed

• Drill

• 3 mm bit (1/8 in.)

• 9 mm bit (3/8 in.)

• 13 mm bit (1/2 in.)

• 25 mm spade bit (1 in.) (fiberglass hull)

• 29 mm spade bit (1 1/8 in.) (fiberglass hull)

• 32 mm spade bit (11/4 in.) (fiberglass hull)

• 32 mm hole saw (1 1/4 in.) (metal hull)

• Bandsaw or table saw

• Slip-joint pliers or crescent wrench

• Masking tape

• Marine sealant

• Epoxy or exposed core sealant (cored fiberglass hull)

About the Transducer

The transducer transmits and receives sound waves through the

water, and relays sound-wave information to your Garmin sonar

device.

Mounting Location Considerations

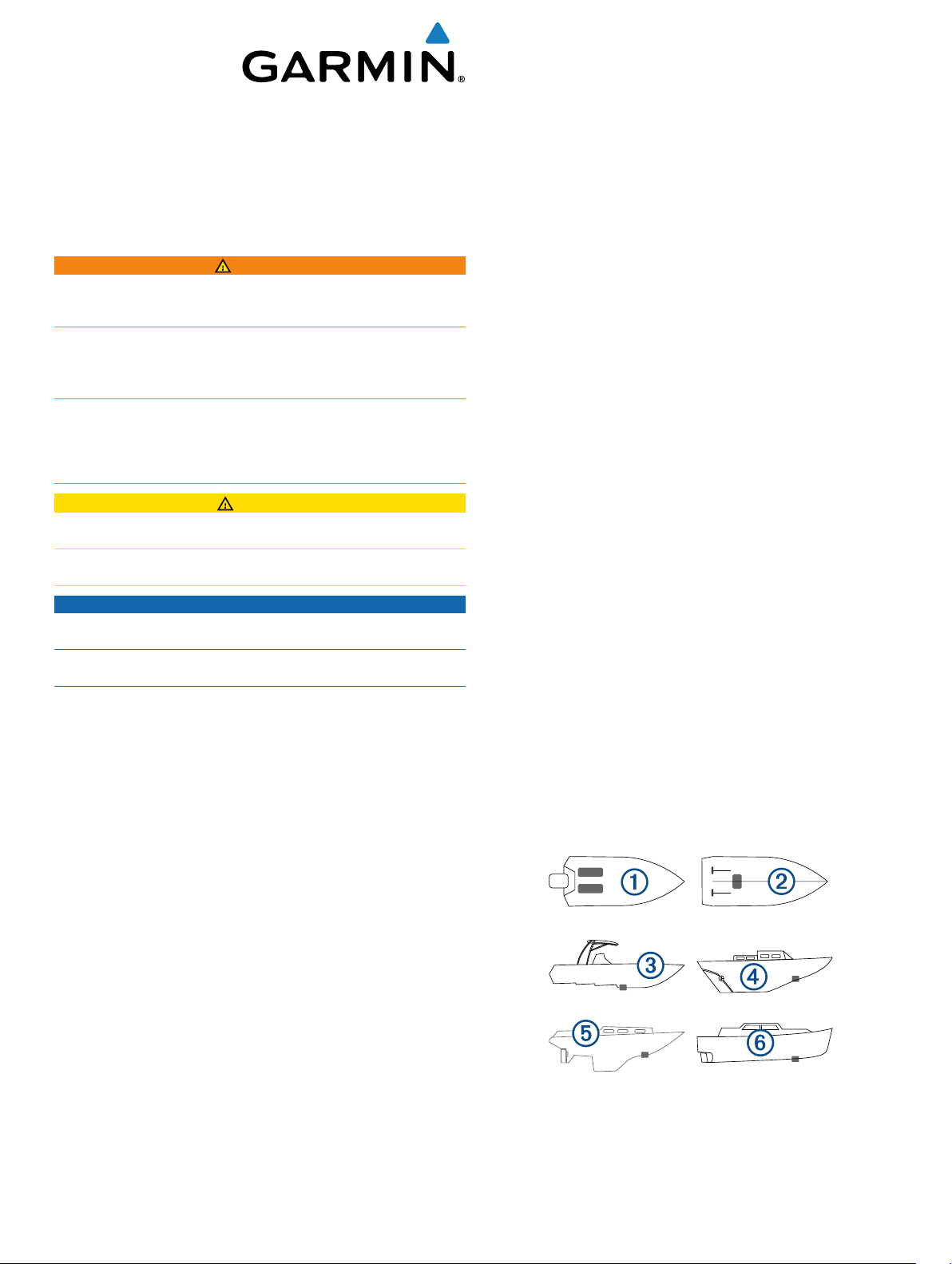

• On outboard and sterndrive vessels À, the transducer should

be mounted in front of and close to the engine or engines.

• On inboard vessels Á, the transducer should be mounted in

front of and far away from the engine propeller and shaft.

• On step-hull vessels Â, the transducer should be mounted in

front of the first step.

May 2015

Printed in Taiwan 190-01774-02_0B

• On full-keel vessels Ã, the transducer should be mounted at

a slight angle that aims at the bow, not parallel to the

centerline.

• On fin-keel vessels Ä, the transducer should be mounted

from 25 cm to 75 cm (from 10 to 30 in.) in front of the keel

and a maximum of 10 cm (4 in.) to the side of the centerline.

• On vessels with displacement hulls Å, the transducer should

be mounted approximately 1/3 aft of the waterline length of

the vessel from the bow, and from 150 to 300 mm (from 6 to

12 in.) to the side of the centerline.

