Page 1

System Maintenance Manual

GRA 55/5500 Bell 206 STC

Contains Instructions for Continued Airworthiness

for Bell 206 STC

190-01277-A3 July 2014 Revision 1

Page 2

System Maintenance Manual

GRA 55/5500 Bell 206 STC

as installed in

Bell 206B, 206L Series

Reg. No. S/N

Contains Instructions for Continued Airworthiness

for Bell 206 STC

Dwg. Number:

190-01277-A3 Rev. 1

Garmin International, Inc.

1200 E. 151st Street

Olathe, Kansas 66062 USA

190-01277-A3 System Maintenance Manual GRA 55/5500 Bell 206 STC

Rev. 1 Page A

Page 3

© 2014 Garmin International, Inc. or its subsidiaries

All Rights Reserved

Except as expressly provided herein, no part of this manual may be reproduced, copied, transmitted,

disseminated, downloaded or stored in any storage medium, for any purpose without the express prior

written consent of Garmin. Garmin hereby grants permission to download a single copy of this manual and

of any revision to this manual onto a hard drive or other electronic storage medium to be viewed and to

print one copy of this manual or of any revision hereto, provided that such electronic or printed copy of this

manual or revision must contain the complete text of this copyright notice and provided further that any

unauthorized commercial distribution of this manual or any revision hereto is strictly prohibited.

At Garmin, we value your opinion.

For comments about this guide, please e-mail Techpubs.Salem@garmin.com

Garmin International Inc.

1200 E. 151st Street

Olathe, Kansas 66062

Telephone: (913) 397-8200

www.garmin.com

Aviation Dealer Technical Support

Telephone (Toll Free): (888) 606-5482

Fax: (913) 397-0868

Fax (Toll Free): (800) 801-4670

E-mail: orders@garmin.com

avionics@garmin.com

warranty@garmin.com

.

Garmin AT, Inc.

2345 Turner Rd. SE

Salem, OR 97302 USA

Telephone: (503) 581-8101

Telephone (Toll Free): (800) 525-6726

Canada: (800) 654-3415

Fax: (503) 364-2138

E-mail: support.salem@garmin.com

Garmin (Europe) Ltd.

Liberty House, Hounsdown Business Park

Southampton, Hampshire SO40 9LR U.K.

Phone: +44 (0) 23 8052 4000

Fax: +44 (0) 23 8052 4004

Aviation Support +44 (0) 87 0850 1243

190-01277-A3 System Maintenance Manual GRA 55/5500 Bell 206 STC

Rev. 1 Page B

Page 4

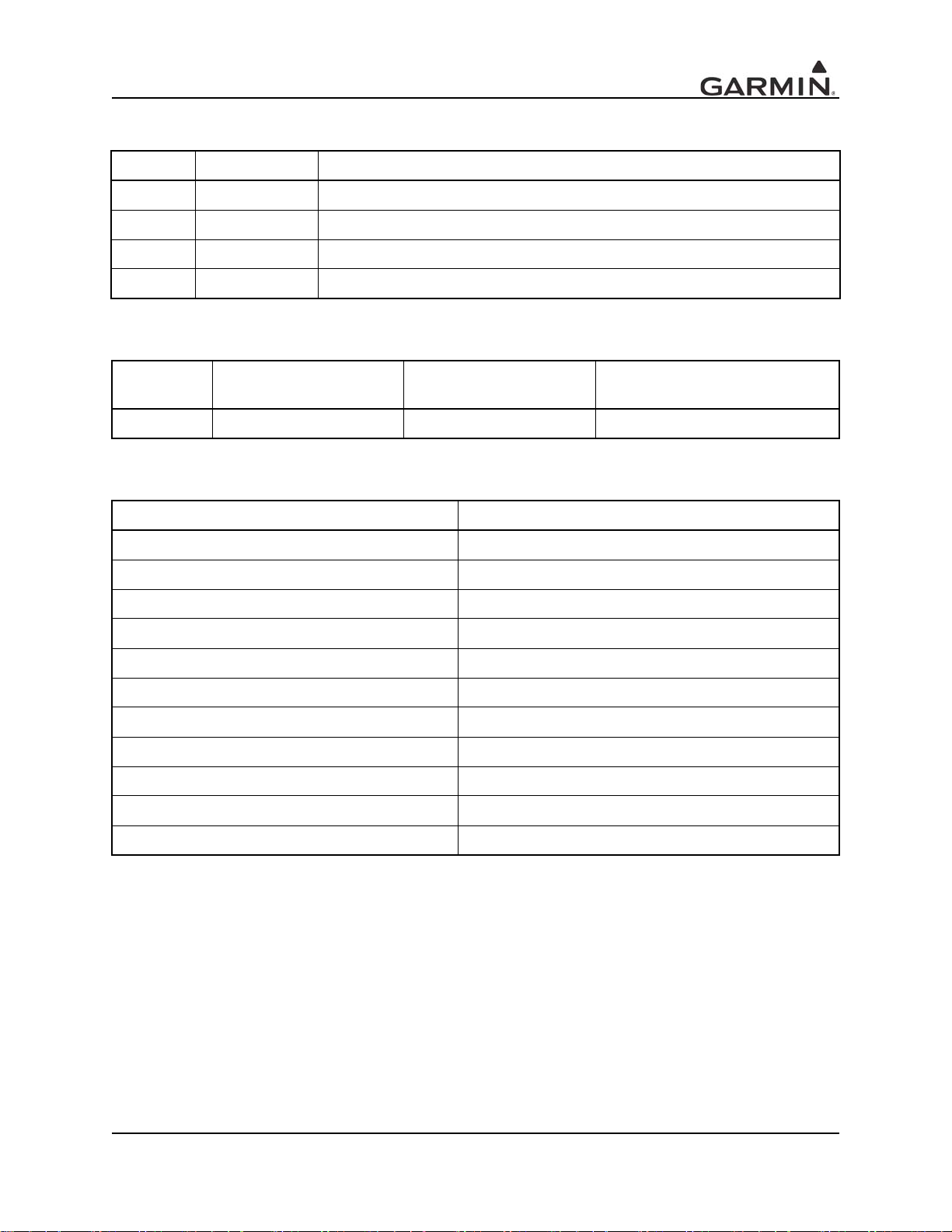

RECORD OF REVISIONS

Revision Revision Date Description

1 07/11/2014 Initial Release

CURRENT REVISION DESCRIPTION

Revision

1 All All Initial Release

Section

Number(s)

Page

Number(s)

DOCUMENT PAGINATION

Section Pagination

Table of Contents ii through v

Section 1 1-1 through 1-2

Section 2 2-1 through 2-1

Section 3 3-1 through 3-8

Section 4 4-1 through 4-6

Section 5 5-1 through 5-7

Section 6 6-1 through 6-3

Section 7 7-1 through 7-1

Section 8 8-1 through 8-2

Section 9 9-1 through 9-1

Description of Change

Appendix A A-1 through A-7

190-01277-A3 System Maintenance Manual GRA 55/5500 Bell 206 STC

Rev. 1 Page C

Page 5

INFORMATION SUBJECT TO EXPORT CONTROL LAWS

WARNING

CAUTION

NOTE

This document may contain information which is subject to the Export Administration Regulations

(“EAR”) issued by the United States Department of Commerce (15 Code of Federal Regulations (CFR),

Chapter VII, Subchapter C) and which may not be exported, released, or disclosed to foreign nationals

inside or outside of the United States without first obtaining an export license. A violation of the EAR may

be subject to a penalty of up to 10 years imprisonment and a fine of up to $1,000,000 under Section 2410

of the Export Administration Act of 1979. Include this notice with any reproduced portion of this

document.

This information in this document is subject to change without notice. Visit the Garmin web site

(

www.garmin.com) for current updates and supplemental information concerning the operation of

Garmin products.

