Page 1

UA

Back

IS T

RAN

FA-

100

SPO

NDER

PRINTED IN JAPAN

Page 2

9-52 Ashihara-cho,9-52 Ashihara-cho,

A

A

*

00080932513

**00080932513

*

*

00080932513

**00080932513

*

Nishinomiya, 662-8580, JAPANNishinomiya, 662-8580, JAPAN

Telephone :Telephone : 0798-65-21110798-65-2111

FaxFax 0798-65-42000798-65-4200

::

The paper used in this manual

is elemental chlorine free.

FURUNO Authorized Distributor/DealerFURUNO Authorized Distributor/Dealer

ll rights reserved.

ll rights reserved.

Pub. No.Pub. No. IME-44170-H5IME-44170-H5

(( AKMUAKMU ))

FA-100FA-100

Printed in JapanPrinted in Japan

FIRST EDITION :FIRST EDITION : SEP.SEP. 20022002

H5H5 :: OCT.OCT. 17, 200517, 2005

* 0 0 0 8 0 9 3 2 5 1 3 ** 0 0 0 8 0 9 3 2 5 1 3 *

Page 3

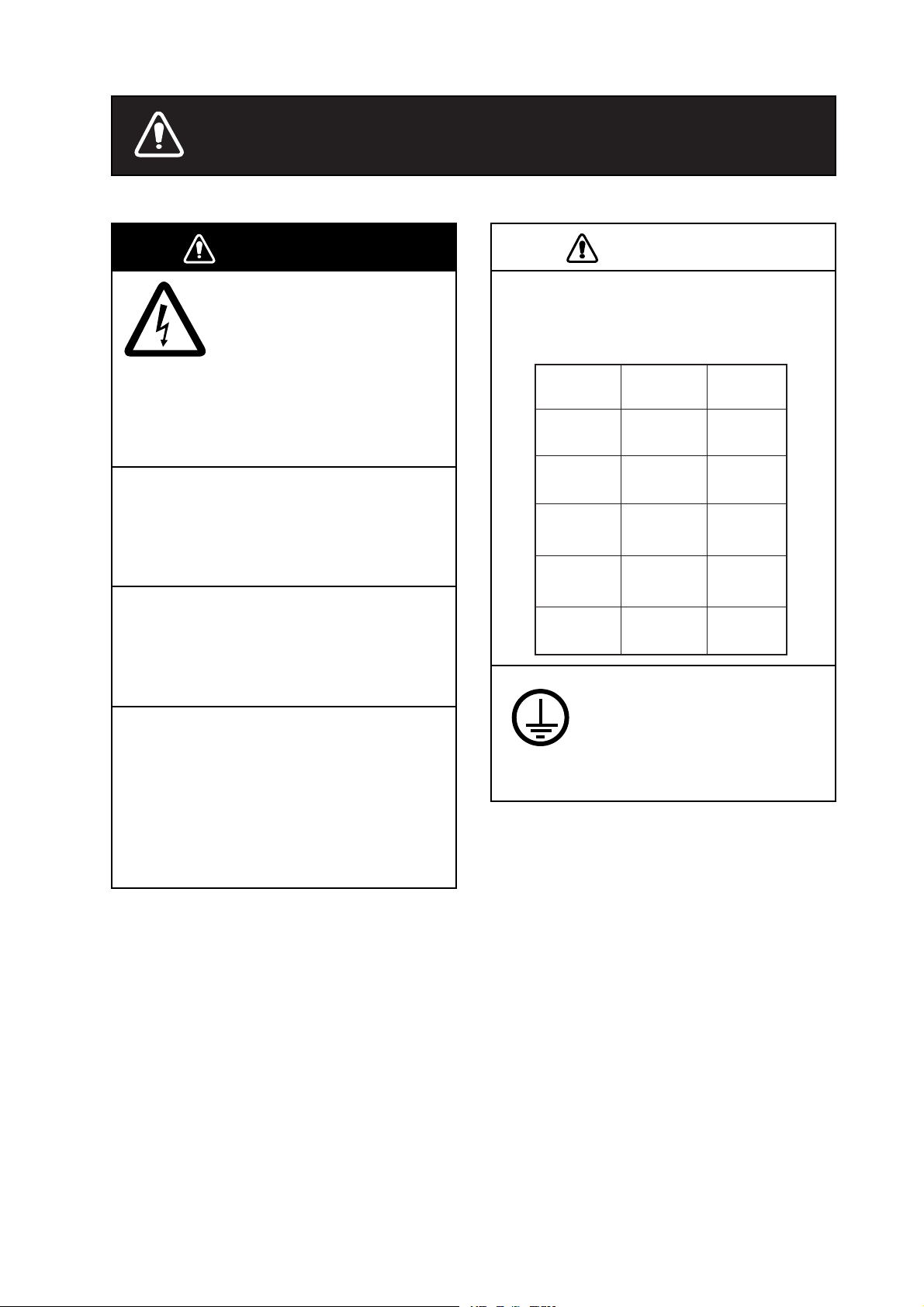

SAFETY INSTRUCTIONS

WARNING

ELECTRICAL SHOCK HAZARD

Do not open the equipment

unless totally familiar with

electrical circuits and

service manual.

Only qualified personnel

should work inside the

equipment.

Turn off the power at the switchboard

before beginning the installation.

Fire or electrical shock can result if the

power is left on.

Do not install the equipment where it

may get wet from rain or water splash.

Water in the equipment can result in fire,

electrical shock or damage the equipment.

Be sure that the power supply is

compatible with the voltage rating of

the equipment.

Connection of an incorrect power supply

can cause fire or damage the equipment.

The voltage rating of the equipment appears

on the label above the power connector.

CAUTION

Observe the following compass safe

distances to prevent interference to a

magnetic compass:

Standard

compass

FA-100

CB-100

GVA-100

DB-1

PR-240-CE

1.0 m 0.6 m

0.6 m 0.4 m

0.3 m 0.3 m

0.3 m 0.3 m

0.9m 0.6 m

Attach securely protection

earth to the ship's body.

The protection earth is required

to the power supply to prevent

electrical shock

Steering

compass

i

Page 4

TABLE OF CONTENTS

SYSTEM CONFIGURATION................................................................................iii

EQUIPMENT LISTS............................................................................................. iv

1. MOUNTING....................................................................................................... 1

1.1 Antenna Unit....................................................................................................................1

1.1.1 GPS antenna unit ...............................................................................................1

1.1.2 VHF antenna ......................................................................................................3

1.1.3 GPS/VHF combined antenna ..............................................................................5

1.2 Transponder Unit.............................................................................................................8

1.3 Junction Box..................................................................................................................10

1.4 Power Supply (option) ...................................................................................................11

1.5 Pilot Plug (option)..........................................................................................................11

2. WIRING ...........................................................................................................12

3. INPUT/OUTPUT SIGNAL ............................................................................... 15

3.1 Inputs from Sensors.......................................................................................................15

3.2 Input/Output of AIS Signal .............................................................................................16

3.3 Input of Gyrocompass Signal.........................................................................................17

3.4 Alarm Signal Output.......................................................................................................17

3.5 LAN Input/Output...........................................................................................................18

3.6 Pilot Plug.......................................................................................................................18

3.7 Jumper Setting in the Junction Box................................................................................19

3.8 Input/Output Sentences.................................................................................................20

3.9 Changing Ship’s Mains Specifications............................................................................21

4. SETTING AND ADJUSTMENT.......................................................................22

4.1 Setting MMSI, IMO No., Name and Call Sign ................................................................22

4.2 Setting GPS Antenna Position and Ship’s Type .............................................................24

4.3 System Settings.............................................................................................................26

PACKING LIST

OUTLINE DRAWINGS

INTERCONNECTION DIAGRAM

ii

Page 5

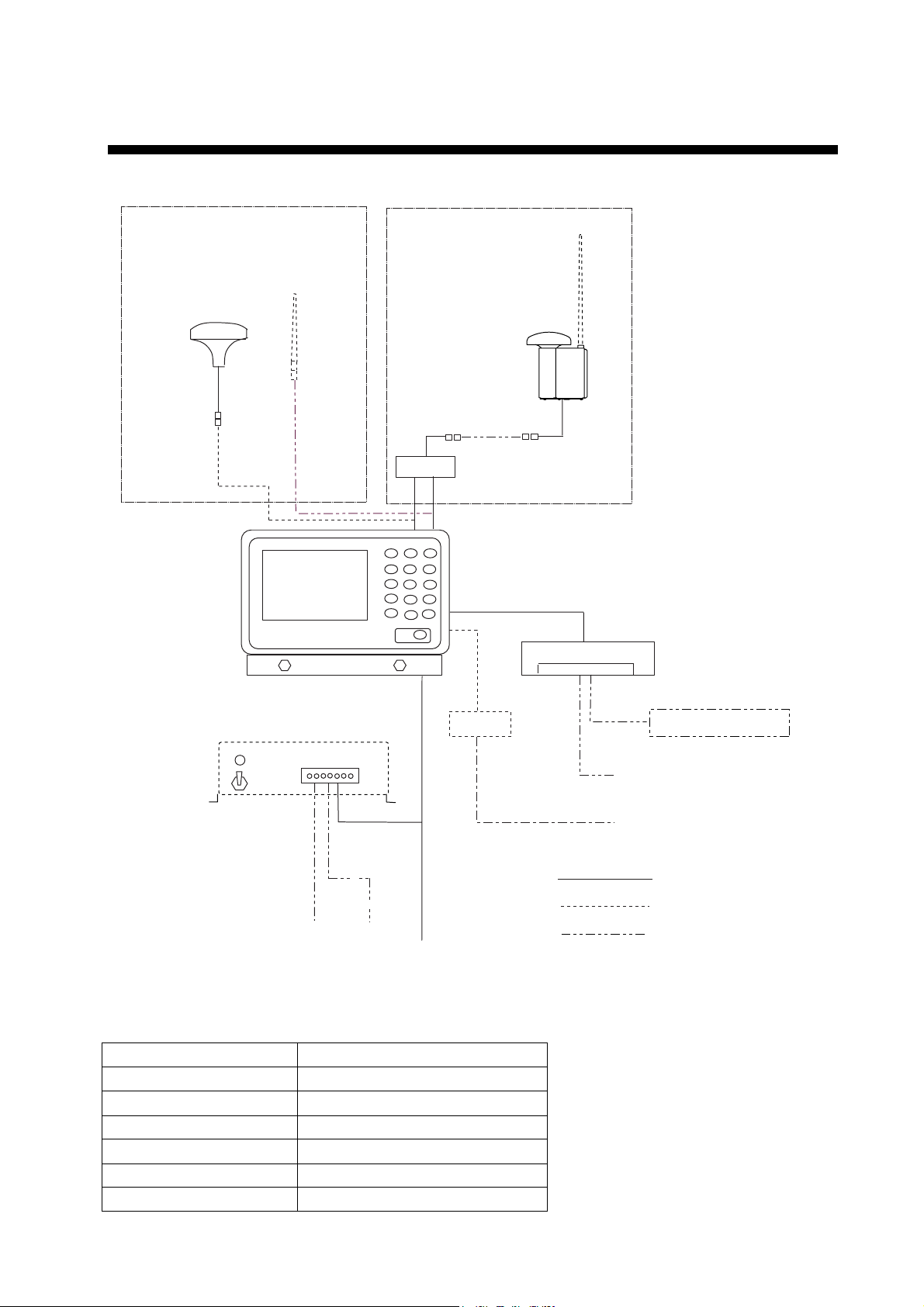

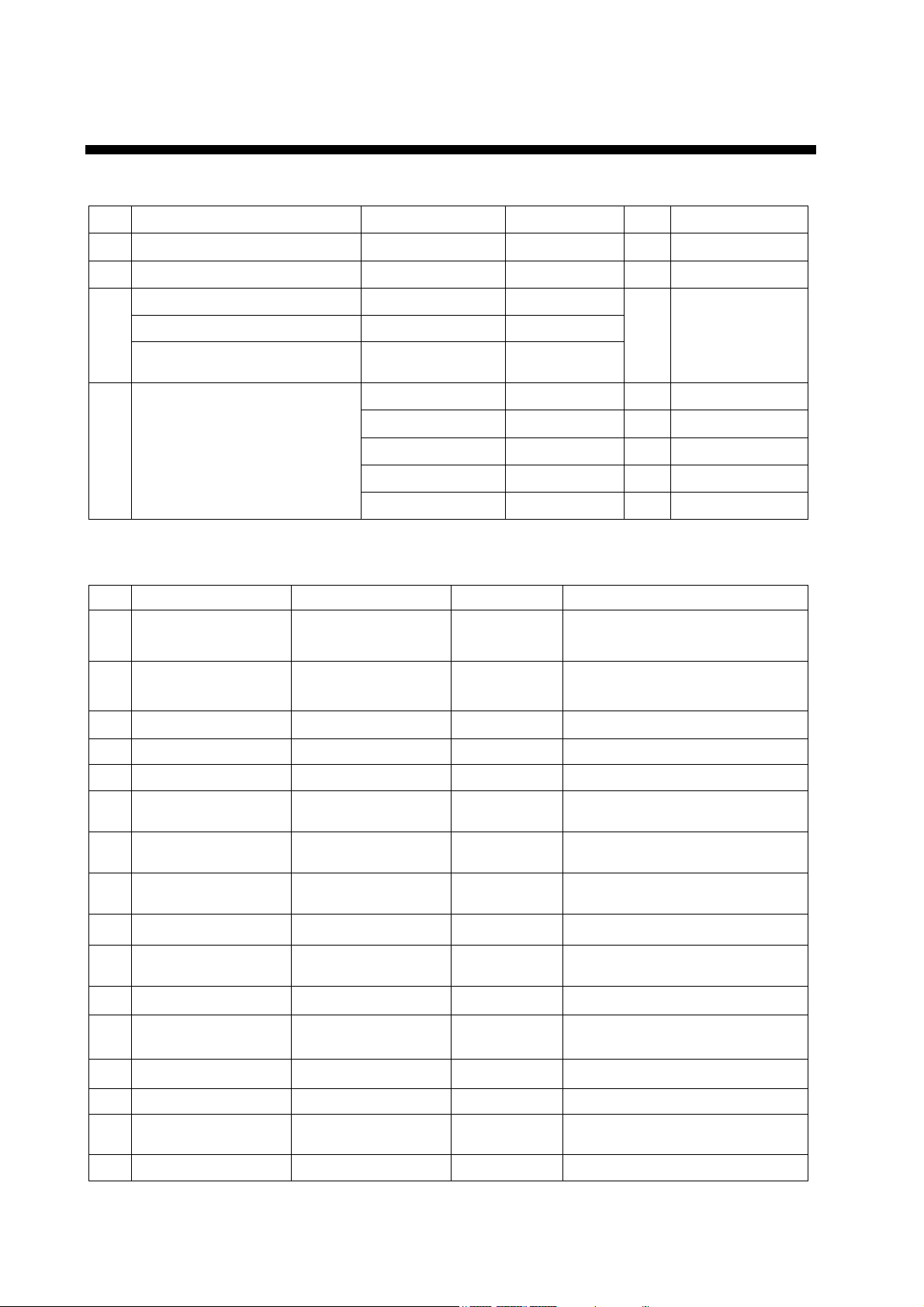

SYSTEM CONFIGURATION

Either

GPS antenna

GPA-017S

GSC-001

Power supply

PR-240-CE

VHF whip antenna

GPS/VHF

combined antenna

GVA-100

Distributor unit

DB-1

Transponder unit

FA-100

AD-100

Junction box CB-100

GPS Navigator *

Ship’s mains

100-115/200-230 VAC

f, 50/60Hz

1

24 VDC

12-24 VDC

Category of the units

GPA-017S Exposed to the weather

GSC-001 Exposed to the weather

GVA-100 Exposed to the weather

FA-100 Protected from the weather

CB-100 Protected from the weather

DB-1 Protected from the weather

PR-240-CE Protected from the weather

Other external equipments

Gyrocompass

: Standard

: Option

: Local supply

*: External GPS Navigation is required.

iii

Page 6

v

EQUIPMENT LISTS

Standard supply

No. Name Type Code no. Qty Remarks

1 Transponder Unit FA-100 - 1

2 Junction Box CB-100 - 1

GPS Antenna GPA-017S -

3

GPS Antenna GSC-001 GPS/VHF Combined

Antenna

4 Installation Materials

**: for Japan only

GVA-100* -

CP24-00101* 005-950-730 1 For DB-1

CP24-00102* 005-950-700 1 For FA-100

CP05-08701* 005-949-280 1 For CB-100

CP24-00121** 005-952-350 1 For GPA-017S

CP24-00141* 005-952-330 1 For GVA-100

Optional supply

1

Select one.

