Page 1

PRO-RANGE 30” - 36” ELECTRIC INDUCTION

INSTALLATION INSTRUCTIONS

INSTRUCTIONS D’INSTALLATION

INSTRUCCIONES PARA LA INSTALACIÓN

Page 2

Page 3

Pay attention to these symbols present in this manual:

EN

TABLE OF CONTENTS PAGE

1 - Special Warnings 2

Before Starting Installation 2

Mobile Home Installation 2

2 - Product Dimensions and Cutout Requirements 3

Anti-Tip Bracket Installation 5

3 - Installation Information 6

4 - Installation Instructions 7

5 - Electrical supply 9

6 - Electrical connections 11

4-wire connection 12

3-wire connection 12

Direct Electrical Connection to the Circuit Breaker,

Fuse Box or Junction Box 13

7 - Final checklist 14

DANGER

You can be killed or seriously injured if you don’t

IMMEDIATELY follow instructions.

WARNING

This is the safety alert symbol. This symbol alerts you to

potential hazards that can kill or hurt you and others. You

can be killed or seriously injured if you don’t follow these

instructions.

READ AND SAVE THESE INSTRUCTIONS.

To installer:

Leave these instructions with the appliance.

To customer:

Retain these instructions for future reference.

IMPORTANT: Save these instructions for the local electrical

inspector use.

INSTALLER: Please leave this manual with owner for future

reference.

OWNER: Please keep this manual for future reference.

WARNING

If the information in this manual is not followed exactly, a fire

or explosion may resulting in product and property damage

and / or personal injury or death.

Do not store or use gasoline or other flammable vapours and

liquids in the vicinity of this or any other appliance.

1

Page 4

EN

1 - Special Warnings

IMPORTANT INSTRUCTION

Special Warnings

Please read all instruction before using this appliance.

Proper installation is your responsibility. Have a qualified

technician install this range.

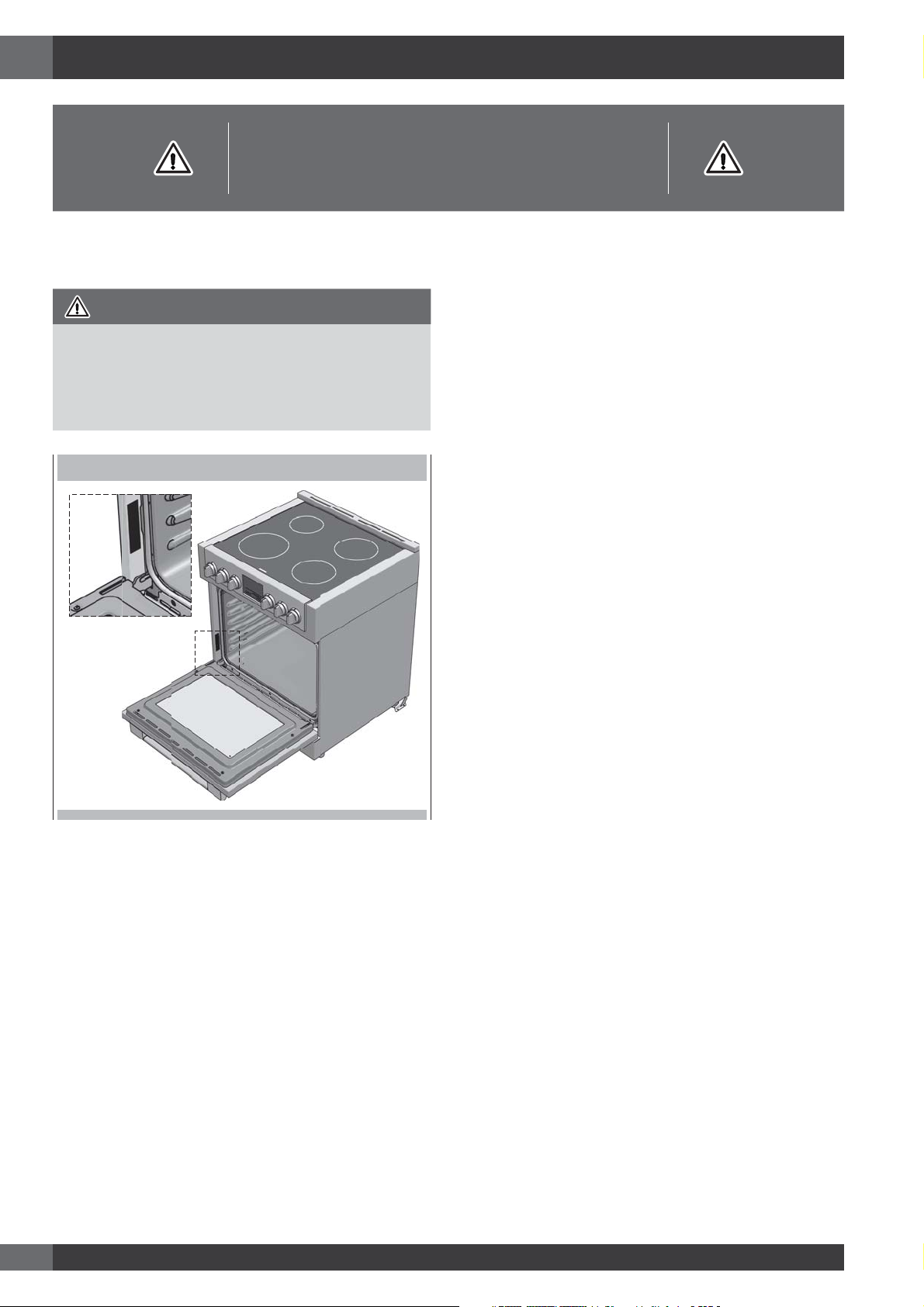

IMPORTANT

- Observe all governing codes and ordinances.

- Write down the model and serial numbers before installing

the range. Both numbers are on the serial rating plate refer

to the illustration below.

LOCATION OF RATING PLATE

Mobile Home Installation

The installation of this appliances must conform to the

Manufactured Home Construction and Safety Standards, Title

24 CFR, Part 3280 (formerly the Federal Standard for Mobile

Home Construction and Safety; Title 24 HUD part 280); or

when such standard is not applicable, the Standard for

Manufactured Home Installations (Manufactured Home Sites,

Communities and Setups), ANSI A225.1 - latest edition, or

with local codes.

In Canada, the installation of this appliances must conform

with the current standards CAN/CSA-Z240 - latest edition, or

with local codes.

Before Starting Installation

• Check location where range will be installed. The location

should be away from strong drafty areas, such as windows,

doors and strong heating vents or fans.

• Electrical grounding is required. See “Electrical

Requirements”

• Assure that electrical installation is adequate and in

conformance with National Electrical Code, ANSI/

NFPA 70 - latest edition**, or Canadian Electrical Code,

part 1 C22.1 (latest edition)*** and all local codes and

ordinances.

Copies of the standards listed may be obtained from:

** National Fire Protection Association One Batterymarch Park

Quincy, Massachusetts 02269

*** CSA International 8501 East Pleasant Valley Rd. Cleveland,

OH 44131-5575

2

Page 5

35

3/4

(9

1,0)

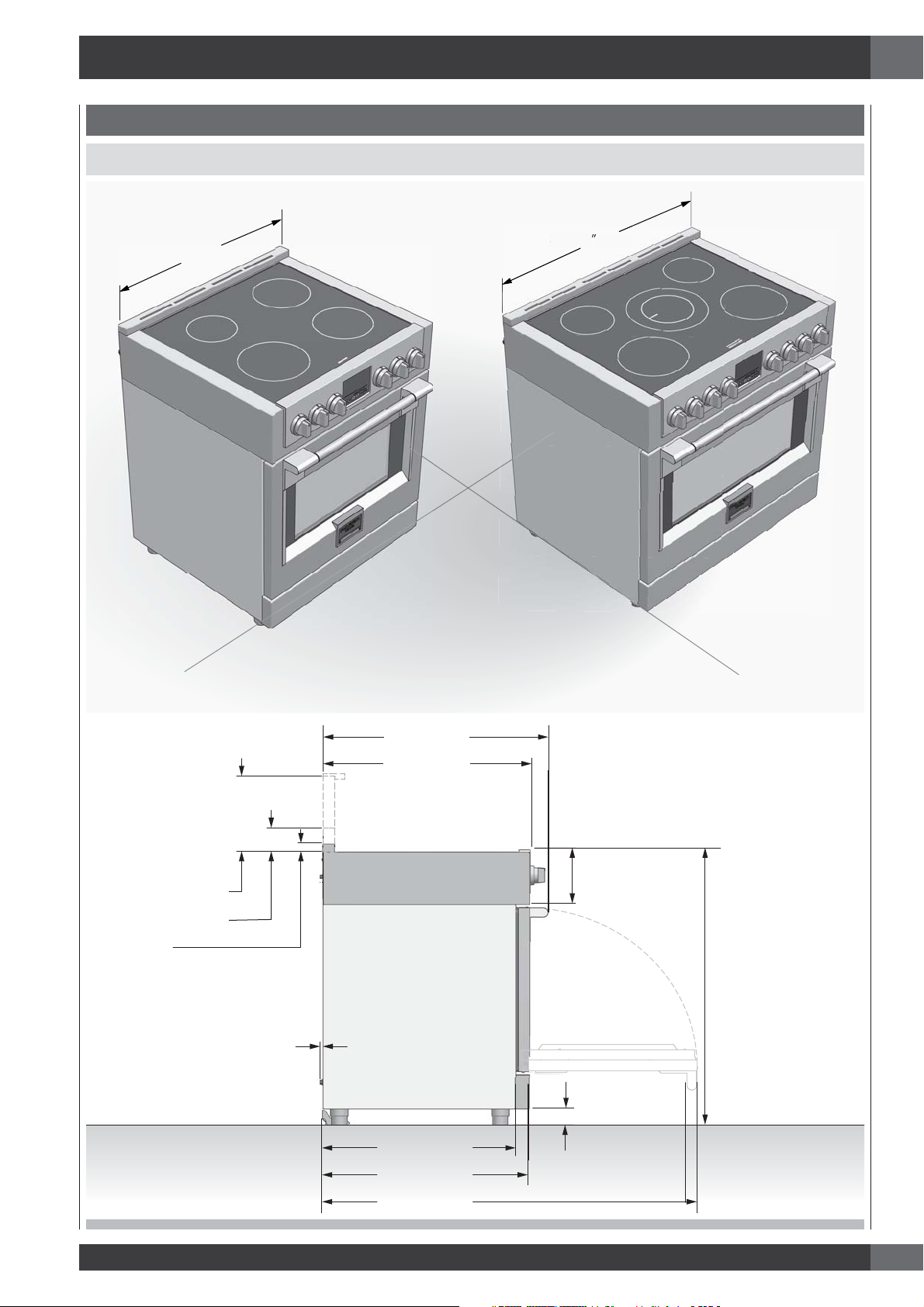

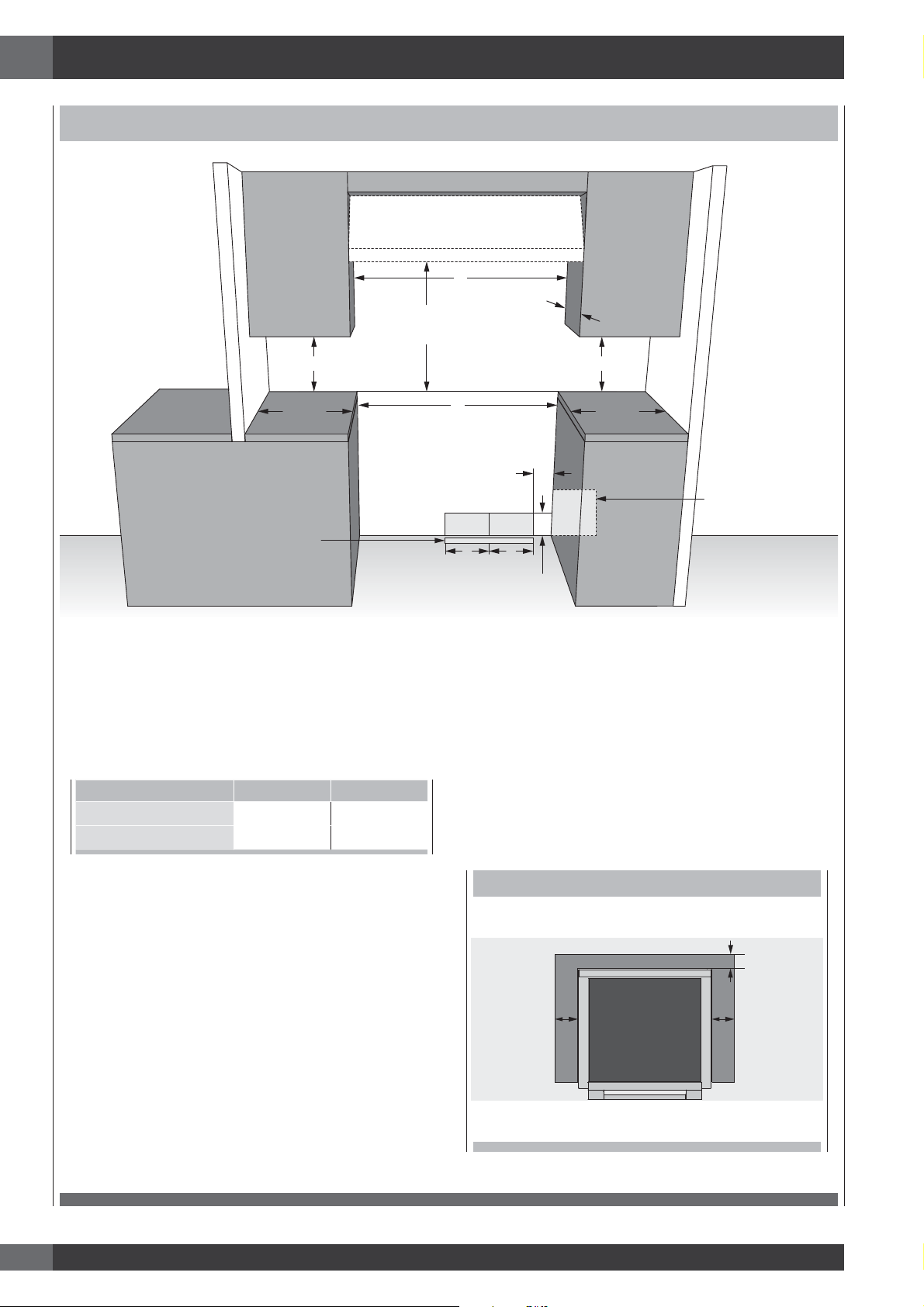

2 - Product Dimensions and Cutout Requirements

PRODUCT DIMENSIONS

30” Wide Range Models

EN

29 3/4” (75,8)

