Page 1

C150-E21 1-01EN

fi-4640S Image Scanner

Cleaning and Maintenance

Page 2

Revisions, Disclaimers

Revisions

Edition Date published Revised contents

01 July, 2001 First edit ion

FCC declaration: This equipment has been tested and found to comply with

the limits for a Class B digital device, pursuant to Part 15 of the FCC Rules.

These limits are designed to provide reasonable protection against harmful

interference in a residential installation. This equipment generates, uses, and

can radiate radio frequency energy and, if not installed and used in accordance

with the instruction manual, may cause harmful interference to radio communications. However, there is no guarantee that interference will not occur in a

particular installation. If this equipment does cause harmful interference to radio

or television reception, which can be determined by turning the equipment off

and on, the user is encouraged to try to correct the interference by one or more

of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from that to which

the receiver is connected.

• Consult the dealer or an experienced radio/TV technician for help.

Specification No. C150-E211-01EN

FCC warning: Changes or modifications not expressly approved by the party

responsible for compliance could void the user's authority to operate the

equipment.

NOTE

• The use of a non-shielded interface cable with the referenced device is

prohibited. The length of the parallel interface cable must be 3 meters (10

feet) or less. The length of the serial interface cable must be 15 meters (50

feet) or less.

• The length of the power cord must be 3 meters (10 feet) or less.

i

Page 3

This Class B digital apparatus complies with Canadian ICES-003.

Cet appareil numérique de la classe B est conforme à la norme NMB-003 du

Canada.

High Safety Required Use: The Product is designed, developed and manufactured as contemplated foe general use, including without limitation, general

office use, personal use and household use, but is not designed, developed and

manufactured as contemplated for use accompanying fatal risks or dangers

that, unless extremely high safety is secured, could lead directly to death,

personal injury, severe physical damage or other loss (hereinafter "High Safety

Required Use"), including without limitation, nuclear power core control, airplane

control, air traffic control, mass transport operation control, life support, weapon

launching control. The Customer shall not use the Product without securing the

sufficient safety required for the High Safety Required Use. In addition, Fujitsu

(or other affiliate's name) shall not be liable against the Customer and/or any

third party for any claims or damages arising in connection with the High Safety

Required Use by the Customer of the Product.

As an ENERGYSTAR ® Partner, Fujitsu Limited declares that this scanner meets

the ENERGYSTAR ® guidelines for energy efficiency. ENERGYSTAR ® is a U. S.

registered mark.

Changes

The contents of this manual may be revised without prior notice.

FUJITSU reserves the right to make changes to any products herein, to improve reliability, function, or design, without further notice and without obligation.

Copyrights

All Rights Reserved, Copyright © 2001, FUJITSU LIMITED.

Printed in Japan.

No part of this manual may be reproduced in any form without permission.

ii

Page 4

Fujitsu Offices

Please send your comments on this manual or on Fujitsu products to the

following addresses:

FUJITSU COMPUTER PRODUCTS OF

AMERICA,INC.

2904 Orchard Parkway,San Jose.

California 95134-2022,U.S.A.

TEL:1-408-432-6333

FAX:1-408-432-3908

http://www.fcpa.com/

FUJITSU AUSTRALIA LIMITED

Fujitsu Hause 2 Julius Avenue North Ryde

N.S.W 2113 AUSTRALIA

TEL:61-2-9776-4555

FAX:61-2-9776-4019

http://www.fujitsu.com.au/

FUJITSU CANADA,INC.

2800 Matheson Blvd.East,Mississauga.

Ontario L4W 4X5,CANADA

TEL:1-905-602-5454

FAX:1-905-602-5457

http://www.fujitsu.ca/

FUJITSU DEUTSCHLAND GmbH.

Frankfurter Ring 211,

8000 München 40,F.R,GERMANY

TEL:49-89-32378-0

FAX:49-89-32378-100

http://www.fujitsu.de/

FUJITSU ESPAÑA,S.A

Edificio torre Europa 5

Paseo de la Castellana 95

Madrid 28046,SPAIN

TEL:34-1-581-8000

FAX:34-1-581-8300

http://www.fujitsu-europe.com/home/

a

FUJITSU FRANCE S.A.

I, Place des Etats-Unis, SILIC 310,

94588 Rungis cedex, FRANCE

TEL:33-1-4180-3880

FAX:33-1-4180-3866

http://www.fujitsu-europe.com/home/

FUJITSU COMPUTERS (SINGAPORE) PTE,

LTD.