No. Name Type Code no. Remarks

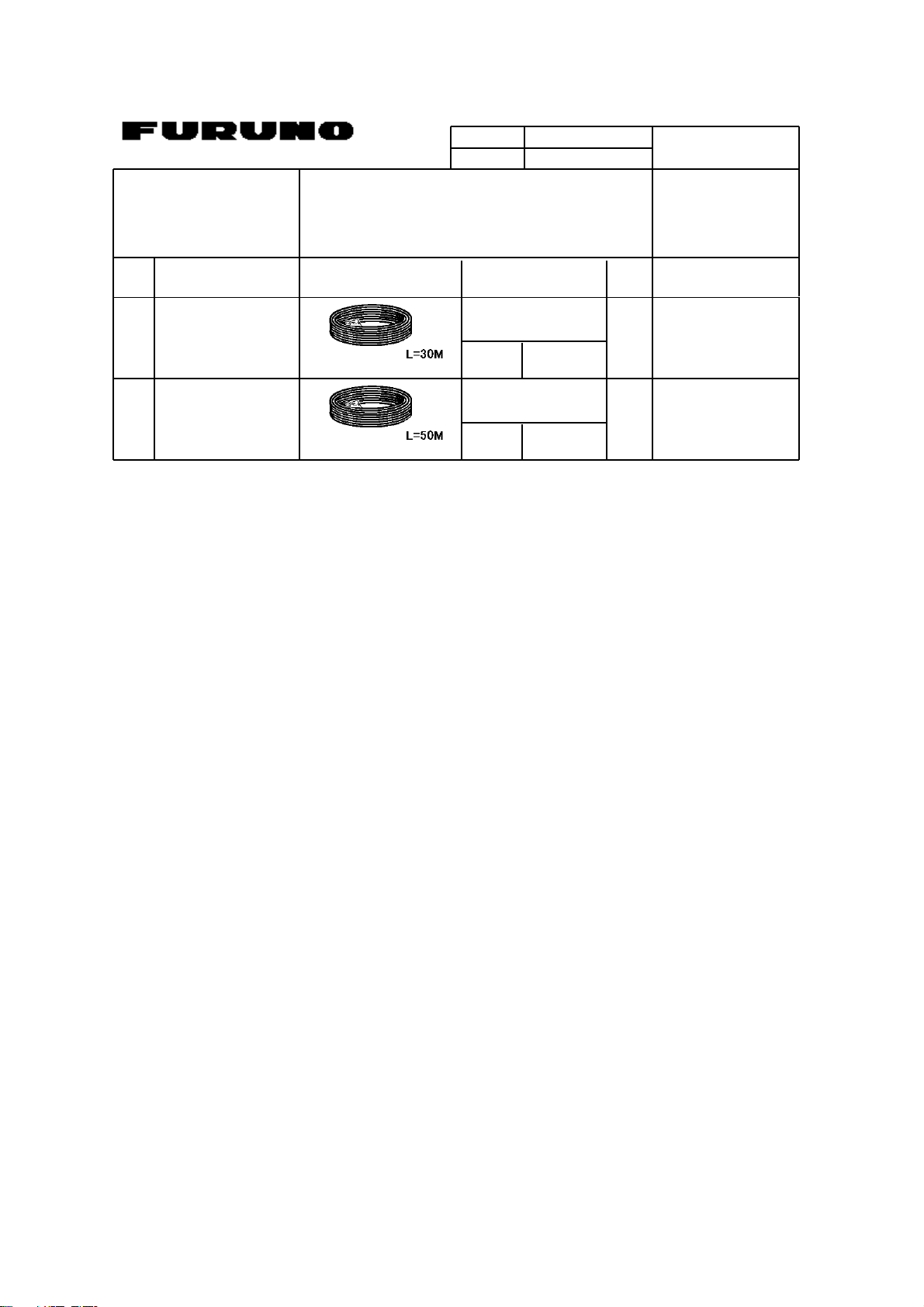

1 Antenna cable set CP20-01700(30m) 004-372-110 For GPS or Combined antenna

8D-FB-CV *30M*, CP20-01701

2 Antenna cable set CP20-01710(50m) 004-372-120 For GPS or Combined antenna

8D-FB-CV *50M*, CP20-01701

3 Flush mount kit A OP24-1 005-950-740

4 Flush mount kit B OP24-2 005-950-750

5 Mast mount fixture CP20-01111 004-365-780 For GPA-017S

6

Right-angle

antenna base

7

L-angle antenna

base

8

Antenna base for

rail mount

9 VHF whip antenna FAB-151D 000-572-029 For Japan only

10

Antenna fixing

bracket

11 VHF whip antenna 150M-W2VN 000-113-498 For outside Japan

12 Power supply PR-240-CE -

No.13-QA330 000-803-239 For GPA-017S

No.13-QA310 000-803-240 For GPA-017S

No.13-RC5160 000-806-114 For GPA-017S

4-310071 000-572-184 For FAB-151D

Include installation materials

CP24-00151*

13 Pilot plug OP24-3 000-053-911

14 AD-100 AD-100 - For gyrocompass

15

PC AIS

software kit

16 φ80 Mast mount kit OP24-5 005-954-510 For Combined antenna

*: Refer to packing list at the back of this manual.

i

OP24-24-1 005-954-420 CD-ROM, USB protect key

Page 7

1. MOUNTING

1.1 Antenna Unit

1.1.1 GPS antenna unit

Install the GPS antenna unit referring to the drawing at the back of this manual D-1.

When selecting a mounting location for the antenna, keep in mind the following

points.

• Select a location out of the radar beam. The radar beam will obstruct or prevent

reception of the GPS satellite signal.

• There should be no interfering object within the line-of-sight to the satellites. Objects

within line-of-sight to a satellite, for example, a mast, may block reception or prolong

acquisition time.

• Mount the antenna unit as high as possible to keep it free of interfering objects and

water spray, which can interrupt reception of GPS satellite signal if the water freezes.

Extending antenna cable

Three types of antenna cable extensions are optionally available.

a) Antenna cable set CP20-01700

Antenna Unit

Conversion

0.6 m

1 m

◆ Waterproofing connector

Wrap connector with vulcanizing tape and then vinyl tape. Bind the tape end with

a cable-tie.

Cable Assy.

NJ-TP-3DXV-1

Antenna Cable

30 m 1 m

Fabricate locally. (See next page.)

: Connector

FA-100

Waterproofing connector

b) Antenna cable set CP20-01710 (8D-FB-CV, 50m)

Connect the cable the same as a) above.

c) Cable type RG-10U/Y (shipyard supply)

Note: The length of this cable should be less than 20 m to prevent signal loss.

The coax. coupling cable assy.(type: NJ-TP+3DXV-1, code no.

000-123-809), coaxial connector(N-P-8DFB; supplied), vulcanizing tape

and vinyl tape are required. Fabricate both ends of the cable as shown in

the figure on the next page.

1

Page 8

How to attach the connector N-P-8DFB for cable 8D-FB-CV

Outer Sheath

Dimensions in millimeters.

Armor

Inner Sheath Shield

50

30

Remove outer sheath and armor by the dimensions

shown left.

Expose inner sheath and shield by the dimensions

shown left.

Cover with heat-shrink tubing and heat.

30

Clamp

Nut

Gasket

(reddish

brown)

Trim shield here.

Insulator

10

Clamp

Aluminum Foil

Cut off insulator and core by 10mm.

Twist shield end.

Ship on clamp nut, gasket and clamp as shown left.

Fold back shield over clamp and trim.

Cut aluminum foil at four places, 90° from one

another.

Trim aluminum

tape foil here.

Clamp Nut

Solder through

the hole.

Fold back aluminum foil onto shield and trim.

1

5

Pin

Shell

Expose the insulator by 1mm.

Expose the core by 5mm.

Slip the pin onto the conductor. Solder them together

through the hole on the pin.

Insert the pin into the shell. Screw the clamp nut into

the shell.

(Tighten by turning the clamp nut. Do not tighten by

turning the shell.)

How to attach connector N-P-8DFB

2

Page 9

1.1.2 VHF antenna

Location

Location of the mandatory AIS VHF-antenna should be carefully considered. Digital

communication is more sensitive than analog/voice communication to interference

created by reflections in obstructions like masts and booms. It may be necessary to

relocate the VHF radiotelephone antenna to minimize interference effects.

To minimise interference effects, the following guidelines apply:

• The AIS VHF antenna should be placed in an elevated position that is as free as

possible with a minimum of 0.5 meters in the horizontal direction from constructions

made of conductive materials. The antenna should not be installed close to any large

vertical obstruction. The objective for the AIS VHF antenna is to see the horizon

freely through 360 degrees.

• The AIS VHF antenna should be installed safely away from interfering high-power

energy sources like radar and other transmitting radio antennas, preferably at least 3

meters away from and out of the transmitting beam.

• There should not be more than one antenna on the same plane. The AIS VHF

antenna should be mounted directly above or below the ship’s primary VHF

radiotelephone antenna, with no horizontal separation and with a minimum of 2.8

meters vertical separation. If it is located on the same plane as other antennas, the

distance apart should be at least 10 meters.

Cabling

• The cable should be kept as short as possible to minimize signal attenuation.

Coaxial cables equal to or better than RG10U/Y are recommended.

• All outdoor installed connectors on coaxial cables should be fitted with preventive

isolation such as vulcanizing tape to protect against water penetration into the

antenna cable.

• Coaxial cables should be installed in separate signal cable channels/tubes and at

least 10 cm away from power supply cables. Crossing of cables should be done at

right angles (90°). The minimum bend radius of the coaxial cable should be 5 times

the cable's outer diameter.

• Install the VHF whip antenna referring to the outline drawing at the back of this

manual. Separate this antenna from other VHF radiotelephone antennas as shown

on the next page to prevent interference to the FA-100.

3

Page 10

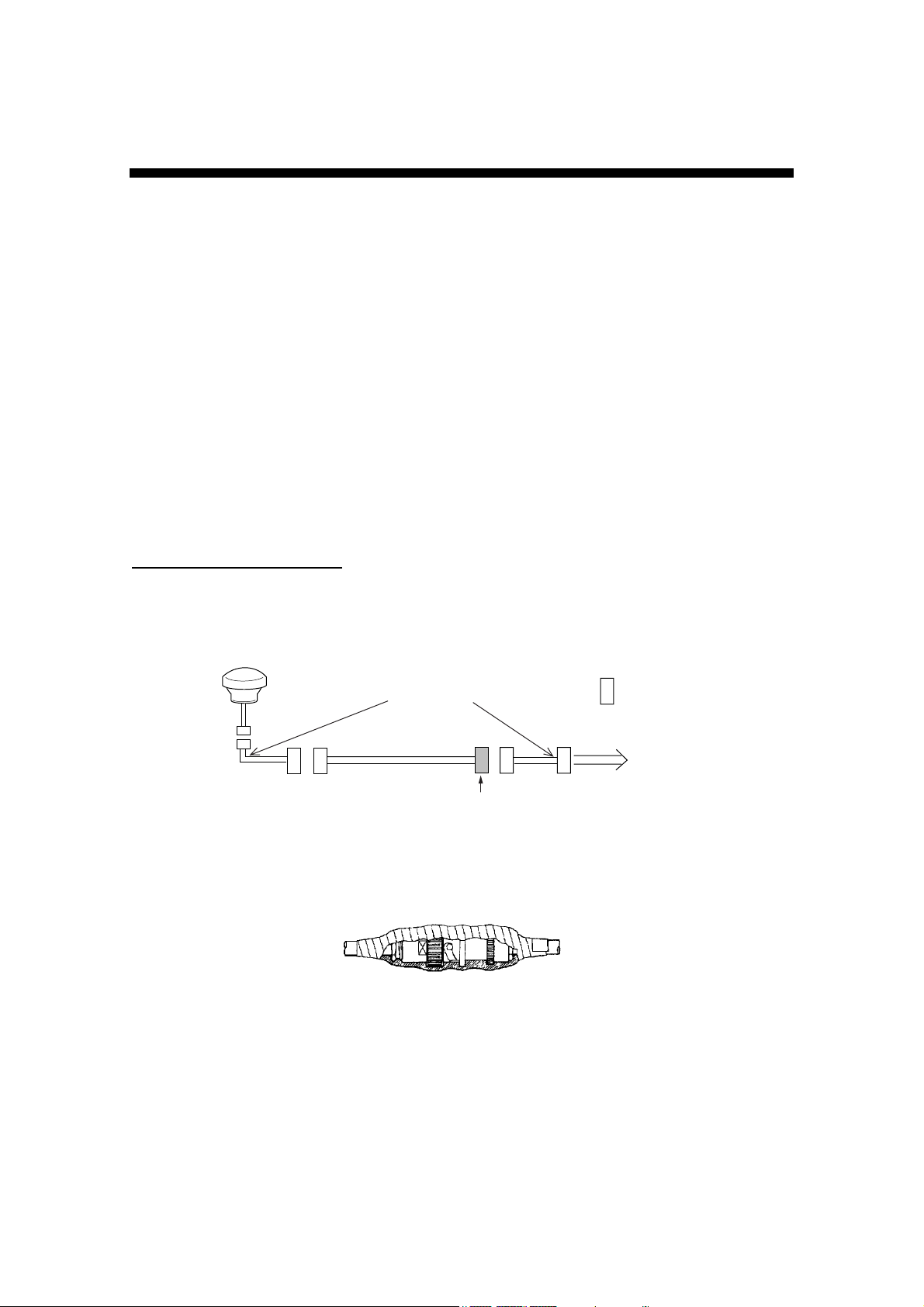

Horizontal separation distance

Whip antenna for AIS

(GPS/VHF combined

antenna)

Other VHF whip antenna

More than 10 m

Vertical separation distance

More than

2.8 m

More than 0.5 m

• When coaxial cable RG-10U/Y (shipyard supply) is used, attach the coaxial plug

M-P-7 (dockyard supply) as shown on the next page.

