Page 1

FEATURES OF MAGNUM JUNIOR

The Magnum series are pistol grip type of AM 2 channel digital proportional radio control sets and are the best in their class.

TRANSMITTER FP-T2PKA,

• Newly designed cockpit type control panel

• Human-engineered size and design are easy to use.

•Steering rate adjuster The steering servo travel volume (right 81 left

evenly from neutral) can be adjusted simultaneously, while running.

•Throttle

• Wheel angle adjuster. The turning angle of the steering wheel can

• Neutral adjuster. The throttle trigger throttle stroke/brake deflection

•Servo reversing switch (steering and throttle) is standard Each servo

• Since a level meter is provided, battery consumption can be seen at

• Crystal can be changed from the outside. Crystal can be immediately

• Power supply can be changed to a nicad battery system. FP-T2PKA

RECEIVER

• BEC (Battery Eliminator Circuitry) system allows sharing of the

•

RECEIVER

• High performance AM 4 channel receiver in which miniature size and

• Short (50cm) antenna designed for miniature models is easy to mount.

•

Narrow

• Noise resistance achieved by using a pulse noise rejection circuit.

• New CMOS miniature 1C used in the data coder increases reliability

• New type sub miniature, highly reliable pins used at the crystal socket

• Thick film gold-plated connector pins eliminate poor contact and

ATV

and set with two trimmers, independently. FP-T2PKA

be increased and decreased. This allows operation at the best angle

stroke (back stroke) can be freely selected to match the application

can be reversed from the outside. This is extremely convenient when

connecting the linkages.

a glance.

changed during competitions, etc. except 72 MHz and 75 MHz on

transmitter.

The throttle

FP-R102GR_____________________

running Nicd battery and eliminates the need for a regulator and

diode.

Crystal socket

pins. Reliability is increased and the crystal can be changed from

the outside.

uses a new type

FP-R104H_______________________

light weight have been achieved by using the PC board space to the

maximum.

(27MHz only)

band

channel interference.

substantially.

also increase reliability The crystal can be changed from the outside.

improve reliability against shock and vibration.

design using a narrow band ceramic filter

SERVO FP-S148, S129, S132H

•Motor

uses

the

and smooth operation. (S148, S129)

• These heavy-duty & water/dust tight servos are designed for use with

Futaba digital proportional

• New indirect driver potentiometer improves vibration and shock re-

sistance and increases neutral precision tremendously.

• Futaba low-power custom 1C provides high starting torque, narrow

dead band, and excellent trackability.

• Fiberglass-reinforced PBT (polybutylene terephthalate) injection

molded servo case is mechanically strong and invulnerable against

glow fuel.

• Strong polyacetal resin ultra-precision servo gear features smooth

operation, positive neutral, and very little backlash.

• Fiberglass-reinforced epoxy resin PC board with thru-the-hole plating

improves servo amp vibration and shock resistance.

• Thick film gold-plated connector pins eliminate poor contact and

improve reliability against shock and vibration.

• Special grommet bushing simplifies servo mounting and improves the

cushioning effect.

• Six special adjustable splined horns are available.

• Maximum output torque of 48.7oz-in.(3.0kg-cm/3 5kg-cm) allows

use in almost any model (S148, S129)

• High operating speed of 0.13 sec/60° makes it perfect when especially

high speed is necessary. (S132H)

newest helical type

(FP-T2PK)_____________

servo

travel

volume

of

highly

reliable

rotor

for

improved

radio

control

sets

(S129)

can

be adjusted

subminiature

resists

output

adjacent

torque

SET CONTENTS AND RATINGS

MAGNUM JUNIOR

Transmitter

Receiver

Servo

Others

TRANSMITTER FP-T2PKA.

Operating system : Pistol grip type, 2-channel

Transmitting frequency : 27MHz band 72/75MHz band

Modulation system : AM (amplitude modulation)

Power requirement 12V, AA penlight battery x 8

Receiver

Receiving frequency 75MHz

Intermediate frequency 455kHz

Selectivity :3kHz/-3dB

Receiving range 550 yards (500m) on the ground when

Power supply 4.8V to 8.4V

Current drain 7.2V/13mA, 4.8V/33mA

Dimensions 1.46 x 2.19 x 0.75 in. (37 x 55.5 x 19 mm)

Weight 1.34 oz (38g)

