Page 1

Pub. 42004-723L2G

GAI-TRONICS® CORPORATION

A HUBBELL COMPANY

Industrial Communications System

®

Hazardous Area Page/Par ty

T ABLE OF C ONTENTS

General Information .......................................................................................................................1

Product Overview ................................................................................................................................... 1

Features .................................................................................................................................................... 1

Options ..................................................................................................................................................... 2

Installation ......................................................................................................................................2

Important Safety Instructions................................................................................................................ 2

Mounting the Enclosure ......................................................................................................................... 4

Cable Entries ........................................................................................................................................... 5

Field Wiring ............................................................................................................................................. 6

Speaker Jumper Impedance Configuration ......................................................................................... 8

Station

Settings and Adjustments ................................................................................................................9

Opening the Station ................................................................................................................................ 9

Jumper Settings ..................................................................................................................................... 10

Speaker Mute ...................................................................................................................................................... 10

Speaker Gain Setting........................................................................................................................................... 10

Level Adjustments ................................................................................................................................ 11

Transmit Level .................................................................................................................................................... 11

Receiver Volume ................................................................................................................................................ 11

Speaker Volume .................................................................................................................................................. 11

Attach the Front Cover ........................................................................................................................ 11

Operation .......................................................................................................................................11

Options ...........................................................................................................................................12

ICS SmartSeries .................................................................................................................................... 12

General ................................................................................................................................................................ 12

Features ............................................................................................................................................................... 12

Adjustments ........................................................................................................................................................ 13

Opening the Station ........................................................................................................................................ 13

Setting the Address ......................................................................................................................................... 13

ALS Minimum Level ..................................................................................................................................... 13

ALS Offset Level ........................................................................................................................................... 13

SmartSeries VLC Level .................................................................................................................................. 14

Speaker Impedance Supervision ..................................................................................................................... 14

FSK Signal Gain ............................................................................................................................................. 15

Attaching the Front Cover .............................................................................................................................. 15

Operation ............................................................................................................................................................ 15

Paging with ADVANCE Head End ................................................................................................................ 15

GAI-Tronics Corporation 400 E. Wyomissing Ave. Mohnton, PA 19540 USA

610-777-1374 800-492-1212 Fax: 610-796-5954

V

ISIT WWW.GAI-TRONICS.COM FOR PRODUCT LITERATURE AND MANUALS

Page 2

TABLE OF CONTENTS P UB. 42004-723L2G

Paging without ADVANCE Head End ........................................................................................................... 15

Station Time-out Features .............................................................................................................................. 16

All Call Paging Utilizing a Merge/Isolate Cabinet ......................................................................................... 16

Emergency Party Line (EPL) ......................................................................................................................... 17

Paging with Alternate Page Destination Utilizing ADVANCE Head End ..................................................... 17

VLC ........................................................................................................................................................ 18

General ................................................................................................................................................................ 18

Features ............................................................................................................................................................... 18

Adjustments ........................................................................................................................................................ 19

Opening the Station ........................................................................................................................................ 19

50 kHz Alignment .......................................................................................................................................... 19

Speaker Mute .................................................................................................................................................. 19

Audio Alignment ............................................................................................................................................ 19

Page Disable Control ...................................................................................................................................... 20

Remote Output Switching (Available with RTU Only) ................................................................................. 20

Attaching the Front Cover .............................................................................................................................. 20

RTU ........................................................................................................................................................ 21

General ................................................................................................................................................................ 21

Features ............................................................................................................................................................... 21

With SmartSeries PCBA and ADVANCE Head End..................................................................................... 21

With VLC PCBA ............................................................................................................................................ 21

Installation .......................................................................................................................................................... 22

Opening the Station ........................................................................................................................................ 22

Field Wiring ................................................................................................................................................... 22

Attaching the Front Panel ............................................................................................................................... 22

Non-supervised Output Wiring Configuration ............................................................................................... 22

Supervised Output Wiring Configurations with SmartSeries Option ............................................................. 23

Input 1 or 2 Wiring Configuration with the SmartSeries Option .................................................................... 24

Troubleshooting ............................................................................................................................25

Opening the Station .............................................................................................................................. 25

Jumper Settings ..................................................................................................................................... 25

P4 Standard Jumper Configuration ..................................................................................................................... 25

Attaching the Front Cover ................................................................................................................... 29

Specifications ................................................................................................................................29

GAI-Tronics Corporation 400 E. Wyomissing Ave. Mohnton, PA 19540 USA

610-777-1374 800-492-1212 Fax: 610-796-5954

V

ISIT WWW.GAI-TRONICS.COM FOR PRODUCT LITERATURE AND MANUALS

Page 3

Pub. 42004-723L2G

GAI-TRONICS® CORPORATION

Industrial Communications System

Hazardous Area Page/Par ty

General Information

Product Overview

The GAI-Tronics Industrial

Communications System

(ICS) Page/Party

modular industrial

communications system that

can include from two to

possibly hundreds of stations.

stations are wired in

All

parallel and additional stations

can be added to the system at

any time.

®

is a

A HUBBELL COMPANY

®

Station

The standard configuration of

the ICS Hazardous Area

Page/Party

outdoor, multi-party,

®

station is an

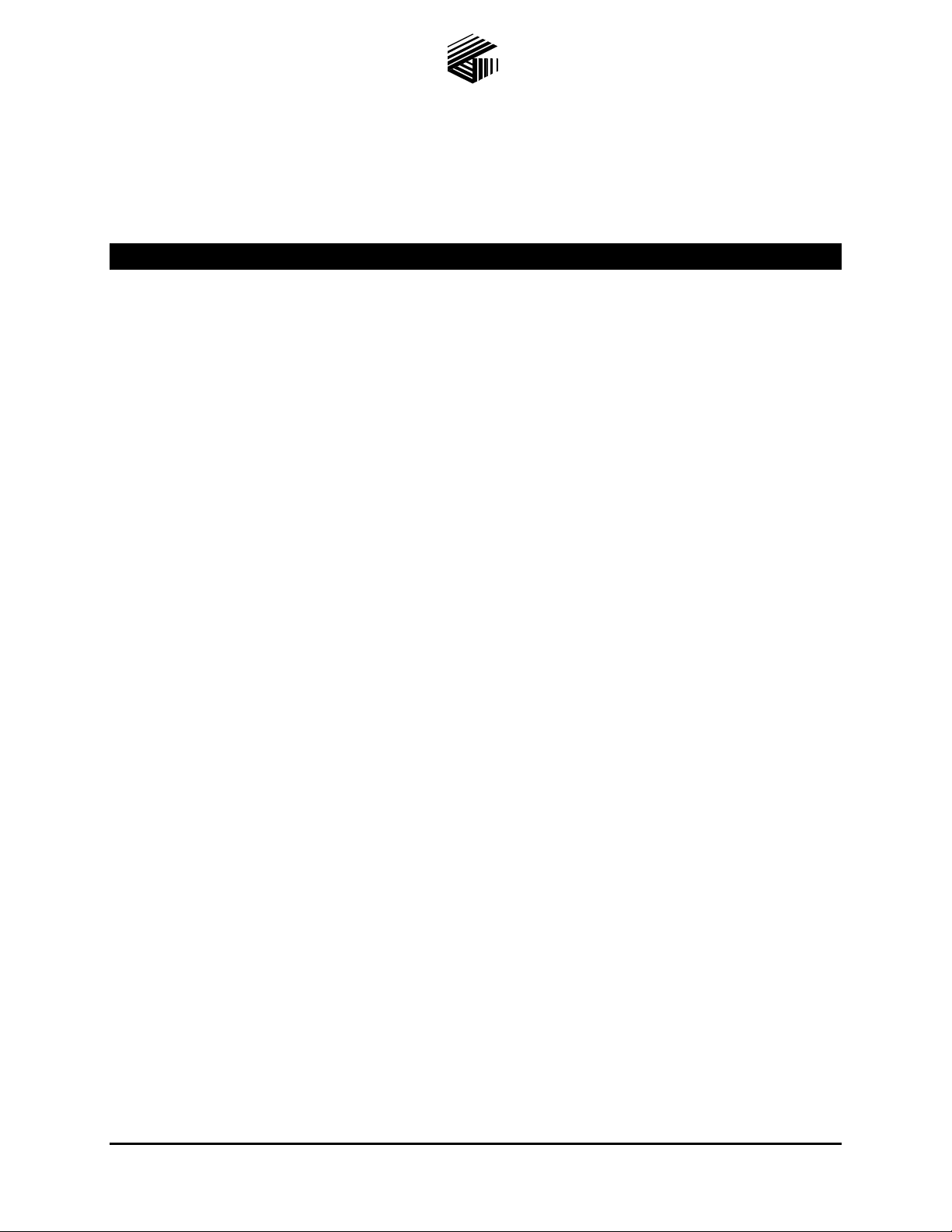

Figure 1. ICS Hazardous Area Station Front Panel with all options

handset/speaker amplifier

station using ac power. They are constructed of cast aluminum and are extremely weatherproof and

corrosion-resistant. A number of options are available to add to station capabilities. See Features and

Options below for more details.

®

The ICS Page/Party

series Page/Party

Page/Party

®

systems.

