Fulton Electric Steam Boiler User Manual

Installation Operation And

Maintenance Manual

Fulton Electric Boilers

(Steam Models)

Serial # : ___________________________

Model # : ___________________________

Fulton Order # : ___________________________

Sold To : ___________________________

Job Name : ___________________________

Date : ___________________________

ProductBulletin

Date: January 22, 2010

Subject: Water Chemistry Requirements for Fulton Steam Products

Products: ICS/ICX, FB-A, FB-F, FB-S, VMP, PVLP, PHP, Electric Steam Boilers and Unfired Steam Generators

Please note that the water chemistry is different for carbon steel vs. stainless steel pressure vessels and vertical vs. horizontal orientation.

Effective immediately, please use the limits below. Should you have any questions, please do not hesitate to contact Fulton at 315-298-5121.

Water Chemistry Requirements for Fulton Steam Products (to 300 psig MAWP)

|

|

Carbon Steel |

|

|

Stainless Steel |

|||

|

Feedwater |

Vertical |

|

Horizontal |

Feedwater |

|

Vertical |

Horizontal |

|

|

Boiler/Steam |

|

Boiler/Steam |

|

|

Boiler/Steam |

Boiler/Steam |

Parameter |

|

Pac Water |

|

Pac Water |

|

|

Pac Water |

Pac Water |

pH |

7.5-9.5 |

8.5-10.5 |

|

8.5-10.5 |

6.0-9.5 |

|

8.5-10.5 |

8.5-10.5 |

Feedwater |

140F* |

--- |

|

--- |

140F* |

|

--- |

--- |

Temperature |

|

|

|

|

|

|

|

|

Hardness as |

<2ppm |

<10 ppm |

|

<15 ppm |

<2 ppm |

|

<10 ppm |

<15 ppm |

CaCO3 |

|

|

|

|

|

|

|

|

Chlorides |

--- |

--- |

|

--- |

--- |

|

50 ppm |

50 ppm |

Total |

--- |

<300 ppm |

|

<500 ppm |

--- |

|

<300 ppm |

<500 ppm |

Alkalinity |

|

|

|

|

|

|

|

|

Total |

--- |

<2000 ppm |

|

<3000 ppm |

--- |

|

<2000 ppm |

<3000 ppm |

Dissolved |

|

|

|

|

|

|

|

|

Solids |

|

|

|

|

|

|

|

|

Suspended |

No visual |

No visual |

|

No visual |

No visual |

|

No visual |

No visual |

Solids |

turbidity** |

turbidity** |

|

turbidity** |

turbidity** |

|

turbidity** |

turbidity** |

Total Organic |

No sheen |

No sheen |

|

No sheen |

No sheen |

|

No sheen |

No sheen |

Carbon |

No foam+ |

No foam+ |

|

No foam+ |

No foam+ |

|

No foam+ |

No foam+ |

Iron |

Colorless |

Colorless |

|

Colorless |

Colorless |

|

Colorless |

Colorless |

|

liquid++ |

liquid++ |

|

liquid++ |

liquid++ |

|

liquid++ |

liquid++ |

|

|

|

|

|

|

|

|

|

Dissolved |

<1ppm* |

ND |

|

ND |

<5ppm |

|

ND |

ND |

Oxygen |

|

|

|

|

|

|

|

|

Visual Oil |

ND |

ND |

|

ND |

ND |

|

ND |

ND |

Conducivity |

--- |

<2985 |

|

<4477 |

--- |

|

<2985 |

<4477 |

(uS/cm) |

|

|

|

|

|

|

|

|

NOTES: *This is a minimum temperature. Feedwater temperatures below 200F will require an oxygen scavenger.

**Suspended solids: Take a water sample. After the sample sits for 10 minutes, no solids should be visible.

+Total Organic Carbon: Take a water sample. Shake vigorously for 30 seconds. No sheen or foam should be visible.

++Iron: Take a water sample. Hold the sample against a white background. The water should have no visible yellow, red or

orange tinge. ND: None Detected.