20 Science Park Road #03-01, Tele Teck Park

Singapore Science Park II, Singapore 117674

Republic of Singapore

TEL:65-777-6577

FAX:65-771-5669

http://www.fujitsu-computers.com.sg/

FUJITSU HONG KONG Limited

10/F, Lincoln House, Taikoo Place,

979 King’s Road, Island East, Hong Kong

TEL:852-827-5780

FAX:852-827-4724

TLX:62667

http://www.fujitsu.com.hk/

FUJITSU ITALIA S.p.A.

Via Nazario Sauro, 38

20099 Sestos, Giovanni (MI), ITALY

TEL:39-2-26294-1

FAX:39-2-26294-201

http://www.fujitsu-europe.com/home

FUJITSU NORDIC AB

Kung Hans väg,S-192 68 Sollentuna, SWEDEN

TEL:46-8-626-4500

FAX:46-8-626-4588

http://www.fujitsu-europe.com/home

FUJITSU EUROPE LTD.

2,Longwalk Road,Stockey Park,Uxbridge

Middlesex,UB11 1AB,U.K

TEL:44-81-573-4444

FAX:44-81-573-2643

http://www.fujitsu-europe.com/home

FUJITSU LIMITED

International Operations

Marunouchi 1-6-1, Chiyoda-ku,

Tokyo 100 JAPAN

TEL:(81-3)3216-3211

FAX:(81-3)3213-7174

TLX:J2283

Cable:”FUJITSU LIMITED TOKYO”

http://www.fujitsu.co.jp/

iii

Page 5

Note, Liability

READ ALL OF THIS MANUAL CAREFULLY BEFORE USING THIS PRODUCT. IF NOT USED CORRECTLY, UNEXPECTED INJURY MAY BE

CAUSED TO USERS OR BYSTANDERS.

While all efforts have been made to ensure the accuracy of all information in

this manual, FUJITSU assumes no liability to any party for any damage caused

by errors or omissions or by statements of any kind in this manual, its updates

or supplements, whether such errors are omissions or statements resulting from

negligence, accidents, or any other cause. FUJITSU further assumes no

liability arising from the application or use of any product or system described

herein; nor any liability for incidental or consequential damages arising from the

use of this manual. FUJITSU disclaims all warranties regarding the information

contained herein, whether expressed, implied, or statutory.

iv

Page 6

Preface

This manual explains how to clean and maintain the fi-4640S image scanner.

The fi-4640S is a very fast and highly functional image scanner developed for

high quality image processing, using charge-coupled device (CCD) image

sensors. This scanner features high speed simplex scanning with an automatic

document feeder (ADF).

Refer to the Operator’s Guide for basic information about the fi-4640S.

v

Page 7

Conventions

Important information that requires special attention is indicated as follows:

WARNING

WARNING indicates that serious personal injury may result if you do not follow

a procedure correctly.

CAUTION

CAUTION indicates that minor personal injury, loss of data, or damage to the

scanner may result if you do not follow a procedure correctly.

Official Fujitsu part names are indicated with an initial capital letter, as in the

part name “Pick roller”.

NOTE

A NOTE provides “how-to” tips or suggestions to help you perform a procedure

correctly.

vi

Page 8

CONTENTS

CHAPTER 1 DESCRIPTION ............................................................... 1-1

CHAPTER 2 CLEANING ..................................................................... 2-1

CHAPTER 3 REPLACEMENT OF PARTS.......................................... 3-1

Units ............................................................................... 1- 2

Assemblies..................................................................... 1- 4

Operator Panel................................................................ 1 -5

Panel Display.................................................................. 1-6

Cleaning Supplies and Area Requiring Cleaning.............. 2-2

Supplies .................................................................... 2- 2

Areas Requiring Cleaning.......................................... 2- 3

Cleaning the ADF............................................................ 2 -4

Cleaning the Flatbed ..................................................... 2-10

Pad Assembly ................................................................ 3-2

Pick Roller ...................................................................... 3-4

CHAPTER 4 TROUBLESHOOTING .................................................... 4-1

Clearing Paper Jams....................................................... 4-2

Initial Checks .................................................................. 4-3

Problem Checklist......................................................... 4-20

vii

Page 9

CHAPTER

1

DESCRIPTION

DESCRIPTIONCLEANINGREPLACEMENT

CHAPTER

CHAPTER

CHAPTER

2

3

4

REPLA CEMENT OF PARTS

TROUBLESHOOTING

CLEANING

OF PARTS

TROUBLESHOOTING

Page 10

CHAPTER

1

DESCRIPTION

This chapter describes units, assemblies, indicators and LED

functions.

Units

Assemblies

Operator Panel

Panel Display

1-1

Page 11

Units

6

1

ADF

2

ADF

lever

3

ADF paper chute

Document cover

7

Document holding pad

5

Stacker

13

Power switch

12

Power inlet

4

Oparator panel

11

EXT

connector

9

Option board slot

(Third party slot)

10

Interface

connector

8

Document bed

1-2

Page 12

o

N

Function

1

Automatically feeds documents to the reading position.

