Page 1

C150-E192-01EN

fi-4990C Image Scanner

Operator's Guide

Page 2

fi-4990C

Image Scanner

Operator's Guide

Page 3

Edition

This equipment has been tested and found to comply with the limits for a Class A

digital device, pursuant to Part 15 of the FCC Rules. These limits are designed to

provide reasonable protection against harmful interference when the equipment is

operated in a commercial environment. This equipment generates, uses, and can

radiate radio frequency energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful

interference in which case the user will be required to correct the interference at his

own expense.

This digital apparatus does not exceed the Class A limit for radio noise emissions

from digital apparatus set out in the Radio interference Regulations of the Canadian

Department of Communications.

Le pésent appareil numérique n’ément pas de bruits radioélectriques dépassant les

limites applicables aux appareils numériques de la classe A prescridtes dans le

Réglesment sur le brouillage radioélectrique dicté par le ministere des Communications du Canada.

Date published

01 February, 2001 First edition

Specification No. C150-E192-01EN

Revised contents

MaschinenlärmInformationsverordnung 3. GSGV, 18-01. 1991: Der arbeisplatzbezogene Schalldruckpegel beträgt 70 dB (A) oder weniger gemäß ISO7779.

The contents of this manual may be revised without prior notice.

All Rights Reserved, Copyright © 2001 FUJITSU LIMITED.

Printed in Japan.

No part of this manual may be reproduced in any form without permission.

Page 4

Please send your comments on this manual or on Fujitsu products

to the following addresses:

North American contact:

FUJITSU COMPUTER PRODUCTS OF

AMERICA, INC.

2904 Orchard Parkway, San Jose.

California 95134-2009, U.S.A.

Phone: (1-408) 432-6333 Fax: (1-408) 894-1709

HOME PAGE: http://www.fcpa.com/

FUJITSU CANADA, INC.

2800 Matheson Boulevard East, Mississauga,

Ontario L4W 4X5, Canada

Phone: (1-905) 602-5454 Fax: (1-905) 602-5457

HOME PAGE: http://www.fujitsu.ca/

European contact:

FUJITSU EUROPE LTD.

2, Longwalk Road, Stockley Park, Uxbridge,

Middlesex UBII IAB, England

Phone: (44-20) 8573-4444 Fax: (44-20) 8573-2643

HOME PAGE: http://www.fujitsu-europe.com/

FUJITSU DEUTSCHLAND GmbH.

Frankfurter Ring 211, 80807 München, Germany

Phone: (49-89) 32-378-0 Fax: (49-89) 32-378-100

FUJITSU ITALIA S.p.A.

Via Nazario Sauro, 38, 20099 Sesto S,

Giovanni (MI), Italy

Phone: (39-02) 26294-1 Fax: (39-02) 26294-201

FUJITSU NORDIC AB

Kung Hans Väg 12, S-192 68 Sollentuna, Sweden

Phone: (46-8) 626-4500 Fax: (46-8) 626-4588

FUJITSU ICL ESPAÑA, S.A

Almagro, 40 28010 Madrid, Spain

Phone: (34-91) 581-8000 Fax: (34-91) 581-8300

FUJITSU FRANCE S.A.

1, Place des Etats-Unis, SILIC 310,

94588 Rungis cedex, France

Phone:

(33-1) 41-80-38-80 Fax: (33-1) 41-80-38-66

Australian contact:

FUJITSU AUSTRALIA LTD.

Fujitsu House 2 Julius Avenue

North Ryde N.S.W. 2113, Australia

Phone: (61-2) 9776-4555 Fax: (61-2) 9776-4556

HOME PAGE: http://www.fujitsu.com.au/

Asian contact:

FUJITSU HONG KONG LTD.

10/F, Lincoln House, 979 King’s Road,

Taikoo Place, Island East, Hong Kong

Phone: (852) 2827-5780 Fax: (852) 2827-4724

HOME PAGE: http://www.fujitsu.com.hk/

FUJITSU KOREA LTD.

6th Fl., Korea Financial center building,

Yoido-Dong 23-6, Young DungPo-gu, Seoul,

Republic of Korea

Phone: (82-2) 3787-6000 FaX: (82-2) 3787-6074

HOME PAGE: http://www.fujitsu.co.kr/

FUJITSU COMPUTER (SINGAPORE) PTE. LTD.

20 Science Park Road, #03-01, Tele Tech Park

Singapore Science Park II,

Singapore 117674, Republic of Singapore

Phone: (65) 777-6577 Fax: (65) 771-5669

HOME PAGE: http://www.fsl.com.sg/

FUJITSU TAIWAN LTD.

8F, Hung Tai Center, 168-170

Tun Hwa North Road, 1st Sec. Taipei, Taiwan, R.O.C.

Phone: (886-2) 2545-7700 Fax: (886-2) 2717-4644

FUJITSU (MALAYSIA) SDN, BHD.

7th Fl., Wisma Damansara, Jalan Semantan,

50490. Kuala Lumpur, Malaysia

Phone: (60-3) 254-3644 Fax: (60-3) 253-3940

FUJITSU SYSTEMS BUSINESS (THAILAND) LTD.

12th Fl., Olympia Thai Tower,

444 Rachadapisek Road, Samsennok,

Huay Kwang, Bangkok 10320, Thailand

Phone: (66-2) 512-6066 Fax: (66-2) 512-6068

FUJITSU LIMITED (JAPAN)

Computer Products Business Group

4-1-1, Kamikodanaka, Nakahara-ku, Kawasaki-shi,

Kanagawa-ken 211-8588, Japan

Phone: (81-44) 754-8347 Fax: (81-44) 754-8348

HOME PAGE: http://www.fujitsu.co.jp/hypertext/

scanner/eng/

Page 5

IMPORTANT NOTE TO USERS

READ CAREFULLY ALL OF THIS MANUAL BEFORE USING THIS PRODUCT.

IF NOT USED CORRECTLY, UNEXPECTED DAMAGES MAY BE CAUSED TO

THE USERS OR THE BYSTANDERS.

While all efforts have been made to ensure the accuracy of all information in this

manual, FUJITSU assumes no liability to any party for any damage caused by

errors or omissions or by statements of any kind in this manual, its updates or

supplements, whether such errors are omissions or statements resulting from

negligence, accidents, or any other cause. FUJITSU further assumes no liability

arising from the application or use of any product or system described herein; nor

any liability for incidental or consequential damages arising from the use of this

manual. FUJITSU disclaims all warranties regarding the information contained

herein, whether expressed, implied, or statutory.

FUJITSU reserves the right to make changes to any products herein, to improve

reliability, function, or design, without further notice and without obligation.

This Product is designed, developed and manufactured as contemplated for

general use, including without limitation, general office use, personal use and

household use, but is not designed, developed and manufactured as contemplated

for use accompanying fatal risks or dangers that, unless extremely high safety is

secured, could lead directly to death, personal injury, severe physical damage or

other loss (hereinafter “High Safety Required Use”), including without limitation,

nuclear power core control, airplane control, air traffic control, mass transport

operation control, life support, weapon launching control.

You shall not use this Product without securing the sufficient safety required for the

High Safety Required Use.

If you wish to use this Product for High Safety Required Use, please consult with

our sale person in charge before such use.

i

Page 6

Preface

This manual explains how to use the fi-4990C image scanner. This scanner

can be equipped with an optional endorser; however, Illustrations in this

manual do not include the endorser except those in Chapter 5. For details

of the endorser, refer to its Operator Guide.

This manual contains COMPONENTS, INSTALLATION AND CONNECTIONS, OPERATING INSTRUCTION, DOCUMENT SPECIFICATION,

SPECIFICATIONS, and SETUP, BROWSE, AND TEST MODES.

Refer to the CD-ROM for the information about the routine operation of the

fi-4990C.

The CD-ROM contains OPERATING INSTRUCTION, CLEANING, REPLACEMENT OF PARTS, ADJUSTMENT and TROUBLESHOOTING.

The fi-4990C is very fast and highly functional image scanner developed for

volume filing, using charge-coupled device (CCD) image sensors. This

scanner features duplex scanning and high quality image processing with an

automatic document feeder (ADF).

ii

Page 7

Conventions

Special information, such as warnings, cautions, and notes are indicated as

follows:

WARNING

WARNING indicates that serious personal injury may result if you do not follow

a procedure correctly.

CAUTION

CAUTION indicates that minor personal injury, loss of data, or damage to the

scanner may result if you do not follow a procedure correctly.

NOTE

NOTE indicates remarks, tips, and other useful supplementary information.

The following symbols are used in this manual.

Used for general WARNING and CAUTION.

Used for NOTE.

iii

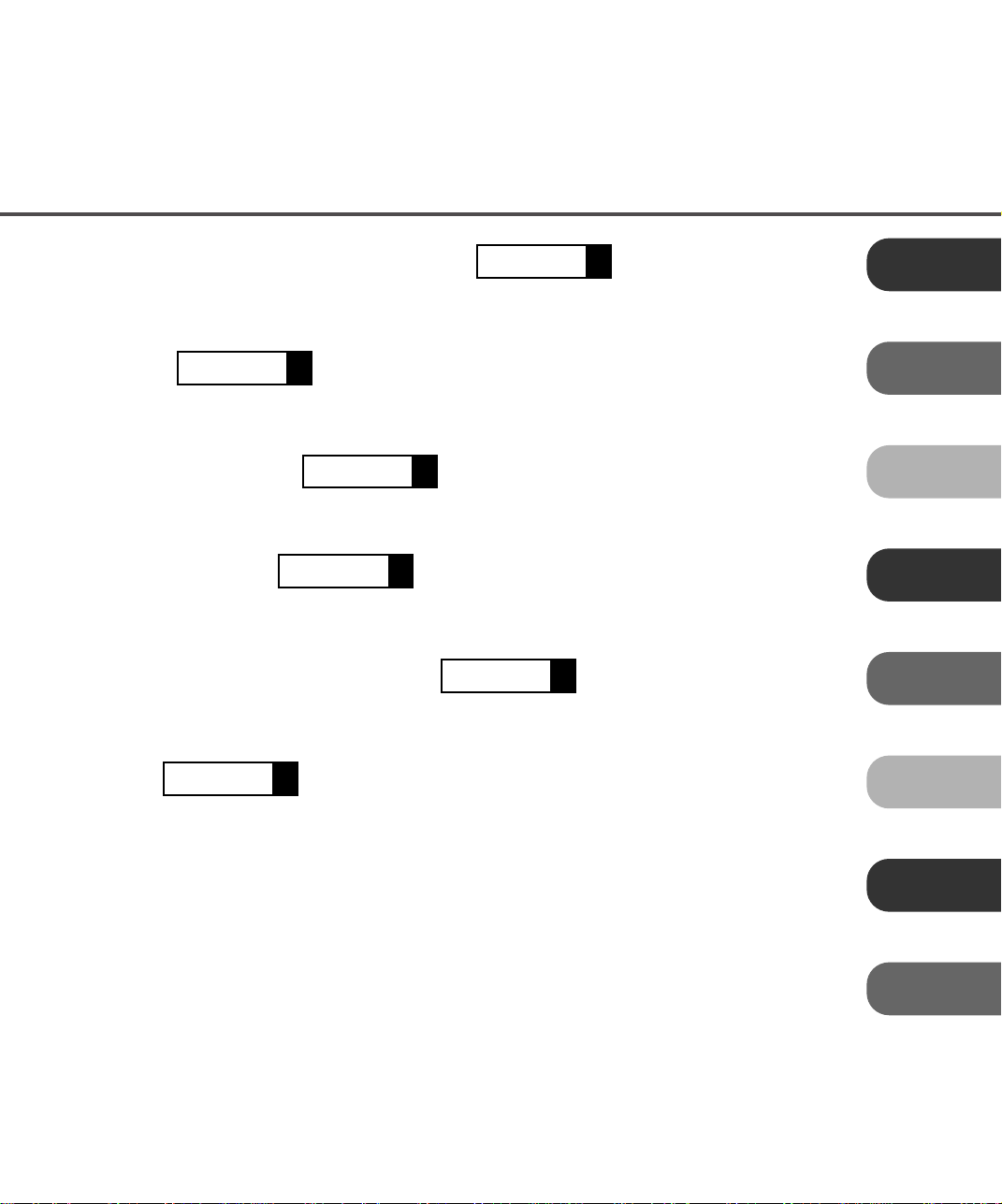

Page 8

CONTENTS

q CHAPTER 1 COMPONENTS

q CHAPTER 2 INSTALLATION AND CONNECTIONS

q CHAPTER 3 OPERATING INSTRUCTION

q CHAPTER 4 DOCUMENT SPECIFICATION

Checking the Components .........................................................1- 1

Units and Assemblies ................................................................ 1- 2

Operator Panel ..........................................................................1-5

Buzzer .......................................................................................1-8

Precautions ................................................................................ 2-1

Inspection .................................................................................. 2-2

Cable Connection ....................................................................... 2-4

Turning the Power On ...............................................................3-1

Basic Operation of the Operator Panel......................................3-2

Document Size........................................................................... 4-1

Document Quality ......................................................................4-2

Document Limitations ................................................................4-5

Grounding Color Area................................................................4-7

Drop-out Color ...........................................................................4-8

Job Separation Sheet ................................................................4-9

q CHAPTER 5 SPECIFICATIONS

Installation Specifications ..........................................................5-1

External Dimensions..................................................................5-2

Consumables.............................................................................5-3

Options ......................................................................................5-4

q CHAPTER 6 SETUP, BROWSE, AND TEST MODES

Setup, Browse, and Test Modes ...............................................6-1

Activating the Setup or Browse Mode .......................................6-2

Contents of the Setup or Browse Mode.....................................6-4

Activating the Test Mode .........................................................6-49

Contents of the Test Mode ......................................................6-51

q GLOSSARY OF TERMS ................................................................................ GL-1

q INDEX ............................................................................................................. IN-1

v

Page 9

CHAPTER

CHAPTER

INSTALLATION AND CONNECTIONS

2

CHAPTER

CHAPTER

4

OPERATING INSTRUCTION

3

DOCUMENT SPECIFICATION

1

COMPONENTS

COMPONENTS

INSTALLATION AND

CONNECTIONS

OPERATING

INSTRUCTION

DOCUMENT

SPECIFICATION

CHAPTER

CHAPTER

SETUP, BROWSE, AND TEST MODES

6

SPECIFICATIONS

5

GLOSSARY OF TERMS

SPECIFICATIONS

SETUP, BROWSE,

AND TEST MODES

GLOSSARY

OF TERMS

INDEX

INDEX

vii

Page 10

CHAPTER

1

COMPONENTS

After unpacking the scanner, confirm that all the components have been

received. This chapter describes the components of the scanner, part

names, and operator panel arrangement and their function.