Hazardous Area station is similar to and compatible with existing GAI-Tronics 700

®

systems. ICS hazardous area Page/Party® stations can replace or be added to existing

Fea tures

Provides one-way page announcements over system speakers

Includes a high efficiency (>80%) Class D paging amplifier to provide up to 30 watts of speaker

output

Provides full-duplex party line communication

Includes universal ac power supply with power factor correction

Field upgradeable options

Durable cast aluminum

enclosure

GAI-Tronics Corporation 400 E. Wyomissing Ave. Mohnton, PA 19540 USA

610-777-1374 800-492-1212 Fax: 610-796-5954

V

ISIT WWW.GAI-TRONICS.COM FOR PRODUCT LITERATURE AND MANUALS

Page 4

Pub. 42004-723L2G

ICS Hazardous Area Page/Par ty

®

Station Page 2 of 31

Options

Single party line operation

Speaker amplifier only (no handset)

Alternate page destination

Emergency page line (EPL)

Multiple hazardous area approvals

PVC or Hytrel handset cords in 6-, 15-, or 25-foot lengths

Conformal coating for PCBA

24 V dc power

Volume Level Control (VLC) technology for alternate page volume

SmartSeries technology featuring Ambient Level Sensing (ALS) and available remote monitoring

Remote Terminal Unit (RTU) operation

All Call

Installation

Important Safety Instructions

1. Read, follow, and retain instructions – All safety and operating instructions should be read and

followed before operating the unit. Retain instructions for future reference.

2. Heed warnings – Adhere to all warnings on the unit and in the operating instructions.

3. Attachments – Attachments not recommended by the product manufacturer should not be used, as

they may cause hazards.

4. Servicing – Do not attempt to service this unit by yourself. Opening or removing covers may expose

you to dangerous voltage or other hazards. Refer all servicing to qualified service personnel.

5. This permanently connected apparatus must have a UL Listed 15-amp circuit breaker incorporated in

the electrical installation of the building.

USA and Canada Consult the National Electrical Code (NFPA 70), Canadian Standards Association

(CSA 22.1), and local codes for specific requirements regarding your installation. Class 2 circuit wiring

must be performed in accordance with NEC 725.55.

WARNING

from a battery charger without the batteries connected.

In 24 V dc systems: Under NO condition should this equipment be operated

In 24 V dc systems, most chargers have an unloaded output of 35 to 45 volts that can quickly damage the

equipment designed for nominal 24 volts. The maximum battery voltage should never exceed the

maximum specified input voltage.

f:\standard ioms - current release\ 42004 instr. manuals\42004-723l2g.doc

11/14

Page 5

®

ICS Hazardous Area Page/Par ty

Station Page 3 of 31

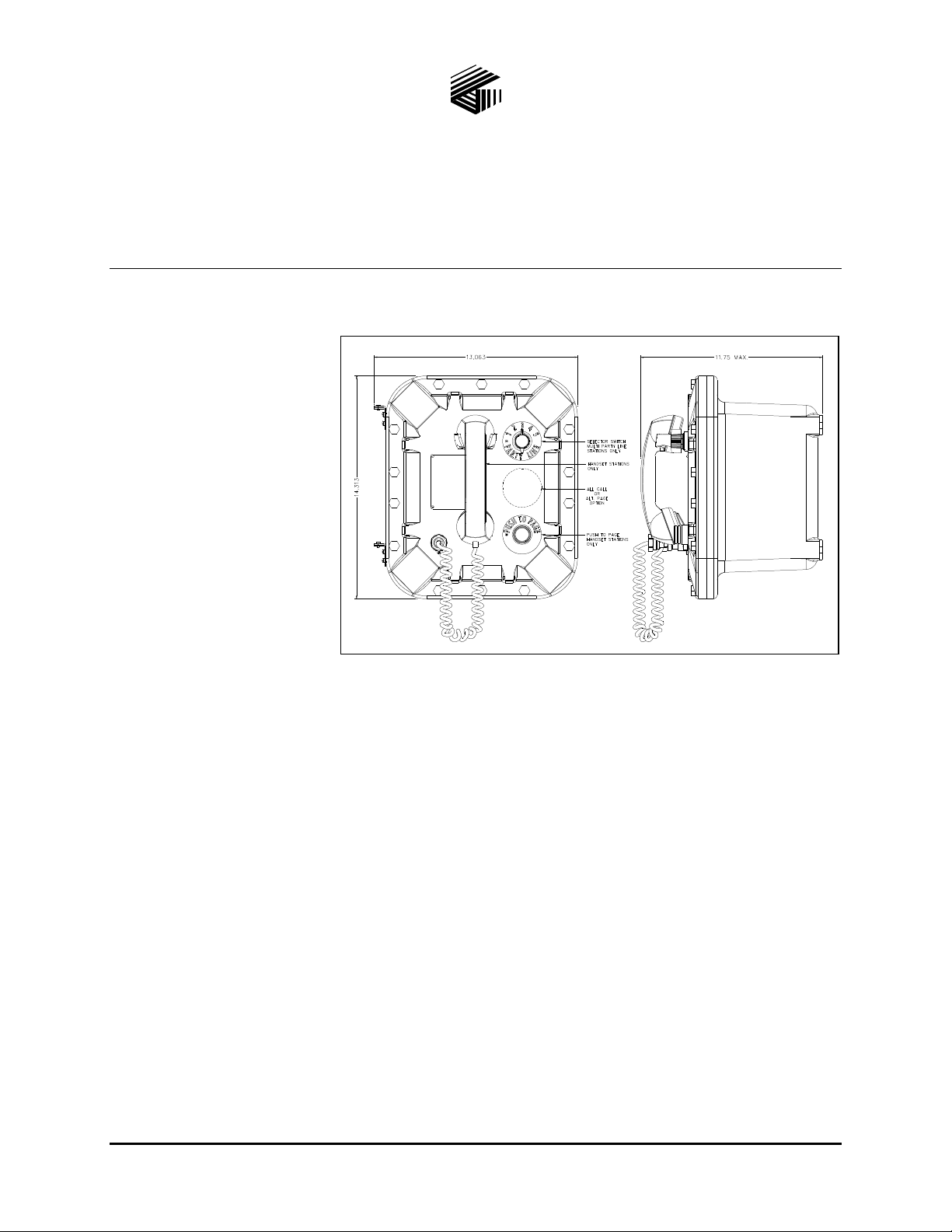

These enclosures must be installed by trained, qualified and

competent personnel. Installation must comply with state and

national regulations, as well as safety practices for this type of

equipment.

Pub. 42004-723L2G

WARNING

Do not install this equipment in

hazardous areas other than those indicated on the

approval listing in the “Specifications” section of this

manual. Such installation may cause a safety hazard and

consequent injury or property damage.

The mounting location must be flat and provide proper

clearance, rigidity and strength to support the enclosure and all

contained devices. The enclosures are equipped with factoryinstalled hinges. The enclosures should be mounted with

hinges on the left.

WARNING

Do not mount the enclosure with

hinges on the top or bottom side.

Securely fasten the enclosure to the mounting location, using

3/8-inch (10mm) diameter steel mounting bolts and washers,

or washer head bolts.

WARNING

Do not disconnect equipment while energized.

Insure proper grounding to protective earthing.

Figure 2. ICS Hazardous Area Multi-

Party Station

Inspect and clean the machined flange flame joint surfaces of both the cover and box. Surfaces must be

smooth, free of nicks, scratches, dirt or any foreign particle build-up that would prevent a proper seal.

Surfaces must seat fully against each other to provide a proper explosion-proof joint. Clean surfaces by

wiping with a clean lint-free cloth.

Apply a light coat of Killark “LUBG” lubricant to flange surfaces and close the cover. Install and tighten

all cover bolts to 30 ft.-lbs. Make certain no cover bolts are omitted. Use only those bolts supplied with

the enclosure.

When installing an add-on station, consult the appropriate system layout diagrams. These figures, when

used in conjunction with the station installation information and cable layout guide, should provide all the

information necessary to install additional Page/Party stations.