35 3/4” (91,0)

9" (22.8) [optional]

3" ( 7.6) [optional]

1" ( 2.5)

3/8” (1)

29 3/4” (75.6)

27 1/2” (69.7)

25 3/4” ( 65.4)

27 1/4” ( 69.1)

7 3/8” (18.7)

1 3/8” (3.5)

TO

3 3/8” (8.5)

Max. 37 1/4” (94.7)

Min. 35 3/8” (89.8)

47 3/4” (121.4)

3

Page 6

EN

2 - Product Dimensions and Cutout Requirements

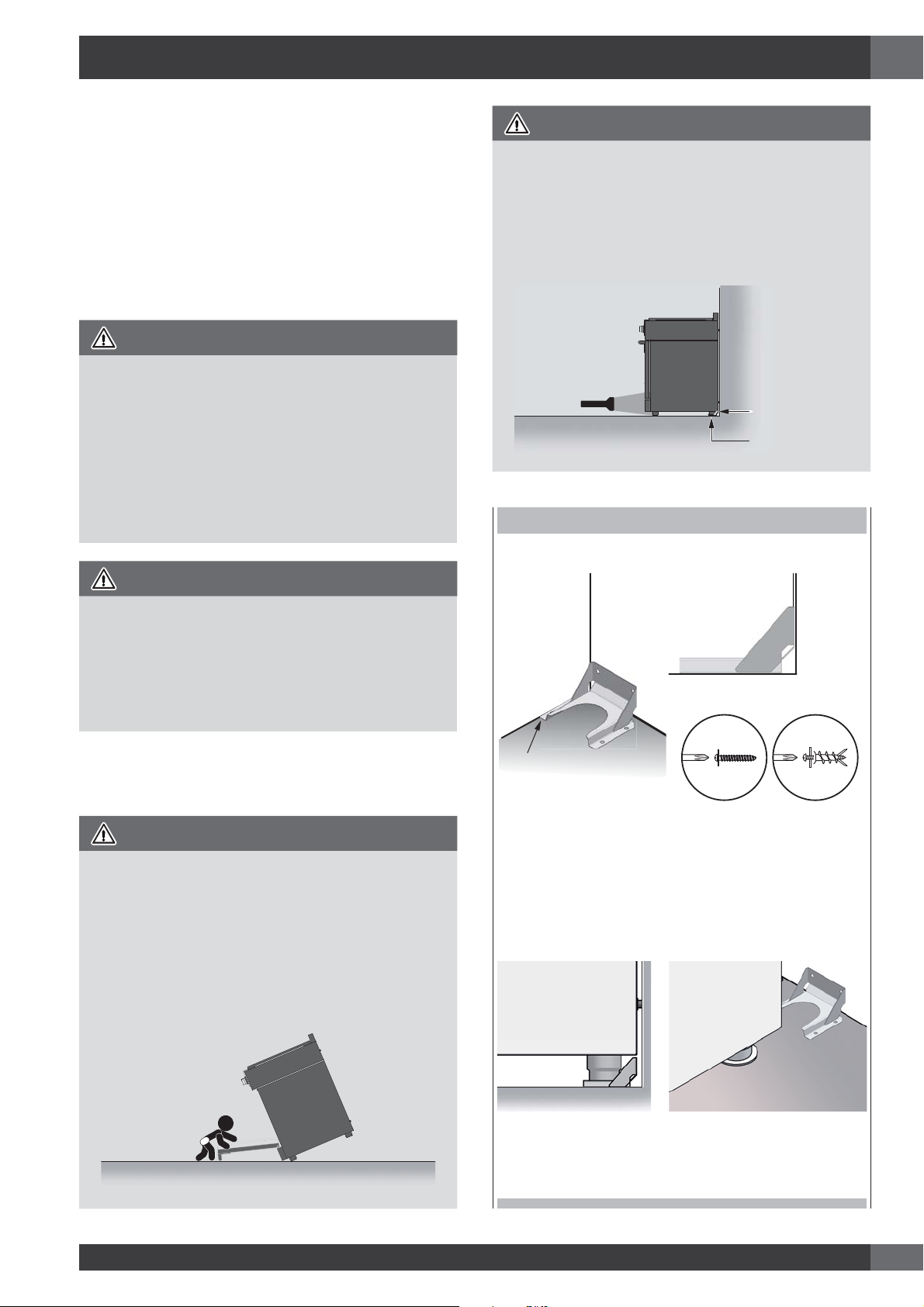

CUTOUT REQUIREMENTS

C

Max. 13” (33)

Min. 18” (45.7)

Min. 6”

(15.2)

*Suggested location

of utilities

Min. 18” (45.7)

Min. 6”

(15.2)

2” (5.1) max. protusion from

wall for gas or electrical supply

Min. 30” (76.2)

To bottom of

ventilation hood

A

3” (7.6)

ELECTRICGAS

B B

4” 3/4 (12.3)

The surface of the entire back wall above the range and below the hood must be covered with a noncombustible material.

*Consult local code for exact location requirements.

OPENING WIDTH A & C B

Range 30” 30" (76.2) 6” (15.2)

Range 36” 36" (91.4) 7” (17.8)

Note: Clearances to non-combustible materials must

conform with local codes or, in the absence of local

codes, with the National Fuel Gas Code, ANSI

Z223.1/NFPA 54.

Minimum clearances:

Above cooking surface (above 36” [91.4 cm])

• Sides 3” (7.6 cm)

• Within 3” (7.6 cm) side clearance, wall cabinets no

deeper than 13” (33.0 cm) must be minimum 18” (45.7

cm) above cooking surface.

• Wall cabinets directly above product must be a minimum

of 30” (76.2 cm) above cooking surface.

• Rear - 0” with 3” (7.6 cm) backguard.

ADDITIONAL CLEARANCES:

For island installation, maintain 2-½ in. minimum from

cutout to back edge of countertop and 3 in. minimum from

cutout to side edges of countertop (see top view).

FLUSH ISLAND TRIM INSTALLATION

BACK

min 2 1/2” (6.3)

min 3” (7.6) min 3” (7.6)

4

Page 7

2 - Product Dimensions and Cutout Requirements

EN

Before moving the range, protect any finished flooring and

secure oven door(s) closed to prevent damage.

Vent hood Combinations:

It is recommended that these ranges be installed in conjunction

with a suitable overhead vent hood.

Install a hood with at least 450 CFM.

Due to the high heat capacity of this unit, particular attention

should be paid to the hood and ductwork installation to assure

it meets local building codes.

WARNING

Clearances to horizontal surfaces above the range, measured

to the cooking surface are below. Failure to comply may

result in fire hazard.

• Installations without a hood require 30” (76) minimum to

combustibles.

• A custom hood installation with exposed horizontal

combustible surfaces must have an Auto-On feature.

• For other installations with a hood, refer to the hood

installation instructions for specific hood clearances.

WARNING

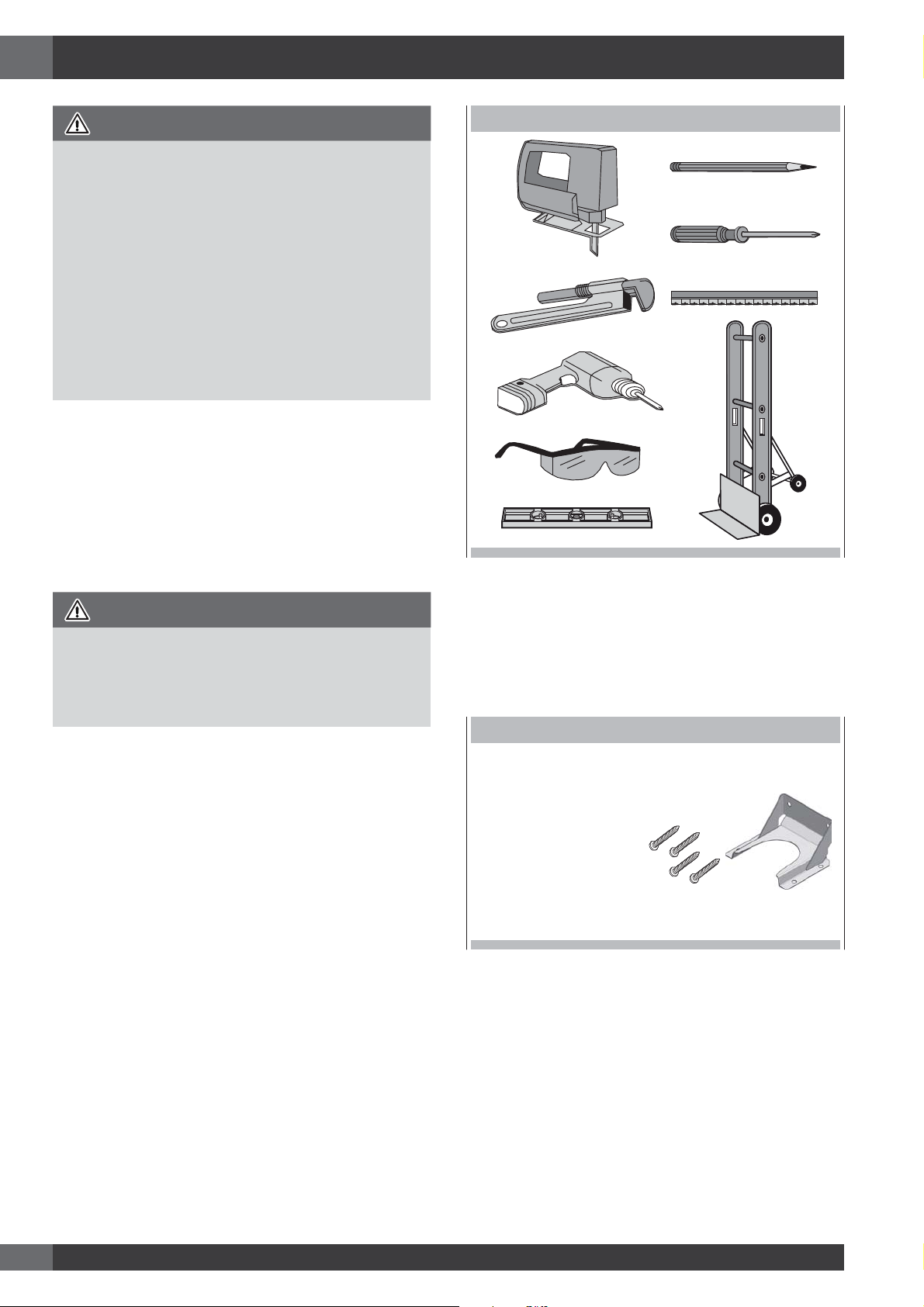

To verify the anti-tip bracket is installed and engaged:

• Slide range forward.

• Look for the anti-tip bracket securely attached to floor or wall.

• Slide range back so rear range foot is under anti-tip bracket.

• See installation instructions for details.

Anti-Tip Bracket

Range Foot

ANTI-TIP BRACKET INSTALLATION

CAUTION

These ranges weigh up to 400 pounds. Some disassembly

will reduce the weight considerably. Due to the weight and

size of the range and to reduce the risk of personal injury or

damage to the product:

TWO PEOPLE ARE REQUIRED FOR PROPER INSTALLATION.

Anti-Tip Bracket Installation

WARNING

Tip Over Hazard

A child or adult can tip the range and be killed.

Ensure the anti-tip bracket is engaged when the range is

moved.

Do not operate range without anti-tip bracket installed and

engaged.

Failure to follow these instructions can result in death or serious

burns to children and adults.

WALL

ANCHOR

CABINET

SIDEWALL

FLUSH

BACKWALL

ANTI-TIP

BRACKET

For Concrete or Cement Construction:

You must use appropriate fastening hardware (not

provided).

Secure the bracket to the wall and/or floor with at least 4

wood screws (provided).

The anti-tip bracket should be inserted into the opening on

the anti-tip brace on the range.

5

Page 8

EN

3 - Installation Information

WARNING

• Excessive Weight Hazard

Use two or more people to move and install range.

Failure to do so can result in back or other injury.

• Cut Hazard

Beware of sharp edges. Use the polystyrene ends when

carrying the product. Failure to use caution could result in

minor injury or cuts.

Do not obstruct the flow air at the oven vent nor around the

base or beneath the lower front panel of the range. Avoid

touching the vent openings or nearby surfaces as they may

become hot while the oven is in operation.

CHOOSING RANGE LOCATION

Carefully select the location where the range will be placed.

The range should be located for convenient use in the kitchen,

but away from strong drafts.

Strong drafts may be caused by open doors or windows, or by

heating and/or air conditioning vents or fans.