4

Page 11

How to att ach the plug M-P-7

Lay the coaxial cable and attach an M-type plug (if necessary) to the cable as

follows.

5 mm

30 mm

2 mm

1. Remove the sheath by 30 mm.

Sheath

2. Bare 23 mm of the center conductor. Trim

braided shield by 5 mm and tin.

3. Slide coupling ring onto cable.

4. Screw the plug assembly on the cable.

Braided shield

Conductor

Insulator

5. Solder plug assembly to braided shield

through solder holes. Solder contact sleeve

to conductor.

Plug assembly

Contact sleeve

6. Screw coupling ring into plug assembly.

Coupling ring

Solder both

sides of hole.

Cut conductor here.

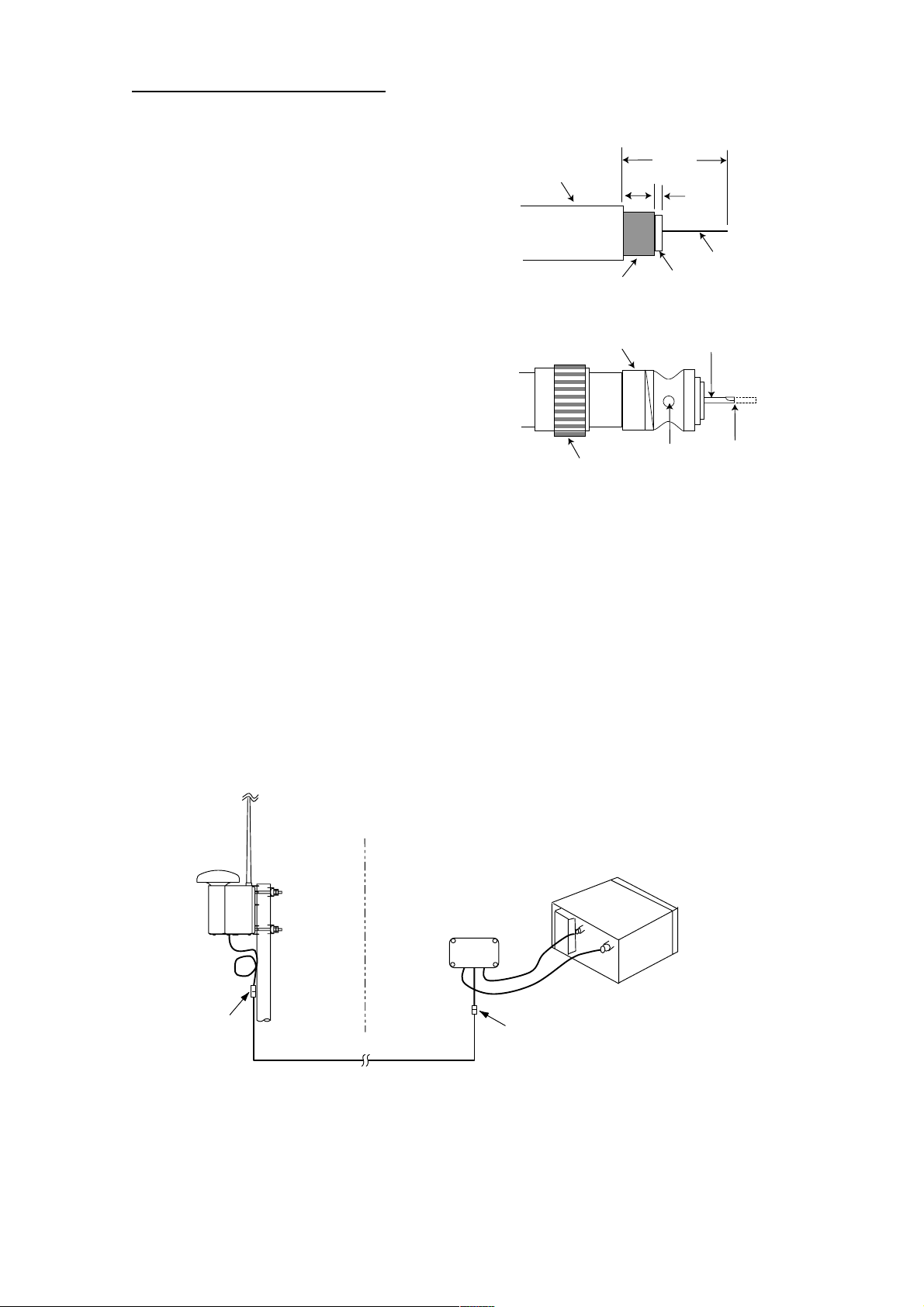

1.1.3 GPS/VHF combined antenna

Install the combined antenna unit referring to the outline drawing. When selecting a

mounting location for the antenna, keep in mind the following points.

• Select a location out of the radar beam. The radar beam will obstruct or prevent

reception of the GPS satellite signal.

• There should be no interfering object within the line-of-sight to the satellites. Objects

within line-of-sight to a satellite, for example, a mast, may block reception or prolong

acquisition time.

• Mount the antenna unit as high as possible. Mounting it this way keeps it free of

interfering objects and water spray, which can interrupt reception of GPS satellite

signal if the water freezes.

• Also, refer to the antenna installation guidelines page 3.

Outdoor

N-P-8DFB

RG-10U/Y

Indoor

Distributor DB-1

GPS

VHF

N-P-8DFB

Transponder unit

Installation overview of GP S /VHF com bined antenna

Note: Optional φ80 mast mount kit (Type: OP24-5, Code no.: 005-954-510) is

required to fix the GPS/VHF combined antenna to the mast (φ60 - 80).

5

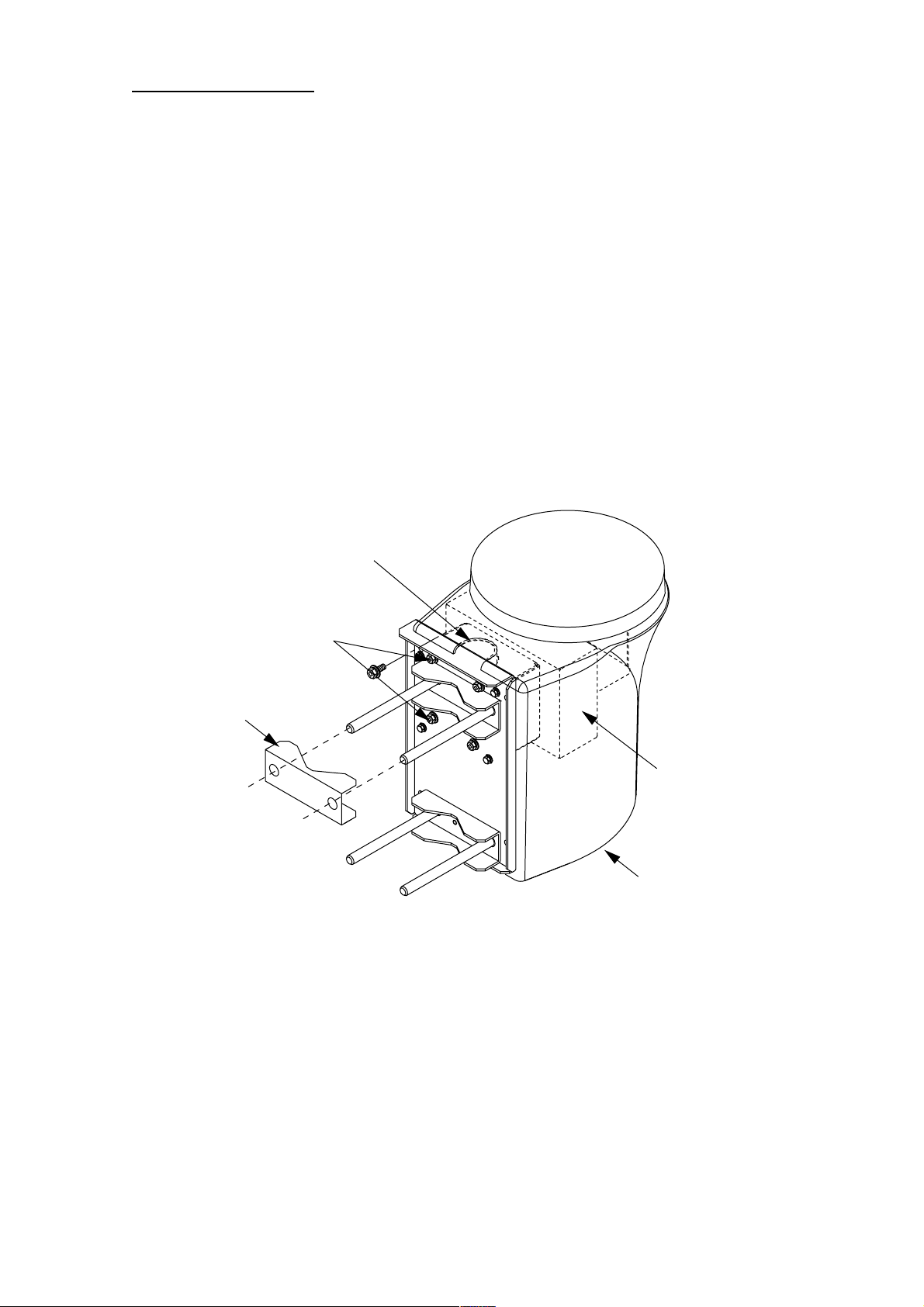

Page 12

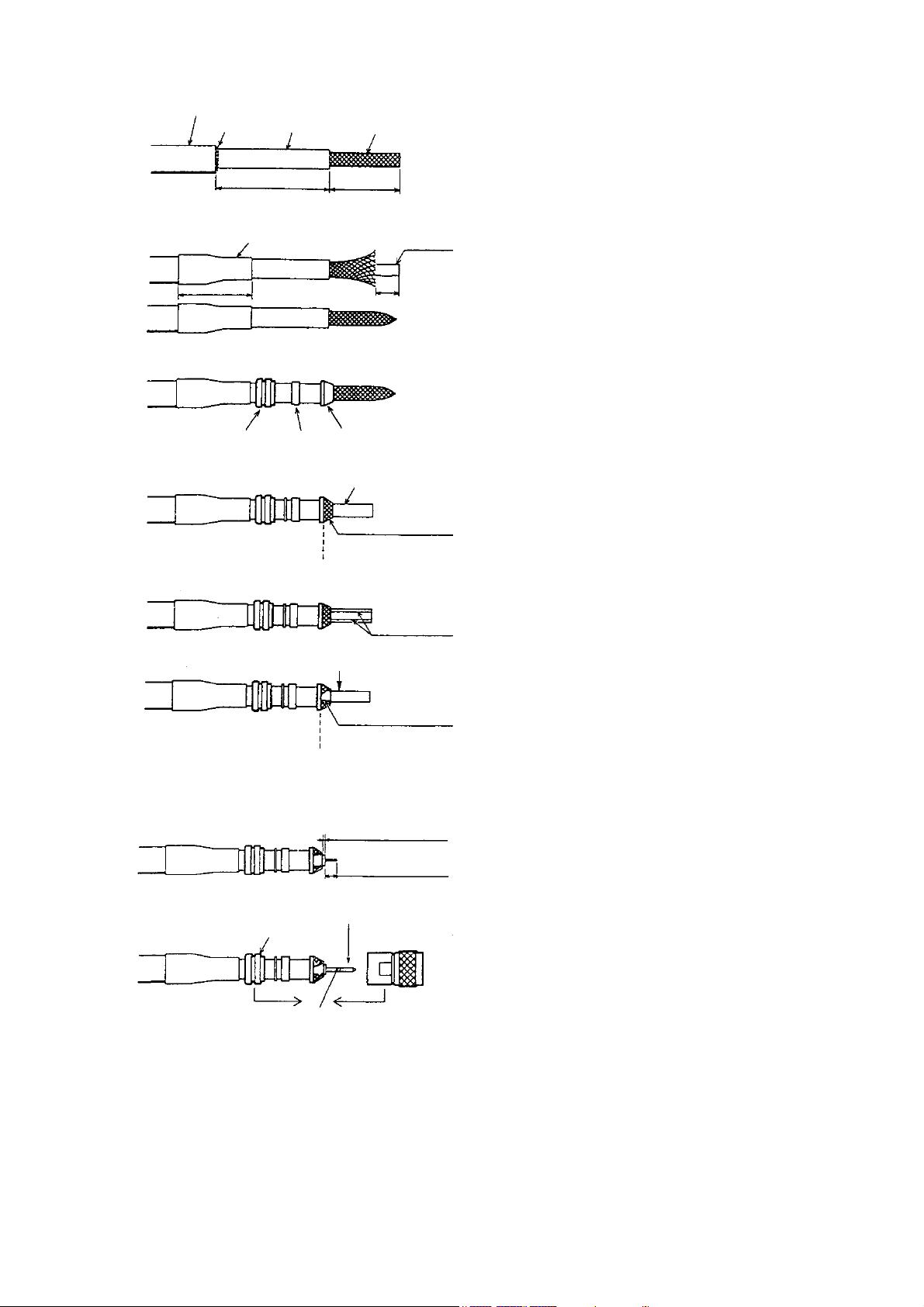

Mounting procedures

1. Dismount the bottom cover, cut the cable-tie inside the unit and take out the

coaxial connector attached to the combined box.

2. Loosen four screws to loosen whip antenna fixture and pull out the coaxial

connector coming from the combined box through the hole in the whip antenna

fixture.

3. Connect the coaxial connector to the whip antenna base and wrap the junction

part of the whip antenna with vulcanizing tape and then vinyl tape for

waterproofing.

4. Insert the whip antenna from the top of the combined antenna.

5. Secure the whip antenna with whip antenna fixture.

6. Using a new plastic band (supplied), secure the cables and coaxial connector

inside the antenna case.

7. Mount the bottom cover.

8. Fix the GPS/VHF combined antenna to the ship’s stanchion (40 to 50 mm

diameter) with antenna fixing brackets, flat washers and hex. nuts.

Note: Coat the exposed parts of bolts and nuts with silicon sealant.

Whip antenna fixture

Loosen four screws.

