Page 1

Installation Manual

MARINE RADAR FR-2125V

SAFETY INSTRUCTIONS ......................................................i

SYSTEM CONFIGURATION ............................................... iii

EQUIPMENT LISTS.................................................................iv

MOUNTING

1.1 Antenna Unit .................................................................... 1-1

1.2 Display Unit...................................................................... 1-5

WIRING

2.1 Antenna Unit .................................................................... 2-1

2.2 Display Unit...................................................................... 2-5

2.3 Changing AC Power Specification................................. 2-12

INITIALIZA TION AND ADJUSTMENT

3.1 Tuning Initialization .......................................................... 3-1

3.2 Accessing Menus for Initialization and Adjustment.......... 3-1

3.3 Adjusting Video Signal Level ........................................... 3-1

3.4 Heading Alignment........................................................... 3-2

3.5 Adjusting Sweep Timing................................................... 3-3

3.6 Suppressing Main Bang................................................... 3-3

3.7 Confirming Magnetron Heater Voltage ............................ 3-4

3.8 Initial Setting Menus ........................................................ 3-5

INSTALLATION OF OPTIONAL EQUIPMENT

4.1 Gyro Converter GC-8....................................................... 4-1

4.2 ARP Board ARP-26.......................................................... 4-8

4.3 RP Board RP-26 ............................................................ 4-10

4.4 Performance Monitor PM-30.......................................... 4-15

4.5 Alarm Kit ........................................................................ 4-16

4.6 AC-DC Conversion Kit ................................................... 4-18

4.7 Connection of Rate-of-Turn Signal ................................ 4-19

4.8 V-Console Kit ................................................................. 4-20

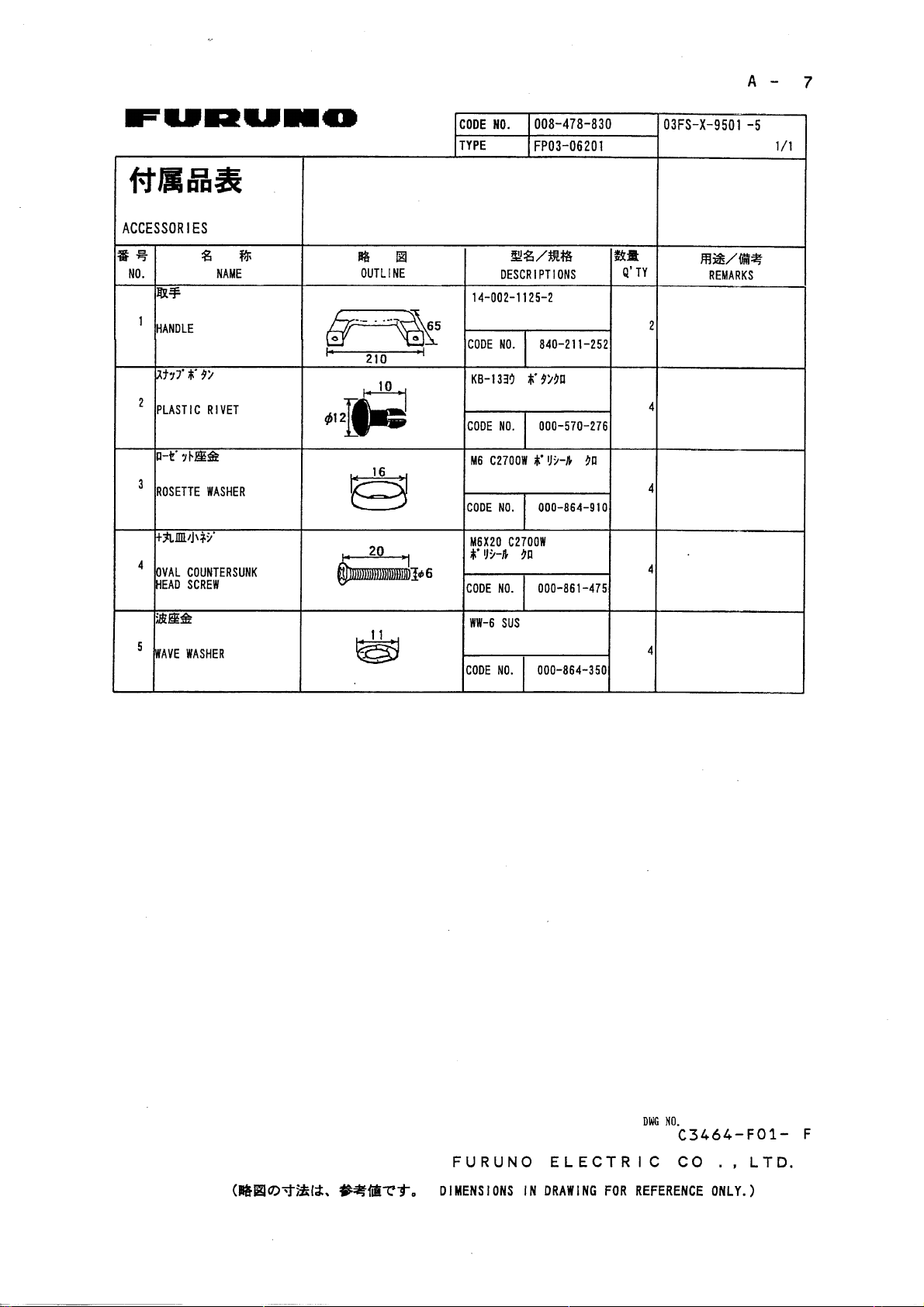

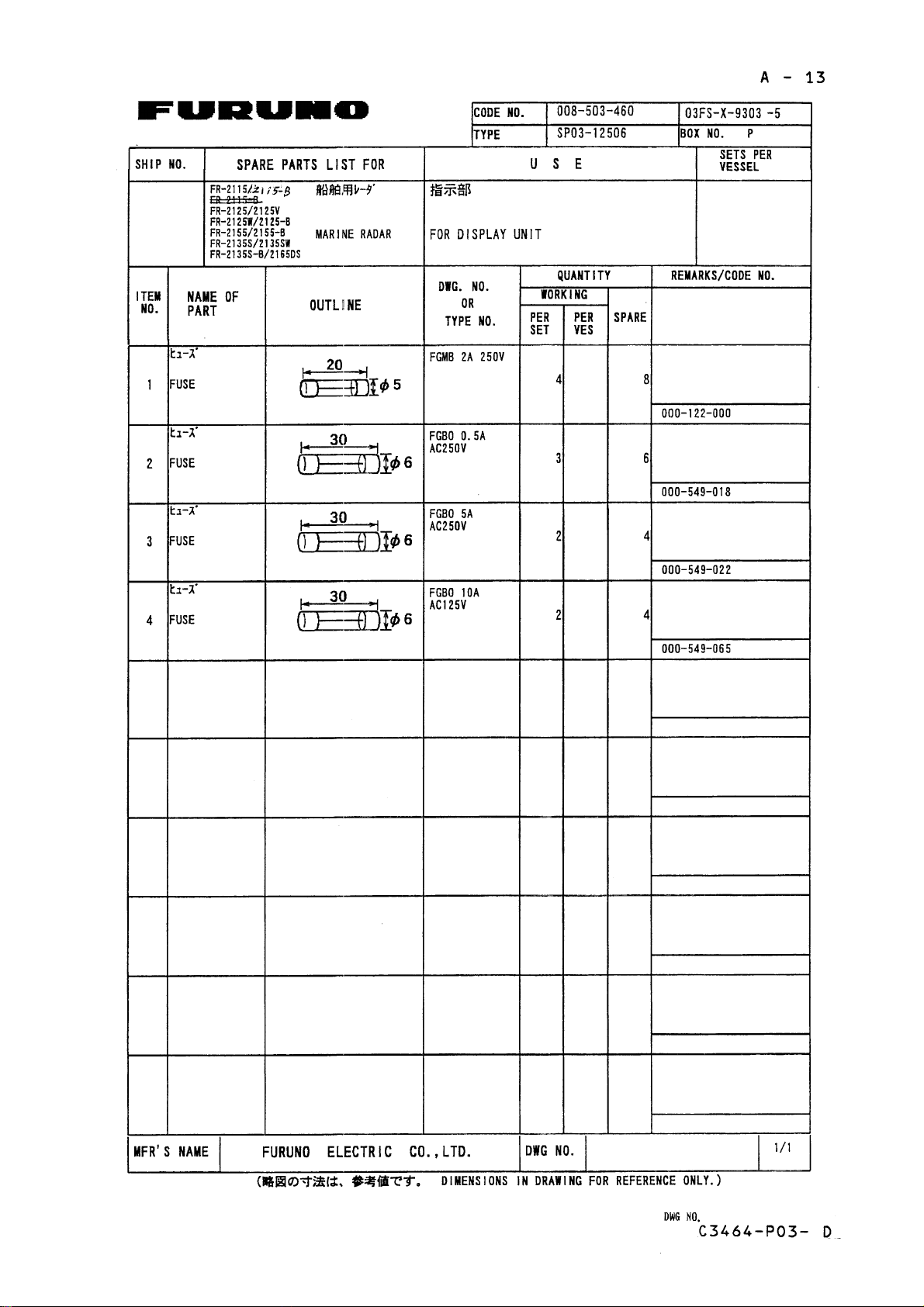

PACKING LISTS.................................................................... A-1

OUTLINE DRA WINGS........................................................D-1

INTERCONNECTION DIAGRAM................................... S-1

SCHEMATIC DIAGRAMS.................................................. S-2

Page 2

9-52 Ashihara-cho,9-52 Ashihara-cho,

A

A

*00080875300**00080875300*

*00080875300**00080875300*

*IME34710K00**IME34710K00*

Nishinomiya, JapanNishinomiya, Japan

Telephone :Telephone : 0798-65-21110798-65-2111

Telefax :Telefax : 0798-65-42000798-65-4200

Your Local Agent/DealerYour Local Agent/Dealer

ll rights reserved.

ll rights reserved.

PUB.No.PUB.No. IME-34710IME-34710-K-K

(( TENITENI ))

FR-2125VFR-2125V

Printed in JapanPrinted in Japan

FIRST EDITION :FIRST EDITION : APR.APR. 19991999

K :K : JAN.JAN. 08,200208,2002

* 0 0 0 8 0 8 7 5 3 0 0 ** 0 0 0 8 0 8 7 5 3 0 0 *

*IME34710K00**IME34710K00*

* I M E 3 4 7 1 0 K 0 0 ** I M E 3 4 7 1 0 K 0 0 *

Page 3

SAFETY INSTRUCTIONS

WARNING

Radio Frequency Radiation

Hazard

The radar antenna emits electromagnetic

radio frequency (RF) energy which can be

harmful, particularly to your eyes. Never

look directly into the antenna aperture from

a close distance while the radar is in

operation or expose yourself to the transmitting antenna at a close distance.

Distances at which RF radiation levels of

100 and 10 W/m

table below.

Note: If the antenna unit is installed at a

close distance in front of the wheel house,

your administration may require halt of

transmission within a certain sector of

antenna revolution. This is possible—Ask

your FURUNO representative or dealer to

provide this feature.

ledoM

V5212-RF

2

exist are given in the

rotaidaR

epyt

FA21NX

FA02NX

FA42NX

otecnatsiD

2

m/W001

tniop

esactsroW

m1.1

otecnatsiD

2

m/W01

tniop

esactsroW

m0.01

WARNING

Do not open the equipment

unless totally familiar with

electrical circuits and

service manual.

ELECTRICAL

SHOCK

HAZARD

Construct a suitable service platform

from which to install the antenna unit.

Serious injury or death can result if someone falls from the radar antenna mast.

Turn off the power at the mains switchboard before beginning the installation.

Fire, electrical shock or serious injury can

result if the power is left on or is applied

while the equipment is being installed.

Do not install the display unit where it

may get wet from rain or water splash.

Only qualified personnel

should work inside the

equipment.

Wear a safety belt and hard

hat when working on the

antenna unit.

Serious injury or death can

result if someone falls from

the radar antenna mast.

Water in the display unit can result in fire,

electrical shock or equipment damage.

i

Page 4

WARNING

Be sure that the power supply is

compatible with the voltage rating of

the equipment.

Connection of an incorrect power supply

can cause fire or equipment damage. The

voltage rating of the equipment appears

on the label above the power connector.

Use only the specified power cable.

Fire or equipment damage can result if a

different cable is used.

CAUTION

Ground the equipment to

prevent electrical shock and

mutual interference.

Observe the following compass safe

distances to prevent deviation of a

magnetic compass:

Standard

compass

Display Unit 1.40 m 1.05 m

Antenna Unit 2.15 m 1.60 m

Steering

compass

ii

Page 5

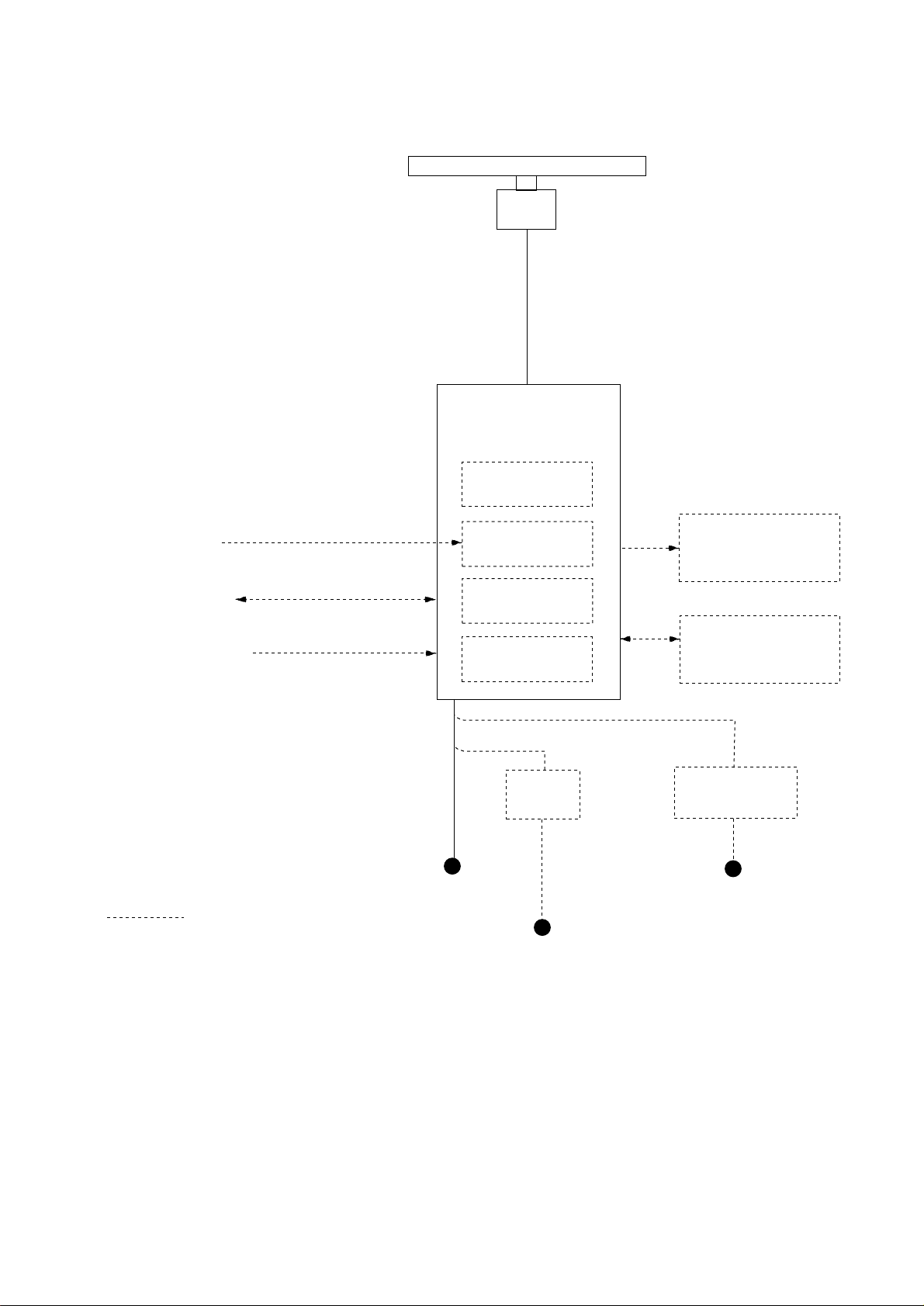

SYSTEM CONFIGURATION

ANTENNA UNIT

XN12AF-RSB-0074-063

XN12AF-RSB-0075-063

XN20AF-RSB-0074-063

XN20AF-RSB-0075-063

XN24AF-RSB-0074-063

XN24AF-RSB-0075-063

DISPLAY UNIT

RDP-126

ARPA

ARP-26*

Gyrocompass

Navigator

Speed Log

Option

IEC-61162-1 Serial Data

(Input/Output)

IEC-61162-1 Serial Data

(Input)

* Not available for statute

mile-(SM) type radar.

Ship's Mains

24-32 VDC

or

100-115/220-230 VAC

1f, 50/60 Hz

Gyro Converter

GC-8

Video Plotter

RP-26*

Alarm Kit

DC spec

Rectifier

RU-3424

Slave Display

FMD-8010

Performance

Monitor

PM-30

AC spec

Transformer Unit

RU-1803

440 VAC

1f, 50/60 Hz

AC spec or DC spec to be selected.

iii

Page 6

Standard Supply

emaNepyT.oNedoCytQskrameR

EQUIPMENT LISTS

360-4700BSR-FA21NX—

360-5700BSR-FA21NX— 10242-30PC,mm0021,mpr24

annetnA

tinU

tinUyalpsiD621-PDR—1

00521-30PS093-980-000

straPerapS

01521-30PS193-980-000

00191-30PC393-980-000

noitallatsnI

slairetaM

seirosseccA

01191-30PC493-980-000

02191-30PC593-980-000

01170-30PF535-980-000

05560-30PF735-980-000

360-4700BSR-FA02NX— 10191-30PC,mm0002,mpr42

1

360-5700BSR-FA02NX— 10191-30PC,mm0002,mpr24

360-4700BSR-FA42NX— 10191-30PC,mm0042,mpr42

360-5700BSR-FA42NX— 10191-30PC,mm0042,mpr24

1

1

1

,sniams'pihsCD

,sniams'pihsCAV001

51-57-30S

)elbaclangism51(

02-57-30S

03-57-30S

,10170-30PF

)V(TRCrevoctsuD

epytelosnocroF

,10170-30PF

,40560-30PF

)V(TRCrevoctsuD

10242-30PC,mm0021,mpr42

50520-30PS,10521-30PS

60521-30PS,10521-30PS

,)tinuannetnA(40191-30PC

,)tinuyalpsiD(50191-30PC

,)tinuannetnA(40191-30PC

,)tinuyalpsiD(50191-30PC

,)tinuannetnA(40191-30PC

,)tinuyalpsiD(50191-30PC

,20560-30PF,10260-30PF

,20560-30PF,10260-30PF

S

e

e

p

a

c

k

i

n

g

l

i

s

t

s

iv

Page 7

Optional Equipment

emaNepyT.oNedoCskrameR

retrevnoCoryG2-8-CG025-644-800redroetarapeS

hctiwsretnI7-JR—

hctiwsretnI8-JR—

rotinoMecnamrofreP03-MP—

tinUremrofsnarT8571-UR614-030-000CAV022/011/001roF

tinUremrofsnarT3081-UR024-030-000CAV044roF

reifitceR4243-UR794-030-000

rotinoMecnamrofreP

tiKnoitallatsnI

*APRAE2-62-PRA005-584-800

*rettolPoediV

yalpsiDevalS0108-DMF—

daeHlortnoCetarapeS

tiKgnitnuoM

elbaCrewoPm51-)C2X8(S-VVC436-065-000tinuyalpsid.cepsCDroF

tiKmralA651-30PO056-005-800

tiKnoisrevnoCCD-CA

tiKelosnoC-V461-30PO267-980-000

051-30PO094-584-800

E2-T-62-PR015-584-800

E2-Z-62-PR025-584-800daehlortnocepytetarapesroF

751-30PO036-005-800

42-161-30PO067-994-800tinuannetnampr42roF

24-161-30PO077-994-800tinuannetnampr24roF

* Not available with statute mile (SM)-type radar.

v

Page 8

1.1 Antenna Unit

Mounting considerations

• The antenna unit is generally installed either on top of the wheelhouse or on

the radar mast, on a suitable platform. Locate the antenna unit where there is a

good all-round view.

(a) On bridge (b) Common mast (c) Radar mast

• No funnel, mast or derrick should be within the vertical beamwidth of the antenna in the bow direction, especially zero degrees ±5°, to prevent blind sectors and false echoes on the radar picture.