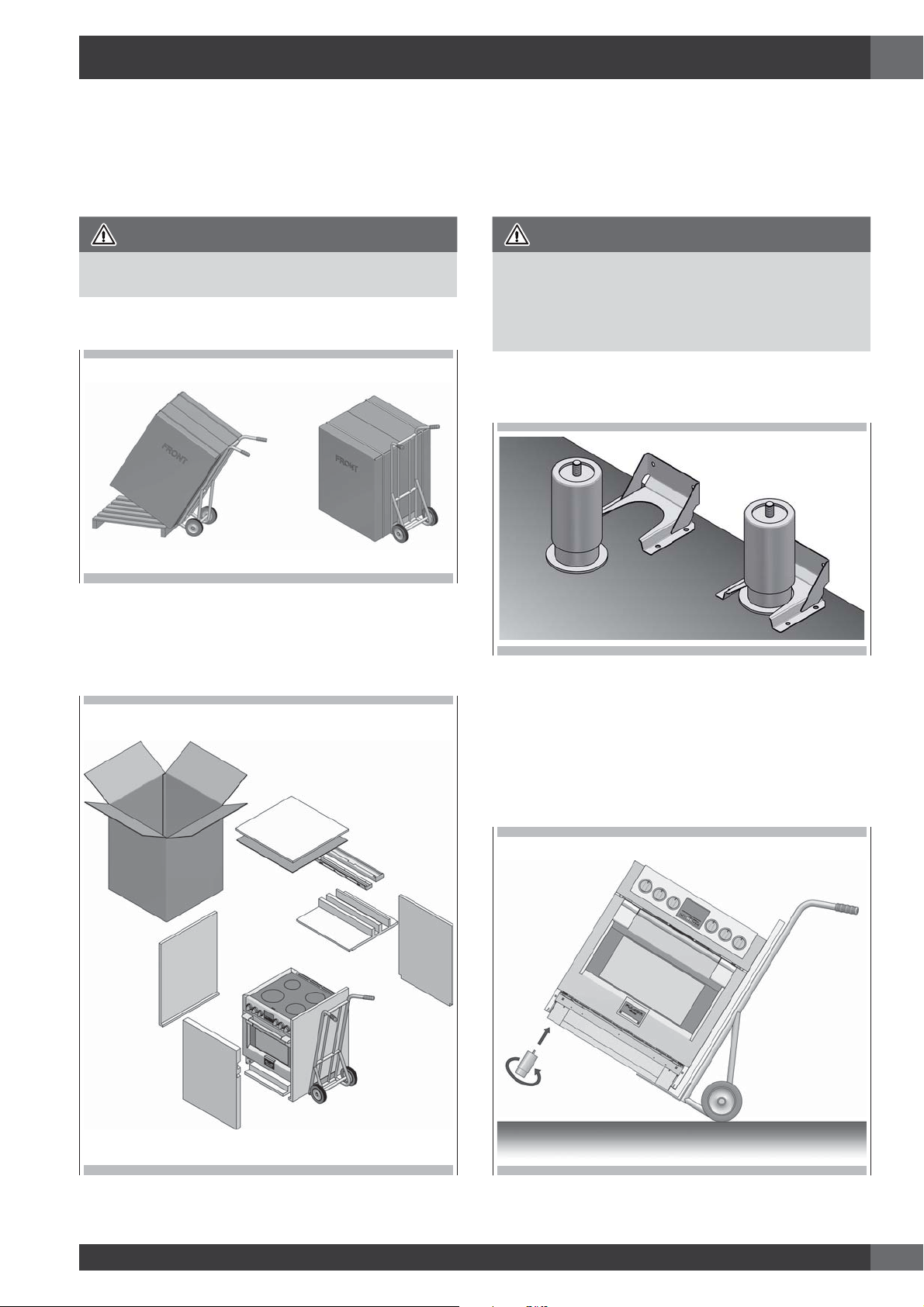

TOOLS WILL YOU NEED

IMPORTANT NOTE

When installing against a combustible surface, a minimum

riser is required for a the range, Follow all minimum

clearances to combustible surfaces shown in the illustration

on the previous pages.

Before moving the range, protect any finished flooring and

secure oven door(s) closed to prevent damage.

Do not lift or carry the range door by the door handle.

To eliminate the risk of burns or fire by reaching over heated

surface units, cabinet storage space located above the surface

units should be avoided. If cabinet storage is to be provided,

the risk can be reduced by installing a range hood that projects

horizontally a minimum of inches beyond the bottom of the

cabinets.

Remove packaging materials and literature package from the

cooktop before beginning installation.

Remove Installation Instructions from the literature pack and

read them carefully before you begin

MATERIALS PROVIDED

ANTI-TIP BRACKET

BRACE ABD SCREWS

6

Page 9

4 - Installation Instructions

EN

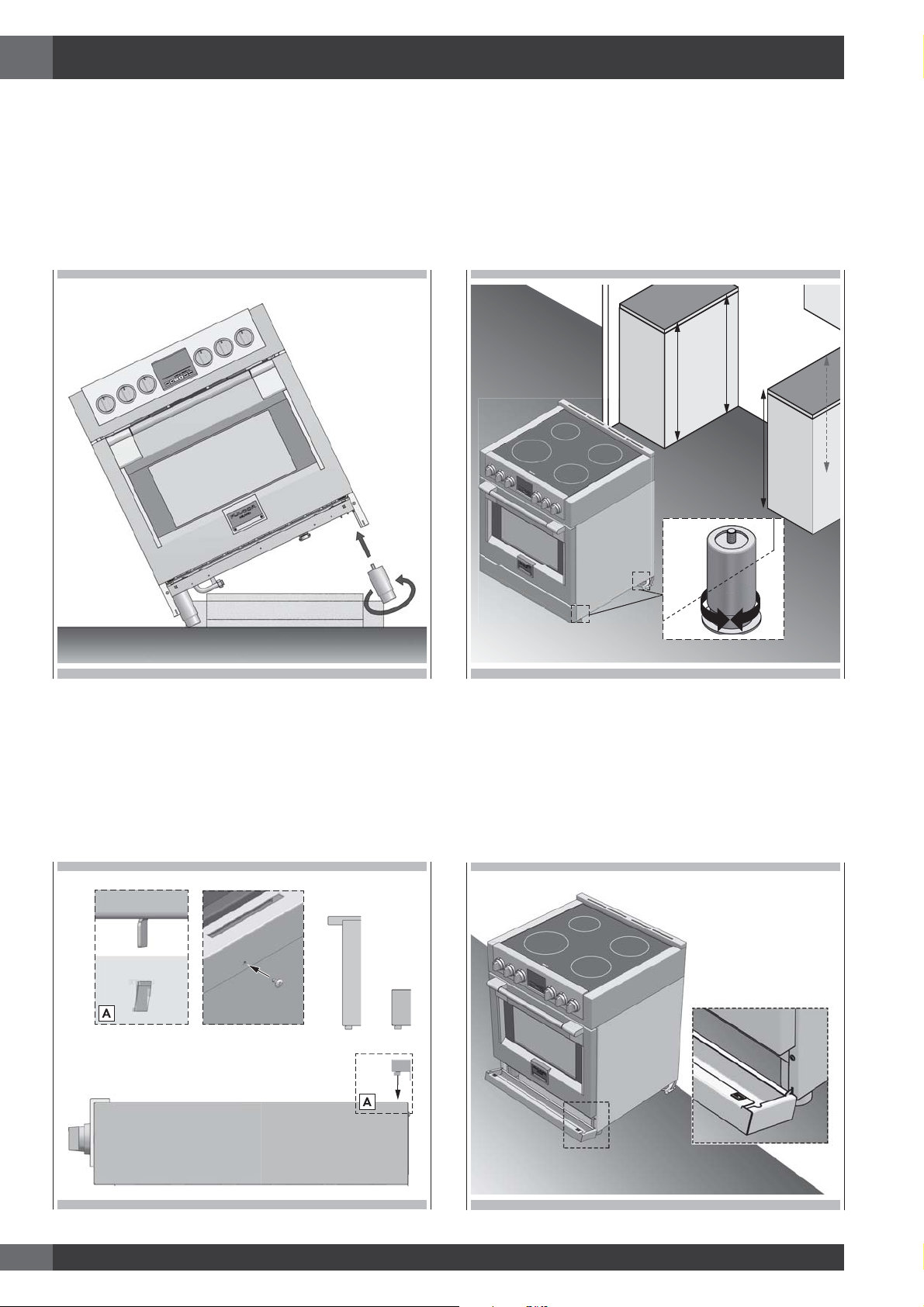

STEP 1

Cut the banding and remove the appliance from the pallet by a

hand-truck inserting the blade under the foam base.

CAUTION

Stand clear. The ends of the cut banding may snap toward you.

STEP 3

Move the range indoors before installing the legs, position the

appliance near its final location as the legs are not suitable for

moving the appliance over long distances.

Legs are packed in the cardboard top pack.

CAUTION

Doors and passageways leading to the installation location

require at least 31” opening. If the opening is less than 31”,

the oven door(s) and control knobs must be removed.

(see Use & Care manual for oven door removal instructions).

Note: the legs with collar must be mounted on the back of range

to engage the anti tip device.

STEP 2

Remove Installation Instructions from the top of range and read

them carefully before you begin.

STEP 4

With the foam base still in place, tilt the range laterally and

screw in the first pair of legs.

7

Page 10

EN

4 - Installation Instructions

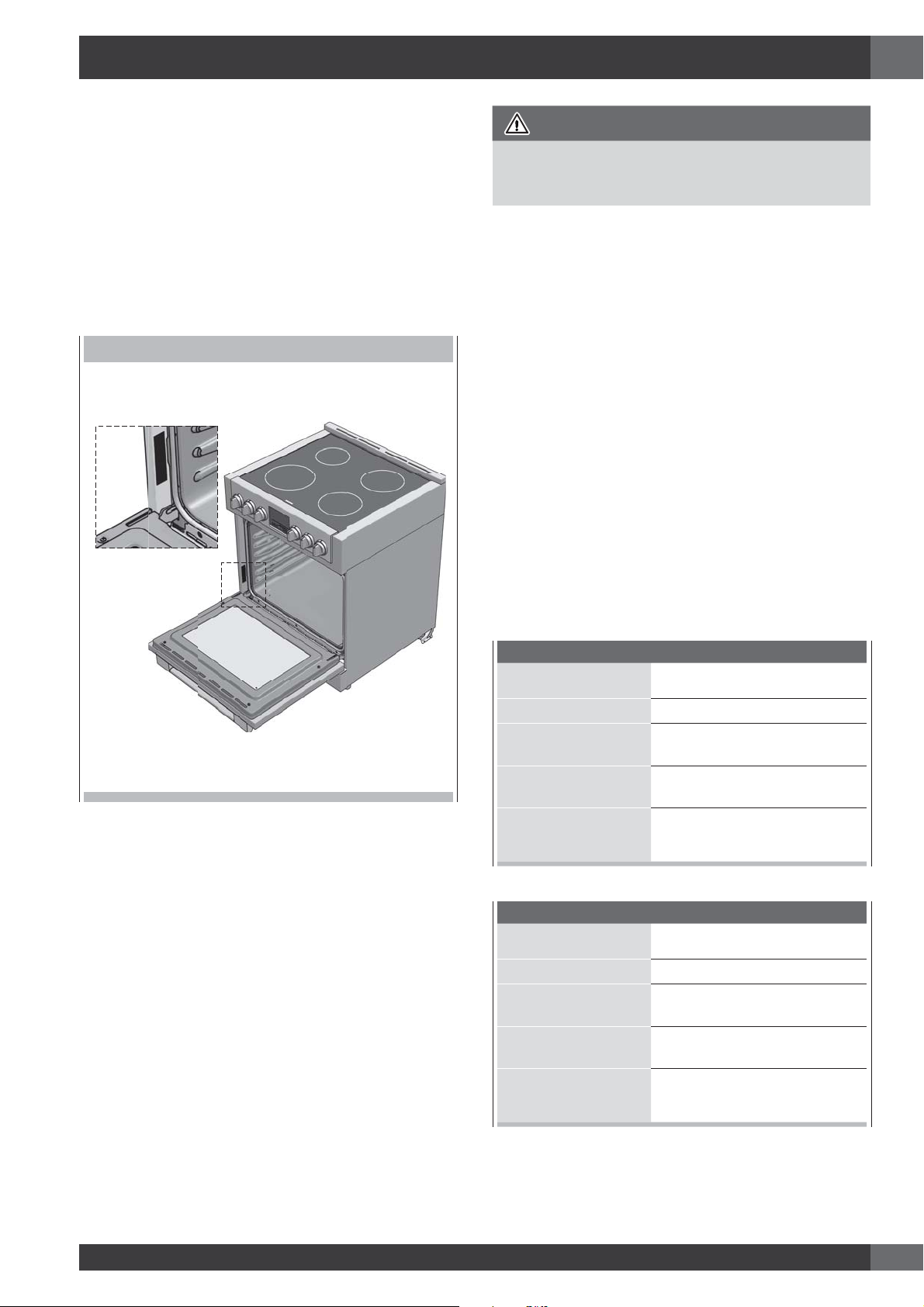

STEP 5

Pull out the hand-truck, tilt the range laterally and insert the

second pair of legs. Remove the base

STEP 7

After the electrical and gas connections (see both paragraphs

for instructions) measure the four corners in cutout area to verify

if flooring is level. Adjust the leveling legs to the desired height

and ensure range is level. Turn the bottom section of each leg

counter-clockwise to raise the leg and clock wise to lower it.

Ensure floor is protected. Slide unit into place making sure to

engage the anti-tip bracket.

STEP 6

Install the backsplash (if provided) by the three screws on the

back and the toe kick

3”9”

STEP 8

Hook tabs on bottom of toekick into slots on either side of

the frame and rotate up until clips at top of toekick engage

securely.

NOTE: Be sure the toekick snaps securely.

8

Page 11

5 - Electrical supply

EN

Before installing the oven have a qualified electrician verify

that your home is provided with adequate electrical service

and that the addition of the oven will not overload the

branch circuit on which it is to be installed.