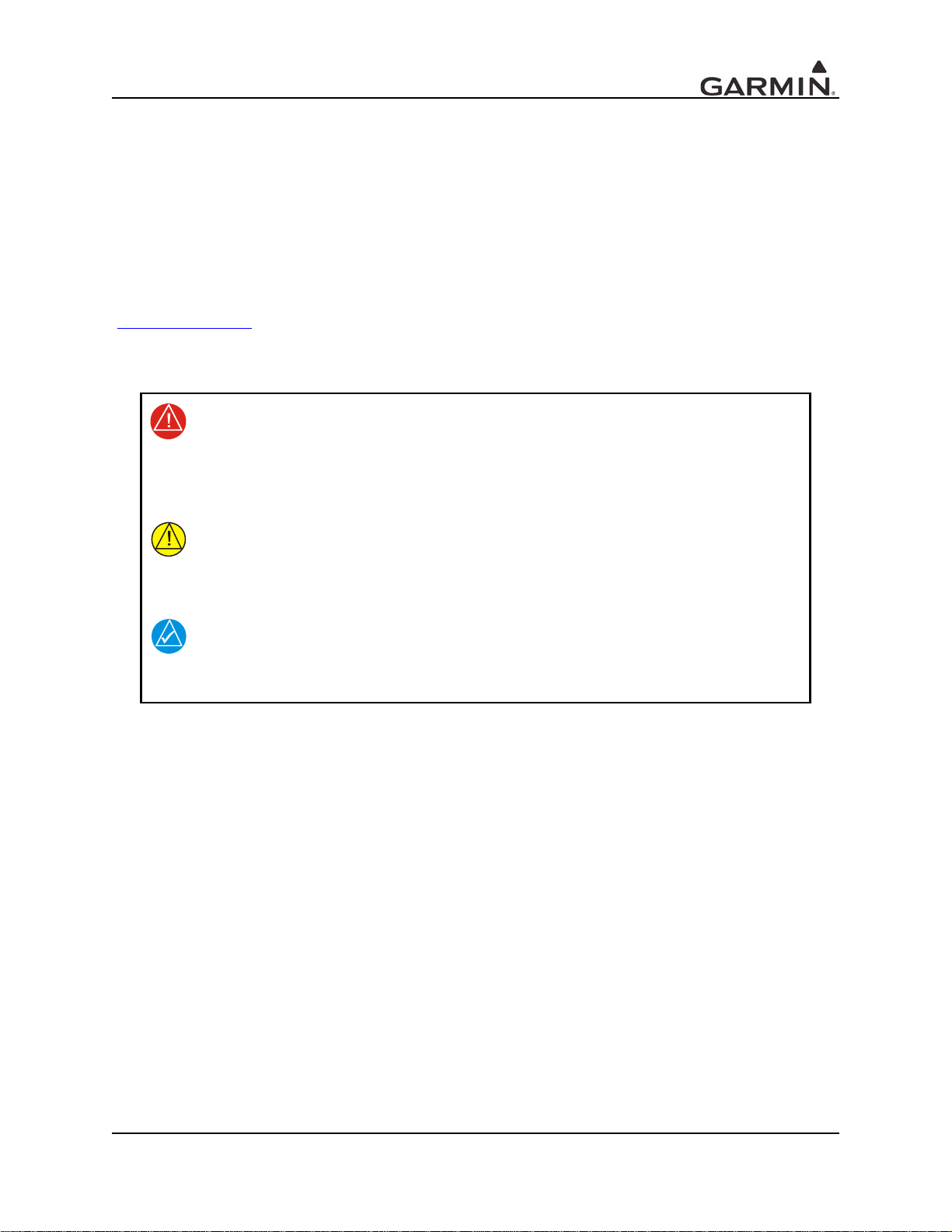

DEFINITIONS OF WARNINGS, CAUTIONS, AND NOTES

Warnings are used to bring to the installer’s immediate attention that not only

damage to the equipment but personal injury may occur if the instruction is

disregarded.

Cautions are used to alert the individual that damage to equipment may result

if the procedural step is not followed to the letter.

Notes are used to expand and explain the preceding step and provide further

understanding of the reason for the particular operation.

190-01277-A3 System Maintenance Manual GRA 55/5500 Bell 206 STC

Rev. 1 Page i

Page 6

TABLE OF CONTENTS

1 INTRODUCTION .............................................................................................................................1-1

1.1 Purpose ......................................................................................................................................1-1

1.2 Scope .........................................................................................................................................1-1

1.3 Document Control ...................................................... ..................................................... ..........1-1

1.4 Permission to Use Certain Documents ......................................................................................1-1

1.5 Definitions .................................................................................................................................1-1

1.6 Terminology ..............................................................................................................................1-2

1.7 Publications ...............................................................................................................................1-2

1.7.1 Applicability ........................................................................................................... 1-2

1.7.2 Definition of Abbreviations ................................................................................... 1-2

1.7.3 Precautions .............................................................................................................1-2

1.7.4 Units of measurement ............................................................................................ 1-2

1.7.5 Referenced publications (or their later revisions) ..................................................1-2

1.7.6 Retention ................................................................................................................ 1-2

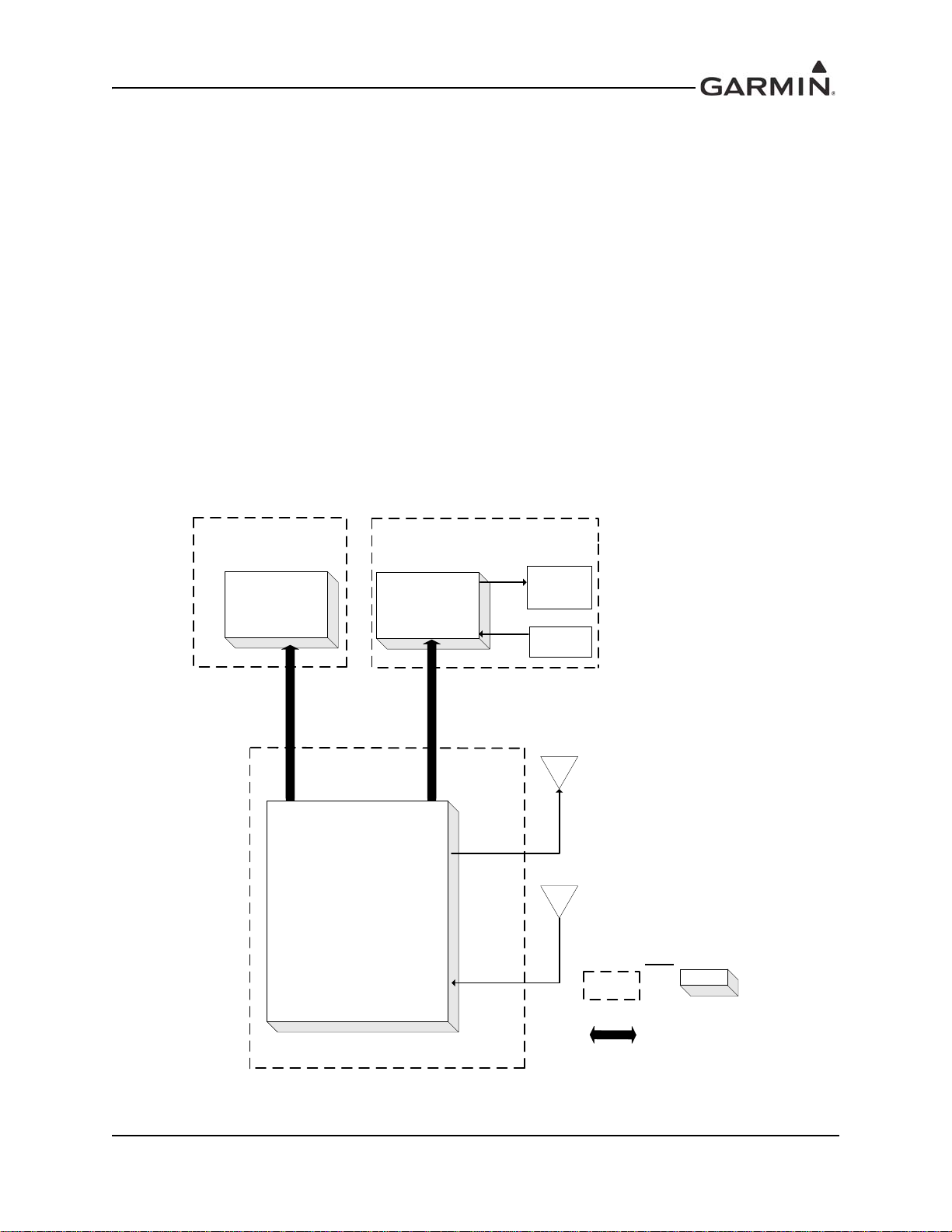

2 SYSTEM DESCRIPTION ................................................................................................................2-1

2.1 Description of Alteration ...........................................................................................................2-1

2.2 Block Diagram ..........................................................................................................................2-1

3 GRA 55/5500 CONTROL AND OPERATION .............................................. ..... .... .......................3-1

3.1 Control, Operating, and Testing Information ............................................................................3-1

3.2 Downloading and Installing the GRA 55/5500 Retrofit Installation Tool ................................3-1

3.3 Using the GRA 55/5500 Retrofit Installation Tool ...................................................................3-2

3.4 Installation Tool Pages ..............................................................................................................3-2

3.4.1 Status Page ............................................................................................................. 3-3

3.4.2 Configuration Page ................................................................................................ 3-4

3.4.3 Software Page ........................................................................................................ 3-5

3.4.4 Diagnostics Page .................................................................................................... 3-6

3.4.5 Utilities Page ..........................................................................................................3-7

3.4.6 Zero-Foot Calibration ............................................................................................ 3-8

4 INSTRUCTIONS FOR CONTINUED AIRWORTHINESS ........................................................4-1

4.1 Servicing Information ............................................................. ..... .............................................4-1

4.2 Periodic Maintenance ................................................................................................................4-1

4.3 Special Tools .............................................................................................................................4-1

4.4 Maintenance Intervals ................ ........................................................... .... ..... ...........................4-2

5 TROUBLESHOOTING INFORMATION .....................................................................................5-1

5.1 GRA 55/5500 General Troubleshooting ...................................................................................5-1

