Page 1

Page 2

(

C

9-52, Ashihara-cho,

Nishinomiya, Japan

Telephone: 0798-65-2111

Telefax: 0798-65-4200

All rights reserved.

Printed in Japan

Your Local Agent/Dealer

FIRST EDITION : AUG. 1995

M : JUL. 3, 2001

PUB. No. IME-34070-M

TENI)

FAR/FR-2835S

Page 3

Page 4

Page 5

TABLE OF CONTENTS

EQUIPMENT LISTS............................................................................ v

1. MOUNTING

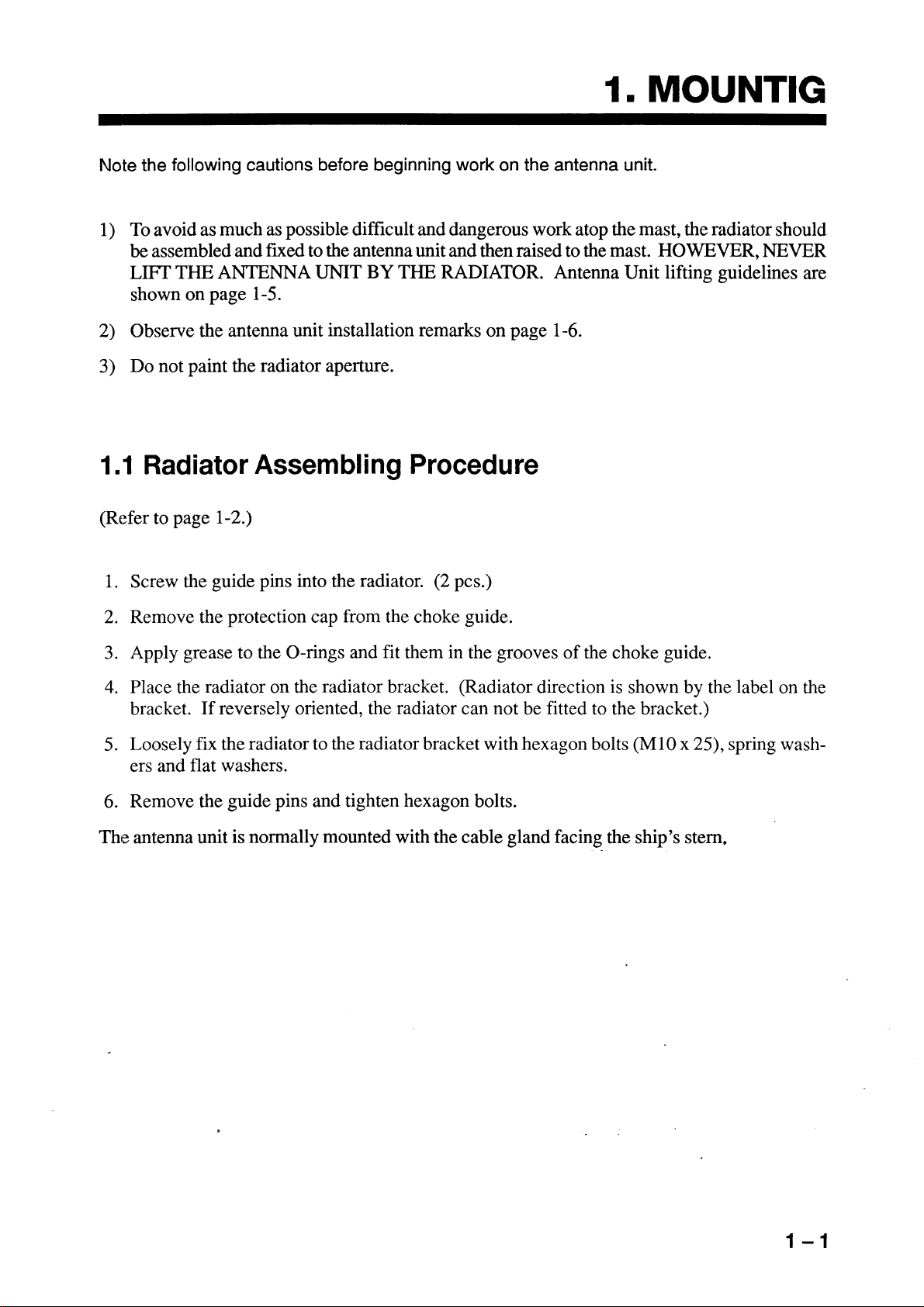

1.1 Radiator Assembling Procedure ......................................................................................1-1

1.2 Mounting Structures ........................................................................................................1-3

1.3 Mounting the Antenna Unit on the Mounting Platform...................................................1-4

1.4 Mounting the Display Unit ..............................................................................................1-8

1.5 Mounting the Separate Type Control Panel .....................................................................1-9

2. CONNECTIONS

2.1 Antenna Unit Connections ...............................................................................................2-1

2.2 Display Unit Connections................................................................................................2-6

2.3 Changing Power Specifications.....................................................................................2-13

2.4 Power Supply Unit.........................................................................................................2-14

3. INITIALIZATION AND ADJUSTMENT

3.1 Menus for Initialization and Adjustment .........................................................................3-1

3.2 Heading Alignment ..........................................................................................................3-2

3.3 Adjusting Sweep Timing .................................................................................................3-2

3.4 Adjusting Video Signal Level..........................................................................................3-3

3.5 Suppressing Main Bang...................................................................................................3-4

3.6 Confirming Tuning ..........................................................................................................3-4

3.7 Confirming Magnetron Heater Voltage ...........................................................................3-5

3.8 Initial Settings Menus ......................................................................................................3-6

3.9 Setting the Function Keys................................................................................................3-8

3.10 Default of InitialSetting Menus ...................................................................................3-11

3.11 How to adjust ARP board ............................................................................................3-12

3.12 Installation Check List.................................................................................................3-14