Be sure your appliance is properly installed and grounded

by a qualified technician. Ask your dealer to recommend a

qualified technician or an authorized repair service.

This appliance is manufactured with a green GROUND

wire connected to the oven chassis Junction Box or Wall

Receptacle Location.

Suggested location of the junction box or wall receptacle is

showed in “Cutout requirements” Figure.

LOCATION OF RATING PLATE

WARNING

Risk of Electric Shock, frame grounded to neutral of

appliance through a link

Grounding through the neutral conductor is prohibited for

new branch-circuit installations (1996 NEC); mobile homes;

and recreational vehicles, or in an area where local codes

prohibit grounding through the neutral conductor. For

installations where grounding through the neutral conductor

is prohibited:

- Disconnect the ground from the neutral at free end of

conduit;

- Use grounding terminal or lead to ground unit; and

- Connect neutral terminal or lead to branch circuit neutral

in usual manner.

A 3-wire* or 4-wire single phase 120/240 or 120/208

Volt, 60 Hz AC only electrical supply is required on a

separate circuit fused on both sides of the line (time-delay

fuse or circuit breaker is recommended). DO NOT fuse

neutral.

Your local codes and ordinances, of course, take precedence

over these instructions. Complete electrical connections

according to local codes and ordinances.

A UL listed conduit connector must be provided at each end

of the power supply conduit (at the range and at the junction

box).

• Wire sizes and connections must conform with the rating

of the range.

In the United States:

Be sure that the electrical and grounding connections and

also wire size are adequate and in conformance with the

National

Electrical Code, ANSI/ NFPA 70-latest edition and all local

codes and ordinances.

NOTE: FOR USE WITH 208 V, 60 HZ SUPPLY VOLTAGE,

SEE CONNECTING TO 208 VOLT CIRCUIT.

ELECTRICAL REQUIREMENTS 30”

Electrical Supply 120-240V or 120-208V, 60 Hz

Service 50 amp dedicated circuit

Total Amps 120/240V 45.8 Amps

120/208V 48.5 Amps

Max Connected Load 120/240V 11.00 kW

120/208V 10.00 kW

Min Supply Wire L1, L2, ground 8 AWG

Neutral 10 AWG

ELECTRICAL REQUIREMENTS 36”

Electrical Supply 120-240V or 120-208V, 60 Hz

Service 50 amp dedicated circuit

Total Amps 120/240V 61.0 Amps

120/208V 63.0 Amps

Max Connected Load 120/240V 14.60 kW

120/208V 13.30 kW

Min Supply Wire L1, L2, ground 8 AWG

Neutral 10 AWG

In Canada:

Be sure that the electrical connection and wire size are

adequate and in conformance with CSA Standard C22.1,

Canadian Electrical Code, Part 1 - latest edition, and all

local codes and ordinances.

(*) Power limitation at 50.0 Amps

9

Page 12

EN

WARNING

ELECTRICAL SHOCK HAZARD

• The electrical power to the appliance branch circuit

must be shut off while line connections are being made.

• Do not use an extension cord with this appliance.

• Electrical ground is required on this appliance.

• The free end of the green wire (the ground wire) must

be connected to a suitable ground. This wire must

remain grounded to the appliance.

• If cold water pipe is interrupted by plastic, non metallic

gaskets, union connections or other insulating materials,

DO NOT use for grounding.

• DO NOT ground to a gas pipe.

• DO NOT have a fuse in the NEUTRAL or GROUNDING

circuit. A fuse in the NEUTRAL or GROUNDING circuit

could result in an electrical shock.

• Check with a qualified electrician if you are in doubt as

to whether the appliance is properly grounded.

• Failure to follow these instructions could result in serious

injury or death.

10

Page 13

6 - Electrical connections

EN

CAUTION

Do not repair or replace any part of the appliance unless

specifically recommended in the manual. All other servicing

should be done by a qualified technician. This may reduce

the risk of personal injury and damage to the appliance.

Never modify or alter the construction of the appliance by

removing panels, wire covers, screws, or any other part of

the product.

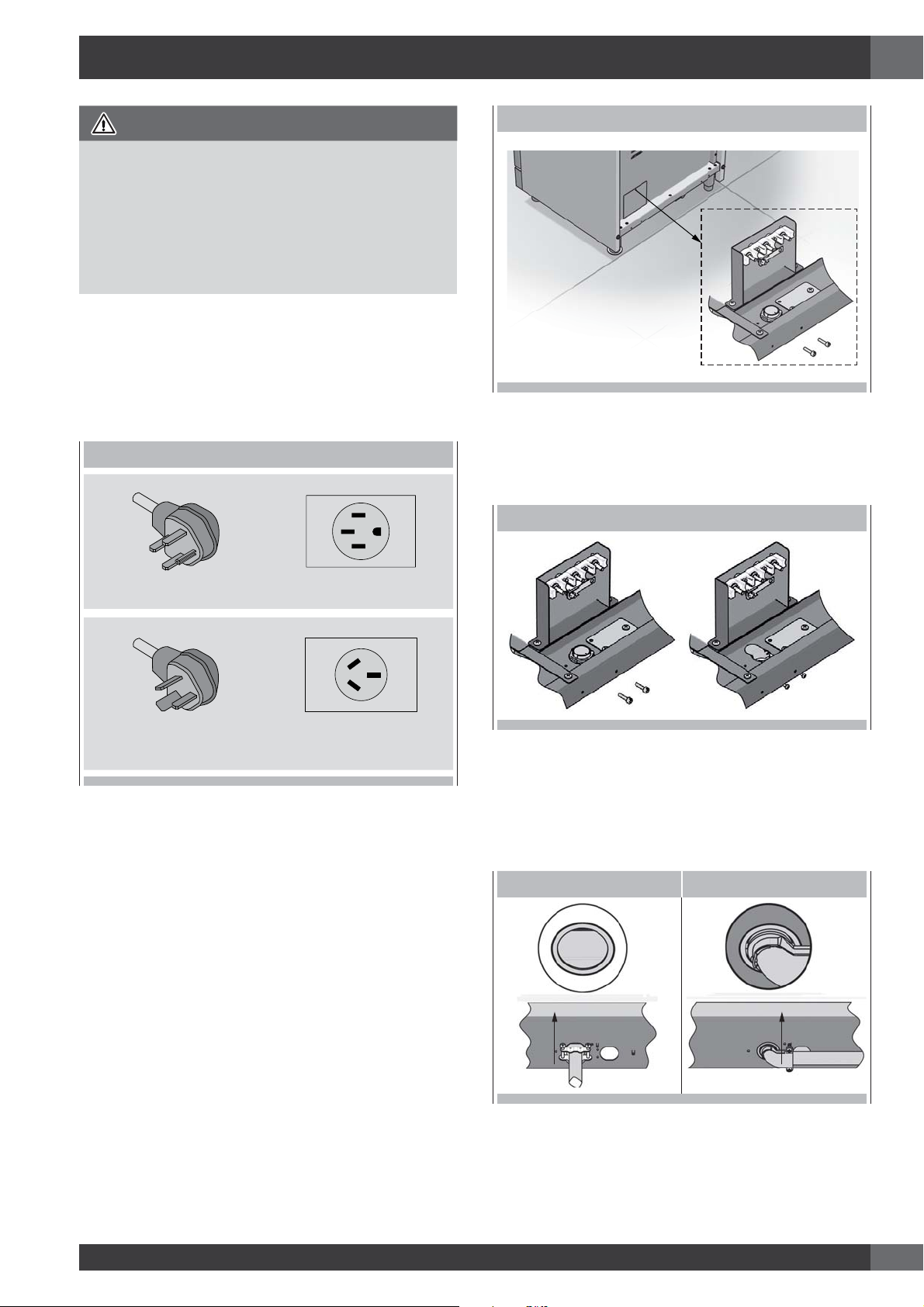

Factory Connected Power Supply Cord

Your range is equipped with a factory-connected power cord.

Cord must be connected to a grounded 120/240 volt or

120/208 volt range outlet. If no outlet is available, have one

installed by a qualified.

PLUG POWER SUPPLY CORD

LOCATION OF ELECTRICAL CONNECTION

3) Add strain relief if not provided.

NOTE: If necessary remove the knockout to insert the strain relief.

Power supply cord strain relief

• Assemble a UL listed strain relief in the opening.

UL LISTED STRAIN RELIEF

NEMA 14-50P Plug NEMA 14-50R Receptacle

NEMA 10-50P Plug

(for US only)

Power Supply Cord Kit or Flexible Conduit (for US only)

The user is responsible for connecting the power supply cord to

the connection block located behind the back panel access cover.

This appliance may be connected by means of permanent

“hard wiring” (flexible armored or nonmetallic shielded

copper cable), or by means of a power supply cord kit. Use

only a power supply cord kit rated at 125/250 volts minimum

and marked for use with ranges. Cord must have either 3 or

4 conductors. Terminals on end of wires must either be closed

loop or open-end spade lugs with upturned ends.

For 30” and 36” ranges use a power supply cord kit rated at

minimum 50A that is marked for use with nominal 1-3/8 in

(34.93 mm) diameter connection openings.

1) Disconnect power.

2) Remove the terminal block cover screws located on the back

of the range.

NEMA 10-50R Receptacle

(for US only)

• Feed the power supply cord or flexible conduit through

the strain relief in the cord/conduit plate on bottom of

range. Allow enough slack to easily attach the wiring to the

terminal block.

• Tighten strain relief screw against the power supply cord or

flexible conduit.

POWER SUPPLY CORD FLEXIBLE CONDUIT

4) Complete installation following instructions for your type of

electrical connection:

• 4-wire (recommended)

• 3-wire (if 4-wire is not available)

11

Page 14

EN

6 - Electrical connections

IF YOUR HOME HAS AND YOU WILL BE

CONNECTING TO:

4-wire receptacle

A UL listed, 250-

(NEMA type 14-50R)

50-amp, range

volt minimum,

power supply

cord

ELECTRICAL CONNECTION OPTIONS

CONNECTION

IF YOUR HOME HAS AND YOU WILL BE

TYPE:

3-wire receptacle

(NEMA type 10-50R)

CONNECTING TO:

A UL listed, 250-

volt minimum,

50-amp, range

power supply

cord

CONNECTION

TYPE:

4-wire direct

A fused

disconnect or

5"

(12.7 cm)

circuit breaker

box

TERMINAL BLOCK - GROUND STRAP

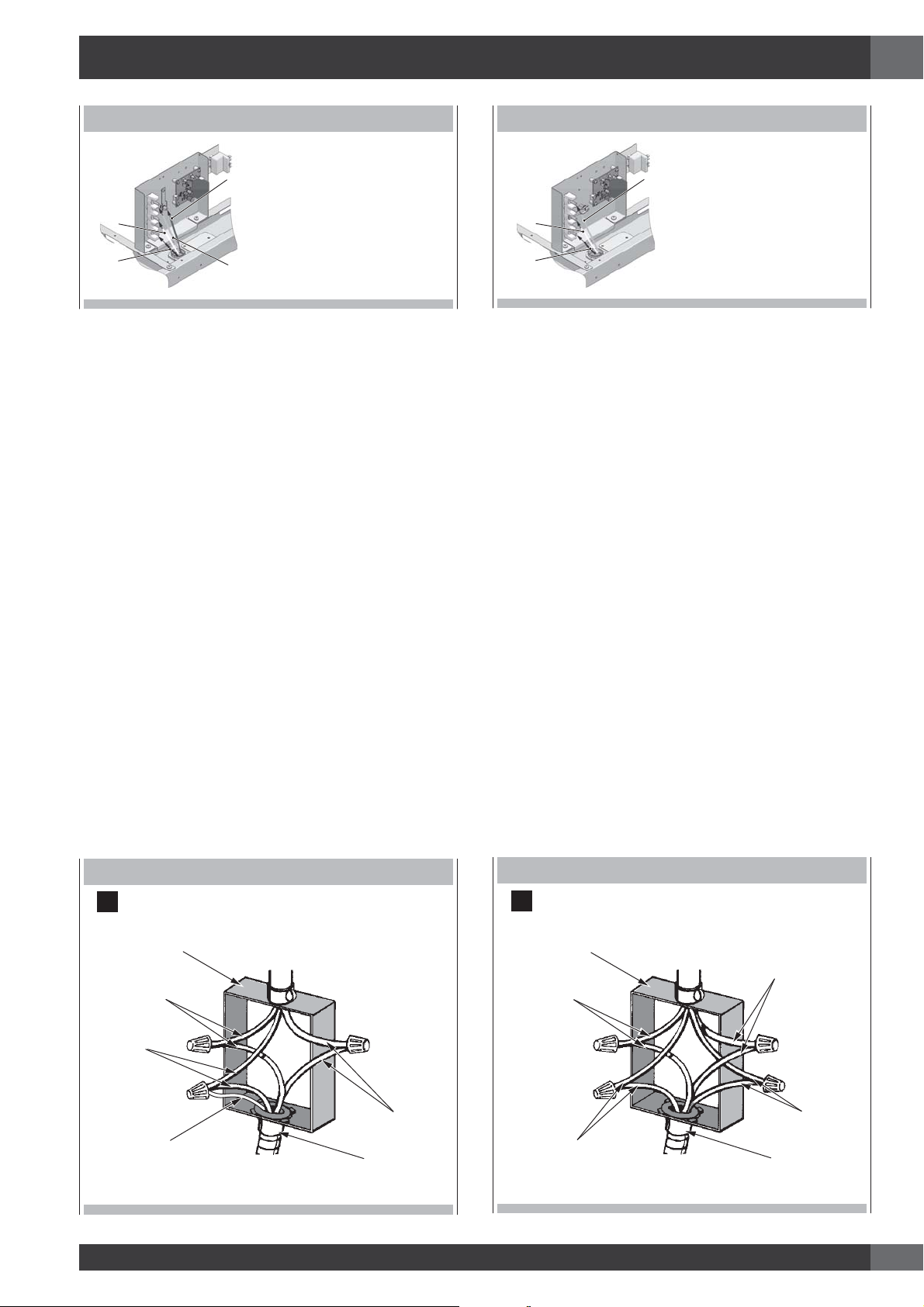

4-wire connection

Part of metal ground strap must be removed.