6 REMOVAL AND REPLACEMENT INFORMATION ...............................................................6-1

6.1 Unit Installation .........................................................................................................................6-1

6.1.1 Installation Procedure ............................................................................................ 6-1

6.1.2 Removal Procedure ................................................................................................ 6-1

6.2 Rack Installation ........................................................................................................................6-1

6.2.1 Installation Procedure ............................................................................................ 6-1

6.2.2 Removal Procedure ................................................................................................ 6-1

6.3 Antenna Installation ..................................................................................................................6-1

190-01277-A3 System Maintenance Manual GRA 55/5500 Bell 206 STC

Rev. 1 Page ii

Page 7

TABLE OF CONTENT CONTINUED

6.3.1 Installation Procedure ............................................................................................ 6-1

6.3.2 Removal Procedure ................................................................................................ 6-2

7 RETURN TO SERVICE PROCEDURE ........................................................................................7-1

7.1 Return to Service .......................................................................................................................7-1

7.2 Maintenance Records ................................................................................................................7-1

8 LIMITATIONS AND ADDITIONAL REQUIREMENTS ...........................................................8-1

8.1 Diagrams ...................................................................................................................................8-1

8.2 Special Inspection Requirements ..............................................................................................8-1

8.3 Application of Protective Treatments .......................................................................................8-1

8.4 Data Relative to Structural Fasteners ........................................................................................8-1

8.5 Additional Instructions ..............................................................................................................8-1

8.6 Overhaul Period .........................................................................................................................8-1

8.7 ICA Revision and Distribution ..................................................................................................8-1

8.8 Assistance ..................................................................................................................................8-1

8.9 Implementation and Record Keeping ........................................................................................8-2

9 AIRWORTHINESS LIMITATIONS SECTION ..........................................................................9-1

APPENDIX A AIRCRAFT SPECIFIC INFORMATION .............................................. A-1

A.1 Weight and Balance ................................................................................................................. A-5

190-01277-A3 System Maintenance Manual GRA 55/5500 Bell 206 STC

Rev. 1 Page iii

Page 8

LIST OF FIGURES

Figure 2-1. GRA 55/5500 Block Diagram ............................................................................ 2-1

Figure 3-1. Installation Tool Page Tabs ................................................................................ 3-2

Figure 3-2. Status Page .......................................................................................................... 3-3

Figure 3-3. Configuration Page .............................................................................................3-4

Figure 3-4. Software Page .....................................................................................................3-5

Figure 3-5. Diagnostics Page ................................................................................................. 3-6

Figure 3-6. Utilities Page ....................................................................................................... 3-7

Figure 6-1. GRA 55/5500 Installation ................................................................................... 6-2

Figure 6-2. Rack Installation .................................................................................................6-3

Figure 6-3. GRA 55/5500 Antenna Installation .................................................................... 6-3

Figure A-1. GRA STC Equipment Fuselage Station Location for Bell 206 ......................... A-1

Figure A-2. GRA STC Equipment Fuselage Station Location for Bell 206L Series ............ A-1

Figure A-3. GRA 55/5500 Unit and Rack Installation in the Bell 206B, 206L Series ......... A-2

Figure A-4. Overhead Circuit Breaker Panel in Bell 206B, 206L Series ............................. A-3

Figure A-5. GRA 55/5500 Wire Routing in the Bell 206B, 206L Series ............................. A-4

Figure A-6. GRA 55/5500 Unit Location and Moment Arm in Bell 206B, 206L Series ..... A-5

Figure A-7. Bell 206B LRU and Antenna Locations ............................................................ A-6

Figure A-8. Bell 206L Series LRU and Antenna Locations ................................................. A-7

190-01277-A3 System Maintenance Manual GRA 55/5500 Bell 206 STC

Rev. 1 Page iv

Page 9

LIST OF TABLES

Table 4-1. Maintenance Intervals for GRA 55/5500 ...........................................................4-2

Table 4-2. Maintenance Intervals for Antennas Replaced Under this STC ......................... 4-4

Table 5-1. GRA 5500 Fault Descriptions ............................................................................ 5-1

Table A-1. Bill of Materials ................................................................................................. A-2

Table A-2. Circuit Breaker Placard ..................................................................................... A-3

Table A-3. Weight and Balance Details .............................................................................. A-5

190-01277-A3 System Maintenance Manual GRA 55/5500 Bell 206 STC

Rev. 1 Page v

Page 10

1 INTRODUCTION

1.1 Purpose

This document provides Instructions for Continued Airworthiness in compliance with requirements of 14

CFR §27.1529, and Part 27 Appendix A. This ICA is to be used by the agency installing the Garmin GRA

55/5500 radar altimeter system under the GRA 55/5500 STC. This document includes information

required by the operator to adequately maintain the Garmin GRA55/5500 system as installed by this STC.

1.2 Scope

This document provides Instructions for Continued Airworthiness for the Bell 206B, 206L, L-1, L-3, and

L-4 rotorcraft, modified by the installation of the Garmin GRA 55/5500 STC.

1.3 Document Control

This document is released, archived, and controlled in accordance with the Garmin document control

system.

1.4 Permission to Use Certain Documents

Permission is granted to any corporation or person to use GRA 55/5500 STC documents to accomplish the

Instructions for Continued Airworthiness and show compliance with STC engineering data when applying

for approval. This permission does not construe suitability of the documents. It is the responsibility of the

applicant to determine the suitability of the documents for the ICA.

1.5 Definitions

The following terminology is used within this document:

1. ACO:Aircraft Certification Office

2. AEG:Aircraft Evaluation Group

3. AGL:Above Ground Level

4. BIT:Built-In Test

5. CFR:Code of Federal Regulations

6. FAA:Federal Aviation Administration

7. FMCW: Frequency Modulated Continuous Wave

8. FOD:Foreign Object Damage

9. ICA:Instructions for Continued Airworthiness

10. LRU:Line Replaceable Unit

11. NAV:Navigation

12. ODA:Organization Designation Authorization

13. PMI:Principal Maintenance Inspector

14. POI:Principal Operations Inspector

15. RX:Receive

16. STC:Supplemental Type Certificate

17. TSO: Technical Standard Order

18. TX:Transmit

190-01277-A3 System Maintenance Manual GRA 55/5500 Bell 206 STC

Rev. 1 Page 1-1

Page 11

1.6 Terminology

Except where specifically noted, references made to the ‘GRA’ will equally apply to the GRA 55 and GRA

5500 radar altimeters.

Also, except where specifically noted, references made to the ‘Bell 206L Series’ will apply equally to the

Bell 206L, Bell 206L-1, Bell 206L-3, and Bell 206L-4 models.

1.7 Publications

Content, Scope, Purpose and Arrangement:This document identifies the Instructions for Continued

Airworthiness for the modification of the aircraft by the installation of the Garmin GRA 55/5500 Part 27

STC.

1.7.1 Applicability

Applies to aircraft altered by the installation of the Garmin GRA 55/5500 Part 27 STC.

1.7.2 Definition of Abbreviations

See Section 1.5 and Section 1.6.

1.7.3 Precautions

None.

1.7.4 Units of measurement

None.

1.7.5 Referenced publications (or their later revisions)

1. Bell Model 206B Maintenance Manual, Bell Document BHT-206B-MM, Revision 12, 1 June

2012

2. Bell Model 206L Maintenance Manual, Bell Document BHT-206L-MM, Revision 36, 1 June 2012

3. Bell Model 206L1 Maintenance Manual, Bell Document BHT-206L1-MM, Revision 33, 1 June

2012

4. Bell Model 206L3 Maintenance Manual, Bell Document BHT-206L3-MM, Revision 19, 1 June

2012

5. Bell Model 206L4 Maintenance Manual, Bell Document BHT-206L4-MM, Revision 16, 1 June

2012

6. Structural Repair Manual for Bell Model 206 Series Helicopters, BHT-206-SRM-1, Revision 1,

April 1995

7. Electrical Standard Practices Manual for all Bell Helicopter Commercial Products, BHT-ELECSPM, Revision 2, July 2012

1.7.6 Retention

This document, or the information contained within, will be included in the aircraft’s permanent records.

190-01277-A3 System Maintenance Manual GRA 55/5500 Bell 206 STC

Rev. 1 Page 1-2

Page 12

2 SYSTEM DESCRIPTION

0DLQ

3URFHVVLQJ

8QLW

7;

/58

0LFURSURFHVVRU

EDVHGVXEV\VWHP

$5,1&

*5$

3)'

&RORU

'LVSOD\

.QREV

%XWWRQV

.(<

5;

$5,1&&RQWURO'LVSOD\8QLW

*+

*71

$5,1&

*71;;;;

2.1 Description of Alteration

This STC upgrades the existing functionality of the Bell 206B, 206L series aircraft avionics system as

summarized below.