Opens/closes ADF to enable the removal of jammed documents.

2

3

Holds the documents to be fed by ADF.

Displays the status of the scanner. Also displays buttons that enable the

4

operator to change settings in Feed mode, Manual Feed mode, and Setup

mode.

5

Stacks the read documents.

6

Covers the document to be read.

7

Presses the document to the Document bed.

8

Holds the document to be read. Also called Fl atbed (FB).

9

An option board is installed.

DESCRIPTION

10

11

12

13

Connects to the host system with inte rface cables.

Connects to an optional imprinter.

Connect the power cable from an AC power outlet here.

Pow er s witc h.

1-3

Page 13

Assemblies

Stacker

Thumb screw

Guide A ASY

Pick roller 2

Pad ASY

Pick roller 1

1-4

Page 14

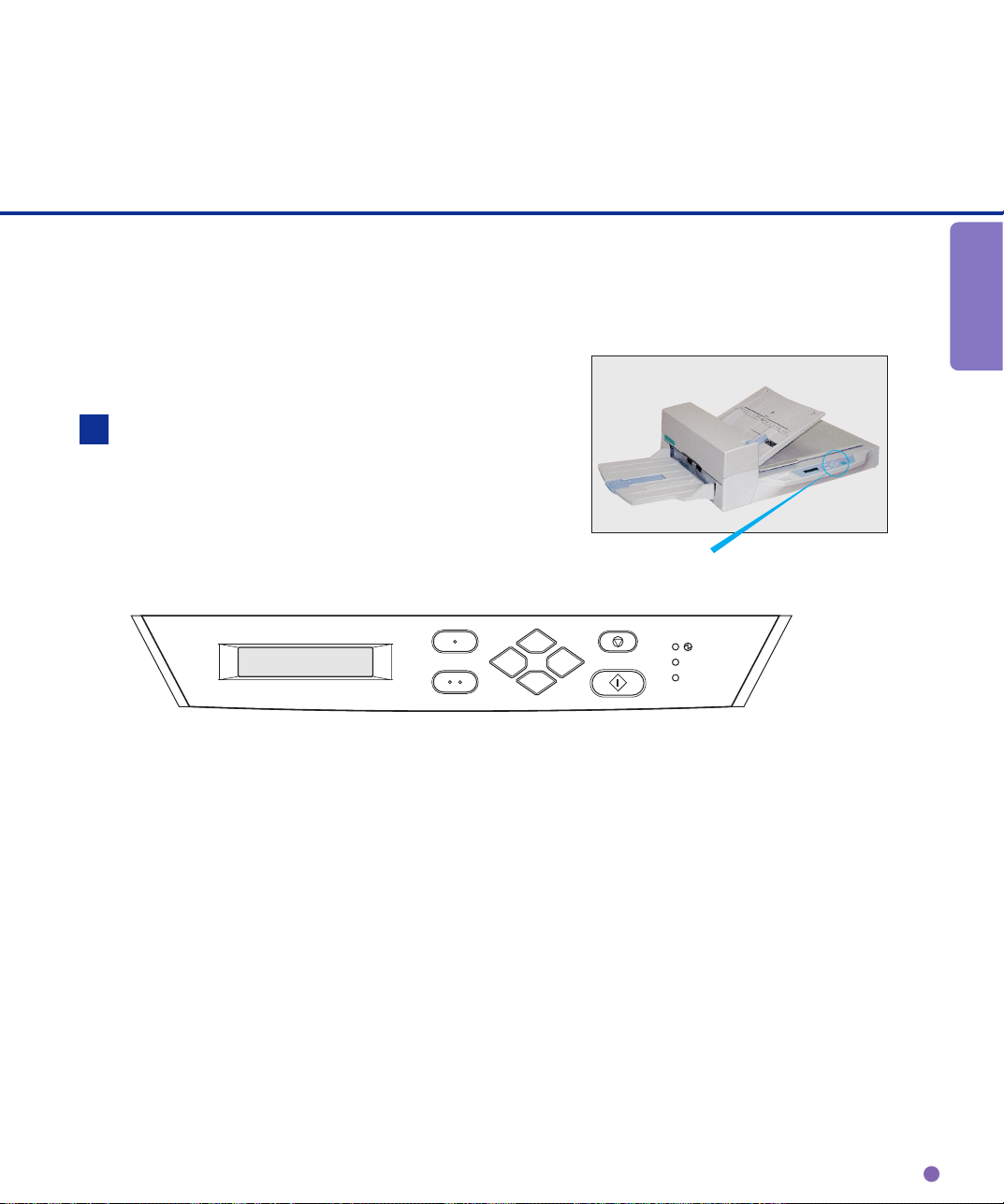

Operator panel

The Operator panel is located on the

upper right hand side of the scanner.