1) Use Phillips screwdriver to remove the ground-link screw

from the back of the range. Save the ground-link screw and

the end of the ground link under the screw.

2) Feed the power supply cord through the strain relief in the

cord/conduit plate on bottom of range. Allow enough slack

to easily attach the wiring to the terminal block.

3) Use Phillips screwdriver to connect the green ground wire

from the power supply cord to the range with the groundlink screw. The ground wire must be attached first.

4) Use 3/8” nut driver to connect the neutral (white) wire to the

enter terminal block post with one of the 10-32 hex nuts.

(Refer to the “Electric Connection Options” table to see the

appropriate connection type)

5) Connect line 1 (black) and line 2 (red) wires to the outer

terminal block posts with 10-32 hex nuts.

6) Securely tighten hex nuts.

7) Replace terminal block access cover.

3-wire direct

A fused

disconnect or

5"

(12.7 cm)

A. Metal ground strap

B. Ground-link screw

circuit breaker

box

3-wire connection

Use this method only if local codes permit connecting chassis

ground conductor to neutral wire of power supply cord:

1) Feed the power supply cord through the strain relief in the

cord/conduit plate on bottom of range. Allow enough slack

to easily attach the wiring to the terminal block.

2) Use 3/8 nut driver to connect the neutral (white) wire to the

center terminal block post with one of the 10-32 hex nuts.

(Refer to the “Electric Connection Options” table to see the

appropriate connection type)

3) Connect line 1 (black) and line 2 (red) wires to the outer

terminal block posts with 10-32 hex nuts.

4) Securely tighten hex nuts.

5) Replace terminal block access cover.

12

“30” INDUCTION RANGE 4-WIRE CONNECTION

A

B

D

C

A. Red

B. White

C. Green

D. Black

“30” INDUCTION RANGE 3-WIRE CONNECTION

A

C

B

A. Red

B. White

C. Black

Page 15

6 - Electrical connections

EN

“36” INDUCTION RANGE 4-WIRE CONNECTION

A

A. Green

B. Red

C

D

B

C. White

D. Black

“36” INDUCTION RANGE 3-WIRE CONNECTION

A

A. Red

B

B. White

C. Black

C

Direct Electrical Connection to the Circuit Breaker, Fuse Box or Junction Box

If the appliance is connected directly to the circuit breaker, fuse box or junction box, use flexible, armored or non metallic sheathed

copper cable (with grounding wire).

3-WIRE BRANCH CIRCUIT (for US only)

Refer to Figure A:

where local codes allow the connection of GROUND wire from

the range to the branch circuit NEUTRAL wire (gray or white

colored wire):

- If local codes permit, connect the green GROUND wire from

the range and the white wire from the oven to the branch

circuit NEUTRAL wire (gray or white colored wire).

- Connect the red and black leads from the range to the

corresponding leads in the junction box.

4-WIRE BRANCH CIRCUIT (for US only)

Refer to Figure B:

- Disconnect ground from neutral at free end of conduit.

- Connect the green GROUND wire from the range to the

GROUND wire in the junction box (bare or green colored

wire).

- Connect the red and black leads from the range to the

corresponding leads in the junction box.

- Connect the white wire from the range to the NEUTRAL (gray

or white) wire in the junction box.

DO NOT ground to a gas supply pipe.

DO NOT connect to electrical power supply until appliance is

permanently grounded. Connect the ground wire before turning

on the power.

GROUNDED NEUTRAL

A

Junction box

Red wires

White wires

Bare or

green wire

Cable from

power supply

Cable

from oven

Black wires

UL listed conduit

connector

DO NOT ground to a gas supply pipe.

DO NOT connect to electrical power supply until appliance is

permanently grounded. Connect the ground wire before turning

on the power.

UNGROUNDED NEUTRAL

B

Junction box Cable from

Red wires

Bare or

green wire

power supply

Cable

from oven

White wires

Black wires

UL listed conduit

connector

13

Page 16

EN

7 - Final checklist

CONNECTING TO 208 VOLT CIRCUIT

To prevent improper connections leading to damage of

electrical components and so voiding the warranty, the

following steps must be performed:

1. Check the electrical requirements and make sure you have

the correct electrical supply and that the range is properly

grounded.

2. Before the range is connected, turn on the power supply.

3. Check power at the junction box wires using a voltmeter

having a range of 0-250 VAC. If you have installed the

oven for use on 240 Volt supply, you should find that the

voltage reading between the black and red wires (Line to

Line) should be 220 to 240 Volts. If you have modified the

range(s) for use on 208 Volt, the voltage reading between

the black and red wires should be 190 to 208 Volts.

4 Connect the range to the power supply.

5. Set the clock by following these steps:

• Press

• Immediately press

• Press

• Immediately press

TIME

key twice until the display shows “SET TIME”.

+

or - keys to set hours.

TIME

key again to change minutes.

+

or - keys to set minutes, hold to

change by ten (10) minutes step.

• Press

TIME

key or wait for a few seconds.

Clock is now set.

This option is provided for areas where standard 240 Volt

service is not available. This option must be accessed with the

appliance connected to power source, and using the following

sequence:

1. Within five minutes from power up, hold

MENU

and

TIME

keys for 3 seconds to enter the user option menu. The

display shows as follows:

2. Hold then

TIME

and

LIGHT

keys until the display becomes

dark.

3. Hold

MENU

and

LIGHT

further, until the time display shows

“Volt” and temperature module shows “240” blinking,

waiting for an input.

4. Using + or - keys, the control toggles between 240V

MENU

and 208V options. Hold

5. Hold

TIME

and

LIGHT

keys in order to quit the selection.

to confirm.

6. Test the bake mode by following this step:

• Move cooking mode knob to “BAKE” position.

• Cooling fan, oven lights, preheat led will turn on.

• A beep is sounded when the oven reaches the preset

350 °F (175 °C) and the preheat light turn off.

• Move the knob back to “OFF” position to stop cooking.

7. To check the other oven functions refer to the “Using the

Oven Controls” section of the USE AND CARE MANUAL.

8. If the oven is working properly, turn off the power supply to

the oven.

9. Place the cover on the junction box and make sure the cover

is securely fastened and turn on the power to the oven.

IMPORTANT

Leave these INSTALLATION instructions as well as the USE

AND CARE MANUAL with the owner.

MENU

6. Hold

key for 3 seconds to quit the user option menu.

The voltage setting is stored and kept even after a long

power-off.

14

Page 17

Veuillez prêter attention à ces symboles que vous rencontrerez

dans ce manuel :

FR

TABLES DES MATIERES PAGE

1 -

Avertissement Spéciaux

Avant de Procéder à l’Installation

Installation autocaravane

2 -

Dimensions et Dispositions pour la Découpe

Instructions d’installation des supports anti-bascules

3 -

Consignes d’installation

4 -

Instructions d’Installation

Alimentation électrique

5 6 -

Connexions électriques

Connexion 4 fils

Connexion 3 fils 12

Connexion directement au disjoncteur, à la boîte

à fusibles ou à la boîte de jonction

7 - Liste de vérification finale 14

11

12

13

DANGER

2

2

2

3

5

6

7

9

Si vous ne suivez pas IMMEDIATEMENT ces instructions,

vous courez le risque de mourir ou d’être sérieusement

blessé.

AVERTISSEMENT

Ce symbole signifie que la sécurité est en danger. Il signale

les risques potentiels qui peuvent entraîner la mort ou des

blessures à l’opérateur ou aux autres.

Si vous ne suivez pas ces instructions à la lettre, vous courez

le risque de mourir ou d’être sérieusement blessé.

BIEN LIRE CES INSTRUCTIONS ET LES CONSERVER.

À l’installateur :

Laissez ces instructions avec l’appareil.

Au client :

Gardez ces instructions comme référence future.

IMPORTANT: Gardez ces instructions pour une utilization

d’inspection électrique locale

INSTALLATEUR: Veuillez laisser ce manuel au propriétaire

pour de futures références.

PROPRIETAIRE: Veuillez garder ce manuel pour de futures

références.

AVERTISSEMENT

Le respect minutieux des indications fournies dans ce manuel

est indispensable pour éviter le risque de feu ou d’explosion

susceptible d’endommager les biens et les produits et de

provoquer des blessures, voire même la mort.

Ne pas stocker ou utiliser de l’essence ou d’autres liquides

inflammables à proximité de cet appareil ou de tout autre

appareil électroménager.

1

Page 18

FR

1 - Avertissement Spéciaux

INSTRUCTION IMPORTANT

Avertissement Spéciaux

Veuillez lire les instructions avant toute utilisation

Il est de votre responsabilité d’installer l’appareil correctement.

Confiez l’installation de cette cuisinières à un technicien qualifié.

AVERTISSEMENT

- Respecter les règlements et ordonnances en vigueur.

- Avant l’installation de la cuisinière, noter le modèle et

les numéros de série. Les deux numéros se trouvent sur

la plaque de données dans la position indiquée dans la

figure ci-dessous.

POSITION DE LA PLAQUE SIGNALÉTIQUE

Vous pouvez demander une copie des standards répertoriés à:

** National Fire Protection Association One Batterymarch Park

Quincy, Massachusetts 02269

*** CSA International 8501 East Pleasant Valley Rd. Cleveland,

OH 44131 – 5575

Installation autocaravane

L’installation de cette table de cuisson doit être conforme

aux Normes de Construction et de Sécurité des Habitations,

titre 24 CFR, Partie 3280 (jadis la Norme Fédérale pour la

Construction et la Sécurité des Autocaravanes; titre 24HUD

partie 280); ou lorsque de telles normes ne sont pas

applicables, la Norme pour les Installations des Habitations

(Emplacements, Communautés et Structures Habitations),

ANSI 225.1 - dernière édition ou aux réglementations locales.

Au Canada, l’installation de cette table de cuisson doit être

conforme aux normes en vigueur CAN/CSA-Z240 - dernière

édition ou aux réglementations locales.

Avant de Procéder à l’Installation

• Vérifiez l’endroit où la cuisinières sera installée. La table de

cuisson ne doit pas se trouver dans une zone de courants

d’air forts, par exemple de fenêtres ou de portes ni près de

calorifères ou de ventilateurs.

• L’appareil doit nécessairement être relié à la terre. Voir

«Conditions requises électricité».

• Veuillez vous assurer que l’installation électrique est

adéquate et conforme à la Réglementation Électrique

Nationale ANSI/NFPA 70 – dernière édition** ou à la

Réglementation Électrique du Canada, C22.1 – 1982 et

C22.2 N° 01982 (ou dernière édition)*** et à tous les

règlements et ordonnances en vigueur localement.

2

Page 19

2 - Dimensions et Dispositions pour la Découpe

35

3/4

(9

1,0

)

DIMENSIONS DU PRODUIT

Modèles de cuisinière 30”

FR

29 3/4” (75,8)

35 3/4” (91,0)

9" (22,8) [optionnel]

3" ( 7,6) [optionnel]

1" ( 2,5)

3/8” (1)

29 3/4” (75,6)

27 1/2” (69,7)

25 3/4” ( 65,4)

27 1/4” ( 69,1)

7 3/8” (18,7)

1 3/8” (3,5)

À

3 3/8” (8,5)

Max. 37 1/4” (94,7)

Min. 35 3/8” (89,8)

47 3/4” (121,4)

3

Page 20

FR

2 - Dimensions et Dispositions pour la Découpe

DISPOSITIONS POUR LA DÉCOUPE

C

Min. 30” (76,2)

Jusqu’au bas

de la hotte

Min. 18” (45,7)

Max.

Min. 18” (45,7)

13” (33)

Min. 6”

(15,2)

Bordure minimale de 2 po (5,1)

depuis le mur pour l’alimentation

en gaz ou électrique

A

ÉLECTRIQUE

GAZ

B B

4” 3/4 (12,3)

3” (7,6)

Min. 6”

(15,2)

*Position suggérée des

équipements

La totalité de la surface du mur arrière ainsi que la surface se trouvant au-dessus de la table de cuisson doit être faite d’une matière ignifuge.

*Consulter les réglementations locales pour les exigences exactes de localisation.

LARGEUR D’OUVERTURE A & C B

Cuisinière 30 po 30" (76,2) 6” (15,2)

Cuisinière 36 po 36" (91.4) 7” (17.8)

ESPACE SUPPLÉMENTAIRES:

Pour une installation en îlot, maintenir une distance minimum

de 6,3 cm (2 ½ po) entre le bord et le dos du comptoir et

7,6 cm (3 po) minimum sur les côtés du comptoir (voir vue

de dessus).

Remarque: La distance par rapport aux matériaux non

combustible doit respecter les réglementations

locales ou, en l’absence de celles-ci, avec le

« National Fuel Gas Code », ANSI Z223.1/

INSTALLATION ÉBARBER

NFPA 54.

Dégagements minimums d’une construction:

Au-dessus de la surface de cuisson [au-dessus de 36 po (91,4 cm)]

• Côtés - 3 po (7,6 cm)

• Avec un dégagement latéral de 3 po (7,6 cm) ou moins,

les placards muraux ne mesurant pas plus de 13 po (33

cm) de profondeur doivent se trouver à 18 po (45,7 cm)

minimum au-dessus de la surface de cuisson.

• Les armoires murales juste au-dessus du produit doivent

se trouver à 30 po (76.2 cm) minimum au-dessus de la

surface de cuisson

• Arrière - 0 po avec dosseret de 3 po (7,6 cm).