(M5x16)

Antenna fixing bracket

GPS/VHF Combined antenna

Combined box

Bottom cover

6

Page 13

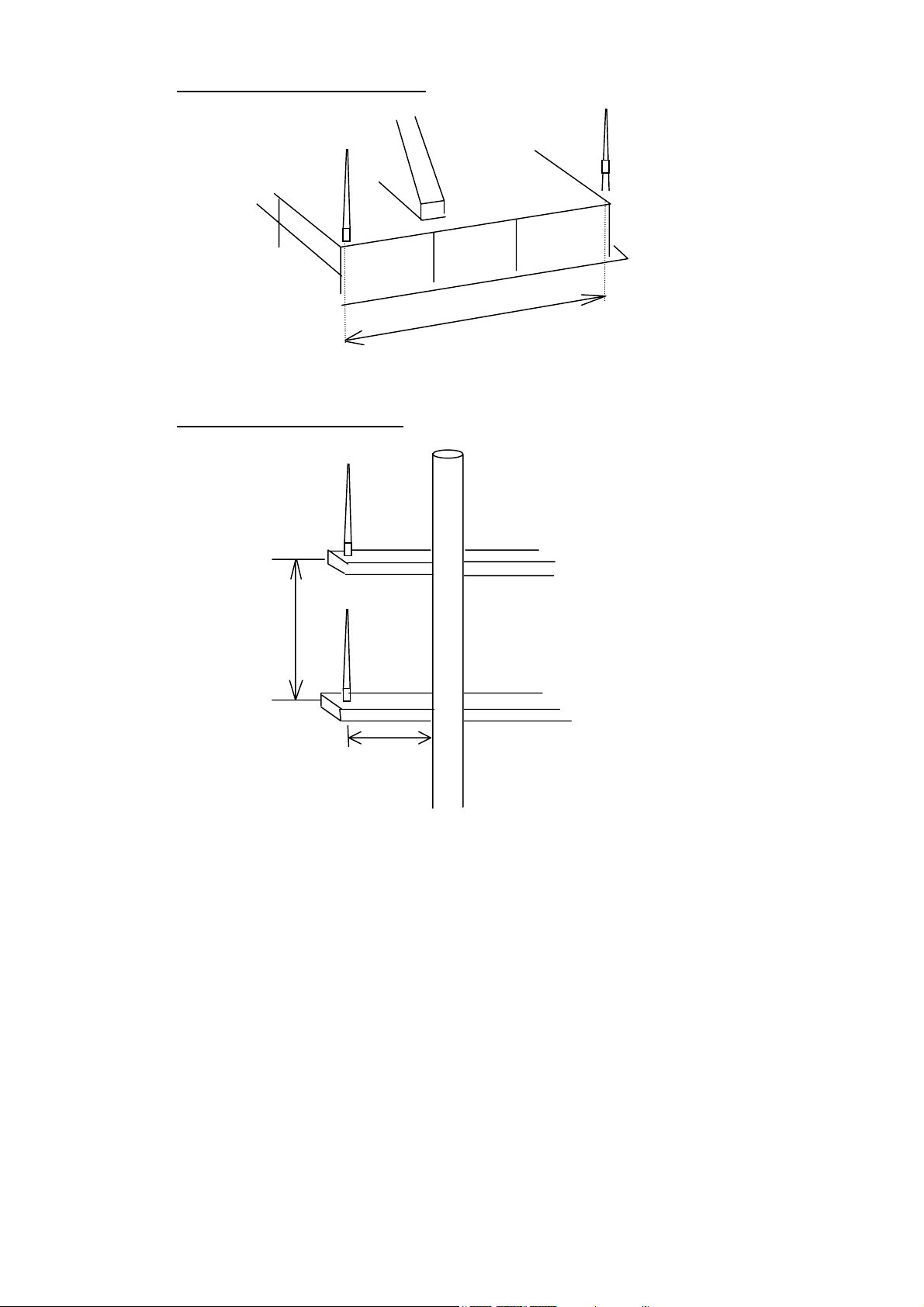

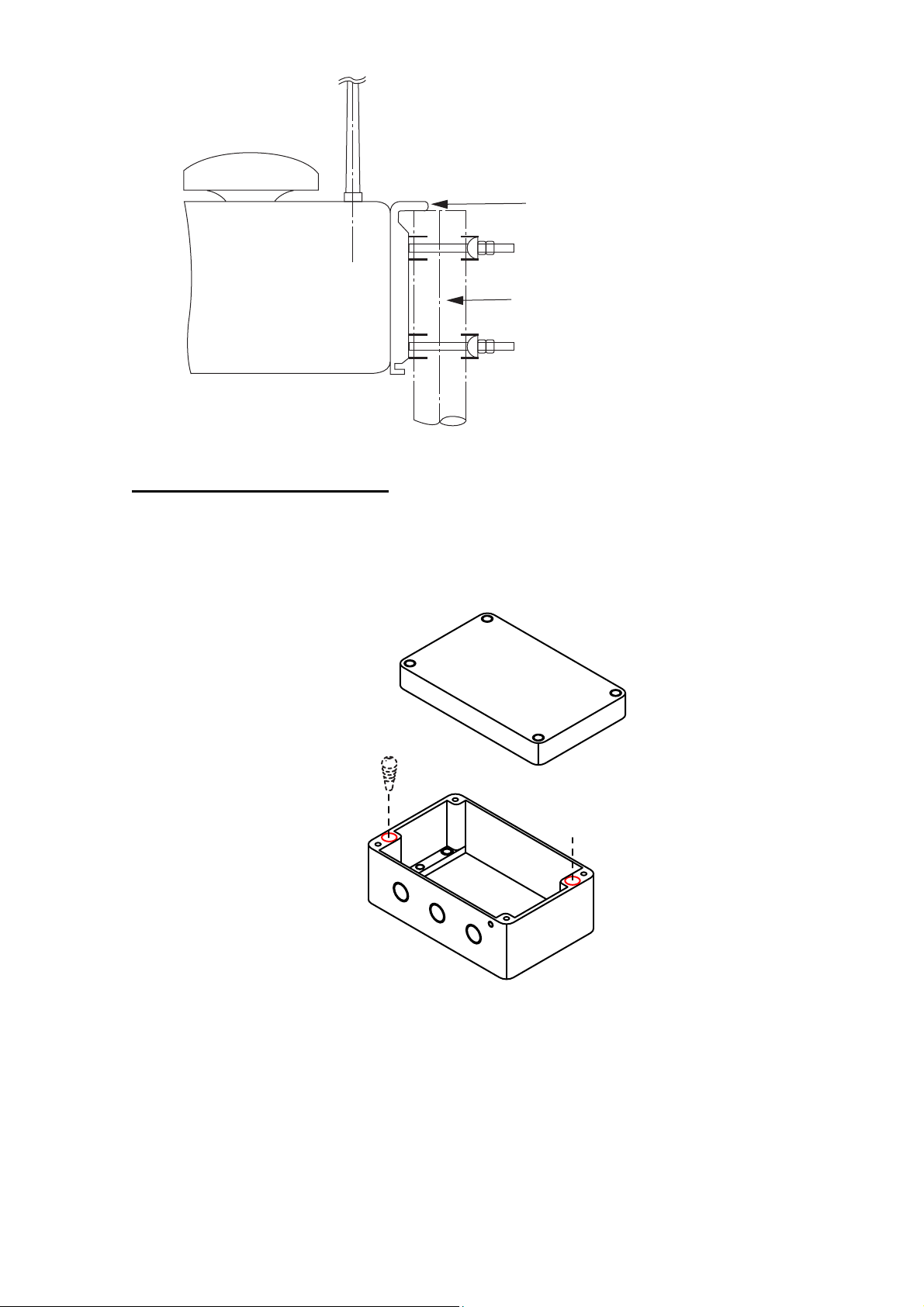

Thetopofthestanchioncome

intocontactwiththeflange.

Stanchion

Installing distributor unit DB-1

The length of the cable between the distributor unit and transponder unit is 1 m so

locate the distributor unit within 1 m from the transponder unit. Fix the distributor

unit on the bulkhead, facing the cable entrance downward. Remove the lid of the

distributor unit and secure the unit with two tapping screws.

Tappingscrew

(4x30)

Note: Be sure no foreign material or water enters the distributor unit.

7

Page 14

1.2 Transponder Unit

The transponder unit can be installed on a desktop or flush mounted in a panel.

Install it on the chart table or near the steering place, referring to the outline

drawing.

When selecting a mounting location for the transponder, keep the following in mind:

• Keep the transponder out of direct sunlight.

• The temperature and humidity should be moderate and stable.

(Operating temperature range: -15°C to +55°C)

• Locate the unit away from exhaust pipes and vents.

• The mounting location should be well ventilated.

• Mount the unit where shock and vibration are minimal.

• Keep the unit away from electromagnetic field generating equipment such as

motor, generator.

• For maintenance and checking purposes, leave sufficient space at the sides and

rear of the unit and leave slack in cables. Refer to the outline drawing.

• A magnetic compass will be affected if the unit is placed too close to it. Observe

the following compass safe distances to prevent disturbance to the magnetic

compass:

Standard compass: 1.0 meters

Steering compass: 0.6 meters

Desktop mounting

1. Remove two hex. bolts from the lower part of the transponder unit and dismount

the mounting base.

2. Fix the mounting base to the desktop with four tapping screws (6x20: supplied)

or hex. bolts.

3. Place the transponder unit on the mounting base and secure it with two hex.

bolts.

Service clearance

more than 130 mm

Remove two hex. bolts.

120 mm

120 mm

φ8

Front

Mounting base

8

Page 15

Flush mounting

Optional flush mount kit A or B is required for flush mounting. For mounting

dimensions, refer to the outline drawing at the back of this manual.

Flush mount kit A: Type OP24-1 Code no. 005-950-740

Name Type Code no. Qty

1 Cosmetic panel 24-003-2811 100-299-540 1

2 +Tapping screw 5x25 000-802-082 4

1. Cut out a hole in the mounting location, referring to the outline drawing.

2. Remove two hex bolts to dismount the mounting base.

3. Remove six hex bolts from the bottom of the transponder unit to dismount the

mounting pedestal.

4. Set the transponder unit to the cosmetic panel and fix them with six hex bolts.

5. Set the assembly (transponder unit and cosmetic panel) to the hole and fix it

with four tapping screws (5x25).

Flush mount kit B: Type OP24-2 Code no. 005-950-750

Name Type Code no. Qty

1 Mounting bracket 24-003-2821 100-299-550 1

2 Hex bolt M5x25 000-862-125 6

3 Hex nut M5 000-863-108 6

4 Flat washer M5 000-864-128 6

5 Spring washer M5 000-864-258 6

1. Cut out a hole in the mounting location, referring to the outline drawing.

2. Dismount the mounting base and mounting pedestal from the transponder unit.

3. Set the transponder unit to the hole. Using six hex bolts, attach the mounting

bracket at the bottom of the transponder unit from the rear of the flush mounting

panel.

4. Fix with six sets of hex bolt, nut, flat washers and spring washers from the rear

of the flush mounting panel.