The panel consists of an LCD (16

characters x 2 lines), LEDs, and

buttons.

Arrangement

DESCRIPTION

Operator panel

Exit

Enter

Previous

Next

Stop

Send To/

Start

Read

Check

1-5

Page 15

Panel Display

Button/LED Function

Name of the button and

LED

Button Next

Previous

Exit When you are entering settings on the Operator panel, pressing this button

Enter

Send To/

Start

Stop Operarional only during the read operation when the video interface option is

LED

Read

Check

Function

Displays the next LCD screen.

Displays the previous LCD screen.

Moves the curs or to t he l ef t.

Moves the cursor to the right.

returns you immediately to the Scanner Ready screen.

Enters the parameter currently selected by the cursor.

Operational only while the Read lamp lights when Manual start mode is set or

the video interface option is used, and starts the reading. Some application

software packages might use this button.

used, and stops the reading.

When the Check LED lights, pressing this button releases the error status

(turns off Check and returns to the Scanner Ready screen). Also turns off the

Check lamp.

Indicates that the scanner is On.

Indicates the scanner is reading or ready to read.

l If lit, this indicates that an alarm occurred. Pressing the Stop button

turns the Check lamp Off.

l If it blinks at one second intervals, this means that a jam or double feed

has been detected. If the problem is jammed paper, removing the jammed

paper turns off the Check lamp. If the problem is double feed, pressing

the Stop button turns off the Check lamp.

l If it blinks at four seconds intervals, this means that cleaning the ADF is

necessary.