4

DOS

min 2 1/2” (6,3)

min 3” (7,6) min 3” (7,6)

Page 21

2 - Dimensions et Dispositions pour la Découpe

FR

Avant de déplacer la cuisinière, protégez tout plancher fini et

fixez la (les) porte(s) du four en position fermée pour éviter tout

dommage.

Disposition de hotte d’extraction:

Il est recommandé d’installer nos cuisinières avec une hotte

d’extraction suspendue.

Installez une hotte disposant d’une capacité d’évacuation d’au

moins 450 CFM.

Cet appareil produisant une importante quantité de chaleur,

vous devez porter une attention toute particulière à l’installation

de la hotte et de la conduite d’aération afin de vous assurer

qu’elle répond aux normes de construction en vigueur dans

votre region.

AVERTISSEMENT

Il faut prévoir les dégagements ci-dessous par rapport

aux surfaces horizontales qui se trouvent au-dessus de la

cuisinière.

Le non-respect de cette consigne pourrait présenter un risque

d’incendie.

• Pour les installations dépourvues de hotte, prévoyez un

espace minimum de 30” (76 cm) entre l’appareil et tout

élément inflammable situé au-dessus de celui-ci.

• Il est possible d’installer une hotte spéciale à proximité

d’éléments horizontaux inflammables dans la mesure

où celle-ci dispose d’une fonction de mise en marche

automatique.

• Pour obtenir les spécifications relatives aux espaces

d’autres installations pourvues d’une hotte, veuillez vous

reporter aux instructions fournies avec celle-ci

AVERTISSEMENT

Pour vérifier que la bride anti-basculement est bien installée et engagée:

• Faire glisser la cuisinière vers l’avant.

• Vérifier que la bride antibasculement est bien fixée au plancher

ou au mur.

• Faire de nouveau glisser la cuisinière vers l’arrière de sorte que le

pied de la cuisinière se trouve sous la bride antibasculement.

• Voir les instructions d’installation pour plus de détails.

Bride antibasculement

Pied de la cuisinière

INSTALLATION DE LA BRIDE ANTI-BASCULEMENT

MUR

ARRIÈRE

PAROI LATÉRALE

DE L'ARMOIRE

ANCRAGE

AU MUR

ATTENTION

Ces cuisinières pèsent plus de 180 kg. Afin d’éviter tout

risque de blessure ou d’endommagement de l’appareil et

compte tenu du poids et de la taille de la cuisinière:

DEUX PERSONNES SONT NÉCESSAIRES POUR UNE

INSTALLATION ADÉQUATE DES CUISINIÈRES.

Instructions d’installation des supports anti-bascules

AVERTISSEMENT

Risque de basculement

Un enfant ou une personne adulte peut faire basculer la cuisinière, ce

qui peut causer un décès. S’assurer que le dispositif antibascule est

réengagé lorsque la plage est déplacée.

Ne pas faire fonctionner la cuisinière si la bride antibasculement n’est

pas installée et engagée. Le non-respect de ces instructions peut causer

un décès ou des brûlures graves aux enfants et aux adultes.

ÉGALITÉ

ANTIBASCULEMENT

SUPPORT

Pour les constructions en ciment ou béton:

Vous devez utiliser les éléments fixationappropriés (non

fournis). Fixez le support sur le sol et/ou le mur à l’aide les 4

vis à bois (fournies).

Le support anti-basculement devrait être inséré dans

l’ouverture de l’équerre antibasculement sur la cuisinière.

5

Page 22

FR

3 - Consignes d’installation

AVERTISSEMENT

• Risque du fait du poids excessif

Soyez à deux personnes ou plus pour porter et installer la

cuisinières. Sinon, vous risquez de vous blesser au dos ou

de subir d’autres blessures.

• Risque de coupure

Méfiez-vous des bords tranchants et des extrémités du

polystyrène lorsque vous portez le produit. Sinon, vous

risquez de vous couper ou de vous faire légèrement mal.

Ne pas boucher le flux d’air au niveau de l’ouverture

de ventilation du four ni au-dessous du panneau frontal

inférieur de la cuisinière. Éviter de toucher les ouvertures

de ventilation ou les surfaces voisines car ces surfaces

pourraient se réchauffer pendant que le four est en service.

CHOIX DE LA POSITION DE LA CUISINIÈRE

Choisissez attentivement l’emplacement d’installation de la

cuisinière.

La cuisinière doit être positionnée pour être utilisée dans la

cuisine, mais loin des courants d’air.

Une porte ou une fenêtre ouvertes, l’air mis en mouvement par

les ventilateurs de chauffage/climatisation peuvent causer des

courants d’air forts.

LES OUTILS DONT VOUS AUREZ BESOIN

NOTE IMPORTANTE

Si vous installez la cuisinière contre une surface combustible,

veillez à prévoir un minimum de rehausse.

Respectez toutes les distances par rapport aux surfaces

combustibles qui sont indiquées dans les pages précédentes

Avant de déplacer la cuisinière, protégez le sol et fixez la porte

du four en position fermée afin de prévenir tout dommage.

Évitez absolument de soulever ou de porter la cuisinière en la

tenant par la poignée de la porte.

Pour éliminer le risque de brûlure ou d’incendie à cause

d’une surchauffe de la surface des unités, évitez de placer

une armoire de rangement au-dessus de l’unité. Si vous avez

une armoire au-dessus de la cuisinière, vous pouvez réduire

le risque en installant à une certaine distance au-dessous de

la partie inférieure de l’armoire un écran de protection qui

projette horizontalement.

Avant de commencer l’installation, enlevez les matériaux

d’emballage et les manuels d’explication sur la table de

cuisson; puis retirez du manuel d’explication, les instructions

concernant l’installation et lisez-les avec attention.

MATÉRIEL FOURNI

SUPPORT

ANTIDÉRAPANT,

ÉQUERRE ET VIS

6

Page 23

4 - Instructions d’Installation

FR

ÉTAPE 1

Coupez les bandes et retirez l’appareil de la palette à l’aide

d’une transpalette à main en introduisant la fourche sous le

bloc de mousse.

ATTENTION

Tenez-vous à distance. Les extrémités des bandes coupées

pourraient se retourner contre vous.

ÉTAPE 3

Portez la cuisinière à l’intérieur. Avant d’installer les pieds,

placez l’appareil près de son emplacement d’installation finale

car les pieds ne sont pas adaptés pour déplacer l’appareil sur

de longues distances.

Les pieds sont emballés séparément sous carton.

ATTENTION

Les portes et les passages portant au lieu d’installation doivent

avoir une ouverture d’au moins 31’’. Si l’ouverture est de moins

de 31’’, il est nécessaire d’enlever la porte du four et les boutons

de commande (voir le manuel d’utilisation et d‘entretien pour

les instructions de démontage de la porte du four).

Remarque: Dans la partie postérieure, monter les pieds à collier

de façon à ce qu’ils s’enclenchent dans le dispositif

anti-retournement.

ÉTAPE 2

Prenez les instructions d’installation présentes sur la cuisinière

et lisez-les attentivement avant de commencer.

ÉTAPE 4

Avec la base en mousse encore en place, faites basculer la

cuisinière latéralement et visser la première paire de pattes.

7

Page 24

FR

4 - Instructions d’Installation

ÉTAPE 5

Retirez la transpalette, inclinez la cuisinière latéralement pour

visser la deuxième paire de pieds. Enlevez la base.

ÉTAPE 7

Après les raccordements électriques et de gaz (voir les

paragraphes d’instructions correspondants), mesurez la

hauteur aux quatre coins pour vérifier si le sol est nivelé.

Ajustez les pattes de nivellement à la hauteur souhaitée et

assurez-vous que la cuisinière est nivelée. Tournez la partie

inférieure de chaque patte dans le sens anti-horaire pour lever

la patte et dans le sens horaire pour la baisser. Assurez-vous

que le sol est protégé. Faites glisser l’unité de façon à engager

la bride anti-basculement.

ÉTAPE 6

Installez le dosseret (si fourni) au moyen de trois vis dans la

partie postérieure et la plinthe

3”9”

ÉTAPE 8

Accrochez les pattes au bas de la plinthe dans les fentes de

chaque côté du cadre et tournez vers le haut jusqu’à ce que

les clips sur le haut de la plinthe s’enclenchent correctement.

REMARQUE : Veiller à ce que la plinthe soit bien fixée

8

Page 25

5 - Alimentation électrique

FR

Avant d’installer le four, faites vérifier par un électricien

compétent que votre installation électrique domestique est

correcte et qu’en ajoutant le four, vous n’allez pas surcharger

le circuit de dérivation sur lequel il est installé. Votre appareil

doit être convenablement installé et connecté à la terre par

un électricien qualifié. Demandez à votre revendeur de vous

conseiller un technicien qualifié ou un centre de réparation

agréé. Cet appareil est fabriqué avec un câble de TERRE

vert connecté avec le bâti du four. Position de la boîte de

raccordement ou de la boîte encastrée. Pour la position

suggérée de la boîte de raccordement ou de la boîte

encastrée, voir le paragraphe « Exigences de découpe ».

POSITION DE LA PLAQUE SIGNALÉTIQUE

AVERTISSEMENT

Risque de choc électrique, bâti mis à la terre connecté au

neutre de l’appareil à travers un lien

Il est interdit d’effectuer la mise à la terre à travers le

conducteur neutre pour l’installation d’un circuit de

dérivation neuf (1996 NEC); les maisons mobiles et les

véhicules de loisirs, ou dans une zone dans laquelle la mise

à la terre à travers le conducteur neutre est interdite. Pour

installations dans lesquelles la mise à la terre à travers le

conducteur neutre est interdite :

- Déconnecter la terre du neutre à l’extrémité libre du

circuit.

- Utiliser le terminal de mise à la terre ou le porter jusqu’à

l’unité de mise à la terre.

- Utiliser le terminal neutre ou le porter jusqu’au neutre du

circuit de dérivation en procédant comme d’habitude.

Le four est conçu pour être raccordé à une alimentation

électrique à trois ou quatre fils, monophasée, 120/240 ou

120/208 Volt, 60 Hz AC , sur un circuit séparé doté de

fusibles sur les deux côtés de la ligne (il est recommandé

de prévoir un sectionneur ou un fusible temporisé). Ne pas

installer de fusible sur le neutre.

Les normes et réglementations locales prévalent sur ces

instructions.

Effectuez les connexions électriques conformément aux

normes et réglementations locales. Un raccord de conduit

conforme UL doit être prévu à chaque extrémité du conduit

d’alimentation électrique (à la cuisinière et à la boîte de

raccordement).

• Les dimensions des fils et les connexions doivent être

adaptées aux valeurs nominales de la cuisinière.

États-Unis:

Assurez-vous que les branchements électriques et ceux

de mise à la terre ainsi que la taille des câbles soient

conformes à la dernière édition du code américain National

Electrical Code, ANSI/ NFPA 70 et aux standards et aux

règlementations locales.

Canada:

Assurez-vous que l’alimentation électrique et les dimensions

des fils sont adaptées et conformes au CSA Standard

C22.1, Canadian Electrical Code, Part 1 -dernière édition

et tous les codes et réglementations locaux.

REMARQUE: POUR UTILISATION AVEC TENSION

D’ALIMENTATION 208 V, 60 HZ, VOIR LES

RACCORDEMENTS À UN CIRCUIT 208 V.

EXIGENCES ÉLECTRIQUES CUISINIÈRES À UN FOUR 30”

Alimentation électrique

Service

Intensité électrique

Charge max. de

connexion

Fil d’alimenation min. L1, L2, mis à la terre 8 AWG

EXIGENCES ÉLECTRIQUES CUISINIÈRES À UN FOUR 30”

Alimentation électrique

Service

Intensité électrique

Charge max. de

connexion

Fil d’alimenation min. L1, L2, mis à la terre 8 AWG

(*) Puissance limitée à 50.0 Amp

120/240 ou 120/208 volts CA, 60 Hz

circuit dédié de 50 ampères

120/240V 45.8 Ampères

120/208V 48.5 Ampères

120/240V 11.00 kW

120/208V 10.00 kW

Neutre

120/240 ou 120/208 volts CA, 60 Hz

circuit dédié de 50 ampères

120/240V 61.0 Ampères

120/208V 63.0 Ampères

120/240V 14.60 kW

120/208V 13.30 kW

Neutre

10 AWG

10 AWG

9

Page 26

FR

5 - Alimentation électrique

AVERTISSEMENT

DANGER D’ELECTROCUTION

• L’alimentation électrique du circuit du branchement du

apareil doit être coupée lorsque les connexions des

lignes sont mises en place.

• N’utilisez pas de cordon d’extension avec cet appareil.

• Une mise électrique à la terre est nécessaire pour cet

appareil.

• L’extrémité libre du fil vert (le fil de garde) doit être

connectée à la masse appropriée. Ce fil doit rester

branchée à la masse au apareil.

• Si un tuyau d’eau froide est interrompu par un plastique,

des joints non métalliques; des connexions d’union ou

d’autres matériaux isolants. NE L’UTILISEZ pas pour

mettre à la masse.

• Ne branchez pas la masse à un tuyau à gaz.

• N’AYEZ PAS de fusible en position neutre ou un circuit

à la masse.

• Un fusible dans un circuit neutre ou à la masse pourrait

entraîner une électrocution.

• Vérifiez avec un électricien qualifié si vous avez un

doute si votre appareil est correctement raccordé à la

masse.

• Si vous ne suivez pas bien ces instructions, cela peut

entraîner des blessures graves ou la mort.

10

Page 27

6 - Connexions électriques

FR

CAUTION

Ne réparez ou ne remplacez pas des pièces de l’appareil si

ce n’est pas spécifiquement recommandé dans le manuel.

Tous les autres dépannages doivent être effectués par un

technicien qualifié. Ce qui réduirait les risques de blessures et

d’endommagements du apareil. Ne modifiez jamais ou n’altérez

jamais la construction de l’appareil en enlevant des panneaux,

des couvertures de fil, des vis, ou toute autre pièce du produit.