RECEIVER FP-R4H,

Miniature 4 channel AM receiver

Receiving frequency :27MHz band 72/75MHz

Intermediate frequency :455kHz

Power requirement :4.8V to 6.0V

Current drain :10mA

Dimensions :1.26 x 2.05 x 0.77 in. (32 x 52 x 19.4 mm)

Weight :

Receiving range :

SERVO

Control system :+pulse width control

Operating angle : One side 45° or more

Power

Current drain (IDLE)

Output torque :

Operating speed :

Dimensions

Weight : 1.5 oz. (44.4g)

SERVO

Control system :+pulse control

Operating angle :Rotary system, one-side 45" or greater

Power requirement :4.8V to 6.0V (shared with receiver)

Current drain :6.0V, 8mA (at idle)

Output torque

Operating speed

Dimensions :1.79 x 0.9 x 1.71 in. (45.5 x 23

Weight :2.1 oz (60g)

SERVO

Operating system :+pulse control

Operating angle :Rotary system, one-side 40" or greater

Power requirement :4.8V to 6.0V (shared with receiver)

Current drain :6.0V, 8mA (at idle)

Output torque :25.02 oz-in (1.8kg-cm)

Operating speed :0.13 sec/60°

Dimensions :1.46 x 0.71 x 1.20 in. (37 x 18 x 30.5 mm)

Weight :1.13oz(32g)

PP-R102GR

PP-S148__________________________

requirement

FP-S129____________________________

FP-S132H___________________________

FP-T2PKA

FP-R102GR or FP-R104H

FP-S148 x 2 or FP-S129 or

FP-S132H

Switch, battery holder, etc.

(FP-T2PK)_____________

________________________

used with FP-T2PKA (At the best radio

wave condition of environment)

(FP-R104H)_________________

1.06 oz (30g

220

with

condition of environment)

:

4.8V-6V

: 6.0V, 8mA (at idle)

42 oz. in. (3 kg-cm)

0.22 sec/60°

: 1.59 x 0.77 x 1.4in. (40.4 x 19.8

x

(including trim)

:48.7 oz-in (3.5kg-cm)

:0.25 sec /60"

x

43 5 mm)

(including trim)

)

yards(200m) on the ground when used

the

FP-T2PKA(At

36

mm)