4. INSTALLATION OF GYRO CONVERTER GC-8 (option)

4.1 General Procedure for Installing and Setting up the GYRO CONVERTER Board ........4-1

4.2 Connection of External Power Supply ............................................................................4-3

4.3 Confirming Gyrocompass Specifications ........................................................................4-3

4.4 Changing Settings on the GYRO CONVERTER Board .................................................4-4

4.5 Setting the Bearing on the Radar Display........................................................................4-8

iii

Page 6

LIST OF INSTALLATION MATERIALS, ACCESSORIES AND

SPARE PARTS

LIST OF INSTALLATION MATERIALS, ACCESSORIES AND SPARE PARTS

......................................................... L-1 to L-13

OUTLINE DRAWINGS

OUTLINE DRAWINGS........................................................................................... D-1 to D-6

SCHEMATIC DIAGRAMS

SCHEMATIC DIAGRAMS .......................................................................................S-1 to S-6

iv

Page 7

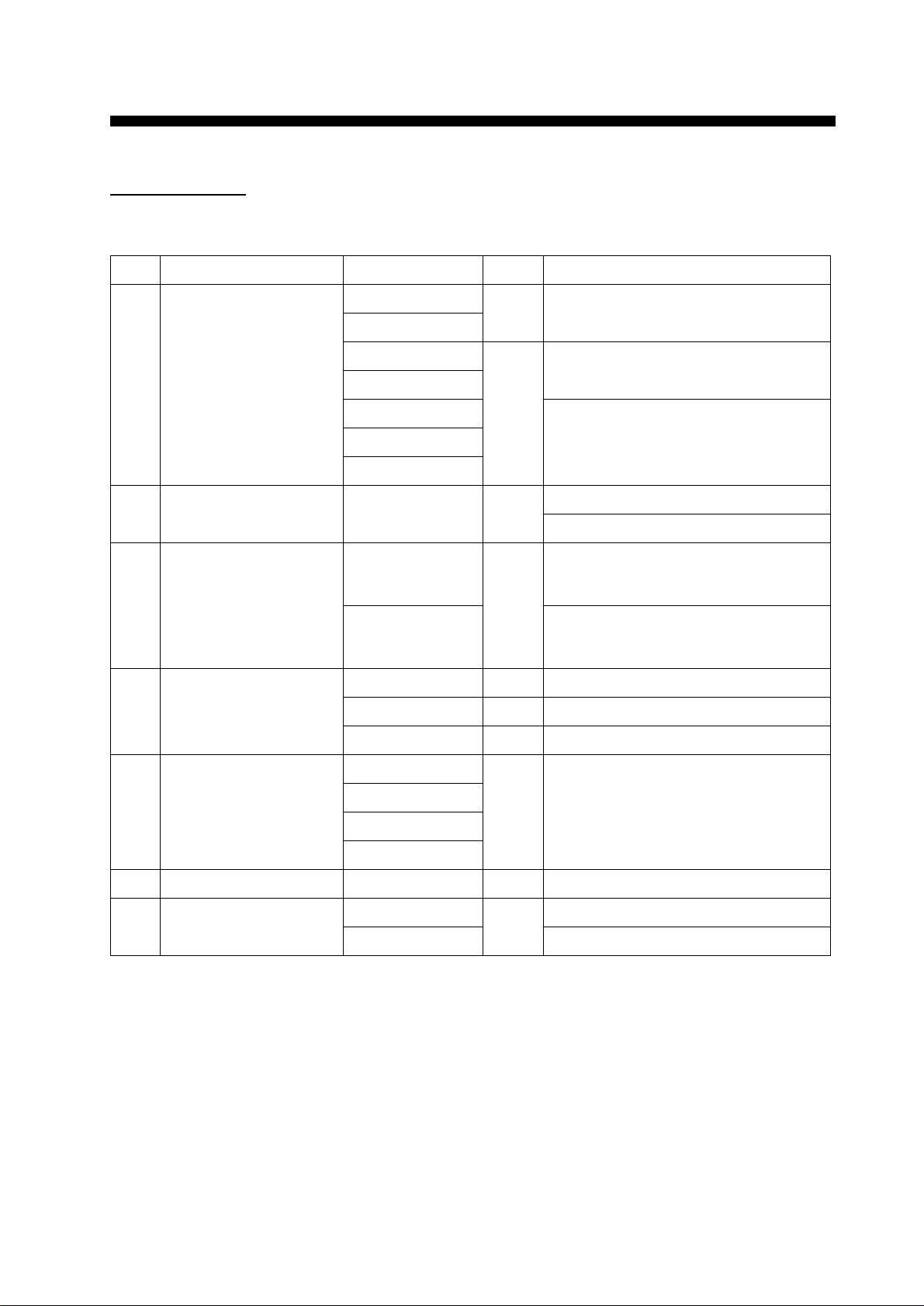

Complete set

.oNemaNepyTytQskrameR

1tinurennacSFA63-NS1rotaidarannetnA

FA03-NS

6200-BSR1tinurennacS

1300-BSR

8800-BSRCSHroftinurennacS

9800-BSR

0900-BSR

2tinuyalpsiD511-PDR1 epyttnuomlatsedeP

EQUIPMENT LISTS

epytpotelbaT

3seirosseccA01750-30PFtes1,10750-30-PF,tinulortnocni-tliubroF

1181

03750-30PF,10750-30-PF,tinulortnocetarapesroF

4slairetamnoitallatsnI30641-30PCtes1tinurennacsroF

20641-30PCtes1tinuyalpsidroF

70931-30PCtes1tinuylppusrewoproF

5elbaclangiS*m51*5986-WR1

*m02*5986-WR

*m03*5986-WR

*m06*5986-WR

6straperapS00611-30PStes110311-30PS,02301-30PS

7tinUylppuSrewoPS-32-07-400-USP1 A3.2,CAV002/002,ø3

S-01-08-400-USPA0.1,CAV044/083,ø3

-331-30,50750-30-PF,40750-30-PF

-30-PF,40750-30-PF,30750-30-PF

1181-331-30,50750

v

Page 8

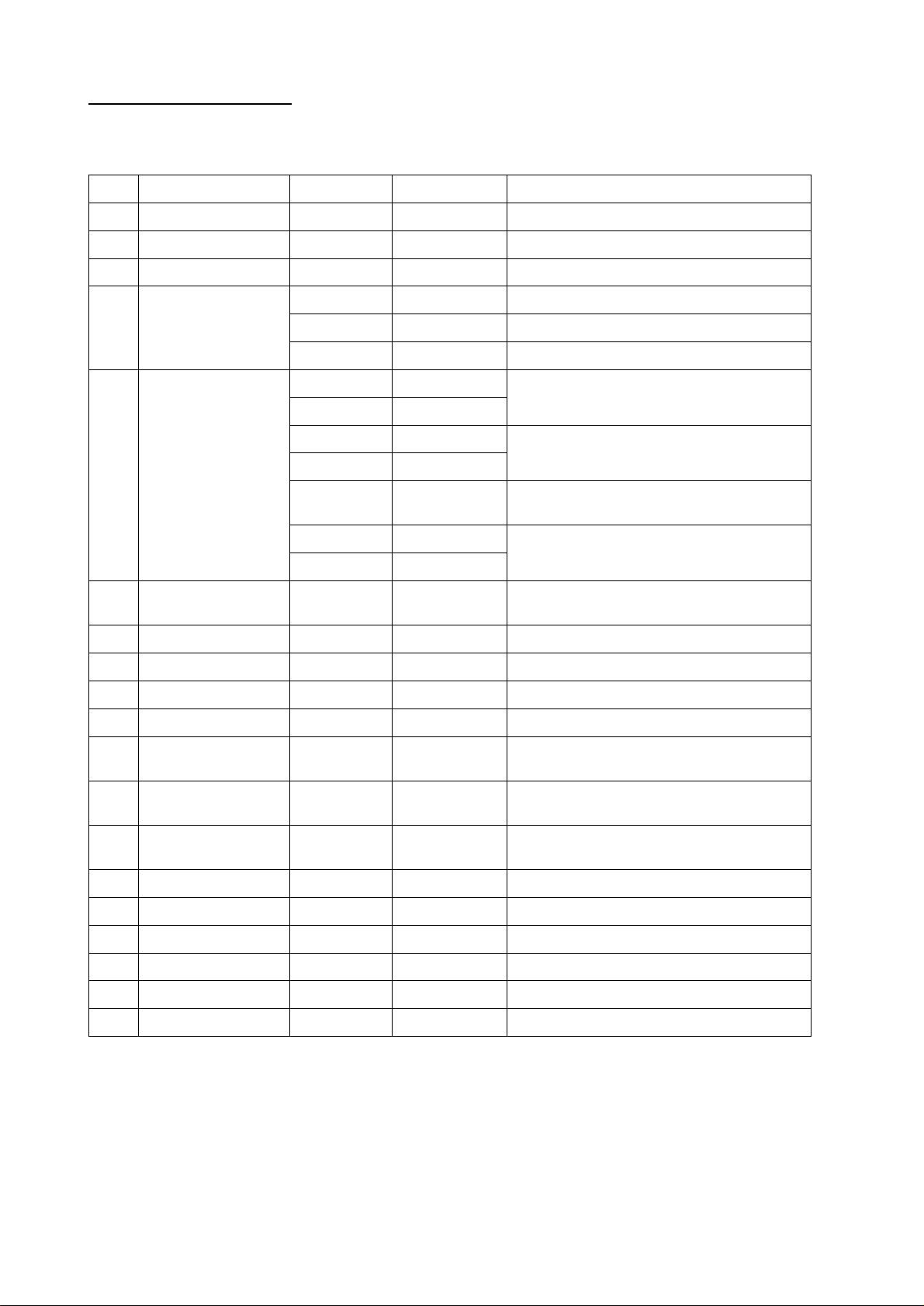

Optional equipment

.oNemaNepyT.oNedoCskrameR

1spirgdnaH07-30PO024-324-800tinuyalpsidroF

2etalpgnixifdracM331-30PO004-254-800

3dooH4750-30PF018-954-800

4revoctinuyalpsiD621-30PO028-954-800tinulortnocni-tliub/wpotelbaT

721-30PO067-954-800tinulortnocetarapes/wpotelbaT

821-30PO098-954-800tnuomlatsedeP

5tinuyalpsiD

tiknoisrevnoc

6lenaplortnoC

etalpgnixif

7rettolpoediV52-PR

8retrevnocoryG2-8-CG025-644-800slairetamnoitallatsnihtiW

9hctiwsretnI7-JR

01rezzublanretxE12-30PO790-030-000rotcennochtiw,m1

11ecnamrofreP

rotinom

21tinuegnaR

tiknoisrevnoc

1-921-30PO038-954-800ni-tliub/epytpotelbatmorfstrevnoC

2-921-30PO014-254-800

1-031-30PO009-954-800etarapes/epytpotelbatmorfstrevnoC

2-031-30PO034-254-800

131-30PO019-954-800potelbatottnuomlatsedepmorfstrevnoC

1-231-30PO029-954-800potelbatottnuomlatsedepmorfstrevnoC

2-231-30PO054-254-800

431-30PO043-164-800ottinulortnocepytetarapesgninetsafroF

05-MP

1-011-30PO016-644-800mkoT

tnuomlatsedepottinulortnoc

tnuomlatsedepottinulortnoc

tinulortnocni-tliub/epyt

tinulortnocetarapes/epyt

potelbata

31tinuegnaR

tiknoisrevnoc

41tinuyalpsidroloC141-DC

51tinuyalpsidevalS0008-DMF

61tinuremrofsnarT8571-UR614-030-000CAV001otCAV022strevnoC

71tinuremrofsnarT3081-UR024-030-000CAV001otCAV044strevnoC

81hctiwsretnI8-JR

91tinuecafretnI0032-FI224-200-000

2-011-30PO002-254-800msoT

vi

Page 9

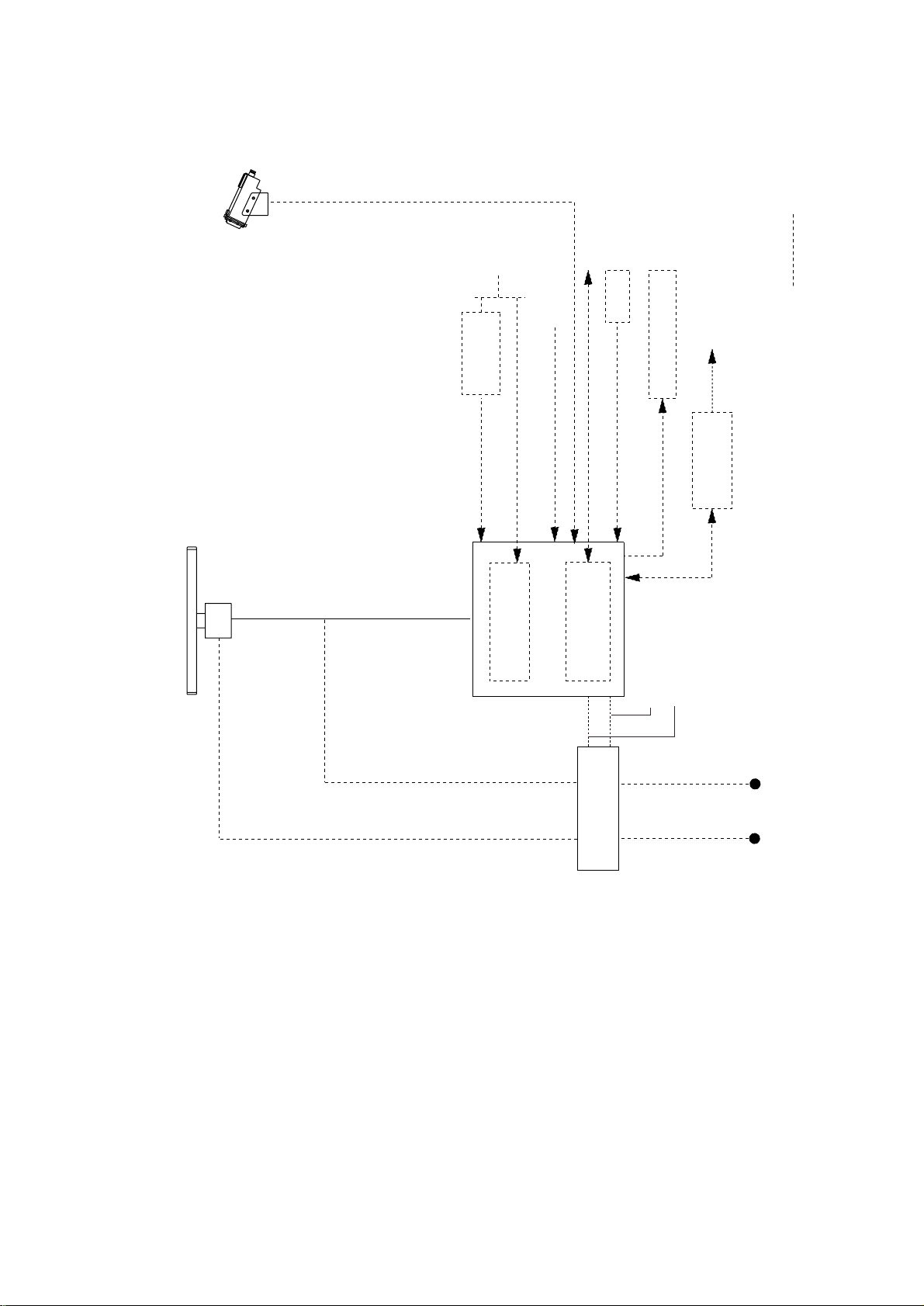

PM-50

250V-DPYC(Y)-1.25

115/230 VAC, 1φ

Optional Supply

Performance Monitor (option)

SCANNER ANTENNA

RSB-0026/0031

RSB-0088/0089/090 (For HSC)