Câble d’alimentation électrique branché à l’usine

Votre cuisinière est équipée d’un câble d’alimentation installé à

l’usine. Le câble doit être raccordé à une prise mise à la terre de

120/240 V ou 120/208 V. S’il n’y a pas de prise disponible, faitesen installer une par un électricien qualifié.

CABLE DE ALIMENTACIÓN ELÉCTRICA

POSICIÓN DEL EMPALME ELÉCTRCO

3) Ajouter le dispositif de décharge si non fourni.

REMARQUE: si nécessaire, enlever le prédécoupé pour mettre en

place le dispositif de décharge.

Dispositif de décharge du cordon d’alimentation électrique

• Installer dans l’ouverture un dispositif de décharge homologué UL.

AÑADIR EL DISPOSITIVO DE

DESCARGA SI NO HA SIDO ENTREGADO

NEMA 14-50P Plug NEMA 10-50P Plug

NEMA 14-50R Receptacle NEMA 10-50R Receptacle

(solamente para US)

Cordon d’alimentation électrique ou conduit flexible (uniquement

pour US)

L’utilisateur est responsable du branchement du cordon d’alimentation

électrique au bloc de raccordement qui se trouve derrière le portillon

d’accès du panneau postérieur. L’appareil doit être raccordé avec

un cordon d’alimentation électrique. Utiliser uniquement un cordon

d’alimentation à 125/250 V min. et adapté à l’utilisation avec des

cuisinières. Le cordon doit avoir 3 ou 4 conducteurs. Les terminaux

à l’extrémité des câbles doivent être fermés en boucle ou par des

cosses à fourche à extrémités recourbées.

Pour les cuisinières de 30” et 36”, utiliser un cordon d’alimentation

calibré à au moins 50A destiné à être utilisé avec des ouvertures de

connexion de diamètre nominal de 1-3/8 in (34.93 m).

1) Débrancher l’alimentation.

2) Enlever les vis du couvercle de la plaque à bornes située dans la

partie postérieure de la cuisinière.

• Introduire le cordon d’alimentation ou le conduit flexible à travers

le dispositif de décharge jusqu’à la plaque située sur le fond de la

cuisinière. Laisser suffisamment de jeu pour fixer confortablement

le câblage à la plaque à bornes.

• Serrer la vis du dispositif de décharge contre le câble d’alimentation

électrique ou le conduit flexible.

CABLE DE ALIMENTACIÓN TUBO FLEXIBLE

4) Terminez l’installation en suivant les instructions adaptées à votre

type de connexion électrique :

• 4 fils (recommandé)

• 3 fils (si la connexion à 4 fils n’est pas disponible)

11

Page 28

FR

6 - Connexions électriques

SI VOTRE CONNEXION

RÉSIDENTIELLE EST:

4 fils réceptacle (NEMA

type 14-50R)

ET VOUS ALLER

CONNECTER À:

homologué UL

A, 250 V min.,

50 A, cordon

d’alimentation de

la cuisinière

OPTIONS DE CONNEXION ÉLECTRIQUE

TYPE DE

CONNEXION:

SI VOTRE CONNEXION

RÉSIDENTIELLE EST:

3 fils réceptacle

(NEMA type 10-50R)

ET VOUS ALLER

CONNECTER À:

homologué UL

A, 250 V min.,

50 A, cordon

d’alimentation de

la cuisinière

TYPE DE

CONNEXION:

4 fils déconnecteur

à fusible direct

A ou boîte de

5"

(12.7 cm)

disjoncteurs

BORNIER – CÂBLE DE TERRE

Connexion 4 fils

Enlever une partie de tresse de masse métallique.

1) À l’aide d’un tournevis Philips, enlever la vis de raccordement de terre

de la partie arrière de la cuisinière. Garder la vis de raccordement

de terre et l’extrémité du raccordement de terre sous la vis.

2) Acheminer le cordon d’alimentation électrique à travers le dispositif

de décharge jusqu’à la plaque pour cordon/conduit située sur

le fond de la cuisinière.Laisser suffisamment de jeu pour fixer

confortablement le câblage à la plaque à bornes.

3) À l’aide du tournevis Philips, connecter le câble vert de terre du

cordon d’alimentation électrique à la cuisinière moyennant la vis

de raccordement de terre. Fixer d’abord le câble de terre.

4) À l’aide d’un tournevis à douille 3/8” , connecter le câble neutre

(blanc) au bloc à bornes d’entrée moyennant un écrou hexagonal

10-32. (Consulter le tableau « Options de connexion électrique »

pour le type de raccordement approprié)

5) Raccorder les câbles ligne 1 (noir) et ligne 2 (blanc) au bloc à

bornes extérieur avec des écrous hexagonaux 10-32.

6) Serrer à fond les écrous hexagonaux.

7) Remettre en place le portillon d’accès au bloc à bornes.

3 fils déconnecteur

à fusible direct

A ou boîte de

5"

(12.7 cm)

A.

Tresse de masse métallique

B. Vis de raccordement de terre

disjoncteurs

Connexion 3 fils

N’utiliser cette méthode que si les réglementations locales permettent

de raccorder le conducteur de terre du bâti au câble neutre du cordon

d’alimentation électrique:

1) Introduire le cordon d’alimentation à travers le dispositif de

décharge jusqu’à la plaque située sur le fond de la cuisinière.

Laisser suffisamment de jeu pour fixer confortablement le câblage

à la plaque à bornes.

2) À l’aide d’un tournevis à douille 3/8” , connecter le câble neutre

(blanc) au bloc à bornes d’entrée moyennant un écrou hexagonal

10-32.

(Consulter le tableau « Options de connexion électrique » pour le

type de raccordement approprié)

3) Raccorder les câbles ligne 1 (noir) et ligne 2 (rouge) au bloc à

bornes extérieur avec des écrous hexagonaux 10-32.

4) Serrer à fond les écrous hexagonaux.

5) Remettre en place le portillon d’accès au bloc à bornes.

12

CONNEXION À 4 FILS GAMME INDUCTION “30”

A

B

D

C

A. Rouge

B. Blanc

C. Vert

D. Noir

CONNEXION À 3 FILS GAMME INDUCTION “30”

A

C

B

A. Rouge

B. Blanc

C. Noir

Page 29

6 - Connexions électriques

FR

CONNEXION À 4 FILS GAMME INDUCTION “36”

A

A. Vert

B. Rouge

C

D

B

C. Blanc

D. Noir

CONNEXION À 3 FILS GAMME INDUCTION “36”

A

A. Rouge

B

B. Blanc

C. Noir

C

Connexion directement au disjoncteur, à la boîte à fusibles ou à la boîte de jonction

Si l’appareil est raccordé directement au disjoncteur, à la boîte à fusibles ou à la boîte de jonction, utiliser un câble en cuivre engainé flexible,

blindé ou non métallique (avec câble de mise à la terre).

3-CÂBLAGE DU CIRCUIT DE DÉRIVATION (US seulement)

Voir la figure A pour toute consultation :

Si les codes locaux permettent de raccorder le fil de TERRE de la

cuisine au fil NEUTRE du circuit de dérivation (fil gris ou blanc) :

- Si les réglementations locales le permettent, raccorder le câble vert

de TERRE partant de la cuisinière et le câble blanc allant du four au

fil NEUTRE di circuit de dérivation (fils gris ou blanc).

- Connecter les fiches noire et rouge de la cuisinière aux

correspondantes sur la boîte de jonction.

4-CIRCUIT DE DÉRIVATION 4 FILS (US seulement)

Voir la figure B pour toute consultation :

- Déconnecter la terre du neutre à l’extrémité libre du conduit.

- Raccorder le fil de TERRE vert de la cuisine au fil de TERRE de la

boîte de jonction (fil nu ou vert).

- Connecter les fiches noire et rouge de la cuisinière aux

correspondantes sur la boîte de jonction.

- Raccorder le fil blanc de la cuisinière au NEUTRE (gris ou blanc)

de la boîte de jonction.

NE PAS effectuer le raccordement de terre sur un tuyau d’amenée de gaz.

NE PAS connecter à l’alimentation électrique tant que l’appareil n’a

pas été mis à la terre de façon permanente. Connecter le fil de terre

avant de mettre l’appareil sous tension.

NEUTRE MIS À LA TERRE

A

Boîte de jonction

Fils rouges

Fils blancs

Fils vert ou

dénudés

Cable de

l’alimentation

Cable

du four

Fils noir

Connecteur de

conduit listé U.L.

NE PAS effectuer le raccordement de terre sur un tuyau d’amenée de gaz.

NE PAS connecter à l’alimentation électrique tant que l’appareil n’a

pas été mis à la terre de façon permanente. Connecter le fil de terre

avant de mettre l’appareil sous tension.

NEUTRE NON MIS À LA TERRE

B

Boîte de jonction Cable de

Fils rouges

Fils vert ou

dénudés

l’alimentation

Cable

du four

Fils blancs

Fils noir

Connecteur de

conduit listé U.L.

13

Page 30

FR

7 - Liste de vérification finale

Afin d’éviter des erreurs de raccordement pouvant porter à la

détérioration des composants électriques et à la perte d’effet

de la garantie, suivre les indications suivantes :

1. Vérifier les conditions électriques requises et s’assurer que

l’alimentation électrique est correcte et que la cuisinière est

mise à la terre correctement.

2. Avant que la cuisinière ne soit branchée, branchez

l’alimentation principale.

3. Vérifier l’arrivée de courant aux câbles de la boîte de

jonction à l’aide d’un voltmètre ayant une plage de travail

de 0-250 VAC. Si vous avez installé le four pour l’utiliser

sous une alimentation de 240 V, le voltage affiché entre les

fils noir et rouge (ligne à ligne) devrait être compris entre

220 et 240 V. Si vous avez modifié la cuisine pour l’utiliser

sous 208 V, le voltage affiché entre les fils noir et rouge

devrait être compris entre 190 et 208 V.

4 Branchez la cuisinière à la source d’alimentation.

5. Régler la minuterie en procédant comme suit :

TIME

• Pressez la touche

jusqu’à ce que la mention « SET

TIME » s’affiche.

• Pressez immédiatement les touches

+

ou - pour

régler l’heure.

• Appuyez encore sur le bouton

TIME

pour changer les

minutes.

• Presser immédiatement les touches

+

ou - pour

régler les minutes; maintenir enfoncé pour changer de

10 en 10 minutes.

• Pressez

TIME

ou attendez quelques secondes.

La minuterie est maintenant réglée.

6. Testez le mode de cuisson en procédant de la manière

suivante :

• Placez le bouton de mode de cuisson sur la position «

BAKE ».

• Le ventilateur de refroidissement, les lumières du four et le

voyant de préchauffage s’allument.

• Un bip sonore indique que le four a atteint la température

de consigne de 350° °F (175° °C) et le voyant de

préchauffage s’éteint.

• Reporter le bouton à la position « OFF » pour interrompre

la cuisson.

CONNEXION A UN CIRCUIT DE 208 VOLT

Cette option existe pour les régions où le standard de 240 Volt

n’est pas disponible. Il faut accéder à cette option quand le

apareil est branché à une source d’alimentation, et en utilisant

les séquences suivantes :

1. Dans les cinq minutes après avoir allumé le apareil, appuyés

sur les clés

MENU

et

TIME

pendant 3 secondes pour entrer

le menu option menu utilisateur. L’affichage indique ce qui

suit :

2. Appuyez sur les clés

TIME

et

LIGHT

jusqu’à ce que l’écran

nes’assombrisse.

3. Appuyez encore sur

MENU

et

LIGHT

, jusqu’à ce

quel’affichage horaire indique “Volt” et que le module

températureclignote un “240”, attendant une entrée.

4. En utilisant les clés + ou -, la commande alterne

entre lesoptions 240V et 208V. Appuyez sur

MENU

pour

confirmer.

5. Maintenez les clés

TIME

et

LIGHT

afin de quitter la

sélection.

MENU

6. Maintenez la clé

pendant 3 secondes pour quitter

lemenu option utilisateur.

Le réglage de la tension est enregistré et gardé même après

unelongue coupure.

7. Pour tester les autres fonctions du four, consulter la section «

UTILISATION DES COMMANDES DU FOUR » du manuel

d’utilisation et d’entretien.

8. Si le four fonctionne correctement, couper l’alimentation

électrique.

9. Mettre le couvercle sur la boîte de jonction et veiller à ce

qu’elle soit bien fixée, puis rallumer l’alimentation électrique

du four.

AVERTISSEMENT

Laissez ces instructions d’INSTALLATION et le MANUEL

D’UTILISATION ET D’ENTRETIEN au propriétaire.

14

Page 31

Preste la debida atención a los siguientes símbolosque

encontrará en el manual:

ES

TABELA DE CONTENIDO

1 - Advertencias Especiales 2

Antes de comenzar la instalación 2

Instalación en Casas Móviles 2

2 - Dimensiones del Producto y de Encastre 3

Instructions d’installation des supports

anti-bascules 5

3 - Información de instalación 6

4 - Instrucciones para la Instalación 7

5 - Alimentación eléctrica 9

6 - Conexiones eléctricas 11

Conexión de 4 cables 12

Conexión de 3 cables 12

Conexión directa al disyuntor, a la caja de

fusibles o a la caja de conexión. 13

7 - Lista de verificación final 14

PAG E

PELIGRO

Si no sigue estas instrucciones de forma INMEDIATA, puede

correr peligro de muerte o de resultar gravemente herido.

ADVERTENCIA

• Este es el símbolo de los avisos relacionados con la

seguridad: alerta sobre potenciales peligros que pueden

derivar en muerte o daños a las personas.

• Si no sigue estas instrucciones, puede correr peligro de

muerte o de resultar gravemente herido.

LEA Y CONSERVE ESTAS INSTRUCCIONES.