Checking the Components

Units and Assemblies

Operator Panel

Buzzer

Page 11

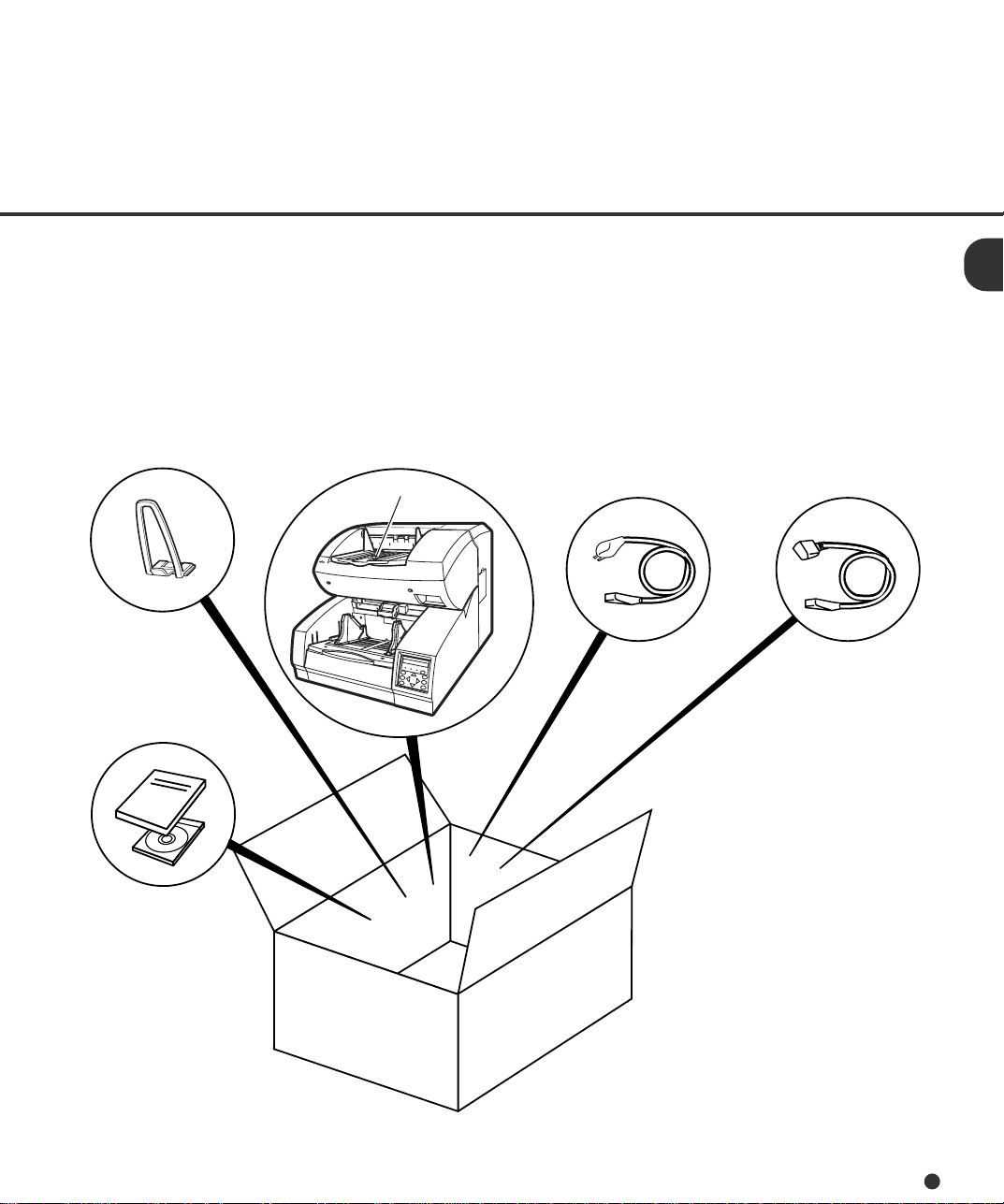

Checking the Components

These are high precision components and must be handled with care.

Confirm that all the components shown in the following figure have been received. Mount the stop

lever on the stacker of the scanner.

If any component is missing, please contact your sales agent.

* Stop lever

Operator’s Guide

(this manual) and

two CD-ROMs

Scanner

*

Power cable

for North America

Power cable

for Europe

or

1-1

Page 12

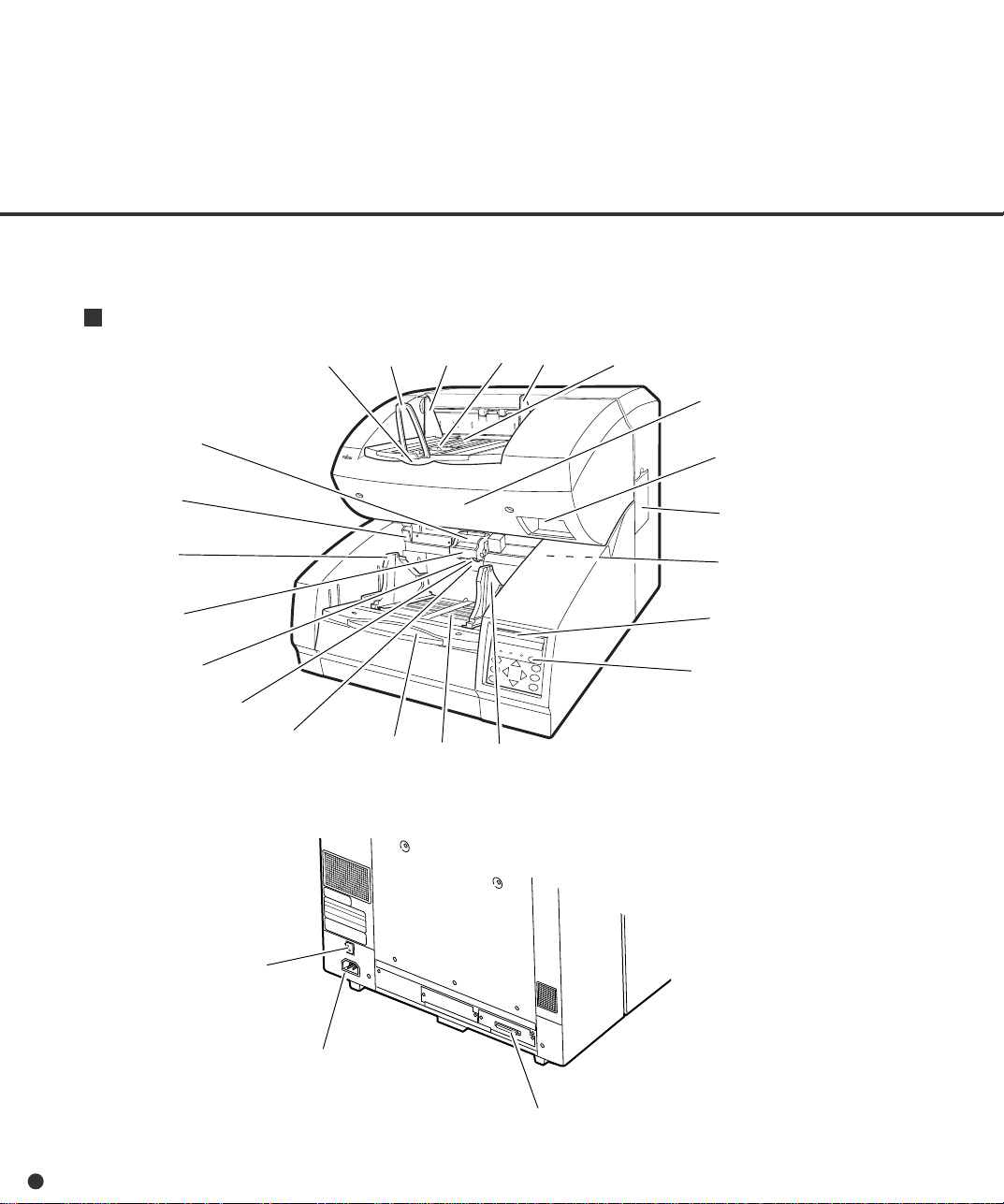

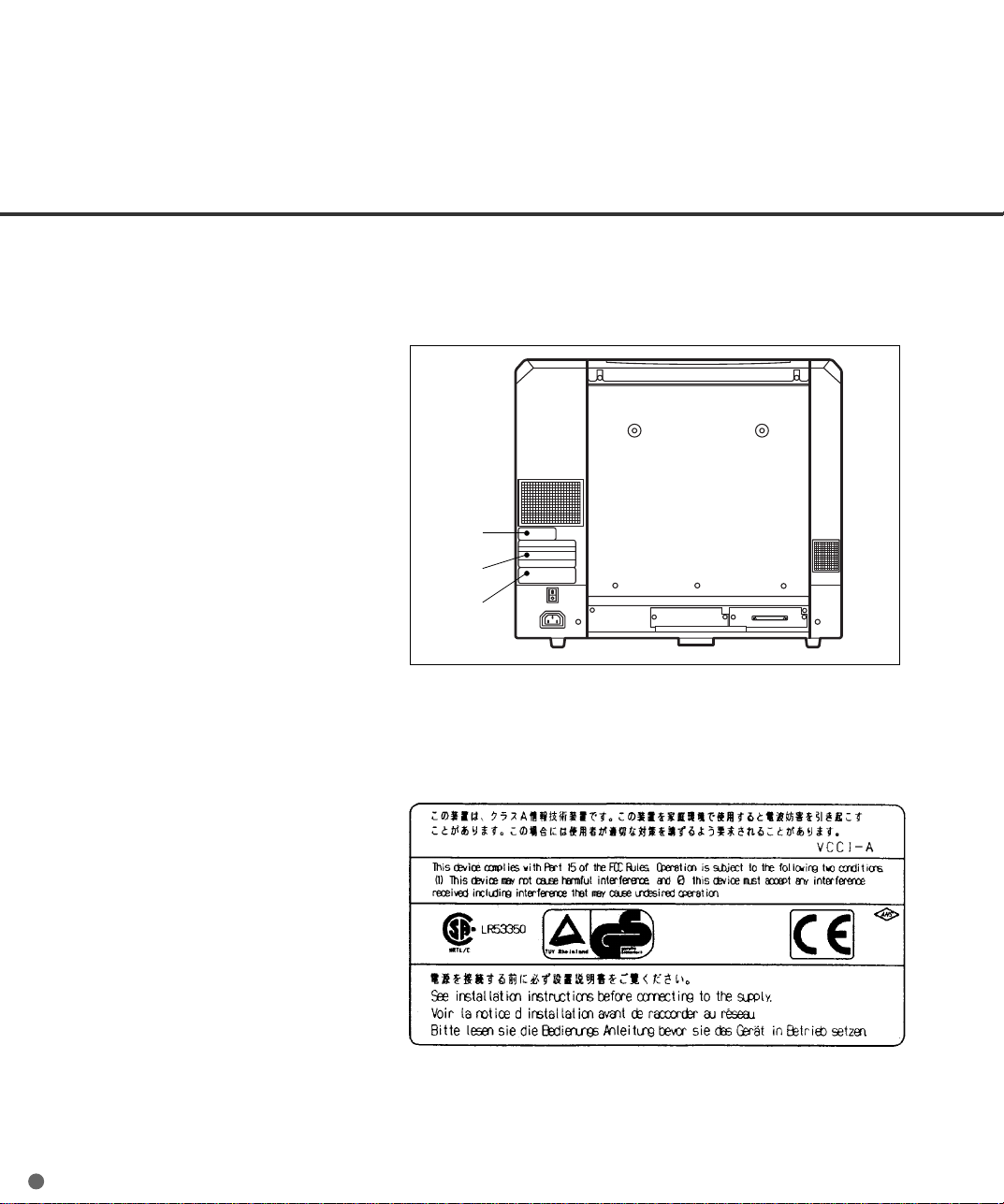

Units and Assemblies

This section shows the exterior view and assemblies of the scanner. This section also provides names

of each part and describes their functions.

