Fulton 15E, 8E, 6E, 40E, 10E OPERATOR, SERVICE & PARTS MANUAL

...

R

Fulton Boiler Works (Great Britain) Ltd.

OPERATOR,SERVICE & PARTS MANUAL

SERIES 'E' - GAS FIRED STEAM BOILERS (6E - 60E)

GFSE-Std-0202

WARNING

WARNING

Steam Boilers are a potential hazard possibly fatal if not properly maintained.

CAUTION

It is vitally important that the instructions given in this manual are strictly adhered to.

Failure to carry out the daily, weekly, monthly and six monthly checks could result in a drastic reduction in the life expectancy of the boiler.

NOTE

The Pressure system and Transportable Gas Containers Regulations 1989

Fulton Boilers fall within the scope of the Pressure Systems Examination Scheme and Section 40 of the Health and Safety at Work Act, 1974.

Regularinspectionsarethereforerequiredbya'CompetentPerson'atintervalsnotexceeding 14 months.

The scope of the examination and the actual intervals between examinations is at the discretion of the competent person.

It is the responsibility of the user to provide a written scheme of examination for those parts of the system in which a defect may give rise to danger.

Instructions in this manual are provided for the safe operation and maintenance of the boiler and do not cover periodic statutory inspections.

For further information contact:-

(a)SAFed

SAFETY ASSESSMENT FEDERATION Limited. Nutmeg House,

60 Gainsford Street, Butlers Wharf, London, SE1 2NY

(b)Health and Safety Executive local office.

(c)Your insurance company/broker

GFSE-Std-0499

|

|

|

|

|

|

|

|

|

|

|

|

|

LIST OF CONTENTS |

|

|

TITLE |

SECTION |

||

INTRODUCTION |

1 |

||

General |

1.1 |

||

Technical Data |

1.2 |

||

INSTALLATION |

2 |

||

General |

2.1 |

||

Siting |

2.2 |

||

Ventilation |

2.3 |

||

Flue Outlet |

2.4 |

||

Water Supply |

2.5 |

||

Blowdown Valves |

2.6 |

||

Main Steam Valve |

2.7 |

||

Steam Safety Valves |

2.8 |

||

Water Gauge Set |

2.9 |

||

Gas Supply |

2.10 |

||

Electrical Requirements |

2.11 |

||

Steam Pressure Gauge |

2.12 |

||

Plumbing |

2.15 |

||

Commissioning the Boiler |

2.16 |

||

Cleaning the Steam Lines and Pressure Vessel |

2.17 |

||

L.P. Supplement - Gas Supply - Propane/Butane |

2.18 |

||

OPERATION |

3 |

||

General |

3.1 |

||

Boiler Controls |

3.2 |

||

Control Panel - Indicator Lights |

3.3 |

||

Filling the Boiler - All Models |

3.4 |

||

Starting the Burner - All Models |

3.5 |

||

Daily Checks |

3.6 |

||

Pump Check |

3.6.1 |

||

1st. Low Water Check |

3.6.4 |

||

Overiding Low Water Check |

3.6.5 |

||

Blowdown Procedures |

3.7 |

||

Evaporation Checks |

3.8 |

||

MAINTENANCE |

4 |

||

General |

4.1 |

||

Weekly |

4.2 |

||

Monthly |

4.3 |

||

Three Monthly |

4.4 |

||

Six Monthly |

4.5 |

||

GENERAL DATA |

5 |

||

SPARE PARTS |

6 |

||

GFSE-Std-0499

SAFETY

SAFETY

The instructions provided for the operation and maintenance of the boiler MUST be observed. Failure to do so could result in damage to the boiler and serious personal injury.

WARNING

WARNING

It is the responsibility of the installer to ensure all parts supplied with the boiler are fitted in a correct and

safe manner.

WARNING

Only qualified persons should be allowed to operate and maintain the boiler and its equipment. Boilers should always be drained through an approved Blowdown Vessel.