f:\standard ioms - current release\ 42004 instr. manuals\42004-723l2g.doc

11/14

Page 6

Pub. 42004-723L2G

ICS Hazardous Area Page/Par ty

®

Station Page 4 of 31

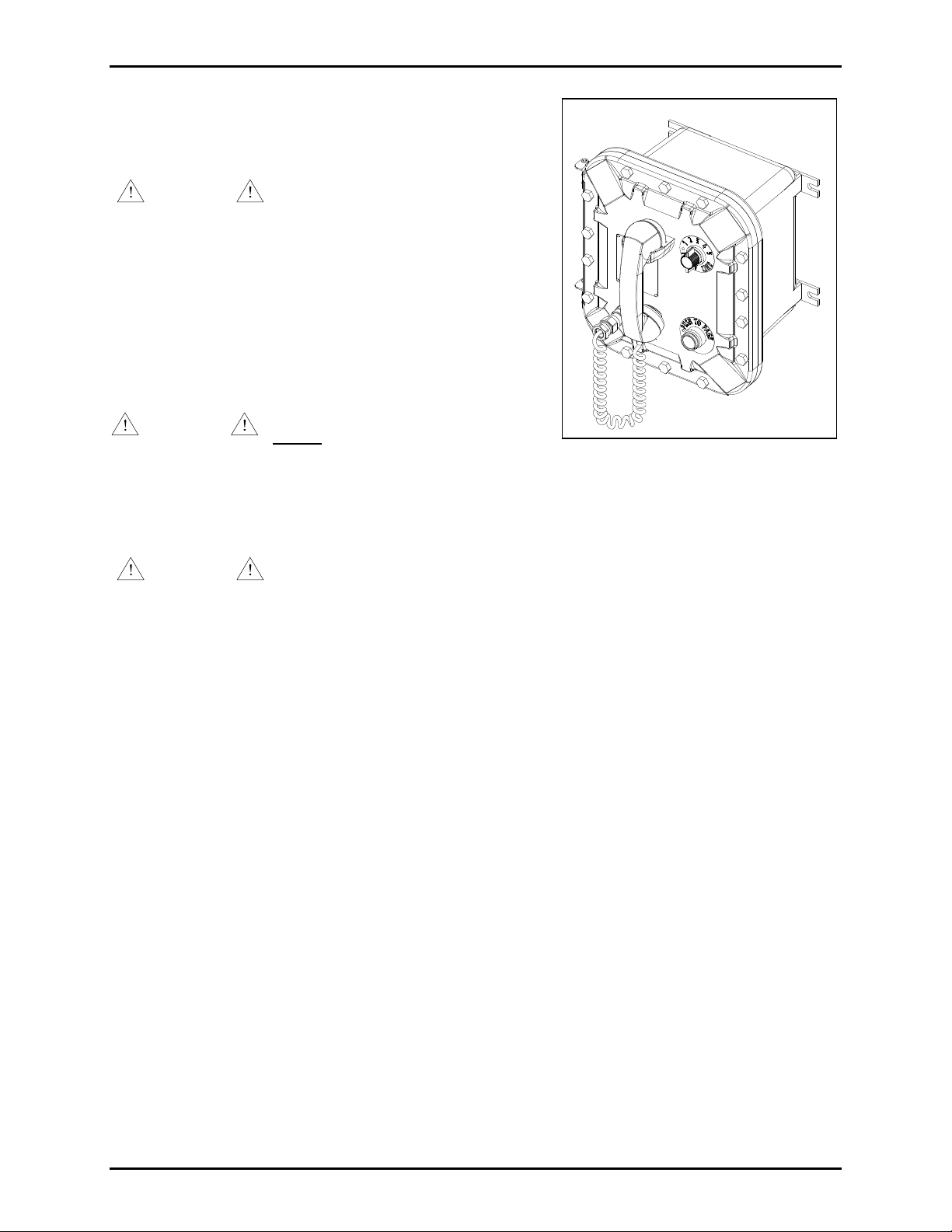

Mounting the Enclosure

NOTE: The mounting surface must be able to support the weight of the aluminum enclosure. See the

Specification section for the weights and dimensions of the unit.

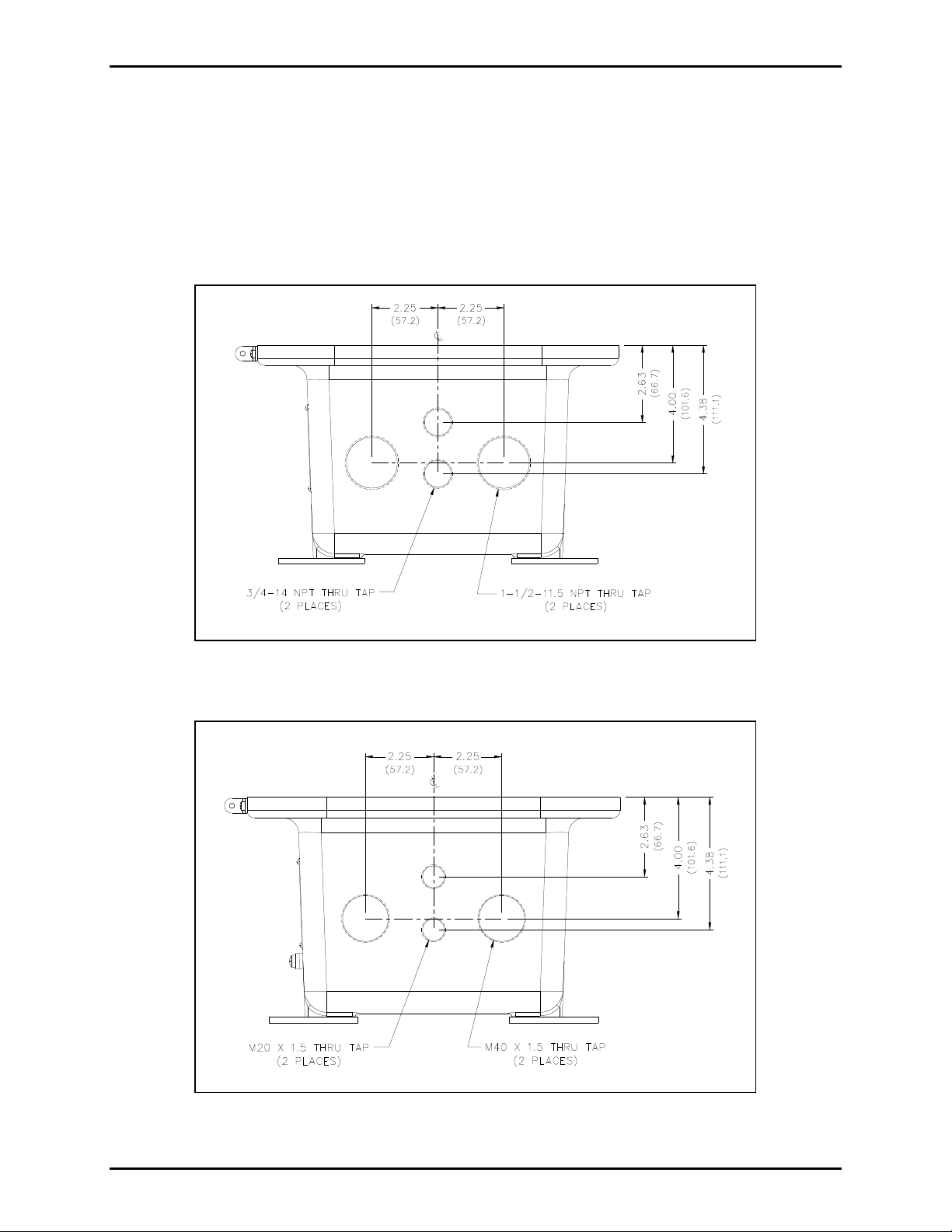

Figure 3. Enclosure Mounting Details

The enclosure must be securely fastened with 3/8-inch (10mm) diameter steel mounting bolts located on

all four mounting feet. Stainless steel hardware is recommended in outdoor applications.

N

OTE: Refer to the Killark Installation, Operation, and Maintenance Data Sheet enclosed with the unit

for additional information.

The suggested mounting height for all station enclosures is 48 inches (1219 mm) to the bottom of the

enclosure.

f:\standard ioms - current release\ 42004 instr. manuals\42004-723l2g.doc

11/14

Page 7

Pub. 42004-723L2G

ICS Hazardous Area Page/Par ty

®

Station Page 5 of 31

Cable Entries

Refer to Figure 4 for the standard NPT conduit entries, and Figure 5 for the standard metric cable gland

entries. Ensure any unused openings are sealed with proper fittings per local standards. All metric cable

entry devices and blanking elements shall be certified in type of explosion protection flameproof

enclosure “d” with an IP66 rating, suitable for conditions of use and correctly installed. Use field wiring

suitable for the ambient temperature. Any conduit NPT plugs (blanking elements) will need to be

explosion-proof with a Type 4X rating.

Figure 4. Standard NPT Conduit Entries

Figure 5. Standard Metric Cable Gland Entries

f:\standard ioms - current release\ 42004 instr. manuals\42004-723l2g.doc

11/14

Page 8

Pub. 42004-723L2G

ICS Hazardous Area Page/Par ty

®

Station Page 6 of 31

Field Wiring

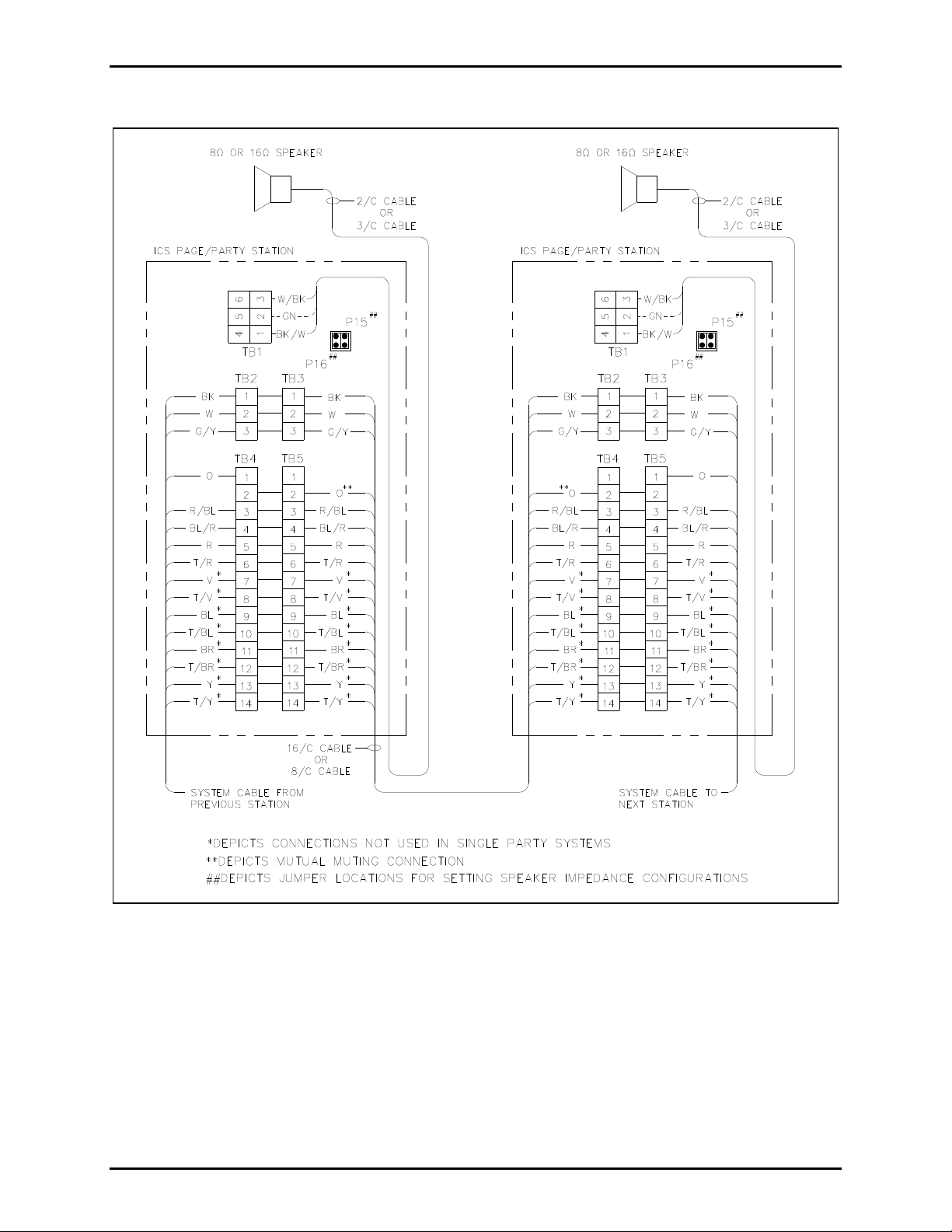

The ICS Page/Party® Station provides terminal blocks for field wiring. Each connection for the system

cable has two terminals for daisy-chain wiring. Attach #6 spade lugs to the wires before attachment to the

terminal blocks for the most secure connection. Torque the terminal block screws to 8–10 in-lbs.