Units

16

19

1718

17

15

12

6

7

4

8

9

10

11

20

5

4

3

13

14

7

1

2

1-2

21

22

Page 13

No. Name Function

1 Operator panel Used to operate the scanner.

2 Power switch Used to power on or off.

3 Hopper Document input tray.

4 Hopper guides Used to adjust the document width.

5 Hopper extension For use with long documents.

6 Automatic document feeder (ADF) Feeds documents automatically.

7 ADF release lever Used to open the ADF.

8 Pick roller unit Picks top page in document stack.

9 Guide plate The pad unit is mounted on.

10 Pad Separates top page from document stack.

11 Brake roller Separates top page from document stack.

12 Upper transport unit Opens for easy access.

13 Lever Used to open the upper transport unit.

14 Side cover Opens to access back-side lamp.

15 Stacker Document exit tray.

16 Check stopper Adjustable stopper for shorter length documents.

17 Stacker guides Helps guide documents into stacker.

18 Stop lever Used to keep documents in the stacker.

19 Stacker extension For use with long documents.

20 Main line switch Controls supply of line power to the scanner.

21 Power inlet Power cable connection.

22 Interface connectors Ultra Wide SCSI (1pcs.)

1-3

Page 14

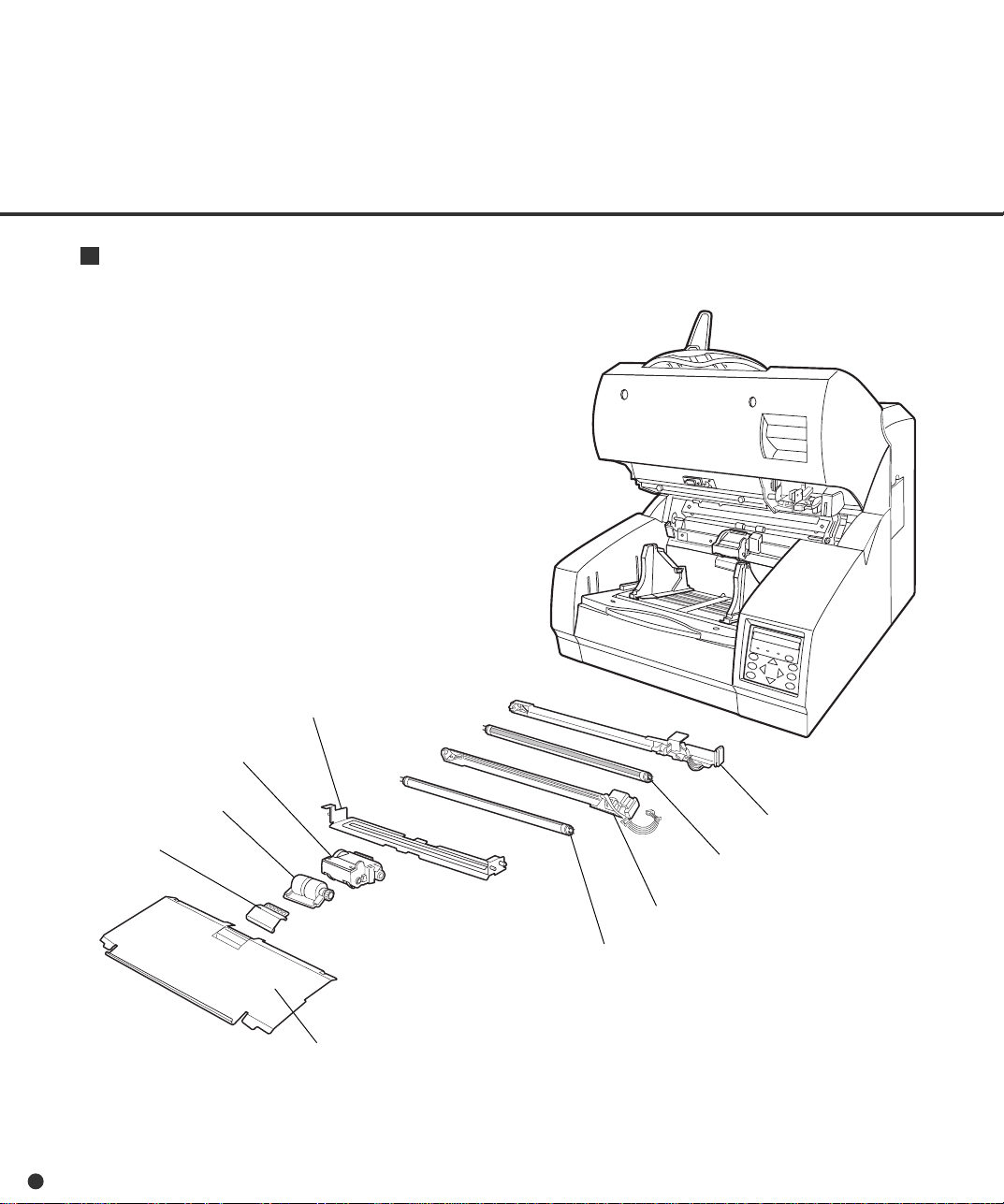

Assemblies

Lower sheet guide assembly

Pick roller unit

1-4

Brake roller

Pad

Lamp unit (back side)

Lamp

Lamp unit (front side)

Lamp

Guide plate

Page 15

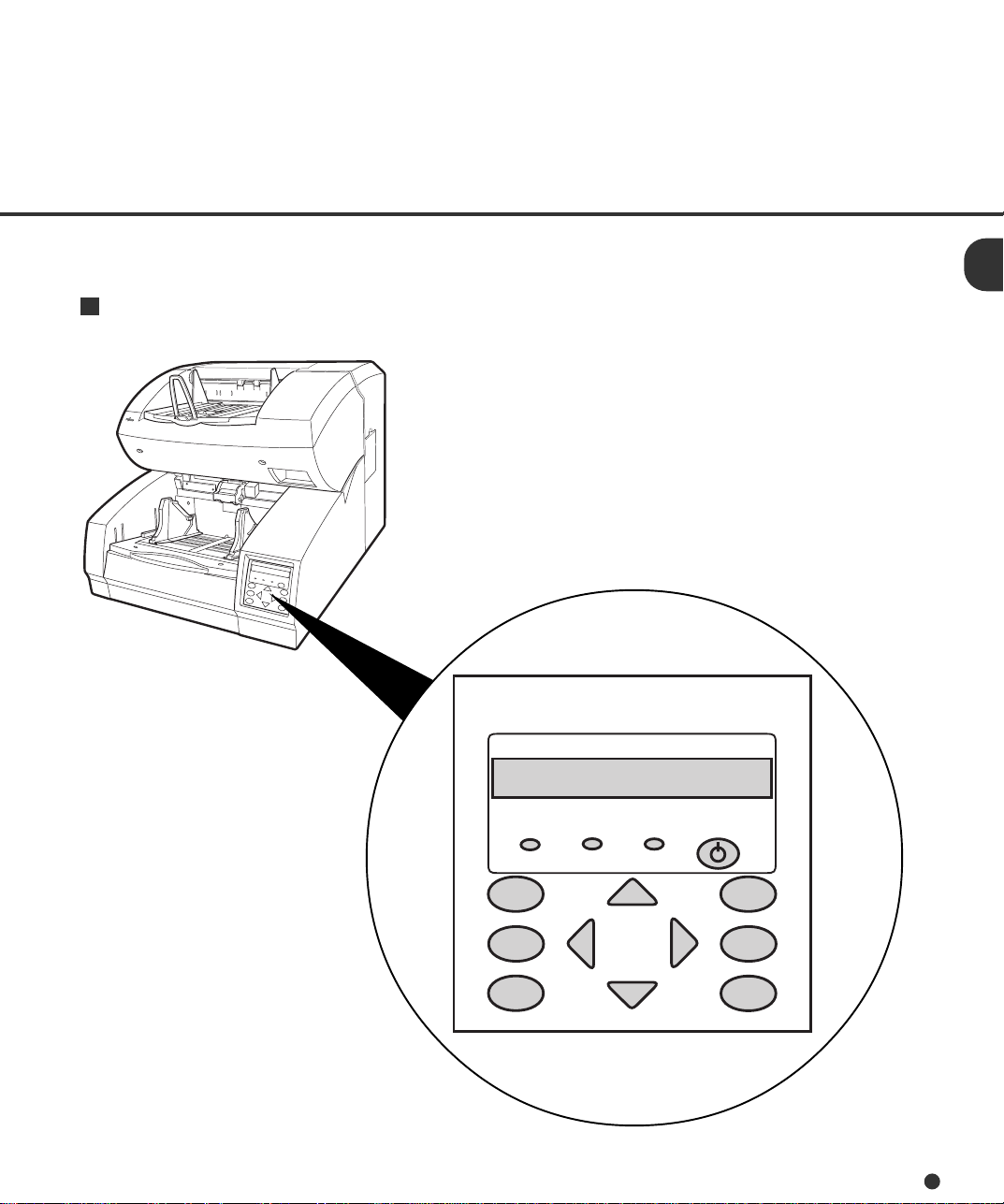

Operator Panel

The operator panel is located at the lower right hand side of the scanner. The panel consists of an

LCD (24 character x 2 line), LEDs, and buttons.

Arrangement

Operator panel

CHECK

LCD

POWER

24 characters x 2 lines

DATA

F1

F2

F3

MENU

ENTER

CANCEL

1-5

Page 16

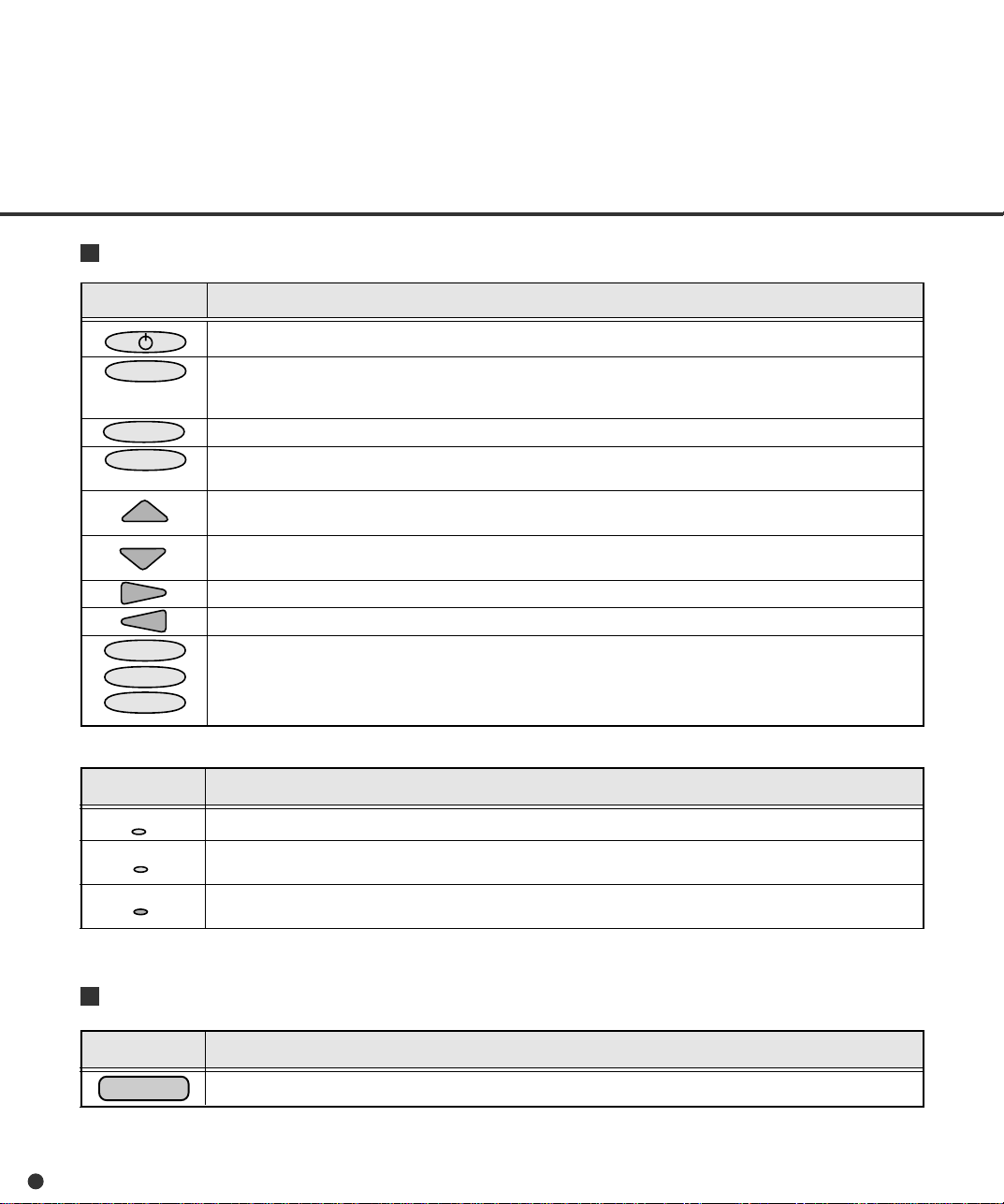

Button/LED Function

Button name Function

Turns on or off the power when the main line switch is set to “I”.

MENU

ENTER

CANCEL

F1

F2

F3

LED Function

Sets the scanner in setup or browse mode. It is also used to set test mode. (See Chapter 6)

Setup mode is used for customizing the scanner. Browse mode is used for glancing conditions of the scanner.

Test mode is used for testing the scanner offline.

Used in setup, browse, or test mode.

• Clears an error if any.

• Used in setup, browse, or test mode.

• Lifts the hopper in normal mode without errors.

• Used in setup, browse, or test mode.

• Lowers the hopper in normal mode without errors.

• Used in setup, browse, or test mode.

Used in setup, browse, or test mode.

Used in setup, browse, or test mode.

Available as shortcut keys when functions are defined in setup mode.

POWER

DATA

CHECK

LCD Display

LCD Function

1-6

Lights when the power is on.

Lights when the image buffer contains data.

Blinks when an equipment error occurs.

Displays equipment status or error contents.

Page 17

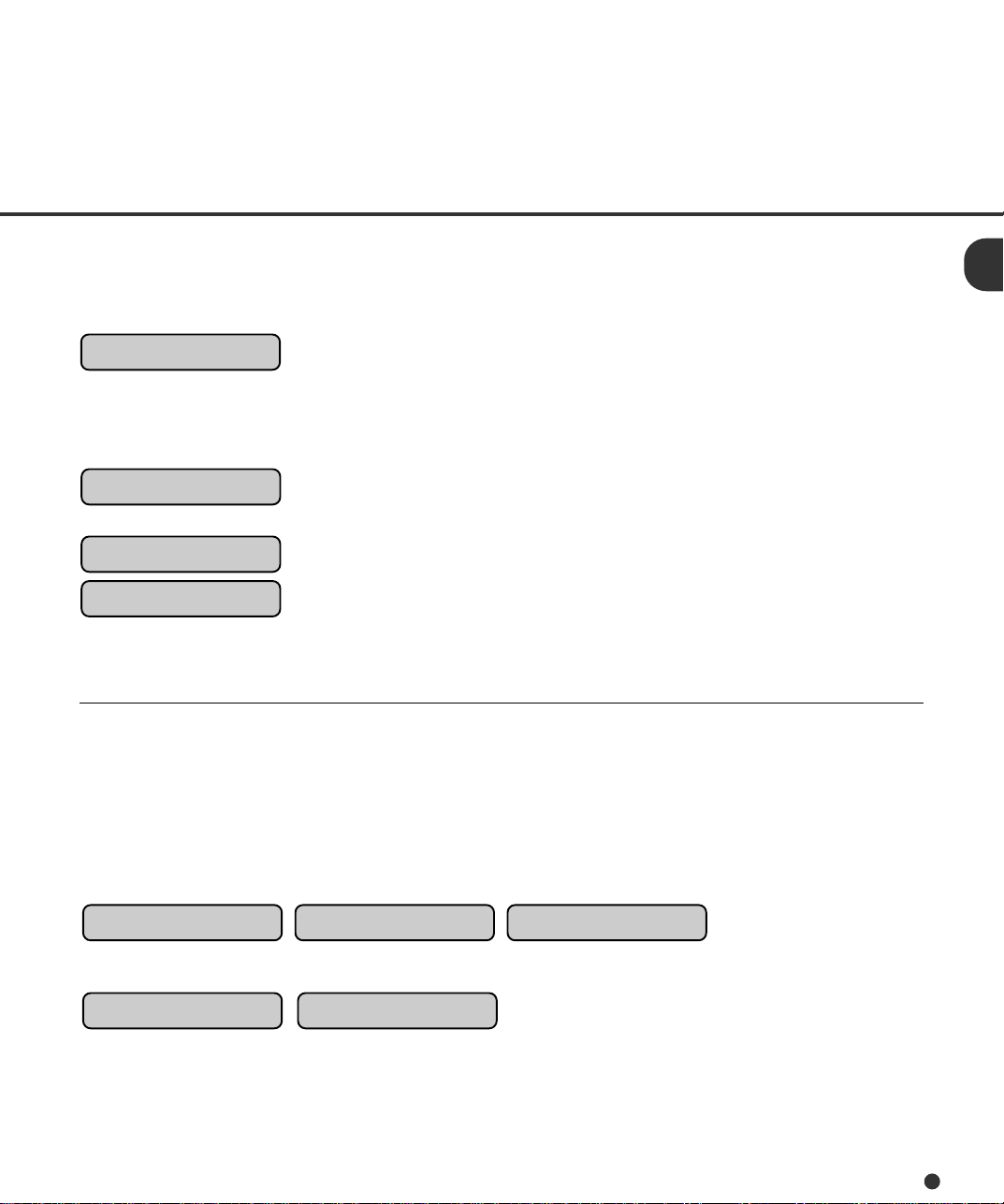

Operation status display

After power is turned on, the LCD indicates the following messages in normal mode.