1-6

Page 16

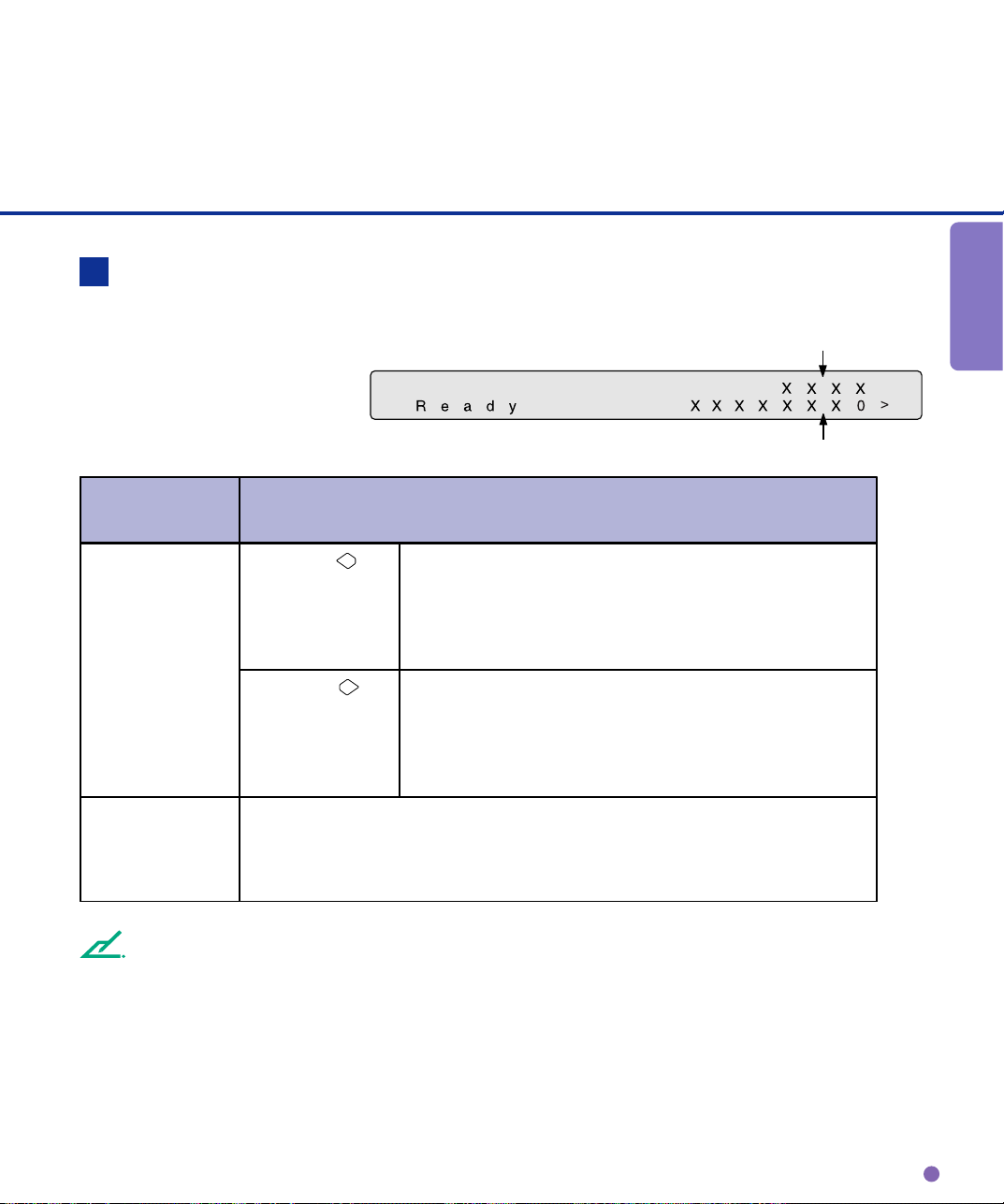

Counter Display

The scanner is provided with a

counter display.

Counter Function

Paper counter

Abrasion counter

DESCRIPTION

Paper counter When the

button is pressed

When the

button is pressed

Abrasion counter Abrasion counter counts the accumulated number of the scanned sheet. This

counter increments at every 10 sheets. This counter is useful to check the

cleaning cycle or par ts replac ement cycle. How to reset is described in

Chapter 6 of the Operator’s Guide.

NOTE

When the counter value is 0, no number is displayed.

The paper counter counts the number of scanned sheets

from the star t of re ading until Paper Empty or until an

error is detected. The counter is automatically reset at

the start of r eading. The counter is used for checking

the number of sheets scanned at one time.

This counter increments each time a document is

scanned. The counter is not initialized until the power is

turned off. The counter can be used, for example, for

checking the number of sheets that have been scanned

in one day.

1-7

Page 17

Panel Display

Operation status

The operation status is indicated by the following messages:

<Power-on>

<Reading>

<Low Power Mode> When the Scanner Display turns Off and the power indicator

remains “On”, the scanner is in the Low Power Mode.

NOTE

One of the following will wake up the scanner:

• Pressing any button.

• Setting the paper on the ADF.

• Sending a command from the host computer.

<Waiting for Start> The scanner displays the following screen when waiting for the

Start button to be pressed:

(Only When the Video Interface

Option is installed.)

<Cleaning request> When the Pick roller cleaning is necessary, the scanner displays

the following on the upper line:

When the ADF glass cleaning is necessary, the scanner displays

the following on the LCD:

Clean the Pick roller or the ADF glass in accordance with the

instructions given in chapter 2, Cleaning the ADF, and chapter 3,

Pick Roller.