9

Page 16

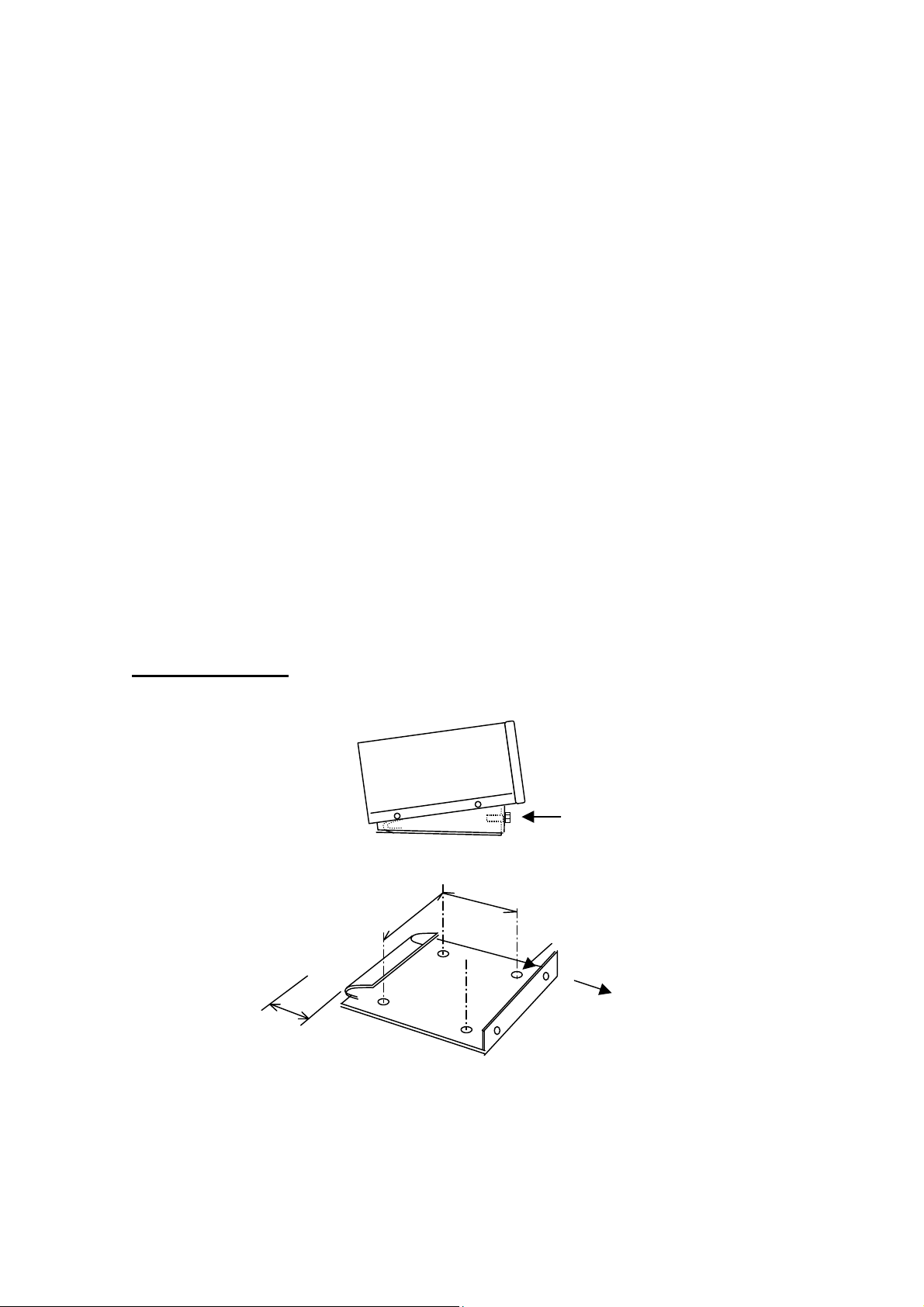

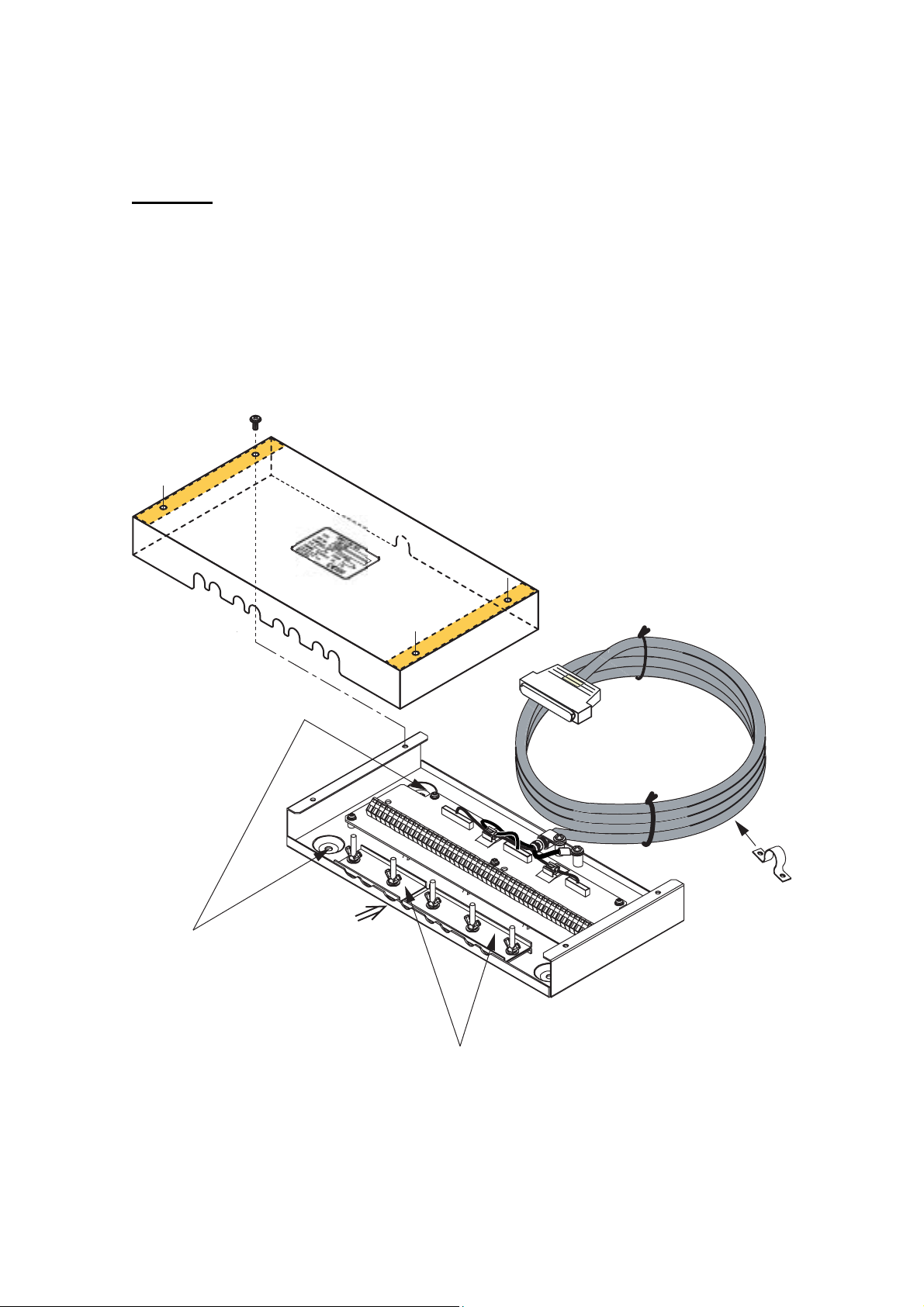

1.3 Junction Box

Mount the junction box where the junction box is protected from rain and water

splash.

Mounting

1. Open the lid of the junction box and fix the junction box with four tapping screws

(5x20). Avoid bundling the 3.3 m cable of the junction box together with any

power cable. This causes malfunction.

2. Connect cables to the terminal board, referring to Chapter 2 and 3.

3. Fix the lid after connecting external equipment.

4. Clamp the cable with several U-type cable clamps (local supply) at suitable

intervals.

Fixing holes

(5x20 tapping screws)

10

Cable entry

Cable clamp

Clamp the cable with

U-type cable clamps.

Page 17

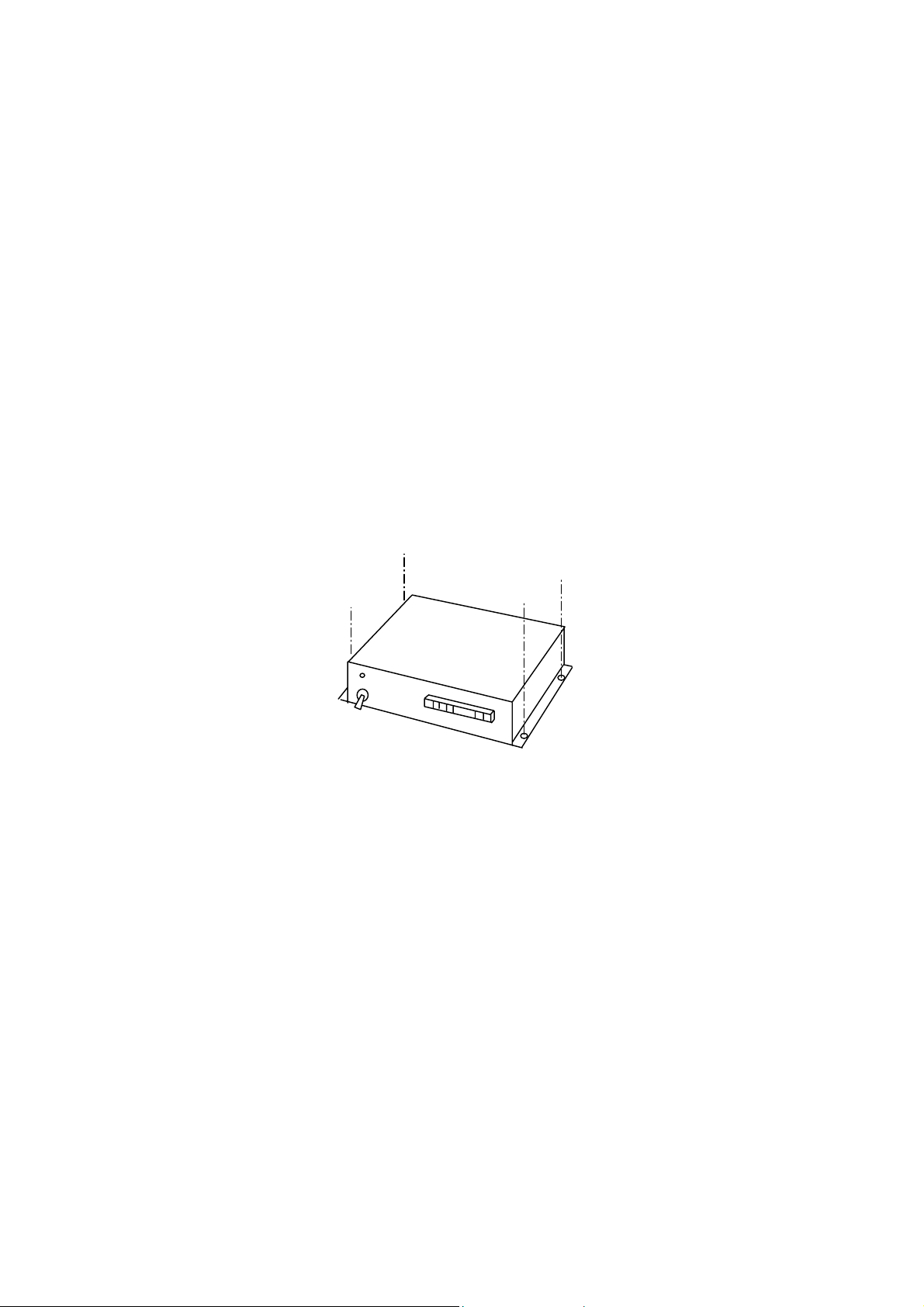

1.4 Power Supply (option)

The length of the power cable between the power supply and the transponder unit

is 3.5 m. Keep this length in mind when selecting a mounting location. A longer

cable should not be used – voltage drop will result, affecting performance.

When selecting a mounting location for the unit, keep the following in mind:

• Keep the unit out away from areas subject to water splash.

• Locate the unit away from exhaust pipes and vents.

• The mounting location should be well ventilated.

• Mount the unit where shock and vibration are minimal.

• A magnetic compass will be affected if the unit is placed too close to it. Observe

the following compass safe distances to prevent disturbance to the magnetic

compass:

Steering compass: 0.6 m

Standard compass: 0.9 m

Fix the unit with four tapping screws (4x16) to a desktop or the deck as shown in

the figure below. It is not necessary to open the cover.

1.5 Pilot Plug (option)

The pilot plug should be mounted near where the pilot steers the ship. This plug is

used to connect a PC to display AIS information for use by the pilot. Refer to the

outline drawing at the back of this manual for mounting dimensions.

11

Page 18

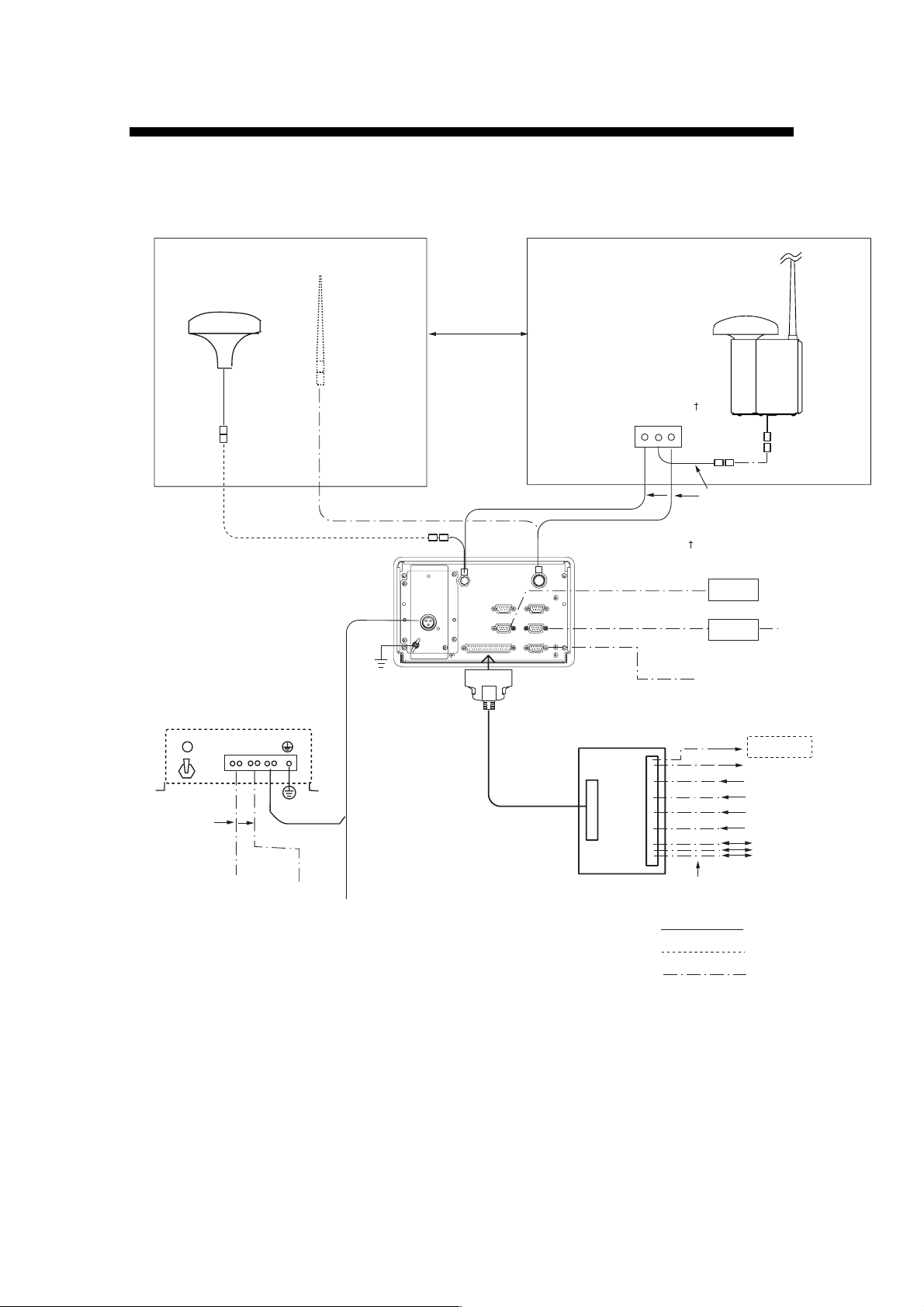

2. WIRING

Connect the equipment, referring to the interconnection diagram at the back this

manual.

GPS Antenna

GPA-017S

GSC-001

0.6 m

***

8D-FB-CV, 30 m/50 m: Option

RG-10/UY: Local supply

Power Supply

PR-240-CE

DC

AC

DC

OUT

IN

IN

1.5 sq

DPYC-1.5**

Ship’s mains

100-115/200-230 VAC

1φ, 50/60 Hz

24 VDC

150M-W2VN

Either one

RG-10/UY

GPS ANT

MJ-A3SPF0013-035 (3.5 m) *

12-24 VDC

(Connect to the alternative

power source.)

VHF ANT

AUX-2

AUX-1

LAN

AD-10 IN

EXTRA I/O

Transponder

unit

FA-100

Approx. 3.3 m

Junction Box

CB-100

GPS/VHF Conbined

Antenna GVA-100

Distributor unit

DB-1

LAN cable

(category 4 or higher)

TTYCS-1Q**

TTYCS-1Q** or TTYCS-4**

0.9 m

***

***

RG-10/UY

Attached to Distributor

(approx. 1m)

: ground is not required.

PC

AD-100

Gyrocompass

AIS sentence out

(4800 bps)

Pilot Plug

Alarm out

GPS receiver

Heading sensor

Speed sensor or ROT

Beacon receiver

AIS data In/Out

: Standard

: Option

: Local Supply

*: If the ship’s mains is 12 VDC, cable length should be less than 50 cm.

EXTRA IO port: Outputs AIS sentence (4800 bps).

AUX-1, AUX-2 port: Not used.

12

Page 19

**: DPYC-1.5, TTYCS-1Q and TTYCS-4 are Japan Industry Standard cable.

Use them or the equivalents.

DPYC-1.5

φ = 11.7 mm

Conductor

S = 1.5 mm

φ = 1.56 mm

TTYCS-4 (Four twisted pairs)

φ = 18.5 mm

Shield

Conductor

S = 0.75 mm

φ = 1.11 mm

***: Waterproofing connectors

Armor

Sheath

2

Sheath

Armor

Sheath

2

TTYCS-1Q (Four core twisted)

Armor

Sheath

φ = 11.3 mm

Conductor

S = 0.75 mm

φ = 1.11 mm

Shield

2

Wrap connector with vulcanizing tape and then vinyl tape. Bind

the tape end with a cable-tie.

Waterproofing connector

13

Page 20

Cable Connection at Junction Box

Cable fabrication

Connection

Armor Sheath

Clampherebycableclamp.