Please wait Wait for a moment. This is indicated when processing takes a long

time.

When this is displayed after turning power on, the second line

indicates initializing messages.

Ready The scanner can receive a command from the host computer or

can be set in setup, browse, or test mode.

Manual Feeding Load documents on the hopper table manually.

Feeding The scanner is feeding documents. The second line indicates the

number of documents fed per batch.

Error status display

When the scanner detects errors, the LCD indicates the following messages. There are two types of

errors: temporary errors and equipment errors.

Temporary errors (Ex.): The message is cleared just by following the next message.

Hopper empty Mis-pick Cover open

Equipment errors (Ex.): To clear the message, you must clean or replace the specified part.

Optical error: Front Optical error: Back

1-7

Page 18

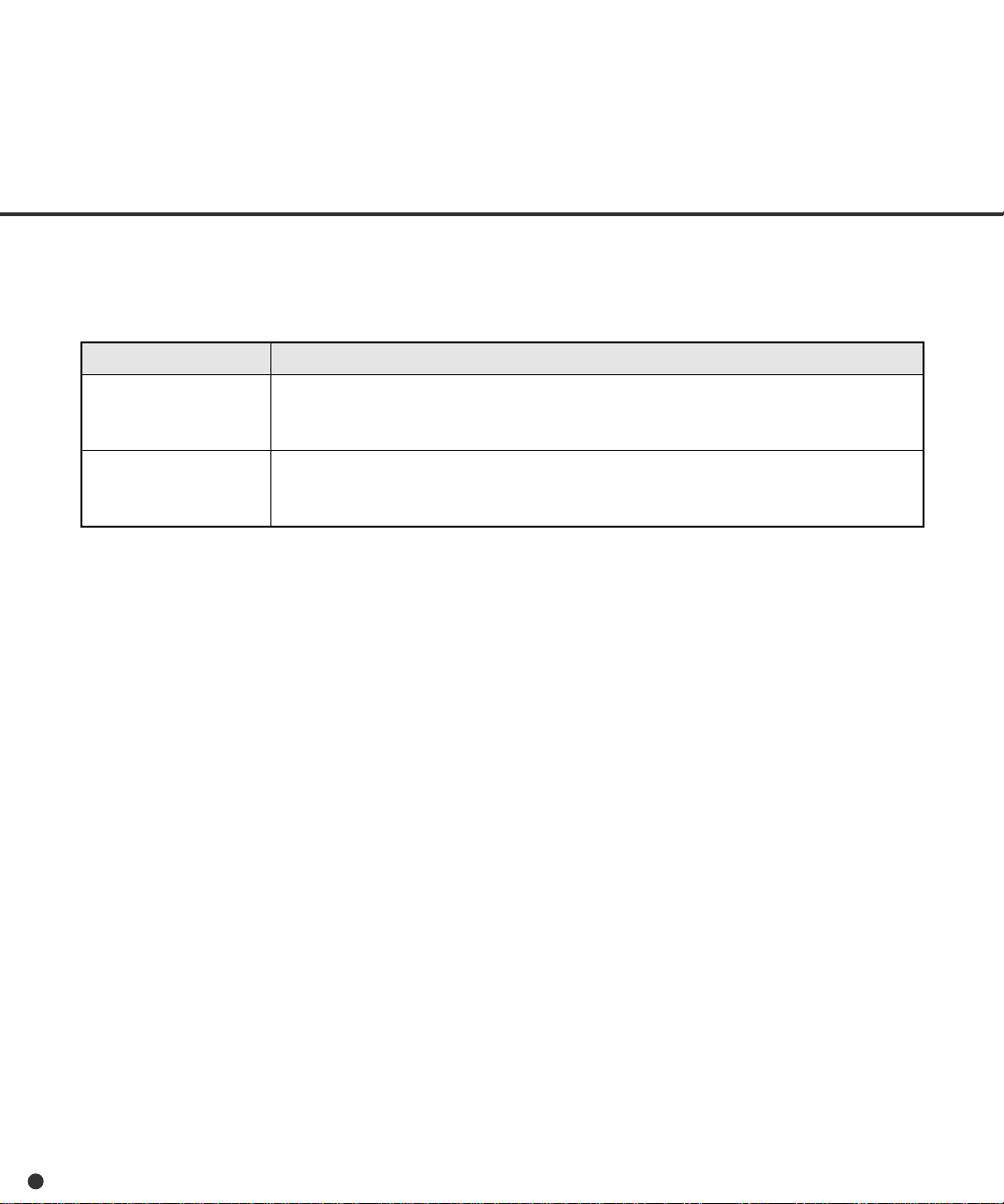

Buzzer

The scanner has a buzzer to indicate that an error has occurred or an operator panel button is

pressed. The buzzer function can be set on or off by following the procedure “Buzzer” in Chapter 6

SETUP, BROWSE, AND TEST MODES.

Sound condition Function

Error occurred Sounds continuously. The buzzer turns off when any button is pressed or the

power is turned off. Even when a button is pressed, the scanner continues

to display the error.

Button pressed Sounds briefly. This sound cannot be disabled by the buzzer setup.

1-8

Page 19

CHAPTER

2

INSTALLATION AND CONNECTIONS

The chapter describes how to install and connect the scanner.

Precautions

Inspection

Cable Connection

Page 20

WARNING

Place the machine with no portion of the scanner hangs over the desktop.

Never attempt to move or relocate the machine without help. And hold the

horizontal plane of the scanner bottom. (Not inclined plane)

ACHTUNG

Precautions

This section describes precautions when installing the scanner.

Do not install the scanner in the following places and environments.

• Place the scanner away from electrical noise sources, strong magnetic fields and air flow. If the scanner

is used near an air conditioner, copying machine, or TV set, the scanner may operate incorrectly.

• Keep the scanner out of the sun and away from heaters. These environments may shorten the scanner

life or cause hardware failures.

• Do not install the scanner in a place where vibrations may occur. This environment may cause hardware

failures or may cause the scanner to operate incorrectly.

• Do not install the scanner in a humid, dusty, or damp places. These environments may shorten the

scanner life or cause hardware failures. Do not place the scanner where liquid spills may occur.

Stellen Sie den Scanner sicher auf eine waagerechte, ebene Flache.

Bewegen Sie den Scanner nicht ohne Hilfe.

• Be aware of the static electricity. Be sure that the flooring and the desk are made of materials that do

not generate the static electricity.

See Chapter 5 SPECIFICATIONS for the information such as the size of the installation space.

2-1

Page 21

Inspection

This section describes how to check the labels.

Three labels

Label C

Label A

Label B

2-2

Label A (An example)

Page 22

Label B (An example)

MODEL fi-4990C IMAGE SCANNER

PART NO. CA04315-B107 AC100-240V

SER. NO. 1 phase 50/60Hz

DATE 2001-02 2.9/1.5A 65 kgf

FUJITSU LIMITED

Label C (An example)

MODEL NAME fi-4990C

PART NO. CA04315-B107

MODEL - 0 1 2 3 4 5 6 7 8 9

REV. - 0 1 2 3 4 5 6 7 8 9

- 0 1 2 3 4 5 6 7 8 9

MADE IN JAPAN

2-3

Page 23

Cable Connection

This section describes how to connect the cables.

Connect the cables as follows:

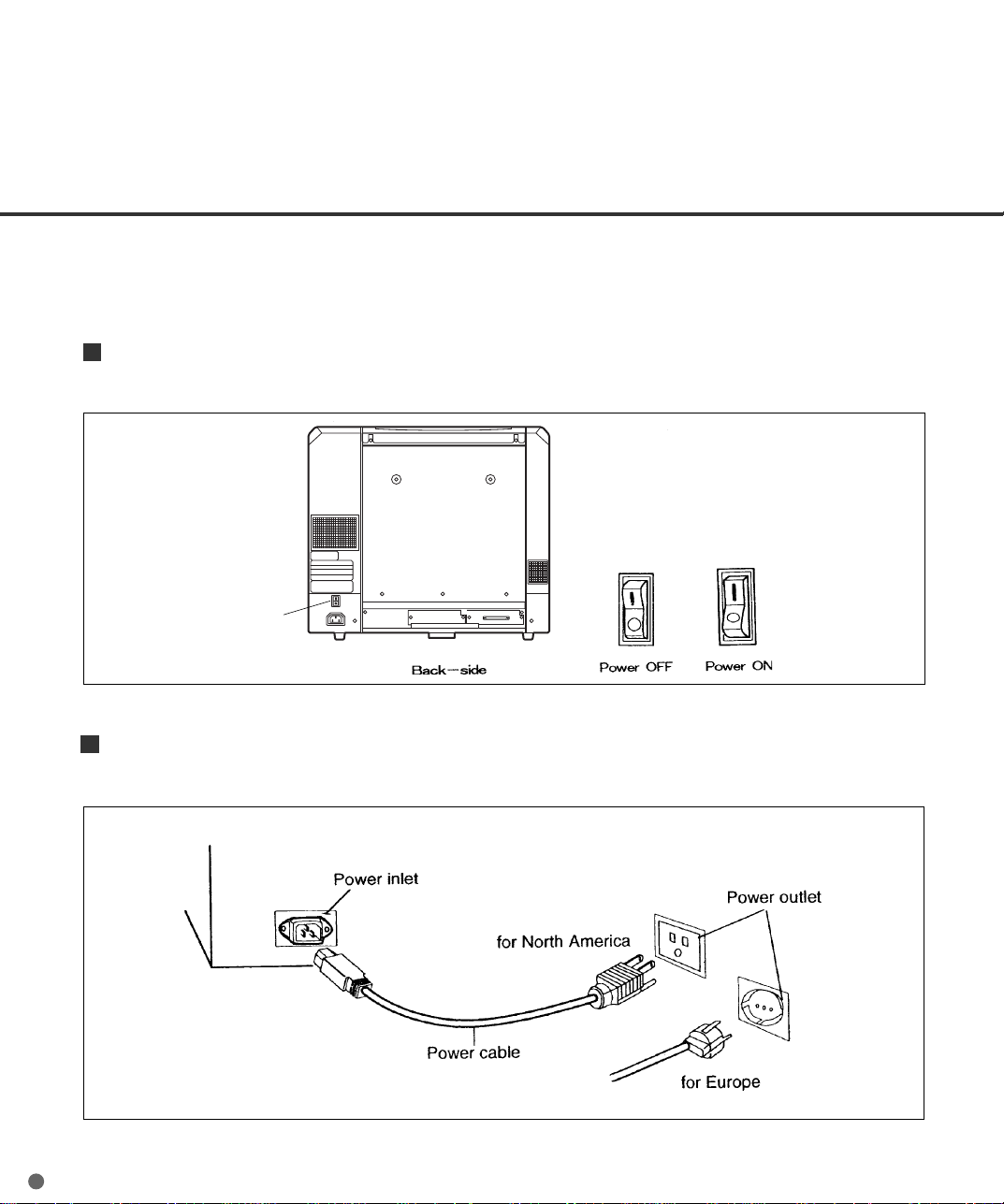

Turning the main line switch off

Press “O” side of the main line switch to turn the power off.

Main line switch

Connecting the power cable

Connect the power cable to the power inlet of the device and a power outlet.

2-4

Page 24

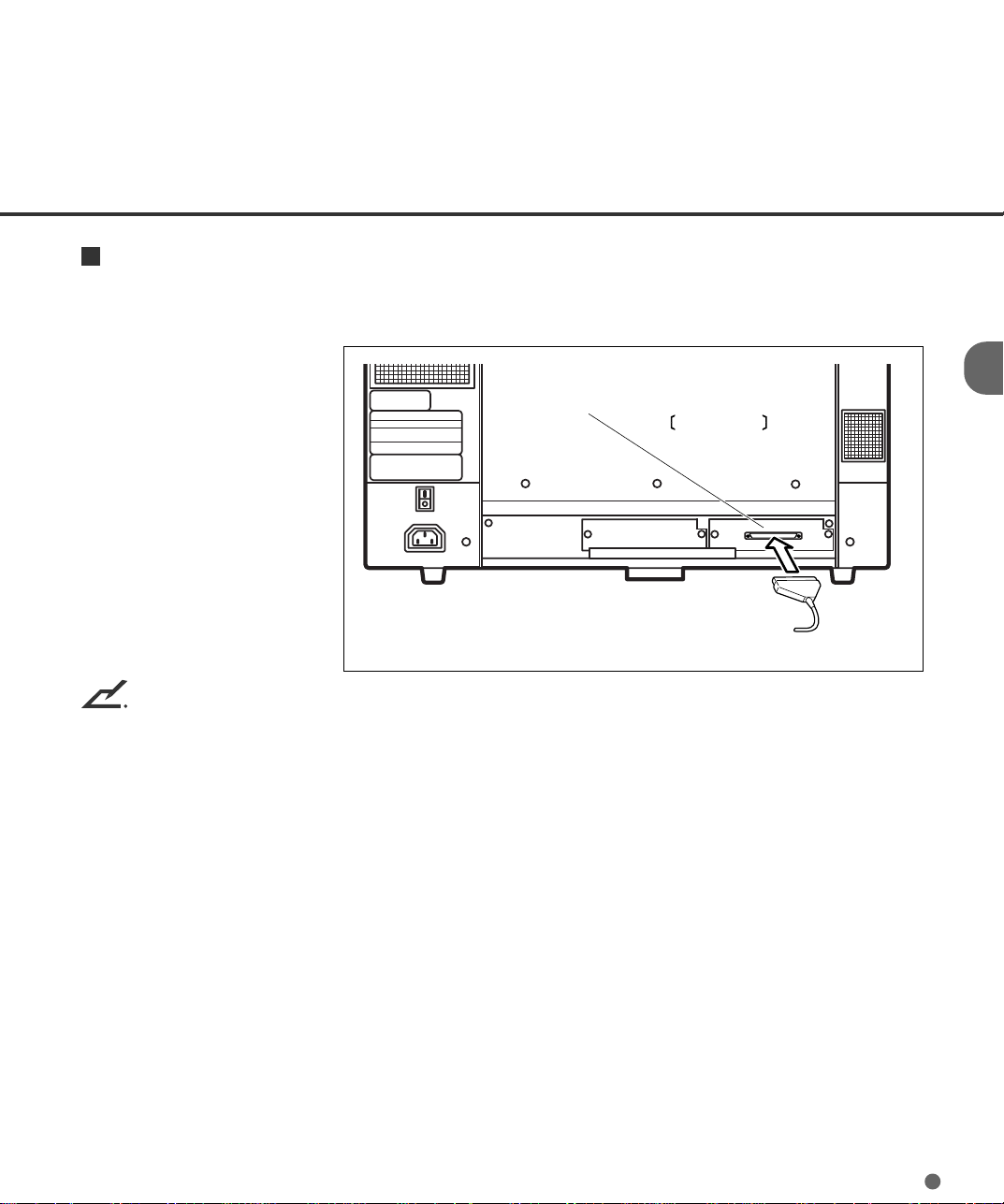

Connecting the interface cable

Connect the appropriate SCSI interface cables and secure them with hooks or screws.