Product Bulletin

2010-001PB

The Fulton Companies

972 Centerville Road

Pulaski, N.Y. 13142

Contents

Section 1Safety Warnings

and Precautions

PAGE 3

2Installation

PAGE 7

3Operation

PAGE 19

4Maintenance

PAGE 23

5Parts and

Warranty

PAGE 31

Electric IOM 1

2Electric IOM

Section 1Safety Warnings

and Precautions

2

3

4

5

Electric IOM 3

Safety Warnings and Precautions

This manual is provided as a guide to the correct operation and maintenance of your Fulton Electric Steam Boiler, and should be permanently available to the staff responsible for the operation of the electric boiler.

These instructions must not be considered as a complete code of practice, nor should they replace existing codes or standards which may be applicable.

The requirements and instructions contained in this section generally relate to the standard Fulton Electric Steam Boiler. When installing a packaged unit, this entire section should be read to ensure that the installation work is carried out correctly.

Prior to shipment the following tests were made to assure the customer the highest standards of manufacturing:

a)Material inspections.

b)Manufacturing process inspections.

c)ASME welding inspections.

d)ASME hydrostatic test inspection.

e)Electrical components inspection.

f)Operating test. (panel powered up)

g)Final Engineering Inspection

h)Crating inspection.

All units are crated for fork lift transport. Once uncrated, all units can be transported with a forklift. Under no circumstances should weight be allowed to bear on the jacket, control panel, or fan housing of any Fulton Boiler.

Rigging your boiler into position should be handled by a competent rigger experienced in handling heavy equipment.

NOTE

The installation of the Fulton Electric Steam Boiler should be carried out by competent personnel in accordance with all relevant safety regulations. A complete list of all safety precautions may be found in the safety summary at the conclusion of Section 1. It is the responsibility of the installer to ensure that the installation is in compliance with these regulations.

NOTE

If it is necessary to store the boiler for a prolonged period of time prior to installation, the boiler should be stored at a minimum 40 degree F in an atmosphere in which excessive moisture cannot damage the controls or the steel casing. If the storage is to be over sixty days, one element should be removed. Place several bags of dry dessicant inside the boiler. Bolt a blank flange over the element mounting plate to seal the boiler. If handholes are provided, these can be used to provide an opening versus an element to place the dessicant.

For Your Safety

The following WARNINGS, CAUTIONS, and NOTES appear in various sections of this manual. They are repeated on these safety summary pages as an example and for emphasis.

WARNINGS must be observed to prevent serious injury, or death to personnel.

CAUTIONS must be observed to prevent damage or destruction of equipment or loss of operating effectiveness.

NOTES must be observed for essential and effective operating procedures, conditions, and as a statement to be highlighted.

It is the responsibility and duty of all personnel involved in the operating and maintenance of this equipment to fully understand the WARNINGS, CAUTIONS, and NOTES by which hazards are to be eliminated or reduced. Personnel must become familiar with all aspects of safety and equipment prior to operation or maintenance of the equipment.

WARNING

Improper installation or maintenance of gauge glass and connections can cause immediate or delayed breakage resulting in bodily injury and/or property damage.

WARNING

When stopping the boiler for any extensive repairs, shut off main power switch and pull main disconnect switches on both the boiler side as well as the feed water side.

WARNING

Prior to the commencement of any work requiring the removal of cover plates and the opening of the control panel box, the electrical supply to the boiler must be disconnected.

WARNING

Prior to powering the boiler up, all electrical contacts shall be re-torqued to the individial components manufacturers recommendations.

CAUTION

Do not downsize piping below safety valve size.

CAUTION

Unless otherwise specified, the steam safety valve supplied with the boiler is pre-set. This valve is provided as a safety device for the boiler and should not be used as the sole protection for other equipment using steam from the boiler. Do not tamper with the setting (It could accidentally be set at a pressure higher than the design pressure of the boiler and, therefore ,create a hazardous condition.

CAUTION

Do not exceed pressure rating on boiler.

CAUTION

In general, ensure that the boiler area is in conformance with established boiler room requirements. Review national and local codes.

4Electric IOM

Safety Warnings and Precautions

CAUTION

Do not tamper with the safety features of the low water safety cut out.