MOUNTING

Figure 1-1 Mounting methods

• It is rarely possible to place the antenna unit where a completely clear view in

all directions is available. Thus, you should determine the angular width and

relative bearing of any shadow sectors for their influence on the radar at the

first opportunity after fitting.

• Locate the antenna of a direction finder clear of the antenna unit to prevent

interference to the direction finder. A separation of more than two meters is

recommended.

• T o lessen the chance of picking up electrical interference, avoid where possible

routing the signal cable near other onboard electrical equipment. Also avoid

running the cable in parallel with power cables.

• A magnetic compass will be affected if placed too close to the antenna unit.

Observe the following compass safe distances to prevent deviation of a magnetic compass: Standard compass, 2.15 m, Steering compass, 1.60 m.

• Do not paint the radiator aperture, to ensure proper emission of the radar waves.

• The signal cable run between the antenna and the display unit is available in

lengths of 15 m (standard), 20 m, and 30 m. Whatever length is used it must be

unbroken; namely, no splicing allowed.

• The antenna base is made of cast aluminum. To prevent electrolytic corrosion

of the antenna base, use the seal washers and corrosion-proof rubber mat.

• Deposits and fumes from a funnel or other exhaust vent can adversely affect

the aerial performance and hot gases may distort the radiator portion. The antenna unit must not be mounted where the temperature is more than 70°C.

• Leave sufficient space around the unit for maintenance and servicing. See the

antenna unit outline drawing for recommended maintenance space.

1-1

Page 9

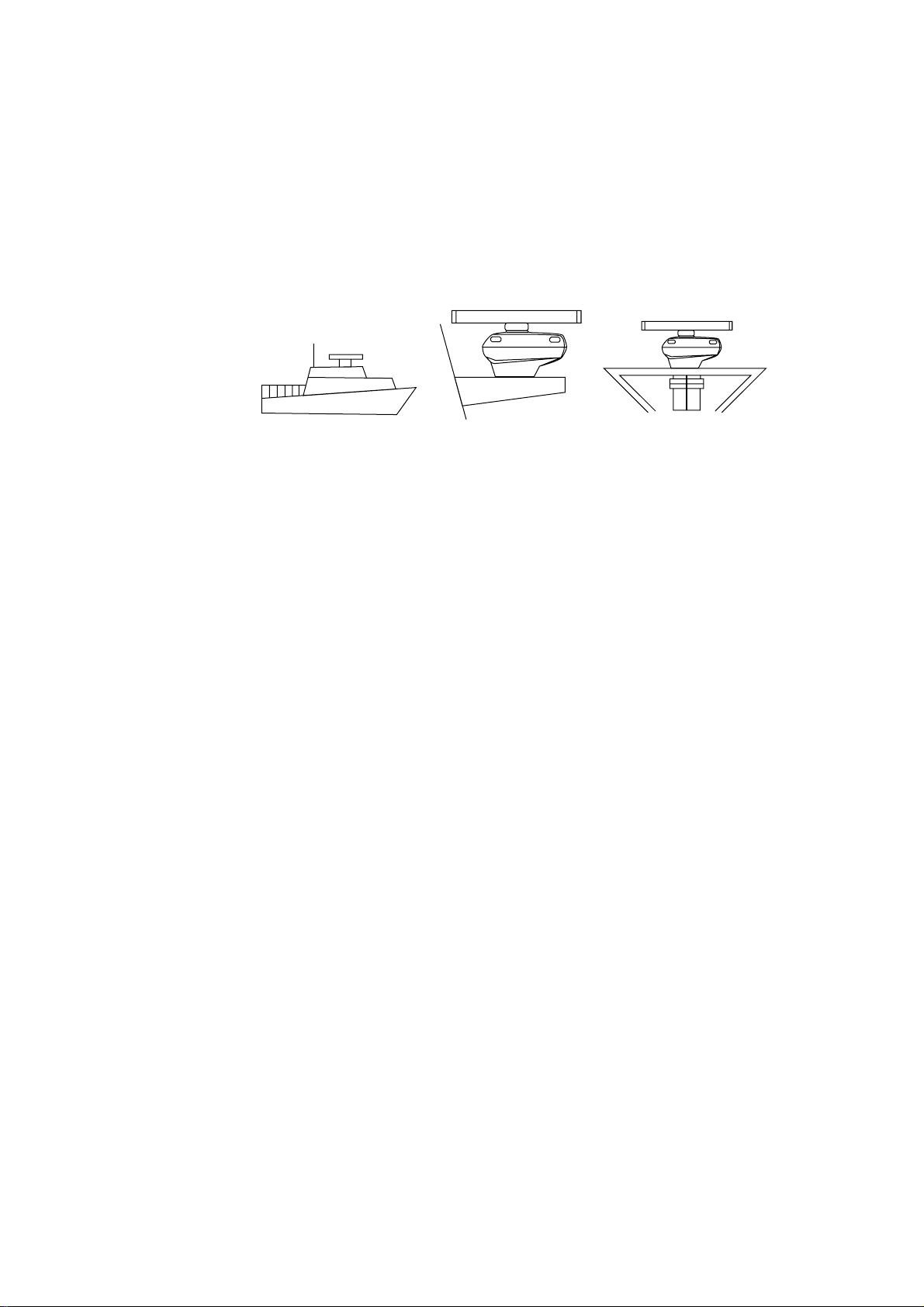

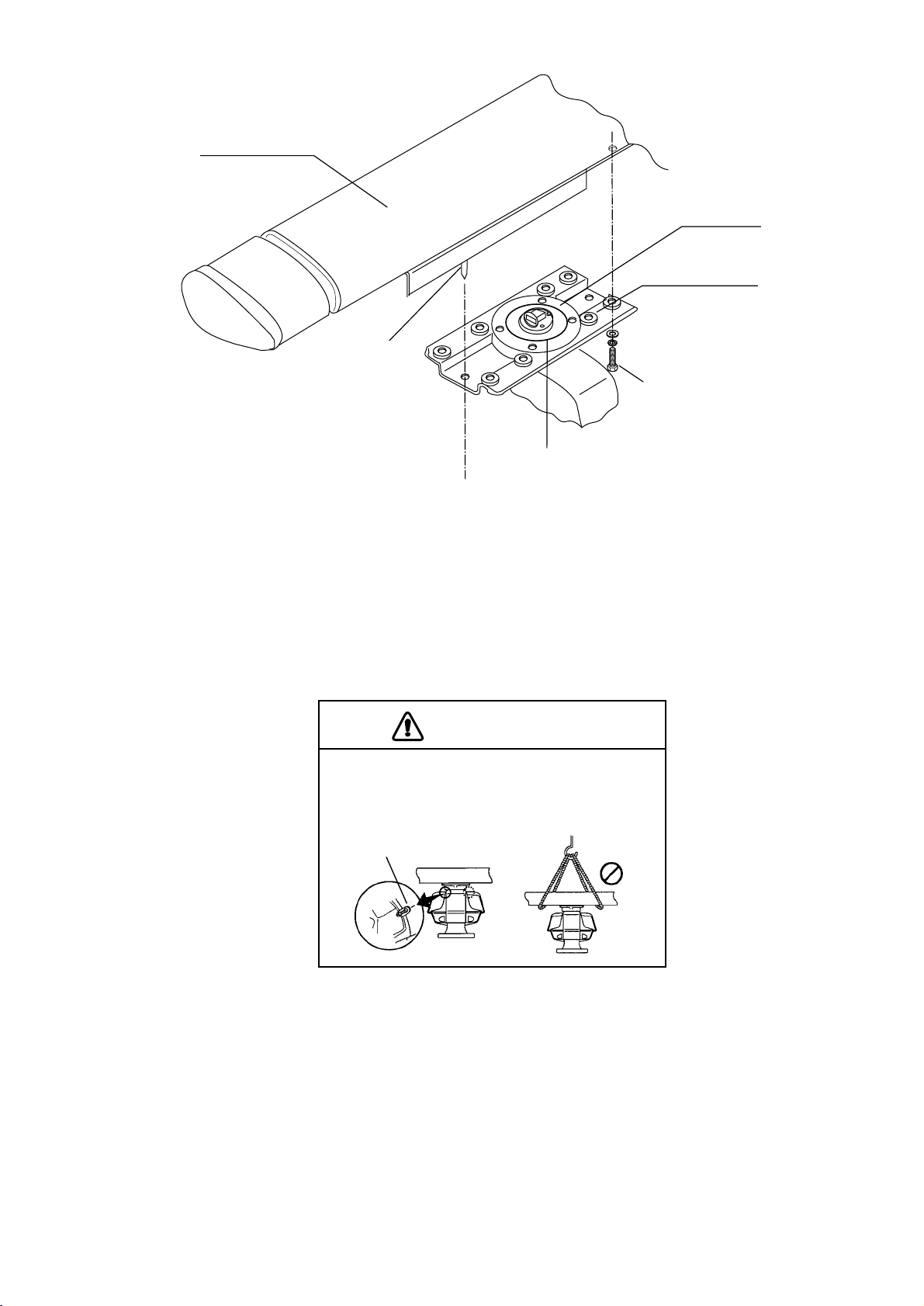

Assembling the antenna unit

The antenna unit consists of the antenna radiator and the antenna unit chassis,

and they are packed separately. Fasten the antenna radiator to the antenna unit

chassis as follows:

1. For the XN20AF, XN24AF, attach two guide pins to the underside of the an-

tenna radiator.

2. Remove the waveguide cap from the radiator bracket. The cap may be discarded.

3. Coat the waveguide flange with anticorrosive sealant as shown in Figure 1-2.

10 mm

Hole for

guide pin

5 mm

O-ring

Hole for

guide pin

Anticorrosive sealant

Figure 1-2 Coating the waveguide flange with anticorrosive sealant

4. Coat fixing holes for the antenna radiator with anticorrosive sealant.

5. Grease the O-ring and set it to the O-ring groove of the radiator flange.

6. Set the antenna radiator to the radiator bracket.

7. For the XN20AF, XH24AF, coat hex bolts (M8X40, slotted washer head, 8

pcs.) with anticorrosive sealant and use them to loosely fasten the antenna

radiator to the antenna unit chassis. For the XN12AF , coat hex bolts, flat washers and spring washers with anticorrosive sealant and use them to loosely fasten the antenna radiator to the antenna unit chassis.

8. For the XN20AF, XN24AF, remove two guide pins (inserted at step 1), and

then tighten fixing bolts.

CAUTION

Be sure to remove the guide pins.

Injury may result if the guide pins loosen

and fall.

1-2

Page 10

Antenna radiator

Waveguide

Radiator bracket

Guide pin

(XN20AF,

XN24AF

only)

O-ring

Hex bolt (M8X40), 8 pcs.

(XN20AF, XN24AF only)

Hex bolt (M8X35), 8 pcs.

Flat washer

Spring washer

(XN12AF only)

Figure 1-3 Fastening the radiator to the radiator bracket

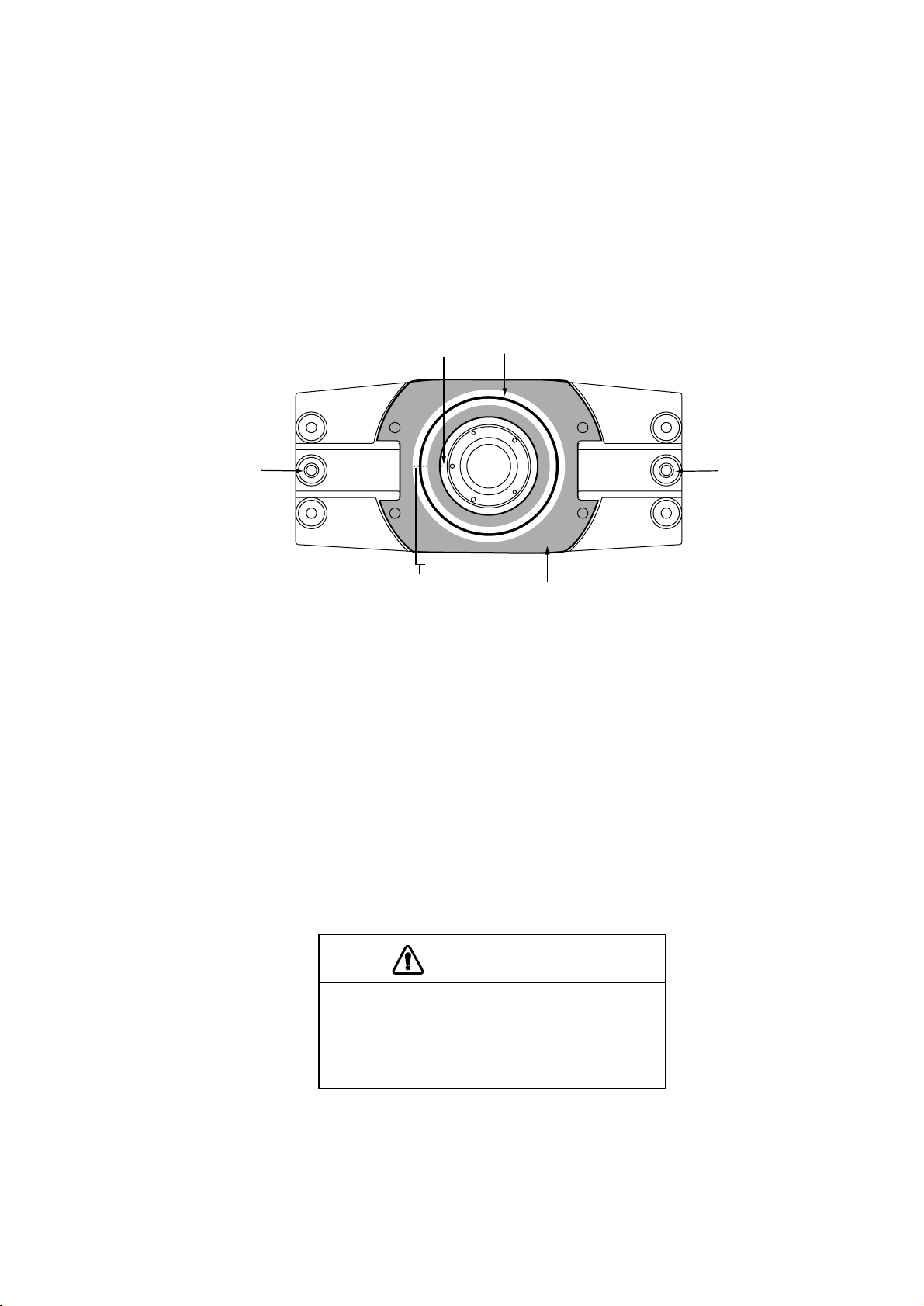

Fastening the antenna unit to the mounting platform

The antenna unit may be assembled before hoisting it to the mounting platform.

However, do not hoist the antenna unit by the radiator. Always hoist the unit by its

housing. When using a crane or hoist, hoist the unit by the hoist rings which should

be fastened to the bolt fixing covers of the antenna housing.

CAUTION

DO NOT hoist the antenna unit by the

radiator; lift it by the hoist rings. (Be sure to

remove rings after hoisting the antenna unit.)

Hoist

ring

1. Construct a suitable mounting platform referring to the outline drawing at the

back of the manual.

2. Drill four mounting holes of 15 mm diameter and one cable entry hole of about

50 mm diameter in the mounting platform.

NO!

3. Lay the rubber mat (supplied) on the mounting platform.

1-3

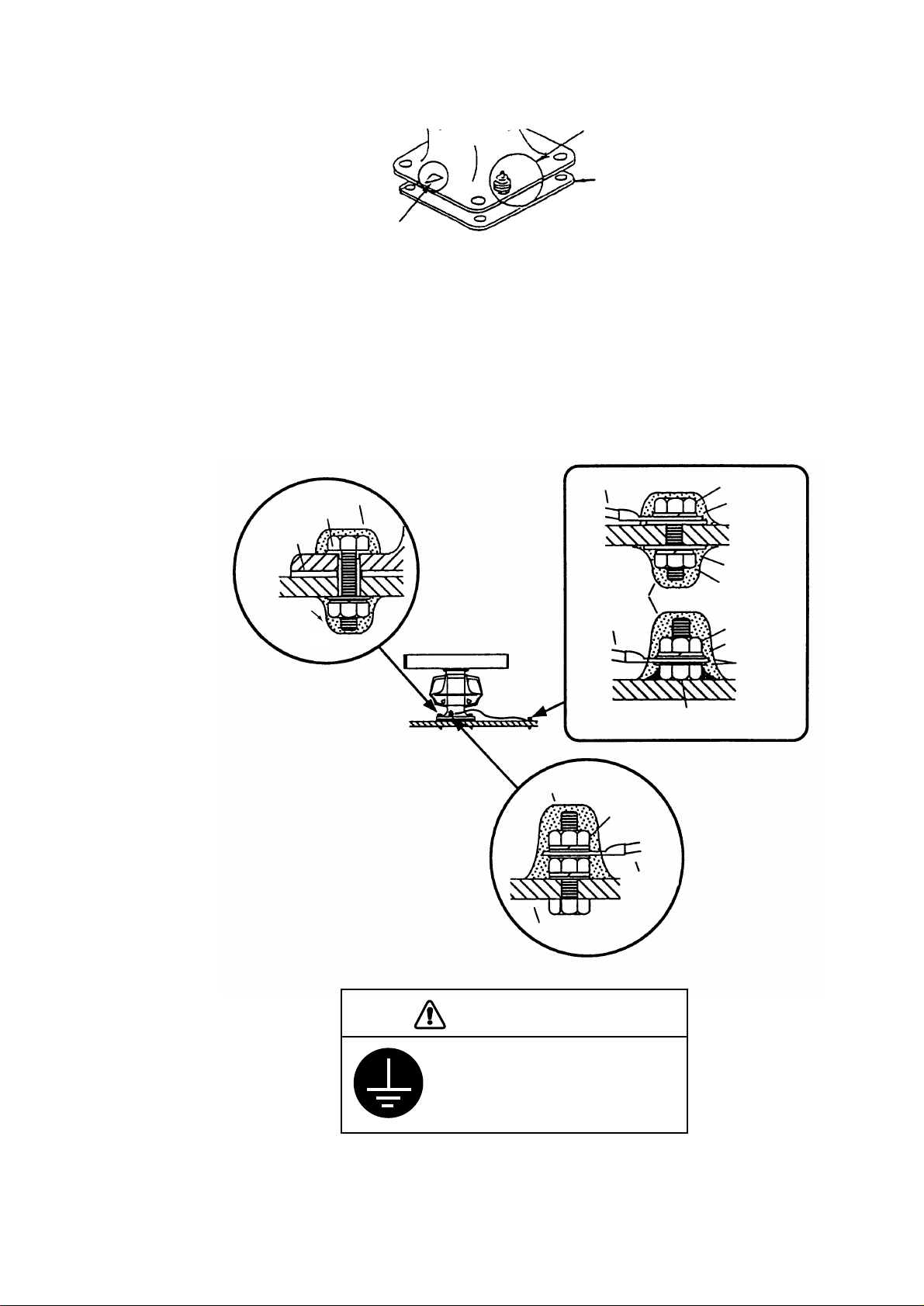

Page 11

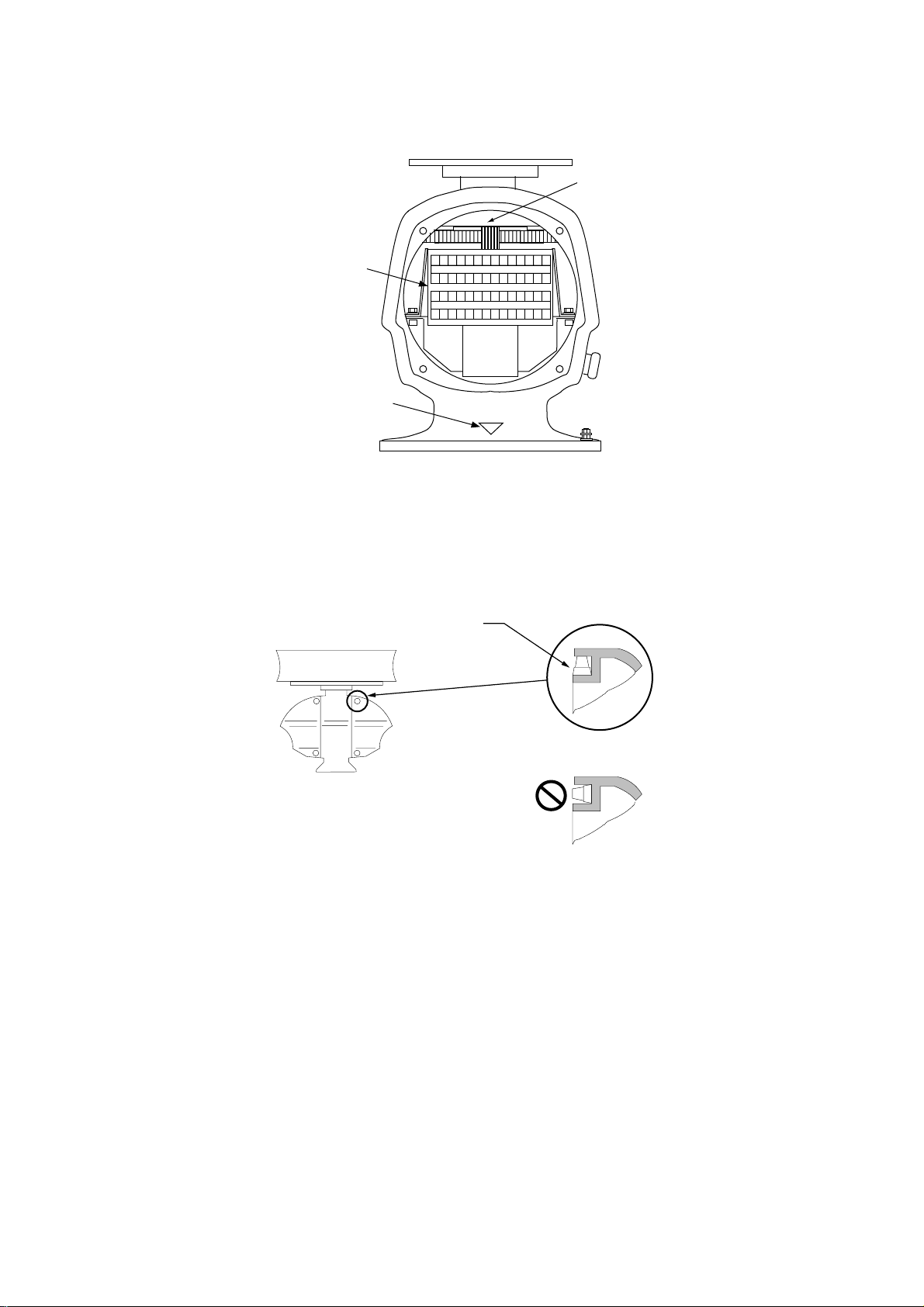

4. Place the antenna unit on the rubber mat orienting the unit so the bow mark on

its base is facing the ship’s bow.