(0.90–1.13 n-m) when attaching the spade lugs.

The terminal blocks on the Termination PCBA are labeled to coincide with the color code used on GAITronics 60029 series multi-party cable or 60038 series single party cable. Refer to Figure 6 for a sample

wiring diagram.

In certain circumstances where paging audio induces feedback, muting the speakers of two or more

stations during a page, referred to as mutual muting, can eliminate such feedback problems. This function

is enabled by connecting the spare orange wire between stations to terminal block TB4-2 or TB5-2.

f:\standard ioms - current release\ 42004 instr. manuals\42004-723l2g.doc

11/14

Page 9

ICS Hazardous Area Page/Par ty

®

Station Page 7 of 31

Pub. 42004-723L2G

Figure 6. Typical Page/Party

®

ICS Station Wiring Diagram

After all adjustments have been completed, inspect and clean the machined flange joint surfaces of both

the cover and box. Surfaces must be smooth, free of nicks, scratches, dirt or any foreign particle build-up

that would prevent a proper seal. Surfaces must seat fully against each other to provide a proper

explosion-proof joint. Clean surfaces by wiping with a clean lint-free cloth.

Apply a light coat of Killark “LUBG” lubricant to flange surfaces and close the cover. Install and tighten

all cover bolts to 30 ft.-lbs. Make certain no cover bolts are omitted. Use only those bolts supplied with

the enclosure.

f:\standard ioms - current release\ 42004 instr. manuals\42004-723l2g.doc

11/14

Page 10

Pub. 42004-723L2G

ICS Hazardous Area Page/Par ty

®

Station Page 8 of 31

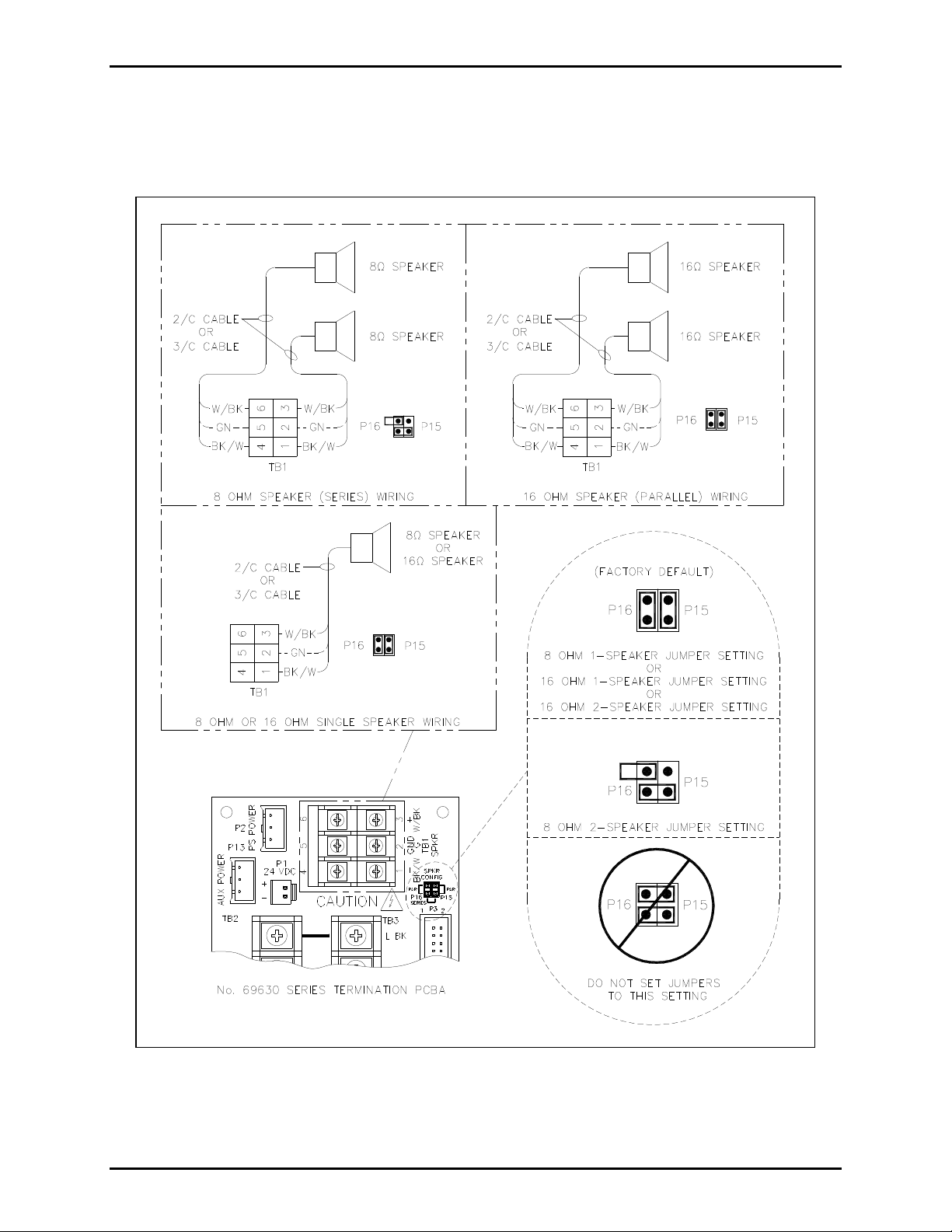

Speaker Jumper Impedance Configuration

Configure speaker jumpers P15 and P16 for the appropriate impedance for either 8-ohm or 16-ohm

speakers as shown in Figure 7 below.

Figure 7. Speaker Jumper Impedance Configuration Options for 8-ohm or 16-ohm Speakers

f:\standard ioms - current release\ 42004 instr. manuals\42004-723l2g.doc

11/14

Page 11

®

ICS Hazardous Area Page/Par ty

Station Page 9 of 31

Settings and Adjustments

Opening the Station

Pub. 42004-723L2G

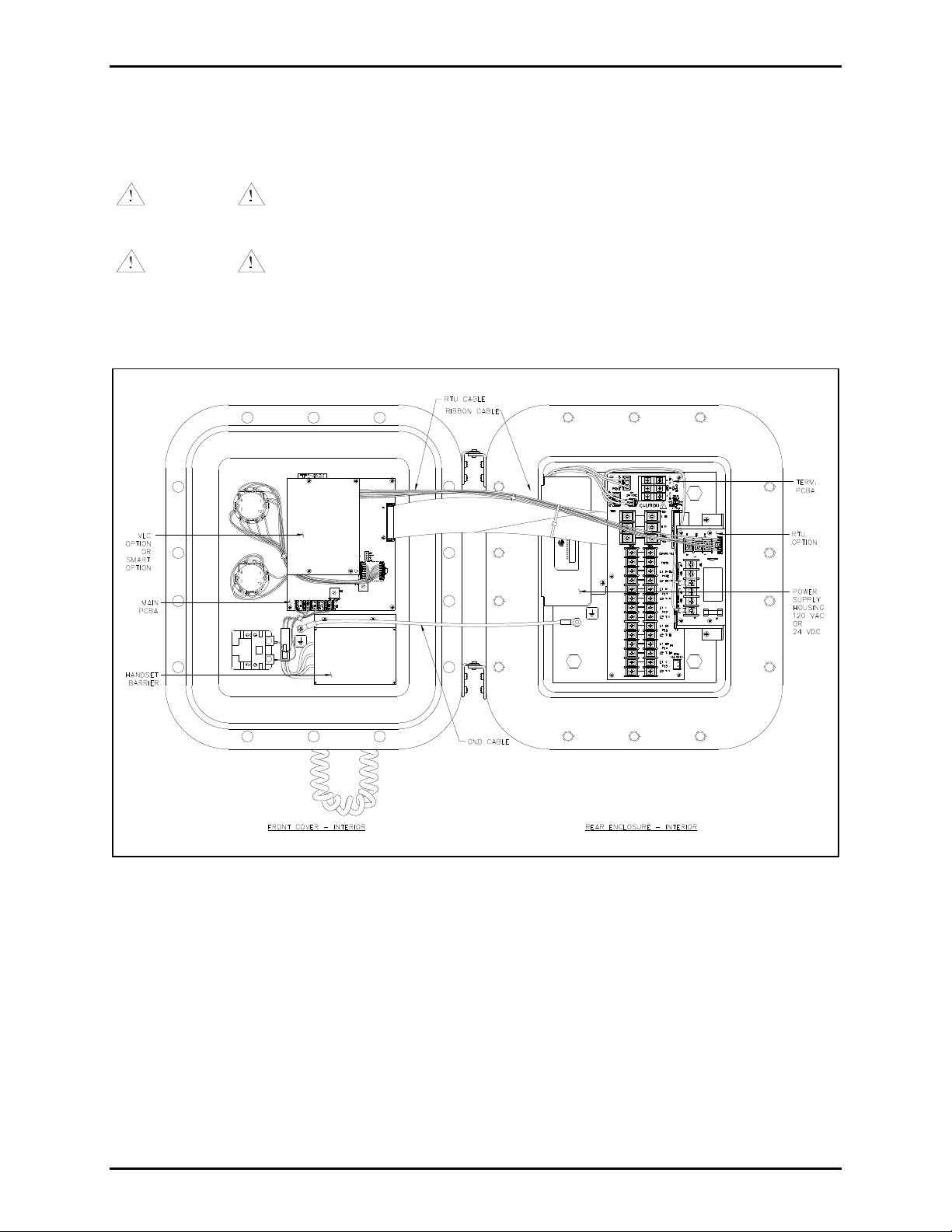

WARNING

Before performing any of the following settings and adjustments, remove all

power from the station.

