Garmin GPSMAP 722 Installation manual

GPSMAP® 702/902 SERIES

TA-2016/3368

TA-2017/085

INSTALLATION

INSTRUCTIONS

Mounting Style Drill Bit Sizes

Bail with included M4 wood screws 3.2 mm (1/8 in.)

Flush 13 mm (1/2 in.)

Flush with included M3.5 wood screws (702 series) 2 mm (5/64 in.)

Flush with included M4 wood screws (902 series) 3.2 mm (1/8 in.)

Flush with included machine screws and nut plates 6 mm (1/4 in.)

4 mm (3/16 in.)

Flush with included M3.5 machine screws and

tapped holes (702 series)

Flush with included M4 machine screws and tapped

holes (902 series)

• #2 Phillips screwdriver

• Jigsaw or rotary tool

• File and sandpaper

• Marine sealant (recommended)

M3.5 tap

M4 tap

Important Safety Information

WARNING

See the Important Safety and Product Information guide in the

product box for product warnings and other important

information.

When connecting the power cable, do not remove the in-line

fuse holder. To prevent the possibility of injury or product

damage caused by fire or overheating, the appropriate fuse

must be in place as indicated in the product specifications. In

addition, connecting the power cable without the appropriate

fuse in place voids the product warranty.

CAUTION

Always wear safety goggles, ear protection, and a dust mask

when drilling, cutting, or sanding.

NOTICE

When drilling or cutting, always check what is on the opposite

side of the surface.

To obtain the best performance and to avoid damage to your

boat, install the device according to these instructions.

Read all installation instructions before proceeding with the

installation. If you experience difficulty during the installation,

contact Garmin® Product Support.

Contacting Garmin Support

• Go to support.garmin.com for help and information, such as

product manuals, frequently asked questions, videos, and

customer support.

• In the USA, call 913-397-8200 or 1-800-800-1020.

• In the UK, call 0808 238 0000.

• In Europe, call +44 (0) 870 850 1241.

Software Update

You may need to update the chartplotter software after

installation. For the instructions on how to update the software,

see the owner's manual at garmin.com/manuals/GPSMAP702

-902.

Tools Needed

• Drill

• Drill bits appropriate for the device and mounting style

Mounting Considerations

NOTICE

This device should be mounted in a location that is not exposed

to extreme temperatures or conditions. The temperature range

for this device is listed in the product specifications. Extended

exposure to temperatures exceeding the specified temperature

range, in storage or operating conditions, may cause device

failure. Extreme-temperature-induced damage and related

consequences are not covered by the warranty.

When selecting a mounting location, you should observe these

considerations.

• The location should provide optimal viewing as you operate

your boat.

• The location should allow for easy access to all device

interfaces, such as the keypad, touchscreen, and card

reader, if applicable.

• The location must be strong enough to support the weight of

the device and protect it from excessive vibration or shock.

• To avoid interference with a magnetic compass, the device

should not be installed closer to a compass than the

compass-safe distance value listed in the product

specifications.

• The location must allow room for the routing and connection

of all cables.

• The location must not be a flat, horizontal surface. The

location should be in a vertical angle.

The location and viewing angle should be tested before you

install the device. High viewing angles from above and below

the display may result in a poor image.