RW-6895

Gyro Converter

CO-SPEVV-SB-C

DISPLAY UNIT

Gyro

Speed Log

250V-DPYC(Y)-1.25

250V-MPYC(Y)-5

Gyro Interface GC-8

INS

NAV

External Buzzer

CO-SPEVV-SB-C

Video Protter RP-25

2C 1.5 m

250V-DPYC(Y)-3.5

Other Radar

system

RJ-7/8

Interswitch

250V-MPYC(Y)-5

FR/FAR-2835S System Configuration

250V-DPYC(Y)-3.5

Power Supply

PSU-004

250V-DPYC(Y)-3.5

For display unit

Display unit

115/230 VAC, 1φ

660V-TPYC(Y)-3.5

250V-TPYC(Y)-3.5

For scanner unit

380 VAC, 3φ, 50 Hz

440 VAC, 3φ, 60 Hz

(For HSC)

Scanner unit

220 VAC, 3φ, 50 Hz

220 VAC, 3φ, 60 Hz

220 VAC, 3φ, 50 Hz

220 VAC, 3φ, 60 Hz

440 VAC, 3φ, 60 Hz

vii

Page 10

Page 11

Page 12

Page 13

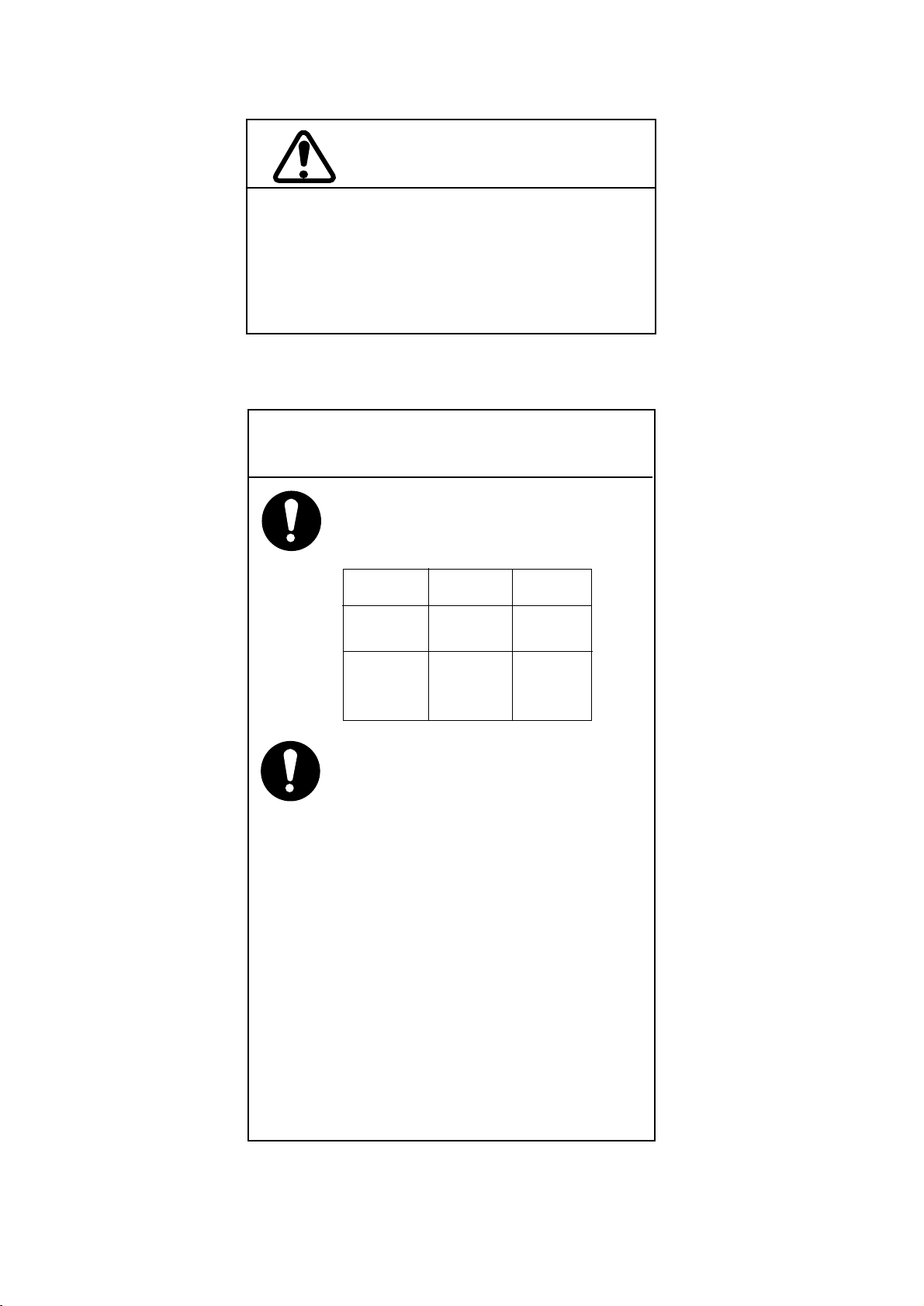

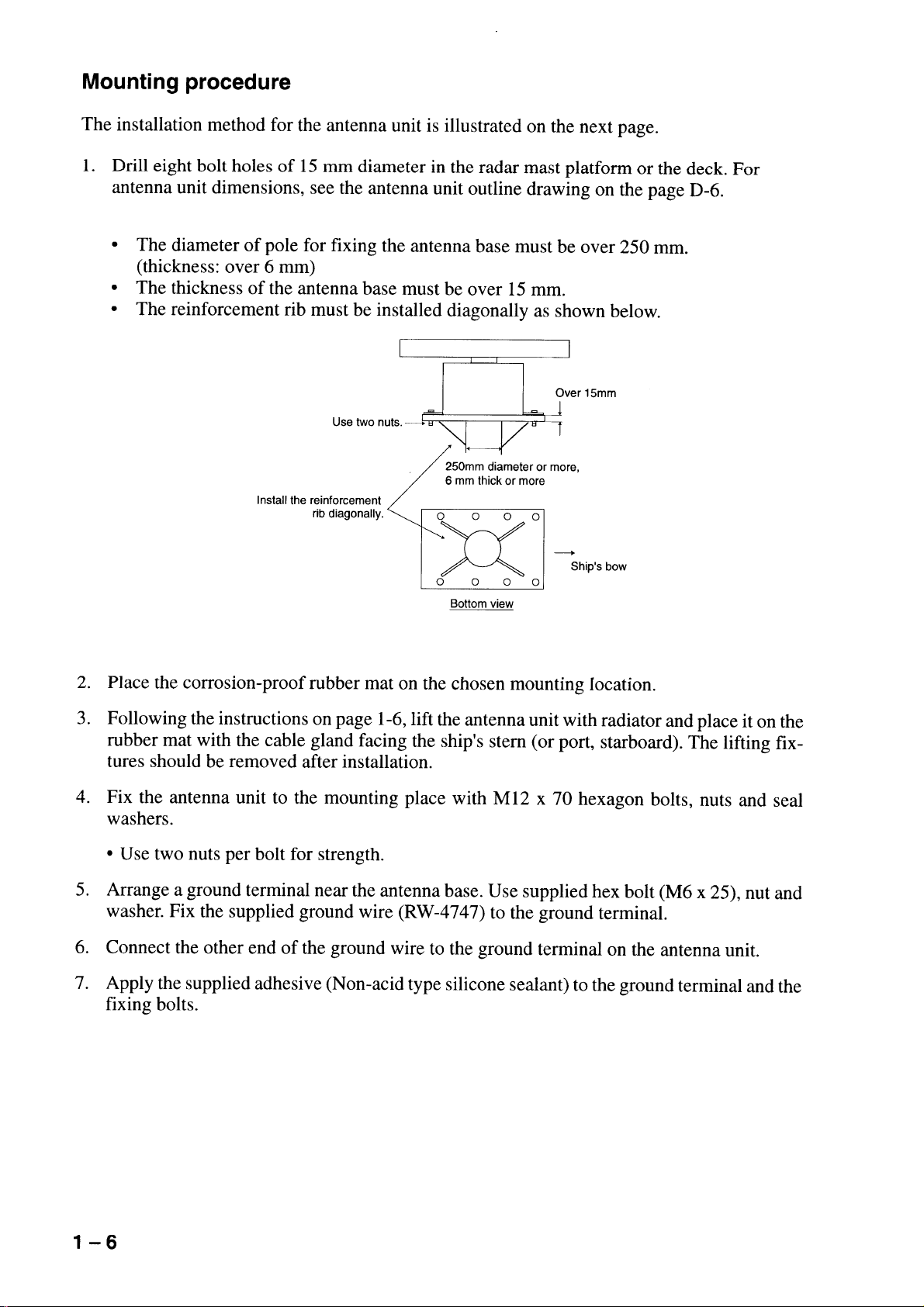

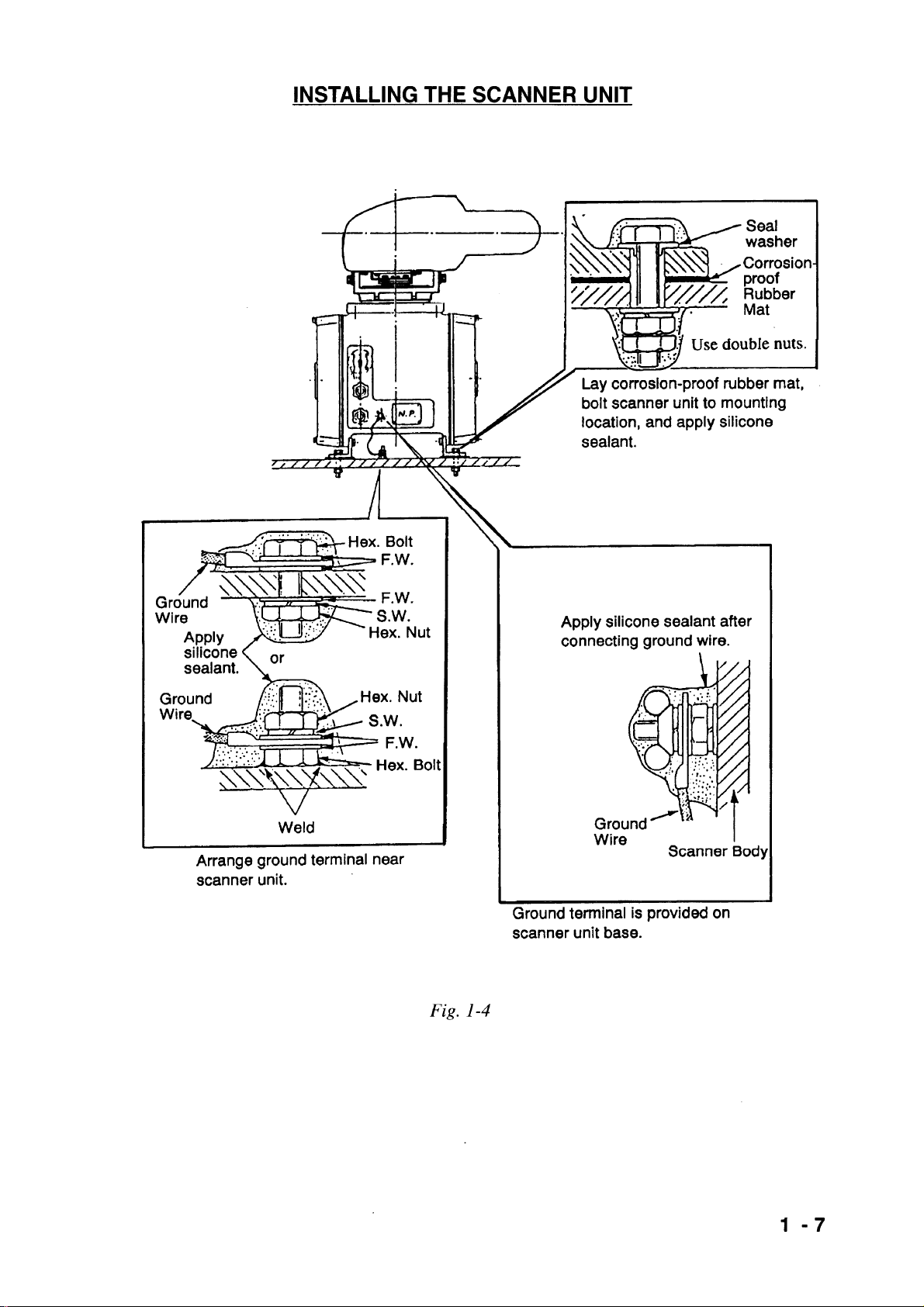

1.3 Mounting the Antenna Unit on the Mounting Platform

CAUTION

1) Work at high places is dangerous. Always wear a

hard hat and safety belt when working on the

antenna unit mast.

2) Both a service platform and steps to the service

platform must be mounted to provide safe access

for service personnel. Improperly installed

platforms present a hazard to service personnel.

Siting considerations

CAUTION

A magnetic compass will be affected if

placed too close to the antenna unit.

Below are the minimum safe distances

for magnetic cpmpassis.

Antenna

RSB-0026

RSB-0031

Standard

Compass

4.8 m

Steering

Compass

3.6 m

RSB-0088

RSB-0089

RSB-0090

Consider the following points when selecting

a mounting location for the antenna unit.

¥ No funnel, mast or derrick should be within

the vertical, beam width of the antenna in

the bow direction, especially zero degrees

–5°, to prevent blind sectors and false

echoes on the radar picture.

¥ Fumes from the funnel or other exhaust

vent can adversely affect performance and

hot gas can distort the radiator. The antenna

unit must not be mouonted in a place where

the temperture may exceed 70°C.

¥ Leave sufficient space around the unit for

maintenance ans servicing. See the

antenna unit outline drawing for recommen ded maintenance space.