• The transducer should be mounted parallel to the bow-stern

axis of your vessel.

• The transducer should not be mounted behind strakes, struts,

fittings, water intake or discharge ports, or anything that

creates air bubbles or causes the water to become turbulent.

The transducer must be in clean (non-turbulent) water for

optimal performance.

• The transducer should not be mounted in a location where it

might be jarred when launching, hauling, or storing.

• On single-drive boats, the transducer must not be mounted in

the path of the propeller.

The transducer can cause cavitation that can degrade the

performance of the boat and damage the propeller.

• On twin-drive boats, the transducer should be mounted

between the drives, if possible.

Fairing Block Angle Cut

A fairing block positions your transducer parallel to the water line

for increased sonar accuracy. You must measure the deadrise

angle of your boat hull to determine if a fairing block is

necessary to mount the transducer. If the deadrise angle of your

mounting location exceeds 5°, you should use a fairing block to

mount the transducer.

Deadrise Angle

Deadrise is the angle formed between a horizontal line and a

boat hull at a single point. You can measure the deadrise angle

with an angle finder, a protractor, or a digital level. You can also

ask your boat manufacturer for the deadrise angle of the specific

point on your boat hull.

NOTE: A boat may have several deadrise angles depending on

the shape of the hull. Measure the deadrise angle only at the

location where you plan to install the transducer.