Interface connector

for SCSI

Back – side

Interface cable

for SCSI

NOTE

• SCSI-ID is set to No. 5 at shipment. Refer to Chapter 6 when changing the setting.

2-5

Page 25

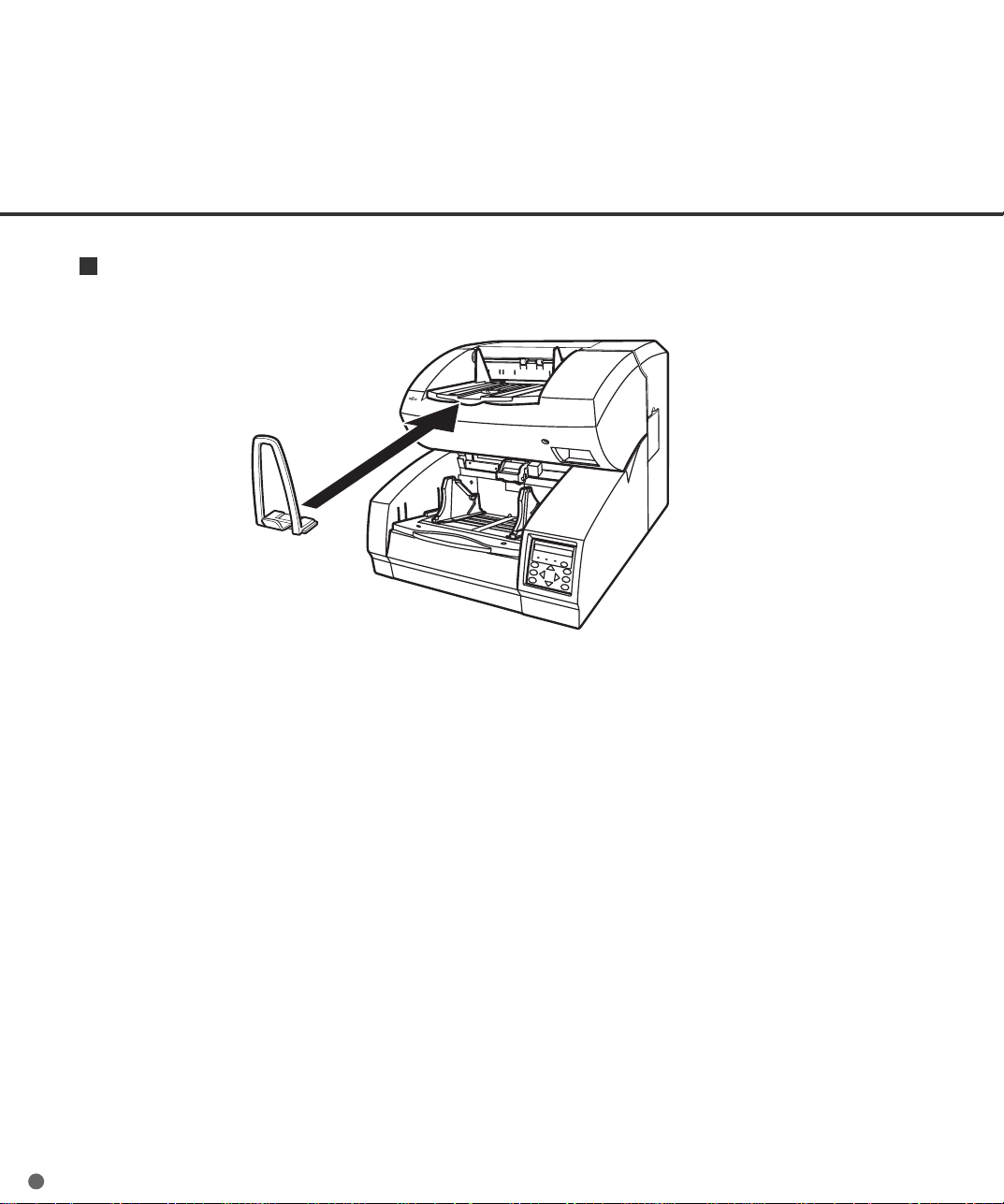

Attach the stop lever to the scanner.

Insert the stop lever to the scanner. (Into the gap in the stacker)

2-6

Page 26

CHAPTER

3

OPERATING INSTRUCTION

This chapter describes how to turn the power on, and also describes how to operate the operator panel (basic operation).

Refer to Reference Guide about information on loading document and

opening/closing the upper transport unit.

Turning the Power On

Basic Operation of the Operator Panel

Page 27

3

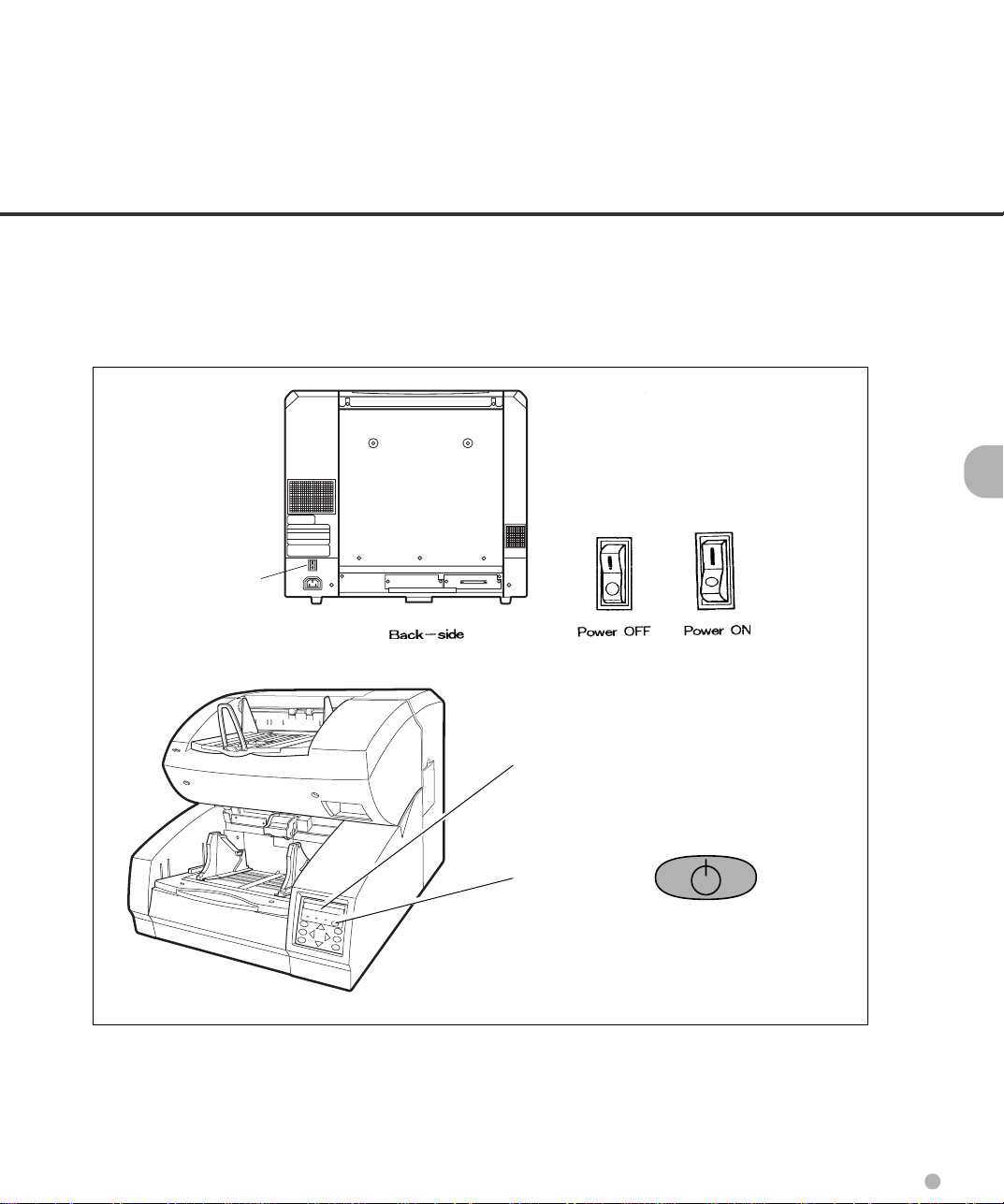

Turning the Power On

This section describes how to turn the power on.

Press “I” side of the main line switch located at the back of the scanner. Press the power switch of

the operator panel. The power goes on and the green POWER lamp at the operator panel lights.

Main line switch

Operator panel

Power switch

3-1

Page 28

Basic Operation of the Operator Panel

This section describes basic operation of the operator panel including how to enter the mode selection mode in which you can use setup mode, browse mode, and test mode.

Displaying detailed information if an error occurred

If an error occurs, the CHECK LED blinks and the error message is displayed on the LCD. For

example, the LCD indicates as follows:

Hopper empty

Press

CANCEL

to clear the error (Temporaly errors will clear, equipment errors will not).

3-2

Page 29

Lifting or lowering the hopper

When the scanner has no error (the CHECK LED does not light), pressing lifts the hopper

and pressing lowers the hopper.

CAUTION

During hopper height adjustment, do not touch the hopper table or do not put

anything on the hopper table to prevent your fingers from being caught. If

something is caught in the mechanism, the scanner may be damaged.

This function is valid when:

Ready is displayed.

In details:

• The DATA LED does not light (the scanner contains no data),

• The scanning operation is not in progress,

• The scanner is not in test mode (except the offline feed test), and

• The scanner is not in setup or browse mode.

The hopper stops at the pick position or at the 250-, 500-, or 1000-sheet position depending on the

hopper height adjustment in setup mode. At the pick position, the top paper of stack (the hopper

table when no paper is loaded on the hopper) is aligned to the pick roller. At the 250-sheet position,

for example, the hopper table can load about 250 sheets of paper.

Each time you press or , the hopper lifts or lowers by one position. Pressing when paper

is loaded, the hopper lifts up to the pick position.

3-3

Page 30

Clearing a consumable life alarm

This scanner has the consumable counter to estimate consumable life of the scanner. When the

consumable counter reaches the prescribed value, the LCD indicates an alarm that the consumable may be expired. For example, the following message appears:

Consumable life alarm

AAAAAAAA MMMM

In this case, press

CANCEL

. The LCD indicates the following message:

Reset Consumable Counter?

Yes:Enter No:Cancel

Yes (press

No (press

ENTER

CANCEL

): The scanner resets the consumable counter to zero.

): The scanner does not reset the consumable counter. In this case, the

consumable life alarm recurs when the next sheet is fed.

3-4

Page 31

Confirming the number of sheets processed by the scanner

The LCD indicates the numbers of sheets scanned during online or in test mode (offline feed test).

The LCD indicates the numbers as follows:

Scanning

AAAAAAAA MMMM

Value Meaning Description

AAAAAAAA Abrasion counter Eight columns of numbers indicate the accumulative

number of sheets fed by this scanner.

MMMM Batch counter Four columns of numbers indicate the number of sheets fed

per hopper.

3-5

Page 32

Using the function buttons (F1, F2, and F3)

This scanner has the three function buttons (

F1

,

F2

, and

) to save time when

F3

using a setup function which is likely to require tedious operation. Use these buttons as shortcut

keys when you frequently use certain setup functions for your jobs. See Chapter 6 for details.

You can use function buttons after allocating a setup function to it. This allocation can be done in

setup mode. After allocation, the allocated function can be easily accessed just by pressing the

function button. For allocatable setup functions, see Chapter 6.

The function buttons are available when:

Ready is displayed.

In details:

• The DATA LED does not light (the scanner contains no data),

• The scanning operation is not in progress,

• The scanner is not in test mode, and

• The scanner is not in setup or browse mode.

The function buttons are available even in the setup mode lock state (see Chapter 6).

3-6

Page 33

Using the setup, browse, and test modes

This scanner has the setup mode, browse mode, and test mode to ease operation for customizing

the scanner, glancing setup conditions of the scanner, and testing the scanner offline respectively.

There are two ways to enter these modes:

• Press

• Turn the power on while pressing

Available functions differ with the two ways. For details, see Chapter 6.

In the following way, you can use the setup mode and browse mode.

POWER ON

Please wait

MENU

when the LCD indicates “Ready” or

MENU

Ready

CANCEL

.

MENU

: Cursor buttons

: Blinking

<<MODE SELECT>>

SETUP BROWSE

ENTER

<<SETUP MODE>>

ENTER

<<SETUP MODE>>

XXXXX

ENTER

CANCEL

CANCEL

CANCEL

<<MODE SELECT>>

SETUP BROWSE

ENTER

<<BROWSE MODE>>

ENTER

<<BROWSE MODE>>

XXXXX

ENTER

CANCEL

CANCEL

CANCEL

3-7

Page 34

In the following way, you can use the test mode in addition to the setup mode and browse mode.

To quit these modes, turn the power off.

POWER ON with MENU ON

T Please wait

* Turn off to quit <<MODE SELECT>>.

<<MODE SELECT>>

SETUP BROWSE TEST

ENTER

CANCEL

<<SETUP MODE>>

ENTER

CANCEL

<<SETUP MODE>>

XXXXX

ENTER

CANCEL

<<MODE SELECT>>

SETUP BROWSE TEST

ENTER

CANCEL

<<BROWSE MODE>>

ENTER

CANCEL

<<BROWSE MODE>>

XXXXX

ENTER

CANCEL

*

: Cursor buttons

: Blinking

<<MODE SELECT>>

SETUP BROWSE TEST

ENTER

ENTER

ENTER

<<TEST MODE>>

<<TEST MODE>>

Offline Feed Test

CANCEL

CANCEL

CANCEL

3-8

Page 35

Transition of operator panel status and display

The following outlines the transition of status and display of the operator panel.

CANCEL

Error message

Error

occurred

POWER ON

Ready

(normal mode)

MENU

Mode select screen

(Setup and Browse)

ENTER

Setup mode

CANCEL

CANCEL

F1, F2, F3

ENTER

Browse mode

POWER ON with MENU ON

Shortcut to

setup functions

Mode select screen

(Setup, Browse, and Test)

CANCEL

ENTER

Test mode

Turn power

off to quit.