1-8

Page 18

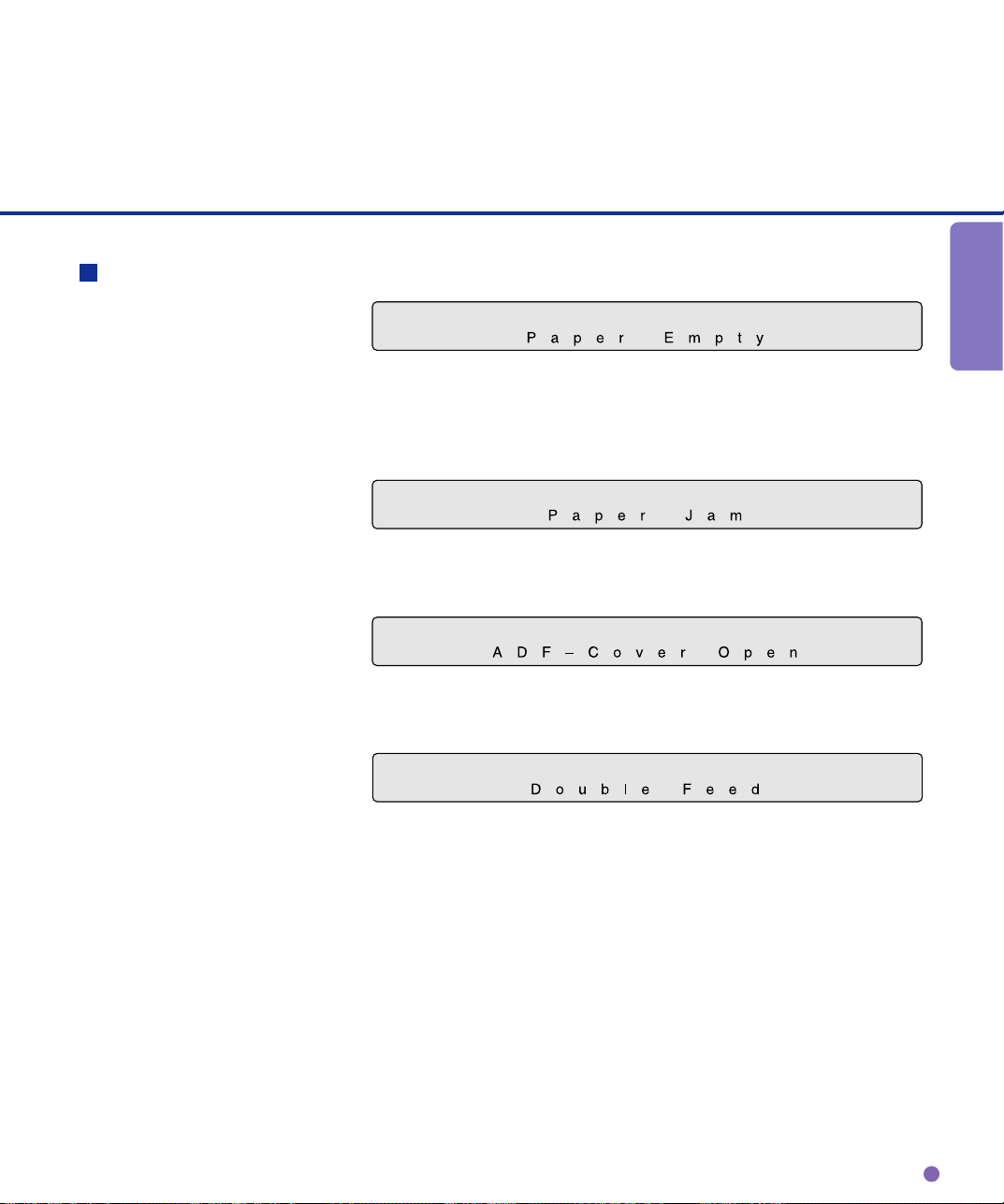

Temporary error

<Hopper empty>

<Jam>

<ADF cover open>

<Double feed error>

DESCRIPTION

This message is displayed if there is no more paper on the ADF

paper chute during a read operation in ADF mode. Fill the ADF

paper chute with paper. To enable the read operation, press the

stop button.

This message is displayed if a document is jammed in the ADF.

See Chapter 4 for removing jammed ducuments.

This message is displayed if the ADF is not closed completely.

Close the ADF completely, and enable the read operation.

This message is displayed when the ADF detects a Double feed

error. Check the document and re-scan it.

1-9

Page 19

Alarm

One of the following messages is displayed if an error occurs in the scanner. If one of the following

error messages is displayed, turn the power Off and then On again. If the same message is displayed,

contact your service representative.

<Optical alarm>

<FB mechanism alarm>

NOTE

When the total number of sheets scanned by the ADF is less than 100, the message above and the

message below are displayed alternately. Remove the bracket (Shipping Lock) that holds the carrier

in place.

<Motor fuse alarm>

<Lamp fuse alarm>

<Image transfer alarm>

(only when SCSI is used)

<Memory alarm>

1-10

Page 20

<EEPROM alarm>

<FAN alarm>

<IPC board alarm>

NOTE

When this message is displayed, turn Off system power and then turn it On again. Alternatively,

replace the current cable with one recommended by the manufacturer of the SCSI board. When the

cause of the alarm has been corrected, the scanner automatically resumes operation once power is

turned On again.

DESCRIPTION

1-11

Page 21

CHAPTER

2

CLEANING

This chapter describes cleaning supplies, areas that require cleaning, and procedures for cleaning the ADF and the flatbed.

Cleaning Supplies and Areas Requiring

Cleaning

Cleaning the ADF

Cleaning the Flatbed

2-1

Page 22

Cleaning Supplies and Areas Requiring Cleaning

Document cover

Document

holding pad

Document

bed

Supplies

Supply No.

Cleaning paper 0631180 Every 5,000 sheets 10 sheets

Cleaner F2 0631160 • Plastic rollers (*2) 1 bottle

Cleaner F1 or 0631150 • PAD assembly 1 bottle.

Isopropyl alcohol Every 5,000 sheets Apply Cleaner F1

• Pick roller/Feed rollers/ to cloth.

Glass/Sheet guide

Every 5,000 sheets

Cotton swab

Dry cloth

For more information on cleaning supplies, contact your dealer.

*1 If the display on the operator panel shows “Please clean Pick-roller”, then clean it regardless of the

frequencies recommended here.

*2

CAUTION

Do not clean the rubber rollers with cleaner F2.

*3 Refer to the Abrasion counter on the Operator panel to estimate when the next cleaning is necessary.

NOTE

When the following paper types are used, it may be necessary to clean more frequently:

• Paper with a smooth surface, such as coated paper.

• Paper almost entirely covered with printing.

• Paper with special chemical coatings, such as carbonless paper.