FP-T2PK

band

the

best

radio

wave

Page 2

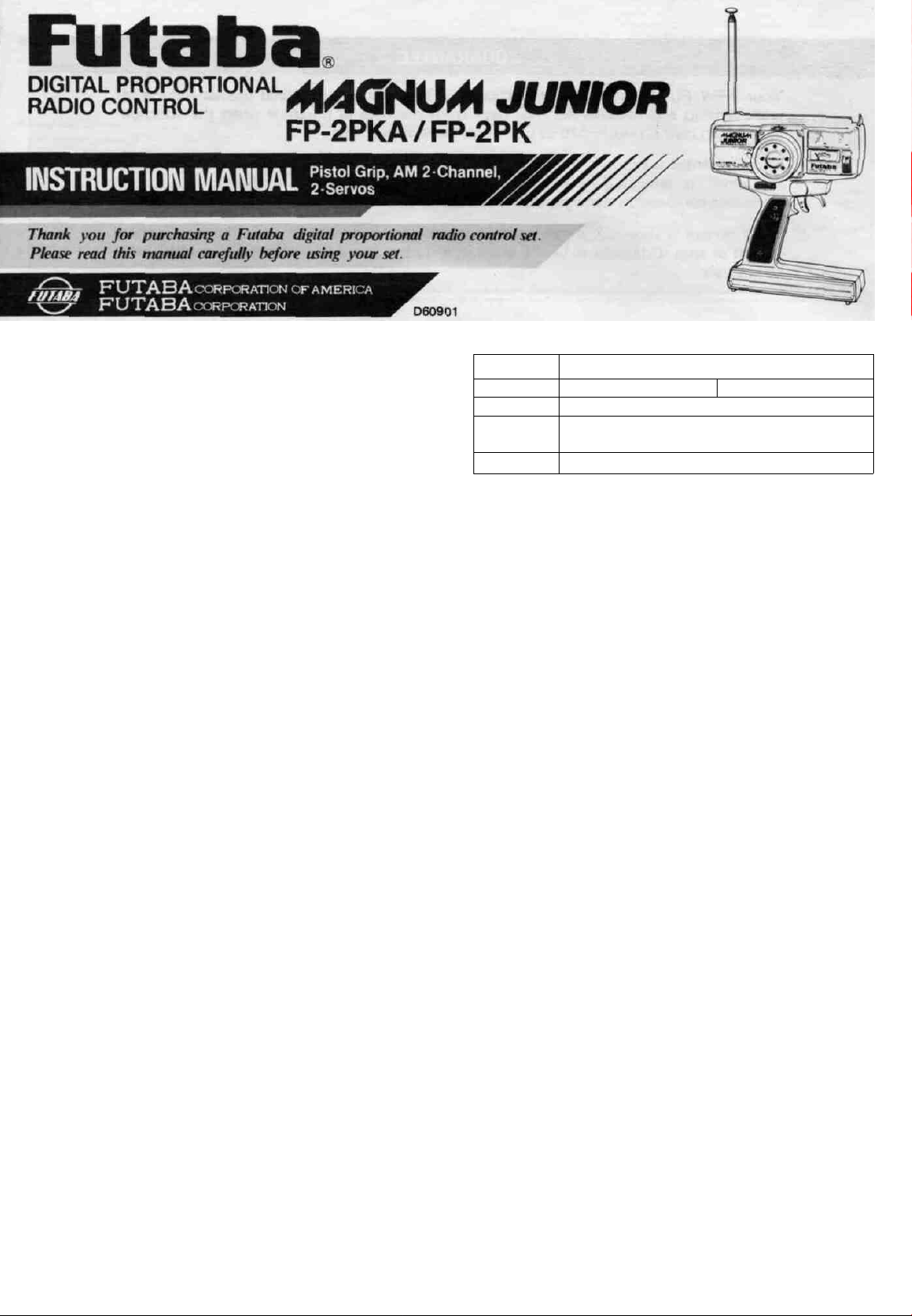

TRANSMITTER FP-T2PKA (FP-T2PK)

HANDLING INSTRUCTIONS

The name of each part of the transmitter

is shown in Fig. 1 and Fig. 2. Learn them

before operating your set.

Page 3

The servo reversing switches are assumed to be in the normal

position in the descriptions in this section. When the servo

switches are in the reverse position, operation is the opposite

of that described here.

(1) Steering wheel (rudder)

Steering (rudder) operation.

(2) Throttle trigger (throttle lever)

Engine control/motor control operation.