WARNING

WARNING

Do not try to do repairs or any other maintenance work you do not understand. Obtain a Service Manual from Fulton or call a Fulton Service Engineer

WARNING

Do not change the boiler fuel without consulting the boiler manufacturer.

WARNING

WARNING

Understand the electrical circuit before connecting or disconnecting an electrical component. A wrong connection can cause injury and or damage.

WARNING

WARNING

Non-approved modifications can cause injury and damage. Contact your Fulton dealer before modifying the boiler.

WARNING

WARNING

A defective boiler can injure you or others. Do not operate a boiler which is defective or has missing parts. Make sure that all maintenance procedures are completed before using the boiler.

WARNING

WARNING

You can be injured if you use faulty lifting equipment. Make sure the lifting equipment is in good condition. Make sure that lifting tackle complies with all local regulations and is suitable for the job

CAUTION

CAUTION

Obey all laws and local regulations which affect you and your boiler.

WARNING

WARNING

The installation of Gas appliances including the flue system should only be carried out by Corgi Registered engineers.

CAUTION

CAUTION

HYDRAULIC TEST - RISK OF BRITTLE FRACTURE Hydraulic testing requires specialist equipment and is normally only required by engineering surveyors / inspectors.The material the boiler is manufactured from, has not been impact tested, as it is not a requirement of BS2790 (boiler construction standard). In order to ensure the material / pressure vessel does not suffer from brittle fracture, hydraulic testing should not be carried out below 5OC.

WARNING

WARNING

The importance of correct boiler water and feed water cannot be over emphasised, see the relevant section in this manual.

CAUTION

CAUTION

LOW FEED WATER TEMPERATURE

Low feed water temperature can result in thermal shock to the boiler pressure vessel. Return the maximum amount of condensate and if necessary preheat the feed water. If in doubt consult FBW.

WARNING

WARNING

Operating the boiler beyond its design limits can damage the boiler, it can also be dangerous. Do not operate the boiler outside its limits. Do not try to up grade the boiler performance by unapproved modifications.

WARNING

WARNING

DANGER FROM HOT SURFACES

Steam Boilers have high temperature surfaces, that if touched may cause serious burns. Only competant and qualified personnel should work on or in the locality of a steam boiler and ancillary equipment. Always ensure the working area and floor are clear of potential hazards, work slowly and methodically.

WARNING

WARNING

DANGER FROM INCOMPLETE COMBUSTION The importance of correct burner adjustment to achive low emissions, safe, clean and efficient combustion is paramount. Poor combustion, where unburnt gas forms carbon monoxide is both a health hazard, and the potential risk to the boiler from overheating, caused by re-burning of the unburnt gas in the secondary flue passes.

GFSE-Std-0499

|

|

|

|

|

|

|

|

|

|

|

|

TITLE |

FIG. NO. |

||

Gas Fired Steam Boiler |

1 |

||

General Arrangement |

2 |

||

Typical Installation |

3 |

||

Typical Flue Connection |

3A |

||

Water Gauge Set |

4 |

||

Steam Pressure Gauge |

5 |

||

Burner Electrode Settings |

6 |

||

Commissioning the Boiler |

7 |

||

Monobloc Gas Valve |

9 |

||

L.P. Gas Train |

10 |

||

Boiler Operation |

11 |

||

Control Panel 6E/30E |

12 |

||

Control Panel 40E/60E |

13 |

||

Water Gauge Blowdown Sequence |

14 & 14A |

||

Fault Finding Check List |

15 |

||

Boiler Maintenance |

16 |

||

Handhole Assembly |

17 |

||

Burner Assembly |

18 |

||

Flue Cleaning |

19 |

||

Boiler Dimensions |

20 |

||

Level Controller - Type LC1 |

21 |

||

SPARE PARTS

See index in Spare Parts Section

GFSE-Std-0499

1 |

1 |

FIG.1 GAS FIRED STEAM BOILER

1 |

GFSE-Std-0499 |

1

INTRODUCTION

SECTION 1

1.1General (Fig. 1)

The Fulton Series E Gas Fired Steam Boiler is a vertical two pass boiler of simple and efficient design and construction. Every care has been taken in the manufacture of the boiler to ensure that quality and reliability standards are maintained. However, satisfactory performance can only be ensured if the installation recommendations, operating routines and maintenance schedules laid out in this manual are adhered to.