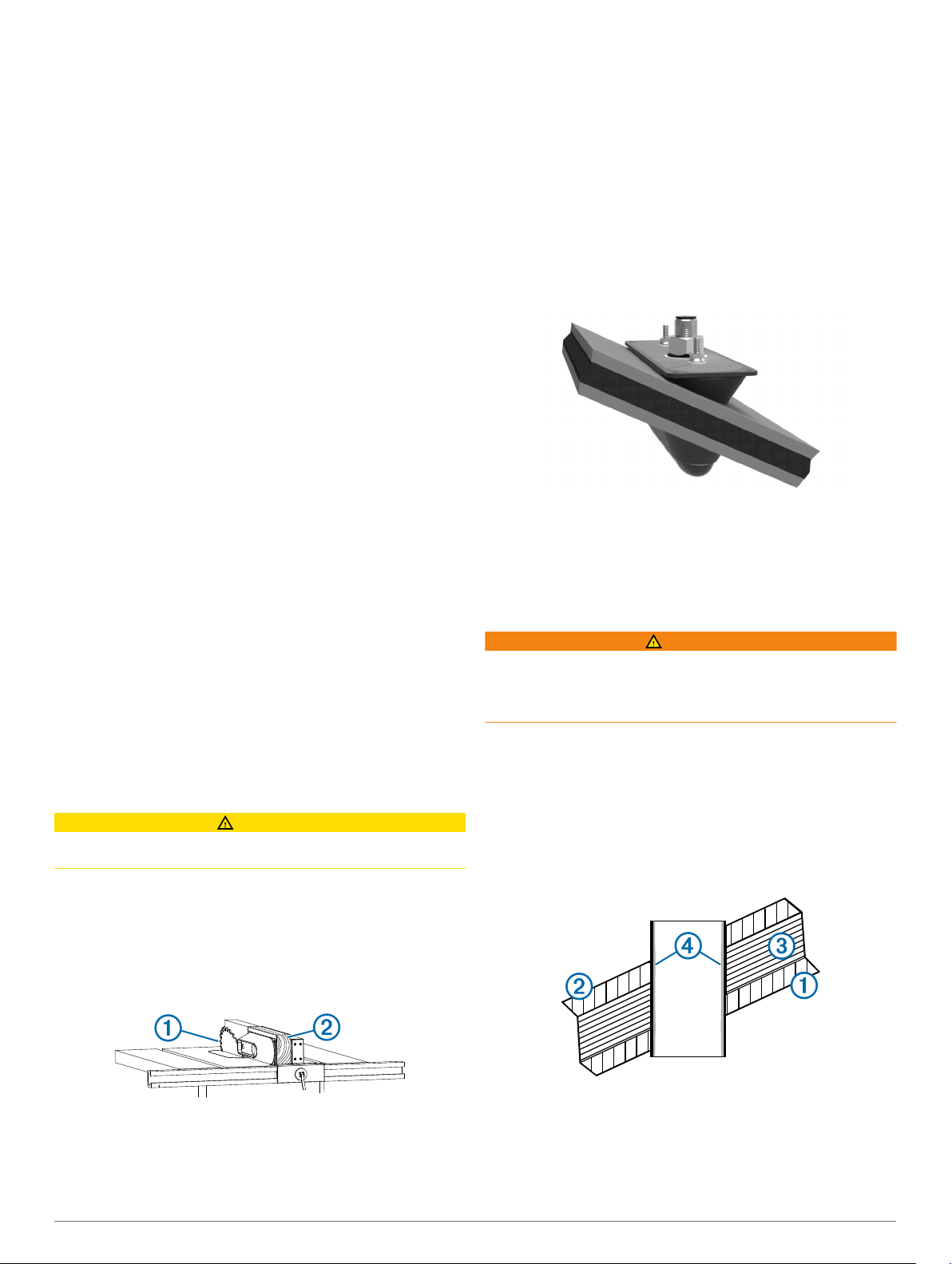

Cutting the Fairing Block

CAUTION

Always wear safety goggles, ear protection, and a dust mask

when drilling, cutting, or sanding.

Using wood screws, attach the fairing block to a piece of

1

wood.

The wood becomes a cutting guide for the fairing block.

Measure the deadrise angle of the hull at the mounting

2

location.

Tilt your table saw blade À to match the deadrise angle and

3

secure the cutting fence.

NOTE: The maximum cutting angle of the fairing block is 25°.

Cut the fairing block.

6

Using a rasp or power tool, shape the fairing block to the hull

7

as precisely as possible.

Use the remaining section of the fairing block as the backing

8

block inside the hull.

Cored Fiberglass Boat Hull Installation Instructions

Thru-Hull Transducer in a Cored Hull with a Fairing Block

If the deadrise angle of your mounting location exceeds 5°, you

must use a fairing block to mount the device.

Drilling the Transducer Stem Hole and the Anti-Rotation Bolt Holes in a Cored Fiberglass Hull

Before you can drill holes for the anti-rotation bolts, you must

drill the hole for the transducer stem (Drilling the Transducer

Stem Hole and the Anti-Rotation Bolt Holes in a Cored

Fiberglass Hull) and you must cut the fairing block (Cutting the

Fairing Block).

WARNING

The device must be installed with at least one of the included

anti-rotation bolts. Failure to do so could result in the device

rotating while the boat is moving and could cause damage to

your vessel.

The core must be cut and sealed carefully to protect against

water seepage.

Select a mounting location without surface irregularities or

1

obstructions.

Using the template, mark the location of the stem hole and

2

anti-rotation bolts.