WARNING

To reduce the risk of hazardous atmospheres, disconnect the equipment

from the supply circuit before making any adjustments to the amplifier’s handset level.

Remove all cover bolts from the enclosure. Swing the front door open to access the internal PCBAs.

Figure 8. ICS Hazardous Area Station (AC Version shown) – Interior View

f:\standard ioms - current release\ 42004 instr. manuals\42004-723l2g.doc

11/14

Page 12

ICS Hazardous Area Page/Par ty

®

Station Page 10 of 31

Pub. 42004-723L2G

Figure 9. 69557 Series Main PCBA

Jumper Settings

Speaker Mute

The station can mute the speaker amplifier during page operation to eliminate feedback. P11 in the EN

position (default) mutes the speaker during page activation. P11 in the DIS position allows broadcast to

the speaker during paging.

Speaker Gain Setting

P9 can limit the maximum speaker output level. P9 in the HI position (default) represents a 30-watt

maximum output. P9 in the LO position represents a 2-watt maximum output.

WARNING

speaker damage.

Maximum output power may exceed rated speaker wattage resulting in

f:\standard ioms - current release\ 42004 instr. manuals\42004-723l2g.doc

11/14

Page 13

Pub. 42004-723L2G

ICS Hazardous Area Page/Par ty

®

Station Page 11 of 31

Level Adjustments

Transmit Level

The Transmit Level potentiometer, R34, adjusts the signal level from the handset or optional auxiliary

headset microphone to the page or party lines.

Receiver Volume

The Receiver Volume potentiometer, R5, adjusts the signal level to the handset receiver from the page or

party lines. It does not adjust the signal level to the optional auxiliary headset.

Speaker Volume

The Speaker Volume potentiometer, R91, adjusts the signal level to the speaker from the page line. The

default setting is 4 watts for an 8-ohm speaker and 2 watts for a 16-ohm speaker.

Warning – Maximum output power may exceed rated speaker wattage resulting in speaker damage.

Attach the Front Cover

After all adjustments have been completed, inspect and clean the machined flange joint surfaces of both

the cover and box. Surfaces must be smooth, free of nicks, scratches, dirt or any foreign particle build-up

that would prevent a proper seal. Surfaces must seat fully against each other to provide a proper

explosion-proof joint. Clean surfaces by wiping with a clean lint-free cloth.

Apply a light coat of Killark “LUBG” lubricant to flange surfaces and close the cover. Install and tighten

all cover bolts to 30 ft.-lbs. Make certain no cover bolts are omitted. Use only those bolts supplied with

the enclosure.

It may become necessary to re-terminate some or all of the enclosures in a system. If so, strip the wires

back to clean copper and connect only one wire to each connector to allow for easier future

troubleshooting.

OTE: Refer to the Killark Installation, Operation, and Maintenance Data Sheet enclosed with the unit for

N

additional information.

Operation

For paging and subsequent party line conversation, the station operator lifts the handset, selects a free

party line using the five-position rotary selector switch (if equipped), and presses the handset pressbar or

headset page switch. The station operator pages the desired individual and designates the party line on

which that individual should respond. The individual then responds by approaching the nearest ICS

Page/Party

Full-duplex communication can then be held on the party line without broadcasting over the speakers.

After the conversation is complete, all parties should place the handset back on hook.

®

station, selecting the appropriate party line and lifting the handset or connecting a headset.

N

OTES: The ICS Page/Party

®

station incorporates a noise-canceling microphone to reduce transmitted

ambient noise. This requires the user to place the microphone as close as possible to their mouth.

f:\standard ioms - current release\ 42004 instr. manuals\42004-723l2g.doc

11/14

Page 14

Pub. 42004-723L2G

ICS Hazardous Area Page/Par ty

®

Station Page 12 of 31

Options

The ICS Page/Party® Station options are factory installed.

ICS SmartSeries

General

The 69552 SmartSeries PCBA adds microprocessor control to the ICS Page/Party® station, providing

additional sensor and monitoring capabilities. SmartSeries and VLC PCBAs cannot be installed in the

same station.

Features

When used with or without ADVANCE head-end equipment:

Ambient Level Sensing (ALS) circuitry automatically changes the local speaker’s paging volume in

response to varying background noise

Off-hook timeout prevents noise being introduced to a party line by electronically placing the handset

“on-hook” after 8 minutes

Page timeout limits a single page broadcast to two minutes, freeing the page line for emergencies

When used with ADVANCE head-end equipment:

Station monitoring of key components (including handset, amplifier and local speaker) provides fast

notification of any faults

Ability to accept supervised contact closure inputs and provide a supervised relay output (requires

RTU option)

Figure 10. 69552 SmartSeries PCBA

f:\standard ioms - current release\ 42004 instr. manuals\42004-723l2g.doc

11/14

Page 15

ICS Hazardous Area Page/Par ty

Adjustments

Opening the Station

®

Station Page 13 of 31

Pub. 42004-723L2G

WARNING

Before performing any of the following settings and adjustments, remove all

power from the station.

WARNING

To reduce the risk of hazardous atmospheres, disconnect the equipment

from the supply circuit before making any adjustments to the amplifier’s handset level.

Remove all cover bolts from the enclosure. Swing the front door open to access the internal PCBAs.

Setting the Address

For the SmartSeries option to function properly, each station in an ADVANCE system zone must be

given a unique address using the hexadecimal switches, S1 (Hi Address) and S2 (Lo Address). Each

switch contains 16 settings, labeled 0–F. A small arrow on each switch indicates the setting.

The station address is determined by the high address setting followed by the low address setting. For

example, to assign an address of 05, the high station address is set to 0 and the low address is set to 5.

Valid address settings are 05 to FE. Record the address assigned for each station in the system for your

records. If the SmartSeries PCBA is installed in a system without an ADVANCE head end, set the

address to 04 (default).

ALS Minimum Level

The ALS minimum level is the lowest speaker output level that the station will maintain. To set the ALS

minimum level, turn R91 fully counterclockwise

. Listen for a single beep from the speaker indicating the

speaker amplifier is in the Minimum Level Adjustment mode. If the page line is in use immediately after

the beep tone, the page signal should be used to make the minimum level adjustment. If the page line is

inactive following the beep tone, a continuous tone is activated to make the minimum level adjustment.

After the tone is activated, all page line activity is ignored until completion of the adjustment.

This test tone is used as a reference to adjust the speaker amplifier output level to the desired volume.

Adjust R91 to the desired output. The test tone automatically shuts off 5 seconds after the last

adjustment. The factory default setting for minimum level is 4.0 watts nominal into an 8-ohm load.

ALS Offset Level

The ALS offset level allows the output of the speaker amplifier to maintain a set difference or “offset”

between the ambient noise level and the speaker output level. To set the ALS offset level, turn R91 fully

clockwise and listen for the two beep tones indicating that the station is in the Offset Adjustment mode.

If the page line is in use immediately after the two beep tones are heard, the page signal should be used to

make the offset level adjustment. If the page line is inactive immediately following the beep tones, a

continuous tone is activated to make the offset level adjustment. After the tone is activated, all page line

activity is ignored until completion of the adjustment. Adjust R91 to the desired offset level.

N

OTE: This adjustment should be made under maximum ambient noise level conditions. The ALS offset

level must always be set higher than the ALS minimum level setting.

f:\standard ioms - current release\ 42004 instr. manuals\42004-723l2g.doc

11/14

Page 16

Pub. 42004-723L2G

ICS Hazardous Area Page/Par ty

SmartSeries VLC Level

®

Station Page 14 of 31

When activated, the VLC overrides the ALS minimum level setting allowing the speaker volume to

change to a preset level during an emergency page. To adjust the VLC Level, force the station into the

VLC mode by having someone execute a page from a station programmed by the MCU to activate the

VLC function. During the page, turn the R91 control fully counterclockwise

, and listen for two beep

tones through the page speaker indicating the VLC Adjustment mode has been activated. After the two

beep tones, turn the R91 control to the desired speaker level using the live paging signal to adjust the

level. The station automatically exits the VLC Adjustment mode and reverts to normal operation 5

seconds after the last pot adjustment.

OTE: The system must be equipped with an ADVANCE head end to activate the VLC function.

N

Speaker Impedance Supervision

When this feature is configured, the station will supervise the speaker line for changes in the speaker line

impedance. To perform this function the station must be calibrated for the impedance of the speaker(s)

attached. If the station has never been previously calibrated, the station will report a speaker fault within

15 minutes of being configured for this feature. The station may be calibrated either “locally” at the

station or “remotely” by a system command from the ADVANCE head end. See the ADVANCE System

Programming Manual for details of “remote” calibration.