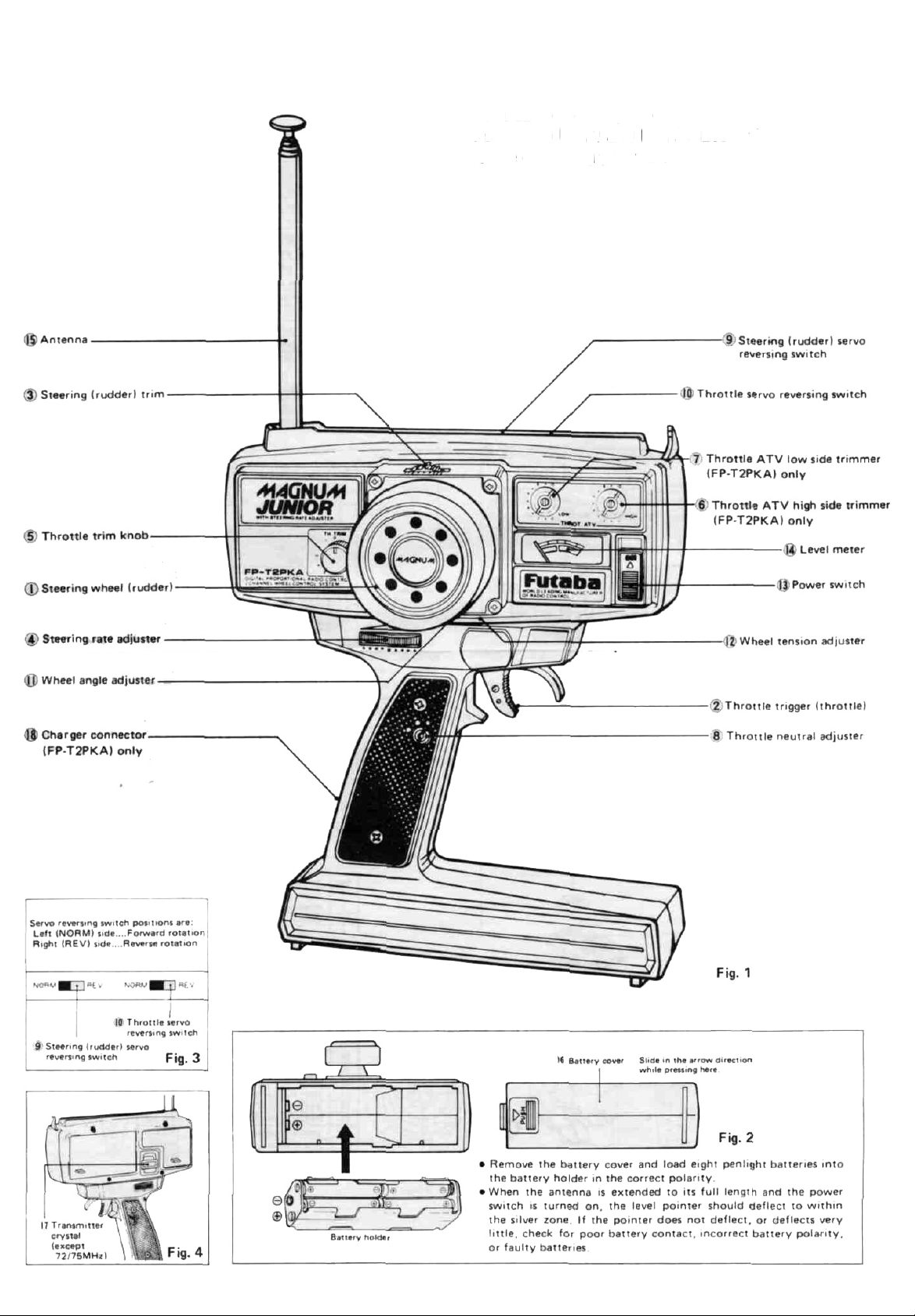

The throttle neutral position can be set to one of three position by

turning

the 8 throttle

Fig. 5. Set it to match the application.

When set to 1 ) the full deflection angle is 40°

When set to 2 ) the throttle throw is 27° and the

brake deflection angle is 13°.

When set to 3 ) the throttle and brake (reverse)

throws are both 20°.

• For engine cars, position 2 is recommended.

• For electric cars, position 3 is recommended when equipped

with reverse mechanism and position 2 is recommended when

equipped with a brake and forward only

neutral adjuster

with a coin

as

shown

Fig.

in

5

(8) Throttle neutral adjuster

This adjuster

throttle trigger. Set it to the point at which it stops with a click

with a screwdriver, coin, etc.

9 Steering (rudder) servo reversing switch

10 Throttle servo reversing switch

(11) Wheel

The wheel angle adjuster changes the operating angle of the (1) Steer-

ing wheel as shown in Fig. 8.

(12) Wheel tension adjuster

This is a phillips head screw which adjusts the steering force of the

steering wheel.

angle

sets

the

adjuster

throttle

trigger

neutral

point

as

described

in

(2)

(3) Steering trim

Steering (rudder) trim

(4) Steering rate adjuster

The steering servo steering angle can be freely set as shown in Fig. 6

with a ratcheted adjuster installed which enables you to adjust steer-

ing servo travel volume to match a car to the course, even while running.

Neutral

The steering angle can be

set within this range.

30%~100%

Steering servo

(5) Throttle trim knob

(6) Throttle ATV high side trimmer ATV... Adjustable Travel Volume.

(7) Throttle ATV low side trimmer

Throttle ATV is a device which permits independent adjustment of

the throttle servo left and right sides (from neutral) as shown in Fig.

7 with trimmers (6) and (7). (FP-T2PKA)

Fig.

(13) Power switch

When set in the direction of the A mark (upper position), the switch

is turned on and the pointer of the level meter deflects.

(14) Level meter

When the 13) power switch is set to ON, the level meter pointer

should deflect to within the silver zone. If the pointer stops near the

boundary between the silver and red zones, the battery is low, and

the range of the radiowaves will be short. When the level meter

pointer drops to the boundary between the silver and red zones,

change the battery.

(15) Antenna

6

95cm antenna. It screws in vertically as shown in Fig. 10.

Remove from

the holder and

screw in vertically.

ATV is the abbreviation

for Adjustable Throttle

Volume and is an extremely convenient device by

which steering servo travel

volume can be adjusted

freely with two trimmers

preloaded.

The relationship between

two trimmers does not

change even when servo is

reversed.

(6)&(7):only

for

FP-T2PKA.

Throttle Servo

Fig.