Drill a 3 mm (1/8 in.) pilot hole through the template and hull

3

at the stem hole location.

Position the fairing block on the table so the cutting guide

4

rests against the fence Á and the angle matches the angle of

the mounting location .

Adjust the cutting fence to ensure the fairing block has a

5

minimum thickness of 13 mm (1/2 in.).

2

The hole must be perpendicular to the water surface.

Place masking tape over the pilot hole and surrounding area

4

outside the hull to prevent damage to the fiberglass.

Using a 25 mm (1 in.) bit at the stem hole location, drill from

5

outside the hull through the outer skin À, inner skin Á, and

the core Â.

The hole must be perpendicular to the water surface.

Sand and clean the inner skin, core, and outer skin around

6

the hole.

Seal the exposed inner core with epoxy Ã, and allow the

7

epoxy to set thoroughly.

While holding a drill with a 9 mm (3/8 in.) bit plumb, drill the

8

anti-rotation bolt holes through the hull from outside the hull.

The holes must be perpendicular to the water surface.

Sand and clean the area around the holes.

9

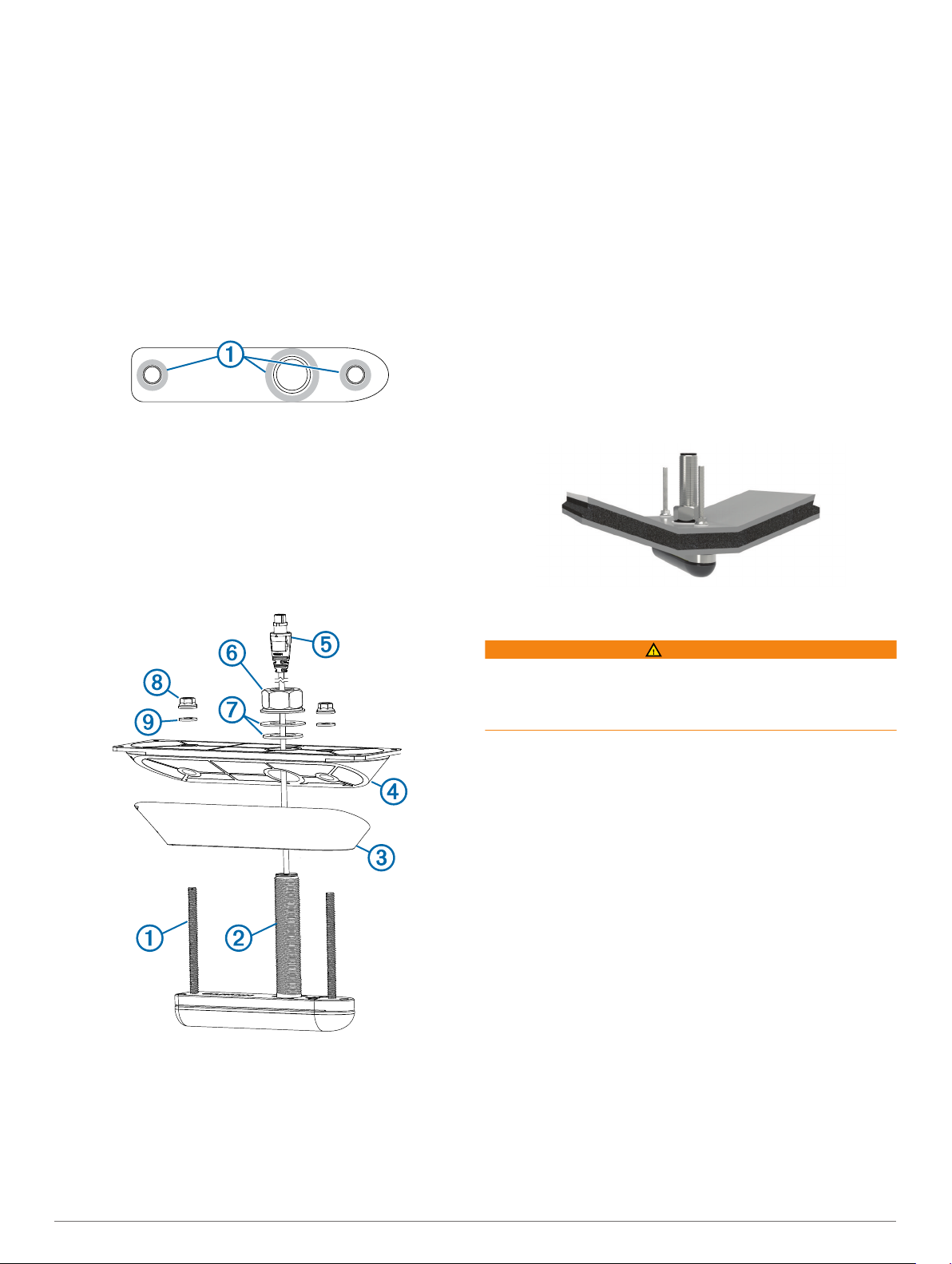

Applying Marine Sealant to a Thru-Hull Transducer

You must apply marine sealant to the transducer to ensure a

tight, waterproof seal between the fairing block and the hull. Do

not apply sealant directly to the stem or anti-rotation bolts.

Apply marine sealant À around the base of the stem and

anti-rotation bolts on the transducer.

Installing the Transducer with a Fairing Block

It is recommended that two installers complete these

instructions, with one positioned outside the boat and one inside

the boat.

NOTE: When installing the transducer in a cored fiberglass hull,

avoid over-tightening the nuts to prevent damaging the hull.

If the anti-rotation bolts À are installed on your transducer,

1

remove them.

Apply marine sealant at the base of the anti-rotation bolts and

2

transducer stem Á.

From inside the hull, slide the backing block onto the

7

transducer stem and seat it firmly against the inner hull.

The fairing and transducer must be parallel to the keel.

From inside the hull, apply the included anti-seize compound

8

to the exposed transducer stem and anti-rotation bolts.

From inside the hull, use slip-joint pliers or a crescent wrench

9

to secure the backing block to the transducer stem with the