CANCEL

3-9

Page 36

3-10

Page 37

CHAPTER

4

DOCUMENT SPECIFICATION

This chapter describes the document size and document quality

of the scanner.

Document Size

Document Quality

Document Limitations

Grounding Color Area

Drop-out Color

Job separation Sheet

Page 38

Document Size

The following figure shows document sizes that the scanner can read.

A

Feeding Direction

Scanner

fi-4990C

Maximum

A

297 (11.7 in)

B

432 (17 in)

B

Minimum

A7 size

= 74 (2.9 in) x 105 (4.1 in):

Available in both portrait

and landscape orientations

(Unit : mm)

4-1

Page 39

Document Quality

This section describes paper types of documents and ream weights of paper available for the scanner, and precautions.

Paper types of documents

The recommended paper types of documents are as follows:

NOTE

Please use the specified paper. (In rare occasion, double feeding or document damage may occur.)

• Fine paper

• Plain paper

• OCR paper

When using any other paper types of documents, place a test batch of documents in to the ADF to

see if it successfully feeds the documents.

NOTE

Documents may be damaged when an error occurs.

Ream weight of paper

The ream weight of paper is as follows:

• 52 to 127 g/m2 (13.9 to 34 lb)

NOTE

4-2

Page 40

lb indicates the pound weight of 500 sheets of 17 x 22 inch paper (3.76 g/m2).

Precautions

Be careful not to scan the following documents. Preliminary document feed testing may be necessary

to avoid the unexpected errors. If the document slips in ADF (JAM error) or double feed occurs

frequently, refer to “Improving Document Separation” in Reference Guide.

• Paper with clips or staples

• Paper with wet ink

• Paper of which thickness is not constantly equal. (like envelope)

• Paper with large rumples or curl. (See NOTE on the next page.)

• Paper with folds or tears

• Tracing paper

• Coating paper

• Carbon paper

• Carbonless paper

• Paper smaller than A7 size, or larger than A3 size

• Other than paper: clothes, metal foils, or OHP films

• Photographic paper

• Paper with notches on its side

• Other than rectangle paper

When scanning a translucent document, set the density to light mode.

To prevent roller smudging, avoid scanning a document filled out in pencil. Clean the roller as often as

possible when scanning many document. Once every 1000 sheets is recommended.

The chemical composition of some carbonless papers may react with the roller rubber and damage the

rubber. Check the carbonless papers before use.

When using carbonless paper, follow these conditions:

• Ream weight of the paper is 52 g/m2 (13.9 lb) or more.

• Hopper load is 500 sheets or fewer.

4-3

Page 41

NOTE

• If carbonless papers are used, clean the roller twice as often as usual.

• Documents should be straightened to fit the condition below.

More than

30 mm

Less than

Feed direction

3 mm

Read surface

Top of the paper

More than

30 mm

Feed direction

Less than

5 mm

Read surface

• When you read curled, wrinkled, or creased documents, documents may not be successfully

arranged in the stacker.

4-4

Page 42

Document Limitations

This section describes restrictions on document used for the scanner.

Areas that must not be perforated

Perforatins are prohibited in the shaded area of Figure 4.1 to avoid document size detection error or

job separation sheet detection error or jam.

113 (4.45") 134 (5.28")

Reading

reference

position

15

(0.59")

79 (3.12") 96 (3.78")

10

(0.39")10(0.39")

Front side

Reading surface

12

12

(0.47")

(0.47")

10

(0.39")10(0.39")

(Unit : mm)

Top of document

Document feeding direction

Bottom of document

10

(0.39")

Center of document

Figure 4.1 Areas that must not be perforated

10

(0.39")

4-5

Page 43

Print phohibit areas on the front and back surfaces

Printing in area A on the front of a document may, in a rare case, cause a document size detection

error. Printing in area B on the front and back of document may, in a rare case, result in a double feed

error. Figure 4.2 shows print prohibit areas on the front and back surfaces.

NOTE

Figure 4.2 shows the document as viewed from the reading surface.

Reading

reference

position

15

Document feeding direction

113 (4.45") 134 (5.28")

79 (3.12") 96 (3.78")

Front side

Reading surface

10

10

(0.39")

(0.39")

34 (1.34")

Center of document

(Unit : mm)

Top of document

: Area A

: Area B

Bottom of document

10

(0.39")10(0.39")

4-6

Figure 4.2 Print prohibit areas on the front and back surfaces

Page 44

Grounding Color Area

As Figure 4.3 shows, the top 3-mm part of the read area on each surface should be left blank

(grounding color) by specifying a drop-out color. If the drop-out color cannot be specified, select

“Photo” for the document type (linedrawing or photograph).

For details of the drop-out color, see Page 4-8.

Reading

reference

Subscanning direction

Main scanning direction

Figure 4.3 Grounding color area

Grounding color

(white) or drop-out

color area

3 mm (0.12")

4-7

Page 45

Drop-out Color

A drop-out color is a color visible by a human eye but not visible to the scanner.

To check the grounding color of document for a drop-out color, use the method and follow the

standards given below.

Print density measurement

The spectrum chart shown in Figure 4.4 is used to measure print density.

The measurement must be made in one of the following ways:

• A light source using fluorescent.

• Macbeth PCS meter PCM II is used, which requires a filter.

100

90

80

70

60

50

40

30

Relative Spectral Power

20

10

0

400

500 600 700

Waveength (nm)

Figure 4.4 Spectrum band

Drop-out color standards

In the spectrum of fluorescent lamp the PCS value must satisfy the following standards:

• Maximum: 0.14 or less

• Average: 0.1 or less

4-8

Page 46

Job Separation Sheet

)

Shape

The following Figure 4.5 shows the shape of the document.

15

(0.59")

Scanning direction

15

(0.59")

Center of document

(Unit : mm

more than 210 (8.27")

Figure 4.5 Shape of document

Document type

The document type and ream weight specifications given in Section 4-2 apply.

However, the document size shall be A4 or larger (210 mm (8.27”) or more wider).

4-9

Page 47

CHAPTER

5

SPECIFICATIONS

This chapter describes the installation specifications, external

dimensions, consumables, option.

Installation Specifications

External Dimensions

Consumables

Options

Page 48

Installation Specifications

The following table lists the installation specifications of the scanner.

Item Specification

Dimensions (mm)

Weight (kg)

Voltage

Input power

Power consumption 250 VA or less

Ambient

condition

Phases

Frequency

Device status Operating Not operating

Temperature 15 to 35°C -20 to 60°C

Humidity 20 to 80 % 8 to 95 %

Width

Depth

Height

590 (23.2 in)

690 (27.2 in)

540 (21.3 in) without optional endorser

610 (24.0 in) with optional endorser

65 (143 lb.)

100 to 240 VAC ±10 %

Single-phase

50/60 Hz + 2% -4%

(60 to 95°F) (-4 to 140°F)

5-1

Page 49

External Dimensions

5-2

(unit: mm)

Page 50

Consumables

The following table lists consumables used for the scanner. Be sure to keep some consumables in stock.

Customer is responsible to change these items periodically. The consumable counter can be used to check

the number of scanned documents. (See page 3-4, 6-22.)

Name Specification Service life and remarks

Lamp CA04315-0430 1000 hours or more. Two lamps used per scanner.

Pad CA04315-G730 300,000 sheets or one year.

Pick roller unit CA04315-F711 300,000 sheets or one year.

Brake roller CA04315-F705 300,000 sheets or one year.

Print head CA01023-0701 20,000 sheets (10 characters/sheet).

Black ink cartridge for endorser.

NOTE

• These service lives (replacement cycles) may be shortened depending on paper types of

documents scanned or wrong cleaning of the scanner.

• When carbon-less paper is used, the replacement cycle is shortened. So, these parts must be

replaced earlier than above.

• Adjust Consumable counter if shortened consumable life is expected. This will ensure

consumables are replaced when needed. (page 6-22)

5-3

Page 51

Options

The following table lists options of this scanner.

Name Specification Remark

Endorser CA04315-D201 Ink jet printing method

• Back-side print

• Max. 33 characters

Contact your Fujitsu sales agent for more information.

5-4

Page 52

CHAPTER

6

SETUP, BROWSE, AND TEST MODES

This chapter describes the setup, browse, and test modes of the

scanner.

Setup, Browse, and Test Modes

Activating the Setup or Browse Mode

Contents of the Setup or Browse Mode

Activating the Test Mode

Contents of the Test Mode

Page 53

Setup, Browse, and Test Modes

This scanner has the setup mode, browse mode, and test mode to ease setting up.

• Setup mode for customizing the scanner for user requirements

• Browse mode for glancing setup conditions of the scanner

• Test mode for testing the scanner offline

There are two ways to enter these modes:

• Way 1

Press

You can use the setup mode and browse mode. To quit a mode, press

• Way 2

Turn the power on while pressing

You can use the test mode in addition to the setup mode and browse mode. To quit a mode, turn

off the power.

Available functions differ with modes or with ways. For details, see descriptions of each function.

Functions not available in setup mode

Way Functions not available

MENU

when the LCD indicates “Ready”.

MENU

CANCEL

MENU

pressed in Ready status TP_IF baud rate, SCSI ID, Product ID, Function key, Setup mode lock

.

.

Functions not available in browse mode

Functions not available

Paper thickness setup

6-1

Page 54

Activating the Setup or Browse Mode

To activate the setup mode, follow these steps:

1. While the LCD is indicating “Ready”, press

The <<MODE SELECT>> screen appears with

MENU

.

Ready

“SETUP” blinking.

<<MODE SELECT>>

SETUP BROWSE

2. Press

ENTER

The <<SETUP MODE>> initial screen (*) appears.

.

* <<SETUP MODE>> Initial screen

<<SETUP MODE>>

3. Press

ENTER

The <<SETUP MODE>> menu screen (**) appears.

.

** <<SETUP MODE>> menu screen

<<SETUP MODE>>

XXXXX

To activate the browse mode, press before step 2 to make “BROWSE” blinking, then follows

steps 2 and 3. The <<BROWSE MODE>> screen appears.

To quit the setup mode, press

CANCEL

.

Button functions in setup or browse mode

Button name Function

MENU

ENTER

CANCEL

Returns to the <<SETUP MODE>> menu screen without saving the change (*).

Returns to the previous screen while saving the change (*).

Returns to the previous screen without saving the change (*).

• Displays the next function at the right in the menu.

• Moves to the right item.

• Displays the next test function at the left in the menu.

• Moves to the left item.

Changes parameters.

Changes parameters.

* In browse mode, “saving the change” does not occur.

6-2

Page 55

Mode selection (

MENU

pressed in Ready status)

There is another mode selection which enables you to execute the user test on the scanner without the

host computer. See “ Activating the Test Mode” later in this chapter.

POWER ON

Please wait

Ready

: Cursor buttons

MENU

CANCEL

: Blinking

<<MODE SELECT>>

SETUP BROWSE

ENTER

<<SETUP MODE>>

ENTER

<<SETUP MODE>>

XXXXX

ENTER

CANCEL

CANCEL

CANCEL

<<MODE SELECT>>

SETUP BROWSE

ENTER

<<BROWSE MODE>>

ENTER

<<BROWSE MODE>>

XXXXX

ENTER

CANCEL

CANCEL

CANCEL

6-3

Page 56

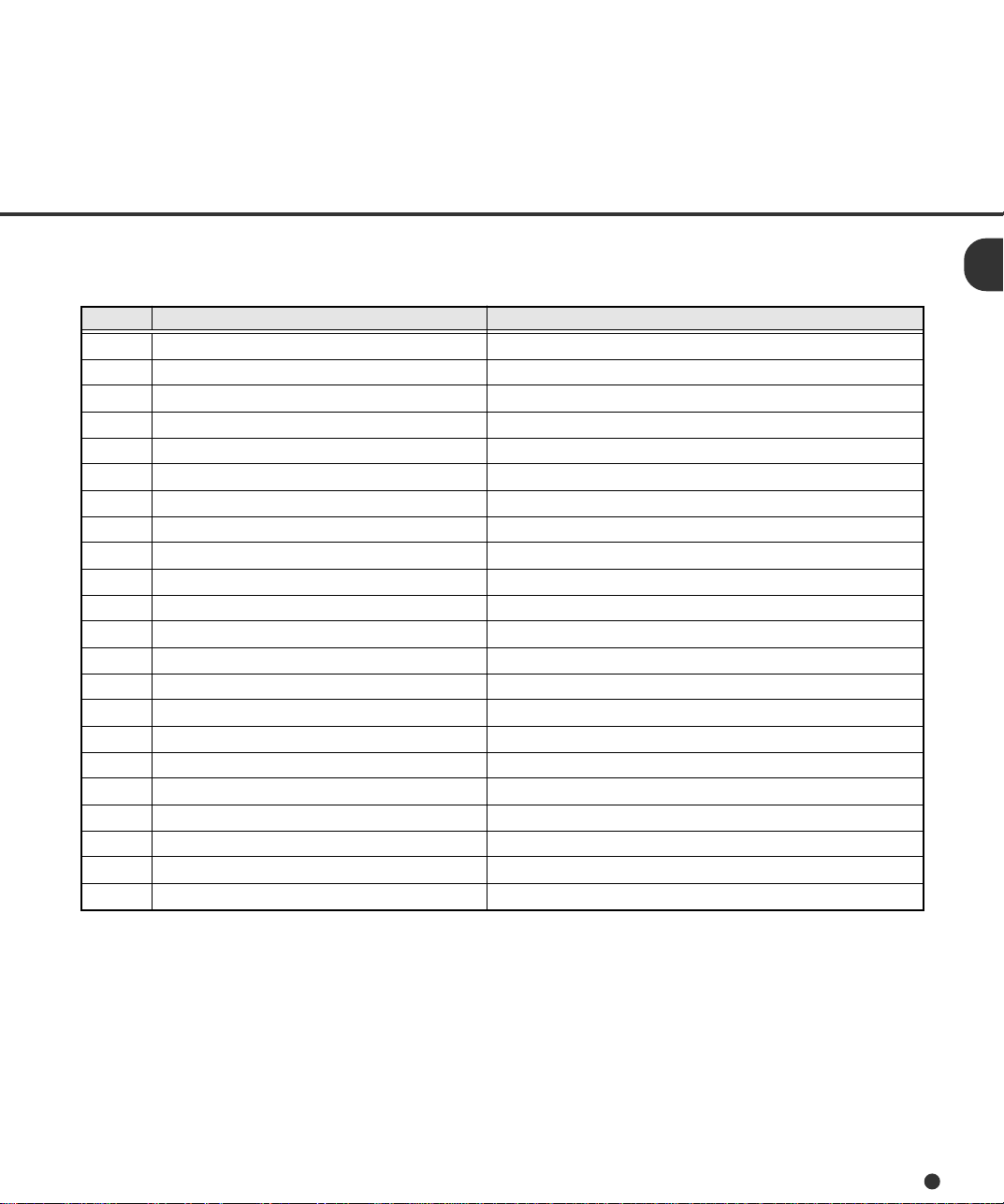

Contents of the Setup or Browse Mode

This section describes the contents of the setup mode.