7

(16) Battery cover

When loading (or changing) the eight penlight batteries, remove this

cover as shown in Fig. 2.

(17) Transmitter crystal

When changing the frequency, replace this crystal. Use the AM crystal set (transmit and receive 1 pair) sold by Futaba. The transmitter

crystal is marked TX and the receiver crystal is marked RX. However,

you are not allowed to change frequency by merely replacing crystal

on both 72 and 75MHz.

Fig. 10

Page 4

The BEC mark is displayed on the front of the receiver of BEC

(Battery Eliminator Circuitry) system sets with a receiver with shared

power supply regulator.

RECEIVER FP-R102GR AND SERVO FP-S148

Fig. 11

(3) When motor car uses an ordi-

nary common power supply

chassis

Red common 2P

connector

(Female pins)

Buy the red common 2P

connector from the kit

manufacturer and connect to

the controller.

Pin 1: Minus

Pin 2. Plus

The Futaba BEC (Battery Eliminator Circuitry) system can also use a common power supply with the conventional four penlight

batteries system (separate power supply).

(2) When motor car uses a speci-

al BEC system chassis (common power supply specifi-

cations)

Red common 2P

connector

Connect to the red common

2P connector of the controller.

Page 5

• A common power supply regulator and diode may also be supplied with the speed controller, depending on the vehicle kit. Since

they cause a voltage drop, always remove them.

• Set the transmitter power switch to ON, then set the receiver power

switch to ON. The servos stop near the neutral position. Operate the

transmitter sticks and check if each servo faithfully follows operation of the sticks.

• Connect the pushrod to each servo horn, then check if the direction of travel of each servo matches the transmitter operation.

• Operate each servo over its full travel and check if the pushrod binds

or

is

too

loose.

adversely affect the servo and quickly drain the battery. Be especially careful when using 8.4V.

•

Always make the

Applying

unreasonable force

full

stroke

(including

Fig.

trim)

13

to

the

of

servo

the

horn

servo

will

horns

• Be alert for noise.

• Even though the receiver antenna wire is long, do not cut or bundle

Receiver antenna

wire

somewhat larger

they move smoothly even when the trim lever and stick are operated

simultaneously in the same direction.

Always solder a noise killing capacitor to the running motor. If

metal pans touch each other due to vibration, noise will be generated and cause the receiver servos to operate erroneously. We recommend the use of noiseless parts.

it. The range of the radiowaves will be shortened.

than

the

full

travel.

Adjust

the

servo

horns

so

that

— Wood screw

ten

cB

• Install the servos firmly. Install

the servo to the servo tray as

shown in the figure. In other

cases, install the servo as described in the model manufacturer's manual.

-Rubber bushing

-Gromet

Fig.

14

• A spare horn is provided. Use it as required.

• Wrap the receiver in sponge rubber and wrap rubber bands around

the sponge rubber. Mount the receiver so it is not exposed to vibra-

tion, does not touch the frame, and does not move.

• When the receiver is installed on a board or used where it may be

splashed with mud and water, place it in a plastic bag, etc. and

wrap a rubber band around the open end of the bag to waterproof

and dustproof the receiver. After use, remove the receiver from the

bag to prevent condensation.

• Use the rubber bands wrapped around the receiver to hold the

CONVERSION TO NICAD SYSTEM

FP-2PKA ONLY

To use a nicad battery with this set, modify

the set with the optional PBPK-11 (2PKA

nicad battery conversion set).

(1) Remove the battery cover and discon-

nect the nine contacts with needle nosed

pliers at shown in Fig. 15. Then install

the transmitter NT-8LP nicad battery

and install the

battery cover.

Fig. 15

Transmitter NT-8LP

nicad battery.

(2) Charging and how to use

(a) Connect the power plug of the FBC-8B

(4) battery charger to the transmitter

charging connector. Connect the 3PC red

male connector to the receiver and servo

NR-4H nicad battery. Plug the battery

charger into a 120 VAC outlet as shown

in

Fig.

(b) Normally recharge the battery for about

(c) If the battery is left discharged for a long

16.

15 hours. If the battery has not been

used for some time or is new, discharge

and recharge it 2 or 3 times before use.

time, its capacity will decrease and the

life of the battery will be shortened.

After use, recharge the battery before

storing it.

servo and switch leads.

• After mounting is complete, recheck each part, then check the

transmitting range by making the transmitter antenna as short as

possible and extending the receiver antenna fully and operating the

set from a distance of 20m to 30m. The movement of each servo

should follow the movement of the transmitter sticks.