¥ Locate the unit well away from the aerial of

a radiotelephone or navigation receiver to

prevent interference. Separation of more

than two meters is recommended.

1-4

Page 14

Page 15

Page 16

Page 17

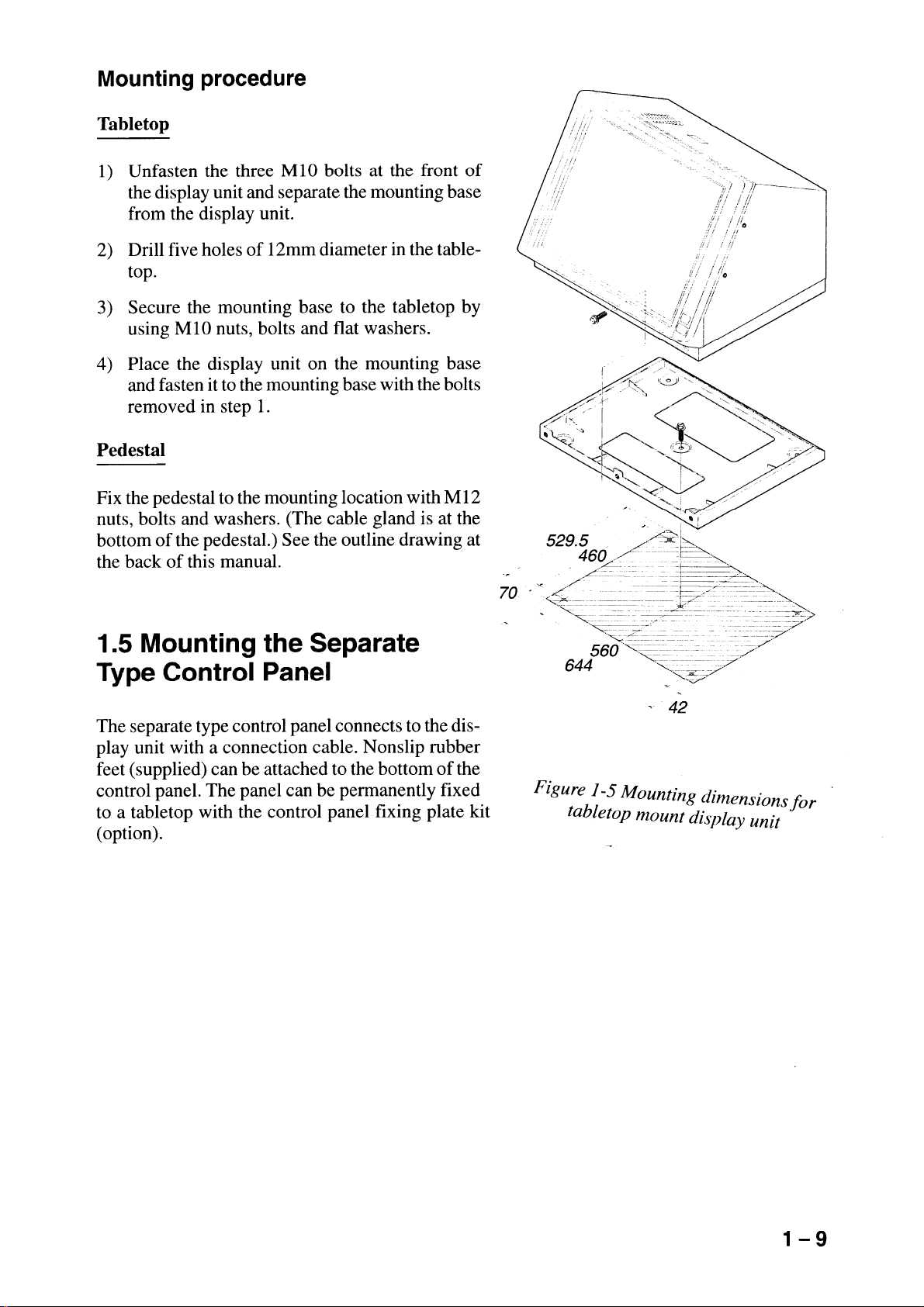

1.4 Mounting the Display Unit

The display unit is designed to be mounted on a tabletop or a pedestal (option).

Before mounting the display unit

If Gyro Converter GC-8 (option) is to be used, install and setup the GYRO PROCESSOR

Board before mounting the display unit, because of the difficulty involved if done after the unit

is mounted, Insstrutions for installtion and setup are in Chapter 4.

Siting considerations

Lpcate the display unit on the bridge in a place where it can be viewed and operated conveniently. In addition, consider the points noted in the figure which follows.

CAUTION

A magnetic compass will be affected if

placed too close to the display unit.

The minimum compass safe distances

for magnetic compasses are

standard compass: 2.7 m

steering compass: 1.8 m

Consider the points mentioned below

when selecting a mounting location for the

display unit.

¥ The orientation of the display unit should

be so the operator views the screen while

facing the bow. This makes determination

of position much easier.

¥ The location should be free of water spray.

¥ The daylight bright type radar display

sunlight. However, locate the unit out of

direct sunlight and away from heat sources

because of heat that can build up inside

the cabinet.

¥ The mounting location should be deter mined consiering the lengt of the signal

cable between the antenna unit and the

display unit. (The signal cable comes in

lengths of 15, 20 or 30 meters; maximum

100 meters.)

¥ Leave sufficient space around the unit for

maintenance and servcing. See the display

unit ouline drawing forrecommended

maintenance space.

1-8

Page 18

Page 19

2. CONNECTIONS

2.1 Antenna Unit Connections

Two cables run between the display unit and the antenna unit, the signalcable and the antenna

cable.