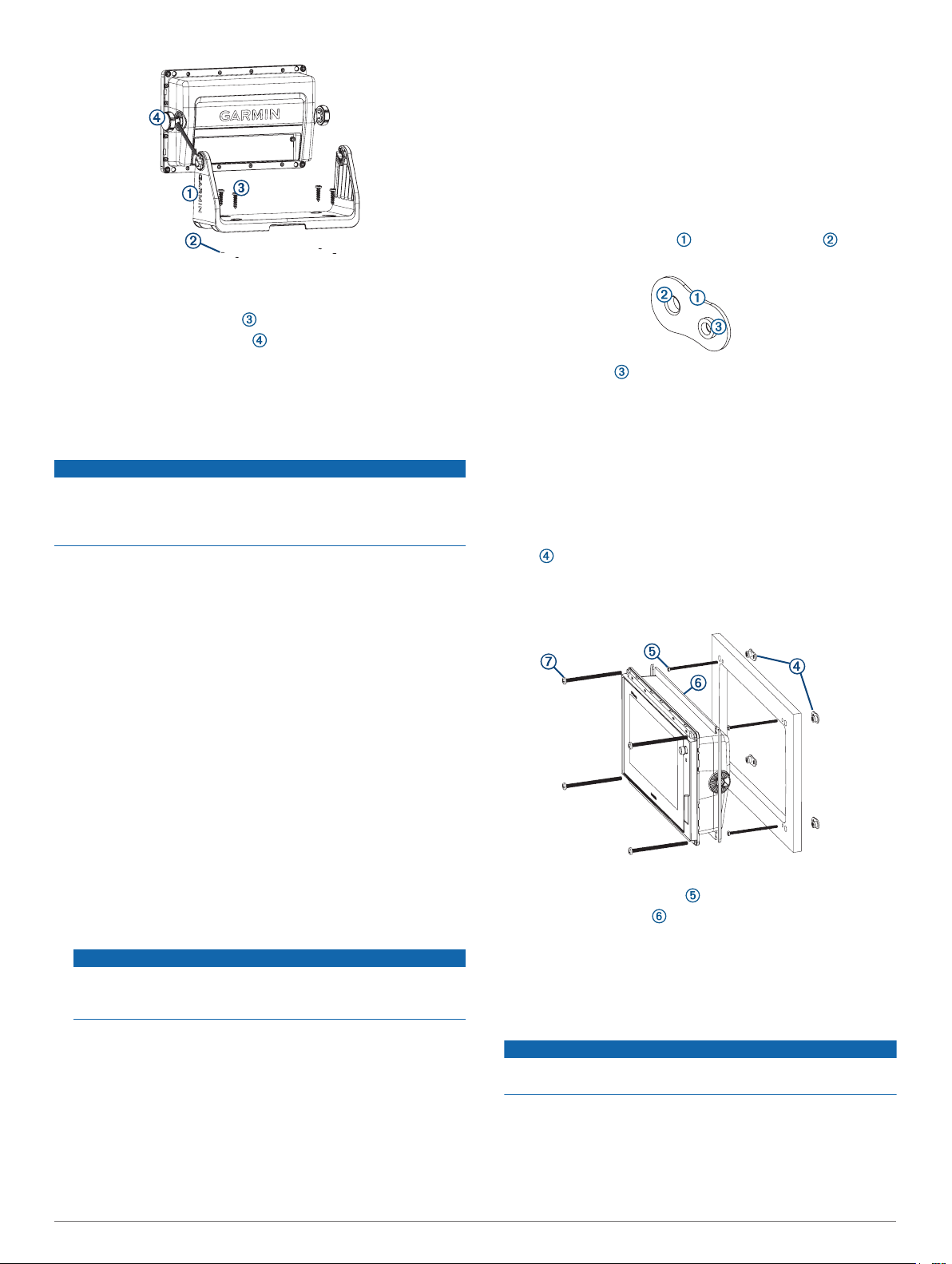

Bail Mounting the Device

NOTICE

If you are mounting the bracket on fiberglass with screws, it is

recommended to use a countersink bit to drill a clearance

counterbore through only the top gel-coat layer. This will help to

avoid cracking in the gel-coat layer when the screws are

tightened.

You can use the included bracket to bail mount the device on a

flat surface.

Using the bail-mount bracket as a template, mark the pilot

1

holes .

GUID-7AA5B76A-FA51-4893-BD66-64487F22275B v6September 2020

Using a 3.2 mm (1/8 in.) drill bit, drill the pilot holes.

2

Secure the bail-mount bracket to the surface using the

3

included M4 wood screws .

Install the bail-mount knobs on the sides of the device.

4

Place the device in the bail-mount bracket, and tighten the

5

bail-mount knobs.