CAUTION

Keep boiler area clear and free from combustible materials, gasoline, and other flammable vapors and liquids.

CAUTION

Do not use harsh compounds that will injure the feed water pump or elements.

CAUTION

Do not clean the gauge or gauge glass while pressurized or in operation.

CAUTION

Prior to performing the “try lever” test, be certain to take precautions as a loud noise and high velocity steam will discharge freely from discharge port and through drain hole provided in the side of the valve body.

NOTE

Where a condensate return tank is to be fitted, this should:

a)Be vented and

b)Have a capacity sufficient to satisfy boiler consumption (normally 10 minutes worth of storage minumum) as well as maintain proper return tank temperature and

c)Vent pipe should not be down-sized (This may cause pressure build up in the condensate tank.)

NOTE

Care should be taken to ensure that the blow off receptacle used meets the regulations covering such items. If in doubt, consult a Fulton Representative for advice.

NOTE

Only properly trained personnel should install and maintain water gauge glass and connections. Wear safety glasses during installation. Before installing, make sure all parts of free of chips and debris.

NOTE

Keep gauge glass in original packaging until ready to install.

NOTE

After Installation is complete and prior to operation, the pressure vessel should be cleaned.

NOTE

Check with local authorities where approval for start-up is required. In some localities, final inspection of services may be required.

NOTE

To ensure that your Fulton Steam Boiler is kept operating safely and efficiently follow the maintenance procedures set forth in this manual.

NOTE

The policy of Fulton Boiler Works, Inc. is one of continuous improvement, and therefore, we reserve the right to change prices, specifications, and equipment without notice.

Electric IOM 5

6Electric IOM

1

Section 2Installation

3

4

5

Electric IOM 7

Installation

Basic Boiler, Condensate Tank, and Blow off Separator Piping Diagram

Steam |

Safety |

Outlet |

|

Valve |

Valve |

Water Bottle for Models 30-100 BHP

Water Column |

|

|

or Water Bottle |

|

|

Electric |

|

|

Control |

|

|

Panel |

|

|

Blowdown |

|

|

Valve |

|

|

Shut-Off |

Check |

Check |

Valve |

Valve |

Valve |

Electric |

|

|

Steam Boiler |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Fast Opening |