For Propane Boilers read Section 2.19 before proceeding.

1.2Technical Data

|

|

|

|

BOILER MODEL |

|

|

|

||

|

6E |

8E |

10E |

15E |

20E |

30E |

40E |

50E |

60E |

Performance |

|

|

|

|

|

|

|

|

|

lb/h (F & A 100oC) |

210 |

280 |

350 |

525 |

700 |

1050 |

1400 |

1750 |

2100 |

kg/h (F & A 100oC) |

96 |

128 |

160 |

240 |

320 |

480 |

640 |

800 |

960 |

Firing Rates |

|

|

|

|

|

|

|

|

|

Approx. BTU input (000) |

255 |

340 |

424 |

637 |

849 |

1273 |

1360 |

2121 |

2546 |

Natural Gas 1035 BTU |

|

|

|

|

|

|

|

|

|

cu.ft./h |

246 |

328 |

410 |

615 |

820 |

1230 |

1700 |

2050 |

2461 |

cu.m/h |

7 |

9.3 |

11.6 |

17.4 |

23.2 |

34.8 |

46.4 |

58.1 |

69.6 |

Electrical Requirements |

|

|

|

|

|

|

|

|

|

FLC (400V, 3ph, 50Hz) amps |

4.7 |

4.7 |

4.7 |

4.7 |

4.9 |

4.9 |

6.9 |

6.9 |

8.6 |

FLC (230V, 1ph, 50Hz) amps |

12.7 |

12.7 |

12.7 |

12.7 |

14.9 |

14.9 |

19.3 |

19.3 |

19.3 |

The full load current (flc) of the feed water pump motor can vary with the type and duty requirements of the pump supplied. The figures quoted above are given as a guide only.