To perform a “local” calibration, first ensure that the station is configured for speaker impedance

supervision. Next, set the station's address to 0x02. Wait until you hear a single-beep tone at the attached

speaker. This should occur within 20 seconds. This tone indicates that a successful calibration was

performed.

If instead a double-beep tone is heard, this indicates that the station attempted to calibrate but was

unsuccessful (the attached impedance is out-of-range). If a tone is not heard, the station may not be

configured for speaker impedance supervision or there is an open connection to the speaker.

After hearing the single beep tone, set the address back to its original value to resume normal station

operation with the new calibration value.

NOTE: If this feature is used, then jumper P9 of the Main PCBA must be in the HI (default) position.

f:\standard ioms - current release\ 42004 instr. manuals\42004-723l2g.doc

11/14

Page 17

Pub. 42004-723L2G

ICS Hazardous Area Page/Par ty

FSK Signal Gain

®

Station Page 15 of 31

The FSK Signal Gain, R13, adjusts the FSK transmit signal strength. It is set at the factory and should

not be adjusted by the installer.

Attaching the Front Cover

After all adjustments have been completed, inspect and clean the machined flange joint surfaces of both

the cover and box. Surfaces must be smooth, free of nicks, scratches, dirt or any foreign particle build-up

that would prevent a proper seal. Surfaces must seat fully against each other to provide a proper

explosion-proof joint. Clean surfaces by wiping with a clean lint-free cloth.

Apply a light coat of Killark “LUBG” lubricant to flange surfaces and close the cover. Install and tighten

all cover bolts to 30 ft.-lbs. Make certain no cover bolts are omitted. Use only those bolts supplied with

the enclosure.

It may become necessary to re-terminate some or all of the enclosures in a system. If so, strip the wires

back to clean copper and connect only one wire to each connector to allow for easier future

troubleshooting.

OTE: Refer to the Killark Installation, Operation, and Maintenance Data Sheet enclosed with the unit for

N

additional information.

Operation

Paging with ADVANCE Head End

Paging and party line operation with the ICS SmartSeries option is similar to standard station operation.

The main differences are that when the handset pressbar or the headset page switch is pressed, a steady

“wait” tone will be heard in the handset/headset earpiece. When the “wait” tone ends, a preannouncement tone, if programmed, will sound, and the operator may place their page. If the system is

busy and the page is denied, the user will hear a busy tone in the handset/headset earpiece.

Paging without ADVANCE Head End

Paging and party line operation will be similar to standard station operation.

f:\standard ioms - current release\ 42004 instr. manuals\42004-723l2g.doc

11/14

Page 18

Pub. 42004-723L2G

ICS Hazardous Area Page/Par ty

Station Time-out Features

®

Station Page 16 of 31

The ICS SmartSeries option supports a page duration limit that sets the maximum duration of each page.

If the page is still active when the page duration limit is reached, the page will be terminated. When used

without an ADVANCE head end, the page duration limit is fixed at 2 minutes.

The ICS SmartSeries option supports an off-hook limit that sets the maximum duration that the station

may be kept off hook. If the off-hook limit is reached, the station will be placed electrically on hook. To

reset the timeout condition, the handset must be physically placed on hook momentarily. When used

without an ADVANCE head end, the off-hook limit is fixed at 8 minutes.

All Call Paging Utilizing a Merge/Isolate Cabinet

Merge/Isolate (M/I) cabinets contain switching relays that are energized by a control signal from

Page/Party

Page/Party

®

stations. When energized, the relays merge (connect together) the page lines of multiple

®

systems. This allows voice pages to be broadcast from all the systems connected to the M/I

cabinet. ICS handset stations with the All Call feature contain a push-button switch on the front panel for

activating an M/I cabinet. Refer to Figure 11.

Figure 11. All Call Selector Switch Location

f:\standard ioms - current release\ 42004 instr. manuals\42004-723l2g.doc

11/14

Page 19

Pub. 42004-723L2G

ICS Hazardous Area Page/Par ty

Emergency Party Line (EP L)

®

Station Page 17 of 31

When connected to an ADVANCE control cabinet, the EPL option enables the ICS SmartSeries Station

to automatically report the following information when the handset is taken off-hook.

Zone number

Station address

Party line (1 or 2)

Paging with Alternate Page Destination Utilizing A DVANCE Head End

For stations with the alternate page destination option, additional programmed page zones can be utilized

with the alternate page selector switch. These alternate page destinations must be software configured in

the central control cabinet of a GAI-Tronics ADVANCE system.

Figure 12. Alternate Page Selector Switch Location

f:\standard ioms - current release\ 42004 instr. manuals\42004-723l2g.doc

11/14

Page 20

Pub. 42004-723L2G

ICS Hazardous Area Page/Par ty

®

Station Page 18 of 31

VLC

General

The 69553 Volume Level Control (VLC) PCBA adds the capability of remotely controlling the local

speaker volume level. When VLC is activated, a remote device transmits a 50 kHz signal over the page

line. The station detects the 50 kHz signal and switches to an alternate speaker volume setting.

VLC and SmartSeries options cannot be used in the same station.

Features

Provides an “alternate” speaker volume setting that is activated by receiving a 50 kHz signal on the

page line.

Allows office or crew quarters speakers to be muted until a high priority message or alarm is

broadcast.

Enables outdoor speaker volume to be reduced at night.

Prevents local handset paging during emergency conditions.

Adds the ability to provide a relay output (requires RTU option)

Figure 13. 69553 Series VLC PCBA

f:\standard ioms - current release\ 42004 instr. manuals\42004-723l2g.doc

11/14

Page 21

ICS Hazardous Area Page/Par ty

Adjustments

Opening the Station

®

Station Page 19 of 31

Pub. 42004-723L2G

WARNING

Before performing any of the following settings and adjustments, remove all

power from the station.

WARNING

To reduce the risk of hazardous atmospheres, disconnect the equipment

from the supply circuit before making any adjustments to the amplifier’s handset level.

Remove all cover bolts from the enclosure. Swing the front door open to access the internal PCBAs.

50 kHz Alignment

The 50 kHz alignment, R5, adjusts the receiver’s frequency for VLC operation. It is set at the factory and

should not be adjusted by the installer.

Speaker Mute

P26 allows for the installer to mute the speaker audio during VLC operation or normal operation. In the

“50kHz” position, the audio is muted during a VLC broadcast. In the “NORM” position, the audio is

muted during normal operation. To operate the unit without the muting feature, remove P26.

Audio Alignment

To set the normal speaker output level, set DIP switch SW2-1 to the “off” position. Set SW2-2 to the

“on” position to enable a reference test tone. Adjust R91 on the Main PCBA (refer to Figure 9 for

location) to the desired audio level. To mute the audio, turn R91 fully counterclockwise and put P26,

MUTE, in the “NORM” position.

OTE: If LED2 on the VLC PCBA is on, indicating the system VLC tone is present, this adjustment

N

cannot be made.

To set the VLC controlled speaker output level, set SW2-1 to the “on” position. Set SW2-2 to the “on”

position to enable a reference test tone. Adjust R12 on the VLC PCBA to the desired audio level. To

mute the audio, turn R91 fully counterclockwise and put P26, MUTE, in the “50KHz” position.

Set SW2-1 and SW2-2 to the “off” position to return to normal system operation.

f:\standard ioms - current release\ 42004 instr. manuals\42004-723l2g.doc

11/14

Page 22

Pub. 42004-723L2G

ICS Hazardous Area Page/Par ty

Page Disable Control

®

Station Page 20 of 31

To disable local paging when the system VLC tone is present, set SW2-3 to the “on” position.

Remote Output Switching (Available with RTU Only)

To activate the RTU relay when the system VLC tone is present, set SW2-4 to the “on” position.

Attaching the Front Cover

After all adjustments have been completed, inspect and clean the machined flange joint surfaces of both

the cover and box. Surfaces must be smooth, free of nicks, scratches, dirt or any foreign particle build-up

that would prevent a proper seal. Surfaces must seat fully against each other to provide a proper

explosion-proof joint. Clean surfaces by wiping with a clean lint-free cloth.

Apply a light coat of Killark “LUBG” lubricant to flange surfaces and close the cover. Install and tighten

all cover bolts to 30 ft.-lbs. Make certain no cover bolts are omitted. Use only those bolts supplied with

the enclosure.

It may become necessary to re-terminate some or all of the enclosures in a system. If so, strip the wires

back to clean copper and connect only one wire to each connector to allow for easier future

troubleshooting.

OTE: Refer to the Killark Installation, Operation, and Maintenance Data Sheet enclosed with the unit for

N

additional information.

f:\standard ioms - current release\ 42004 instr. manuals\42004-723l2g.doc

11/14

Page 23

ICS Hazardous Area Page/Par ty

RTU

General

®

Station Page 21 of 31

Pub. 42004-723L2G

The 69627 Remote Terminal Unit (RTU) PCBA adds remotely controlled dry relay contacts to an ICS

Page/Party

®

station equipped with either a VLC PCBA or a SmartSeries PCBA in conjunction with an

ADVANCE head end. When used with the SmartSeries PCBA in conjunction with ADVANCE head

end, two supervised inputs are also available.

Figure 14. 69627 Series RTU PCBA

Features

With SmartSeries PCBA and ADVANCE Head End

Two dry-contact input circuits (input cable supervision is optional)

Input status is monitored to trigger action in the ADVANCE head end.