Ground

terminal

Rubber

mat

Bow mark

Figure 1-4 Antenna unit, front view

5. Fasten the antenna unit to the mounting platform with M12X60 hex bolts, nuts,

flat washers and seal washers.

6. Using hex bolt (M6X25), nut (M6) and flat washer (M6), establish the ground

system on the mounting platform as shown in Figure 1-5. Connect the ground

wire (RW-4747, 340 mm, supplied) between the grounding point and ground

terminal on the antenna unit. Coat the entire ground system with silicone sealant (supplied).

Anticorrosive sealant

Seal washer

Rubber mat

Anticorrosive

sealant

Ground wire

Anticorrosive

sealant

Ground wire

Anticorrosive sealant

Ground

terminal

Antenna base

Hex bolt

Spring washer

Spring washer

Hex nut

OR

Hex nut

Spring washer

Flat washer

Hex bolt welded to

ship's superstructure

Ground

wire

CAUTION

Ground the equipment to

prevent electrical shock

and mutual interference.

Figure 1-5 How to mount the antenna unit

1-4

Page 12

1.2 Display Unit

Before mounting the display unit

If Gyro Converter GC-8 (option) is to be used, install and setup the GYRO CONVERTER Board before mounting the display unit, because of the difficulty involved

in doing it after the display unit is installed. Instructions for installation and setup of

the board are in Chapter 4.

Mounting considerations

When selecting a mounting location, keep in mind the following points:

• Select a location where the display unit can be viewed and operated conveniently and where the screen can be viewed while facing towards the bow.

• Locate the unit out of direct sunlight and away from heat sources because of

heat that can build up inside the cabinet.

• Locate the equipment away from places subject to water splash and rain.

• The display unit is very heavy. Be sure the mounting location is strong enough

to support the weight of the unit under the continued vibration which is normally

experienced on the ship. If necessary reinforce the mounting location.

• Determine the mounting location considering the length of the signal cable between the antenna unit and the display unit. (The signal cable comes in lengths

of 15, 20 or 30 meters; maximum 100 meters).

• Leave sufficient space on the sides and rear of the unit to facilitate maintenance. Also, leave a foot or so of “service loop” in cables behind the unit so it

can be pulled forward for servicing or easy removal of connectors.

• A magnetic compass will be affected if placed too close to the display unit.

Observe the following compass safe distances to prevent deviation of a magnetic compass: Standard compass, 1.40 m, Steering compass, 1.05 m.

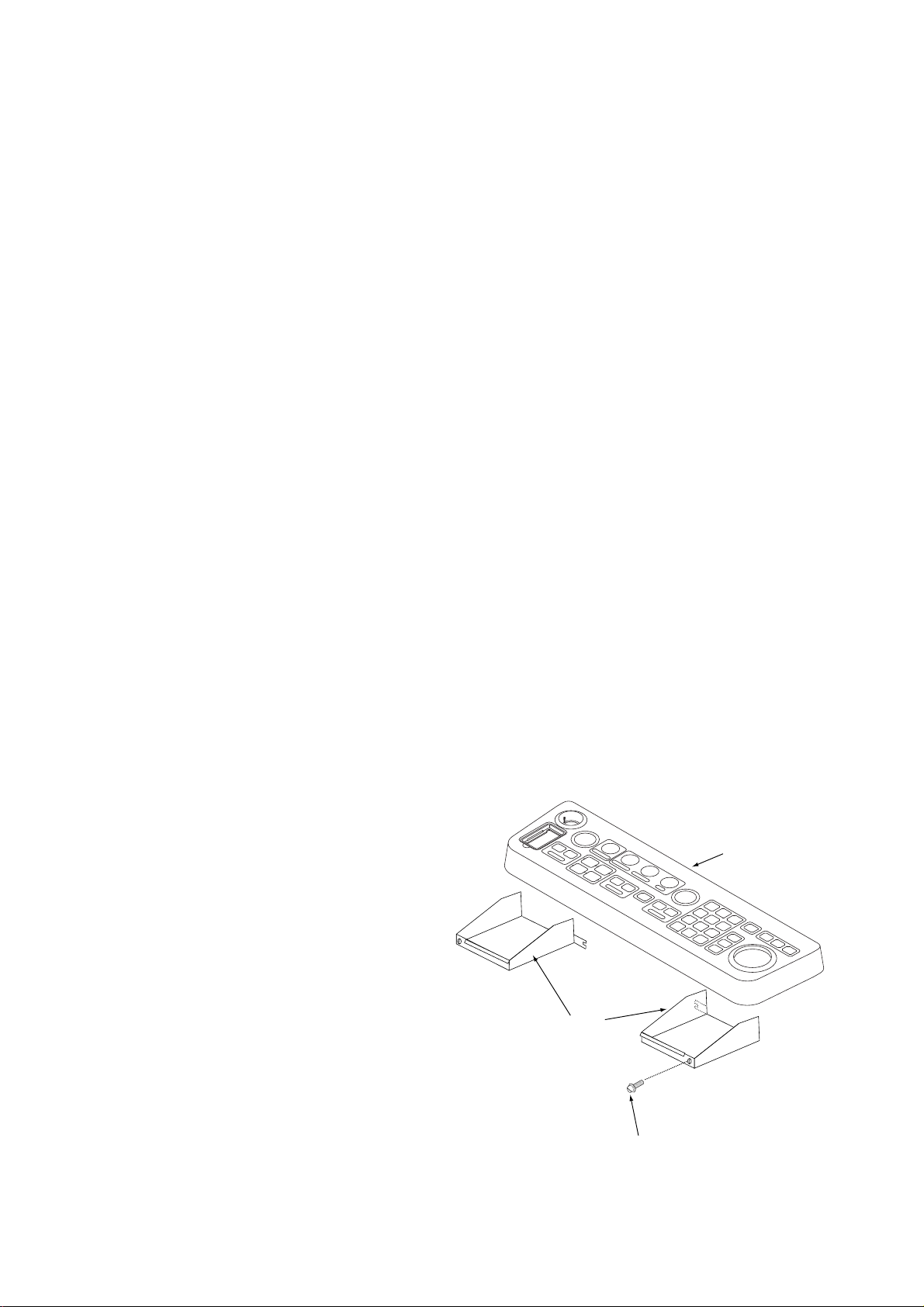

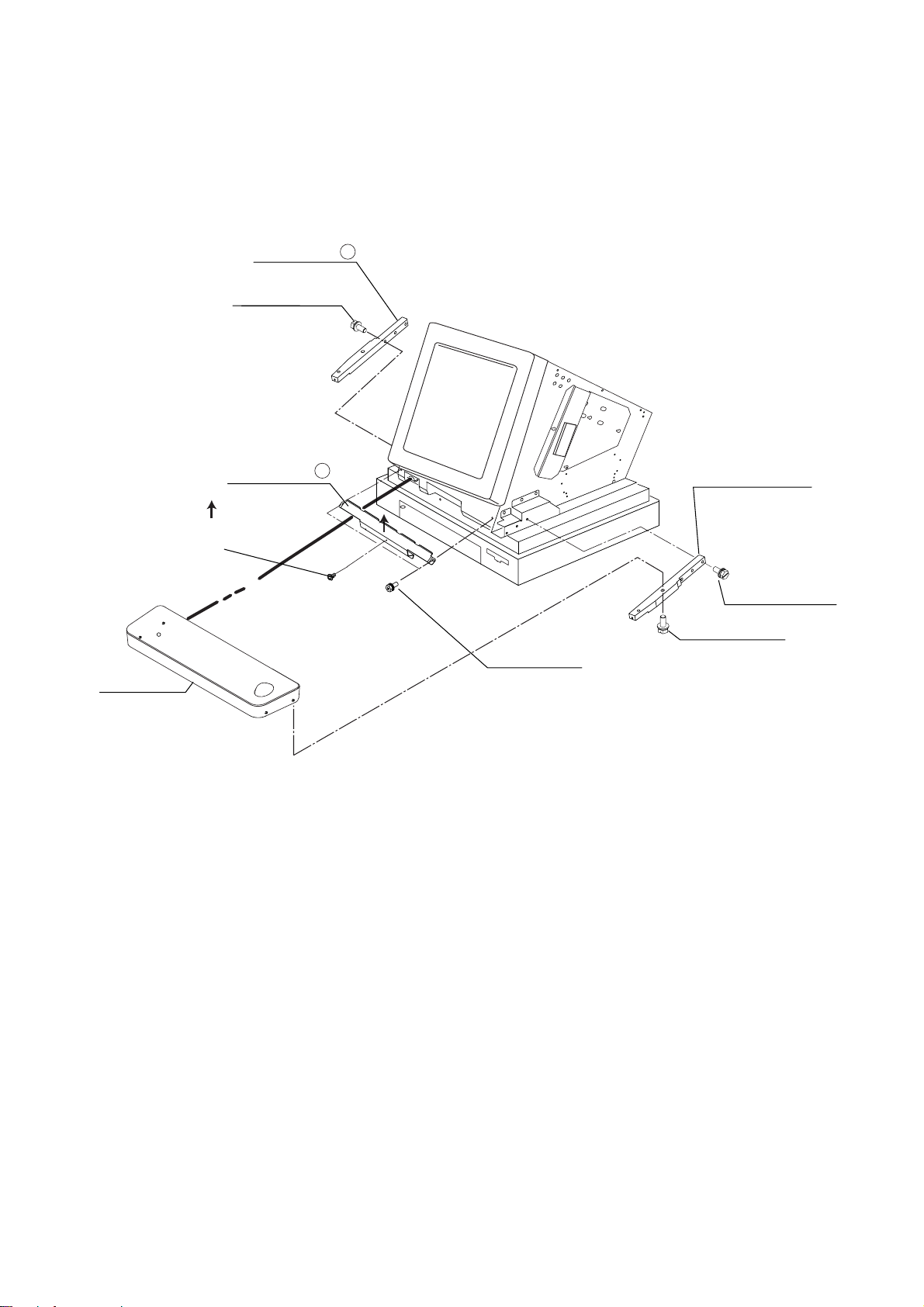

Mounting procedure

Control Head

Tabletop mounting

Two people are necessary to

complete this procedure.

1. Make four holes of 12 mm diameter in the mounting location

referring to the outline drawing

at end of this manual.

Left and right

arm covers

2. Unfasten the screws fixing the

right and left arm covers on the

control head.

3. Unfasten four M10 bolts hidden

by the arm covers.

M4X10

Figure 1-6 Control head

1-5

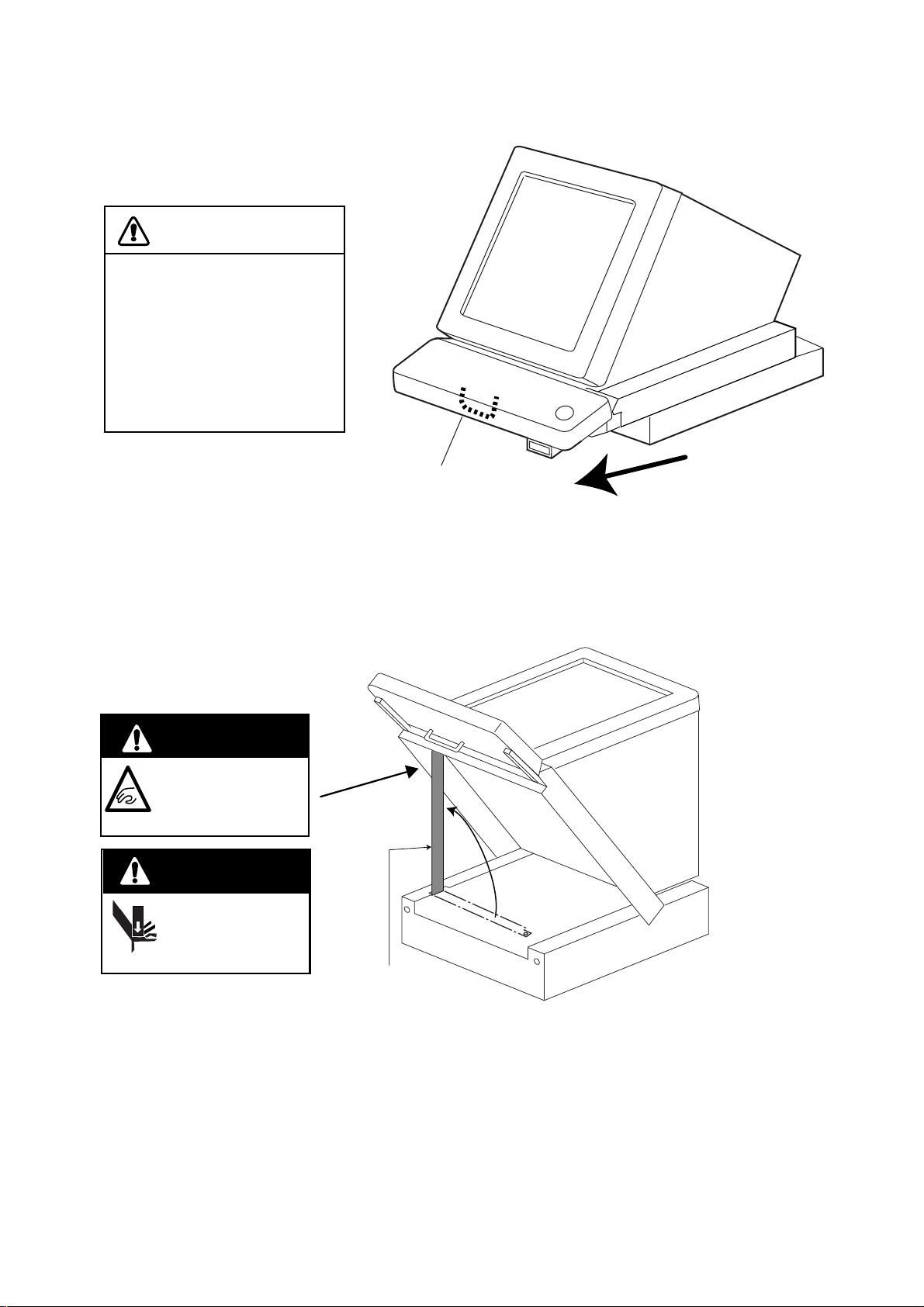

Page 13

4. While one person is holding the mounting base at the sides, pull the handle on

the underside of the control head to draw the display unit toward you until you

hear a click.

CAUTION

Use two people to complete

this step.

The display unit may fall to

the deck when it is pulled

forward, since the mounting

base is not yet fastened to

the mounting location.

Handle

Pull

Figure 1-7 Display unit

5. This step requires two people to complete. While raising the monitor until the

CRT is horizontal, fix the stay as follows:

a)Raise the stay as shown below.

Two warning labels on

the underside of monitor

HORIZONTAL

WARNING

Possibility of injury.

Hold handle when

mounting display unit.

WARNING

Display unit may fall.

Lock stay before

servicing.

Stay

Figure 1-8 Display unit, inside view

1-6

Page 14

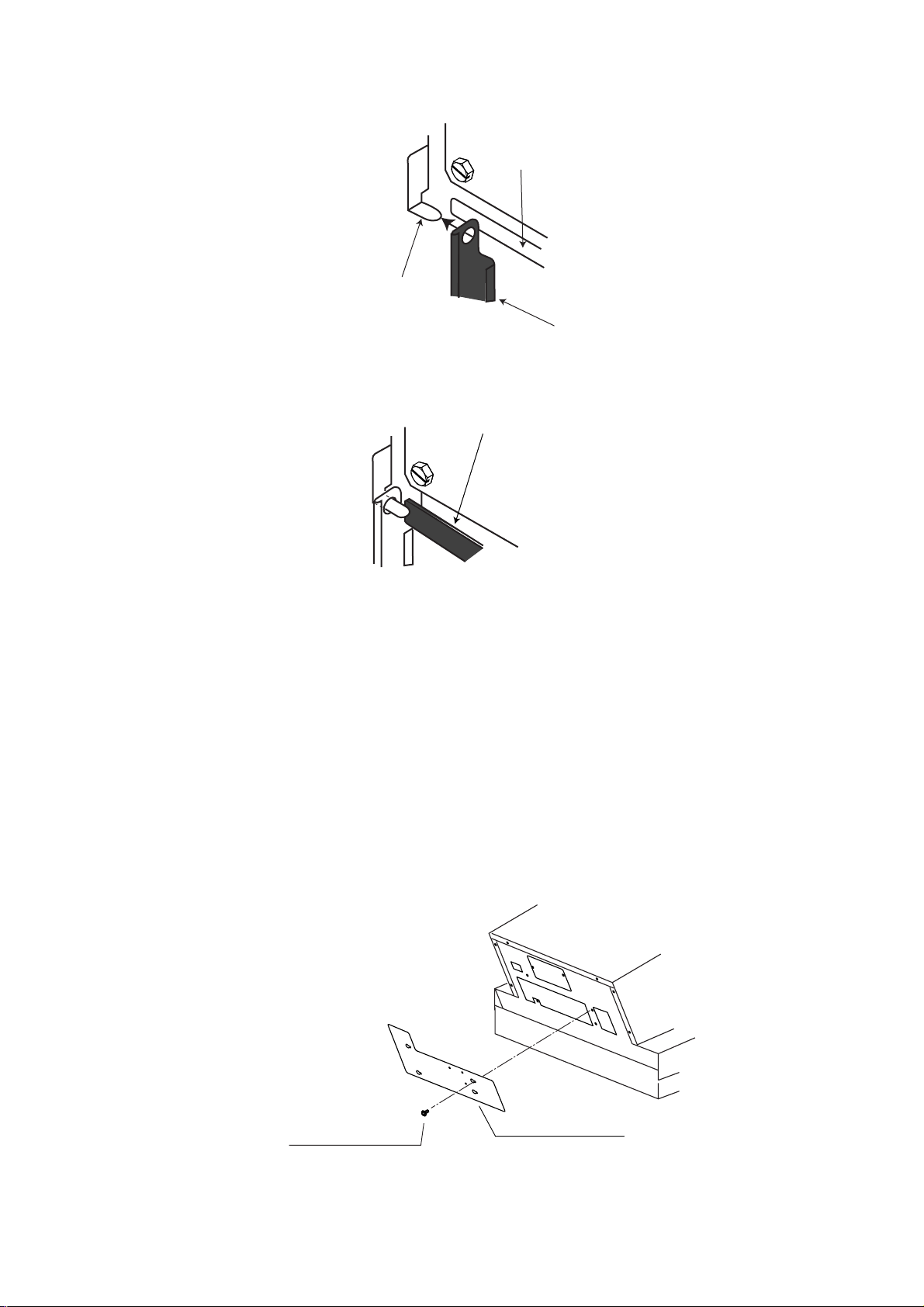

b)While pushing the stopper, set the catch on the display unit in the hole at the

front edge of the stay.