Shield

5to6mm

30

1

2

3

Core 5-6 mm

Procedure

1. Insert driver from direction 1 .

2. Tilt slightly toward 2 .

3. Insert cable core to 3 .

14

Page 21

3. INPUT/OUTPUT SIGNAL

3.1 Inputs from Sensors

There are three input ports (SENSOR 1, 2 and 3) which are based on the IEC

61162-1/2. The protocol is RS422. If there is no HDT signal from a gyrocompass,

connect the gyrocompass signal (Synchro or step signal) to the “AD-10 IN” port

(D-sub 9 pins) of the transponder unit via the FURUNO A/D Converter AD-100 (See

page 16).

TB1 in the junction box

1 TD3-A

2 TD3-B

3 GND ISO

4 RD3-A

5 RD3-B

6 GND ISO

7 TD2-A

8 TD2-B

9 GND ISO

10 RD2-A

11 RD2-B

12 GND ISO

13 TD1-A

14 TD1-B

15 GND ISO

16 RD1-A

17 RD1-B

18 GND ISO

SENSOR 3 (EXT GPS IN)

TTYCS-1Q

(4 cores twisted)

GPS navigator only

Isolated GND

SENSOR 2

TTYCS-1Q

Heading Signal (HDT)

Isolated GND

SENSOR 1

TTYCS-1Q

Speed Signal (SOG)

Isolated GND

19 TD5-A

20 TD5-B

21 GND

22 RD5-A

23 RD5-B

24 GND

TTYCS-1Q

DGPS

Beacon

Receiver

GND 0V

15

Page 22

3.2 Input/Output of AIS Signal

Three input/output ports are provided for RS-422 protocol, based on the IEC

61162-1/2. Data transmission rate is selectable from 4800 bps and 38.4 kbps.

Normally, Radar/ECDIS/PC, etc. are connected to these ports to exchange data

with the AIS. PC standard protocol RS-232C is also provided in the D-sub port of

the transponder unit.

TB1 in the junctionbox

TTYCS-4

25 TD4-A

RD-A

26 TD4-B

27 GND ISO

28 RD4-A

29 RD4-B

30 GND ISO

31 TD6-A

32 TD6-B

33 GND ISO

34 RD6-A

35 RD6-B

36 GND ISO

37 TD8-A

38 TD8-B

39 GND ISO

40 RD8-A

41 RD8-B

42 GND ISO

TTYCS-4

TTYCS-4

RD-B

Isolated GND

TD-A

TD-B

Isolated GND

RD-A

RD-B

Isolated GND

TD-A

TD-B

Isolated GND

RD-A

RD-B

Isolated GND

TD-A

TD-B

Isolated GND

L/R (INMARSAT) or

ECDIS/RADAR

EXTRA I/O

PC I/O

43 TD (232C)

44 RD (232C)

21 GND

TTYCS-1Q

Rx port

Tx port

GND

Note: For TD (232C) and RD (232C), use one twisted pair for TD and one twisted

pair for RD, separately. Use pin #21 for SG.

16

Page 23

3.3 Input of Gyrocompass Signal

If the gyrocompass has no HDT signal, the AD-10 format (FURUNO format) signal

can be input via the FURUNO A/D Converter AD-100. Connect the AD-100 to the

“AD-10 IN” port (D-sub 9 pin) on the rear panel of the transponder unit.

FA-100

AD-10 IN

DATA-H

DATA-L

CLOCK-H

CLOCK-L

GND

F.GND

>1>

>2>

>3>

>4>

>8>

>9>

Twisted pair cable (Example: TTYCS-1Q cable)

to DATA terminal of AD-100

Note: Set data output interval for 200 ms (instead of 25 ms) by internal jumper

inside the AD-100.

3.4 Alarm Signal Output

The FA-100 generates an alarm signal (relay contact signal) for hardware failure

such as transmitter block or sensor abnormality. For details of alarm type, see the

operator’s manual.

Two kinds of contact signals, on (normal closure) or off (normal open), are output,

and are selected at the junction box CB-100 according to the alarm generator

connected. The maximum current and voltage of the contact are 1 A, 125 VAC and

60 VDC. Normally connect to the NC (normal close) between #45 and #47.

TB-1 in the junction box

45 AOL

46 AOH

47 AOC

#45-#47: Normal Close

#46-#47: Normal Open

47: common line

17

Page 24

3.5 LAN Input/Output

The FA-100 supports Ethernet based on LAN. Its protocol is 10BASE-T and the

transmission rate is 10 Mbps. To connect the FA-100 with other equipment (such as

a PC), use a LAN cable category 4 or higher with shield (SDT). Connect it to the

PC with an RJ-45 connector, and connect to the FA-100 with a D-sub 9 pin

connector, to avoid noise leakage. To use a commercial LAN cable, remove one

connector and solder a D-sub 9 pin connector, supplied in the installation materials.

RJ-45 (Category 4 and higher, SDT)

FA-100

LAN (10B-T)

TD+

TD-

RD+

RDGND

F.GND

>1>

>2>

>3>

>4>

>8>

>9>

Twisted pair cable

3 RD+

6 RD1 TD+

2 TD-

3.6 Pilot Plug

Use the twisted cable TTYCS-4 between the junction box and the pilot plug. The

cable between the PC and the pilot plug should be prepared by the ship’s pilot.

Pilot plug

Junction box

Terminal board

37 TD8-A

38 TD8-B

39 GND ISO

40 RD8-A

41 RD8-B

42 GND ISO

TTYCS-4

TB1

TD A

TD B

RD-A

RD-B

SHIELD

J1

>1>

>2>

>3>

>4>

>5>

>6>

>7>

>8>

>9>

PC

18

3mm Crimp-on lug

206486-1

(AMP)

Page 25

3.7 Jumper Setting in the Junction Box

Each RS-422 RX line (on the PCB 24P0031 in the junction box) has a jumper block

with 240 ohms termination resistor. The junction box is shipped with all jumper

blocks connected between the #3 and #4 terminals pins, terminating RX lines with

240 ohms. Assuming that an external equipment has the output voltage of ±5 V,

more than 21 mA of output current is required.

If multiple equipment are connected to an output port of an external equipment,

change to jumper block setting to between the #1 and #2 pins to reduce the load on

the FA-100. Then, the input impedance of the RS-422 RX lines in the FA-100

becomes more than 2.4 k ohms.

We recommend that you leave the connection of the jumper block between #3 and

#4 pins if only the FA-100 is connected to an external equipment.

Jumper block (6 pcs)

2

Factory setting: #3-#4

1

4

3

19

Page 26

3.8 Input/Output Sentences

1) SENSOR 1, SENSOR2, and SENSOR3 ports

These ports can receive IEC61162-1/2 standard data. The transmission rate of

sensor 1, 2, and 3 is selectable from 4800 bps and 38.4 kbps through the menu.

Input sentences are as follows:

$xxDTM

$xxOSD, $xxRMC, $xxROT, $xxVBW, $xxVTG

Note: The talker of the underlined sentences has priority as

follows:

Other sentences disregard talker.

2) PC I/O, LR or ECDIS/RADAR, EXTRA I/O and EXTRA 1 I/O ports

These ports can receive or output IEC61162-1/2 standard data. The transmission

rate of signals is selectable from 4800 bps and 38.4 kbps through the menu. The

transmission rate of the EXTRA IO port signal is fixed to 4800 bps.

Input sentences are as follows:

$xxABM, $xxACA, $xxACK, $xxAIR

$xxBBM, $xxDTM

$xxGLL, $xxGNS, $xxHDT, $xxLRF

$xxLRI, $xxOSD, $xxRMC

$xxSSD, $xxVBW, $xxVSD, $xxVTG

Note: The talker of the underlined sentences has priority as

follows:

Other sentences disregard talker.

Output sentences are as follows:

$AIABK, $AIACA, $AIALR, $AILRF,

$AILR1, $AILR2, $AILR3, $AITXT,

$AIVDM, $AIVDO

, $xxGBS, $xxGGA, $xxGLL, $xxGNS, $xxHDT

GN>GP>GL>LC>IN

, $xxGBS, $xxGGA

, $xxROT

GN>GP>GL>LC>IN

20

Page 27

3.9 Changing Ship’s Mains Specifications

The power supply PR-240-CE is shipped ready for connection to a 200-230 VAC

ship’s mains. If the ship’s mains is 100 VAC – 115 VAC, change the tap connection

and terminal board connection as below. Attach label supplied as accessories to

the punch mark in the front panel according to the ship’s mains.

Ship’s mains Tap connection Terminal board

connection #1 & #2

100-115 VAC SEL 115 V b

200-230 VAC SEL 230 V a

200-230 VAC

1

2

White

Black

3

(a)

1

2

3

4

5

6

7

8

Punch mark

100-115 VAC

1

2

3

(b)

SEL

115 V

SEL

230 V

White

Black

Front

Heat sink

Terminal board connection

Top view (Cover removed)

Tap connection (Pull out to remove)

21

Page 28

4. SETTING AND ADJUSTMENT

After installing the equipment, set up the own ship’s static information (MMSI, IMO

number, ship’s name, call sign, type of ship and GPS antenna position). Also, set

up the system settings.

4.1 Setting MMSI, IMO No., Name and Call Sign

1. While holding down the [0] key, press the [POWER] key.

2. After the following message appears, release the [0] key. (It takes several

seconds before the message appears.)

NOW STARTING

CHECKING MEMORY

3. After the following window appears, enter the password. Note that the password

is known by only the FURUNO dealer.

[ENTER PASSWORD]

PASSWORD:

4. Press the [ENT] key to display the SET MMSI & IMO# window.

[SET MMSI & IMO#]

Asterisk marks

current selection.

5. Enter ship’s MMSI (Maritime Mobile Service Identity) in nine digits.

6. Press the [NEXT] key to select IMO#.

7. Enter ship’s IMO number in nine digits. If the IMO number has 7 digits, enter “0”

twice followed by IMO#. IF the ship has no IMO number, enter all zeroes.

8. Press the [NEXT] key to select NAME.

MMSI :

IMO# :

NAME :

C.SIGN :

SET: [ENT]

22

Page 29

9. Enter ship’s name, using up to 20 alphanumeric characters. To switch between

alphabet and numerical character, press the [SFT] key. To enter an alphabet,

press corresponding key several times until desired letter is displayed. For

example, if you press the [2] key continuously, the character A, B and C appear

cyclically. If you want to enter the same letter or an other letter with the same

key (for example, AA or AC), press the [6] key while pressing the [SFT] key, to

send the cursor to the next position.

10. Press the [NEXT] key to select C.SIGN.

11. Enter call sign, using up to seven alphanumeric characters.

12. Press the [ENT] key to register data. The INIT SETTINGS sub-menu appears.

23

Page 30

4.2 Setting GPS Antenna Position and

Ship’s Type

1. In the INIT SETTING sub-menu, press the [6] key to open the SET ANTENNA

POS window.

SET ANTENNA POS

1 INTERNAL ANT POS

2 EXTERNAL ANT POS

SET ANTENNA POS window

2. With 1 selected, press the [ENT] key. The 1 is for entering internal GPS antenna

position and 2 is for external GPS which is connected to the AIS.

[INTERNAL ANT POS]

A

A: 000 m

B: 000 m

B

C: 00 m

CD

D: 00 m

INTERNAL ANT POS window

3. Enter locations of GPS antenna, by using the numeric keys and the [NEXT] key,

and finally press the [ENT] key.

A: Distance from bow to GPS antenna position

B: Distance from stern to GPS antenna position

C: Distance from port to GPS antenna position

D: Distance from starboard to GPS antenna position

4. Enter external GPS antenna position similar to how you entered internal GPS

antenna position.

5. Press the [MENU] key to return to the INIT SETTINGS sub-menu.

6. Press the [4] key to display the SET TYPE&CREW window.

[SET TYPE&CREW]

CREW : 0012

TYPE CLASS : A

TYPE NO. : 0

TYPE NAME

TYPE CLASS cannot

be changed.

(A = IMO type)

24

SET TYPE&CREW window

Page 31

7. Press the [NEXT] key to select TYPE NO.

Confirm type of ship with ship’s captain before setting it.

8. Press the [2], [4], [6] or [8] key as appropriate to select your ship’s type,

referring to the list on below.

10 FUTURE USE ALL SHIPS OF THIS TYPE 60 PASSENGER SHIPS ALL SHIPS OF THIS TYPE

11 FUTURE USE CARRYING DG, HS, OR MP(A) 61 PASSENGER SHIPS CARRYING DG, HS, OR MP(A)

12 FUTURE USE CARRYING DG, HS, OR MP(B) 62 PASSENGER SHIPS CARRYING DG, HS, OR MP(B)

13 FUTURE USE CARRYING DG, HS, OR MP(C) 63 PASSENGER SHIPS CARRYING DG, HS, OR MP(C)

14 FUTURE USE CARRYING DG, HS, OR MP(D) 64 PASSENGER SHIPS CARRYING DG, HS, OR MP(D)

15 FUTURE USE FUTURE USE 65 PASSENGER SHIPS FUTURE USE

16 FUTURE USE FUTURE USE 66 PASSENGER SHIPS FUTURE USE

17 FUTURE USE FUTURE USE 67 PASSENGER SHIPS FUTURE USE

18 FUTURE USE FUTURE USE 68 PASSENGER SHIPS FUTURE USE

19 FUTURE USE NONE 69 PASSENGER SHIPS NONE

20 WIG

21 WIG CARRYING DG, HS, OR MP(A) 71 CARGO SHIPS CARRYING DG, HS, OR MP(A)

22 WIG CARRYING DG, HS, OR MP(B) 72 CARGO SHIPS CARRYING DG, HS, OR MP(B)

23 WIG CARRYING DG, HS, OR MP(C) 73 CARGO SHIPS CARRYING DG, HS, OR MP(C)

24 WIG CARRYING DG, HS, OR MP(D) 74 CARGO SHIPS CARRYING DG, HS, OR MP(D)

25 WIG FUTURE USE 75 CARGO SHIPS FUTURE USE

26 WIG FUTURE USE 76 CARGO SHIPS FUTURE USE

27 WIG FUTURE USE 77 CARGO SHIPS FUTURE USE

28 WIG FUTURE USE 78 CARGO SHIPS FUTURE USE

29 WIG NONE 79 CARGO SHIPS NONE

30 FISHING 80 TANKER

31 TOWING 81 TANKER CARRYING DG, HS, OR MP(A)

LENGTH OF THE TOW EXCEEDS 200M OR BREADTH EXCEEDS 25M

32

33 ENGAGED IN DREDGING OR UNDERWATER OPERATIONS 83 TANKER CARRYING DG, HS, OR MP(C)

34 ENGAGED IN DIVING OPEARATIONS 84 TANKER CARRYING DG, HS, OR MP(D)

35 ENGAGED IN MILITARY OPEARATIONS 85 TANKER FUTURE USE

36 SAILING 86 TANKER FUTURE USE

37 PLEASURE CRAFT 87 TANKER FUTURE USE

38 FUTURE USE 88 TANKER FUTURE USE

39 FUTURE USE 89 TANKER NONE

40 HSC

41 HSC CARRYING DG, HS, OR MP(A) 91 OTHER TYPE OF SHI CARRYING DG, HS, OR MP(A)

42 HSC CARRYING DG, HS, OR MP(B) 92 OTHER TYPE OF SHI CARRYING DG, HS, OR MP(B)

43 HSC CARRYING DG, HS, OR MP(C) 93 OTHER TYPE OF SHI CARRYING DG, HS, OR MP(C)

44 HSC CARRYING DG, HS, OR MP(D) 94 OTHER TYPE OF SHI CARRYING DG, HS, OR MP(D)

45 HSC FUTURE USE 95 OTHER TYPE OF SHI FUTURE USE

46 HSC FUTURE USE 96 OTHER TYPE OF SHI FUTURE USE

47 HSC FUTURE USE 97 OTHER TYPE OF SHI FUTURE USE

48 HSC FUTURE USE 98 OTHER TYPE OF SHI FUTURE USE

49 HSC NONE 99 OTHER TYPE OF SHI NONE

50 PILOT

51 SEACH AND RESCURE VESSELS

52 TUGS

53 PORT TENDERS

VESSELS WITH ANTI-POLUUTION FACILITIES OR EQUIPMENT

54

55 LAW ENFOREMENT VESSELS

56 SPARE-FOR ASSIGNMENTS TO LOCAL VESSELS

57 SPARE-FOR ASSIGNMENTS TO LOCAL VESSELS

58 MEDICAL TRANSPORTS

59 SHIPS ACCORDING TO RESOLUTION NO 18

ALL SHIPS OF THIS TYPE 70 CARGO SHIPS ALL SHIPS OF THIS TYPE

ALL SHIPS OF THIS TYPE

82 TANKER CARRYING DG, HS, OR MP(B)

ALL SHIPS OF THIS TYPE 90 OTHER TYPE OF SHI ALL SHIPS OF THIS TYPE

WIG: Wing in ground

HSC: High speed craft

DG: Dangerous goods

HS: Harmful substances

MP: Marine pollutants

0-9: Undefined

9. Press the [ENT] key to return to the INIT SETTING sub-menu.

25

Page 32

10. Press the [MENU] key. The SAVE confirmation window appears.

SAVE ?