• Paper including a great quantity of calcium.

• When reading a great many documents written with a pencil.

RemarksSupplies Frequencies (*1)(*3)

Apply Cleaner F2

to cotton swab.

2-2

Page 23

Areas Requiring Cleaning

Area

Flatbed

ADF

ADF

Name

Document holding pad

Document bed

Pad

Glass/Sheet guide

Pick roller

Plastic rollers

Feed rollers

Pick arm rollers

Cleaning paper

with Cleaner F1

Document holding

pad

Document bed

with Cleaner F1

Feed rollers

Dry cloth

Pick arm

roller

Cotton swab

with Cleaner F1 or F2

Sheet guide

Pad

(white part)

Plastic rollers

CLEANING

Pick roller

Plastic rollers

Glass

2-3

Page 24

Cleaning the ADF

pow-on

Cleaning the ADF with cleaning paper

Pull the ADF lever to open the

1

ADF.

Lightly spray a new piece of

2

cleaning paper with cleaner

F1.

Place the cleaning paper on

3

the ADF so that the edge of the

short side touches the Plastic

roller.

Close the ADF and turn the

4

power on to start the cleaning.

After making sure the cleaning

5

stops, turn the power off.

Turn the cleaning paper

6

upside down, repeat steps 1

through 5.

Cleaning paper

Cleaning

paper

Plastic

rollers

2-4

Page 25

Cleaning the ADF with a Dry cloth or a Cloth with Cleaner F1

Pull the ADF lever to open the

1

ADF.

Use a dry cloth or a cloth

2

moistened with Cleaner F1 to

softly remove dirt and dust as

follows.

Pad assembly :

Wipe the pad in a downward

direction (as indicated by the arrow).

Be careful not to catch the spring for

the Pick roller when wiping.

CLEANING

Pad assembly

Glass:

Wipe the glass lightly.

NOTE

If the glass is dirty, the image may include

black vertical stripes.

Glass

2-5

Page 26

Pick roller:

Wipe the roller.

Pick roller

Be careful not to damage the surface

of the roller and the mylar strip above

the Pick roller.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Feed rollers :

and Plastic rollers

Wipe the rollers.

Be careful not to damage the surface

of the rollers.

2-6

Feed rollers

Plastic rollers

Plastic rollers

Page 27

Sheet guide (white part):

Sheet guide (white part)

Wipe the sheet guide.

NOTE

If the Sheet guide is dirty, the front image may

show vertical stripes.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Close the ADF to lock the ADF

3

lever.

CAUTION

Don’t wipe the pad rubbers with the F2 cleaner.

CLEANING

2-7

Page 28

Cleaning the Pick Arm Rollers

Pull the ADF lever to open the

1

ADF.

Moisten a cotton swab or Dry

2

cloth with F1 or F2 Cleaner.

Wipe the small Plastic rollers

3

at the tip of the Pick Arm.

Wipe the small Plastic rollers

4

and the Pick Arm with a clean,

dry cloth to dry them.

NOTE

When non-carbon paper is used, the Pick Arm rollers may become dirty with a black substance. Use Cleaner

F2 to remove the contamination.

CAUTION

Don’t wipe the pad rubbers with the F2 cleaner.

2-8

Page 29

Cleaning the Plastic rollers with Cleaner F2

Pull the ADF lever to open the

1

ADF.

Moisten a cotton swab with

2

Cleaner F2.

Wipe the Plastic roller

3

surfaces.

CAUTION

Don’t wipe the Pick Rollers with a cotton swab

using cleaner F2.

Wipe the Plastic roller surface

4

with a clean, dry cloth. Allow it

to dry.

Plastic rollers

CLEANING

Plastic rollers

2-9

Page 30

Cleaning the Flatbed

Cleaning the Flatbed with a Cloth and Cleaner F1

Document cover

Document

holding pad

Document bed

NOTE

Window or glass cleaner, excluding those not allowed for plastics, can be used instead of cleaner F1.

However, do not use organic solvents like thinner.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Open the Document cover.

1

Apply Cleaner F1 to a clean

2

cloth.

Wipe the Document holding

3

pad and the Document bed.

Allow them to dry.

4

NOTE

Be sure to prevent liquid from seeping through the opening between the Document bed and the plastic cover.

2-10

Page 31

CHAPTER

3

REPLACEMENT OF PARTS

This chapter describes how to replace the pad assembly and the

pick roller.

Pad Assembly

Pick Roller

3-1

Page 32

Pad Assembly

ADF lever

Pad ASY

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

NOTE

The life span of the pad assembly is about

100,000 sheets or one year. Use the Abrasion

counter on the Operator panel to estimate when

the Pad assembly needs replacement. The life

span may be decreased by as much as half

when carbonless paper is read frequently.