Stopper

Catch

Stay

Figure 1-9 Setting catch to hole in stay

c)Release hand from stopper.

Release stopper;

fix stay.

Figure 1-10 Stay fixed

6. Fasten the display unit to the mounting location at front fixing holes (2 points)

with M10 bolts, nuts and flat washers, using the pipe box spanner (supplied).

You cannot fasten the display unit at the rear fixing holes while the monitor is

raised.

7. Retract the stay and lower the monitor. Pull the monitor toward you by the

handle at the front of the display unit until you hear a click.

8. The rear left fixing hole is hidden under the PTU board cover. Remove the

cover as follows:

(1) Unfasten three M4X8 screws to remove the lead-in cover (V) which hides

the PTU section. Slide the cover to remove it.

REAR SIDE

Pan-head Screw

M4X8, 4 pcs.

Lead-in Cover (V)

Figure 1-11 How to remove the lead-in cover

1-7

Page 15

(2) Unfasten five M3X8 screws at the top of the PTU board cover and two

M4X8 screws at the front of the PTU cover. Slide the PTU board cover

forward.

Fixing hole (rear)

*Screw

(M3X8, 5 pcs.)

Slide forward

J106

J105

J104

J103

*

Knob

Screw (M4X8, 2 pcs.)

Fixing hole (front)

J446

J466

J462

J465

*

*

*

Figure 1-12 How to dismount the PTU cover

(3) Remove the cover by grasping the knob on the top of the cover.

10.Use M10 bolts, nuts and flat washers to fix the display unit at the rear mounting

holes, using the pipe box spanner (supplied).

11.Close the PTU board cover.

12.Push the monitor forward until you hear a click.

13.Refasten the bolts removed at step 3.

14. Fasten the left and right arm covers with M4X10 screws.

Console type mounting

1. Make six holes of 15 mm diameter and a cable entrance hole through the deck

referring to the outline drawing at end of this manual.

2. Open the front cover.

3. Fix the equipment by using M12 bolts, nuts and washers.

4. Hoist the console to the deck by using the eye bolts attached to the console.

Remove the eye bolts and set the cosmetic caps (w/washers) to the eye bolt

holes.

1-8

Page 16

Separating the control head

The control head connects to the display unit with a connection cable, thus it can

be located where desired, using the separate control head kit (option).

Separate type control head kit (Type: OP03-157, Code No.: 008-500-630)

emaNepyTytQ.oNedoCskrameR

.yssAelbaCP1/P02BS4642LU1218-041-0002249S30,m01

teeFrebbuRpilsnoN3005-JS4787-108-000epatdedis-elbuodhtiW

)V(revoCtnorFrotinoM1371-441-301065-472-001

etalPgnixiFBK1961-441-301049-362-001

)V(etalPeldnaH2371-441-301075-472-001eldnahgnixifroF

BKrevoCtsuD3961-441-301067-172-001

wercStespU403SUS01X5M2882-208-000

wercSgnidniB0072C8X4M2704-608-000

Display unit modification procedure

1. Raise the monitor unit and fix it with the stay. Refer to procedure for tabletop

mounting on page 1-5.

2. Inside the display pedestal, unplug two connectors from the control head cable

(P412 from MOTHER Board and J583) and unfasten two earth wires.

PTU COVER

Control Head

Cable

P412

J583

J418

Earth Wire

MB 03P9251

INT

03P9252

Figure 1-12 Display unit, inside view

1-9

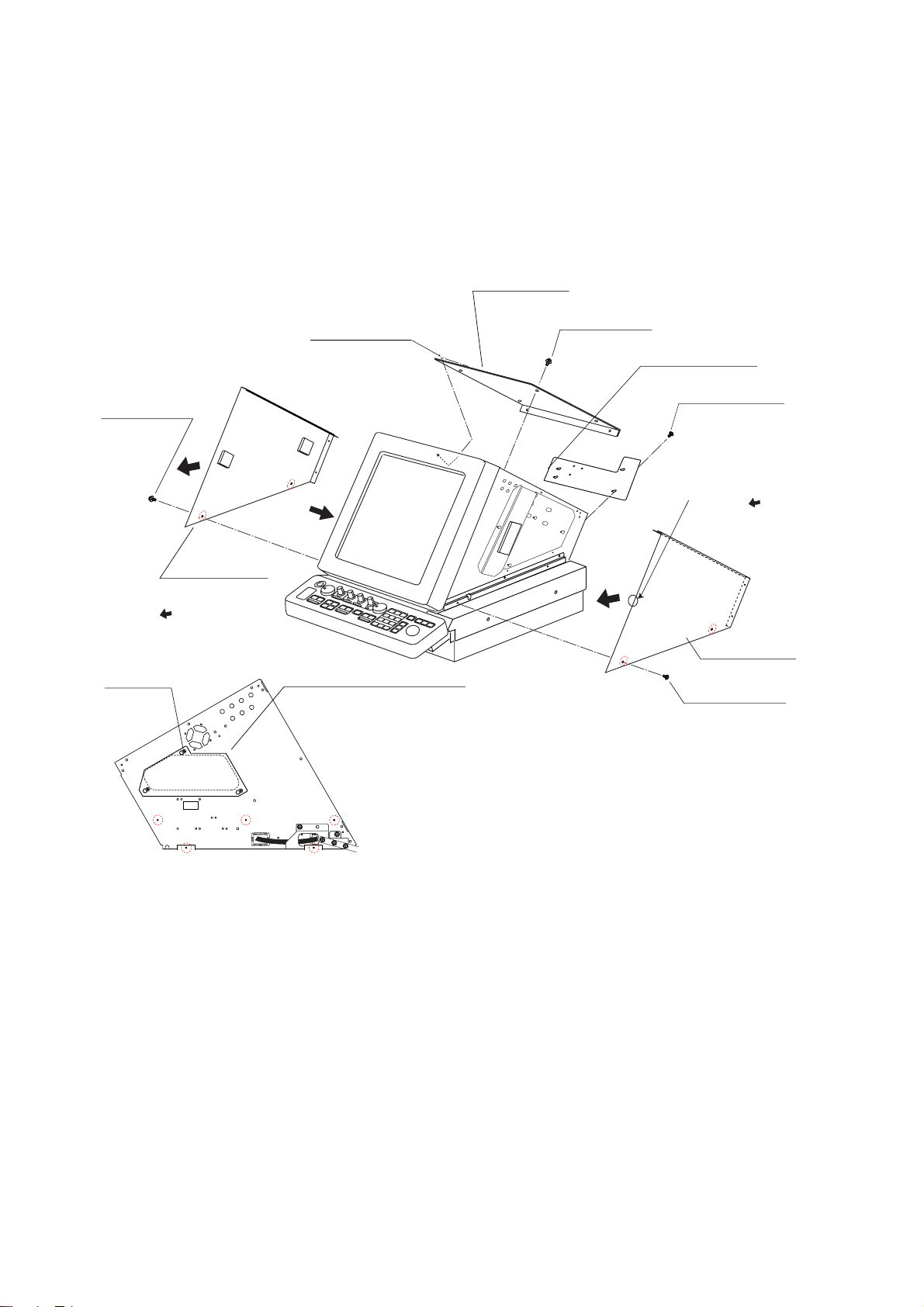

Page 17

3. Retract the stay to lower the monitor.

4. Unfasten eight binding screws (M4X8) to dismount the top cover 1, right cover

2 and left cover 3.

5. Loosen three screws (M4X10) fixing the left maintenance cover (4). Slide the

cover to dismount it.

6. Loosen four screws (M4X10) fixing the lead-in cover (5) at the rear of the

display pedestal. Slide the cover to dismount it.

Top Cover (1)

Binding Screw

M4X8, 2 pcs.

Left Cover (3)

Push in direction

of arrow

Pan-head Screw

M4X10, 3 pcs.

Touching inside

of CRT panel

A

Left Maintenance Cover (4)

A EXPLODED VIEW

Binding Screw

M4X8, 4 pcs.

Lead-in Cover (5)

Pan-head Screw

M4X10, 4 pcs.

Push in

direction of

arrow.

(Do same on

other side.)

Left Cover (2)

Binding Screw

M4X8, 2 pcs.

Figure 1-13 How to dismount covers

7. At the left side of the monitor, unfasten the clamp which fixes the control head

cable.

8. At the rear of the display pedestal, fasten the clamp which fixes the control

head cable.

1-10

Page 18

Monitor

Control Head Cable

J582

J581

Remove clamp from rear side

Remove clamp

from left side

Figure 1-14 Clamp position

11.Unfasten four upset screws (6) at the bottom of the right and left KB arms to

dismount the control head.

12.Unfasten three screws (M4X10) and two screws (M4X8) to remove the right

lower cover (7) and the left lower cover (8).

Pan-head Screw (M4X10, 3 pcs., upper)

Binding Screw (M4X8, 2 pcs., lower)

Clamp

Left Lower Cover (8)

Control Head

Upset Screw (6)

(M5X25, 4 pcs.,

including those on

opposite side)

Right KB Arm

Right Lower Cover (7)

Pan-head Screw (M4X10, 3 pcs., upper)

Binding Screw (M4X8, 2 pcs., lower)

Figure 1-15 Display unit, front view

1-11

Page 19

13.Unfasten three screws (M5X25) to remove the right KB arm (9) and the left KB

arm (q0).

14.Unfasten one screw (M4X10), two screws (M5X12) to dismount the panel cover

(q1).

15.Fasten the two upset screws (M5X12) unfastened at step 14 at the front bottom

of the control head.

Left KB Arm (11)

Screw

M5X25, 3 pcs.

Pan-head Screw

M4X10

Control Head

Panel Cover (10)

Push up

to fix

Figure 1-15 Detaching the control head

Screw

M5X12, 2 pcs.

Right KB Arm (9)

Screw

M5X25, 3 pcs.

Screw

M5X25 (4 pcs.,

incl. those on

opposite side)

1-12

Page 20

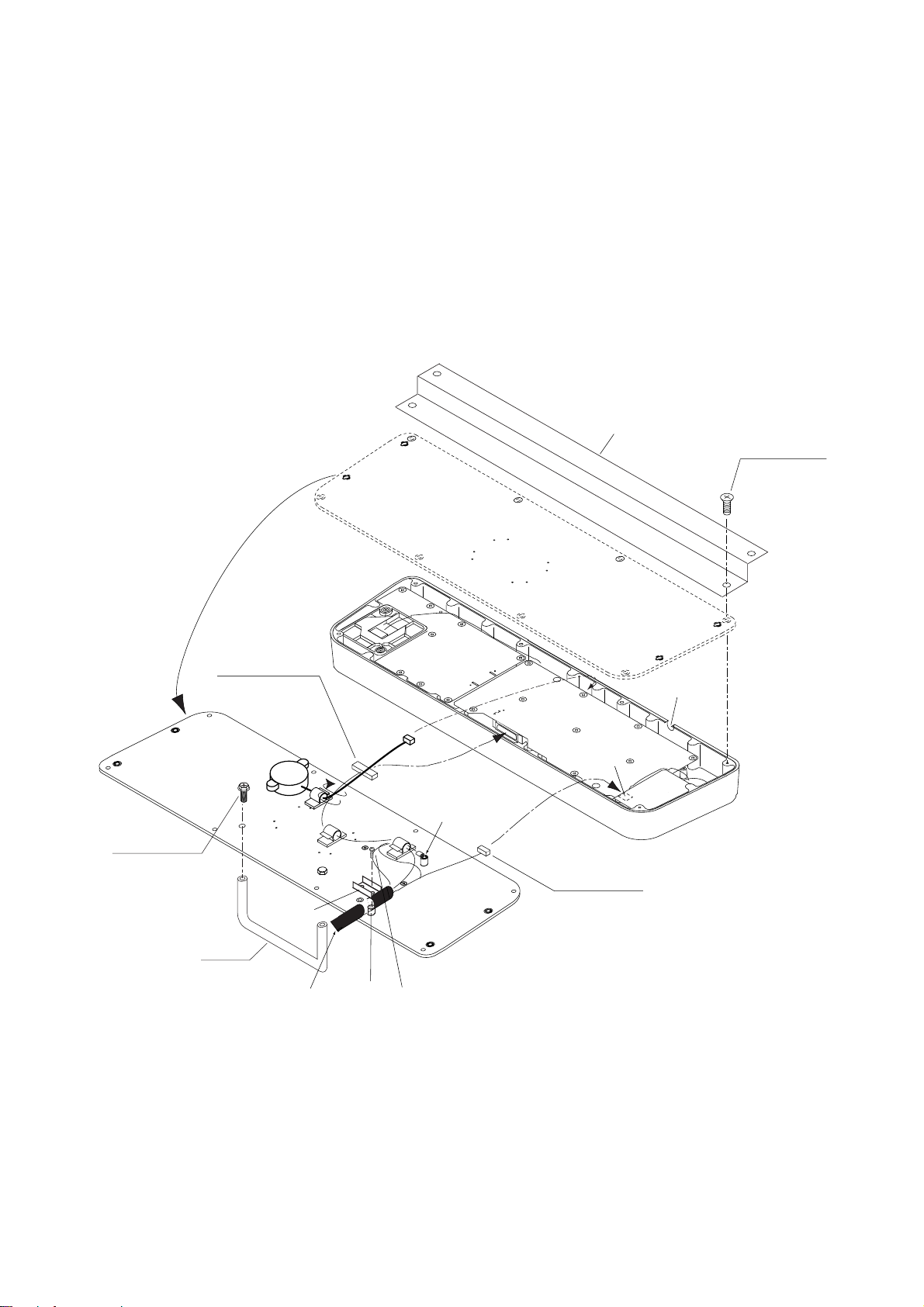

Control head modification procedure

1. Unfasten eight screws (M4X8) on the underside of the control head. Unplug

connectors P314, P312 and P317 from the control head. Separate the KB bottom plate from the control head.

2. Unfasten the screw (M4) fixing the ground terminal and two screws (M4X8)

fixing the clamp. Remove the connection cable assy.

3. Unfasten two screws (M6X12) from the inside of the bottom plate of the control

head to dismount the handle.

4. Replace the cable assy. with cable assy. UL2464SB2-0P/1P (10 m, supplied)

as below and reassemble the control head.

KB Fixing Plate

Screw

M4X8 (8 pcs.)

P312 FX Connector

KB BOTTOM

PLATE

Upset Screw

M6X12 (2 pcs.)

Handle

KB Clamp

Replace with

cable assy. in

kit.

J314 (underside)

J312 (underside)

Earth Wire

Spacer

Pan-head Screw M4X8 (2 pcs.)

Be careful not to pinch cable between

KB clamp and spacer.

Figure 1-16 Control head

J317 (underside)

P314 XH3P

Lay cable in slot.

1-13

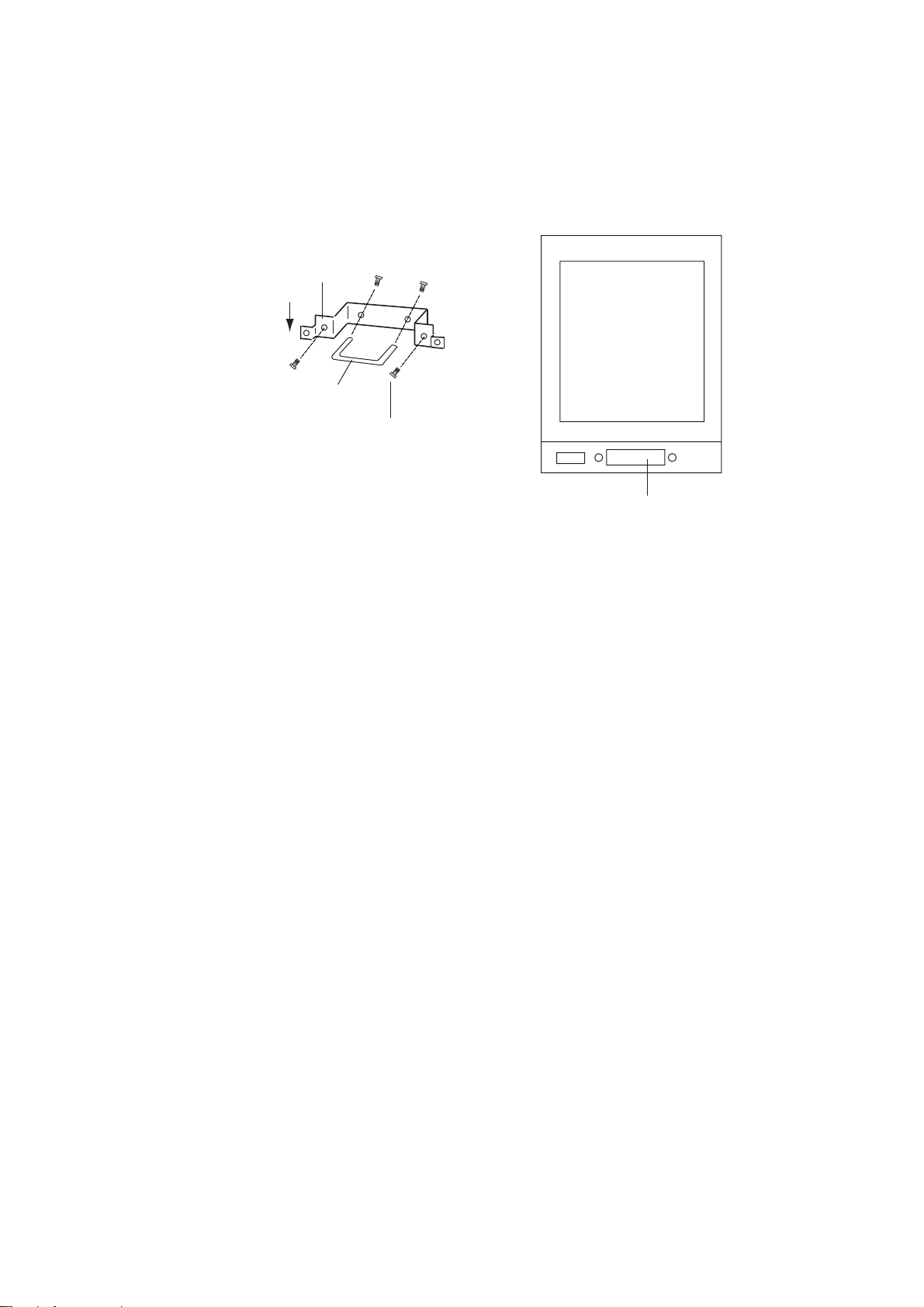

Page 21

Wiring between display unit and control head

1. Fasten the handle to the supplied handle plate (V), using the screws formerly

used to fixed the handle.

2. Using two upset screws (M5X10, supplied), fasten the handle plate (V) to the

location shown in Figure 1-17.

Handle Plate (V)

DOWN

Handle

Upset Screw

2 pcs.

Insert handle

plate (V) here.

Figure 1-17 Attaching the handle plate (V)

3. Pull the monitor forward.

4. Lead in the control head cable through the cable clamp at the rear of the display unit. See pages 2-9 and 2-10 for location of cable clamp.

5. Raise the monitor and fix it with the stay. (See page 1-5 for instructions.) Inside

the display unit, plug in two connectors and fasten two ground wires. See Figure 1-12 for location.

6. Retract the stay to lower the monitor.

7. Fasten two bolts (M10) at the front of the display unit. For location see step 3 on

page 1-5.

8. Attach the monitor cover (supplied) to the handle plate with two M4X8 binding

screws (supplied).

9. Attach right and left lower covers, left maintenance cover , right and left covers,

lead-in cover, top cover, and right and left arm covers in that order.

1-14

Page 22

10.Attach rubber to feet to the bottom of the keyboard if the keyboard is not going

to be permanently fixed. To fix the keyboard to a desired location, fasten the KB

fixing plate to the keyboard and desired location with two upset screws (M5X25,

formerly used to fasten KB arms) and two tapping screws (φ6.5, local supply)

as below.

KB Fixing Plate

CONTROL HEAD TOP VIEW

Figure 1-18 How to attach KB fixing plate

11.Set dust cover KB (supplied) on the control head.

CONTROL HEAD

SIDE VIEW

KB Fixing

Plate

φ6.5

Tapping

Screw

M5X25

Upset

Screw

1-15

Page 23

2.1 Antenna Unit

The magnetron in the transceiver module will demagnetize if it contacts ferrous material. When

dismounting the transceiver module, lay it on its

side or on top of non-ferrous material as shown

below.