• The crystal can be changed from the outside of the receiver case.

Always use a Futaba transmitter and receiver crystal pair as the

replacement crystals.

(d) Always recharge the battery before use.

(e) A fully charged battery can be used for

about two hours at 10 minutes/flight.

Notes: FBC-8B (4)

(1) First, connect to TX Nicd and red lamp goes on.

(2) Then, connect to RX Nicd after connecting, L,E,D, changes color from red to greenish

red (orange) which indicates that both TX and RX Nicds are being charged.

(3) In case of separate charging, L,E,D, color will be: RX Nicd — Green

TX Nicd - Red

Page 6

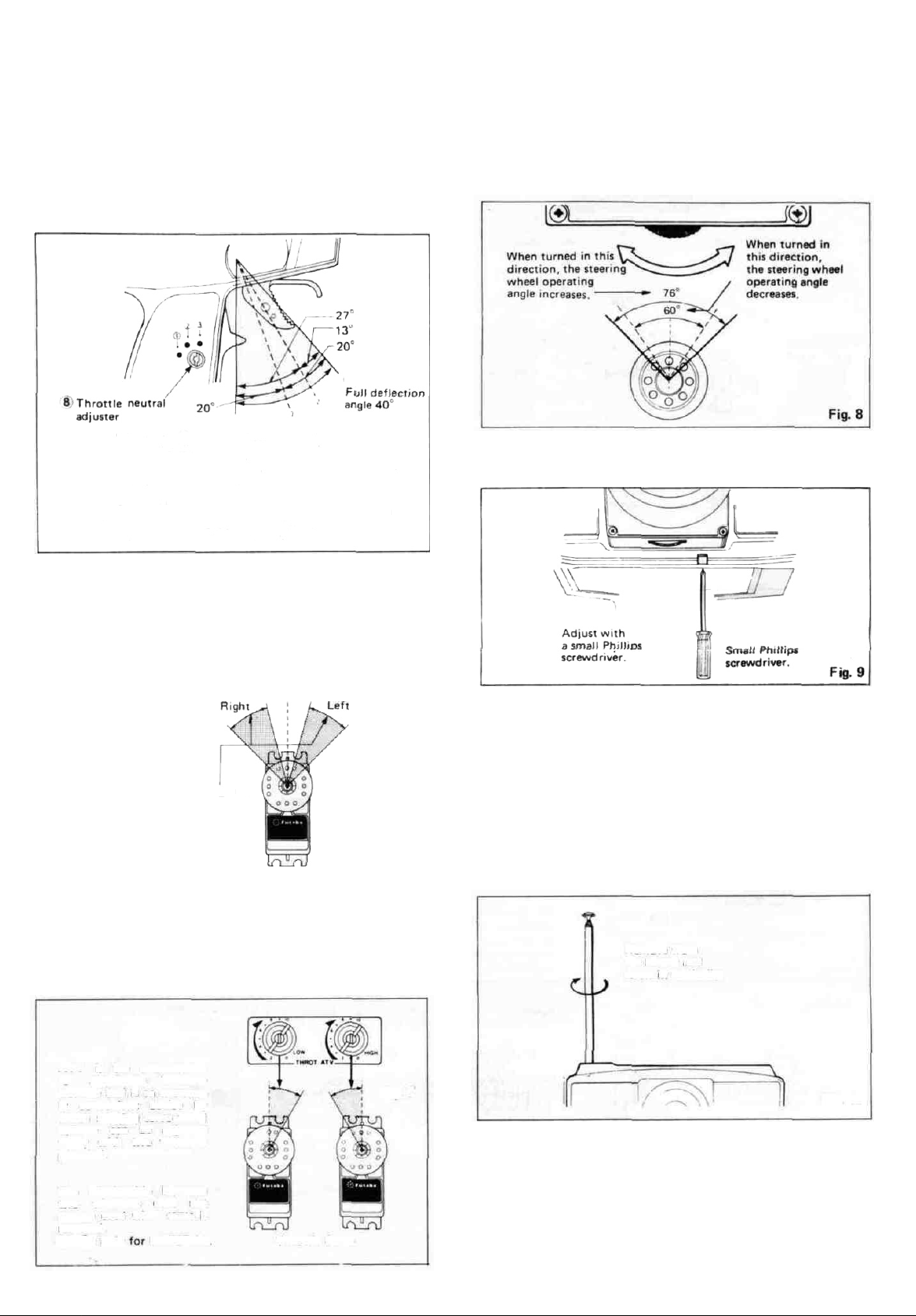

MOTOR CAR

Operation of the throttle (engine control) servo can be set as

shown in this figure by 2, throttle trigger operation.