Install the trim caps by snapping them in place around the

6

edges of the device.

Flush Mounting the Device

NOTICE

Be careful when cutting the hole to flush mount the device.

There is only a small amount of clearance between the case and

the mounting holes, and cutting the hole too large could

compromise the stability of the device after it is mounted.

The included template and hardware can be used to flush mount

the device in your dashboard. There are three options for

hardware based on the mounting surface material.

• You can drill pilot holes and use the included wood screws.

• You can drill holes and use the included nut plates and

machine screws. The nut plates can add stability to a thinner

surface.

• You can punch and tap holes, and use the included machine

screws.

Trim the template, and make sure it fits in the location where

1

you want to mount the device.

Secure the template to the mounting location.

2

Using a 13 mm (1/2 in.) drill bit, drill one or more of the holes

3

inside the corners of the solid line on the template to prepare

the mounting surface for cutting.

Using a jigsaw or a rotary tool, cut the mounting surface

4

along the inside line on the template.

Place the device in the cutout to test the fit.

5

If necessary, use a file and sandpaper to refine the size of

6

the cutout.

If necessary, remove the trim caps.

7

NOTICE

Use a plastic pry tool when possible. Using a metal pry tool,

such as a screwdriver, can damage the trim caps and the

device.

After the device fits correctly in the cutout, ensure the

8

mounting holes on the device line up with the larger holes on

the template.

If the mounting holes on the device do not line up, mark the

9

new hole locations.

Based on your mounting surface and model, drill or punch

10

and tap the larger holes:

• For the included wood screws on 702 models, drill 2 mm

(5/64 in.) holes, and skip to step 18.

• For the included wood screws on 902 models, drill 3.2 mm

(1/8 in.) holes, and skip to step 18.

• For the included nut plate and machine screws, drill 6 mm

(1/4 in.) holes in the larger hole locations.

• For the included machine screws without the nut plate on

702 models, punch and tap M3.5 holes, and skip to step

18.

• For the included machine screws without the nut plate on

902 models, punch and tap M4 holes, and skip to step 18.

If you are using a nut plate, starting in one corner of the

11

template, place a nut plate over the larger hole drilled in

the previous step.

The smaller hole on the nut plate should line up with the

smaller hole on the template.

If the smaller hole on the nut plate does not line up with the

12

smaller hole on the template, mark the new hole location.

If you are using a nut plate, drill a 4 mm (3/16 in.) hole in the

13

smaller hole location.

Repeat to verify placement of the remaining nut plates and

14

holes on the template.

Remove the template from the mounting surface.

15

Starting in one corner of the mounting location, place a nut

16

plate on the back of the mounting surface, lining up the

large and small holes.

The raised portion of the nut plate should fit into the larger

hole.

Secure the nut plates to the mounting surface by fastening

17

the smaller machine screws through the smaller holes.

Install the foam gasket on the back of the device.

18

The pieces of the foam gasket have adhesive on the back.

Make sure you remove the protective liner before installing

them on the device.

If you will not have access to the back of the device after you

19

mount it, connect all necessary cables to the device before

placing it into the cutout.

NOTICE

To prevent corrosion of the metal contacts, cover unused

connectors with the attached weather caps.

Apply marine sealant between the mounting surface and the

20

device to properly seal and prevent leakage behind the

dashboard.

If you will have access to the back of the device, apply

21

marine sealant around the cutout.

Place the device into the cutout.

22

2

Secure the device to the mounting surface using the larger

23

machine screws or the included wood screws.

Wipe away all excess marine sealant.

24

Install the trim caps by snapping them in place around the

25

edges of the device.

Cable and Connection Considerations

• The cables may have been packaged without the locking

rings installed. If so, you should route the cables before you

install the locking rings.

• After connecting a locking ring to a cable, make sure the ring

is securely connected and the O-ring is in place so the

connection remains secure.