WIRING

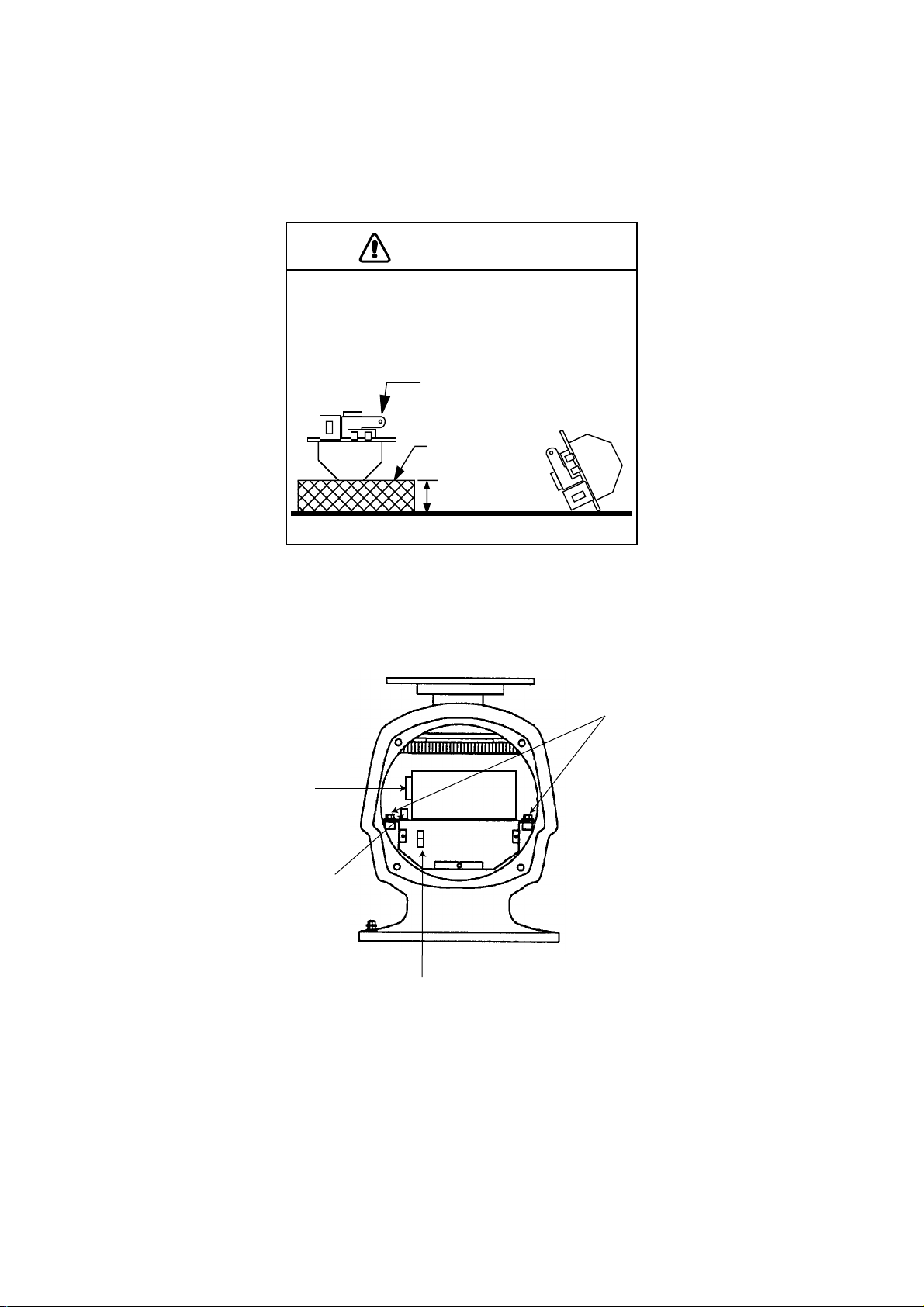

CAUTION

Transceiver module

(magnetron inside)

Non-ferrous

block

Height more

than 5 cm

1. Open the antenna unit cover.

2. Disconnect plugs P611, P801 and P821.

3. Unfasten the transceiver module (two bolts). Remove the transceiver module.

Fixing

bolts

J611

J801

J821

Figure 2-1 Antenna unit, front view

2-1

Page 24

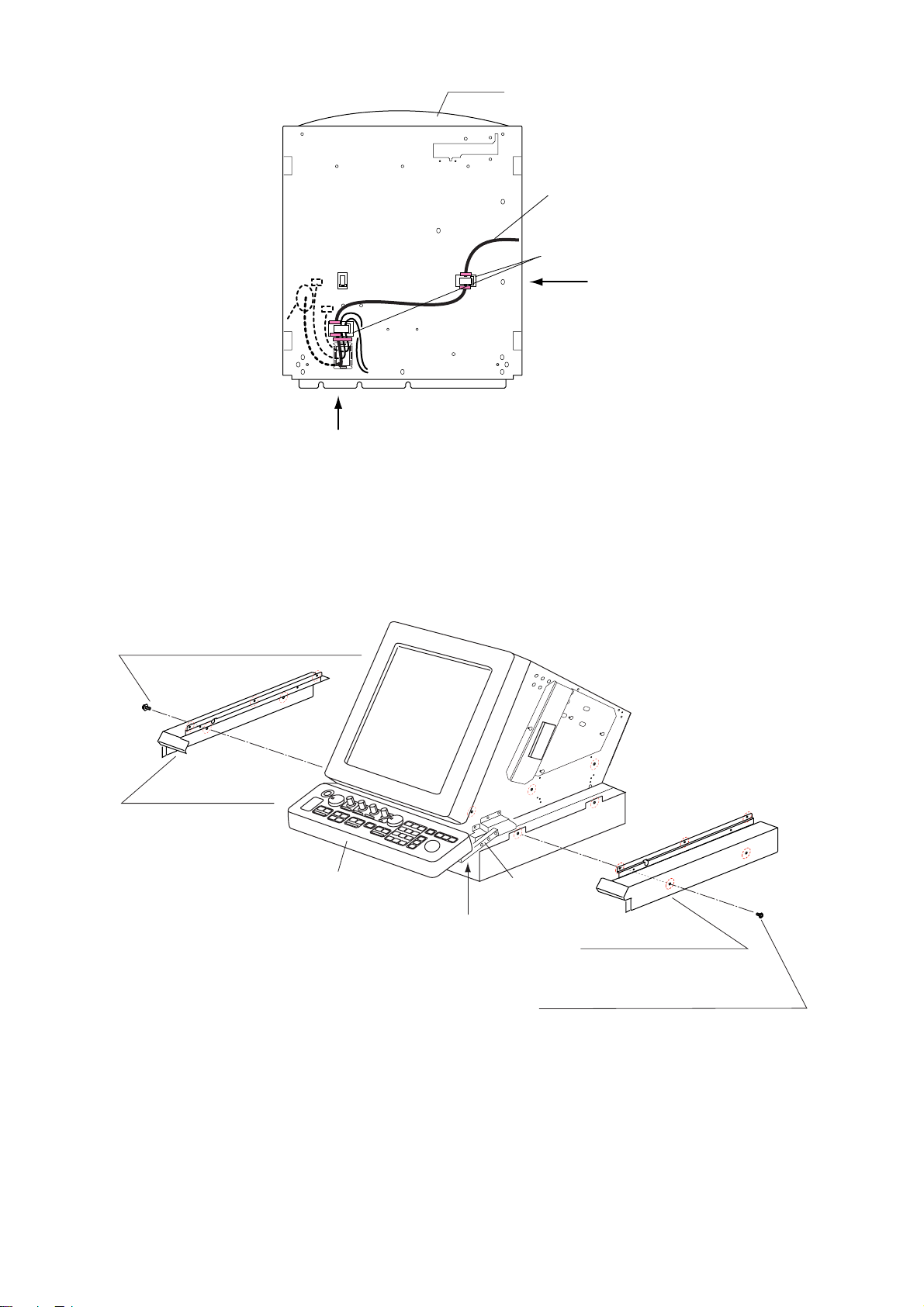

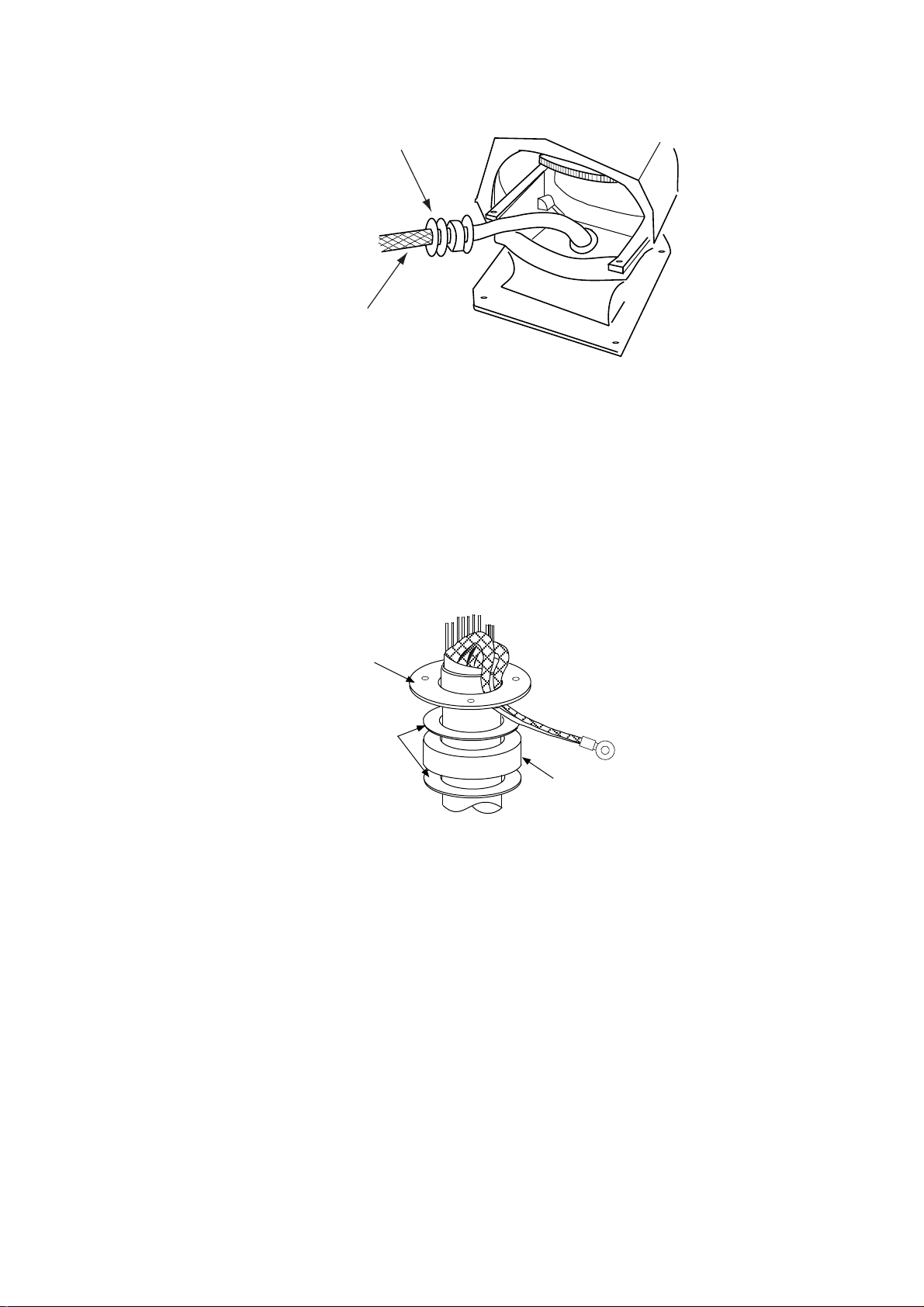

4. Unfasten the four fixing bolts on the cable gland at the base of the antenna unit.

Remove clamping ring, rubber gasket and washers.

From left: Clamping ring,

washer, rubber gasket

and washer

Signal cable

Figure 2-2 Antenna unit, front view, cover removed

5. Pass the signal cable through the cable entry hole in the antenna unit mounting

platform. Trim the cable so about 80 cm of it protrudes past the cable gland.

6. Slide the clamping ring, washer, rubber gasket and washer onto the cable in

that order.

7. Fabricate the signal cable as shown on page 2-4.

8. Referring to Figure 2-3, pass the outer and inner shields between the signal

cable and the clamping ring. Fasten the cable gland.

Clamping

ring

Washers

Rubber

gasket

Figure 2-3 Passing cable shields between cable and clamping ring

9. Connect the signal cable to the terminal board RTB801 by referring to the interconnection diagram. Leave “slack” in the coaxial wire to prevent breakage.

10.Bind cores of cables with cable ties.

11.Mount the transceiver module. Connect plugs P611, P801 and P821. Fasten

shield to ground terminal in the transceiver module.

2-2

Page 25

12.If the antenna unit is mounted 2° or more left of ship’s bow, adjust the position

of S901 so it becomes “on” (contact between #1 and #2 on pcb MP-3795). To

access S901, open the bow side cover; S901 is above the drive gear.

S901

RTB801

Bow mark

1 2 345 67891011121314

15 16171819 20 212223 24 25 26 2728

Figure 2-4 Antenna unit, front view

13.Confirm that all screws are tightened and all wiring is properly made. Coat

waterproofing gasket, bolts and tapping holes of antenna unit with silicone

grease. Check that the waterproofing gasket is seated as shown in Figure 2-5.

Close the antenna unit cover.

Coat gasket with silicone grease.

DO NOT use silicone sealant.

CORRECT

WRONG

Figure 2-5 Correct seating of waterproofing gasket

2-3

Page 26

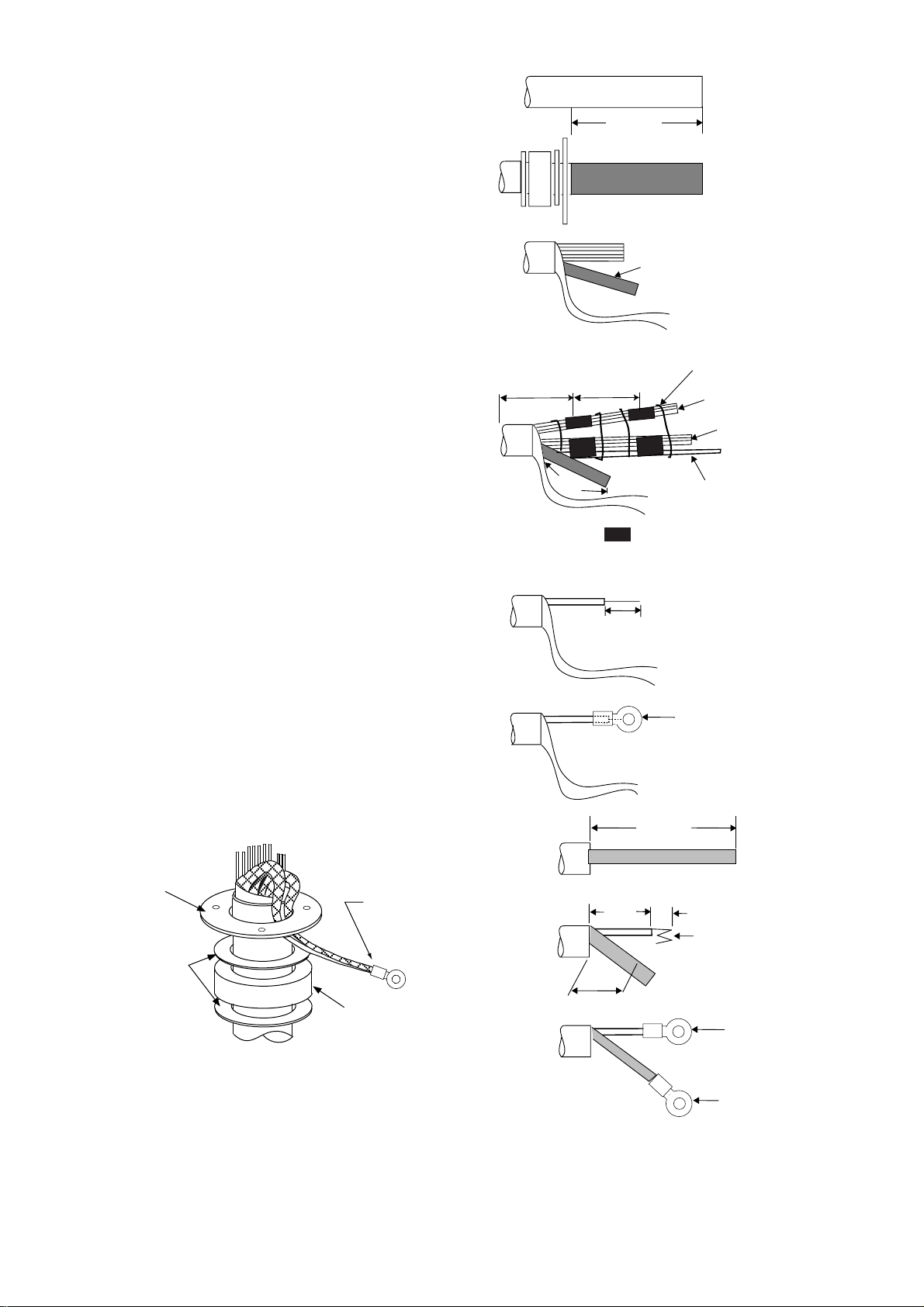

Fabricating signal cable S03-75

VINYL SHEATH

1. Remove the vinyl sheath by 450 mm.

2. Slide the clamping ring, washer, rubber gasket and washer onto the signal cable in that

order.

3. Unravel the outer shield to expose the cores

in the outer layer. Then, unravel the inner

shield to expose the cores in the inner layer.

Label all inner cores to aid in identification.

4. Attach EMI cores to all inner cores and all

outer cores, and tie cables with cable ties.

Note: There are two types of EMI cores, thick

and thin.

5. Trim each core (except coaxial wire) considering its location on the terminal board.

6. Trim the inner and outer shields leaving 500

mm each. Twist shields together and attach

crimp-on lug FV5.5-4 (Blue, ø4).

7. Remove insulation of each core by about 6

mm. Fix crimp-on lug FV1.25-M3 (Red, ø3)

to each core.

8. Fabricate the coaxial cable. Make the length

10 mm longer than the shield to prevent wire

strain. Attach crimp-on lug FVD1.25-3 (Red,

ø3) to coaxial cable.

Less than

100 mm

500mm

450 mm

70-130 mm

6 mm

Inner shield

Cable tie

Outer cores

Inner cores

Coax cable

= EMI cores

Outer cores: (RFC-13) thick

Inner cores: (RFC-10) thin

Crimp-on lug

(FV1.25-M3,

Red, φ3)

Clamping

ring

Washers

Crimp-on lug

(FV5.5-5, Blue, φ4)

Rubber

gasket

Figure 2-7 How to ground

signal cable S03-75

2-4

2C-2V

75 mm

50 mm

45 mm

Cut here

6 mm

Fold four times

Crimp-on lug

(FVD1.25-3,

Red, φ3)

Crimp-on lug

(FV1.25-3,

Red, φ3)

Figure 2-6 How to fabricate

signal cable S03-75

Page 27

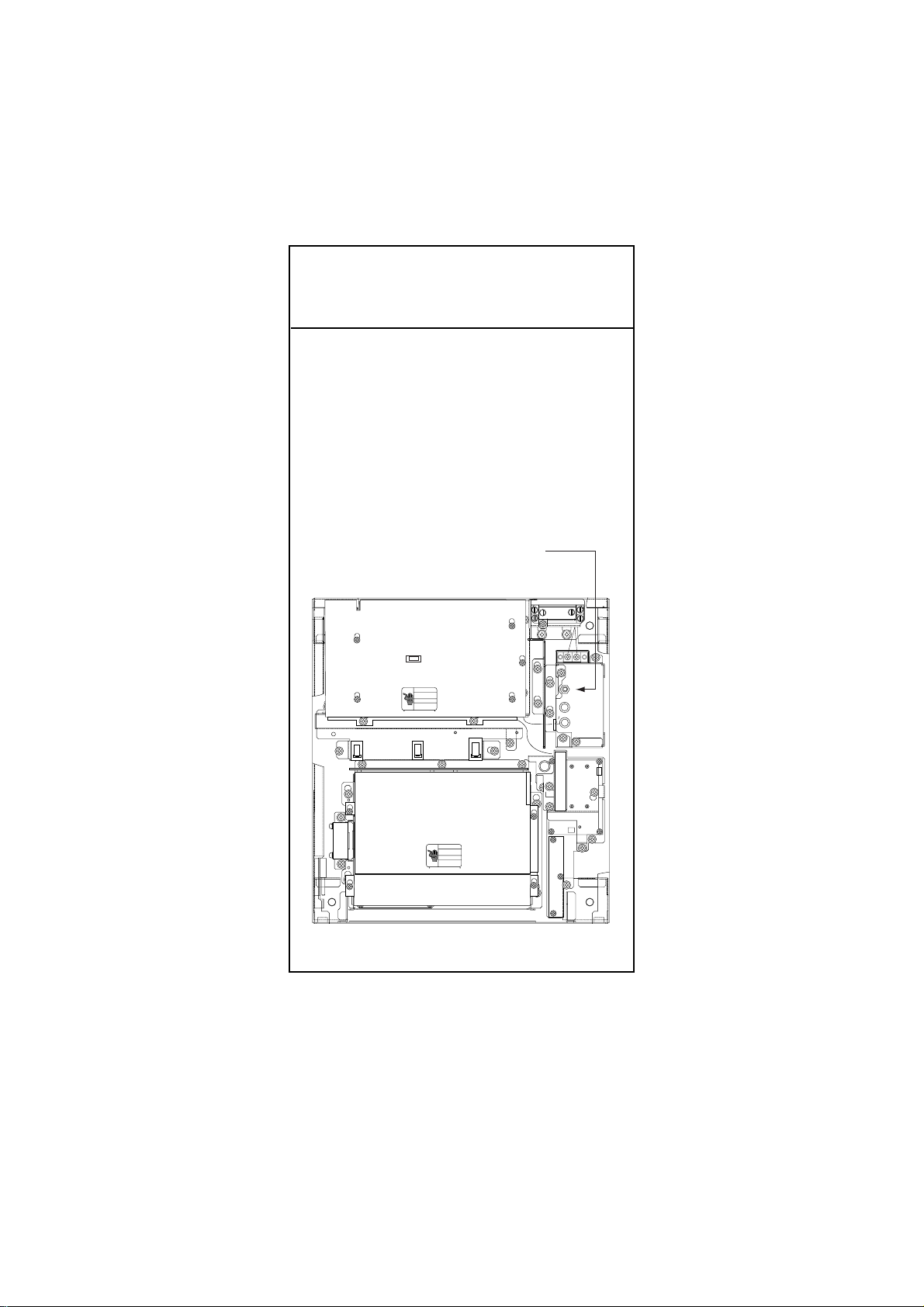

2.2 Display Unit

Two cables are terminated at the display unit: the signal cable S03-75 and the

power cable. The signal cable comes with a connector preattached to it for connection to the display unit. Fabricate the power cable as shown on the next page.