Miscellaneous |

|

|

|

|

|

|

|

|

|

Water Content (Imp Gal) |

13 |

15 |

20 |

33 |

64 |

141 |

204 |

204 |

223 |

Water Content (Litres) |

59 |

68 |

91 |

150 |

291 |

640 |

927 |

927 |

1022 |

Approx. Net Weight (lb) |

1540 |

1590 |

1785 |

2130 |

3135 |

4480 |

6728 |

6728 |

6944 |

Approx. Net Weight (kg) |

700 |

720 |

810 |

965 |

1420 |

2030 |

3050 |

3050 |

3150 |

Nat. Gas Head |

|

|

|

|

|

|

|

|

|

Pipe Size (in.) |

1 |

1 |

1 |

1.25 |

1.25 |

1.5 |

2 |

2 |

2 |

Required Vertical |

2060 |

2160 |

2210 |

2365 |

2440 |

2745 |

2845 |

2845 |

3000 |

Clearance (mm) |

|

|

|

|

|

|

|

|

|

(Floor to Ceiling) |

|

|

|

|

|

|

|

|

|

GFSE-Std-0499 |

2 |

2 |

2 |

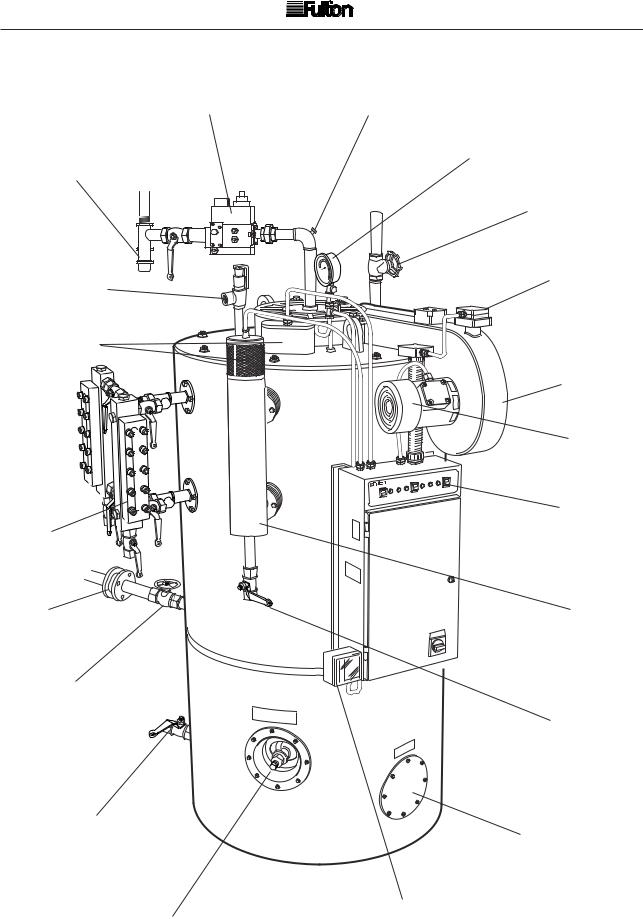

MODULAR

GAS UNIT

SCALE

TRAP

STEAM SAFETY

VALVE

WATER LEVEL

PROBES

WATER

GAUGE

CHECK

VALVE

STOP

VALVE

MAIN

BLOWDOWN

VALVE

HAND HOLE

PRESSURE

TEST POINT

STEAM

PRESSURE

GAUGE

MAIN STEAM

VALVE

AIR SAFETY

SWITCH

BLOWER

HOUSING

BURNER

MOTOR

CONTROL

PANEL

WATER

COLUMN

COLUMN

BLOWDOWN

VALVE

CLEAN OUT

DOOR

PRESSURE

CONTROL

FIG. 2 GENERAL ARRANGEMENT

|

|

|

3 |

GFSE-Std-0499 |

|

2 |

2 |

INSTALLATION

SECTION 2

2.1GENERAL (Figs. 2 and 3)

The installation of a Series E Gas Fired Steam Boiler should be carried out by competent personnel in accordance with all relevant safety regulations. It is the responsibility of the installer to ensure that these regulations are complied with.

The requirements and instructions contained in this Section generally relate to the boilers being installed to operate on natural or manufactured gas. Where the boiler is to operate on L.P. Gas, special reference should be made to Section 2.10 - Gas Supply, and Section 2.18 L.P. Gas Supply.

2.2SITING

The boiler house should be sufficiently large to allow easy and safe access to all parts of the boiler for operational and maintenance purposes. Reference should be made to Section 5 - General Data to ascertain the relevant dimensions and special note taken of the required vertical clearance.

The flooring must be level, laid in a non-combustible material and be of sufficient strength to support the boiler.

2.3VENTILATION

Adequate fresh, clean air is necessary for safe and efficient combustion, and should be provided at high and low level in accordance with BS 6644 1991.

Note:

(a)Ensure there is adequate ventilation in the boiler room. Lack of ventilation will create a high temperature and cause control lockout.

(b)Do not keep exhaust fans running with windows, doors and vents closed, this will interfere with the necessary boiler draught.

(c)Do not store chemicals such as perclorethylene in the boiler house, the fumes may damage the boiler and flue and cause the burner to lock out on flame failure.

Boiler Model |

6E |

8E |

10E |

15E |

20E |

30E |

40E |

50E |

60E |

|

|

|

|

|

|

|

|

|

|

High Level (cm2) |

305 |

360 |

420 |

560 |

700 |

980 |

1260 |

1540 |

1820 |

Low Level (cm2) |

610 |

720 |

835 |

1115 |

1395 |

1960 |

2520 |

3085 |

3645 |

|

|

|

|

|

|

|

|

|

|

GFSE-Std-0499 |

4 |

2 |

2 |

PIPE SAFETY VALVE

TO SAFE AREA,

FITTING

UNIONSANDDRAIN

|

|

STEAM SUPPLY |

|

DRAFTSTABILISER |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(WHEREFITTED) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