NEUTRAL POSITION

Settable within

this range with the

0) throttle trim knob.

USING THE ANTENNA FREQUENCY FLAG

(2) Throttle trigger

throttle stroke

6 Adjustable

within this

range by

throttle

ATV High.

(FP-T2PKA)

Throttle (engine control)

•See the figure for the motor, battery.

and speed controller wiring.

Brake Speed

control control

OFF

QwOQOwwvO

(2)Throttle trigger

brake stroke

servo

Adjustable

within this

range by

throttle

ATV

Low.

(FP-T2PKA)

Fig.

17

• When the drive battery is also used as

the receiver servo

power supply with a

motordriven car, pay

careful attention to

the power supply

polarity and voltage.

With Futaba proportional R/C power

supplies, red represents + and black

represents - .

•SPLINED HORNS

This horn permits shifting of the

servo neutral position at the servo

horn. Setting and shifting the

neutral position

a) Angle divisions

Fig.

20

1) The splined horn has 25 seg-

ments. The amount of change per

segment is; 360-25=14.4°

2) The minimum adjustable angle

is determined by the number of

arms or number of the holes. For

four arms, the minimum adjustable

angle is:

360°-———

b) Effect

(25X4)

Number of divisions

———3.6°

Baseline A

Fig. 19

To shift the holes center line to

the right (clockwise) relative to

baseline A, shift arm 2 to the position of arm 1 and set it to the

position closest to baseline A.

Example For a four arm horn,

the angular shift per segment is

14.4°. The shift to the right is 90°

-

(14.4 x 6) = 3.6°

To shift by the same angle in the

opposite direction, use the oppo-

site arm number.

Fig. 22

For a six arm horn, turn the arm

counterclockwise and set arm 2

to the position of arm 1. The adjustable angle is 60° - (14.4 x 4)

=2.40.

Arm 3 shift 4.8° to the right, arm

6

shifts

2.4° to

the

left,

and

shifts 7.2° to the right and left.

arm

4

Motor and controller

circuit diagram

Fig. 18

The following splined horns are optional.

HORN A

HORN B

HORN C

HORN D

Fig. 21

HORN E

HORN F

Fig. 23

Fig.

24

Page 7

FP-S148

Fig.

25

No.

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

17.

18.

19.

20.

21.

22.

23.

Part name

Upper case

Middle case

Bottom case

Metal bearing

Metal bearing

Potentiometer

Potentiometer drive plate

Motor

Motor pinion

Screw

1st gear

2nd gear

3rd gear

Final gear

Intermediate shaft

2nd shaft

Servo horn D

Binding head tapping screw 2.6 x 8

Printed wiring board S148

3PB-WRB300G

w/gum bush

Pan head truss screw

Nameplate S148

Part

No.

PCS-48

PCS-48

PCS-48

S04137

S04136

139668

S02753

S91239

802461

J50002

FGS-48

FGS-48

FGS-48

FGS-48

S02495

S02494

FSH-6W

FSH-4I

AS1157

AT2453

890045

S50360

860099

FP-S129

FP-S132H

Fig.

26

Part name

No.

1.

Upper case

Middle case

2

Bottom case

3.

4.

Motor

Motor pinion

5.

Screw 2x3

6.

7.

1st gear

2nd gear

8.

3rd gear

9.

Final gear

10.

11.

Metal bearing

Potentiometer

12.

Potentiometer drive plate

13.

Seal ring

14.

Intermediate shaft

15.

2nd shaft

16.

17

Servo horn D

Binding head tapping screw

18.

2.6x8

0 ring 32.60

19.

Printed wiring board

20.

21.

S129.....3PBWRB300

Neoseal sponge 5x15x15

22

Neoseal sponge 3x15x7

23.

Phillips pan head screw

24.

0 ring 1.6

25.

Name plate

26.

No.

Part name

1

Upper case

Middle case

2

Bottom case

3

4

Metal bearing

Potentiometer

5

VR drive plate

6

Motor

7

Motor pinion

8

1st gear

9

2nd gear

10

11

3rd gear

Final gear

12

Intermediate shaft

13

14

2nd shaft

Ball bearing

15

Servo horn 0

16

Horn mounting screw

17

S132H Printed wiring board

18

S132H 3PBWRB-300

19

Lead wire packing

20

Case mounting screw

21

S132H Name plate

22

Part No.