The display unit designed to run on AC

power has a power switch inside its

base which cuts off 100/200 VAC power

to the display unit. Pull the display unit

forward several centimeters to access

the switch. TURN THE SWITCH OFF

(as well as the main POWER switch)

WHENEVER ACCESSING INSIDE THE

DISPLAY UNIT.

POWER Switch in AC

Powered Display Unit

POWER Switch

J106

J105

J104

J103

J446

J466

J462

J465

Display unit, inside view

2-5

Page 28

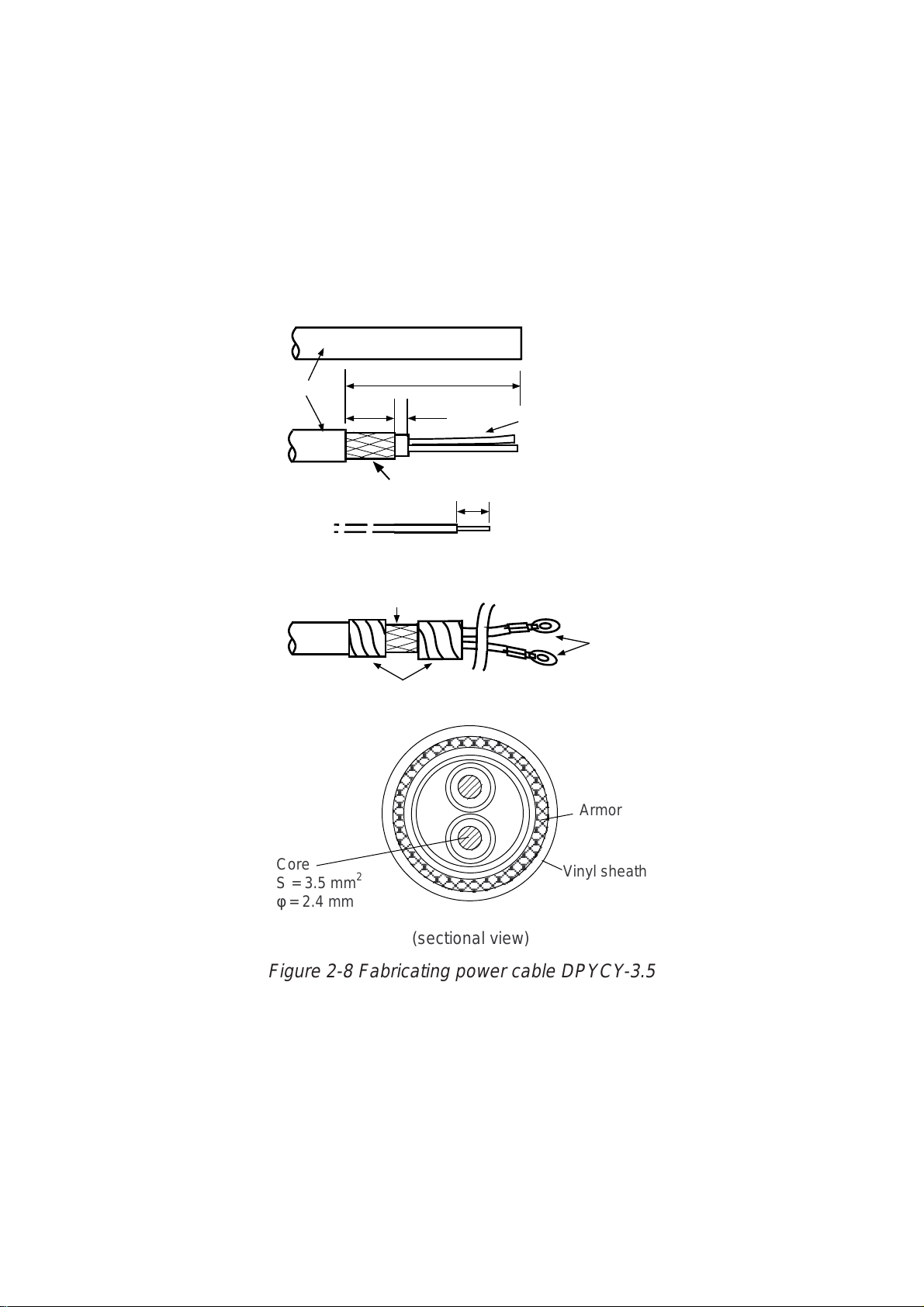

Fabricating the AC power cable (supplied)

1. Remove the vinyl sheath by 80 mm.

2. Cut off jute tape wrapped around the armor.

3. Unravel the armor to expose the cores by about 35 mm.

4. Remove insulation of cores by about 10 mm. Fix crimp-on lugs type FV5.5-4 to

the cores.

5. Cover the armor with vinyl tape, leaving the portion which will lie inside the

cable clamp untaped.

(a)

Vinyl sheath

(b)

(c)

(d)

DPYCY-3.5

Approx. 80 mm

40 mm

Clamp here.

5 mm

Armor

Taping

Core

10 mm

Crimp-on lug

FV5.5-4

Armor

Core

S = 3.5 mm

φ = 2.4 mm

2

(sectional view)

Vinyl sheath

Figure 2-8 Fabricating power cable DPYCY-3.5

2-6

Page 29

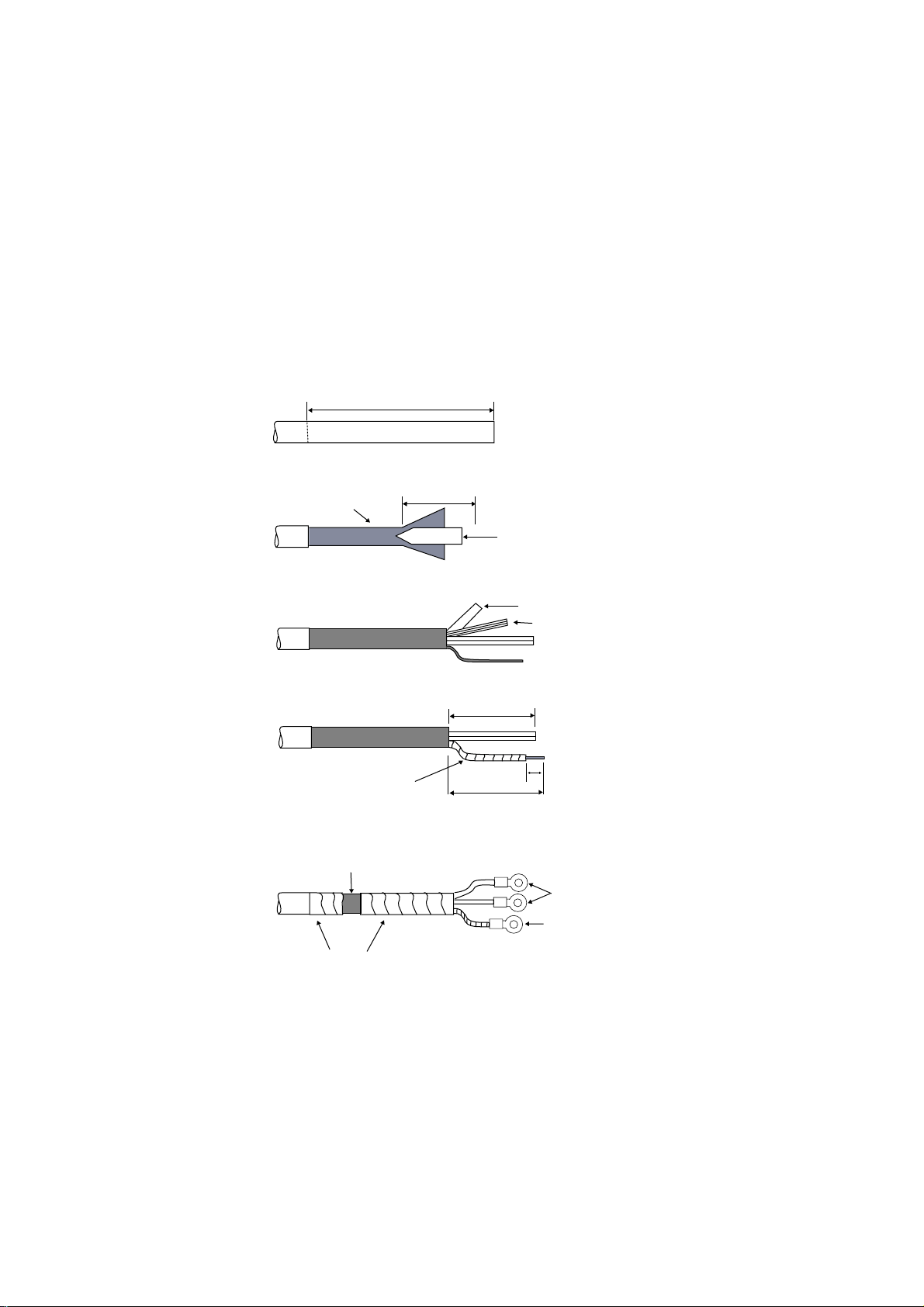

Fabricating the DC power cable (CVV-S 8X2C, option)

1. Remove the vinyl sheath by 100 mm.

2. Unravel the braided shield 60 mm from end of cable.

3. Remove the jute tape and inclusion from cable.

4. Expose the cores by 50 mm.

5. Expose the shield by 60 mm. Tape 10 mm of the shield tip.

6. Remove the sheath of cores by 10 mm. Attach crimp-on lugs type 8NK4 to the

cores and crimp-on lug type FV5.5-4 (yellow) to the shield.

7. Tape the cable as shown in the figure below. Fasten the shield to screw (M4) on

the cable clamp.

100 mm

CVV-S 8X2C

Braided Shield

Taping

Fasten cable

clamp here.

Taping

60 mm

Core

Jute Tape

Inclusion

50 mm

10 mm

60 mm

Crimp-on Lug

8NK4

Crimp-on Lug

FV5.5-4

Figure 2-9 Fabricating power cable CVV-S 8X2C

2-7

Page 30

Leading cables into the display unit

The cable clamp may be positioned within the display unit (default arrangement),

outside the display unit or at the bottom of the display unit (when using console

mount, for example). When the cable clamp is located outside or beneath the display unit, use the bottom clamp front plate and bottom clamp rear plate (supplied

with installation materials).

Also, use the shielding foam (supplied) to guard against noise.

Cable fed from rear of display unit (Default method)

Nav equipment

(Gyrocompass)

Keyboard

Log

PWR

Cable position in clamp

(Display unit, rear view)

ANT

Slave display

Navigation

External CRT

Hex bolt

M5X12 SUS,

2 pcs

Hex bolt

M5X35 SUS,

2 pcs

Hex bolt

M5X35 SUS,

2 pcs

Pan-head screw

M4X8

(D) Rear clamp

plate

(C) Signal clamp

(Aluminum)

(B) Power clamp

(Aluminum)

(D) Rear clamp plate

(C) Signal cable

(Aluminum)

(B) Power clamp

(Aluminum)

(A) Rear clamp base

(Display unit, right-hand side view)

Figure 2-10 Default cable clamp position

• Place shielding foam between cables, and then attach foam to aluminum clamps.

• Fill unused clamp holes with shielding foam.

(Construction of

cable clamp)

Make sure foam contacts rear chassis.

Rear cable entrance

Cable

Shielding foam

(Display unit, rear view)

(A) Rear clamp

base

2-8

Page 31

Cable fed from outside display unit

Shielding foam

(D) Rear clamp plate

(C) Signal clamp

(Aluminum)

(B) Power clamp

(A) Rear clamp base

M5X10 (2 pcs)

(Installation materials)

Bottom clamp front plate

(Installation materials)

(Aluminum)

Rear cable entrance

Figure 2-11 Clamp position outside display unit (display unit right side view)

• Place shielding foam between cables inside of display unit, and then attach

foam to chassis.

• Fill unused clamp holes with shielding foam.

Cables fed from bottom of display unit (for console mount)

Lead in cables through the cable clamp at the rear of the console and ground their

shields in the cable clamp. For signal cable, remove vinyl sheath where cable lies

in cable clamp. Fasten cables with cable ties.

Seventh hole

from the top

Power Cable

(For display unit)

Close shutter door and cover

Close shutter and cover

with aluminum tape to

it with aluminum tape to keep

keep foreign objects out

foreign objects out of the

of the display unit.

display unit.

Performance

Monitor

Cable Arrangement in the Console (Top view)

SIGNAL CABLE:

Remove the vinyl sheath here.

(1300 mm from display unit end

of cable remove sheath by 70 mm.)

Gyrocompass

Power Cable

(For PM)

Log

NAV

Signal Cable

ARPA

Slave Display

Figure 2-12 Clamp position at bottom of display unit

2-9

Page 32

Connections

Raise the monitor and fix it with the stay. (For procedure see page 1-5.) Remove

the shield cover from the INT Board. Connect signal, power, gyro and log cables

as shown below. Optional equipment are connected to the INT Board. Be sure to

ground the display unit.

PTU BOARD

03P9245

MOTHER BOARD

03P9251

J448

Antenna

Unit

Fasten shield here.

(Tabletop type)

Connect coax

cable here.

DJ1

J5

J4

Gyro

Log

Ship’s

mains

Ground terminal

(Tabletop type)

Fasten shields

together here.

(Console type)

Terminal

board

POWER switch (AC only)

(Turn off before accessing

inside the display unit.)

Signal cable should

1

touch edge of

partition board.

Fasten TX-HV

line to #1 terminal.

To fasten;

1. Unfasten screws.

2. Slide terminal forward.

3. Lift terminal to remove it.

J442

J443

J444

J463

J457

J458

J453

J451

J452

INT BOARD

03P9252

J450

J454

J455

J466

J462

J456

GYRO CONVERTER

BOARD 64P1106

Fix the DJ1 connector with

two M3X8 screws (supplied).

J445

Location of connectors

on the INT Board. See

next page for connector

J448

J446

J467

J449

J465

description.

Bind the cables so as not to pinch them

between the monitor and mounting base.

Take special care with the high voltage

line.

M4X8 (2 pcs.)

CAUTION

Ground the equipment to

prevent electrical shock

and mutual interference.

3

2

1

2

3

4

5

6

7

8

Figure 2-13 Display unit, inside view

2-10

Page 33

Connectors on the INT Board

Table 2-1 Connectors on the INT Board

emanlangiSnoemaN

bcp

langiStupnI

langisoryG4Jnip3,HVbcpnO:*

goldeepS

langis

youbradaR

langis

etomeR

lanretxE

APRA

langis

langis

GOL844Jnip3,HN .cte,mn/seslup002

RADAR

YOUB

RADAR-TXE

langisyalpsid

langiStuptuO

yalpsidevalS

7-JRro

APRA-TXE444Jnip8,HN,gniraeb,gnidaeH

EVALS244J

.on

5Jnip5,HV

rotcennoC

544Jnip4,HN

854Jnip8,HN

344J

rotcennoC

epyt

nip8,HN,141-DC,041-DC

elbacilppA

tnempiuqe

,005-DG

,2KM005-DG

,008-DMF

08-DMF11*0

skrameR

)noitpo(6011P46A

reggirtxT

,gniraeb,gnidaeH

reggirtxT,oediv

roftinuyalpsiD:1*

ebnacV5212-RF

evalssadesu

.tinuyalpsid

langisrezzuBZUB-TXE154Jnip9,HNpma/wrekaepSlangisrekaepS

langisrotinoM944Jnip01,HN,suonorhcnysREV

,suonorhcnysROH

oediv

)tamrofCSTN(

C232-SRC232-SR654Jnip4,HX

golanAGOLANA354Jnip3,HNlangisTOR

lanretxE

rezzub

atadSNIATAD.SNI554Jnip5,HN

7-JR7-JR754Jnip51,HN

8-JR8-JR614Jnip4,HNdraoBrehtoMnO

atadvaNATADVAN054Jnip5,HN

atadAPRAATADAPRA454Jnip5,HN

MRALATXE

)CA(

langiStuptuO/tupnI

254Jnip3,HN

1529P30

FFO_NO_MPTNIRP_MP114Jnip3,HXdraoBrehtoMnO

1529P30

Note: How to attach NH connector is shown on the next page.

2-11

Page 34

How to attach NH connector

HOW TO ATTACH NH CONNECTOR TO SIGNAL CABLE

NH connector wire

NH connector

housing

1

Insert NH connector

wire into NH connector

housing.

Shrink tubing

20mm

2

Cut shrink tubing

in 20 mm lengths and

slip onto each wire.

Solder

3 Solder connector

to signal cable.

Figure 2-14 How to attach NH connector

2.3 Changing AC Power Specification

For 100 V AC or 220 V AC power , add or delete jumper wires on the PTU Board and

change the power fuses inside the display unit as shown in the table below according to ship’s mains. The figure below shows the location of the power fuses and the

jumper wires on the PTU Board.

4

Heat shrink

tubing with soldering iron.

Table 2-2 Jumper wire setting on the PTU board, fuse rating and power specification

BCP.cepSrewoP

annetnA

mpr

1PJ2PJ3PJ4PJ19PJ29PJ

A5429P30CAV511/011/001mpr42SEYSEYSEYONONON

C5429P30CAV511/011/001mpr24SEYSEYSEYONSEYSEY

D5429P30CAV032/022mpr42ONONONSEYONON

F5429P30CAV032/022mpr24ONONONSEYSEYSEY

Jumper wire to use:

JP1: 0.8 dia. gilded wire

JP2, JP3, JP4, JP91, JP92: type ERD-S2TCOV

03P9245

C11

C12

Fuse

JP1

JP2

T21

T1

JP92

JP3

JP4

U92

JP91

rewoP

sesuF

A01

A5

PTU Board

Figure 2-15 Display unit, inside view

2-12

Page 35

INITIALIZATION AND ADJUSTMENT

3

.1 Tuning Initialization

Tune the radar as follows: Press [RADAR MENU] [0] [0] [2] [0] [0] [0] (TUNE

INITIALIZE on the RADAR 3 menu) and press the [ENTER] key.

3.2 Accessing Menus for Initialization and Adjustment

To access them do the following:

1. T urn on the power.

2. Press the [RADAR MENU] key five times while pressing and holding down

the [HL OFF] key. A beep sounds to confirm operation.

Restoring default settings

1. Press [RADAR MENU] [0] [0] [0] [2] [0] [0] [0] to display the INITIAL SETTING

4 menu.

2. Press the [0] key to select FACTORY DEFAULT.

3. Press the [ENTER] key five times, and turn the power off and on again.

4. "Initializing" appears during restoring. It takes about 90 seconds to restore the

default settings, after which the normal display appears.

3.3 Adjusting Video Signal Level

When the signal cable is very long, the video amplifier input level decreases,

shrinking target echoes. To prevent this, confirm (and adjust if necessary) video

amplifier input level.

1. Connect an oscilloscope to TP6 on the INT Board (03P9252) in the display

unit.