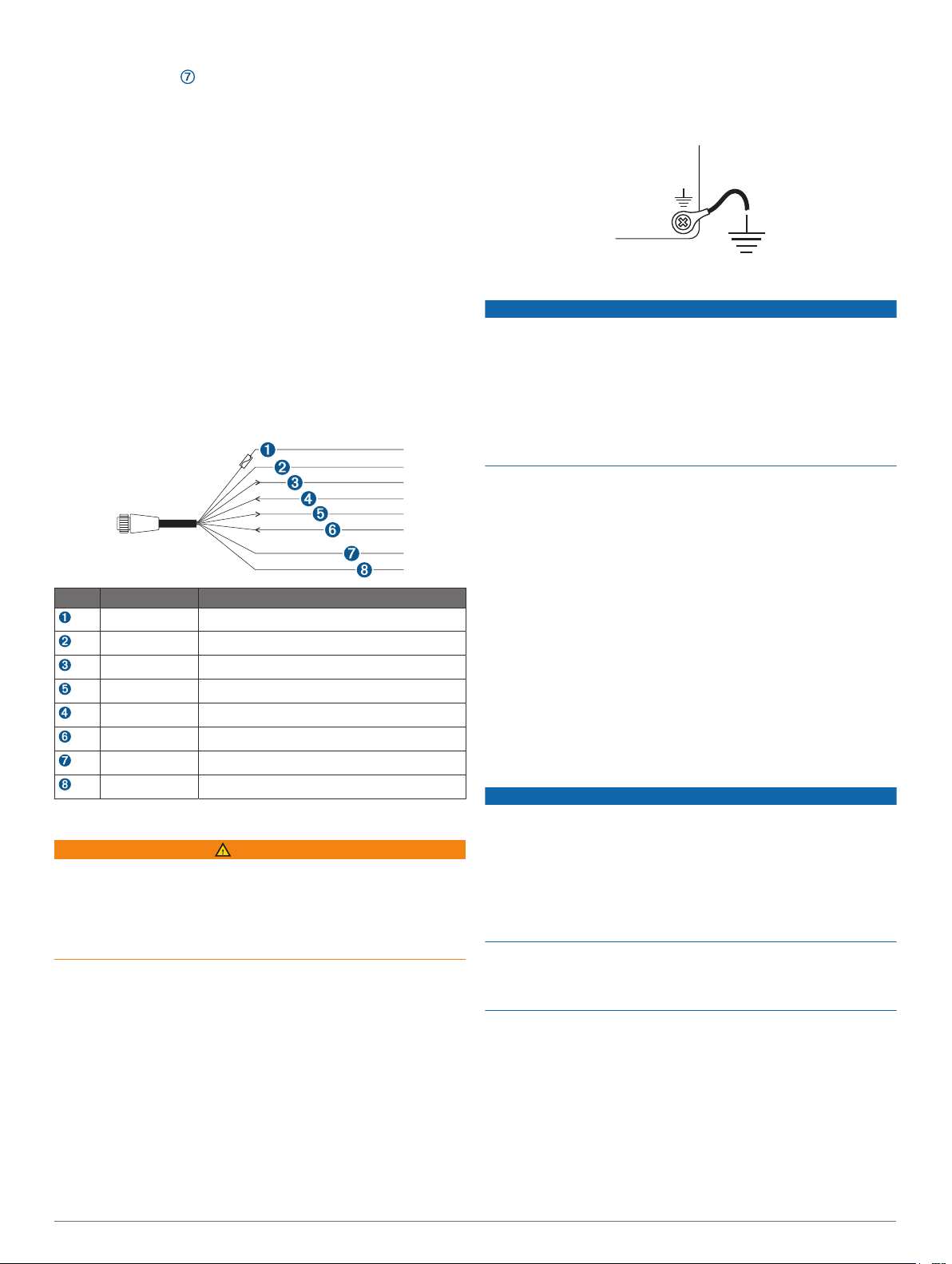

Power/NMEA® 0183 Cable

• The wiring harness connects the device to power, NMEA

0183 devices, and a lamp or a horn for visible or audible

alerts.