FCS-29

S91212

S05402

J50002

FGS-29

FGS-29

FGS-29

FGS-29

S04134

139995

S02753

S90415

S04287

S01351

FSH-6W

FSH-41

S90420

AS

1206

FPC-8M

S90336

S90333

J50400

S90410

S80702

Pan

No.

FCS-32H

S04133

i39995

S05626

S91249

S02788

FGS-32H

S02480

S02481

S04130

FSH 6W

FSH-41

AS1271

FPC-8M

S90045

J50082

S60128

Fig.

27

Page 8

GUARANTEE

Your NEW FUTABA Digital Proportional R/C system is guaranteed against defects in

workmanship and material for 180 days from the date of purchase when the attached

registration card is returned to us within ten days of purchase.

This Guarantee is null and void if the R/C system has been improperly handled, damaged

in a crash, or tampered with and does not cover the replacement of plastic housings or

electronic components damaged due to the use of improper voltages.

When service is required, please take your equipment to your local authorized service

station or ship it directly to us. All postage, shipping, and insurance charges must be paid

by the user.

REPAIR SERVICE

• When requesting repair of trouble that has occurred suddenly of from long use, describe the trouble symptoms in as much detail as possible.

This will facilitate detection of the trouble point and shorten the repair period greatly.

• Defects caused by faulty materials of workmanship will be corrected free of charge.

• This limited warranty is null and void if the set has been tampered with or dis-

assembled.

Refer to warranty statement for details.

Futaba.

Digital

Proportional

Frequencies

(For U.S.A.)

• The frequency of Futaba digital proportional sets can be changed within their own band.

There

are

75 MHZ.) Please see chart listed below for specific frequency and its intended use. Please

4 different

note there are specific frequencies allocated for aircraft only and surface only use.

• The frequency can be changed within the same BAND by using a precisely matched pair

of Futaba crystals. However, Futaba recommends that you return your system to our

factory service department for frequency changing, as tuning may be necessary for proper

operation. Changing frequency from one band to another is NOT possible.

• Always change frequency flag when frequency is changed. The frequency flag is to be

attached to the top of antenna and the channel designation to the base. (See Drawing)

•

It

is

illegal

to

change

bands

crystals

for

of

you

72-75

to

choose

MHZ

from

bands

(27

in

the

MHZ,

U.S.A.

50-53

MHZ, 72 MHZ, and

Frequency Channel No. Flag Color

26-27

MHZ - Aircraft/Car/Boat

26.996 Brown

27.046 RW

27.096 Orange

27.146 Yellow

27.196 Green

27.266 Blue

60/53 MHZ - Aircraft/car/boat Fcc

A

matuer License required

50.800 RC00

60.840 RC02

50.880 RC04

50

920

RO6

50.960 RC08

63. 100 Black-Brown

63.200 Black-Red

53.300 Black-Orange

53.400 Black-Yellow

53 500 Black-Green

53. 600 Black-Blue

53. 700 Black-Violet

53. 800 Black-Grey

72 MHZ - Aircraft only

72.030 12 *72.470 34

72.070 14 72.550 38

72.110 16 72.590 40

72.150 18 72.630 42

72. 190 20 72.670 44

72.230 22 72.710 46

72.270 24 72.760 48

72.310 26 72.790 GO

72.360 28 72.830 62

72390 30 72.870 64

72430 32 72.910 66

75 MHZ - Car/Boat only

76.430 62 75.750 78

76.470 64 76.790 80

76.610 66 76.830 82

76.650 68 76.870 84

76.690 70 *75.910 86

• 75.630 72 • 76.960 88

76.670 74 *76.990 90

76.710 76

Effective

Color

Channel No.

Color

1, 1988

FUTABA ' CO

555 West

Victoria

RPORAT10N

Street

Compton.

OF

AMERICA

Calif

90220

USA

Phone 213 537 9610 Telex 230691227 Facsimile 2136378529

FUTABA

CORPORATION

Tokyo Office Inagaki BIdg .1 21 3. Kanda Suda cho. Chiyoda ku, Tokyo 101 Japan

Phone (03)255 6811 Facsimile (031255 6880

Printed in Taiwan

Loading...

Loading...