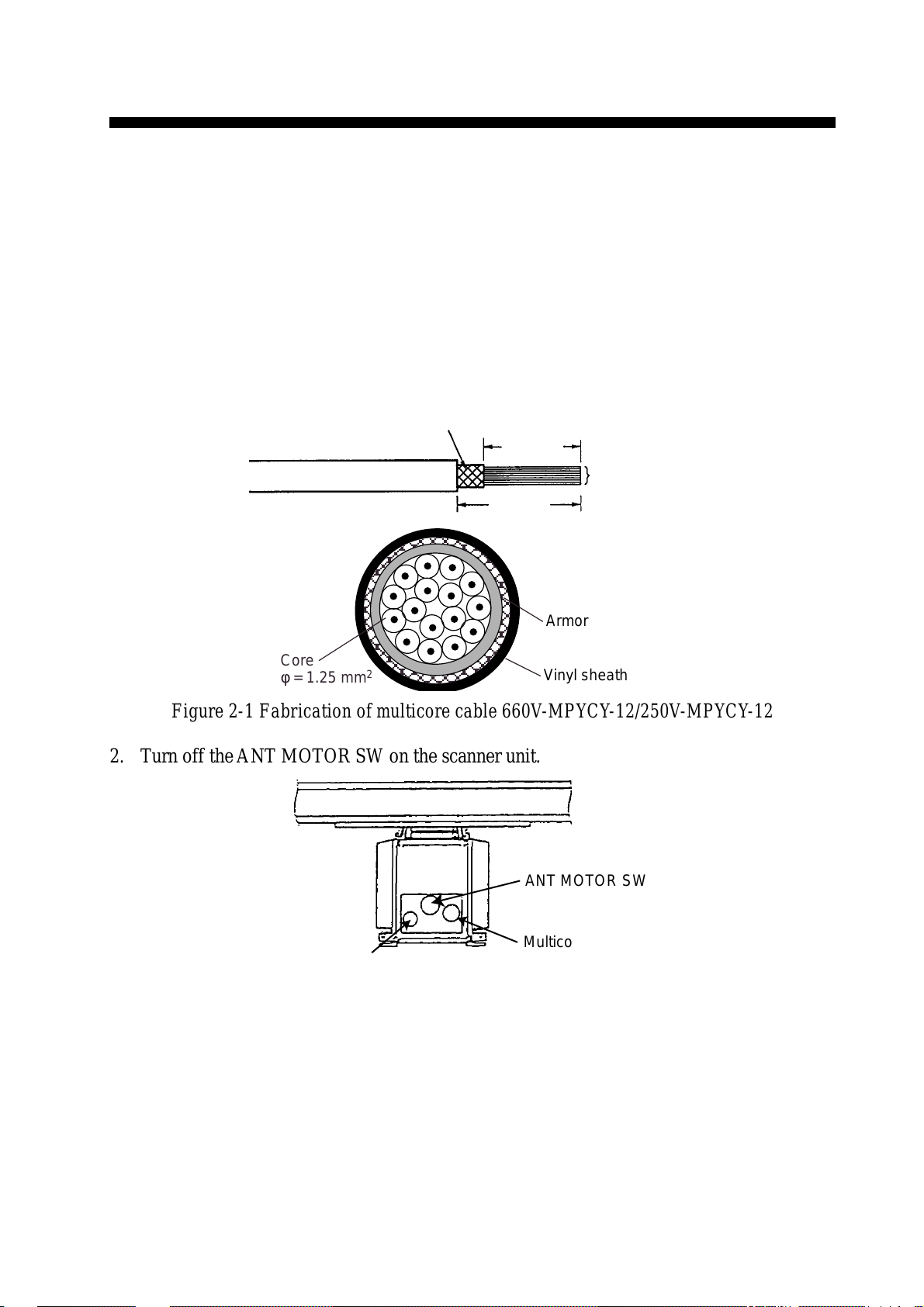

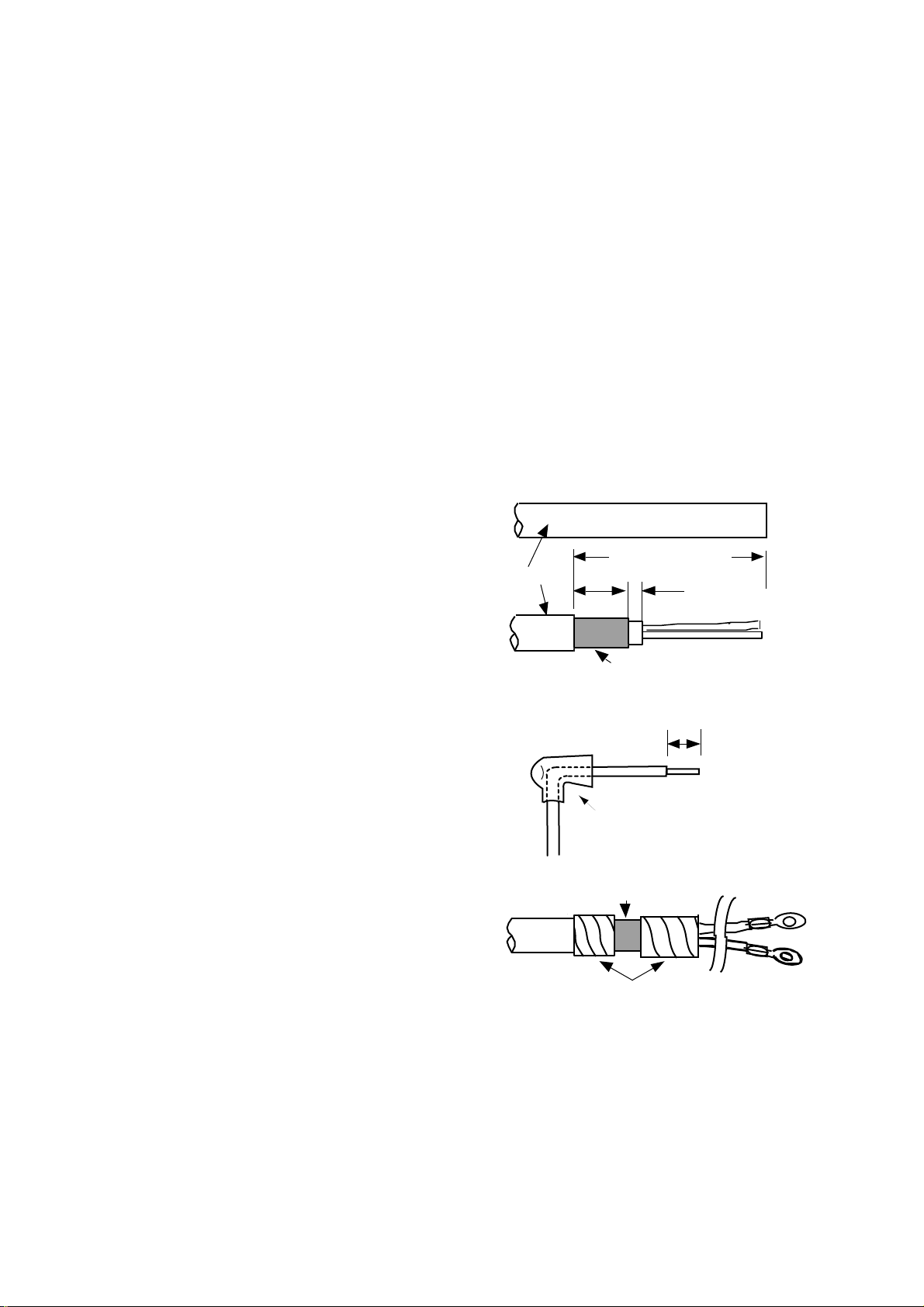

Fabricating antenna cable 660V-MPYCY-12/250V-MPYCY-12 (JIS cable)

1. Shorten the cable making the length from the cable gland to the cable end inside the scanner

unit 450 mm. Remove the vinyl sheath of the cable by 450 mm; the armor by 440 mm.

Armor

440 mm

Conductors

450 mm

Armor

Core

φ = 1.25 mm

2

Vinyl sheath

Figure 2-1 Fabrication of multicore cable 660V-MPYCY-12/250V-MPYCY-12

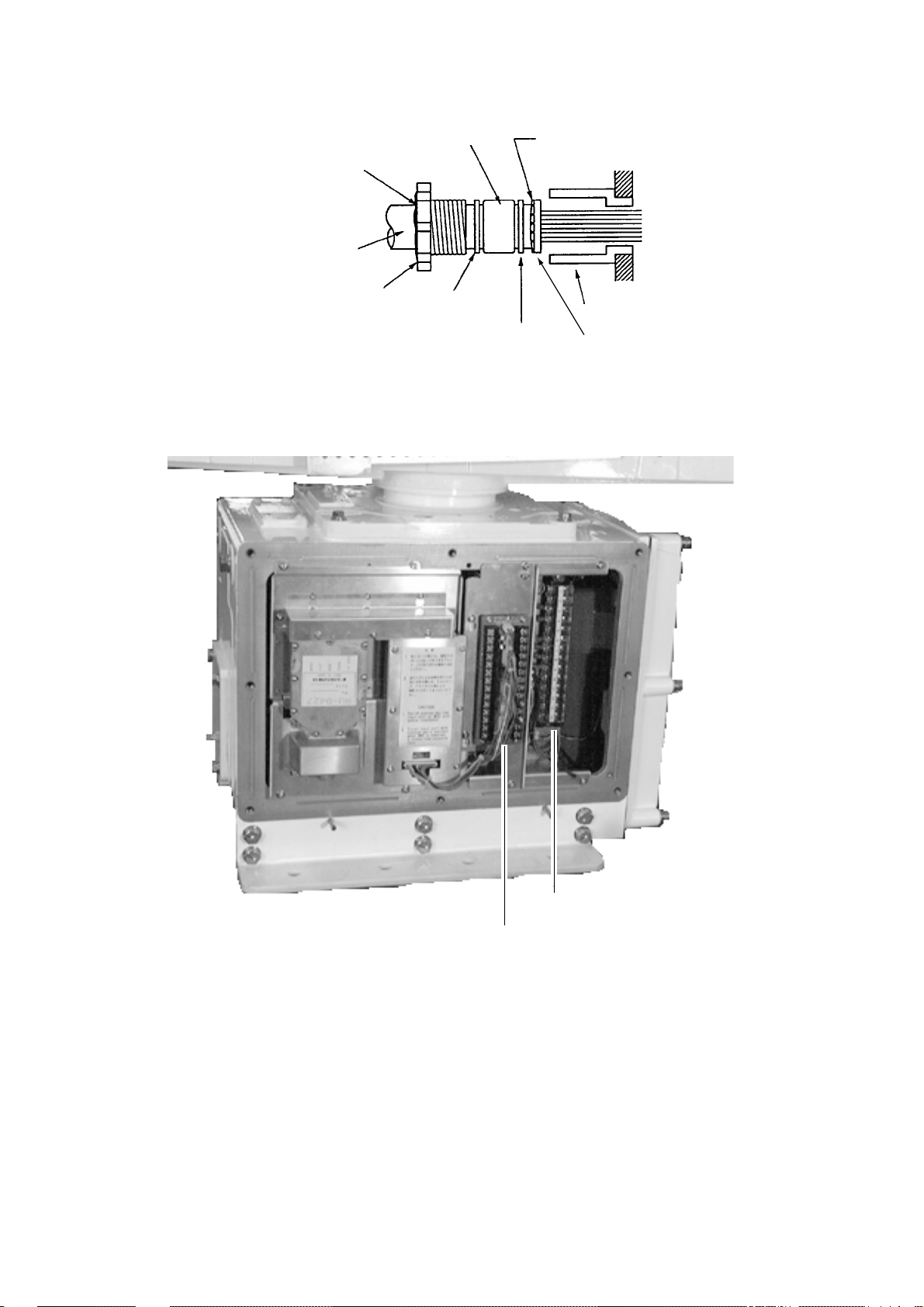

2. Turn off the ANT MOTOR SW on the scanner unit.

ANT MOTOR SW

Signal cable

(RW-6895)

Multicore cable

(250V-MPYCY-12 or

660V-MPYCY-12)