• If it is necessary to extend the NMEA 0183 or alarm wires,

you must use 22 AWG (.33 mm²) wire.

• This cable provides one differential NMEA 0183 input and

output port.

Item Wire Color Wire Function

Red Power

Black Ground (power and NMEA 0183)

Blue NMEA 0183 TxA (Out +)

Gray NMEA 0183 TxB (Out -)

Brown NMEA 0183 RxA (In +)

Violet NMEA 0183 RxB (In -)

Orange Accessory on

Yellow Alarm low

Connecting the Wiring Harness to Power

WARNING

When connecting the power cable, do not remove the in-line

fuse holder. To prevent the possibility of injury or product

damage caused by fire or overheating, the appropriate fuse

must be in place as indicated in the product specifications. In

addition, connecting the power cable without the appropriate

fuse in place voids the product warranty.

Route the wiring harness to the power source and to the

1

device.

Connect the red wire to the positive (+) battery terminal, and

2

connect the black wire to the negative (-) battery terminal.

If necessary, install the locking ring and O-ring on the end of

3

the wiring harness.

Insert the cable into the POWER connector on the back of

4

the device, pushing firmly.

Turn the locking ring clockwise to attach the cable to the

5

device.

Additional Grounding Consideration

This consideration is applicable only to devices that have a

grounding screw. Not all models have a grounding screw.

This device should not need additional chassis grounding in

most installation situations. If you experience interference, the

grounding screw on the housing can be used to connect the

device to the water ground of the boat to help avoid the

interference.

Garmin Marine Network Considerations

NOTICE

A Garmin Power over Ethernet (PoE) Isolation Coupler (P/N

010-10580-10) must be used when connecting any third-party

device, such as a FLIR® camera, to a Garmin Marine Network.

Connecting a PoE device directly to a Garmin Marine Network

chartplotter damages the Garmin chartplotter and may damage

the PoE device. Connecting any third-party device directly to a

Garmin Marine Network chartplotter will cause abnormal

behavior on the Garmin devices, including the devices not

properly turning off or the software becoming inoperable.

This device can connect to additional Garmin Marine Network

devices to share data such as radar, sonar, and detailed

mapping. When connecting Garmin Marine Network devices to

this device, observe these considerations.

• All devices connected to the Garmin Marine Network must be

connected to the same ground.

• A Garmin Marine Network cable must be used for all Garmin

Marine Network connections.

◦ Third-party CAT5 cable and RJ45 connectors must not be

used for Garmin Marine Network connections.

◦ Additional Garmin Marine Network cables and connectors

are available from your Garmin dealer.

• The ETHERNET ports on the device each act as a network

switch. Any compatible device can be connected to any

ETHERNET port to share data with all devices on the boat

connected by a Garmin Marine Network cable.

NMEA 2000® Considerations

NOTICE

If you are connecting to an existing NMEA 2000 network,

identify the NMEA 2000 power cable. Only one NMEA 2000

power cable is required for the NMEA 2000 network to operate

properly.

If you are connecting this device to an existing NMEA 2000

network or engine network by another manufacturer, you should

install a NMEA 2000 Power Isolator (010-11580-00) between

the existing network and the Garmin devices.

If you are installing a NMEA 2000 power cable, you must

connect it to the boat ignition switch or through another in-line

switch. NMEA 2000 devices will drain your battery if the NMEA

2000 power cable is connected to the battery directly.

This device can connect to a NMEA 2000 network on your boat

to share data from NMEA 2000 compatible devices such as a

GPS antenna or a VHF radio. The included NMEA 2000 cables

and connectors allow you to connect the device to your existing

NMEA 2000 network. If you do not have an existing NMEA 2000

network you can create a basic one using cables from Garmin.

If you are unfamiliar with NMEA 2000, you should read the

“NMEA 2000 Network Fundamentals” chapter of the Technical

Reference for NMEA 2000 Products. You can find this document

using the “Manuals” link on the product page for your device at

www.garmin.com.

3

Loading...

Loading...