The GRA 55/5500 radar altimeter system features: two antenna architecture for transmitting and receiving

radio waves for altitude quantities, remote mounted LRU transceiver for quantifying Above Ground Level

(AGL) altitude information, and interface capabilities to the existing aircraft G500H Flight Deck System

(FDS) for pilot display of aircraft altitude and system degraded warnings. The GRA 55/5500 radar

altimeter may also integrate with an installed Garmin GTN 6XX/7XX for the purpose of providing the

optional 50 ft callout as part of optional HTAWS functionality.

The GRA 55/5500 LRU which is 3.99"x3.02"x11.62" mounted, is located on the supplied mounting rack

that is electrically bonded to the avionics shelf. The two approved radar altimeter antennas are optimally

located on the underside of the tailboom, separated by a minimum distance of 20" on center using

approved antenna mounts installed via STC SR09598RC, STC SR02162LA or other mounting provisions

that are compatible with the approved radar altimeter antennas. The system requires a 5 Amp minimum

circuit breaker installed on the overhead panel to supply power.

2.2 Block Diagram

Figure 2-1. GRA 55/5500 Block Diagram

190-01277-A3 System Maintenance Manual GRA 55/5500 Bell 206 STC

Rev. 1 Page 2-1

Page 13

3 GRA 55/5500 CONTROL AND OPERATION

NOTE

3.1 Control, Operating, and Testing Information

The GRA 55/5500 is a fully automated, remote-mounted LRU which requires no user controls or inputs.

The GRA 55/5500 displays the radar altitude height above ground level on compatible display systems.

Radar altitudes will be displayed ranging from ground level to 2550ft AGL.

The GRA 55/5500 has a built-in self-test (BIST/BITE) and fault logging functionality which includes

automated self-test and fault detection monitoring of the entire internal TX and RX circuitry. This feature

occurs every time the unit power is cycled and subsequently every minute during normal operation at

calculated altitudes ranging from 250ft to 2550ft AGL and during “No Computed Data” (NCD) conditions.

The GRA 55/5500 will encounter NCD conditions; at actual altitudes above 2550ft AGL, during excess

pitch or roll maneuvering, or anytime the ground reflection is poor.

3.2 Downloading and Installing the GRA 55/5500 Retrofit Installation Tool

GRA 55/5500 configuration, calibration, diagnostics, and software upgrades are performed using a

personal computer (installed with Microsoft Windows XP Service Pack 3 or later) and the GRA 55/5500

Retrofit Installation Tool, Garmin part number 006-A0451-00. The tool is available for download from the

Dealer Resource Center portion of the Garmin website (www.garmin.com). See the accompanying

“readme” file in the tool’s installation directory for the latest instructions.

A standard USB-A plug to USB-B plug commercial cable (not provided) is required to

interface between a personal computer USB-A receptacle and the GRA 55/5500 USB-B

receptacle installed in the wiring harness. This dongle cable is required to use the GRA

55/5500 Retrofit Installation Tool.

Installation

1. Once downloaded, launch the installation file from the directory in which it is stored (or use the

web browser’s download shortcuts).

2. The GRA 55/5500 Retrofit Installation Tool Setup Wizard will begin.

3. Click “Next” as prompted by the setup wizard, and adjust any settings (e.g. installation directory)

as needed.

4. The last screen of the setup wizard will show “Installation Complete.” Click the “Close” button to

close the setup wizard.

190-01277-A3 System Maintenance Manual GRA 55/5500 Bell 206 STC

Rev. 1 Page 3-1

Page 14

3.3 Using the GRA 55/5500 Retrofit Installation T ool

Once the GRA 55/5500 Retrofit Installation Tool has been installed:

1. Connect the PC to the GRA 55/5500

2. Start the GRA 55/5500 Retrofit Installation Tool from the provided “Start Menu” shortcut, or

launch the application from its program folder

3. Power-up the GRA 55/5500 by applying aircraft power

4. The connection status in the lower, right-hand corner of the GRA 55/5500 Retrofit Installation

Tool will transition from “Not Connected,” to “Connected.”

5. If the GRA 55/5500 Retrofit Installation Tool does not display “Connected” in the lower, righthand corner, check the installation and make sure the GRA 55/5500 has been powered-up and that

the USB cable is properly connected to the PC.

If the PC displays a “Found New Hardware” wizard, the GRA 55/5500 Retrofit Installation Tool was not

able to automatically install the device driver. It may be necessary to manually install the device drivers.

Copies of the drivers’ “.inf” and “.dll” files are located in the target installation directory selected during

installation. Consult the PC’s operating system documentation on manually installing drivers.

3.4 Installation Tool Pages

The Installation Tool contains five tabbed pages, all of which can be useful in troubleshooting a problem.

The pages are: Status, Configuration, Software, Diagnostics, and Utilities (See Figure 3-1).

Figure 3-1. Installation Tool Page Tabs

190-01277-A3 System Maintenance Manual GRA 55/5500 Bell 206 STC

Rev. 1 Page 3-2

Page 15

3.4.1 Status Page

The status page (Figure 3-2) is displayed by selecting the Status tab. This page provides the basic fault

status of the unit. During normal operation, the status of each fault should indicate “normal.” If the unit

indicates a fault, the fault’s entry on the list is displayed in a bold, red font. The status also updates to show

the specific failure under that fault. Table 5-1 identifies the various unit faults that can be encountered

during normal operation of the GRA 55/5500. Use Table 5-1 as a reference to determine the proper actions

to take after a fault has been identified.

Figure 3-2. Status Page

190-01277-A3 System Maintenance Manual GRA 55/5500 Bell 206 STC

Rev. 1 Page 3-3

Page 16

3.4.2 Configuration Page

The configuration page (Figure 3-3) provides an interface to change the unit’s per-airframe configuration.

The configuration tab displays the unit’s current settings. After adjusting any settings, the “Save

Configuration to Unit” button must be clicked to send the configuration values to the GRA 55/5500.

Clicking the button labeled “Restore Defaults to Unit” restores all settings to their default, factory state.

The GRA 55 does not utilize ARINC 429 Channel 2 and that section will not be selectable.

Figure 3-3. Configuration Page

190-01277-A3 System Maintenance Manual GRA 55/5500 Bell 206 STC

Rev. 1 Page 3-4

Page 17

3.4.3 Software Page

The software page (Figure 3-4) provides a list of currently installed software regions on the GRA 55/5500

as well as an interface to load new software regions to the unit.

Figure 3-4. Software Page

190-01277-A3 System Maintenance Manual GRA 55/5500 Bell 206 STC

Rev. 1 Page 3-5

Page 18

3.4.4 Diagnostics Page

The Diagnostics Page (see Figure 3-5) allows the user to download the unit’s assert log. In normal

condition, there should be no logged asserts and this page will be disabled. If an assert has been logged to

the unit, the “Download Asserts” button will be selectable. This will download the logged asserts from the

unit and display them on the Assert Log Records list. Basic information about each assert (the power-on

cycle, the total power-on time, the type of fault or assert, and the status message accompanying the assert)

is displayed.

The “Capture Raw Log to File…” button and the “Export Log to CSV…” button may be used to save the

assert log (for further diagnostic evaluation). The raw log option will be most helpful when communicating

issues to Garmin Engineering. The CSV log option will be most helpful for end-users not familiar with the

internal logging format. These two buttons will only be selectable after the assert log has been downloaded

from the unit.

Figure 3-5. Diagnostics Page

190-01277-A3 System Maintenance Manual GRA 55/5500 Bell 206 STC

Rev. 1 Page 3-6

Page 19

3.4.5 Utilities Page

The Utilities Page (see Figure 3-6) displays statistics and information about the current state of the unit.

These values are updated every two seconds. All values are labeled, and include units (where necessary).

Minimum and Maximum internal temperatures experienced by the unit during operation are also

displayed.

Figure 3-6. Utilities Page

190-01277-A3 System Maintenance Manual GRA 55/5500 Bell 206 STC

Rev. 1 Page 3-7

Page 20

3.4.6 Zero-Foot Calibration

Anytime the GRA 55/5500 is removed and reinstalled in the helicopter, a one-time zero-foot calibration

procedure must be performed on the unit in order to “zero” the altitude outputs from the unit. This

procedure removes the altitude offsets associated with antenna cables, antenna height above ground, etc.

This procedure is performed via the GRA 55/5500 Retrofit Installation Tool.

The following conditions must be met before the zero-foot calibration procedure should be attempted:

1. The entire GRA 55/5500 must be completely installed and mounted in the final configuration as

representative of normal flight conditions.

2. A visual inspection must be performed to verify antenna installation and the antenna coaxial cables

are installed and connected properly.

3. The zero-foot calibration procedure must be performed outdoors on a hard, flat surface and away

from hangars, buildings, or other metal structures that may reflect the radar signal.

4. GRA 55/5500 Retrofit Installation Tool must be connected to the GRA via USB dongle cable.

The GRA 55/5500 Retrofit Installation Tool provides an interface button to initiate the zero-foot

calibration procedure. Clicking this button will make a series of requests to the connected GRA 55/5500.