Double pole, Form “C” relay contact (output cable supervision is optional)

One fuse-protected contact

With VLC PCBA

Double-pole, Form “C” relay

One fuse-protected contact

f:\standard ioms - current release\ 42004 instr. manuals\42004-723l2g.doc

11/14

Page 24

ICS Hazardous Area Page/Par ty

Installation

Opening the Station

®

Station Page 22 of 31

Pub. 42004-723L2G

WARNING

Before performing any of the following settings and adjustments, remove all

power from the station.

WARNING

To reduce the risk of hazardous atmospheres, disconnect the equipment

from the supply circuit before making any adjustments to the amplifier’s handset level.

Remove all cover bolts from the enclosure. Swing the front door open to access the internal PCBAs.

Field Wiring

The RTU PCBA provides terminal blocks for field wiring. Attach spade lugs to the wires before

attachment to the terminal blocks for the most secure connection.

OUTPUT 1A and OUTPUT 1B are activated by either the VLC or SmartSeries PCBA. OUTPUT 1B is

fused on the normally open (N. O.) contact with a T1.6 amp fuse.

Attaching the Front Panel

After all connections have been completed, inspect and clean the machined flange joint surfaces of both

the cover and box. Surfaces must be smooth, free of nicks, scratches, dirt or any foreign particle build-up

that would prevent a proper seal. Surfaces must seat fully against each other to provide a proper

explosion-proof joint. Clean surfaces by wiping with a clean lint-free cloth.

Apply a light coat of Killark “LUBG” lubricant to flange surfaces and close the cover. Install and tighten

all cover bolts to 30 ft.-lbs. Make certain no cover bolts are omitted. Use only those bolts supplied with

the enclosure.

It may become necessary to re-terminate some or all of the enclosures in a system. If so, strip the wires

back to clean copper and connect only one wire to each connector to allow for easier future

troubleshooting.

OTE: Refer to the Killark Installation, Operation, and Maintenance Data Sheet enclosed with the unit for

N

additional information.

Non-supervised Output Wiri ng Configuration

Figure 15. Non-supervised Output with the VLC or SmartSeries Option

f:\standard ioms - current release\ 42004 instr. manuals\42004-723l2g.doc

11/14

Page 25

®

ICS Hazardous Area Page/Par ty

Supervised Output Wiring C onfigurations with S martSeries Option

Station Page 23 of 31

Pub. 42004-723L2G

Figure 16. Supervised Output Wiring with SmartSeries Option

OTE 1: Input 1 is used to monitor Output 1 and is not available for other functions.

*N

OTE 2: Attention: 20 k-ohm, 10-watt supervision resistor

**N

WARNING

Installation of this component shall be carried out by suitably trained personnel in

accordance with the applicable code of practice concerning equipment and protective systems intended

for use in potentially Explosive Atmospheres. This component must be in a suitable enclosure for the

potentially Explosive Atmosphere. During normal operation at 230 V this component can support a

temperature code of T4. This component shall be installed at a location acceptable to the authority having

jurisdiction.

f:\standard ioms - current release\ 42004 instr. manuals\42004-723l2g.doc

11/14

Page 26

®

ICS Hazardous Area Page/Par ty

Station Page 24 of 31

Input 1 or 2 Wiring Configuration with the SmartSer ies Option

Pub. 42004-723L2G

Figure 17. Input 1 or 2 Wiring Configuration with the SmartSeries Option

f:\standard ioms - current release\ 42004 instr. manuals\42004-723l2g.doc

11/14

Page 27

ICS Hazardous Area Page/Par ty

Troubleshooting

Opening the Station

®

Station Page 25 of 31

Pub. 42004-723L2G

WARNING

Before performing any of the following settings and adjustments, remove all

power from the station.

WARNING

To reduce the risk of hazardous atmospheres, disconnect the equipment

from the supply circuit before making any adjustments to the amplifier’s handset level.

Remove all cover bolts from the enclosure. Swing the front door open to access the internal PCBAs.

Jumper Settings

P4 Standard Jumper Configuration

For standard operation, without options, P4 requires jumper installation for proper operation. See Figure

18 for jumper locations.

Figure 18. P4 Jumper Default Settings

f:\standard ioms - current release\ 42004 instr. manuals\42004-723l2g.doc

11/14

Page 28

ICS Hazardous Area Page/Par ty

®

Station Page 26 of 31

Pub. 42004-723L2G

The following tables are provided to aid qualified service personnel in troubleshooting problems with the

ICS Page/Party

®

Station.

Table 1. General Troubleshooting

Problem Potential Cause

Station not

functional

Refer to the “Field Wiring” section on page 6 for proper terminations.

Verify incoming supply voltage at TB2 or TB3 on the Termination PCBA.

Verify regulated 24 V dc at P1 of Termination PCBA. Caution! Supply

voltage present at P2.

Excessive hum or

Inspect the Page/Party® lines for proper line terminations, shorts, and grounds.

buzz during

station operation.

Crosstalk occurs

between

Page/Party

®

lines.

Feedback occurs

Inspect the Page/Party

grounds.

Inspect the Page/Party

Check location and orientation of speakers in the area.

®

lines for proper line terminations, shorts, and

®

party line connections for crossing of the cable pairs.

during page.

Refer to the “Field Wiring” section related to mutual muting on page 6.

Squeal in handset

receiver.

Handset

microphone audio

is too low/loud.

Handset receiver

audio is too

low/loud.

Refer to Speaker Mute on page 10.

Ensure proper termination on Page/Party

®

lines.

Ensure system line balance is connected.

Disconnect headset, if connected.

Refer to the “Transmit Level” section on page 11.

Check jumper settings or cable connections at P4.

Ensure proper termination on Page/Party

®

lines.

Check handset connections.

Check proper cable terminations between Termination and Main PCBAs.

Check operation of hookswitch.

Replace handset.

Refer to “Receiver Volume” on page 11.

Check jumper settings or cable connections at P4.

Ensure proper termination on Page/Party

®

lines.

Check handset connections.

Check proper cable terminations between Termination and Main PCBAs.

Check operation of hookswitch.

Replace handset.

f:\standard ioms - current release\ 42004 instr. manuals\42004-723l2g.doc

11/14

Page 29

Pub. 42004-723L2G

ICS Hazardous Area Page/Par ty

®

Station Page 27 of 31

Table 2. Troubleshooting Standard/VLC Configurations

Problem Potential Cause

Speaker volume is

too low/loud.

Cannot place a

page.

RTU output is not

functional.

Refer to “Speaker Volume” on page 11; or for VLC, “Audio Alignment” on

page 19.

Ensure P15 and P16 are in the correct position for the application.

Ensure the speaker wiring configuration is correct.

Ensure the nominal page line level is correct.

Replace the speaker or driver.

For VLC, refer to “Audio Alignment” on page 19, and “Page Disable

Control” on page 20.

Check handset connections.

Check proper cable terminations between Termination and Main PCBAs.

Check jumper settings or cable connection at P4.

Replace handset.

Ensure the VLC PCBA is installed and operational. Refer to “Remote

Output Switching (Available with RTU Only)” on page 20.

Check fuse F1 on RTU PCBA.

Check the cable connection at P5 on the RTU and VLC PCBA.

RTU input does

not function.

Check RTU terminal connections on TB7. Refer to Figure 15.

Check operation of connected device.

Inputs are only available with SmartSeries option.

f:\standard ioms - current release\ 42004 instr. manuals\42004-723l2g.doc

11/14

Page 30

Pub. 42004-723L2G

ICS Hazardous Area Page/Par ty

®

Station Page 28 of 31

Table 3. Troubleshooting SmartSeries Configurations

Problem Potential Cause

Speaker volume is

too low/loud.

Page/Party®

operation does not

function.

RTU output is not

functional.

Refer to the ADVANCE System Programming manual, Pub. 42004-700L2,

for station configuration.

Refer to the “ALS Minimum Level”, “ALS Offset Level”, and “SmartSeries

VLC Level” sections.

Check cable connection at P4.

Ensure P15 and P16 are in the correct position for the application.

Ensure the speaker wiring configuration is correct.

Ensure the nominal page line level is correct.

Replace the speaker or driver.

Refer to the ADVANCE System Programming manual, Pub. 42004-700L2,

to ensure station address matches ADVANCE configuration.

Refer to “Setting the Address” on page 13.

Check cable connection at P4.

Check proper cable terminations between Termination and Main PCBAs.

Ensure proper termination on Page/Party

®

lines.

Refer to the ADVANCE System Programming manual, Pub. 42004-700L2,

for station configuration.

RTU input does

not function.

For supervised output, ensure no monitored output faults exist.

Check fuse F1 on RTU PCBA.

Check the cable connection at P5 on the RTU and SmartSeries PCBA.

Check RTU terminal connections on TB6 and TB7. Refer to Figure 15 and

Figure 16.

Check operation of connected device.

Refer to the ADVANCE System Programming manual, Pub. 42004-700L2,

for station configuration.

For supervised input, ensure no monitored input faults exist.

Check the cable connection at P5 on the RTU and SmartSeries PCBA.

Check RTU terminal connections on TB6. Refer to Figure 17.

Check operation of connected device.

f:\standard ioms - current release\ 42004 instr. manuals\42004-723l2g.doc

11/14

Page 31

Pub. 42004-723L2G

ICS Hazardous Area Page/Par ty

®

Station Page 29 of 31

Attachin g the Front Co ver

After all troubleshooting has been completed, inspect and clean the machined flange joint surfaces of both

the cover and box. Surfaces must be smooth, free of nicks, scratches, dirt or any foreign particle build-up

that would prevent a proper seal. Surfaces must seat fully against each other to provide a proper

explosion-proof joint. Clean surfaces by wiping with a clean lint-free cloth.