Figure 2-2 Scanner unit, bow view

3. Open the left side cover on the scanner unit with the hex wrench (Supplied).

4. Unfasten the cable gland for the multicore cable and remove the gasket and flat washers.

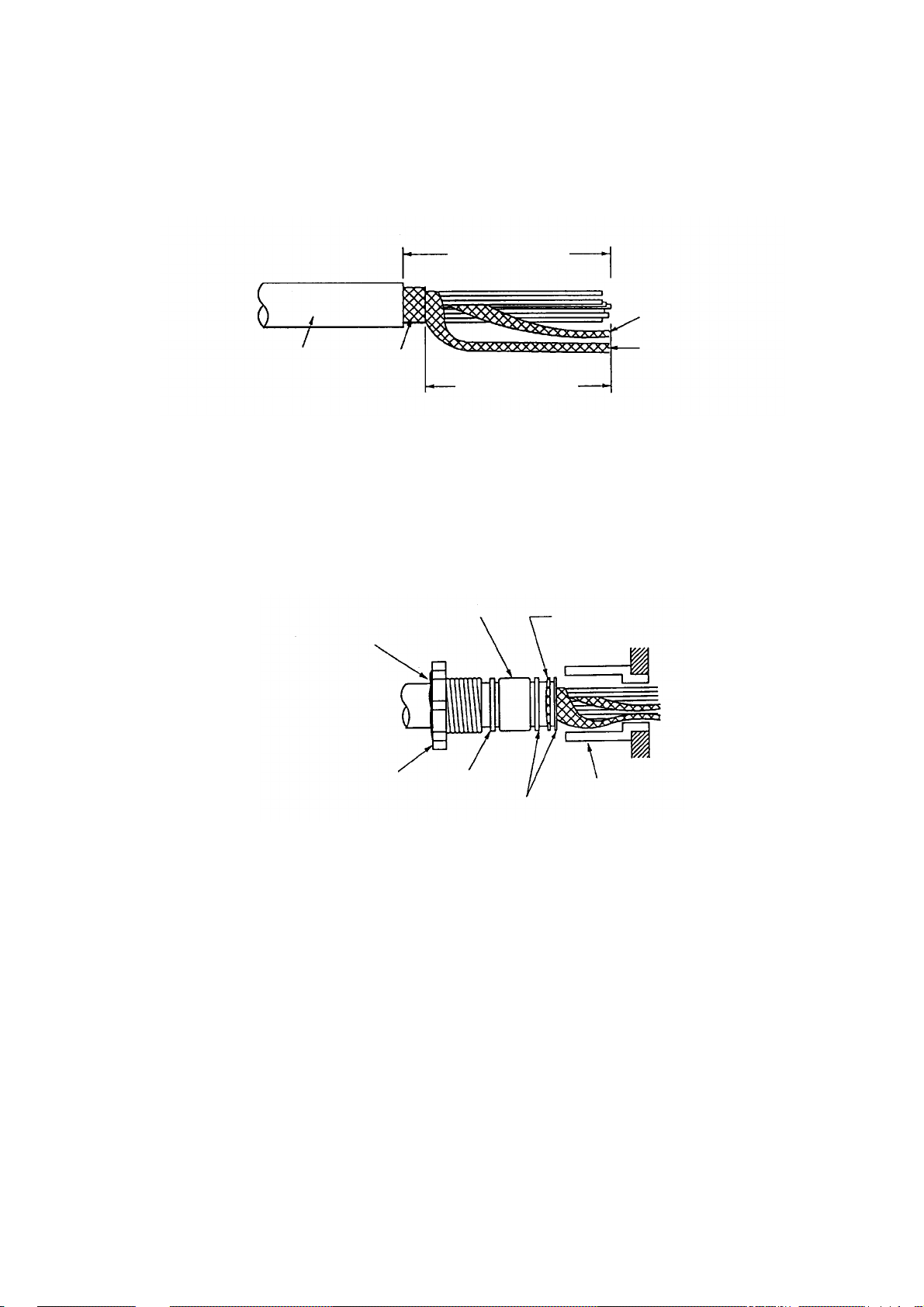

5. As shown in Figure 2-3, slide the clamping gland, flat washers and gasket on the multicore

cable.

2-1

Page 20

6. Fold back armor by 5 mm and pass it through the two flat washers as shown in Figure 2-3.

Gasket

Seal with putty

after tightening.

Vinyl sheath

Clamping gland

Flat

washer

Armor (folded back)

Cable gland

Flat

washer

Flat

washer

Figure 2-3 Passing clamping gland, washers and gasket on the multicore cable

7. Shorten conductors considering their locations on the terminal board STB-1.

STB-1

RTB-801

Figure 2-4 Scanner unit, port side view

8. Confirm that armor is grounded between two flat washers.

9. Remove the sheath of each conductor by 6 mm. Fix crimp-on lugs (FV1.25-4, blue, ø4) to

each conductor. Make sure each connection is secure both electrically and mechanically.

10. Tighten the clamping gland.

11. Seal the cable gland with putty.

12. Connect the conductors to terminal board STB-1 referring to the interconnection diagram

on page S-1.

2-2

Page 21

Fabricating signal cable RW-6895

13. At the signal cable gland on the scanner unit, unfasten the clamping gland and remove

gasket and flat washers.

14. Shorten the signal cable making the length from the cable gland to the cable end 500 mm.

Remove the vinyl sheath by 550 mm; the armor by 540 mm.

Approx. 550 mm

Inner shield

Anti-corrosive

vinyl sheath

Armor

Approx. 540 mm

Outer shield

Figure 2-5 Fabricating the signal cable RW-6895

15. Unravel the outer shield with a screwdriver or similar tool to expose the cores beneath the

outer shield. Similarly, expose the cores beneath the inner shield. Mark all cores for future

identification.

16. As shown in Figure 2-6, slide the clamping gland, washers and gasket onto the signal cable.

Fold back the armor by 5 mm, and then pass it through the two flat washers.

Seal with putty

after tightening.

Clamping gland

Gasket

Washer

Armor

Gland body

Washer

Figure 2-6 Passing clamping gland, washers and gasket on signal cable

17. Unfasten the terminal board R TB-801.

18. Pass the signal cable behind the terminal board plate for cable MPYCY-12, and then pass it

through the locking wire saddle.

2 - 3

Page 22

Terminal board fixing plate for RTB-801

Ground terminal

Figure 2-7 Scanner unit, rear view

Locking wire saddle

Figure 2-8 Scanner unit, rear view

19. Fasten the terminal board fixing plate for RTB-801.

2 - 4

Page 23

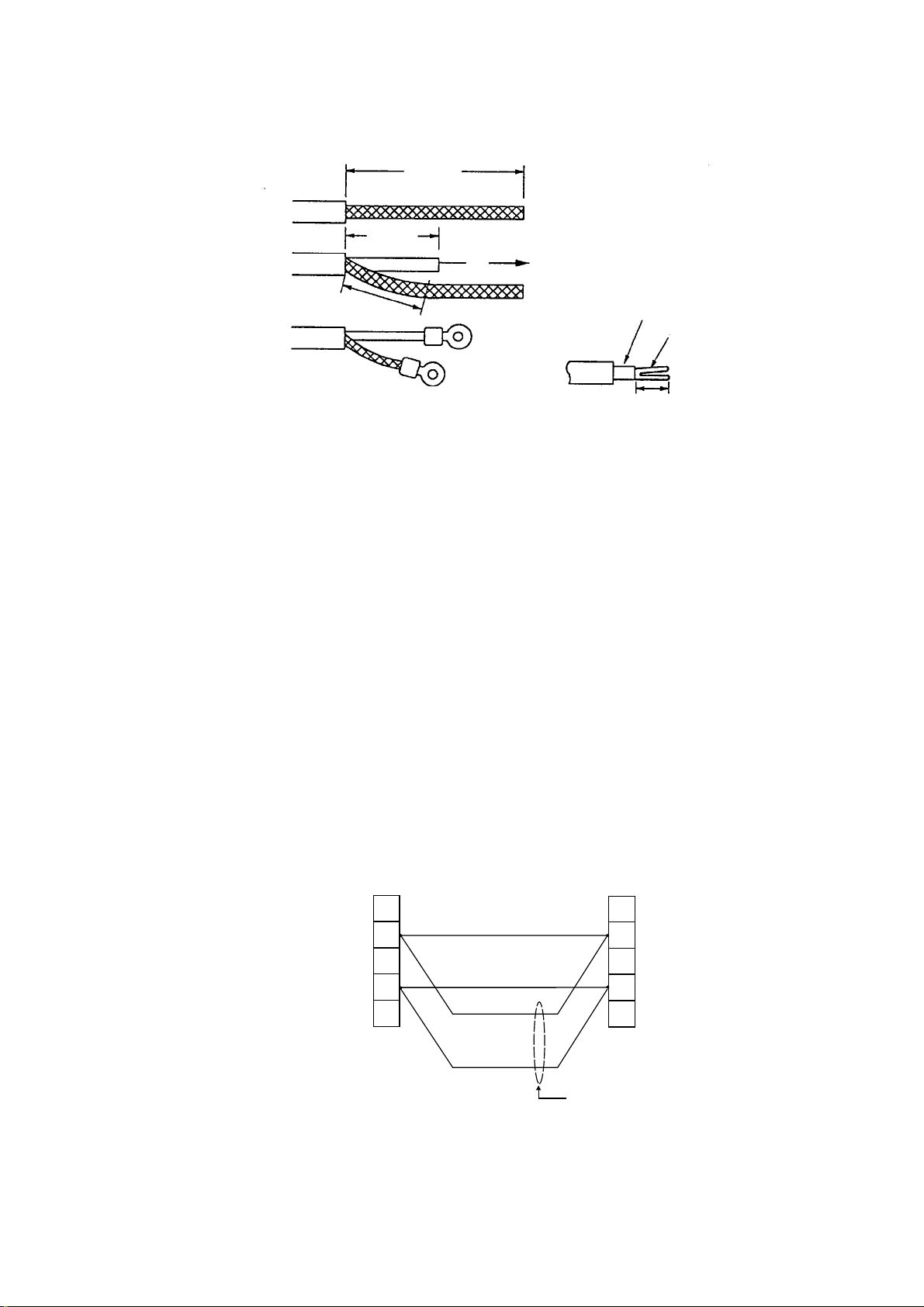

20. Route the signal cable beneath the lower left side of the terminal board fixing plate for the

RTB-801. Shorten conductors of the signal cable considering their locations on the RTB-

801.

50 mm

75 mm

Crimp-on lug

FV1.25-M3

(Red, ∅3)

Fold back the conductor

as illustrated below.

Crimp-on lug

FVD1.25-3

(Red, ∅3)

Inner core

Conductor

6 mm

Coaxial cable

2C-2V

45 mm

Figure 2-9 Fabrication of coaxial cable

21. Shorten the shield considering the distance to the ground terminal on the left side of the

scanner unit chassis. (See Figure 2-7 for location.) Attach the crimp-on-lug FV5.5-4 (ø4,

yellow) to the shield.

22. Remove approx. 6 mm of the vinyl insulation from the end of each conductor and fix the

crimp-on lug FV1.25-M3 (Red) to each conductor. As shown in Figure 2-8, fold back the

coaxial cable four times and attach the crimp-on-lug FVD1.25-3 (ø3, red). Attach the crimpon-lug FVD1.25 (ø3, red) to the shield.

23. Tighten the clamping gland, and then seal the cable gland with putty.

24. Fasten the shield to the ground terminal on the scanner unit chassis.

25. Connect conductors to the terminal board RTB-801 referring to the interconnection diagram.

When the length of the signal cable is more than 150 m, remove the solder at terminal Nos.

24 (red) and 26 (black) on the DJ-1 connector . (#24 and #25 are spares.). Fasten the wires as

shown below.

TB801

14

16

SCANNER

UNIT

Length 150 m

or more

HEATER HOT

+12V

DJ-1

14

16

DISPLAY

UNIT

YELLOW, LARGE

WHITE, LARGE

RED, LARGE

BLACK, LARGE

Figure 2-10 Wiring on terminal boards when length of signal cable is 150 m or more

26. Check for miswiring, loose screws. Grease the fixing bolts for the cover, gasket, and tap

holes in the scanner chassis. Attach the cover.