During the calibration procedure, the GRA 55/5500 Retrofit Installation Tool will report progress updates

next to the “Initiate Calibration Procedure” button. Once the calibration procedure has completed, the text

will display “Calibration Complete” and the status tab will be updated. If the fault list does not annunciate

any faults and the information displayed in the status bar area indicates “0 ft” and “Normal,” the unit has

been successfully calibrated.

190-01277-A3 System Maintenance Manual GRA 55/5500 Bell 206 STC

Rev. 1 Page 3-8

Page 21

4 INSTRUCTIONS FOR CONTINUED AIRWORTHINESS

4.1 Servicing Information

None. In the event of system failure, troubleshoot the GRA 55/5500 in accordance with Section 5 of this

document.

4.2 Periodic Maintenance

The GRA is designed to detect internal failures. A thorough self-test is executed automatically upon

application of power to the unit. Furthermore, automated built-in tests (BIT) are continuously executed

every minute within the altitude range of 250ft to 2550ft.

Operation of the GRA 55/5500 is not permitted unless the inspections described in this section have been

completed within the time intervals prescribed in Table 4-1.

4.3 Special Tools

A milliohm meter with an accuracy of +/- 0.1 milliohms ohms (or better) is required to measure the

electrical bonding between the GRA 55/5500 LRU and aircraft ground.

190-01277-A3 System Maintenance Manual GRA 55/5500 Bell 206 STC

Rev. 1 Page 4-1

Page 22

4.4 Maintenance Intervals

Table 4-1. Maintenance Intervals for GRA 55/5500

Item Description/Procedure Interval

Removal and replacement of the following items. See

Equipment Removal

and Replacement

Test – Bonding Check,

GRA 55/5500 &

MOUNT RACK

Section 6 for removal and replacement instructions.

• GRA 55/5500 Mount Rack

• GRA 55/5500 LRU

• Antenna

Perform an electrical bonding check as follows:

1. Disconnect the wire harnesses from the GRA 55/

5500 at P55001, TX, and RX connections.

2. Measure the resistance between the mounting rack

and a nearby exposed portion of metallic structure.

Verify that the resistance is less than or equal to

2.5 milliohms.

3. Measure the resistance between the GRA 55/5500

LRU and the mounting rack. Verify that the

resistance is less than or equal to 2.5 milliohms.

In the event of a bonding test failure, remove the LRU

and rack, if required, and verify that the mating surfaces

for the LRU and/or mounting rack are free of corrosion

or any other debris. Clean, inspect and re-burnish (if

required) all mating surfaces using approved methods

and solvents per Bell specification

BHT-ELEC-SPM CHP 8.

Reinstall the mounting rack and GRA LRU to the

designated location.

Re-verify the resistance between the mounting rack and

nearby exposed portion of aircraft metallic structure and

ensure that the resistance is less than or equal to

2.5 milliohms.

Re-verify the resistance between the GR A LRU the

mount rack. Ensure the resistance is less than or equal

to 2.5 milliohms.

On Condition

To be performed in

alignment with Bell

206B, 206L series

maintenance

schedule. Every 10

years or every 2000

hours, whichever

comes first.

4. Reconnect the previously disconnected wire

harnesses ensuring that the coaxial connectors are

reconnected into their respective locations.

190-01277-A3 System Maintenance Manual GRA 55/5500 Bell 206 STC

Rev. 1 Page 4-2

Page 23

Item Description/Procedure Interval

Hard Landing

Inspection

1. Complete visual examination of rotorcraft structure

(shelf) supporting GRA unit for damage to verify

integrity, including unit mounting rack and rack

fasteners. Check and re-torque mounting rack

fasteners 20 to 25 in-lbs if required. Repair GRA

unit support structure in accordance with BHT-206SRM-1 Structural Repair Manual, and BHT-ALLSPM Bell Standard Practices Manual if required.

2. Visually inspect integrity of the GRA unit for

damage. Operation of the GRA unit is verified

through unit self-test at power-up.

3. Visually inspect integrity of the GRA antennas,

antenna fasteners, and antenna sealant for

damage. If required, check and re-torque antenna

fasteners 20 to 25 in-lbs, and remove and replace

antenna sealant (MIL-A-46146).

4. Inspect all system connectors for FOD and check

for bent, broken, or recessed pins.

On Condition

190-01277-A3 System Maintenance Manual GRA 55/5500 Bell 206 STC

Rev. 1 Page 4-3

Page 24

Item Description/Procedure Interval

Visual Inspection

The GRA mount, unit and wiring harnesses should be

inspected to ensure continued integrity of the

installation in alignment with Chapter 5, under the

relevant section covering 100-Hour and Annual

Inspections of applicable Bell 206B, 206L series

Model Maintenance Manual. Perform a visual

inspection of the GRA unit, unit mount, and wiring

harnesses to verify integrity.

1. Inspect the GRA unit for sec urity of attachment,

including visual inspection of the mounting rack

and rotorcraft support structure to which the rack

is attached. Verify the fastener heads are in full

contact with unit mounting rack and re-torque 20

to 25 in-lbs if required.

2. Inspect GRA55/5500 unit, unit mounting rack, and

rotorcraft support structure for signs of corrosion

and apparent signs of damage. If corrosion is

found, treat affected areas in accordance with

Chapter 3 of BHT-ALL-SPBM Bell Helicopter

Standard Practices Manual, Revision 2, or later

approved revision. If damage to GRA unit support

structure is found, repair as required in

accordance with BHT-206-SRM-1 Structural

Repair Manual, Revision 3, or later approved

revision.

3. Inspect placards and all labels. Ensure that they

are legible and properly adhered. Damaged

placards and labels should be replaced as

necessary.

4. Inspect wire and shield terminations, condition of

wiring harness, routing, and security of its

attachment/clamping to rotorcraft structure. Check

for chaffed or damage wires and ensure overall

functionality of wire installation.

5. Inspect all system connectors for bent/broken or

recessed pins. Inspect connectors for FOD.

To be performed in

alignment with Bell

206B, 206L series

maintenance

schedule. Every 100

flight hours or every

12 months,

whichever comes

first.

190-01277-A3 System Maintenance Manual GRA 55/5500 Bell 206 STC

Rev. 1 Page 4-4

Page 25

Table 4-2. Maintenance Intervals for Antennas Replaced Under this STC

Item Description/Procedure Interval

Test – Bonding Check,

Antennas

An electrical bonding test must be performed on

antennas installed by this STC.

1. Gain access to the antenna installation.

2. Remove one each mounting screw from the

antenna if not already done. Check that the

remaining hardware is installed and properly

torqued.

3. Measure the resistance between the e xposed metal

in the empty mounting hole of the antenna and a

nearby exposed portion of conductive aircraft

structure (i.e. exposed rivet). Verify that the

resistance is less than or equal to 2.5 milliohms.

4. Reinstall the antenna mounting screw, torque as

specified. Reseal the antenna as required.

In the event of a bonding test failure, remove the failed

antenna, Clean and inspect all hardware and mating

surfaces using approved solvents and metho ds per Bell

specification BHT-ELEC-SPM CHP 8.

For antennas that are secured with nuts and bolts,

clean the fastener hole in the antenna and the

underside of the fastener head itself. Prep the area

underneath the washer on the inner mould line of the

skin in accordance with Bell Specification

BHT-ELEC-SPM CHP 8. If nutplates are used in lieu of

a nut, the technician is only required to clean the

underneath of the fastener head and the fastener hole.

To be performed in

alignment with Bell

206B, 206L series

maintenance

schedule. Every 10

years or every 2000

hours, whichever

comes first.

For antennas that use stud mounts, prep the area

underneath the washer on the inner mould line of the

skin in accordance with Bell Specification

BHT-ELEC-SPM CHP 8.

Re-install using Antenna Installation procedures in

Section 6.3. Any reworked antenna installation shall

have a resistance of less than or equal to 2.5 milliohms.

Re-seal the antenna as per methods specified in

BHT-ELEC-SPM CHP 8.

190-01277-A3 System Maintenance Manual GRA 55/5500 Bell 206 STC

Rev. 1 Page 4-5

Page 26

Item Description/Procedure Interval

Visual inspection on the antenna:

1. Clean the antenna with water and mild soap.

2. Verify there are no cracks on the antenna and

around attachment fasteners.

3. Verify that all sealing fillets around the antenna are

in good condition.

If the antenna is broken, cracked, or dented it must be

replaced.

Visual Inspection of

the antennas

In the event attachment is not secure, re-attach an tenna

and complete the Electrical Bonding Test.

In the event the antenna seal shows signs of damage,

complete the Electrical Bonding Test and re-seal the

antenna.

Visual inspection of the rotorcraft exterior skin around

installed antenna:

1. Clean the exterior of the aircraft skin within a 10

inch radius of the antenna with water and mild

soap.

2. Inspect aircraft skin around the antenna footprint to

verify there are no cracks and aircraft skin is not

deformed.

3. Verify that antenna fasteners are not loose.

If the aircraft skin is cracked, or deformed, the internal

structure must also be inspected for degradation in the

local area. Refer to approved method defined in the

Structural Repair Manual For Bell Model 206 Series

Helicopters, BHT-206-SRM- 1, Section 3 for applicable

repairs.