2. Transmit on the 12 nm range.

3. Adjust R21 on the INT Board so the value of TP6 is 4 Vpp. (For remote display, adjust R134 on the INT Board.)

TP1

R134

R21

INT Board

(03P9252)

Figure 3-1 Display pedestal

3-1

TP6

Page 36

3.4 Heading Alignment

You have mounted the antenna unit facing straight ahead in the direction of the

bow. Therefore, a small but conspicuous target dead ahead visually should appear on the heading line (zero degrees).

In practice, you will probably observe some small bearing error on the display

because of the difficulty in achieving accurate initial positioning of the antenna

unit. The following adjustment will compensate for this error.

Correct bearing

relative to heading

Target

a

270

Antenna mounted

error to port

(HDG SW advanced)

000

010

350

020

340

330

320

310

300

290

280

260

250

240

230

220

210

200

030

040

140

150

160

190

170

180

Picture appears

deviated clockwise.

a

050

060

070

080

090

100

110

120

130

Apparent

position

of target

Antenna mounted

error to starboard

(HDG SW delayed)

Apparent position

of target

Target

b

b

000

010

350

020

340

330

320

310

300

290

280

270

260

250

240

230

220

210

200

030

040

050

060

070

080

090

Correct

100

110

bearing

120

130

relative to

140

150

160

190

170

180

heading

Picture appears

deviated counterclockwise.

Figure 3-2 Heading alignment

1. Press [RADAR MENU] [0] [0] [0] [2] [2] to select HL ALIGN on the INITIAL

SETTING1 menu.

2. Select a target echo (by gyrocompass, for example) at a range between 0.125

and 0.25 nm, preferably near the heading line.

3. Operate the EBL control to bisect the target echo with the heading line. (The

value shown on the display is antenna position in relation to ship's bow.)

4. Press the [ENTER] key to finish.

3-2

Page 37

3.5 Adjusting Sweep Timing

Sweep timing differs with respect to the length of the signal cable between the

antenna unit and the display unit. Adjust sweep timing at installation to prevent

the following symptoms:

• The echo of a "straight" target (for example, pier), on the 0.25 nm range, will

appear on the display as being pulled inward or pushed outward. See Figure

3-3.

• The range of target echoes will also be incorrectly shown.

(1) Correct

Figure 3-3 Examples of correct and incorrect sweep timings

1. Press [RADAR MENU] [0] [0] [0] [2] [3] to select TIMING ADJ on the INITIAL

SETTING1 menu.

2. Transmit on the 0.25 nm range.

3. Adjust radar picture controls to display picture properly.

4. Select a target echo which should be displayed straightly.

5. Adjust the VRM control to straighten the target echo.

6. Press the [ENTER] key.

(2) Target pushed

inward

3.6 Suppressing Main Bang

If main bang appears at the screen center, suppress it as follows.

1. Transmit on a long range about ten minutes.

(3) Target pushed

outward

2. Adjust the [GAIN] control to show a slight amount of noise on the display.

3. Select the 0.25 nm range. Adjust the [A/C SEA] control to suppress sea clutter.

4. Press [RADAR MENU] [0] [0] [0] [2] to open the INITIAL SETTING1 menu.

5. Press the [7] key to select 7. MBS.

6. Adjust the VRM control to adjust timing; the EBL control to adjust level.

7. Press the [ENTER] key.

3-3

Page 38

3.7 Confirming Magnetron Heater Voltage

PM

ON

OFF

TUNE

DEGAUSS ERROR

ANTENNA

switch

ANTENNA

Magnetron heater voltage is adjusted at the factory. However, confirm that it is

within the prescribed rating.

Table 3-1 Magnetron heater voltage rating

gnitaR)Wk52(V5212-RF

mn521.0,YB-TSV4.8-V2.8

egnarxam,XTV5.7-V5.6

1. Press [RADAR MENU] [0] [0] [0] [2] [0] to open the INITIAL SETTING2 menu.

2. Press [5] to select the 5. SCANNER STOPPED field and the TX option.

3. Disconnect connector P821 from the antenna unit.

4. Turn off the ANTENNA switch in the tuning compartment in the display unit.

Figure 3-4 Antenna switch in tuning compartment

5. Turn off screen brilliance.

6. Measure voltage between pins #12(+) and #5(-) on connector P801 on the

RFC Board (03P9243) in the antenna unit.

7. If the voltage is not within the rating shown in Table 3-1, adjust potentiometer

VR1 on the RFC Board.

J611

03P9243

J801

VR1

J821

Figure 3-5 RFC Board

8. Set 5. SCANNER STOPPED on the INITIAL SETTING2 menu to ST-BY.

3-4

Page 39

3.8 Initial Setting Menus

The INITIAL SETTING menus (four menus) and the OWN SHIP INFORMA TION

menu setup the radar according to expected usage, authorities specification, ship's

characteristics, operator's preference, etc. Set items on each menu in accordance with regulations/operator's preference. After entering initial settings, reset

the power.

Press [RADAR MENU] [0] [0] [0] [2]

[OWN SHIP INFORMATION]

1 [INITIAL SETTING(1)]

2 SHIP'S LENGTH 000m

3 SHIP'S WIDTH 00m

4 RADAR POSN FOR BOW 000m

FOR PORT 00m

5 NAV ANT POSN FOR BOW 000m

FOR PORT 00m

6 TURN RATE 00KT 00.0° / s

00KT 00.0° / s

7 SPEED RATE 00KT 0.00KT/s

00KT 0.00KT/s

Press [0]

[INITIAL SETTING 4]

1 [INITIAL SETTING(3)]

2 MODEL FR-2115V, 2125V/

OTHER X-BND/

FR-2165DSV , 2135SWV/

OTHER S-BND

3 TYPE R/N/G/D

4 CTR STC CURVE L/M/H

5 RJ-7 OFF/ON

6 RJ-8 OFF/ON

ANT A FR-2115V, 2125V/

OTHER X-BND/

FR-2165DSV , 2135SWV/

OTHER S-BND

ANT B FR-2115V, 2125V/

OTHER X-BND/

FR-2165DSV , 2135SWV/

OTHER S-BND

7 SHIP'S TYPE DEEP SEA/FISHING/

LONG LINE FISHING

9 CABLE LENGTH 500m/5000m

0 FACTORY DEFAULT

Press [6]

[INITIAL SETTING 1]

1 [FUNCTIONS(4)]

2 HL ALIGN EBL 0.0°

3 TIMING ADJ VRM 00.00

4 ANT HGT 5m/7m/10m/15m/

20m/30mMORE

5 LOG PULSE 200P/NM

6 [OWN SHIP INFORMATION]

7 MBS MBS TIMING VRM 0

MBS LEVEL EBL 0

8 ON TIME 000000.0H

9 TX TIME 000000.0H

0 [INITIAL SETTING(2)]

Press [0]

[INITIAL SETTING 2]

1 [INITIAL SETTING(1)]

2 LOG GYRO INPUT

LOG PULSE/SERIAL DATA

GYRO AD-10/SERIAL DATA

3 OWN SHIP VECTOR COMPASS/COURSE

4 KEY BEEP ON/OFF

5 SCANNER STOPPED ST-BY/TX

6 VIDEO SIG ANALOG/DIGITAL

7 ALARM LEVEL 4/5/6/7

8 DISPLAY MAIN/SUB

9 SECTOR BLKG OFF/ON

000° → 000°

000° → 000°

0 [INITIAL SETTING(3)]

Press [0]

[INITIAL SETTING 3]

1 [INITIAL SETTING(2)]

2 TRAILS RESTART OFF/ON

3 ECHO AVG W/O GYRO OFF/ON

4 HEAD UP TB SCALE DEG/16POINT

5 CTR ECHO STRETCH OFF/ON

6 VIDEO CONTRAST 1/2/3

7 MAXIMUM RANGE 72/96/120

8 ECHO FULL COLOR OFF/ON

9 INDEX LINES 2/3/6

0 [INITIAL SETTING(4)]

Figure 3-6 Initial settings menu

3-5

Page 40

INITIAL SETTING1 menu

Keying sequence: [RADAR MENU] [0] [0] [0] [2]

HL ALIGN: Aligns heading.

TIMING ADJ: Adjusts sweep timing.

ANT HGT: Enter height of antenna above water. Select from 5 m, 7 m, 10 m, 15

m, 20 m, or more than 30 m.

LOG PULSE: Enter speed log's pulse rate.

OWN SHIP INFORMATION: Enter ship's characteristics; length, width, radar

antenna position, navigation antenna position, turn rate, and speed rate. See the

description on the next page for further details.

MBS: Suppresses main bang.

ON TIME, TX TIME: Shows number of hours the radar has been turned on and

transmitted, respectively. Value can be changed.

INITIAL SETTING2 menu

Keying sequence: [RADAR MENU] [0] [0] [0] [2] [0]

LOG GYRO INPUT : Select LOG or GYRO input type. LOG: Select pulse or serial

data. GYRO: Digital from A/D converter or serial data.

OWN SHIP VECTOR: Select reference for own ship vector; compass or course.

KEY BEEP: Turns key response beep on or off.

SCANNER STOPPED: Set to ST-BY in normal use. TX enables transmission

state without antenna rotation.

VIDEO SIG: Set to ANLG (analog) for normal use. Select DIGITAL to adjust QV

(Quantized Video).

ALARM LEVEL: Sets echo strength which triggers guard alarm. "7" is strongest

echo; "4" is medium strength echo.

DISPLAY: Select radar display function; main or sub (slave).

SECTOR BLKG: Sets area (up to 2) where no radar pulses will be transmitted.

For example, set the area where an interfering object at the rear of the antenna

would produce a dead sector (area where no echoes appear) on the display. To

enter an area, select ON and enter relative bearing range of the area.

INITIAL SETTING3 menu

Keying sequence: [RADAR MENU] [0] [0] [0] [2] [0] [0]

TRAILS RESTART: Selects whether to restart or discontinue target trails when

changing the range. ON restarts trailing on newly selected range; OFF discontinues trails.

ECHO A VG W/O GYRO: Echo averaging can be turned on without gyrocompass

connection.

3-6

Page 41

HEAD UP TB SCALE: Bearing scale may be shown in degrees or compass

points in the head-up mode.

CTR ECHO STRETCH: Turn on to enlarge echoes in the range up to the first

range ring.

VIDEO CONTRAST: For factory use. Do not change setting.

MAXIMUM RANGE: For factory use. Do not change setting.

ECHO FULL COLOR: Echoes may be displayed in one color or multi-color. Se-

lect ON for multi-color display.

INDEX LINES: Selects the number of index lines to display; 2, 3, or 6.

INITIAL SETTING4 menu

Keying sequence: [RADAR MENU] [0] [0] [0] [2] [0] [0] [0]

MODEL: Selects radar model.

TYPE: Selects specification of radar.

CTR STC CURVE: Selects level of STC affect; Low, Medium or High.

RJ-7, RJ-8: Selects which Interswitch unit to use.

SHIP'S TYPE: Select class of vessel; deep sea, fishing, long line fishing.

CABLE LENGTH: Set for "500."

FACTORY DEFAULT: Restores all menus' default settings.

OWN SHIP INFORMATION menu

Keying sequence: [RADAR MENU] [0] [0] [0] [2] [6]

SHIP'S LENGTH: Enter ship's length.

SHIP'S WIDTH: Enter ship's width.

RADAR POSN: Enter distance from both bow and port to the radar antenna

location.

NAV ANT POSN: Enter distance from both bow and port to the navigation an-

tenna location.

TURN RATE: Enter ship's turn rate.

SPEED RATE: Enter ship's speed rate.

I/O Data Sentences

Input: GGA, RMA, RMB, RMC, GLL, ZDA, VBW, VHW, VTG, MWV, VWT,

Output: RAOSD, RARSD, RATTM

VWR, VDR, DPT, DBT, DBS, MTW, BWR, BWC, WPL, RTE

Note: Unit of Range Measurement

The default unit of range measurement is NM (nautical miles). To switch to SM, press [4],

[5], [6] while pressing the [HL OFF] key. Then, reset the power.

3-7

Page 42

INSTALLATION OF OPTIONAL EQUIPMENT

4.1 Gyro Converter GC-8

The Gyro Converter GC-8, incorporated inside the radar display unit, converts

analog gyrocompass reading into digital coded bearing data for display on the

radar display.

This section explains how to install and the GC-8 (mainly consisting of the GYRO

CONVERTER Board) and set it up according to the gyrocompass connected.

Installation and connection of the GYRO

CONVERTER Board

Necessary Parts: GC-8 (Code No. 008-446-520)

emaNepyTytQ.oNedoC

draoBretrevnoCoryG6011P461022-214-400

swercSW0072C,8X3M5404-188-000

rekcitS11202-410-461107-231-001

1. Turn off the main POWER switch.

2. Open the monitor and fix it with the stay. (See Chapter 1 for instructions.) Turn

off the internal power switch if so equipped. Unfasten four screws to remove

the shield cover for the INT Board.

3. Fasten the GYRO CONVERTER Board inside the display unit with four washerhead screws (supplied).

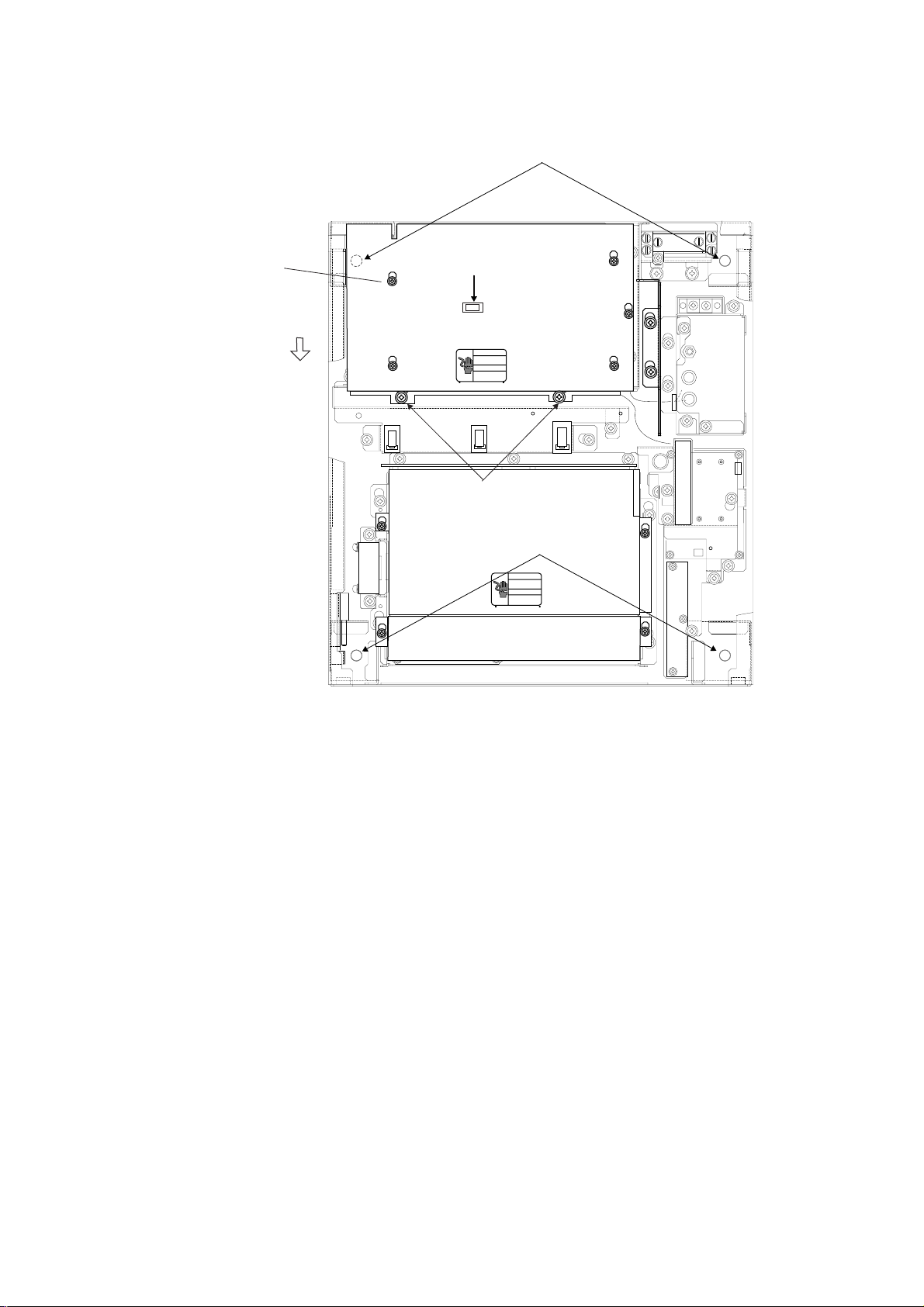

PTU BOARD

03P9245A(-F)

MB BOARD

03P9251

GYRO

CONVERTER

BOARD

64P1106

INT BOARD

03P9252

Figure 4-1 Display unit, inside view

4-1

Page 43

4. Connect the GYRO CONVERTER Board to the INT Board (cables supplied

with GC-8) as shown below.

INT Board GYRO CONVERTER Board

J446 (4P) J7 (5P)

J465 (6P) J1 (14P)

J5

To gyro

J4

J446

J465

INT BOARD

03P9252

J7

J1

Fix cable to chassis

with cable tie.

GYRO CONVERTER

BOARD 64P1106

Figure 4-2 Display unit, inside view

5. Confirm gyrocompass specifications and set the DIP switches and jumper wires

on the GYRO CONVERTER Board according to the gyrocompass connected:

• Setting jumper wires and DIP switches by gyrocompass specifications:

page 4-4

• Setting jumper wires and DIP switches by make and model of gyrocompass: page 4-5

• Location of jumper wires and DIP switches: page 4-6

6. Solder the gyrocompass cable to the VH connector assemblies (supplied).

4-2

Page 44

7. Attach instruction label (supplied) to shield cover for the INT and GYRO CONVERTER boards.

8. Close the monitor.

9. Turn the power off and on again to reset the CPU.

Connection of external power supply

An external power supply is necessary when the repeater signal is step-by-step

type and the step voltage is below 20 V or output voltage is less than 5 W.

1. Cut the jumper wire JP1 on the GYRO CONVERTER Board when an external

power supply is used.

2. Connect the gyro cable and power cable as shown below.

GYRO CONVERTER Board

[A] 64P1106

External Power Supply

20 - 135 VAC

20 - 100 VDC

Gyrocompass

(Step type)

S1

S2

S3

COM

F.G.

J5

1 R2

2 R1/COM

Either connection

in case of DC

polarity.

J4

1S1

2 S2

3 S3

4 T

5 F.G.

Figure 4-3 Connection of external power supply to GYRO CONVERTER Board

DIP switch, jumper wire settings

Default setting

The default setting of all DIP switches is off and all jumpers wire are set to “#1.”

(Note that the jumper wire JP1 is set at #1, #2, and #3.) In those settings the

gyrocompass having the following characteristics can be directly connected; modification of the GYRO CONVERTER Board is not necessary.

AC synchronous signal: 50/60 Hz

Rotor voltage: 60 V to 135 V AC

Stator voltage: 60 V to 135 V AC

Gear ratio: 360X

Supply voltage: 30 V to 135 V AC

4-3

Page 45

If the specifications of the gyrocompass differ from those mentioned above, change

jumper wire and DIP switch settings on the GYRO CONVERTER Board as appropriate. Settings may be changed according to gyrocompass specifications (page

4-4) or make and model of gyrocompass (page 4-5). For the location of DIP switches

and jumper wires, see page 4-6.