included 35 mm hull nut Å, rubber 24 mm washer, and nylon

26 mm washer Æ.

Do not over-tighten the hull nut.

From inside the hull, use slip-joint pliers or a crescent wrench

10

to secure the backing block to the anti-rotation bolts with the

included M8 nuts Ç and 8 mm washers È.

Do not over-tighten the M8 nuts.

Before the sealant hardens, remove all excess sealant on the

11

outside of the fairing block and exterior hull to ensure smooth

water flow over the transducer.

Thru-Hull Transducer in a Cored Hull without a Fairing Block

If the deadrise angle of your mounting location does not exceed

5°, you can mount the device without a fairing block.

Drilling the Transducer Stem and Anti-Rotation Bolt Holes Using a Template

Seat the transducer housing firmly within the fairing block

3

recess.

Apply marine sealant to the face of the fairing block that must

4

contact the hull.

Apply marine sealant to the face of the backing block à that

5

must contact the inner hull.

From outside the hull, insert the transducer cable Ä and

6

transducer stem through the mounting hole.

WARNING

The device must be installed with at least one of the included

anti-rotation bolts. Failure to do so could result in the device

rotating while the boat is moving and could cause damage to

your vessel.

You should follow these instructions if you are not using a fairing

block or isolator plate to mount your transducer.

Trim the included transducer template.

1

Select a mounting location without surface irregularities or

2

obstructions.

Using the template, mark the location of the stem hole and

3

anti-rotation bolts.

While holding a 25 mm (1 in.) spade bit plumb, drill the

4

transducer stem hole from outside the hull.

The hole must be perpendicular to the water surface.

While holding a drill with an 9 mm (3/8 in.) bit plumb, drill the

5

anti-rotation bolt holes from outside the hull.

The holes must be perpendicular to the water surface.

Sand and clean the inner skin, core, and outer skin around

6

the holes.

Applying Marine Sealant to a Thru-Hull Transducer

You must apply marine sealant to the transducer to ensure a

Â

tight, waterproof seal between the fairing block and the hull. Do

not apply sealant directly to the stem or anti-rotation bolts.

Apply marine sealant À around the base of the stem and

anti-rotation bolts on the transducer.

3

Loading...

Loading...