STANDARDBOILER

TRIMSUPPLIED

|

|

STAINLESS |

|

|

|

STEEL |

|

|

CLEAN-OUT |

FEEDWATER |

MAKE-UP SUPPLY |

|

TANK |

||

|

DOOR |

OVERFLOW |

BLOWDOWN |

|

|

|

|

STOP |

|

|

SEPERATOR |

|

CONDENSATE |

|

|

VALVE |

CHECK VALVE |

RETURN |

|

|

|

|

FEEDPUMP

FEEDPUMP

MAIN BLOWDOWN |

STRAINER |

|

F01762 |

|

VALVE |

|

|||

ISOLATING |

PLUGGED |

|||

WATER |

|

|||

|

VALVE |

DRAIN |

||

COLUMN |

|

BLOWDOWN

VALVE

NOTE: A BREAK TANK MAY

BE REQUIRED - CHECK

THE LOCAL WATER

AUTHORITYBYE-LAWS

FIG. 3 TYPICAL INSTALLATION

5 |

GFSE-Std-0499 |

2 |

2 |

2.4FLUE OUTLET

The boiler is supplied with a stainless steel flue spigot that should be inserted into the flue outlet in the back of the boiler and secured with the three angle clips supplied loose in the trim box (see fig. 3A). The height and type of flue will generally be subject to local planning regulations and approvals. The following information is intended to provide assistance where the installation of a simple flue is required. Where multi-boiler flues or difficulties are experienced, specialist advice should be obtained.

The flue diameter must be the same or larger than the flue flange provided with the boiler and the outlet should be at least 2ft (610 mm) higher than the nearest ridge to avoid down draughts. Where a chimney cowl is fitted, care should be taken to ensure that the cross sectional area of the outlet is equal to at least 1.5 times the cross sectional area of the flue, and that it is of the terminal cone type.

Note:

(a)If the flue layout is such that it may produce an excessive up-draught, a draught stabiliser may be required.

(b)Avoid fitting 90deg. elbows whenever possible, if unavoidable compensate by increasing the flue diameter.

(c)Ensure all pipework from the boiler to the main flue has a rising pitch of not less than 15deg.

2.5WATER SUPPLY

The quality of the water used in the boiler will affect the life and performance of the boiler. It is strongly recommended that a reputable water treatment concern is consulted prior to commissioning the boiler. The following water conditions represent those which are considered essential in the boiler.

Total hardness of feedwater in terms of CaCo3 (mg/L) |

Max 2. |

Caustic alkalinity of boiler water in terms of CaCo3 (mg/L) |

300 ppm max. |

Total dissolved solids in boiler water (mg/L) |

2000 ppm max. |

pH value of boiler water |

9.5 to 11.5 |

Connect the feed water pump to the boiler with 1in. bore pipe and insert the stop valve and check valve supplied. It is essential to protect the feedwater pump from damage by foreign matter. A strainer should therefore be inserted in the pump suction pipework.

Note: 1. The boiler feedwater pump may contain an inhibitor and this should be flushed from the pump prior to fitting the pump to the boiler. Failure to do so may result in water bounce or foaming due to the inhibitor forming a seal in the boiler.

2.If the boiler is to be operated with little or no condensate return, consideration should be given to pre-heating the feedwater. If in doubt consult Fulton Boiler Works.

3.The Feedwater inlet connection on some boilers is located on the left hand side of the boiler below the sight glass assembly.

2.6BLOWDOWN VALVES

There are three blowdown valves on the boiler (four if two water gauge sets are fitted), the main valve at the rear of the boiler, the water column blowdown valve and the water gauge blowdown valve. All of these valves must be connected to a blowdown receptacle of approved design. Regulations exist covering such items and care must be taken to ensure compliance with these regulations. If in doubt regarding blowdown arrangements, consult your Fulton agent.