To be performed in

alignment with Bell

206B, 206L series

maintenance

schedule. Every 100

flight hours or every

12 months,

whichever comes

first.

Perform visual

inspection in event of

suspected lightning

strike.

190-01277-A3 System Maintenance Manual GRA 55/5500 Bell 206 STC

Rev. 1 Page 4-6

Page 27

5 TROUBLESHOOTING INFORMATION

5.1 GRA 55/5500 General Troubleshooting

This section provides troubleshooting information for the Garmin GRA 55/5500 Radar Altimeter. All

faulty units must be returned to Garmin for repair.

No internal or comprehensive unit troubleshooting is possible at the dealer service center due to the need

for specialized unit test setups and test software. However, the service center may troubleshoot a unit to

confirm a fault or the status of the unit by utilizing the following methods:

• Checking the status of monitored unit faults

• Checking the unit software versions

• Checking the unit installation configuration

• Downloading and analyzing the unit assert log

• Checking the unit statistics and internal recorded unit temperatures

The troubleshooting methods listed herein are employed using the GRA 55/5500 Retrofit Installation Tool

as described in the following sections.

Table 5-1. GRA 5500 Fault Descriptions

Fault Type Fault Name Description Cause Resolution

Configuration N/A Unit does not boot

Average frequency

of zero-foot signal

Zero-Foot Lock

Calibration

Zero-Foot Cal

is larger/smaller

than allowable

frequencies

Zero-Foot point is

not set

GRA HW Revision

ID invalid for SW

version

GRA Unit ID

invalid (Both

discrete inputs

grounded)

Hardware failure

Improper antenna

connections

Calibration not

complete

Update software to

correct version for

hardware

Check Unit ID

strapping and set

to a valid ID

Return unit to

Garmin for service

Check antenna

installation and all

cable connections

and retry

calibration. Note

there are no assert

log entries for this

fault.

Calibrate unit while

on ground. Note

there are no assert

log entries for this

fault.

190-01277-A3 System Maintenance Manual GRA 55/5500 Bell 206 STC

Rev. 1 Page 5-1

Page 28

Fault Type Fault Name Description Cause Resolution

POST (Power On

Self-Test)

PLL Register

RF Self-Test

Sensor Boot

Various [1]

After programming,

read-back of the

PLL register values

does not match

what was sent from

the CPU

The self-test signal

is not within the

acceptable

frequency range

Sensor processor

software not

successfully loaded

Numerous tests

identified in this

table are run during

Power On Self-Test

(POST). Failure of

these tests is

identified as a

POST fault during

power up and also

identified by the

fault name in the

fault log.

Internal

communication

error

Improper antenna

connections

Internal failure

Internal

communication

error

Various [1]

Cycle power to

unit. If fault

persists, return unit

to Garmin for

service.

Check antenna

installation and all

cable connections.

Download the

assert log and

send to Garmin for

diagnosis. If fault

persists, return unit

to Garmin for

service.

Cycle power to

unit. If fault

persists, return unit

to Garmin for

service.

190-01277-A3 System Maintenance Manual GRA 55/5500 Bell 206 STC

Rev. 1 Page 5-2

Page 29

Fault Type Fault Name Description Cause Resolution

Clock Generator is

read to determine

correct frequency

output.

Sensor is read to

determine correct

operation.

ADC did not

respond to

sampling

conversion

command within

20us

ADC used to

monitor internal unit

voltages fails

self-test

Clock generator

programming

failure

Memory integrity

test

Failed to validate

code sections in

memory

Sensor processor

code failed validity

check

Sensor CPU fails to

respond to Main

CPU or packet

information is not

correct from sensor

Sensor processor

reset signal

triggered by sensor

watchdog

Internal

communication

error

ADC failure

Clock generator

failure

Memory failure

Code corrupted in

flash memory

Code corrupted

during transfer

from flash to RAM

Code corrupted

during transfer

from flash to main

processor

Code corrupted

during transfer

from main to

sensor processor

Sensor processor

failure

Internal

communication

error

Sensor processor

failure

Internal

communication

error

Cycle power to

unit. If fault

persists, return unit

to Garmin for

service.

Cycle power to

unit. If fault

persists, return unit

to Garmin for

service.

Digital HW

Digital HW

Clock Generator I2C

Main Temp Sensor I2C Temperature

RF Temp Sensor I2C

ADC (Voltage Monitor)

ADC Monitor (X)

(Fault also included in

POST, Power On Self

Test Faults) [1]

Clock Generator

Register

DDR

Flash-to-RAM Code

Sensor Code CRC

Sensor Status

Sensor Watchdog

190-01277-A3 System Maintenance Manual GRA 55/5500 Bell 206 STC

Rev. 1 Page 5-3

Page 30

Fault Type Fault Name Description Cause Resolution

Check aircraft

power supply.

Cycle power to

unit.

If fault persists,

download the

assert log and

send to Garmin for

diagnosis.

Check aircraft

power supply.

Cycle power to

unit.

If fault persists,

download the

assert log and

send to Garmin for

diagnosis.

Check aircraft

power supply.

Cycle power to

unit.

If fault persists,

download the

assert log and

send to Garmin for

diagnosis.

Check aircraft

power supply.

Cycle power to

unit.

Check aircraft

power supply.

Cycle power to

unit.

If fault persists,

download the

assert log and

send to Garmin for

diagnosis.

Electrical

(+ / -) 12.5V Monitor

(Fault also included in

POST, Power On Self

Test Faults) [1]

+12.5V RF Monitor

(Fault also included in

POST, Power On Self

Test Faults) [1]

+8V RF Monitor

(Fault also included in

POST, Power On Self

Test Faults) [1]

+80V Backup Monitor

(Fault also included in

POST, Power On Self

Test Faults) [1]

-6V RF Monitor

(Fault also included in

POST, Power On Self

Test Faults) [1]

(+ / -) 12.5 V power

rail outputs

improper voltage

+12.5 V RF power

rail outputs

improper voltage

+8 V RF power rail

outputs improper

voltage

+80 V backup

power rail outputs

improper voltage

-6 V RF power rail

outputs improper

voltage

Aircraft power

input voltage out of

range

Internal power

supply failure

Aircraft power

input voltage out of

range

Internal power

supply failure

Aircraft power

input voltage out of

range

Internal power

supply failure

Aircraft power

input voltage out of

range

Aircraft power

input voltage out of

range

Internal power

supply failure

190-01277-A3 System Maintenance Manual GRA 55/5500 Bell 206 STC

Rev. 1 Page 5-4

Page 31

Fault Type Fault Name Description Cause Resolution

Check aircraft

power supply.

Cycle power to

unit.

If fault persists,

download the

assert log and

send to Garmin for

diagnosis.

Check aircraft

power supply.

Cycle power to

unit.

If fault persists,

download the

assert log and

send to Garmin for

diagnosis.

Check aircraft

power supply.

Cycle power to

unit.

If fault persists,

download the

assert log and

send to Garmin for

diagnosis.

Check aircraft

power supply.

Cycle power to

unit.

If fault persists,

download the

assert log and

send to Garmin for

diagnosis.

Check aircraft

power supply.

Cycle power to

unit.

If fault persists,

download the

assert log and

send to Garmin for

diagnosis.

+5.75V RF Monitor

(Fault also included in

POST, Power On Self

Test Faults) [1]

+5.75V Monitor

(Fault also included in

POST, Power On Self

Test Faults) [1]

Electrical

+3.3V Monitor

(Fault also included in

POST, Power On Self

Test Faults) [1]

+1.9V Monitor

(Fault also included in

POST, Power On Self

Test Faults) [1]

Electrical Current Monitor

+5.75 V RF power

rail outputs

improper voltage

+5.75 V power rail

outputs improper

voltage

+3.3 V power rail

outputs improper

voltage

+1.9 V power rail

outputs improper

voltage

Improper current on

+8 V power rail

Aircraft power

input voltage out of

range

Internal power

supply failure

Aircraft power

input voltage out of

range

Internal power

supply failure

Aircraft power

input voltage out of

range

Internal power

supply failure

Aircraft power

input voltage out of

range

Internal power

supply failure

Aircraft power

input voltage out of

range

Internal power

supply failure

190-01277-A3 System Maintenance Manual GRA 55/5500 Bell 206 STC

Rev. 1 Page 5-5

Page 32

Fault Type Fault Name Description Cause Resolution

Check aircraft

power supply.

Cycle power to

unit.

Return power to

unit. Note there are

no assert log

entries for this

fault.

Cycle power to

unit. If fault

persists, return unit

to Garmin for

service.

If fault persists,

download the

assert log and

send to Garmin for

diagnosis.

If fault persists,

download the

assert log and

send to Garmin for

diagnosis.

Check antenna

installation and all

cable connections.

If fault persists,

download the

assert log and

send to Garmin for

diagnosis.

Check antenna

installation and all

cable connections.

Download the

assert log and

send to Garmin for

diagnosis. If fault

persists, return unit

to Garmin for

service.