Setting method 1: DIP switch settings by gyrocompass specifications

epytssapmocoryG)1ycneuqerF)2

ssapmocoryG

epyt

suonorhcnysCAFFOFFOFFO,2#,1#

suonorhcnysCDFFOFFOFFO,3#,2#

petsCDNOFFOFFO,5#,4#

evaw-lluF

evaw-flaH

WS

WS

4-1

FFONOFFO,5#,4#

tnerrucgnitaslup

NONOFFO,5#,4#

tnerrucgnitaslup

egatlovrotoR)3

WS

5-1

6-1

1PJycneuqerFWS

3#

4#

6#

CDNONOsuonorhcnysCD

6#

6#

egatlovrotatS)4

)2R&1Rneewteb(

egatlovrotoR1-2WS3PJegatlovrotatS2-2WS3-2WS2PJ

CAV54otV02NO2#ro,CAV54otV02

CAV07otV03FFO2#

CAV09otV04NO1#ro,CAV54otV02

CAV531otV06FFO1#

CDV06otV02

CDV06otV02

CAV09otV04NOFFO1#

CAV531otV06FFOFFO1#

WS

7-1

zH06/05FFOFFOsuonorhcnysCA

zH004NOFFOsuonorhcnysCA

zH005FFONOsuonorhcnysCA

8-1

skrameR

tnerrucgnitaslup

tnerrucgnitaslup

tnerrucgnitaslup

petsCD

)2Sdna1Sneewteb(

NOFFO2#

FFOFFO2#

oitaR)5egatlovylppuS)6

oitaR1-1WS2-1WS3-1WSegatlovylppuS4PJ5PJ

x063FFOFFOFFOro,CAV54otV02

x081NOFFOFFO

X09FFONOFFOro,CAV531otV03

X63NONOFFO

CDV06otV02

CDV001otV04

2#2#

1#1#

4-4

Page 46

atadtamrof01-DA)7

lavretnixT

3810-AEMN)8

lavretnixT

:etoN sm52.sm002rosm52nielbaliavasilavretnixTehT

seriwrepmujyb6ot1stroproflavretnignittimsnartatadtceleS

.7PJdna6PJ

.tnempiuqerehtollarofsism002;radarrofsi

xT

lavretni

sdnoces2NO

dnoces1FFO

4-2WS

4-5

Page 47

Setting method 2: DIP switch/jumper settings by make and model of gyrocompass

rekaMsledoMnoitacificepSWS

ONURUF007-YGpetsCD

ztuhcsnA3,2dradnatSsuonorhcnysCA

6,4dradnatSsuonorhcnysCA

02dradnatSpetsCD

awagokoY

cetvaN

htialP(

)epyt

htialPIII/IITAGVANsuonorhcnysCA

cemikoT

yrrepS(

)epyt

ikasawaK18-XGsuonorhcnysCA

nworbamrA1-LKM,01-KM

nostreboR08-RKSpetsCD

3/2/A1/1-C

55-B,55-A

007-ZMCpetsCD

005/X003

3/2-SPI

05-ZMC

etoN

11/2/1-SE

002-GT

H/L732RP

12MG

41-KM

T/2/1-DOM

71-SE,041

302/

0006-GTpetsCD

11-MGsuonorhcnysCA

02-KM

4-DOM

/X052-ZMC

/002/001-ZMC

3/1/Z1-D,RJ-C

/201/101-TLG

701/K601/301

011/A11-SE

0002/R222RP

1E-KN,NE-KN

041/031-RSpetsCD

0005/001-GT

/031/753-RP

202/102-TLG

61-SE,021-RS

,1531SEIRES

x081V001

zH06/05

x063

zH06/05

x063

x081V53

zH06/05

x063

x081V42

petsCD

x081V53

zH06/05

x063

pets

x081V53

zH06/05

x063

zH06/05

x63

zH06/05

x09

petsCD

x081V07

x081V07

petsCD

x081V07

x081V42

zH06/05

x09

petsCD

x081V53

zH06/05

x09

petsCD

x081V05

x081V53

rotcellocnepo,eriw-5

V06/05:egatlovrotoR

V22:egatlovrotatS

V06/05:egatlovrotoR

V09:egatlovrotatS

)+(eriw-3,)-(MOC

suonorhcnysCA

V06/05:egatlovrotoR

V22:egatlovrotatS

)-(eriw-3,)+(MOC

x063suonorhcnysCDFFOFFOFFOFFOFFOFFONONO-NOFFO-omeR

)-(eriw-3,)+(MOC

suonorhcnysCA

V001:egatlovrotoR

V09:egatlovrotatS

)-(eriw-3,)+(MOC

V06/05:egatlovrotoR

V86:egatlovrotatS

suonorhcnysCA

V011/001:egatlovrotoR

V09:egatlovrotatS

suonorhcnysCA

V011/001:egatlovrotoR

V22:egatlovrotatS

)-(eriw-3,)+(MOC

rotcellocnepo,eriw-5

)-(eriw-3,)+(MOC

V001:egatlovrotoR

V09:egatlovrotatS

V001:egatlovrotoR

V09:egatlovrotatS

)-(eriw-3,)+(MOC

)+(eriw-3,)-(MOC

WS

WS

WS

WS

WS

WS

WS

WS

WS

1-1

2-1

3-1

4-1

5-1

6-1

7-1

8-1

1-2

NOFFOFFONOFFOFFONONO- FFOFFO,4#

FFOFFOFFOFFOFFOFFOFFOFFOFFONOFFO,1#

FFOFFOFFOFFOFFOFFOFFOFFOFFOFFOFFO,1#

NOFFOFFONOFFOFFONONO-NOFFO,4#

FFOFFOFFOFFOFFOFFOFFOFFOFFONOFFO,1#

NOFFOFFONOFFOFFONONO-NOFFO-omeR

NOFFOFFONOFFOFFONONO-NOFFO,4#

FFOFFOFFOFFOFFOFFOFFOFFOFFOFFOFFO,1#

NOFFOFFONOFFOFFONONO– NOFFO-omeR

FFOFFOFFOFFOFFOFFOFFOFFOFFOFFOFFO,1#

NONOFFOFFOFFOFFOFFOFFOFFOFFOFFO,1#

FFONOFFOFFOFFOFFOFFOFFOFFOFFOFFO,1#

NOFFOFFONOFFOFFONONO– FFOFFO,4#

NOFFOFFONOFFOFFONONO– FFOFFO,4#

NOFFOFFONOFFOFFONONO– FFOFFO,4#

NOFFOFFONOFFOFFONONO– NOFFO,4#

FFONOFFOFFOFFOFFOFFOFFOFFOFFOFFO,1#

NOFFOFFONOFFOFFONONO– NOFFO,4#

FFONOFFOFFOFFOFFOFFOFFOFFOFFOFFO,1#

NOFFOFFONOFFOFFONONO– FFOFFO,4#

NOFFOFFONOFFOFFONONO– NOFFO,4#

WS

2-2

3-2

1PJ2PJ3PJ4PJ5PJ

2#-1#1#

6#,5#

2#2#1#1#

3#,2#

2#1#1#1#

3#,2#

2#– 2#2#

6#,5#

2#2#1#1#

3#,2#

2#–

ev

2#–

ev

2#– 2#2#

6#,5#

1#1#1#1#

3#,2#

2#–

ev

2#2#1#1#

3#,2#

1#1#1#1#

3#,2#

1#1#1#1#

3#,2#

2#– 1#1#

6#,5#

2#– 1#1#

6#,5#

2#– 1#1#

6#,5#

2#– 2#2#

6#,5#

1#1#1#1#

3#,2#

2#– 2#2#

6#,5#

1#1#1#1#

3#,2#

2#– 1#1#

6#,5#

2#– 2#2#

6#,5#

∗∗

∗∗

∗∗

*: Set JP4 and JP5 according to the voltage of the external power supply.

Note: If CMZ-50 has 35VDC, set JP1 to #4, #5, #6.

4-6

Page 48

Location of DIP switches, jumper wires on the GYRO CONVERTER

Board

JP2

(Rotor voltage)

JP3

(Stator voltage)

JP5, JP4

(Supply voltage)

JP1

(Gyro type)

Fuse

(2A)

J5

(Rotor signal input,

external power input)

J4

(Stator signal input)

SW1

DIP switch

(IEC-61162-1 output port)

64P1106

J6

J7

(Data output port #1)

Figure 4-4 GYRO CONVERTER Board

Setting the heading readout on the radar display

J12

(Data output

port #6)

J11

(Data output

port #5)

J10

(Data output

port #4)

SW2

DIP switch

JP6, JP7

(AD formal

data Tx interval)

J9

(Data output port #3)

J8

(Data output port #2)

Confirm that the gyrocompass is giving a reliable readout. Then, set the heading

readout on the radar display as follows:

1. Press the [RADAR MENU] key to display the FUNCTIONS 1 menu.

2. Press the [0] key twice to display the FUNCTIONS 3 menu.

3. Press the [9] key to select the GYRO SETTING option.

4. Rotate the EBL control to align the radar’s HDG readout with the gyrocompass

heading.

5. Press the [ENTER] key to finish.

4-7

Page 49

4.2 ARP Board ARP-26

The ARP Board ARP-26, which provides ARPA functions, is an optional circuit

board which is accommodated in the display unit. Note that the ARP-26 is not

available with the statute mile-type radar.

Necessary Parts: ARP-26-2E (008-485-500)

emaNepyTytQ.oNedoC

draoBPRAB2009P811056-374-800

Installation of the ARP board

1. T urn of f the power . Remove the front panel from the display pedestal by unfastening four screws.

2. Set the ARP Board in the center slot of the PCB card case.

Display pedestal

Top: RP Board (Option)

Middle: ARP Board (Option)

Bottom: SPU Board

Figure 4-5 Display pedestal, inside view

3. Adjust the ARP Board referring to the procedure below.

ARP board adjustment

1. Turn the GAIN, A/C SEA and A/C RAIN controls fully counterclockwise (OFF).

Transmit on the 12 nm range.

2. Connect a digital multimeter between TP7(+) and TP6(-) on the ARP Board.

4-8

Page 50

TP7

TP6

R104

R103

Figure 4-6 ARP Board (18P9002B)

3. Adjust R104 on the ARP Board so the multimeter reads between 0.09 and 0.14

VDC.

4. Set controls and switches as below.

GAIN: fully clockwise (max.)

Interference rejector: OFF

Range: 24 nm

Echo stretch: OFF

5. Press [RADAR MENU] [0] [0] [0] [0] to open the INITIAL SETTING3 menu.

6. Set the VIDEO SIG field to DIGITAL and press the [ENTER] key.

7. Adjust R103 on the ARP Board so noise just appears on the display.

Too little noise

Proper noise

Too much noise

Figure 4-7 How to adjust noise

8. Set VIDEO SIG to ANALOG and press the [ENTER] key.

Final check

Connect a gyrocompass and a log to the radar and place the radar under transmit

state. Confirm that LEDs CR9, CR10, CR11, CR12, CR15 and CR16 on the ARP

Board are off. If ship's speed is zero, or other signal is not being input, corresponding LED will light.

4-9

Page 51

CR16 LOG

CR15 GYRO

CR12 TRG

CR11 VID

CR10 BRG

CR9 HDG

S1

4#3#2#1#

FFOFFOFFOFFO

Figure 4-8 ARP Board (18P9002B)

4.3 RP Board RP-26

The RP Board RP-26, which provides video plotter functions, consists of a circuit

board and a card drive, both of which are accommodated in the display unit. Note

that the RP-26 is not available with the statute mile-type radar.

Table top/console type

Necessary Parts: RP-26-T-2E (Code No. 008-485-520)

emaNepyTytQ.oNedoCskrameR

.yssAesaBdraC-M—1—

draoBPR8920P411046-784-800

BwercSdaeh-naPW0072C8X4M4544-188-000

BwercSdaeh-naPW0072C8X3M2404-188-000desutoN

,.yssaelbaC,draoBFI

,.yssaesabdrac-M

,esacdrac-M,dildrac-M

revocdrac-M

AwercSdaeh-naPW0072C5X6.2M2379-008-000desutoN

AwercSdaeh-naPW0072C8X3M1401-188-000desutoN

rehsawkcoldehteeTW1915C4M1605-468-000

rehsawkcoldehteeTW1915C3M1405-468-000desutoN

1. Open the monitor and fix it with the stay. See page 1-5 for instructions

4-10

Page 52

2. Remove the right arm cover from the control head. Fasten the M-card base

assy. to the right arm cover as follows:

a) Fasten the ground wire with the M4X8 pan-head screw and the M4 teethed

locked washer as shown below.

b) Fasten the right arm cover to the card case with three M4X8 pan-head screws

(supplied).

Pan-head screw

M4X8

Right arm cover

Ground wire

Pan-head screw

M4X8 (3 pcs.)

FRONT

Card slot

Toothed lock

washer M4

M-card base assy.

Figure 4-9 Fastening the M-card base assy. to the right arm cover

3. Unfasten four M4X8 screws from the PCB card case cover from the display

pedestal.

4. Pass the connector from the M-card base assy. through the hole in the display

pedestal.

PCB card slot

PCB card

case cover

Display pedestal

Figure 4-10 Display pedestal

5. Set the RP Board (14P0298) in the top slot of the PCB card case.

4-11

Page 53

6. Run the connector from the M-card base assy. in front of the GYRO CONVERTER Board as in Figure 4-11.

7. Plug the connector from the M-card base assy. in J1 on the RP Board.

8. Fasten the ground wire from the connector at the location shown in Figure 4-

11.

RP connector

INT Board

Fasten ground wire from connector to this screw.

RP Board

ARP Board

SPU Board

Route cable between ARP and SPU Boards.

GYRO

CONVERTER

Board

(TOP VIEW)

J1

(FRONT VIEW)

FRONT

Figure 4-11 Display pedestal, front and top views

9. Fasten the PCB card case cover to the display pedestal.

10.Close the monitor, and then fasten the right arm cover.

Separate type control head

Necessary parts: RP-26-Z-2E (Code no. 008-491-400)

emaNepyTytQ.oNedoCskrameR

.yssAesaBdraC-M—1—

draoBPR8920P411046-784-800

BwercSdaeh-naPW0072C8X4M4544-188-000

BwercSdaeh-naPW0072C8X3M2404-188-000desutoN

AwercSdaeh-naPW0072C5X6.2M2379-008-000desutoN

AwercSdaeh-naPW0072C8X3M1401-188-000desutoN

rehsawkcoldehteeTW1915C4M1605-468-000

rehsawkcoldehteeTW1915C3M1405-468-000desutoN

,.yssaelbaC,draoBFI

.yssaesabdrac-M

4-12

Page 54

1. Open the monitor and fix it with the stay. See page 1-5 for instructions.

2. Fasten the M-card base assy. with one M4X8 pan-head screw as below.

Fasten with

M4 x 8 screws.

Fasten with M3 x 8

screws (2 pcs.)

Figure 4-12 Display unit, inside view

3. Fasten the ground wire with the M3X8 pan-head screw and M3 teethed lock

washer.

4. Fix the M-card case assy. with two M3X8 pan-head screws.

5. Set the M-card case cover to the hole in the front panel and fix with two M2.6X5

pan-head screws.

Pan-head screw B

Pan-head screw A

M3X8

Teethed lock washer

M3

M4X8

M-card base assy.

1

2

3

4

5

6

7

8

8

1

Pan-head screw

M2.6X5, 2 pcs.

Pull forward

and fix.

M-card case cover

Pan-head screw B

M3X8, 2 pcs.

Figure 4-13 Display pedestal, front view

4-13

Page 55

6. Unfasten four M4X8 screws to remove the PCB card case cover at the front of

the display pedestal.

7. Set the RP Board (14P0298) in the top slot of the PCB card case.

8. Run the connector from the card case in front of the GYRO CONVERTER

Board as shown in Figure 4-14.

9. Plug the connector from the M-card base assy . in J1 on the RP Board as shown

in Figure 4-14.

RP connector

INT Board

Fasten ground wire from connector to this screw.

RP Board

ARP Board

SPU Board

Route cable between ARP and SPU Boards.

GYRO

CONVERTER

Board

(TOP VIEW)

J1

(FRONT VIEW)

FRONT

Figure 4-14 Display pedestal, front and top views

10.Fasten the ground wire from the connector at the location shown in Figure 4-

14.

11.Fasten the PCB card case cover to the display pedestal.

12.Close the monitor.

4-14

Page 56

4.4 Performance Monitor PM-30

Necessary parts: PM-30 and OP03-150 (Code no. 008-485-490)

Contents of Performance Monitor Kit OP03-150

emaNepyTytQ.oNedoC

draoBNI-MP5229P301026-784-800

BwercSdaeh-naPW0072C8X3M3404-188-000

.yssArotcennoCAA-003L-P3HV2410-141-000

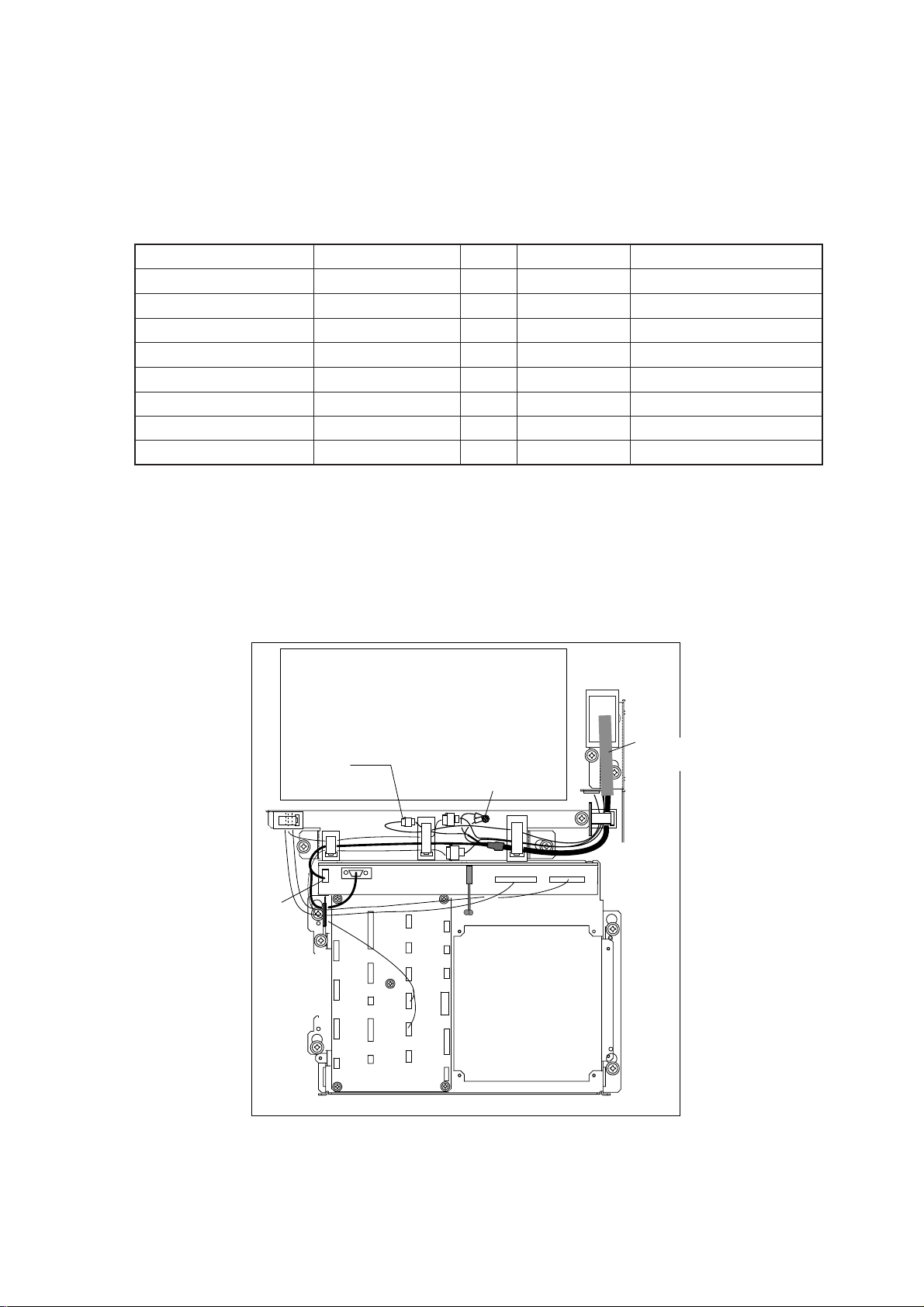

1. Open the monitor and fix it with the stay. See Chapter 1 for instructions.

2. Fasten the PM Board 03P9225 to the location shown below with three screws

(M3X8).

J403

PM Board

03P9225

J401

J411

J402

Figure 4-15 Display unit, inside view

3. Connect J411 to J401 on the PM Board.

4. Connect two connector assemblies (VH3P-L300-AA) to J402 and J403.

5. Solder the other end of the connector assemblies with external cables, one

from ship’s mains and one from the PM-30.

6. Close the monitor.

4-15

Page 57

4.5 Alarm Kit

Necessary parts: OP03-156 (Code no. 008-500-650)

The alarm kit mainly consists of a circuit board and connection cables, and provides alarm output to ship’s bridge alarm system.

Contents of Alarm Kit OP03-156

emaNepyT.oNedoCytQ

draoBMRALA2629P30086-005-8001

.yssArotcennoCHN)P9-9(0991-30007-005-8001

.yssArotcennoCHN)P3(1991-30017-005-8004

dnaBelbaCN3-PH100-075-0001

eiTelbaC001-VC223-075-0003

BwercSdaeh-naPW0072C8X3M404-188-0004

BwercSdaeh-naPW0072C21X4M744-188-0001

Procedure

Refer to the figure below for parts locations.

1. Raise the monitor and fix it with the stay. (See page 1-5 for instructions.)

2. Unfasten four screws to dismount the shield cover for the INT Board.

3. Fasten the ALARM Board to the display unit with four pan-head screws (M3X8,

supplied).

4. Connect the NH connector (9-9P, supplied) between J471 on the ALARM Board

and J451 (EXT-BUZ) on the INT Board, passing it through the cable band and

binding it with existing cable tie.