Apply a light coat of Killark “LUBG” lubricant to flange surfaces and close the cover. Install and tighten

all cover bolts to 30 ft.-lbs. Make certain no cover bolts are omitted. Use only those bolts supplied with

the enclosure.

It may become necessary to re-terminate some or all of the enclosures in a system. If so, strip the wires

back to clean copper and connect only one wire to each connector to allow for easier future

troubleshooting.

N

OTE: Refer to the Killark Installation, Operation, and Maintenance Data Sheet enclosed with the unit for

additional information.

Specification s

Power Requirements

AC/DC Input

AC Power Supply

Input voltage .............................................................................. 120/230 V ac (nominal), 50/60 Hz

Power factor @ nominal 120 V ac ............................................................................................. 0.98

DC Power Supply

Input voltage ........................................................................................................... 24 V dc +/−20%

Current/Power requirements (+/−10%)

Power Consumed

(8-ohm load)

24 V DC

120 V AC

230 V AC

Idle 165 mA/4.0 W 70 mA/8.4 VA 90 mA/20.7 VA

4-watt output (default setting) 460 mA/11.0 W 120 mA/14.4 VA 110 mA/25.3 VA

12-watt output 900 mA/21.6 W 200 mA/24.0 VA 160 mA/36.8 VA

30-watt output 1.95 A/46.8 W 400 mA/48.0 VA 220 mA/50.6 VA

Maximum Current

Consumption (8-o hm l oad)

19.2 V DC

108 V AC

253 V AC

30-watt output 2.44 A/46.8 W 450 mA/48.6 VA 260 mA/65.8 VA

Handset

Microphone ........................................................................................................... Dynamic, noise-canceling

Receiver .................................................................................................... Dynamic, hearing aid compatible

Cord ........................................................................................................... Retractile, 6-foot extended, PVC

Material .................................................................................................................................................. ABS

External control .............................................................................................. Push-to-page handset pressbar

f:\standard ioms - current release\ 42004 instr. manuals\42004-723l2g.doc

11/14

Page 32

Pub. 42004-723L2G

ICS Hazardous Area Page/Par ty

®

Station Page 30 of 31

Handset Amplifier

Output level (compression controlled) .................................................... 1.5 V

Adjustable 0–2.1 V

nominal into 33-ohm load

RMS

RMS

Frequency response ........................................................................... 250–6,500 Hz, +0/−3 dB ref. to 1 kHz

Distortion ......................................................................... <1.5% THD @ 1 kHz (below compression level)

Receiver level................................................................................................................. 200 mV

Adjustable 150–400 mV

, nominal

RMS

RMS

Speaker Amplifier

Maximum output:

8-ohm speaker* ....................................................... 30 watts into 8-ohm load with 1.5 V

input page level

RMS

Adjustable to 30 watts; default: 4 watts @ 8 ohms

16-ohm speaker ..................................................... 15 watts into 16-ohm load with 1.5 V

input page level

RMS

Adjustable to 15 watts; default: 2 watts @ 16 ohms

Frequency response ........................................................................... 250–6,500 Hz, +0/−3 dB ref. to 1 kHz

Distortion ...................................................................................................... <1% THD @1 kHz to 24 watts

<3% THD @ 1 kHz to 30 watts

Input impedance ......................................................................................................................... 50,000 ohms

16 kilohms with SmartSeries option

SmartSeries offset level adjustment range .................................................................................... 0 to 30 dB

*See Figure 19 on page 31.

Enclosure Specifications

Construction/finish ......................................................................... Cast aluminum/gray epoxy powder coat

Mounting ................................................... Wall or column, four 3/8-inch (10mm) mounting feet with slots

Connections................................................................................ Internal screw-type barrier terminal blocks

Dimensions ........................................... 14.31 H 13.06 W 11.68 D inches (363.6 331.8 296.6 mm)

Temperature range (operating and storage) ........................................... (−4º F to +140º F) −20º C to +60º C

Shipping weight ................................................................................................................... 49 lbs. (22.2 kg)

Net weight ............................................................................................................................ 47 lbs. (21.3 kg)

Enclosure ................................................................................................................................ IP66/Type 4X

VLC Option Specifications

VLC minimum input level .............................................................................................................. 50 mV

RMS

VLC tolerance ......................................................................................................................... 50 kHz +/−4%

All Call Option Specifications

All Call control output ..................................................................Sink 50 mA maximum to circuit common

pulled up to 24 V dc maximum

RTU Option Specifications

Output Relay

Maximum load current ................................................................................. 8 amps OUTPUT 1A (unfused)

1.6 amps OUTPUT 1B (fused)

Maximum voltage ............................................................................................................................. 250 V ac

f:\standard ioms - current release\ 42004 instr. manuals\42004-723l2g.doc

11/14

Page 33

Pub. 42004-723L2G

ICS Hazardous Area Page/Par ty

®

Station Page 31 of 31

RTU Input Control (with SmartSeries Option)

Switch type................................................... Normally open (N.O.) or normally closed (N.C.) dry contacts

End-of-line termination ................................................................. 20 kilohms, or 15 kilohms + 5.1 kilohms

Cable resistance .................................................................................... 100 ohms maximum loop resistance

Contact closure resistance ............................................................................................... 1 kilohm maximum

Open fault detection ................................................................................................................... >65 kilohms

Short fault detection ..................................................................................................................... <200 ohms

Approvals

NRTL listed ............................................................. Hazardous locations Class I, Div. 1, Groups B, C & D;

(USA and Canada) Class II, Div. 1, Groups F & G;

Class III, Div. 1

T6, Type 4X

CE Mark

Certificate No.

Notified Body Id No. 0539

UL International DEMKO A/S

Lyskear 8

DK-2730 Herlev

Denmark

DEMKO 09 ATEX 0909372 (ATEX) .......................................................... II 2 G Ex d [ib] IIB + H

IECEx UL 09.0009 (IECEx) .......................................................................... II 2 G Ex d [ib] IIB + H

Typical Continuous Speaker Output Power Derating

1kHz Sinewave into a 8-ohm Load

30

-30°C

25°C

40°C

50°C

60°C

70°C

Watts

25

20

15

10

5

T6

2

T6

2

0

0.1 1 10 100

Minutes

Figure 19. Typical Continuous Speaker Output Power Derating

1 kHz Sine Wave into an 8-ohm Load

f:\standard ioms - current release\ 42004 instr. manuals\42004-723l2g.doc

11/14

Page 34

Warranty

Equipment. GAI-Tronics warrants for a period of one (1) year from the date of shipment, that any

GAI-Tronics equipment supplied hereunder shall be free of defects in material and workmanship, shall

comply with the then-current product specifications and product literature, and if applicable, shall be fit

for the purpose specified in the agreed-upon quotation or proposal document. If (a) Seller’s goods prove

to be defective in workmanship and/or material under normal and proper usage, or unfit for the purpose

specified and agreed upon, and (b) Buyer’s claim is made within the warranty period set forth above,

Buyer may return such goods to GAI-Tronics’ nearest depot repair facility, freight prepaid, at which time

they will be repaired or replaced, at Seller’s option, without charge to Buyer. Repair or replacement shall

be Buyer’s sole and exclusive remedy. The warranty period on any repaired or replacement equipment

shall be the greater of the ninety (90) day repair warranty or one (1) year from the date the original

equipment was shipped. In no event shall GAI-Tronics warranty obligations with respect to equipment

exceed 100% of the total cost of the equipment supplied hereunder. Buyer may also be entitled to the

manufacturer’s warranty on any third-party goods supplied by GAI-Tronics hereunder. The applicability

of any such third-party warranty will be determined by GAI-Tronics.

Services. Any services GAI-Tronics provides hereunder, whether directly or through subcontractors,

shall be performed in accordance with the standard of care with which such services are normally

provided in the industry. If the services fail to meet the applicable industry standard, GAI-Tronics will

re-perform such services at no cost to buyer to correct said deficiency to Company's satisfaction provided

any and all issues are identified prior to the demobilization of the Contractor’s personnel from the work

site. Re-performance of services shall be Buyer’s sole and exclusive remedy, and in no event shall GAITronics warranty obligations with respect to services exceed 100% of the total cost of the services

provided hereunder.

Warranty Periods. Every claim by Buyer alleging a defect in the goods and/or services provided

hereunder shall be deemed waived unless such claim is made in writing within the applicable warranty

periods as set forth above. Provided, however, that if the defect complained of is latent and not

discoverable within the above warranty periods, every claim arising on account of such latent defect shall

be deemed waived unless it is made in writing within a reasonable time after such latent defect is or

should have been discovered by Buyer.

Limitations / Exclusions. The warranties herein shall not apply to, and GAI-Tronics shall not be

responsible for, any damage to the goods or failure of the services supplied hereunder, to the extent

caused by Buyer’s neglect, failure to follow operational and maintenance procedures provided with the

equipment, or the use of technicians not specifically authorized by GAI-Tronics to maintain or service the

equipment. THE WARRANTIES AND REMEDIES CONTAINED HEREIN ARE IN LIEU OF AND

EXCLUDE ALL OTHER WARRANTIES AND REMEDIES, WHETHER EXPRESS OR IMPLIED BY

OPERATION OF LAW OR OTHERWISE, INCLUDING ANY WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

Return Policy

If the equipment requires service, contact your Regional Service Center for a return authorization number

(RA#). Equipment should be shipped prepaid to GAI-Tronics with a return authorization number and a

purchase order number. If the equipment is under warranty, repairs or a replacement will be made in

accordance with the warranty policy set forth above. Please include a written explanation of all defects to

assist our technicians in their troubleshooting efforts.

Call 800-492-1212 (inside the USA) or 610-777-1374 (outside the USA) for help identifying the

Regional Service Center closest to you.

(Rev. 10/06)

Loading...

Loading...