The setup mode can be classified into 35 types.

Setup item

Paper length check

Doublefeed check

Paper thickness setup

Skew check

IPC-3 mode

Hopper height

Paper separation level

Drop-out color

Background changeover

Consumable counter

Consumable counter

reset

Consumable alarm mode

Buzzer

Buzzer volume

LCD contrast

Picking speed

* Endorser Initial setting

* Endorser Reset

Method

* Endorser Reset

* Ink Counter Reset

Description

Enables or disables the function which

detects a paper length error.

Enables or disables the function which

detects the paper thickness.

Sets the permissible paper thickness to

detect a double feed error.

Enables or disables the function which

detects a skew error.

Selects a pattern to be set in the image

processing option.

Sets the initial position of the hopper.

Sets the power of separating sheets of

paper.

Selects a drop-out color.

Sets the Background to “white” or “Black”

Sets the interval (in ten thousands) in which

a consumable alarm occurs.

Reset the accumulated count value of the

consumable counter.

Sets the mode how to notify the alarm

generation when the accumulated

consumable counter value reaches to the

setting value.

Activates or inactivates the buzzer sound

when an error occurs.

Sets the volume of buzzer or click sound.

Sets the contrast of the LCD.

Selects the speed of the pick roller.

Sets whether to enable the endorser

imprinting process, and to set the initial value

of the imprinting number.

Sets whether to reset the number to be

imprinted by Endoser every time when the

Hopper Empty is detected.

Reset the number to be imprinted by Endoser.

Reset the print head life counter.

Remarks

The selection set by the host computer cannot

be changed.

The selection set by the host computer cannot

be changed.

• Overrides the selection set by the host

computer.

The selection set by the host computer cannot

be changed.

The selection set by the host computer cannot

be changed.

Displayed in setup mode selected by turning

power on with

Displayed in setup mode selected by turning

power on with

The details and the operation method, please

refer to the “M4099D/M4099DC/fi-4990/fi-4990C

Image Scanner Operator’s Guide : Option”.

MENU

MENU

pressed.

pressed.

6-4

Page 57

Setup item

Description

Remarks

TP_IF baud rate

SCSI ID

Product ID

Pre-pick

Pick start time

Manual feed timeout

Paper pick retry

Paper feed retry

Function key

Setup mode lock

Language

White follower mode

Interface Board slot

SCSI Bus Width setting

* Printing Position

Selects the control data transfer rate (2400,

4800, 9600, or 19200) for the TP interface.

Sets the SCSI ID of this scanner.

Sets the product ID of this scanner.

Enables or disables pre-picking.

Sets the period from when paper is loaded

manually to when the pick operation starts.

Sets the waiting period from when the host

computer issues a scan command to when

paper is loaded manually.

Sets the pick motor operation time and retry

count.

Sets the feed motor operation time and retry

count.

Allocates setup functions to

F3

and

buttons.

F1

F2

,

Inhibits the operator panel from entering

setup mode from normal mode.

Select the Operation Panel LCD display

language (Japanese/English).

Selects the white Level follower operation “0”

means default “1”means operate like

M3099X scanner.

Selects the Interface Board Slot “1” or “2”.

When connects Narrow SCSI card, Selects

“8 bit”.

Set the Endorser print start position.

Displayed in setup mode selected by turning

power on with

MENU

pressed.

Displayed in setup mode selected by turning

power on with

MENU

pressed.

Displayed in setup mode selected by turning

power on with

Displayed in setup mode selected by turning

,

power on with

MENU

MENU

pressed.

pressed.

• Displayed in setup mode selected by turning

power on with

• Setup functions allocated to

and

buttons are always valid

F3

MENU

pressed.

F1

regardless of this setting.

Displayed in setup mode selected by turning

power on with

MENU

pressed.

Displayed in setup mode selected by turning

power on with

MENU

pressed.

Displayed in setup mode selected by turning

power on with

MENU

pressed.

The details and the operation method, please

refer to the “M4099D/M4099DC/fi-4990/fi-4990C

Image Scanner Operator’s Guide : Option”.

,

,

F2

* If the option is not mounted, the set up item for the option does not display on the screen and skips

to the next item.

6-5

Page 58

Transition of screens in setup mode

This flowchart indicates the transition of screens in setup mode for reference to the setup operation

described in the following pages.

<<SETUP MODE>>

SETUP BROWSE

ENTER

<<SETUP MODE>>

ENTER

<<SETUP MODE>>

Paper Length Check

ENTER

Paper Length Check

OFF 10mm

Paper Length Check

ON 10mm

CANCEL

CANCEL

ENTER/CANCEL

: Blinking

<<SETUP MODE>>

Paper Thickness Check

ENTER

: Cursor buttons

Setup mode menu screen

ENTER

ENTER/CANCEL

Paper Length Check

OFF 10mm

Paper Length Check

OFF 20mm

<<SETUP MODE>>

Langage

ENTER/CANCEL

6-6

Paper Length Check

OFF 15mm

* To save the change,

press ENTER.

To quit without saving

change, press CANCEL.

Page 59

Paper length check

This function sets and detects a difference in paper length. You cannot change settings if they are set by

the host computer.

LCD display

Paper Length Check

Options

On, Off (Default: Off)

10 mm, 15 mm, 20 mm (Default: 10 mm)

Remarks

Checked or not

Difference:

XX mm means that it is not regarded as an

error when the actual difference of paper length

is within the limits of ±XX mm.

The following is an example of operation when you use this function.

1. In <<SETUP MODE>> initial screen, press

ENTER

.

The <<SETUP MODE>> menu screen (Paper

Length Check) appears.

2. Press

ENTER

.

The option select screen indicates the current

options with OFF blinking (blinking indicates

“changeable”).

3. Press or .

The displayed option changes (ON).

<<SETUP MODE>>

<<SETUP MODE>>

Paper Length Check

Paper Length Check

OFF 10 mm

Paper Length Check

ON 10 mm

4. Press .

The current difference 10 mm blinks (blinking

indicates “changeable”).

5. Press or .

The displayed option changes (15 mm or 20 mm).

Paper Length Check

ON 10 mm

Paper Length Check

ON 20 mm

6-7

Page 60

6. When the desired value appears, press

ENTER

to save the change.

The LCD returns to the <<SETUP MODE>>

menu screen (Paper Length Check).

<<SETUP MODE>>

Paper Length Check

7. Press

CANCEL

The LCD returns to the Ready screen.

two times.

Ready

Doublefeed check

This function determines whether or not to enable the paper thickness which is set by the “paper

thickness setup” function to detect a double feed error. You cannot change settings if they are set by

the host computer.

LCD display

Double feed Check

Options

Off, Thickness Check, Thickness & Roller

(Default: Off)

At pick the paper (Default)

At pick + feed the paper

The following is an example of operation when you use this function.

1. In <<SETUP MODE>> initial screen, press

ENTER

.

The <<SETUP MODE>> menu screen (Paper

Length Check) appears.

Remarks

OFF: Set the double feed check to Disabled.

Thickness & Roller check:

Detect the double feed by checking the

document thickness and the rotation of brake

roller.

Thickness check:

Detect the double feed by checking the

document thickness.

<<SETUP MODE>>

<<SETUP MODE>>

Paper Length Check

2. Press .

The <<SETUP MODE>> menu screen

(Doublefeed Check) appears.

6-8

<<SETUP MODE>>

Doublefeed Check

Page 61

3. Press

The option select screen appears with the

current option MODE blinking (blinking

indicates “changeable”).

ENTER

.

Doublefeed Check

MODE TIMING

4. Press

The option select screen appears with the

current option OFF blinking (blinking indicates

“changeable”).

5. Press or .

The displayed option changes (Thickness

Check or Thickness & Roller).

6. Press

The LCD returns to the option select screen

appears with the current option MODE blinking

(blinking indicates “changeable”).

7. Press .

The option select screen appears with the

current option TIMING blinking (blinking

indicates “changeable”).

8. Press

The option select screen appenrs with the

current option At pick the paper blinking.

9. Press or .

The displayed option changes (At pick + feed

the paper).

ENTER

ENTER

ENTER

.

to save the change.

.

Doublefeed Check : MODE

OFF

Doublefeed Check : MODE

Thickness & Roller

Doublefeed Check

MODE TIMING

Doublefeed Check

MODE TIMING

Doublefeed Check : TIMING

At pick the paper

Doublefeed Check : TIMING

At pick + feed the paper

10. Press

The LCD returns to the option select screen

appears with the current option TIMING

blinking.

ENTER

to save the change.

Doublefeed Check

MODE TIMING

6-9

Page 62

11. Press

The LCD returns to the Ready screen.

CANCEL

two times.

Ready

Paper thickness setup

This function sets the paper thickness which is used as the reference for detecting a double feed

error. Whether this function is enabled or disabled is determined by the “paper thickness check”

function in setup mode.

NOTE

This setting cannot be displayed in browse mode.

The following is an example of operation when you use this function.

1. In <<SETUP MODE>> initial screen, press

ENTER

The <<SETUP MODE>> menu screen (Paper

Length Check) appears.

2. Press twice.

The <<SETUP MODE>> menu screen (Paper

Thickness Setup) appears.

3. Press

The paper load prompting screen appears,

requesting adjustment paper.

4. Select thickest paper used for your jobs and put

the paper on the hopper.

.

ENTER

.

<<SETUP MODE>>

<<SETUP MODE>>

Paper Length Check

<<SETUP MODE>>

Paper Thickness Setup

Paper Thickness Setup

Set the adjustment paper

6-10

Page 63

5. Press

CANCEL

The “Adjusting!!” message appears. The scanner

lifts the hopper, feeds the paper, adjusts the

sensing level of the sensor, and saves its value.

After adjustment, the sheet is ejected and the

“Finished!!” message appears for two seconds,

then the LCD returns to the <<SETUP MODE>>

menu screen (Paper Thickness Setup).

If an error (for example, Mis-pick) occurs during

adjustment, remove the paper and press

appears again. Repeat steps 4 and 5.

ENTER

.

. The paper load prompting screen

Paper Thickness Setup

Adjusting!!

Finished!!

<<SETUP MODE>>

Paper Thickness Setup

6. Press

The LCD returns to the Ready screen.

CANCEL

two times.

Ready

6-11

Page 64

Skew check

This function determines if abnormal skew is detected or not. You cannot change the setting if it is

set by the host computer.

Options

Skew Check

The following is an example of operation when you use this function.

1.

In <<SETUP MODE>> initial screen, press

The <<SETUP MODE>> menu screen (Paper

Length Check) appears.

2. Press three times.

The <<SETUP MODE>> menu screen (Skew

Check) appears.

3. Press

The option select screen appears with the

current option OFF blinking (blinking indicates

“changeable”).

4. Press or .

The displayed option changes (ON blinks).

ENTER

On, Off (Default: Off)

.

ENTER

.

RemarksLCD display

<<SETUP MODE>>

<<SETUP MODE>>

Paper Length Check

<<SETUP MODE>>

Skew Check

Skew Check

Check: OFF

Skew Check

Check: ON

5. Press

6. Press

6-12

ENTER

The LCD returns to the <<SETUP MODE>>

menu screen (Skew Check).

CANCEL

The LCD returns to the Ready screen.

to save the change.

two times.

<<SETUP MODE>>

Skew Check

Ready

Page 65

IPC-3 mode

This function selects a pattern to be set in the IPC-3 image processing feature.

LCD display

IPC-3 Mode

The following is an example of operation when you use this function.

1. In <<SETUP MODE>> initial screen, press

ENTER

The <<SETUP MODE>> menu screen (Paper

Length Check) appears.

2. Press four times.

The <<SETUP MODE>> menu screen (IPC-3

Mode) appears.

3. Press

The option select screen appears with the

current setting 0 blinking (blinking indicates

“changeable”).

4. Press or .

The displayed option changes (1, 2, 3, 4, 5).

.

ENTER

Options

0, 1, 2, 3, 4, 5 (Default : 0)

.

Remarks

0: do not select any pattern

1 to 5: select pattern numbers 1 to 5

<<SETUP MODE>>

<<SETUP MODE>>

Paper Length Check

<<SETUP MODE>>

IPC-3 Mode

IPC-3 Mode

0

IPC-3 Mode

5

5. When the desired pattern number appears,

press

The LCD returns to the <<SETUP MODE>>

menu screen (IPC-3 Mode).

ENTER

to save the change.

<<SETUP MODE>>

IPC-3 Mode

6-13

Page 66

NOTE

When you set from the Function Key, the

dialogue appears whether you want to save the

revised data.

If you want to save the process, press “ENTER”key.

And if you do not want to save the process,

press “CANCEL”key.

6. Press

CANCEL

two times.

Ready

The LCD retarns to the Ready screen.

Paper types and corresponding pattern numbers

User’s paper is classified into five types in line art (no halftone) mode as shown in the following table.

• The horizontal axis shows the density and color of background on paper.

• The vertical axis shows the density of characters or lines.

Background density Background color

Normal ←

↑

↓

1: Normal back-

ground and

normal character

2: Normal back-

ground and light

character

Normal

Character

density

Light

* 1 to 5 are pattern numbers.

→ Dark

3: Dark back-

ground and

normal character

Red

4: Light character on

red or similar

background

Green

5: Light character on

green or similar

background

Blue

6-14

NOTE

When IPC-3 mode is executed in online status, the reading parameter is valid or invalid (host

setting is invalid) as follows:

Page 67

Important

When scaned in Grayscale or color, this setting is not in Effect. only effective when scaned in Binary.

Reading parameter validity

Reading parameter

Valid

Invalid

Valid

Invalid

Reading

mode

X

Document

selection

X

Resolution

X

r patterns

X

Line-art/

Photo

X

Contrast

X

Halftone

X

Reading parameter

Automatic

separation

X

DTC

Conversion

Paper

Size

X

X

SharpnessXOutline

X

Portrait/

Landscape

X

extraction

X

Picking

X

Simplified

DTC

X

6-15

Page 68

Hopper height

This function sets the initial height of the hopper. Set the height which you frequently use.

Options

Hopper Height

The following is an example of operation when you use this function.

1. In <<SETUP MODE>> initial screen, press

ENTER

The <<SETUP MODE>> menu screen (Paper

Length Check) appears.

2. Press repeatedly until “Hopper Height”

appears in the lower line of the menu screen.

3. Press

The option select screen appears with the current

height setting 1000 sheets blinking (blinking

indicates “changeable”).

4. Press .

The hopper moves to the 500-sheet position and

the new height setting 500 sheets blinks.

.