2.7MAIN STEAM VALVE

The main steam stop valve should be inserted in the steam line approximately 12in. (305 mm) from the top of the boiler.

GFSE-Std-0499 |

6 |

2 |

2 |

F02490

FIG. 3A TYPICAL FLUE CONNECTION

WORKING |

STEAM |

WATER |

POSITION |

BLOWDOWN |

BLOWDOWN |

F03200

F03190

BLOWDOWN

GAUGE GLASS

FIG 4 WATER GAUGE SET

7 |

GFSE-Std-0499 |

2 |

2 |

2.8STEAM SAFETY VALVES

Safety Valves are factory fitted and preset, they MUST NOT be adjusted. The discharge outlet should be piped to a safe discharge point and the piping so arranged that any condensate trapped in the pipework will drain away from the valve.

(a)The lift pressure is indicated on the safety valve. (Do not adjust).

(b)The safety valve fitted to the boiler is designed to prevent the boiler exceeding it's design pressure.

(c)Any system connected to the boiler not capable of accepting boiler pressure must be protected by a separate safety valve set to the required pressure.

WARNING

WARNING

Factory fitted safety valves are pre-set to protect the boiler only and must not be used protect any other items !

2.9WATER GAUGE SET (The design may vary from that illustrated) Numbers may vary due to individual countries regulations.

Boilers are normally supplied with two complete water gauge sets. These gauges should be fitted as shown in main view Fig. 4. The water gauge glass blowdown cock should be connected to the auxiliary blowdown line from the water column blowdown valve in soft copper tubing. The connection to the gauge cock is 1/8 in. BSP for conventional gauge glasses and 3/8 in. for reflex type gauges, (all connections female).

Mounting manifolds 'C' are only supplied for conventional tubular gauge glasses.

2.10GAS SUPPLY

Verify that the burner is suitable for the type of gas being supplied. Ensure the piping from the meter is the correct size, and that a gas cock is inserted in the line between the boiler and the meter. To avoid pressure drops, eliminate all unnecessary bends and elbows in the pipework between the gas meter and the boiler. A scale trap is provided on the gas train and should be used.

Burners suitable for operation on natural and manufactured gas are supplied with gas trains or a modular gas head which are fitted with pressure regulating governors. No additional pressure regulating devices should be required. A minimum pressure of 7 in. (17.5 mb) water column is required at the gas train for natural gas installations and a minimum pressure of 5 in. (12.5 mb) water column is required at the gas train for manufactured gas installations.

Burners arranged for operation on L.P. gas are supplied with gas trains which include a pressure regulating governor. It is essential that the MAXIMUM pressure of the gas at the gas train does not exceed 32 in. (80 mb) water column and does not fall below 20 in. (50 mb) water column. To obtain these pressures a pressure regulating device or service governor must be fitted to the supply line from the storage tank to the boiler gas train.

2.11ELECTRICAL REQUIREMENTS

An individual wiring diagram for the boiler is located on the inside cover of the control box.

When referring to the electrical specification of the boiler, the reference number located on the rear inside wall of the control box and the wiring diagram number should be quoted.

The audible alarm bells supplied are mounted on the side of the control panel, if not audible they should be repositioned where they can be heard by a person competent to take the appropriate action should the alarm be activated. Unless otherwise specified, the alarms supplied will be mains voltage models. Unless otherwise specified all models are supplied with burner motors and feed water pump motors arranged for operation on a three phase supply.

The power ratings and requirements are given in Section 1.2 - Technical Data.

GFSE-Std-0499 |

8 |

2 |

2 |

STEAM PRESSURE

GAUGE

STEAM COCK

SYPHON

FIG. 5 STEAM PRESSURE GAUGE

2.12STEAM PRESSURE GAUGE (Fig. 5)

The steam pressure gauge assembly should be assembled in accordance with Fig. 5 using a suitable sealant on all joints.

Screw the assembly into the top of the boiler and connect the copper tube from the control panel box to the nipple provided on the assembly.

9 |

GFSE-Std-0499 |

Loading...

Loading...