YES

NO

CANCEL

SAVE confirmation window

11. With YES selected, press the [ENT] key to save the data.

4.3 System Settings

1. Press the [MENU] key to open the main menu.

2. Press the [6] key to open the SYSTEM SETTINGS sub-menu.

[SYSTEM SETTINGS]

1 SET I/O PORT

2 SET CHANNEL

3 SET LR MODE

4 SET OTHER I/O

5 SET BUZZER

SYSTEM SETTINGS sub-menu

3. Press the [1] key to display the SET I/O PORT sub-menu.

[SET I/O PORT]

1 I/O SPEED

2 I/O FUNCTION

3 I/O PRIORITY

4 SET LAN (IP ADDR)

SET I/O PORT sub-menu

4. Press the [1] key to display the I/O SPEED window.

[I/O SPEED]

1 2

+

+

+

+

PC I/O : 38.4 k

SNSR1: 38.4 k

SNSR2: 38.4 k

SNSR3: 38.4 k

[NEXT] key

-

-

-

-

[SFT] +[NENT]

key

[I/O SPEED]

LR : 38.4 k

BCON : 4800

EXTRA1 : 38.4 k

XTRA I/O : 4800

1 2

+

-

+

-

+

-

+

-

26

I/O SPEED window

Page 33

5. Select the appropriate data transmission rate from 4800 bps and 38.4 kbps for

PC I/O, SNSR 1, SNSR 2, SNSR 3, LR, BCON (beacon receiver), EXTRA1 and

EXTRA2, by pressing the [SFT] key. To select each item, press the [NEXT] key.

To go backward, press the [NEXT] key while pressing the [SFT] key.

6. Press the [ENT] key to return to the SET I/O PORT sub-menu.

7. Press the [2] key to display the I/O FUCTION window.

[I/O FUNCTION]

PORT LR: EXT DISP

+

-

I/O FUNCTION window

8. Press the [SFT+/-] key to select EXT DISP or LR, depending on equipment

connected.

EXT DISP: External display, such as radar, ECDIS

LR: Long range communication, such INMARSAT communication equipment

9. Press the [ENT] key to return to the SET I/O PORT sub-menu.

10. Press the [3] key to display the I/O PRIORITY window.

[I/O PRIORITY]

1 L/L COG SOG

2 HDG

3 ROT

4 AIS

I/O PRIORITY window

11. Press the [1] key to display the L/L COG SOG window.

[L/L COG SOG]

SN1:

SN3: 3

EX1 : 4

PC : 6

1

DEFAULT: [CLR]

SN2: 2

LR : 5

LAN: 7

L/L/COG/SOG PRIORITY window

27

Page 34

12. Set L/L position, COG and SOG data priority with the numeric keys according to

sensors connected.

COG: Course over ground

SOG: Speed over ground

13. Press the [ENT] key to return to the I/O PRIORITY window.

Note: If you have entered 8, 9 or the same value for more than one item at step

12, the following error message appears. In this case, press the [ENT]

key and set the priority correctly.

[ERROR]

CAN NOT INPUT

SAME VALUE !

ESC: [ENT]

[ERROR]

OUT OF RANGE !

PRIORITY: 1-7

ESC: [ENT]

ERROR message

14. Set the priority for HDG and ROT similar to how you did for “L/L COG SOG”.

The priority of heading data entered from the AD-10 IN port is the lowest.

15. To set the priority of AIS, press the [4] key to choose AIS.

[AIS]

RESPONSE:PC

- - - - - - - - - - - - - - - - - - - EX1 : ENBL

LR : ENBL

PC : ENBL

LAN: ENBL

DEFAULT: [CLR]

+

-

+

-

+

-

+

-

+

-

AIS PRIORITY setting window

16. With RESPONSE selected, press the [SFT] key to select PC, NONE, LAN, EX1

or LR as appropriate.

Set an output port for response from other party after you transmit messages or

interrogation from the PC, ECDIS, LR, or LAN.

NONE : No output for response

PC : Output to PC I/O port

LAN : Output to LAN port

LR : Output to LR or ECDIS/RADAR port

EX1 : Output to EXTRA1 port

The PC I/O port provides RS-422 and RS-232C terminals. For example, to

connect a PC for pilot, connect it to the RS-422 terminal and set 34.8 Kbps for bit

rate on the PC I/O option in the I/O SPEED window.

17. Press the [NEXT] key to select EX1, LR, PC or LAN.

18. Press the [SFT] key to select ENBL (enable) or DSBL (disable) as appropriate.

This setting is for communication between FA-100 and each external equipment.

“DSBL” disables communication with selected item.

19. Press the [ENT] key and then [MENU] key to return to the SET I/O PORT

sub-menu.

28

Page 35

20. Press [4] key to display the SET LAN (IP ADRS) window.

[SET LAN (IP ADRS)]

IP ADDRESS:

000-000-000-000

SUB NET MASK:

000-000-000-000

PORT NO. 10000

SET LAN (IP ADDR) window

21. If the FA-100 is connected to a network, enter IP address, sub net mask and

port number with the numeric keys and the [NEXT] key.

22. Press the [ENT] key and then the [MENU] key to return to the SYSTEM

SETTINGS sub-menu.

23. Press the [4] key to display the SET OTHER I/O window.

[SET OTHER I/O]

AD-10: DSBL

ROT : 01 SEC

+

-

SET OTHER I/O window

24. Select or set other I/O as follows.

1) AD-10: Select ENBL to use AD-10 format gyrocompass signal.

2) ROT: Set smoothing time (1 to 10 seconds) of the ship’s rate of turn if you are

using a ROT meter. This time is used to smooth the variations of data from the

AD-100 for calculation of ROT.

3) Press the [ENT] key to register setting. The display returns to the SYSTEM

SETTINGS sub-menu.

25. Press the [MENU] key. The following confirmation window appears.

SAVE ?

YES

NO

CANCEL

SA VE confirmation window

26. Select YES and press the [ENT] key. The main menu appears.

29

Page 36

This page is intentionally left blank.

Page 37

PACKING LIST

OUTLINE

Q'TY

A-1

PACKING LIST

PACKING LISTPACKING LIST

FA‑100‑J/E,FA‑100‑J/E‑HK

FA‑100‑J/E,FA‑100‑J/E‑HK

FA‑100‑J/E,FA‑100‑J/E‑HKFA‑100‑J/E,FA‑100‑J/E‑HK

24AA‑X‑9854 ‑1

1/1

NAME

ユニット

ユニット UNIT

ユニットユニット

トランスポンダ部

TRANSPONDERUNIT

工事材料

工事材料 INSTALLATIONMATERIALS

工事材料工事材料

コネクタフード(XM2)

HOUSINGCASE

ケーブル組品MJ

CABLEASSY.

コネクタ(XM2)

CONNECTOR(XM2)

図書

図書 DOCUMENT

図書図書

装備要領書

INSTALLATIONMANUAL

取扱説明書

UNIT

UNITUNIT

INSTALLATIONMATERIALS CP24‑00102

INSTALLATIONMATERIALSINSTALLATIONMATERIALS

DOCUMENT

DOCUMENTDOCUMENT

DESCRIPTION/CODE№

FA‑100

000‑053‑889

XM2S‑0912

000‑145‑422

MJ‑A3SPF0015‑035

000‑137‑340

XM2A‑0901

000‑111‑785

IMJ‑44170‑*

000‑809‑324

OMJ‑44170‑*

**

CP24‑00102

CP24‑00102CP24‑00102

**

1

1

1

1

1

OPERATOR'SMANUAL

1.コ-ド番号末尾の[**]は、選択品の代表型式/コートを表します。

CODE NUMBER ENDED BY "**" INDICATES THE NUMBER OF TYPICAL MATERIAL.

000‑809‑322

1

**

(略図の寸法は、参考値です。DIMENSIONSINDRAWINGFORREFERENCEONLY.)

(略図の寸法は、参考値です。DIMENSIONSINDRAWINGFORREFERENCEONLY.)

(略図の寸法は、参考値です。DIMENSIONSINDRAWINGFORREFERENCEONLY.)(略図の寸法は、参考値です。DIMENSIONSINDRAWINGFORREFERENCEONLY.)

24AA‑X‑9854

Page 38

PACKING LIST

OUTLINE

Q'TY

A-2

PACKING LIST

PACKING LISTPACKING LIST

CB‑100‑A、CB‑100‑A‑HK

CB‑100‑A、CB‑100‑A‑HK

CB‑100‑A、CB‑100‑A‑HKCB‑100‑A、CB‑100‑A‑HK

24AA‑X‑9851 ‑4

1/1

NAME

ユニット

ユニット UNIT

ユニットユニット

接続箱

JUNCTIONBOXUNIT

工事材料

工事材料 INSTALLATIONMATERIALS

工事材料工事材料

+トラスタッピンネジ

+TAPPINGSCREW

UNIT

UNITUNIT

INSTALLATIONMATERIALS CP05‑08701

INSTALLATIONMATERIALSINSTALLATIONMATERIALS

DESCRIPTION/CODE№

CB‑100‑A

000‑053‑873

5X20SUS3041シュ

000‑802‑081

**

CP05‑08701

CP05‑08701CP05‑08701

1

4

1.コ-ド番号末尾の[**]は、選択品の代表型式/コートを表します。

DOUBLE ASTERISK DENOTES COMMONLY USED EQUIPMENT.

(略図の寸法は、参考値です。DIMENSIONSINDRAWINGFORREFERENCEONLY.)

(略図の寸法は、参考値です。DIMENSIONSINDRAWINGFORREFERENCEONLY.)

(略図の寸法は、参考値です。DIMENSIONSINDRAWINGFORREFERENCEONLY.)(略図の寸法は、参考値です。DIMENSIONSINDRAWINGFORREFERENCEONLY.)

24AA‑X‑9851

Page 39

PACKING LIST

A-3

GVA‑100

24AA‑X‑9853 ‑3

1/1

NAME

OUTLINE

DESCRIPTION/CODE№

ユニット UNIT

複合空中線部

GPS/VHFCOMBINEDANTENNA

GVA‑100

000‑053‑810

工事材料 INSTALLATIONMATERIALS CP24‑00141

コネクタ(N)

CONNECTOR

コンベックス

PLASTICBAND

アンテナ取付金具

ANTENNAFIXINGBRACKET

ミガキ平座金

FLATWASHER

N‑P‑8DFB座金付き

000‑140‑463

CV‑200HT

000‑809‑226

24‑003‑3015‑0

100‑302‑670

M8SUS304

000‑864‑130

Q'TY

1

2

2

2

4

六角ナット 1種

HEX.NUT

M8SUS304

8

000‑863‑110

(略図の寸法は、参考値です。DIMENSIONSINDRAWINGFORREFERENCEONLY.)

24AA‑X‑9853

Page 40

CODENO.

A-4

CODENO.

CODENO.CODENO.

TYPE

TYPE

TYPETYPE

004‑365‑780

CP20‑01111

20AG‑X‑9403

‑1

1/1

工事材料表

工事材料表

工事材料表工事材料表

INSTALLATIONMATERIALS

番号

NO.

1

2

3

名 称

NAME

パイプ

PIPE

取付補助金具

INSTALLINGSPACER

パーカークランプ

HOSECLAMP

マスト取付金具

MASTFIXTURE

略 図

OUTLINE

型名/規格

DESCRIPTIONS

20‑007‑3011‑2

CODENO.

20‑007‑3012‑1

CODENO.

NO.6348SUS303

CODENO.

100‑183‑262

100‑183‑271

000‑805‑906

数量

Q'TY

用途/備考

REMARKS

1

1

2

20AG‑X‑9403

FURUNO ELECTRIC CO .,LTD.

(略図の寸法は、参考値です。 DIMENSIONSINDRAWINGFORREFERENCEONLY.)

(略図の寸法は、参考値です。 DIMENSIONSINDRAWINGFORREFERENCEONLY.)

(略図の寸法は、参考値です。 DIMENSIONSINDRAWINGFORREFERENCEONLY.)(略図の寸法は、参考値です。 DIMENSIONSINDRAWINGFORREFERENCEONLY.)

Page 41

PACKING LIST

A-5

PACKING LIST

PACKING LISTPACKING LIST

PR-240-CE

PR-240-CE

PR-240-CEPR-240-CE

24AA-X-9852 -5

1/1

N A M E

ユニット

ユニット UNIT

ユニットユニット

AC-DC電源

POWER SUPPLY UNIT

工事材料

工事材料 INSTALLATION MATERIALS

工事材料工事材料

PR-240-CE電源変更手順書

POWER MODIFICATION PROCEDURES

デンゲンハリマーク

POWER LABEL

+トラスタッピンネジ

+TAPPING SCREW

UNIT

UNITUNIT

INSTALLATION MATERIALS CP24-00151

INSTALLATION MATERIALSINSTALLATION MATERIALS

O U T L I N E

DESCRIPTION/CODE №

PR-240-CE

000-053-879

C52-00205-A

000-147-013

24-003-4101-3

100-299-773

4X16 SUS304 1シュ

000-802-080

CP24-00151

CP24-00151CP24-00151

Q'TY

1

1

1

4

(略図の寸法は、参考値です。 DIMENSIONS IN DRAWING FOR REFERENCE ONLY.)