Instalador:

Deje las instrucciones con el electrodoméstico.

Cliente:

Conserve las instrucciones como referencia futura.

IMPORTANTE: Guarde estas instrucciones para el uso del

inspector eléctrico local.

INSTALADOR: Por favor, deje este manual a propietario para

futuras consultas.

PROPIETARIO: Por favor, conserve este manual para futuras

consultas.

ADVERTENCIA

• La inobservancia de las indicaciones recogidas en

este manual puede derivar en muerte o en daños a las

personas.

• No almacene ni utilice gasolina u otros vapores o líquidos

inflamables cerca de este ni otro electrodoméstico.

1

Page 32

ES

1 - Advertencias Especiales

INSTRUCCIONES IMPORTANTE

Por favor, lea todas las instrucciones antes de utilizar este aparato.

Efectuar una instalación adecuada es responsabilidad suya.

Asegúrese de que el electrodoméstico es instalado por un

técnico cualificado.

IMPORTANTE

- Cumpla todas las normativas y ordenanzas vigentes aplicables.

- Antes de instalar la cocina, comprobar el modelo y los

números de serie. Los dos números se encuentran en la placa

de datos en la posición indicada en la figura a continuación

POSICIÓN DE LA PLACA DE SEÑALIZACIÓN

Puede obtener copias de las normas citadas en:

** National Fire Protection Association One Batterymarch Park

Quincy, Massachusetts 02269

*** CSA International 8501 East Ple0asant Valley Rd. Cleveland,

OH 44131-5575

Instalación en Casas Móviles

La instalación de esta placa de cocina debe cumplir con

el título 24 CFR, Parte 3280 de las Normas de seguridad

y construcción de viviendas prefabricadas o móviles

estadounidenses (Manufactured Home Construction and Safety

Standards, [anteriormente denominada Federal Standard for

Mobile Home Construction and Safety (Norma federal para

seguridad y construcción de casas prefabricadas), Title 24

HUD, Part 280]; o, en caso de que dicha norma no sea

aplicable, deberá seguirse la pauta marcada por la Norma

para instalaciones en casas prefabricadas estadounidense

[(Standard for Manufactured Home Installations (Manufactured

Home Sites, Communities and Setups], ANSI A225.1 (última

edición) o bien, la normativa local existente referente a casas

móviles.

En Canadá, la instalación de esta placa de cocción debe

cumplir con las normativas actuales CAN/CSA-Z240 (última

edición) o con las normativas locales.

Antes de comenzar la instalación

• Examine el lugar en el que va a instalar la placa de cocción.

Debe ubicarla en un lugar alejado de fuertes corrientes de

aire, como ventanas, puertas y ventiladores.

• Es necesario que el electrodoméstico se conecte a una toma

de tierra. Consulte la sección “Conexión eléctrica. Requisitos”.

• Debe asegurarse de que la instalación es adecuada y

conforme con el Código eléctrico americano (National

Electrical Code), ANSI/NFPA 70 (última edición**) o con

el Código eléctrico canadiense (Canadian Electrical Code),

C 22.1 – 1982 y C22.2 Nº 01982 (o la última edición)***

y con todos los códigos y ordenanzas locales.

• Debe asegurarse de que la conexión de gas está conforme

con los códigos y ordenanzas locales.

2

Page 33

2 - Dimensiones del Producto y de Encastre

35

3/4

(9

1,0

)

DIMENSIONES DU PRODUCTO

Modelos de cocina de 30” de ancho

ES

29 3/4” (75,8)

35 3/4” (91,0)

9" (22,8) [opcional]

3" ( 7,6) [opcional]

1" ( 2,5)

3/8” (1)

29 3/4” (75,6)

27 1/2” (69,7)

25 3/4” ( 65,4)

27 1/4” ( 69,1)

7 3/8” (18,7)

1 3/8” (3,5)

A

3 3/8” (8,5)

Max. 37 1/4” (94,7)

Min. 35 3/8” (89,8)

47 3/4” (121,4)

3

Page 34

ES

2 - Dimensiones del Producto y de Encastre

DIMENSIONES DE ENCASTRE

C

Min. 18” (45,7)

Min. 6”

(15,2)

2” (5,1) máxima protuberancia

de la pared al suministro

elèctrico o de gas.

Min. 30” (76,2)

A la parte inferior

de la campana

de ventilaciòn

A

GAS

B B

4” 3/4 (12,3)

3” (7,6)

ELÉCTRICA

Max. 13” (33)

Min. 18” (45,7)

Min. 6”

(15,2)

*Posición sugerida

para los equipos

La supercie de toda la pared trasera sobre la cocina y por debajode la capucha debe cubrirse con un material no combustible.

*Consultar las normas locales para la exigencias exactas de colocación.

ANCHO DE APERTURA A & C B

Estufa de 30” 30" (76,2) 6” (15,2)

Estufa de 36” 36" (91.4) 7” (17.8)

ESPACIOS ADICIONALES:

Para la instalación de la isla, deje un espacio mínimo de

2-½” entre la abertura y el extremo trasero de la mesada y

un mínimo de 3” entre la abertura y los extremos laterales de

la mesada (ver la vista superior).

Nota: La distancia con relación a los materiales no

combustibles debe respetar las normas locales o, en

ausencia de las mismas, el « National Fuel Gas Code

», ANSI Z223.1/NFPA 54.

INSTALACIÓN AL RAS DEL CANTO DE LA ISLA

Distancia mínima a construcciones:

Por arriba de la supercie de cocinar (más de 36” [91.4 cm])

• Lados - 3” (7.6 cm).

• Dentro del espacio lateral de 3” (7.6 cm), los gabinetes

de la pared no más profundos de 13” (33.0 cm) deben

estar a un mínimo de 18” (45.7 cm) por arriba de la

supercie de cocinar.

• Los gabinetes de la pared que estén directamente por

encima del producto deben estar a un mínimo de 30”

(76.2 cm) por arriba de la supercie de cocinar.

• Parte posterior - 0” a la pared posterior de 3” (7.6 cm).

4

PARTE POSTERIOR

min 2 1/2” (6.3)

min 3” (7.6) min 3” (7.6)

Page 35

2 - Dimensiones del Producto y de Encastre

ES

Antes de mover la estufa, proteja cualquier suelo acabado y

asegúrese de que la puerta del horno esté cerrada para que

no se dañe.

Combinaciones de capuchas de ventilación:

Se recomienda que estas cocinas se instalen en conjunto con

una adecuada capucha de ventilación aérea.

Instale una capucha de por lo menos 450 CFM (pies cúbicos

por minuto).

Debido a la elevada capacidad de calor de esta unidad, debe

prestarse especial atención a la instalación de la capucha y

de la red de conductos para garantizar que cumpla con los

códigos de construcción locales.

ADVERTENCIA

Distancias respecto de superficies horizontales sobre la

cocina, medidas en relación a la superficie de cocción.

No cumplir con esto puedo provocar un peligro de incendio.

• Las instalaciones sin capucha requieren un mínimo de 30”

(76) respecto de elementos combustibles.

• Una instalación de capucha a medida con superficies

expuestas horizontales combustibles debe contar con una

función de encendido automático.

ADVERTENCIA

Para comprobar que el taco anti-vuelco está instalado y acoplado:

• Deslice la cocina hacia delante.

• Compruebe si el taco anti-vuelco está fijado firmemente al suelo

o a la pared.

• Deslice la cocina hacia atrás de tal manera que la pata trasera

se encuentre debajo del taco anti-vuelco.

• Para más detalles, consulte las instrucciones de instalación.

Taco anti-vuelco

Pata de la cocina

• Para otras instalaciones con una capucha, consulte las

instrucciones de instalación de capuchas sobre espacios

específicos para capuchas.

PRECAUCIÓN

Estas cocinas pesan hasta 400 libras. Desmontar algunos

elementos reducen su peso en forma considerable. Debido

al peso y tamaño de la cocina y para reducir el riesgo de

lesiones personales o daños al producto:

SE REQUIEREN DOS PERSONAS PARA UNA

INSTALACIÓN.

Instructions d’installation des supports anti-bascules

ADVERTENCIA

Peligro de vuelco

El vuelco de la cocina es un riesgo para todos, niños y adultos, que

puede llegar a provocar la muerte. Cuando se desplace la cocina,

comprobar que el taco anti-vuelco está acoplado. No dejar que la

cocina funciona sin el taco anti-vuelco instalado y acoplado. El no

respeto de estas instrucciones puede provocar quemaduras graves o

incluso la muerte para todos, niños y adultos.

INSTALACIÓN DE LA BRIDA ANTI- VUELCO

PARED DE

FIJACIÓN

PARED LATERAL

DEL GABINETE

A RAS

PARED

TRASERA

SOPORTE

ANTIVUELCO

Para construcciones de concreto o cemento: Deben

utilizarse elementos de sujeción apropiados (no provistos).

Sujete el soporte a la pared y/o piso mediante por lo

menos 4 tornillos para madera (provistos).

El soporte anti- Volcaduras se debe insertar en la abertura

correspondiente a la abrazadera anti-volcaduras de la

cocina.

5

Page 36

ES

3 - Información de instalación

ADVERTENCIA

• Peligro por peso excesivo

Dos personas o más tienen que desplazar e instalar la

cocina.

De lo contrario podrían sufrir daños en la espalda u otros.

• Peligro de corte

Cuidado con las aristas cortantes. Al desplazar el

producto, agarrarlo por los protectores de poliestireno.

De lo contrario podrían sufrir heridas leves o cortes.

ELECCIÓN DE LA POSICIÓN DE LA COCINA

Elija con atención la posición de la cocina.

La cocina se debe colocar en una posición que permita una

utilización práctica, pero alejada de corrientes de aire fuertes.

Una puerta o una ventana abiertas, el aire en movimiento por

ventiladores de calefacción/refrigeración pueden originar

fuertes corrientes de aire.

No taponar los flujos de aire en combustión a nivel de la

apertura de ventilación del horno ni debajo de panel frontal

inferior de la cocina. Evitar tocar las aperturas de ventilación

o las superficies cercanas ya que estas superficies podrían

calentarse mientras que el horno está funcionando.

Es indispensable que haya un aire fresco para una buena

combustión en el quemador.

NOTA IMPORTANTE

HERRAMIENTAS NECESARIAS

Retire el embalaje y separe los manuales de instrucciones

antes de comenzar la instalación.

Lea atentamente los manuales de instalación antes de

comenzar.

Si instala la cocina contra una superficie combustible,

prevea un mínimo de realce Respete todas las distancias

con relación a las superficies combustibles indicadas en las

páginas anteriores.

Antes de desplazar la cocina, proteja el suelo y mantenga la

puerta del horno cerrada para prevenir cualquier daño.

Evitar absolutamente levantar o agarrar la cocina sujetándola

por el asa de la puerta Para eliminar el riesgo de quemaduras

o de incendio a causa de un calentamiento de la superficie de

la unidades, evitar colocar un armario encima de la unidad.

Si tiene un armario encima de la cocina, puede reducir el

riesgo instalando a una cierta distancia por debajo de la parte

inferior del armario una pantalla de protección que recubra

toda la superficie horizontal

MATERIALES PROVISTOS

SOPORTE

ANTIVOLCADURAS,

A BRAZADERA

Y TORNILLOS

6

Page 37

4 - Instrucciones para la Instalación

ES

PASO 1

Cortar las bandas y sacar el aparato del palet con un transpalet

de mano introduciendo la horquilla por debajo del bloque de

gomaespuma.

ATENCIÓN

Mantenerse alejado. Los extremos de las bandas cortadas

podrían golpearle al darse la vuelta.

PASO 3

Llevar la cocina al interior. Antes instalar las patas, ponen el

aparato cerca de su lugar de instalación final ya que las patas

no son adecuadas para desplazar el aparato sobre distancias

largas.

Las patas están embaladas por separado debajo de la caja.

ATENCIÓN

Las puertas y los pasos que conducen al lugar de instalación

deben tener una abertura de 31” por lo menos. Si la

abertura es menor de 31”, es necesario quitar la puerta del

horno y los botones de mando (ver el manual de utilización

y de mantenimiento para las instrucciones de desmontaje de

la puerta del horno).

ADVERTENCIA : En la parte trasera, montar las patas a collar

de manera que se enganchen en el dispositivo

anti-vuelco.

PASO 2

Tomar las instrucciones de instalación presentes en la cocina y

leerlas atentamente antes de empezar.

PASO 4

Sin haber retirado todavía la base de espuma, hacer bascular

la cocina hacia un lado y atornillar el primer par de patas.

7

Page 38

ES

4 - Instrucciones para la Instalación

PASO 5

Retirar el transpalet, inclinar la cocina de lado para atornillar

el segundo par de patas. Retirar la base.

PASO 7

Tras realizar las conexiones de electricidad y de gas (ver los

párrafos de instrucciones correspondientes), medir la altura

en las cuatro esquinas para comprobar que el aparato está

bien nivelado, Regular las patas de nivelación y enganchar el

dispositivo anti-vuelco.

PASO 6

Instalar la parte dorsal (si se entrega) por medio de tres tornillos

en la parte trasera y el pinto.

3”9”

PASO 8

Empujar el zócalo hasta que quede correctamente encajado.

NOTA: Comprobar que el zócalo está acoplado de forma segura

8

Page 39

5 - Alimentación eléctrica

ES

Antes de instalar el horno, hacer que un electricista competente

verifique que su instalación eléctrica doméstica es correcta y

que al añadir el horno, no se pueda producir una sobrecarga

en el circuito de derivación en el que está instalado.

Su aparato debe estar instalado adecuadamente y ser

conectado a tierra por un electricista cualificado.

Pida a su vendedor que le aconseje un técnico cualificado o

un centro de reparación autorizado.

Este aparato está fabricado con un cable de TIERRA verde

conectado con la caja de conexiones y la caja empotrada de

la estructura del horno.