Suspended Power Fail

DDS

TX PLL Lock

LO PLL Lock

Radio HW

Auto RF Self-Test

Main RF Self-Test

Aircraft power lost

for greater than 220

ms

Failure to program

DDS or read back

correct register

information from

the DDS

The TX PLL is not

locked while the

unit is transmitting.

The LO PLL is not

locked while the

unit is transmitting

The self-test signal

is not within the

acceptable

frequency range

The self-test signal

is not within the

acceptable

frequency range

Internal power

supply failure

Aircraft power

failure

Internal

communication

error

Internal failure

Internal failure

Improper antenna

connections

Internal failure

Improper antenna

connections

Internal Failure

190-01277-A3 System Maintenance Manual GRA 55/5500 Bell 206 STC

Rev. 1 Page 5-6

Page 33

Fault Type Fault Name Description Cause Resolution

Installed unit

location is too hot/

Main Temp

(Fault also included in

POST, Power On Self

Test Faults) [1]

Temperature

RF Temp

(Fault also included in

POST, Power On Self

Test Faults) [1]

[1] Fault can be found in the Power on Self Test (POST) fault list and in normal operational

mode fault list. Review Table 5-1 fault tree for identification.

Main board

temperature

greater than 100° C

or less than -60° C

RF board

temperature

greater than 100° C

or less than -60° C

cold

Internal failure

Installed unit

location is too hot/

cold

Internal failure

Return unit to

qualified

temperature range

as specified in

Environmental

Qualification Form

(EQF). If fault

persists, return unit

to Garmin for

service.

Return unit to

qualified

temperature range

as specified in

Environmental

Qualification Form

(EQF). If fault

persists, return unit

to Garmin for

service.

190-01277-A3 System Maintenance Manual GRA 55/5500 Bell 206 STC

Rev. 1 Page 5-7

Page 34

6 REMOVAL AND REPLACEMENT INFORMATION

6.1 Unit Installation

6.1.1 Installation Procedure

1. Place the unit on the mounting rack, ensuring the GRA 55/5500 rear feet are aligned in the

mounting rack slots.

2. Slide the GRA 55/5500 back until the feet are fully engaged with the mounting rack.

3. Lift the lockdown collar in place on the GRA 55/5500 hook and hand turn the lockdown

mechanism knob clockwise until the GRA 55/5500 is secure and the knob cannot reasonably be

ratcheted any tighter by hand.

6.1.2 Removal Procedure

1. Pull back on the lockdown mechanism and simultaneously turn counterclockwise until free.

2. Disengage the lockdown mechanism collar from the GRA 55/5500 hook and slide the

GRA 55/5500 forward to remove from the mounting rack.

6.2 Rack Installation

The GRA 55/5500 mounting surface should be capable of providing a sufficient electrical bond to the

aircraft to minimize Electromagnetic Interference (EMI) and provide protection from High-Intensity

Radiation Fields (HIRF). Bonding resistance measured between the GRA 55/5500 mounting rack and the

airframe must measure less than 2.5 milliohms.

6.2.1 Installation Procedure

1. Clean and inspect the mounting surface of the rack mount. Ensure the bonding surface is adequate

to meet the required resistance measurement of 2.5 milliohms.

2. Place the rack on the mounting shelf assembly with lockdown knob facing forward.

3. Install and secure mount rack with 4 ea. screw (see Table A-1for rack fasteners).

Torque 20-25 in lbs.

4. Perform bond resistance measurement. Value should be less than 2.5 milliohms.

6.2.2 Removal Procedure

1. Remove GRA 55/5500 unit if not already done.

2. Remove 4 ea. screw (see Table A-1for rack fasteners).

3. Remove mounting rack.

6.3 Antenna Installation

6.3.1 Installation Procedure

1. Clean and inspect the antenna mount. Remove debris and excess sealant if replacing existing

antenna.

2. Apply the conductive gasket on the underside of the antenna using the fastener holes as guides.

3. Use MS24693-C272 stainless steel countersunk head machine screws (No. 10, supplied) to secure

antennas. Verify that directional arrow on the antenna is pointed towards the front of the helicopter.

4. Torque antenna fasteners in a star pattern to 20-25 in lbs. Torque should be applied evenly across

all fasteners to avoid deformation of the mounting area.

5. Ensure that the antenna base and antenna mount are in continuous contact with the gasket.

190-01277-A3 System Maintenance Manual GRA 55/5500 Bell 206 STC

Rev. 1 Page 6-1

Page 35

6. Seal the antenna and gasket with an approved sealant compound (MIL-A-46146) along the edge of

UNIT HOOK

ENGAGEMENT

FEET

2 PLACES

FEET ENGAGEMENT

LOCATION

2 PLACES

LOCKDOWN MECHANISM COLLAR

LOCKDOWN MECHANISM KNOB

SECTION VIEW SHOWING

UNIT FEET ENGAGED INTO

MOUNTING RACK

2 PLACES

the antenna where it meets the antenna mount.

6.3.2 Removal Procedure

1. Remove the sealant compound (MIL-A-46146) along the edge of the antenna where it meets the

antenna mount using a non-metallic scraper.

2. Remove the hardware retaining the antenna in place.

3. Lower the antenna enough to disconnect the coaxial connector, and disconnect.

4. Remove the antenna and conductive gasket from the airframe.

190-01277-A3 System Maintenance Manual GRA 55/5500 Bell 206 STC

Rev. 1 Page 6-2

Figure 6-1. GRA 55/5500 Installation

Page 36

COMPARTMENT, BELL 206 L SERIES, OR 206-031-309-115 WEB

INSTALLATION, STA 130.00 TO 192.84, BELL 206B

REF. EXISTING 206-031-339-027 PANEL ASSEMBLY, BAGGAGE

MOUNTING SHELF ASSEMBLY

0.20 4 PLCS

REF. ADDED OR EXISTING

8 PLCS

0.179-100

0.098 THROUGH

TBS

50.22

TBS

31.80

TBS

71.44

S67-2002 RADAR ALTIMETER ANTENNA

INCLUDED WITH 013-00378-00 ANTENNA KIT

EXISTING ANTENNA MOUNTS

S67-200222 CONDUCTIVE GASKET, 0.020 INCH THICK

INCLUDED IN ANTENNA KIT

GARMIN P/N 013-00378-00 (2X)

MS24693-C272 SCREW, MACHINE COUNTERSUNK .1900-32UNF 2A

INCLUDED WITH 013-00378-00 ANTENNA KIT. TYP. 4 PLCS

Figure 6-2. Rack Installation

Figure 6-3. GRA 55/5500 Antenna Installation

190-01277-A3 System Maintenance Manual GRA 55/5500 Bell 206 STC

Rev. 1 Page 6-3

Page 37

7 RETURN TO SERVICE PROCEDURE

7.1 Return to Service

1. Perform Zero-Foot Calibration in accordance with Section 3.4.6.

2. Verify no faults exist in the Assert Log page prior to disconnecting Retrofit Installation Tool.

3. Verify that radar altitude is displayed correctly on the installed display with the GRA 55/5500 and

display powered on. If radar altitude is not displayed, verify correct configuration.

7.2 Maintenance Records

After conducting required return-to-service procedures in accordance with this document, the aircraft may

be returned to service. Record the following information in the aircraft maintenance logs:

1. Software versions loaded as part of any maintenance action.

2. Record part and serial numbers of any LRU that was replaced.

3. Any other applicable information related to the maintenance work performed on the aircraft.

190-01277-A3 System Maintenance Manual GRA 55/5500 Bell 206 STC

Rev. 1 Page 7-1

Page 38

8 LIMITATIONS AND ADDITIONAL REQUIREMENTS

8.1 Diagrams

Aircraft specific LRU locations and wire routing diagram are contained in Appendix A of this document.

Completed forms are to be retained with the aircraft permanent records.

Point-to-point wiring diagrams for the GRA 55/5500, and interfaced equipment shall be included with the

aircraft permanent records.

GRA 55/5500 component locations are described in Appendix A of this document.

8.2 Special Inspection Requirements

Visual inspection of antenna(s) must be performed if aircraft is suspected or was actually struck by

lightning. The scope of inspection shall extend to the GRA 55/5500 antennas and rotorcraft structure

supporting antenna installation to verify there is no damage. See Table 4-2 for inspection criteria.

Execute the system checkout procedure for the GRA 55/5500 system to ensure the system is operating

correctly.

8.3 Application of Protective Treatments

None. N/A.

8.4 Data Relative to Structural Fasteners

See Table A-1 and Figure A-3 for LRU fastener information. See Figure 6-3 for Antenna fastener

information.

8.5 Additional Instructions

None. N/A.

8.6 Overhaul Period

The system does not require overhaul at a specific time period. Power on self-test and continuous BIT will

monitor the health of the GRA system. If the LRU indicates an internal failure, the unit may be removed

and replaced (See Section 6 for Removal and Installation instructions). See Section 5 for troubleshooting

information.