Blowdown |

|||||

|

|

|||||||||

|

|

|

|

|

Valve |

|

Valve |

|||

|

|

|

|

|

|

|

|

|

|

|

8Electric IOM

|

|

|

|

Installation |

|

NOTE |

3. Vent pipe should not be down-sized |

codes. The water gauge blow off valve |

|

Where a condensate return tank is to be |

(This may cause pressure build up in |

should be connected to the main blow off |

||

fitted, this should: |

the condensate tank. |

line. |

||

1. Be vented and |

There are two blow off valves on the boiler; |

NOTE |

||

|

|

the main valve at the rear of the boiler and |

Care should be taken to ensure that |

|

2. Have a capacity sufficient to satisfy |

the water gauge glass blow off valve. The |

the blow off receptacle used meets the |

||

boiler consumption as well as maintain |

boiler blow off valve supplied with the boiler |

regulations covering such vessels. If |

||

proper return tank temperature. |

should be screwed to the blow off pipe at |

in doubt consult a Fulton |

||

|

|

the rear of the boiler and connected to a |

Representative for advice. |

|

|

|

blow off receptacle of approved design |

||

|

|

|

||

|

|

piping. All these procedures should be |

Locating the Boiler |

|

|

|

done in accordance with state and/or local |

||

|

Return |

|

|

The boiler should be located in dry |

|

|

Vent |

surroundings on a level base, as close as |

|

|

|

possible to the steam using machinery. |

||

|

|

|

|

See right hand page for minimum |

|

|

|

|

clearances to ensure that there is sufficient |

|

|

|

|

|

|

|

|

|

room around the boiler to enable the |

|

|

|

|

operator and maintenance engineer to gain |

|

|

|

|

access to all parts of the boiler. Check |

|

|

|

|

location for ease of water supply and |

|

|

|

|

electrical connections. |

Cold Water

Supply

Sight

Glass

Vent

Return |

Blowdown |

|

Condensation |

|

|

Separator |

|

|

Tank |

Outlet |

Temperature |

|

|

|

|

|

Control |

|

|

Valve |

Check

Valve

Thermometer |

Cold Water |

Union |

Inlet |

|

|

Drain |

|

Union |

|

Pump / Strainer |

|

Electric IOM 9

Installation

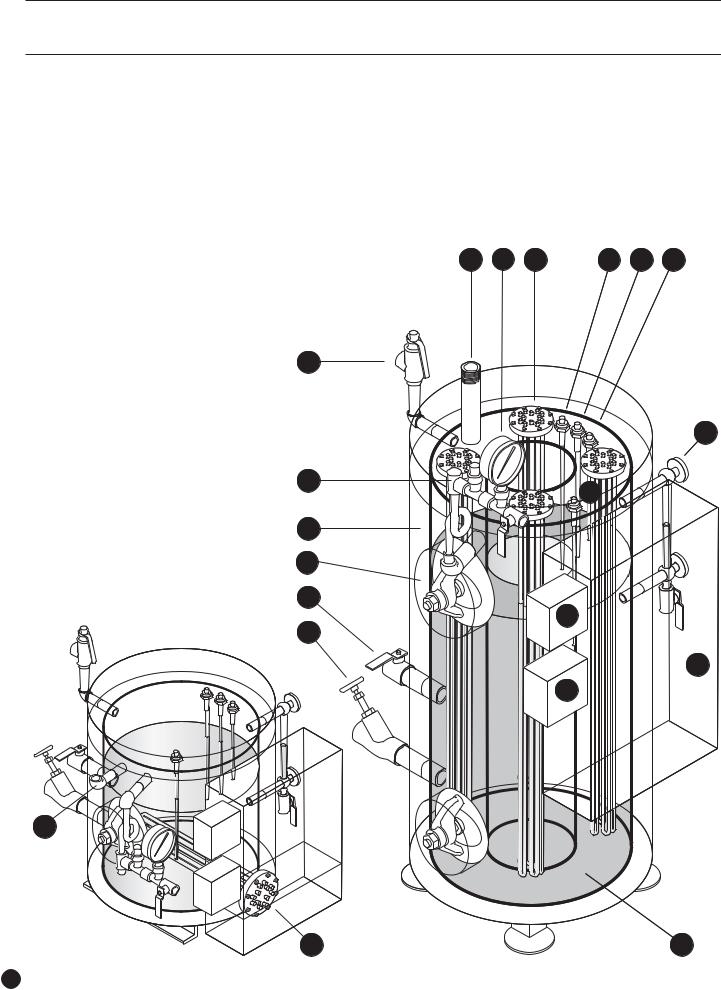

Component Locations of the Fulton 12 to 1000 kW (1.2 to 100BHP) Steam Boilers

1.Pressure Vessel Is Built to ASME Code 5 Year Warranty

2.Electrical Control Panel Box

3.Electric Heating Elements

4.Low Water Cut Off Probe

5.Second (auxiliary) Low Water Cut Off Probe

6.Pump “On” Probe

7.Pump “Off” Probe

8.Sight Glass Assembly

9.Operating pressure control

10.High Limit Pressure Control w/ manual reset

11.Steam Outlet

12.Safety Valve

13.Steam Guage Assembly

14.Steam Pressure Guage

15.High Temperature Insulation Surrounds The Pressure Vessel

16.Large (3” x 4”) Easy Access Handholes

17.Feedwater Shut Off Valve

18.Blowdown Valve

19.Water Bottle Assembly for 300 to 1000 kW Only

NOTE:

All Fulton Electric Steam Boilers have a second (auxiliary) low water cut-off probe

12 to 36 kW (1.2 to 3.6 BHP)

Element(s) are horizontally mounted at the bottom of the pressure vessel. All probes are located in the top of the boiler.

50 to 200 kW (5 to 20 BHP)

Elements are vertically mounted. All probes are located in the top of the boiler.

11 |

14 |

3 |

4 |

6 |

7 |

12

8

13

5

5

15

16

17

10

18

2

9

11

3 |

1 |

10 Electric IOM

Loading...

Loading...