(略図の寸法は、参考値です。 DIMENSIONS IN DRAWING FOR REFERENCE ONLY.)

(略図の寸法は、参考値です。 DIMENSIONS IN DRAWING FOR REFERENCE ONLY.)(略図の寸法は、参考値です。 DIMENSIONS IN DRAWING FOR REFERENCE ONLY.)

24AA-X-9852

Page 42

CODENO.

A-6

CODENO.

CODENO.CODENO.

TYPE

TYPE

TYPETYPE

20AG‑X‑9404

‑1

1/1

工事材料表

工事材料表

工事材料表工事材料表

INSTALLATIONMATERIALS

番号

NO.

1

2

名 称

NAME

アンテナケーブル組品

ANTENNACABLEASSY.

ケーブル組品

CABLEASSY.

GP‑80,GP‑90,SC‑55,GP‑3500/F

GP‑1850,GP‑1650,FA‑100,GP‑1640/F

SC‑60/120,GD/GP‑280/680/380

略 図

OUTLINE

型名/規格

DESCRIPTIONS

8D‑FB‑CV*30M*

CODENO.

8D‑FB‑CV*50M*

CODENO.

000‑111‑547

000‑117‑599

数量

Q'TY

用途/備考

REMARKS

選択 TOBESELECTED

1

選択 TOBESELECTED

1

20AG‑X‑9404

FURUNO ELECTRIC CO .,LTD.

(略図の寸法は、参考値です。 DIMENSIONSINDRAWINGFORREFERENCEONLY.)

(略図の寸法は、参考値です。 DIMENSIONSINDRAWINGFORREFERENCEONLY.)

(略図の寸法は、参考値です。 DIMENSIONSINDRAWINGFORREFERENCEONLY.)(略図の寸法は、参考値です。 DIMENSIONSINDRAWINGFORREFERENCEONLY.)

Page 43

工事材料表

A-7

工事材料表

工事材料表工事材料表

INSTALLATIONMATERIALS

番号

NO.

1

名 称

NAME

変換ケーブル組品

CONVERTCABLEASSY.

略 図

OUTLINE

CODENO.

CODENO.

CODENO.CODENO.

TYPE

TYPE

TYPETYPE

型名/規格

DESCRIPTIONS

NJ‑TP‑3DXV‑1

CODENO.

004‑372‑420

CP20‑01701

000‑123‑809

数量

Q'TY

20AG‑X‑9405

用途/備考

2

‑1

1/1

REMARKS

ビニールテープ

2

VINYLTAPE

コネクタ(N)

3

CONNECTOR

絶縁テープ

4

SELF‑BONDINGTAPE

NO36002X19X10000

クロ エスロン

CODENO.

N‑P‑8DFB

CODENO.

Uテープ 0.5X19X5M

CODENO.

000‑835‑215

000‑111‑549

000‑800‑985

1

1

1

20AG‑X‑9405

FURUNO ELECTRIC CO .,LTD.

(略図の寸法は、参考値です。 DIMENSIONSINDRAWINGFORREFERENCEONLY.)

(略図の寸法は、参考値です。 DIMENSIONSINDRAWINGFORREFERENCEONLY.)

(略図の寸法は、参考値です。 DIMENSIONSINDRAWINGFORREFERENCEONLY.)(略図の寸法は、参考値です。 DIMENSIONSINDRAWINGFORREFERENCEONLY.)

Page 44

CODENO.

A-8

CODENO.

CODENO.CODENO.

TYPE

TYPE

TYPETYPE

004‑365‑780

CP20‑01111

20AG‑X‑9403

‑1

1/1

工事材料表

工事材料表

工事材料表工事材料表

INSTALLATIONMATERIALS

番号

NO.

1

2

3

名 称

NAME

パイプ

PIPE

取付補助金具

INSTALLINGSPACER

パーカークランプ

HOSECLAMP

マスト取付金具

MASTFIXTURE

略 図

OUTLINE

型名/規格

DESCRIPTIONS

20‑007‑3011‑2

CODENO.

20‑007‑3012‑1

CODENO.

NO.6348SUS303

CODENO.

100‑183‑262

100‑183‑271

000‑805‑906

数量

Q'TY

用途/備考

REMARKS

1

1

2

20AG‑X‑9403

FURUNO ELECTRIC CO .,LTD.

(略図の寸法は、参考値です。 DIMENSIONSINDRAWINGFORREFERENCEONLY.)

(略図の寸法は、参考値です。 DIMENSIONSINDRAWINGFORREFERENCEONLY.)

(略図の寸法は、参考値です。 DIMENSIONSINDRAWINGFORREFERENCEONLY.)(略図の寸法は、参考値です。 DIMENSIONSINDRAWINGFORREFERENCEONLY.)

Page 45

Page 46

Oct. 21,'02

D - 2

Page 47

Oct. 21,'02

D - 3

Page 48

Sep.29'05

D-4

Page 49

May20'03

D-4a

Page 50

Feb.22'05

D-5

Page 51

Jan. 9,'03

D - 6

Page 52

Jan. 9, '03

D - 7

Page 53

Mar.11'04

H.Hayashi

D-8

Page 54

Feb.02'05

D-9

Page 55

Nov.28'03

D-10

Page 56

Y.Hatai

D-11

Page 57

Oct.02'03

D-12

Page 58

Y.Hatai

S-1

選択

SELECT

GPSアンテナ

複合空中線部

GPS/VHF ANTENNA

GVA-100

GPS ANTENNA

GPA-017S

OR

GSC-001

N-J-3

VHFアンテナ

VHF ANTENNA

150M-W2VN

OR

FAB-151D

M-P-7

RG-10/UY *1

分配器

DISTRI-

1m

BUTOR

A

B

150M-W2VN

OR

FAB-151D

GSC-001

*2

0.8m

N-J-3

N-P-8DFB

8D-FB-CV,30/50m(L>20m)

RG-10/UY,MAX.20m *1

0.2m

TNC-J-3

1m,φ5.3

NJ-TP-3DXV-1

N-P-8DFB

8D-FB-CV,30/50m(L>20m) *2

RG-10/UY,MAX.20m *1

*2

N-P-8DFB

船内主電源及び

非常電源

SHIP'S MAIN AND

EMERGENCY SOURCE

12-24VDC

C

MJ-A3SPF0015,3.5m,φ6

(02S4100-0)

AC/DC電源ユニット

AC/DC POWER SUPPLY

UNIT

100-115/200-230VAC

φ1,50/60Hz

*DPYC-1.5

PR-240-CE

AC IN (+)

注記

*1)造船所手配。

*2)オプション。

*3)外部GPS受信機からのL/Lデータ入力が必要。

*4)SOG、COGが外部GPSから出力可能な場合は不要。

*5)ROTは接続可能な場合のみ。

*6)AD-10フォーマット(GYRO-IEC61162がないときに必要)

*7)12V仕様の場合、ケーブル最大長は0.5m。

*8)AMP社製。

D

NOTE:

*1: SHIPYARD SUPPLY.

*2: OPTION.

*3: POSITION DATA (L/L) IS REQUIRED BY EXTERNAL GPS RECEIVER.

*4: SPEED LOG IS NOT REQUIRED WHEN SOG (SPEED OVER GROUND) AND

COG (COURSE OVER GROUND) DATA ARE FED BY EXTERNAL GPS RECEIVER.

*5: ROT (RATE OF TURN) INDICATOR CAN BE CONNECTED IF PROVIDED.

*6: GYRO CONVERTOR AD-100 IS REQUIRED WHEN GYRO SIGNAL (IEC61162)

IS NOT AVAILABLE.

*7: MAX. CABLE LENGTH IS 0.5m FOR 12 VDC SPECIFICATIONS.

*8: SUPPLIED BY AMP INC.

CO-0.2x2P: CO-SPEVV-SB-C 0.2x2P,φ10.5

*2

DC OUT

(-)

*2

1m

DB-1

1m

*7

PE, V-2.0SQ *1

保護アース

NJ-TP-3DXV-1

N-P-8DFB

M-P-3

VHF-ANT

TNC-P-3

GPS-ANT

シロクロWHT

M-P-7

1m,φ5.3

MJ-A3SPFD

BLK

3412 56

トランスポンダ部

TRANSPONDER UNIT

FA-100

VHF-ANT

J1

ANT

E

GPS-ANT

J2

POWER

J1(FM-C3MR)

1

(+)

2

(-)

3

GND

24P0020

SNSR3

IEC61162-1/2

SNSR2

IEC61162-1/2

SNSR1

IEC61162-1/2

BEACON

RTCM SC-104

LR OR ECDIS/RADAR

IEC61162-1/2

EXTRA1 I/O

IEC61162-1/2

PC I/O

(RS-422)

(RS-232C)

ALARM OUT

(CONTACT SIG.)

EXTRA I/O

IEC61162-1

LAN(10B-T)

IEC61162-4

(10BASE-T)

AD-10 IN

*6

24P0025

TD3-A

TD3-B

RD3-A

RD3-B

TD2-A

TD2-B

RD2-A

RD2-B

TD1-A

TD1-B

RD1-A

RD1-B

TD5-A

TD5-B

RD5-A

RD5-B

TD4-A

TD4-B

RD4-A

RD4-B

TD6-A

TD6-B

RD6-A

RD6-B

TD8-A

TD8-B

RD8-A

RD8-B

ALOL

ALOH

ALOC

1PPSIN

GND

TD7-A

TD7-B

GNDFG8

LATX-H

LATX-L

LARX-H

LARX-L

GND

GDAT-H

GDAT-L

GCK-H

GCK-L

GND

AUX-1

LOG

LOG-G

PRTX

PRRX

GND

AUX-2

GPEXT-A

GPEXT-B

GPEXR-A

GPEXR-B

GND

接続箱

XM2A-3710

J1

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

TD

30

RD

31

32

33

34

35

NC

36

37

FG

D-SUB 9P

J2

1

2

9

D-SUB 9P

J3

1

2

3

4

8

FG

9

D-SUB 9P

J4

1

2

3

4

8

FG

9

J5

1

2

NOT USED

6

7

8

FG

9

J6

1

NOT USED

2

3

4

8

FG

9

24S0058,3.3m

アオ/アカ1

P

アオ/クロ1

モモ/アカ1

P

モモ/クロ1

P

ダイ/アカ1

P

ダイ/クロ1

ハイ/アカ1

P

ハイ/クロ1 GRY/BLK1

アオ/アカ2

P

アオ/クロ2

モモ/アカ2

P

モモ/クロ2

ミドリ/アカ2

P

ミドリ/クロ2

ダイ/アカ2

P

ダイ/クロ2

ハイ/アカ2

P

ハイ/クロ2 GRY/BLK2

アオ/アカ3

P

アオ/クロ3

モモ/アカ3

P

モモ/クロ3 BLU/BLK3

ミドリ/アカ3 GRN/RED3

P

ミドリ/クロ3 GRN/BLK3

ダイ/アカ3 ORG/RED3

P

ダイ/クロ3 ORG/BLK3

ハイ/アカ3

P

ハイ/クロ3 GRY/BLK3

アオ/アカ4 BLU/RED4

P

アオ/クロ4 BLU/BLK4

モモ/アカ4 PNK/RED4

P

モモ/クロ4

ミドリ/アカ4 GRN/RED4

P

ミドリ/クロ4 GRN/BLK4

TTYCS-1Q,φ13.5 *1

OR CO-0.2x2P

LAN CABLE *1

P

CATEGORY 4 OR ABOVE

P

(MAX.30m)

TTYCS-1Q,φ13.5 *1

OR CO-0.2x2P

BLU/RED1

BLU/BLK1

PNK/RED1

PNK/BLK1

GRN/RED1ミドリ/アカ1

GRN/BLK1ミドリ/クロ1

ORG/RED1

ORG/BLK1

GRY/RED1

BLU/RED2

BLU/BLK2

PNK/RED2

PNK/BLK2

GRN/RED2

GRN/BLK2

ORG/RED2

ORG/BLK2

GRY/RED2

BLU/RED3

BLU/BLK3

PNK/RED3

GRY/RED3

PNK/BLK4

(MAX.30m)

LAN

*6

AD-100 GYRO

DRAWN

Apr. 16 '04

CHECKED

APPROVED

SCALE

DWG. No.

J1

1

2

3

4

5

6

7

8

9

10

J2

1

2

3

4

5

6

7

8

9

10

11

12

J3

1

2

3

4

5

6

7

8

9

10

11

12

13

14

EXTERNAL EQUIPMENT

(IEC61162-1)

TAKAHASHI.T

C4417-C02- K

CB-100

JUNCTION BOX

TD3-A

TD3-B

GNDISO

RD3-A

RD3-B

GNDISO

TD2-A

TD2-B

GNDISO

RD2-A

RD2-B

GNDISO

TD1-A

TD1-B

GNDISO

RD1-A

RD1-B

GNDISO

TD5-A

TD5-B

GND

RD5-A

GND

TD4-A

TD4-B

GNDISO

RD4-A

RD4-B

GNDISO

TD6-A

TD6-B

GNDISO

RD6-A

RD6-B

GNDISO

TD8-A

TD8-B

GNDISO

RD8-A

RD8-B

GNDISO

TD(232C)

RD(232C)

AOL

AOH

AOC

24P0031

K.MIYAZAWA

MASS

1

2

3

1

4

2

5

3,4

6

7

8

9

1

10

2

11

3,4

12

13

14

15

1

16

2

17

3,4

18

19

20

21

22

23RD5-B

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

481PPSIN

TTYCS-1Q,φ13.5 *1

OR CO-0.2x2P (MAX.30m)

TTYCS-1Q,φ13.5 *1

OR CO-0.2x2P (MAX.30m)

TTYCS-1Q,φ13.5 *1

OR CO-0.2x2P

TTYCS-1Q,φ13.5 *1

OR CO-0.2x2P

TTYCS-4,φ16 *1

P

P

TTYCS-4,φ16 *1

P

P

TTYCS-4,φ16 *1

P

P

TTYCS-1Q,φ13.5 *1

TTYCS-1Q,φ13.5 *1

OR CO-0.2x2P

(MAX.30m)

(MAX.30m)

(MAX.30m)

(MAX.30m)

(MAX.15m)

TYPE

名前

EXTERNAL

GPS

*3

GYRO OR

[IMO Res. MSC.116(73)]

THD

*5 *4

ROT OR LOG

DGPS受信機

DGPS BEACON RECEIVER

LONG RANGE COMMUNICATION OR

RADAR/ECDIS

EXTRA I/O (IEC61162-1/2)

パイロットプラグユニット

PILOT PLUG UNIT

OP24-3

(MAX.30m)

*2

1

2

3

4

5

PC I/O (RS-232C)

ALARM

IEC61162-1: 4800BPS

IEC61162-2: 38.4KBPS

IEC61162-4: 10BASE-T

FA-100

国際船舶自動識別装置

206486-1

TX ATX A

TX B

RX A

RX B

SHIELD

1

4

5

6

9

*1 *8

206485

PC

相互結線図

NAME

kg

U-AIS TRANSPONDER

INTERCONNECTION DIAGRAM

Loading...

Loading...