2-5

Page 24

When the De-Icer is installed

1) Before beginning any work on the scanner unit, turn off both the DE-ICER switch (S31) on

the sub panel of the display unit and the breaker for the de-icer line at the main switchboard

to remove the power (100 VAC, 1ø) to the de-icer. (T urning off the power to the display unit

has no effect.)

2) The neck of the scanner unit becomes VERY HOT when the de-icer is working. (The deicer turns on when ambient temperature is below 0°C.)

2.2 Display Unit Connection

Two cables are terminated at the display unit: the signal cable RW-4839 or RW-6895 and the

power cable. The signal cable, available in lengths of 15m, 20m, or 30m, comes with a connector preattached to it for connection to the display unit.

Fabricating power cable DPYCY -3.5

1) Remove the vinyl jacket by 150mm.

2) Cut off jute tape wrapped around the braided

shield.

3) Unravel the braided shield to expose the cores

by about 120mm.

4) Slip the terminal cap onto the core.

5) Remove insulation of cores by about 10mm.

Fix crimp-on lugs to the cores and braided

shield.

6) Cover the braided shield with vinyl tape, leaving the portion which will lie inside the cable

clamp untaped.

(a)

Vinyl jacket

(b)

(c)

(d)

DPYCY-3.5

Approx. 150 mm

15 mm

5 mm

Armor

10 mm

Terminal cap

Clamp here

2-6

Taping

Figure 2-11 How to fabricate

power cable DPYCY-3.5

Page 25

Leading in cables to the display unit

To lead in cables easily, unfasten the cable clamp at the right side of the display unit.

Cable

clamp

Figure 2-12 Location of cable clamp inside the display unit

Tabletop

Cables can be led in through the cable gland at the rear or underside of the unit.

Pedestal

Lead in cables through the cable gland

at the bottom right-hand side of the ped-

Process cable same as

on tabletop type

estal. Pass cables through the cable

clamp and tighten the cable clamp. Fix

cables to the pedestal frame with cable

ties as shown in Figure 2-13. Finally,

pass cables through the cable clamp at

the right side of the display unit and then

tighten the cable clamp.

Leaving sheath

intact, pass cable

through cable

clamp

Figure 2-13 How to lead in cables

through the pedestal

2 - 7

Page 26

Connections

Power cable

Connect the power cable to the filter at the right

hand side of the display unit. Cover the filter terminals with the terminal caps (supplied) to insulate the terminals.

Filter

Power

cable

Figure 2-14 Location of filter

inside the display unit

Gyro signal

Solder the 5 pin and 3 pin VH connectors (supplied) to the gyrocompass cable. Plug in the

connectors on the GYRO CONVERTER Board. For further details, see page 4-2.

GYRO CONVERTER

Board

Rear panel

Figure 2-15 Location of GYRO CONVERTER Board

HOW TO ATTACH NH CONNECTOR TO SIGNAL CABLE

NH connector wire

Shrink tubing

2 - 8

NH connector

housing

1 Insert NH connector

wire into NH connector

housing.

20mm

2 Cut shrink tubing

in 20 mm lengths and

slip onto each wire.

Solder

3 Solder connector

to signal cable.

4 Heat shrink

tubing with soldering iron.

Page 27

Grounding

The display unit must be grounded from

a grounding stud having a wing nut located at the point shown in Figure 2-16.

Tabletop type Pedestal type

CAUTION

An ungrounded unit can cause electrical shock when

its metallic parts are touched and give off or receive

electromagnetic interference.

Figure 2-16 Grounding the display unit

Radar buoy

Solder the radar buoy signal line to the "BUOY" connector on the VDA Board. Connect the

trigger line to the corresponding connector on the INT Board.

Signal input/output circuit (INT Board INT-9170)

Nav data

+5V

J450

1 TXD1-H

2 TXD1-C

3 RXD1-H

4 RXD1-C

+5V

5 DTR1-H

6 DTR1-C

7 DSR1-H

8 DSR1-C

2SC1015

PC900V

+5V

1

2

+5V

+5V+5V

6

Vcc

A

X

GND

OUT

5

4

Figure 2-17 INT Board circuit

For other input/output circuits, see the circuit diagram of the INT Board at the back of this

manual.

2-9

Page 28

Table 2-1 Input and output signals on the INT Board

emanlangiSnoemaN

bcp

langiStupnI

langisoryG*4J

goldeepS

langis

)edit(langis

)deeps(langis

youbradaR

langis

yalpsidetomeR

langis

elgnaredduR

langis

langiStuptuO

APRAlanretxE

langis

GOL844Jnip3,HN.cte,mn/seslup002

rotacidnitnerruC

VAN

rotacidnitnerruC

VAN

YOUB

TOR

rotcennoC

.on

*5J

954Jnip4,HNdesutoN

ESRUOC

064Jnip3,HNdesutoN

DEEPS

RADAR

RADAR-TXE

7-JRro

REDDUR

APRA-TXE444Jnip8,HN5082-AF,gniraeb,gnidaeh

544Jnip4,HN

854Jnip8,HN

464Jnip7,HN

epyt

rotcennoC

nip5,HV

nip3,HV

elbacilppA

tnempiuqe

skrameR

bcpnO:*

)noitpo(6011P46A

reggirtxT

yalpsidevalS

langis

langisrezzuBZUB-TXE154Jnip3,HN3-12-30POlangisevirdrezzub

langisrezzuB

)CA(

langisrotinoM944Jnip01,HN,suonorhcnysREV

8-JR8-JR654Jnip4,HN

atadSNIATAD.SNI554Jnip5,HN

7-JR7-JR754Jnip51,HN

EVALS244J

)CA(

langiStuptuO/tupnI

344J

ZUB-TXE

254Jnip2,HNpma/wrekaepSlangisrekaeps

nip8,HN,141-DC,041-DC

nip8,HN

,gniraeb,gnidaeh

,005-DG

,008-DMF

1*0008-DMF

roftinuyalpsiD:1*

seires0082-RF

desuebnacradar

yalpsidevalssa

.tinu

)tam

reggirtxT,oediv

,suonorhcnysROH

-rofCSTN(oediv

2 - 10

atadvaNATADVAN054Jnip8,HN

atadAPRAATADAPRA454Jnip5,HN

Page 29

J458

J464

J441

J445

J452

J463

J467

J443

DTB-2#1

J442

J461

J460

#8

J444

J448

J457

J450

J454

J455

J451

Figure 2-18 Location of connectors on the INT Board

J449

J459

J456

2 - 11

Page 30

Grounding cables and covering unused cable slots in the cable clamp

Cover unused cable

slots with aluminum tape.

Ground shield

of cables by

Fasten ground wire

of cables by fixing

screws for cable clamp.

cable clamp.

Figure 2-19 Cable clamp

CAUTION

1) The display unit must be grounded. Failure to

ground the unit may cause electrical shock when its

metallic parts are touched and give off or receive

electromagnetic interference.

2) Cover unused cable slots in the cable clamp with

aluminum tape to prevent foreign objects from

falling into the display unit through the cable slots.

2-12

Page 31

2.3 Changing Power Specifications

This radar can be powered by 100V AC or 220V AC, and is set at the factory for connection to

a 100V power supply. To power the unit by 220V AC, remove jumper JP13 on the POWER

Board as shown in the procedure below.

CAUTION

Turn off the power before executing the procedure

shown below.

Procedure

1) Turn off the power.

2) Unfasten the four screws circled in the

illustration at right.

3) Remove the power assembly.

4) Remove the power assembly cover.

5) For 220V power supply, remove jumper

wire JP13 on the POWER Board.

6) Mount the power assembly.

rewoPeriwrepmuJ

31PJ

JP13

RT-9183

C42

CAV001trohS

CAV022evomeR

C8

C6

2-13

Page 32

2.4 Power Supply Unit

Wire the unit as shown in the interconnection diagram.

TB

PTB14

TB

PTB11

Thermal relay

K2

Relay K3

Relay K1

Photo No. 3148

TB

PTB13

TB

PTB12

Figure 2-20 Power supply unit PSU-004

The type and rating of the thermal relay (K2) are as below.

sniaMs'pihStinUrennacS

epyTgnitaR

3,CAV022/002 ∅ 6200-BSRA7.13/HN0-RTA3.2

3,CAV044/083 ∅ 1300-BSRA8.03/HN0-RTA0.1

3,CAV022 ∅ zH05,8800-BSRA7.13/HN0-RT*)XAM(A6.2

3,CAV022 ∅ zH06,9800-BSRA7.13/HN0-RT*)XAM(A6.2

3,CAV044 ∅ zH06,0900-BSRA8.03/HN0-RT*)XAM(A2.1

)2K(yaleRlamrehT

*: Set the rating to maximum ( 2.3A to 2.6A or 1.0A to 1.2A) for HSC radar.

2-14

Page 33

3. INITIALIZATION AND ADJUSTMENT

3.1 Menus for Initialization and Adjustment

Accessing the menus

The menus for initialization and adjustment of this radar are locked to prevent adjustment by

the user. To access them;

1) Turn off the power.

2) Turn on the #4 segment of DIP Switch S1 on the SPU Board.

4

S1

1

Figure 3-1 Display unit (top view, cover removed)

and SPU Board

Menu operation

1) Press the [RADAR MENU] key.

2) Press appropriate numeric key to select menu desired.

3) Press numeric key to select item.

4) Press same numeric key pressed in step 3 to select option.

5) Press [ENTER] to register selection.

Menu description and menu tree

See pages 3-6 and 3-11, respectively.

Restoring default settings

1) Press [RADAR MENU] [0] [0] [2] [0] [0] [0] [0] to select FACT ORY DEFAULT on the

INITIAL SETTING 4 menu.

2) Press the [ENTER] key.

3) Wait for 10 seconds.

4) Turn power off, and on again.

5) Press [RADAR MENU] [0] [0] [2] [0] [0] [0] [2] to select MODEL on the INITIAL

SETTING 4 menu.

3–1

Page 34

6) Press the [2] key several times to select OTHER S-BAND.

7) Press the [ENTER] key.

3.2 Heading Alignment

Antenna unit mounted error (heading reed switch timing error) can be compensated at the display unit.

Correct bearing

relative to heading

Target

α

Antenna mounted error

to port (heading switch

advance)

000

010

350

020

340

330

320

310

300

290

280

270

260

250

240

230

220

210

200

030

150

160

190

170

180

Picture appears

deviated clockwise.

Figure 3-2 Heading alignment error

040

140

050

060

120

130

α

070

080

090

100

Apparent

110

position

of target

Apparent position

Target

β

Antenna mounted error

to starboard (heading

switch delayed)

of target

000

010

350

340

330

320

310

300

290

280

270

260

250

240

230

220

210

200

190

170

180

Picture appears

deviated counterclockwise.