8.7 ICA Revision and Distribution

To revise this ICA, Garmin will follow the Garmin ODA Procedures Manual SOP-0055/ACP-0016 for

Instructions for Continued Airworthiness. The latest revision of this ICA document is available on the

Garmin website (www.flyGarmin.com

select ‘Manuals’. You may also contact Garmin General Aviation Product Support at 866-739-5687 (US

toll free) 913-397-8200 or avionics@garmin.com

be sent to Garmin dealers if a revision is determined to be significant.

). To Access Aviation Manuals, select the ‘Support’ tab and then

. A Garmin Service Bulletin describing ICA revision will

8.8 Assistance

Flight Standards Inspectors or the certificate holder’s PMI have the required resources to respond to

questions regarding this ICA. In addition, the customer may contact Garmin with questions regarding this

equipment and its installation. Garmin Customer Support may be contacted during normal business hours

via telephone 913-397-8200 or from the Garmin web site at www.flyGarmin.com

.

190-01277-A3 System Maintenance Manual GRA 55/5500 Bell 206 STC

Rev. 1 Page 8-1

Page 39

8.9 Implementation and Record Keeping

Modification of an aircraft by this Supplemental Type Certificate obligates the aircraft operator to include

the maintenance information provided by this document in the operator’s aircraft maintenance manual and/

or the operator’s rotorcraft scheduled maintenance program.

190-01277-A3 System Maintenance Manual GRA 55/5500 Bell 206 STC

Rev. 1 Page 8-2

Page 40

Page 41

APPENDIX A AIRCRAFT SPECIFIC INFORMATION

FS 0.00

FS130.00

FS

142.33

WL 51.67

TBS 50.22

TBS 71.44

FS136.45

WL 0.00

GRA RADAR ALTIMETER INSTALLATION

REF. EXISTING AVIONICS SHELF

CIRCUIT BREAKER INSTALLATION

REF. EXISTING ANTENNA MOUNTS

REF. GARMIN

GDU 620 DISPLAY

REF. GARMIN

GTN NAVIGATOR

FS

0.00

FS155.00

FS

161.45

FS

167.33

WL 0.00

WL51.67

TBS 71.44

TBS 50.22

CIRCUIT BREAKER INSTALLATION

GRA RADAR ALTIMETER INSTALLATION

REF. EXISTING AVIONICS SHELF

REF. EXISTING ANTENNA MOUNTS

Figure A-1 and Figure A-2 depicts the typical location for the GRA55/5500 component locations.

Figure A-1. GRA STC Equipment Fuselage Station Location for Bell 206B

Figure A-2. GRA STC Equipment Fuselage Station Location for Bell 206L Series

190-01277-A3 System Maintenance Manual GRA 55/5500 Bell 206 STC

Rev. 1 Page A-1

Page 42

Figure A-3 depicts a typical installation of the GRA55/5500 unit and rack installation as performed in the

COMPARTMENT, BELL 206 L SERIES, OR 206-031-309-115 WEB

INSTALLATION, STA 130.00 TO 192.84, BELL 206B

REF. EXISTING 206-031-339-027 PANEL ASSEMBLY, BAGGAGE

MOUNTING SHELF ASSEMBLY

0.20 4 PLCS

REF. ADDED OR EXISTING

8 PLCS

0.179-100

0.098 THROUGH

Bell 206B and Bell 206L Series and reference notations to the bill of materials. Table A-1 provides the bill

of materials in reference to Figure A-3.

Figure A-3. GRA 55/5500 Unit and Rack Installation in the Bell 206B, 206L Series

Table A-1. Bill of Materials

Item No. Part Number Source Description QTY

1

011-02537-05

011-02537-00 GRA 5500 Radar Altimeter Unit

Garmin

2 015-2573-01 Garmin Connector Kit, GRA Radar Altimeter 1

3 015-2567-00 Garmin Rack, Mounting, GRA Radar Altimeter 1

Best

Source

Best

Source

Best

Source

4 AN525-10R7

5 MS21047-3

6 MS20470AD3-3

GRA 55 Radar Altimeter Unit

Screw, Washer Head, 0.1900-32 UNF-3A, 7/16"

Long

Nut, Self-Locking, Plate, Two-Lug, Low-Height,

Steel

Rivet, Solid, Countersunk 100 Deg, Precision

Head

(1)

4

4

8

190-01277-A3 System Maintenance Manual GRA 55/5500 Bell 206 STC

Rev. 1 Page A-2

Page 43

Figure A-4 depicts the overhead panel location in the Bell 206B, 206L Series.

DETAIL B

CIRCUIT BREAKER LABEL

VIEW A OVERHEAD CONSOLE

CIRCUIT BREAKER FOR GRA RADAR ALTIMETER

REF. LABELS FOR ADDED CIRCUIT BREAKER

B

REF. EXISTING ROTORCRAFT CIRCUIT BREAKER PANEL

AA

REF. EXISTING ROTORCRAFT OVERHEAD CONSOLE

breaker console. Equipment circuit breaker placards are labeled as follows:

LRU Power Input Label

GRA Rotorcraft Power on Connector P55001 Rad Alt

The GRA 55/5500 circuit breaker is located on the Bell 206B and Bell 206L Series overhead circuit

Figure A-4. Overhead Circuit Breaker Panel in Bell 206B, 206L Series

Table A-2. Circuit Breaker Placard

190-01277-A3 System Maintenance Manual GRA 55/5500 Bell 206 STC

Rev. 1 Page A-3

Page 44

Figure A-5 depicts the typical wire harness installation for the GRA 55/5500 system, to include the coaxial

WL0.00

FS 0.00

FS142.33

FS130.00

TBS 50.22

TBS 71.44

TBS 31.8

REF. RADAR ALTIMETER ANTENNAS

REF. GRA 55/5500 WIRING HARNESS

REF. COAXIAL CABLE

REF. CIRCUIT BREAKER

cable installation for the antennas. Due to aircraft configurations, minor deviations may exist to the

depicted routing. For additional details refer to the GRA 55/5500 installation manual.

Figure A-5. GRA 55/5500 Wire Routing in the Bell 206B, 206L Series

190-01277-A3 System Maintenance Manual GRA 55/5500 Bell 206 STC

Rev. 1 Page A-4

Page 45

A.1 Weight and Balance

FS

155.00

FS 130.00

6.20

BL 0.00

6.98

BELL 206B

BELL 206L

The location of equipment as well as the weight and moment arm for the installed item is depicted in

Figure A-6.

Figure A-6. GRA 55/5500 Unit Location and Moment Arm in Bell 206B, 206L Series

Table A-3. Weight and Balance Details

Item Description Part Number

GRA 55 Radar Altimeter

1

(Bell 206B)

GRA 5500 Radar Altimeter

2

(Bell 206B)

GRA 55 Radar Altimeter

3

(Bell 206L Series)

GRA 5500 Radar Altimeter

4

(Bell 206L Series)

011-02537-05 3.5 [1]

011-02537-00 3.5 [1]

011-02537-05 3.5 [1]

011-02537-00 3.5 [1]

Weight

(LB)

[1] Weight specified includes the unit, install rack, and backplate assembly with connectors.

Longitudinal Lateral

ARM (IN) Moment ARM (IN) Moment

136.20 476.70 -6.98 -24.43

161.20 564.20 -6.98 -24.43

190-01277-A3 System Maintenance Manual GRA 55/5500 Bell 206 STC

Rev. 1 Page A-5

Page 46

Figure A-7 depicts the location of the LRUs and antennas for the GRA 55/5500 throughout the aircraft

FS 0.00

FS 130.00

FS

142.33

WL 51.67

TBS 50.22

TBS 71.44

FS 136.45

WL 0.00

GRA RADAR ALTIMETER INSTALLATION

REF. EXISTING AVIONICS SHELF

CIRCUIT BREAKER INSTALLATION

REF. EXISTING ANTENNA MOUNTS

REF. GARMIN

GDU 620 DISPLAY

REF. GARMIN

GTN NAVIGATOR

structure for the Bell 206B rotorcraft. All harnesses fabricated as part of this STC follow existing wire

bundles as depicted in Figure A-5.

Figure A-7. Bell 206B LRU and Antenna Locations

190-01277-A3 System Maintenance Manual GRA 55/5500 Bell 206 STC

Rev. 1 Page A-6

Page 47

Figure A-8 depicts the location of the LRUs and antennas for the GRA 55/5500 throughout the aircraft

FS

0.00

FS 155.00

FS

161.45

FS

167.33

WL 0.00

WL 51.67

TBS 71.44

TBS 50.22

CIRCUIT BREAKER INSTALLATION

GRA RADAR ALTIMETER INSTALLATION

REF. EXISTING AVIONICS SHELF

REF. EXISTING ANTENNA MOUNTS

structure for the Bell 206L Series rotorcraft. All harnesses fabricated as part of this STC follow existing

wire bundles as depicted in Figure A-5.

Figure A-8. Bell 206L Series LRU and Antenna Locations

190-01277-A3 System Maintenance Manual GRA 55/5500 Bell 206 STC

Rev. 1 Page A-7

Page 48

Loading...

Loading...