ENTER

250 sheets, 500 sheets, 1000 sheets

(Default : 1000 sheets)

.

RemarksLCD display

<<SETUP MODE>>

<<SETUP MODE>>

Paper Length Check

<<SETUP MODE>>

Hopper Height

Hopper Height

1000 sheets

Hopper Height

500 sheets

6-16

NOTE

Each time you press or , the hopper

moves to the next position and its position is

automatically saved. Repeat this operation until

the hopper is positioned at the desired height.

Page 69

If an error occurs during positioning, press

CANCEL

. The LCD returns to the option select

screen. Repeat step 4.

5. Press

CANCEL

three times.

Ready

The LCD returns to the Ready screen.

After this setting, the hopper is set at the new

height whenever power is turned on.

Paper separation level

This function sets the power of the brake roller for stabilizing paper separation in picking documents.

LCD display

Paper Separation Level

Options

Thick, Medium Thick, Normal, Medium Thin,

Thin (Default: Normal)

If the following errors frequently occur, set the braking power as explained below.

• Double feed

• Mis-pick

• SF2 did not detect leading edge of paper

Remarks

Thick: strong braking power for thick paper

| (changes according to paper thickness)

Thin: weak braking power for thin paper

6-17

Page 70

Set “braking power” according to the table below.

Setting

Thick

Medium

Thick

Normal

Medium

Thin

Thin

Braking power

Very strong

Strong

Medium

(factory default)

Light

Very light

“Double feed” frequently occurs. “Mis-pick” or “SF2 ···” frequently occurs.

Make the braking

power stronger.

The following is an example of operation when you use this function.

1. In <<SETUP MODE>> initial screen, press

ENTER

.

The <<SETUP MODE>> menu screen (Paper

Length Check) appears.

Make the braking

power weaker.

<<SETUP MODE>>

<<SETUP MODE>>

Paper Length Check

2. Press repeatedly until “Paper Separation

Level” appears in the lower line of the menu

screen.

3. Press

ENTER

.

The option select screen appears with the

current option Normal blinking (blinking

indicates “changeable”).

4. Press or .

The displayed option changes (Thick to Thin).

6-18

<<SETUP MODE>>

Paper Separation Level

Paper Separation Level

Normal

Paper Separation Level

Medium Thin

Page 71

5. When the desired option appears, press

ENTER

The LCD returns to the <<SETUP MODE>>

menu screen (Paper Separation Level).

to save the change.

<<SETUP MODE>>

Paper Separation Level

6. Press

The LCD returns to the Ready screen.

CANCEL

two times.

Ready

6-19

Page 72

Drop-out color

This function sets a drop-out color for front and back sides of paper respectively. You cannot change

settings if they are selected by the host computer.

Options

Drop-out Color

The following is an example of operation when you use this function.

1. In <<SETUP MODE>> initial screen, press

ENTER

The <<SETUP MODE>> menu screen (Paper

Length Check) appears.

2. Press repeatedly until “Drop-out Color”

appears in the lower line of the menu screen.

3. Press

The option select screen appears with the

current setting Green (for Front) blinking

(blinking indicates “changeable”).

4. Press .

Green (current option for Back) blinks (blinking indicates “changeable”).

.

ENTER

Front: Green, Red, Blue (Default: Green)

Back: Green, Red, Blue (Default: Green)

.

RemarksLCD display

<<SETUP MODE>>

<<SETUP MODE>>

Paper Length Check

<<SETUP MODE>>

Drop-out Color

Drop-out Color

Front: Green Back: Green

Drop-out Color

Front: Green Back: Green

5. Press or .

The displayed option changes (Blue or Red).

6-20

Drop-out Color

Front: Green Back: Red

Page 73

6. When the desired option appears, press

ENTER

The LCD returns to the <<SETUP MODE>>

menu screen (Drop-out Color).

to save the change.

<<SETUP MODE>>

Drop-out Color

7. Press

The LCD returns to the Ready screen.

CANCEL

two times.

Background changeover

This function sets the Background to “White” or “Black”.

Options

Background

changeover

The following is an example of operation when you use this function.

1. In <<SETUP MODE>> initial screen, press

ENTER

The <<SETUP MODE>> menu screen (Paper

Length Check) appears.

2. Press repeatedly until “Background

Changeover” appears in the lower line of the

menu screen.

.

Front: White, Black (Default: White)

Back: White, Black (Default: White)

RemarksLCD display

Ready

<<SETUP MODE>>

<<SETUP MODE>>

Paper Length Check

<<SETUP MODE>>

Background Changeover

3. Press

The option select screen appears with the

current setting White (for Front) blinking

(blinking indicates “changeable”).

ENTER

.

Background Changeover

F: White B: White

6-21

Page 74

4. Press .

White (current option for Back) blinks (blinking

indicates “changeable”).

Background Changeover

F: White B: White

5. Press or .

The displayed option changes (Black).

6. Press

The LCD returns to the <<SETUP MODE>>

menu screen (Background Changeover).

7. Press

The LCD returns to the Ready screen.

ENTER

CANCEL

to save the change.

two times.

Background Changeover

F: White B: Black

<<SETUP MODE>>

Background Changeover

Ready

Consumable counter

This function displays or sets a value of the counter which informs the user of the life (replacement

cycle) of a consumable. When the number of sheets fed reaches the set value, an alarm occurs. Set

this value according to types of paper you use. When using fine paper, the standard replacement

cycle of pick roller units, brake rollers, and pads is per three hundred thousands of sheets fed. So,

we recommend you to set the value to 0300000.

LCD display

Consumable Counter

Options

10000 to 2560000 sheets

(Default: 2560000 sheets)

Remarks

This setting can be changed in ten

thousands of sheets. The least four

digits of zeros are automatically

added.

The following is an example of operation when you use this function.

6-22

Page 75

1. In <<SETUP MODE>> initial screen, press

ENTER

The <<SETUP MODE>> menu screen (Paper

Length Check) appears.

.

<<SETUP MODE>>

<<SETUP MODE>>

Paper Length Check

2. Press repeatedly until “Consumable

Counter” appears in the lower line of the

menu screen.

3. Press

The option select screen appears with the

current value blinking (blinking indicates

“changeable”).

4. Press or .

The displayed value changes (1 to 256).

(Value can be changed in ten thousands of

sheets.) Pressing and holding down or

5. When the desired value appears, press

The LCD returns to the <<SETUP MODE>>

menu screen (Consumable Counter).

6. Press

The LCD returns to the Ready screen.

ENTER

speeds up the change.

ENTER

CANCEL

.

to save the change.

two times.

<<SETUP MODE>>

Consumable Counter

Consumable Counter

256 0000 sheets

Consumable Counter

030 0000 sheets

<<SETUP MODE>>

Consumable Counter

Ready

6-23

Page 76

Consumable counter reset

This function is to be used when the consumable parts are replaced before the accumulated value of

the consumable conter reaches to the setting value.

NOTE

You cannot use this function when the setup mode is brought by pressing “MENU” in the Ready

status.

LCD display

Consumable Counter

Reset

The following is an example of operation when you change the setting.

1. <<SETUP MODE>> initial screen, press

ENTER

The <<SETUP MODE>> menu screen (Paper

Length Check) appears.

2. Press repeatedly until “Consumable

Counter Reset” appears in the lower line of

the menu screen.

3. Press

The current option list screen appears with

NO blinking. (blinking indicates “changeable”).

.

ENTER

Options

YES, NO (Default)

.

Remarks

YES: Reset the accumulated

consumable counter value.

NO: cancel the resetting of

consumable counter value.

Consumable Counter Reset

Reest Counter Value

<<SETUP MODE>>

<<SETUP MODE>>

Paper Length Check

<<SETUP MODE>>

NO 00250000

4. Press or .

The displayed option changes (YES blinks).

6-24

Reest Counter Value

YES 00250000

Page 77

5. When the desired option appears, press

ENTER

to resetting the Consumable

Counter.

The LCD returns to the <<SETUP MODE>>

menu screen (Consumable Counter Reset).

Finished resetting!!

6. To quit the <<SETUP MODE>>, turn off the

power.

<<SETUP MODE>>

Consumable Counter Reset

Consumable alarm mode

This function is to be used how to notify the alarm generation when the accumulated consumable

counter value reaches to the setting value.

NOTE

You cannot use this function when the setup mode is brought by pressing “MENU” in the Ready

status.

LCD display

Consumable Alarm

Mode

Options

Alarm & Stop scanning (Default)

Message only

Remarks

Alarm & Stop scanning:

when the accumulated value reaches

to the Consumable Counter Setting

value, the alarm displayes on the LCD

and stop the scanning operation.

Message only:

When the accumulated value reaches

to the Consumable Counter Setting

value, the alarm displays on the LCD.

(scanning operation does not stop.)

6-25

Page 78

The following is an example of operation when you change the setting.

1. <<SETUP MODE>> initial screen, press

ENTER

The <<SETUP MODE>> menu screen (Paper

Length Check) appears.

2. Press repeatedly until “Consumable

Alarm Mode” appears in the lower line of the

menu screen.

3. Press

The current option list screen appears with

“Alarm & Stop scanning” blinking (blinking

indicates “changeable”).

4. Press or .

The displayed option changes (“Message

only” blinks).

5. When the desired option appears, press

ENTER

The LCD returns to the <<SETUP MODE>>

menu screen (Consumable Alarm Mode).

.

ENTER

.

to save the change.

<<SETUP MODE>>

<<SETUP MODE>>

Paper Length Check

<<SETUP MODE>>

Consumable Alarm Mode

Consumable Alarm Mode

Alarm & Stop scanning

Consumable Alarm Mode

Message only

<<SETUP MODE>>

Consumable Alarm Mode

6. To quit the <<SETUP MODE>>, turn off the

power.

6-26

Page 79

Buzzer

This function enables or disables the buzzer sound when an error occurs.

NOTE

The buzzer sounds regardless of this setting when use this function.

Options

Buzzer

The following is an example of operation when you use this function.

1. In <<SETUP MODE>> initial screen, press

ENTER

The <<SETUP MODE>> menu screen (Paper

Length Check) appears.

2. Press repeatedly until “Buzzer” appears

in the lower line of the menu screen.

3. Press

The option select screen appears with the

current setting OFF blinking (blinking indicates

“changeable”).

4. Press or .

The displayed option changes (ON blinks).

.

ENTER

On, Off (Default: Off)

.

RemarksLCD display

<<SETUP MODE>>

<<SETUP MODE>>

Paper Length Check

<<SETUP MODE>>

Buzzer

Buzzer

OFF

Buzzer

ON

5. Press

The LCD returns to the <<SETUP MODE>>

menu screen (Buzzer).

6. Press

The LCD returns to the Ready screen.

ENTER

CANCEL

to save the change.

two times.

<<SETUP MODE>>

Buzzer

Ready

6-27

Page 80

Buzzer volume

This function sets the sound volume of the buzzer in seven steps.

NOTE

This setting is valid both for occurrence of an error and for press of an operator panel button.

LCD display

Buzzer Volume

Options

q q q q q q

to (Default: n n q q q q)

n n n n n n

Remarks

Minimum

to (seven steps)

Maximum

* Symbols of volume may differ from the actual symbols used in the LCD.

The following is an example of operation when you use this function.

1. In <<SETUP MODE>> initial screen, press

ENTER

.

<<SETUP MODE>>

The <<SETUP MODE>> menu screen (Paper

Length Check) appears.

<<SETUP MODE>>

Paper Length Check

2. Press repeatedly until “Buzzer Volume”

appears in the lower line of the menu screen.

3. Press

ENTER

.

The option select screen appears with the

current setting n n q q q q (no blinking but

changeable).

4. Press or .

The displayed option changes (n n n q q q

to n n n n n n, q q q q q q or n q q q q

q).

<<SETUP MODE>>

Min n n q q q q Max

Min n n n q q q Max

Buzzer Volume

Buzzer Volume

Buzzer Volume

6-28

Page 81

5. When the desired option appears, press

ENTER

to save the change.

The LCD returns to the <<SETUP MODE>>

menu screen (Buzzer Volume).

<<SETUP MODE>>

Buzzer Volume

6. Press

CANCEL

two times.

The LCD returns to the Ready screen.

LCD contrast

This function sets the contrast of the LCD on the operator panel in seven steps.

LCD display

LCD Contrast

Options

q q q q q q

to (Default: n n q q q q)

n n n n n n

* Symbols of volume may differ from the actual symbols used in the LCD.

The following is an example of operation when you use this function.

1. In <<SETUP MODE>> initial screen, press

ENTER

.

The <<SETUP MODE>> menu screen (Paper

Length Check) appears.

Remarks

Dark (low contrast)

to (seven steps)

Bright (high contrast)

<<SETUP MODE>>

<<SETUP MODE>>

Paper Length Check

Ready

2. Press repeatedly until “LCD Contrast”

appears in the lower line of the menu screen.

3. Press

ENTER

.

The option select screen appears with the

current setting n n q q q q (no blinking but

changeable).

<<SETUP MODE>>

LCD Contrast

LCD Contrast

Dark n n q q q q Bright

6-29

Page 82

4. Press or .

The displayed option changes (n n n q q q

to n n n n n n, q q q q q q or n q q q q

q).

LCD Contrast

Dark n n n q q q Bright

5. When the desired option appears, press

ENTER

to save the change.

<<SETUP MODE>>

LCD Contrast

The LCD returns to the <<SETUP MODE>>

menu screen (LCD Contrast).

6. Press

CANCEL

two times.

Ready

The LCD returns to the Ready screen.

Picking speed

This function sets the rotational speed of the pick roller. Slow speed is recommended when you use

thin or flexible paper which is liable to mis-pick.

Options

Picking Speed

NOTE

Slow, Middle, Fast (Default: Fast)

Processing speed of scanning is reduced when the picking speed is set “Slow” or “Middle”.

RemarksLCD display

Set “picking speed” according to the table below.

Picking speed

Fast

(factory default)

Middle

Slow

6-30

“Mis-pick” frequently occurs.

Make the picking

speed slow.

Page 83

The following is an example of operation when you use this function.

MENU

1. In <<SETUP MODE>> initial screen, press

ENTER

The <<SETUP MODE>> menu screen

(Paper Length Check) appears.

2. Press repeatedly until “Picking Speed”

appears in the lower line of the menu screen.

3. Press

The option select screen appears with the

current setting Fast blinking (blinking indicates “changeable”).

4. Press or .

The displayed option changes (Fast to Slow).

5. Press

The LCD returns to the <<SETUP MODE>>

menu screen (Picking Speed).

6. Press

The LCD returns to the Ready screen.

.

ENTER

ENTER

CANCEL

.

to save the change.

two times.

<<SETUP MODE>>

<<SETUP MODE>>

Paper Length Check

<<SETUP MODE>>

Picking Speed

Picking Speed

Fast