β

020

030

040

050

060

070

080

090

Correct

100

110

bearing

120

relative to

130

140

heading

150

160

Procedure

1) Turn on the power. Press [RADAR MENU] [0] [0] [2] [2] to select HD ALIGN on the

INITIAL SETTING 1 menu.

2) Select a target echo (by gyrocompass, for example) at a range between 0.125 and 0.25nm,

preferably near the heading mark.

3) Operate the EBL control to bisect the target echo. (The value shown on the display is antenna position in relation to ship's bow.)

4) Press [ENTER] to finish.

3.3 Adjusting Sweep T iming

Sweep timing differs with respect to the length of the signal cable between the antenna unit and

the display unit. Adjust sweep timing at installation to prevent the following symptoms:

• The echo of a "straight" target (for example, pier), on the 0.25nm range, will appear on the

display as being pulled inward or pushed outward. See Figure 3-3.

• The range of target echoes will also be incorrectly shown.

Correct Target pushed Target pushed

inward outward

Figure 3-3 Examples of correct and

3-2

incorrect sweep timings

Page 35

Procedure

1) Turn on the power . Press [RADAR MENU] [0] [0] [2] [3] to select TIMING ADJ on the

INITIAL SETTING 1 menu.

2) Transmit on the 0.25nm range.

3) Adjust radar picture controls to display picture properly.

4) Select a target echo which should be displayed straightly.

5) Adjust the VRM control to straighten the target echo.

6) Press the [ENTER] key.

3.4 Adjusting Video Signal Level

When the signal cable is very long, the video amplifier input level decreases, shrinking target

echoes. To prevent this, confirm (and adjust if necessary) video amplifier input level.

Procedure

1) Connect an oscilloscope to TP3 on the INT Board (INT-9170).

2) Transmit on the 12nm range. Take trigger at TP10 on the same board.

3) Adjust VR1 on the INT Board so the value of TP3 is 4Vpp. (For secondary display, adjust

VR2 for same level.)

VR2

VR1

INT Board

TP3

Figure 3-4 Location of INT Board

3–3

Page 36

3.5 Suppressing Main Bang

If main bang appears at the screen center, suppress it as follows.

Procedure

1) Turn on the power. Transmit on a long range and then wait ten minutes.

2) Adjust [GAIN] control to show a slight amount of noise on the display.

3) Select the 0.25nm range. Adjust the [A/C SEA] control to suppress sea clutter.

4) Open the tuning compartment on the control unit.

5) Set VR901(MBS-L) at two o'clock and then slowly turn VR902 (MBS-T) clockwise to

suppress main bang.

6) If main bang still exists, turn VR901 clockwise slightly, and then slowly turn VR902 clockwise. Note that excessive main bang erases targets in close range.

TUNE

switch

Up: AUTO

Down: MAN

AUTO

AUTO

MAN

ON

OFF

ANTENNA

DEGAUSS

PM-ON/OFF

Tuning compartment

TUNE

GYRO SET

MBS-L

MBS-T

HOLD

ERROR

STBY

TUNE

control

VR901

(MBS-L)

VR902

(MBS-T)

Figure 3-5 Control unit, location of tuning compartment

3.6 Confirming Tuning

The radar receiver can be tuned both automatically and manually . Confirm that the radar can be

tuned both automatically and manually.

Procedure

1) Turn on the power. Set the TUNE switch in the top right hand panel to MANU.

2) Transmit on the 48nm range.

3) Adjust sensitivity and picture brilliance. Turn the [A/C SEA] and [A/C RAIN] controls

fully counterclockwise (off).

4) While observing the picture, turn the [TUNE] control in the tuning compartment slowly

counterclockwise (clockwise) more than twice to get best (worst) tuning point.

3 - 4

Page 37

5) Turn the [TUNE] control slowly clockwise (counterclockwise) to display the longest tuning bar.

6) Set the TUNE switch to AUTO and wait about 10 seconds (about four rotations of the

antenna).

7) Confirm that the radar found best tuning point. Peak tuning is obtained when about 80% of

the tuning indicator lights.

3.7 Confirming Magnetron Heater Voltage

Magnetron heater voltage is adjusted at the factory. Confirm that magnetron heater voltage is

within the prescribed rating as follows:

1) Turn on the radar and select the 0.125 mile range.

2) Press [RADAR MENU] [0] [0] [2] [0] to open the INITIAL SETTING2 menu.

3) Press [5] to select the 5. SCANNER STOPPED field and the TX option.

4) Turn off the antenna switch in the display unit.

5) Connect a multimeter, set to the 10 VDC range, between #12(+) of P801 and the chassis.

6) The multimeter should read 9.2-9.4 V. If not, adjust VR1.

7) “Transmit” on the 48 mile range.

8) The multimeter should read 7.3-8.3V.

9) Press [RADAR MENU] [0] [0] [2] [0] [5] to select the 5. SCANNER STOPPED field and

the ROTATE option.

10) Turn on the ANT MOT OR SW on the scanner unit.

PCB 03P9243

ANT MOTOR SW

Signal cable

Multicore cable

Figure 3-6(a) Scanner unit, bow view

VR1

P801

Figure 3-6(b) Scanner unit, stern side view

3-5

Page 38

Page 39

Page 40

Page 41

Page 42

Page 43

Page 44

Page 45

Page 46

Page 47

Page 48

Page 49

Page 50

Setting method 2: by make and model of gyrocompass

Table 4-2 Setting GYRO CONVERTER Board by make and model of gyrocompass

rekaMsledoMnoitacificepSWS

ONURUF007-YGpetsCD

ztuhcsnA3,2dradnatSsuonorhcnysCA

6,4dradnatSsuonorhcnysCA

02dradnatSpetsCD

awagokoY

cetvaN

htialP(

)epyt

htialPIII/IITAGVANsuonorhcnysCA

cemikoT

yrrepS(

)epyt

ikasawaK18-XGsuonorhcnysCA

nworbamrA1-LKM,01-KM

nostreboR08-RKSpetsCD

3/2/A1/1-C

55-B,55-A

005/X003

003

3/2-SPI

05-ZMC

etoN

11/2/1-SE

002-GT

H/L732RP

12MG

41-KM

T/2/1-DOM

302/

0006-GTpetsCD

11-MGsuonorhcnysCA

4-DOM

/X052-ZMC

/002/001-ZMC

3/1/Z1-D,rJ1-C

/201/101-TLG

701/K601/301

011/A11-SE

0002/R222RP

IE-KN,NE-KN

041/031-RSpetsCD

0005/001-GT

/031/753-RP

71-SE,041

202/102-TLG

61-SE,021-RS

03/02/01-KM

,1531SEIRES

x081V001

rotcellocnepo,eriw-5

zH06/05

x063

zH06/05

x063

x081V53

zH06/05

x063

petsCD

x081V53

zH06/05

x063

pets

x081V53

zH06/05

x063

zH06/05

x63

zH06/05

x09

petsCD

x081V07

x081V07

petsCD

x081V07

x081V42

zH06/05

x09

petsCD

x081V53

zH06/05

x09

petsCD

x081V05

x081V53

V06/05:egatlovrotoR

V22:egatlovrotatS

V06/05:egatlovrotoR

V09:egatlovrotatS

)+(eriw-3,)-(MOC

suonorhcnysCA

V06/05:egatlovrotoR

V22:egatlovrotatS

x063suonorhcnysCDFFOFFOFFOFFOFFOFFONONO-NOFFO-omeR

)-(eriw-3,)+(MOC

suonorhcnysCA

V001:egatlovrotoR

V09:egatlovrotatS

)-(eriw-3,)+(MOC

V06/05:egatlovrotoR

V86:egatlovrotatS

suonorhcnysCA

V011/001:egatlovrotoR

V09:egatlovrotatS

suonorhcnysCA

V011/001:egatlovrotoR

V22:egatlovrotatS

)+(eriw-3,)-(MOC

rotcellocnepo,eriw-5

)-(eriw-3,)+(MOC

V001:egatlovrotoR

V09:egatlovrotatS

V011/001:egatlovrotoR

V09:egatlovrotatS

)-(eriw-3,)+(MOC

)+(eriw-3,)-(MOC

WS

WS

WS

WS

WS

WS

WS

WS

WS

1-1

2-1

3-1

4-1

5-1

6-1

7-1

8-1

1-2

NOFFOFFONOFFOFFONONO- FFOFFO,4#

FFOFFOFFOFFOFFOFFOFFOFFOFFONOFFO,1#

FFOFFOFFOFFOFFOFFOFFOFFOFFOFFOFFO,1#

NOFFOFFONOFFOFFONONO-NOFFO,4#

FFOFFOFFOFFOFFOFFOFFOFFOFFONOFFO,1#

NOFFOFFONOFFOFFONONO-NOFFO,4#

FFOFFOFFOFFOFFOFFOFFOFFOFFOFFOFFO,1#

NOFFOFFONOFFOFFONONO– NOFFO-omeR

FFOFFOFFOFFOFFOFFOFFOFFOFFOFFOFFO,1#

NONOFFOFFOFFOFFOFFOFFOFFOFFOFFO,1#

FFONOFFOFFOFFOFFOFFOFFOFFOFFOFFO,1#

NOFFOFFONOFFOFFONONO– FFOFFO,4#

NOFFOFFOFFONOFFOFFOFFO– FFOFFO,4#

NOFFOFFONOFFOFFONONO– FFOFFO,4#

NOFFOFFONOFFOFFONONO-NOFFO,4#

FFONOFFOFFOFFOFFOFFOFFOFFOFFOFFO,1#

NOFFOFFONOFFOFFONONO– NOFFO,4#

FFONOFFOFFOFFOFFOFFOFFOFFOFFOFFO,1#

NOFFOFFONOFFOFFONONO– FFOFFO,4#

NOFFOFFONOFFOFFONONO– NOFFO,4#

WS

2-2

3-2

1PJ2PJ3PJ4PJ5PJ

2#-1#1#

6#,5#

2#2#1#1#

3#,2#

2#1#1#1#

3#,2#

2#-2#2#

6#,5#

2#2#1#1#

3#,2#

2#-

ev

2#-2#2#

6#,5#

1#1#1#1#

3#,2#

2#–

ev

2#2#1#1#

3#,2#

1#1#1#1#

3#,2#

1#1#1#1#

3#,2#

2#– 1#1#

6#,5#

2#– 1#1#

6#,5#

2#– 1#1#

6#,5#

2#– 2#2#

6#,5#

1#1#1#1#

3#,2#

2#– 2#2#

6#,5#

1#1#1#1#

3#,2#

2#– 1#1#

6#,5#

2#– 2#2#

6#,5#

∗∗

∗∗

4-6

Page 51

Page 52

Page 53

Page 54

Page 55

Page 56

Page 57

Page 58

Page 59

Page 60

Page 61

Page 62

Page 63

Page 64

Page 65

Page 66

Page 67

Page 68

Page 69

Page 70

Page 71

Page 72

Page 73

Page 74

Page 75

Page 76

Page 77

Loading...

Loading...