WARNING

Turn off the power before replacing the Pad

Assembly.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Pick Arm

Pull the ADF lever to open the

1

ADF.

Push the Pick Arm carefully.

2

3-2

Page 33

Slide the Pad Assembly to the

3

left and pull it towards you.

Then, being careful not to hook

the spring for the Pad, remove

the Pad Assembly.

NOTE

Hold both ends of the Pad assembly as shown

in the right photo.

CAUTION

Don’t hold the sensor arm with the Pad

assembly.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Attach the Pad Assembly to

4

Pad assembly

the ADF in the reverse

sequence of step 3.

NOTE

Fit the Pad assembly pin into the larger hole,

then slide it to the right until it stops.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Close the ADF.

5

OF PARTS

REPLACEMENT

3-3

Page 34

Pick Roller

Pick rollers

(Two rollers are included)

NOTE

The life span of the Pick roller is about 200, 000 sheets or one year.

Use the Abrasion counter on the operator panel to estimate when the Pick roller needs replacement.

The life span may be decreased by as much as half when carbonless sheets are frequently read.

WARNING

Turn off the power before replacing the Pick Rollers.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Pull the ADF lever to open the

1

ADF.

Remove the two Thumb

2

screws.

NOTE

Use a Phillips screwdriver if they are tight.

Thumb screws

3-4

Page 35

With both hands, lift up Guide

3

A and disengage its tip from

the right hole. Then lift the right

side of the cover and remove

it.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

To remove the Pick rollers,

4

turn the stopper counterclockwise.

Stopper

Pick roller 2

Pick roller 1

OF PARTS

REPLACEMENT

Position for Replacement

3-5

Page 36

To remove the Pick roller 1,

5

move it to the left and then lift

it.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Immediately after removing the

6

Pick roller 1, remove the Pick

roller 2 in the same way.

3-6

Page 37

To attach the new Pick rollers,

7

place Pick roller 1 from the

right side above the bearing for

Pick roller 1.

NOTE

Pick roller 1 has a groove in its rubber.

Put the shaft of Pick roller 1

into the bearing. Then, slide

Pick roller 1 toward the right

side.

OF PARTS

REPLACEMENT

NOTE

Make sure that the shaft is securely fixed to the bearings.

3-7

Page 38

Attach Pick roller 2, in the

8

same way as Pick roller 1 as

shown in step

Then slide the Pick roller 2

toward right side.

7

.

NOTE

Make sure that the shaft is securely fixed to the bearings.

3-8

Page 39

Turn the stopper clockwise to

9

secure the Pick rollers.

Stopper

OF PARTS

REPLACEMENT

Operating Position

3-9

Page 40

Guide A

10

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

11

12

Attach Guide A in the reverse

sequence of step 3 and align

the screw hole. See the

graphic on page 1-4.

Tighten the thumb screws.

Close the ADF unit.

3-10

Thumb screws

Page 41

CHAPTER

4

TROUBLESHOOTING

This chapter describes how to clear paper jams and run initial

checks. It also contains a Problem Checklist that should be completed before you call a service representative.

Clearing Paper Jams

Initial Checks

Problem Checklist

4-1

Page 42

Clearing Paper Jams

Document

ADF

ADF lever

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Remove all the documents

1

from the ADF paper chute.

Pull the ADF lever to open the

2

ADF.

Remove the jammed

3

document(s).

NOTES

- Inspect the paper and the paper path. Make sure no staples, paper clips or other materials caused the jam.

All staples and paper clips should be removed from all documents bofore scanning.

- Be careful not to pull the spring for the Pad while removing a jammed document.

4-2

Close the ADF so that the ADF

4

lever locks.

Page 43

Initial Checks

If a problem occurs, check the following items before contacting the manufacturer’s authorized service

center.

Symptom 1

The power does not go On.

Is the power cable

connected correctly?

YES

Is the power switch on?

YES

Contact the manufacturer’s authorized

service center.

(No light)

NO

Connect the power cable

correctly.

NO

Press the power switch.

TROUBLESHOOTING

4-3

Page 44

Symptom 2

The operator panel turns “Off”.

Power “On”

Has it been a long time

since the scanner was last

used?

NO

Did the scanner enter this

state quickly?

NO

Did you load the paper on

the ADF?

NO

Have 10 seconds passed

since the PC instructed a

scan?

YES

Press any button on the

operator panel to wake up the

system.

YES

Extend the time for entering

"Low Power Mode" in Set Up

Mode.

YES

Load the paper again, or

press any button on the

operator panel.

YES

Wait for at least 10 seconds.

YES

Contact the manufacturer’s authorized

service center.

4-4

Page 45

Symptom 3

Read operation does not start.

Is the Shipping Lock

placed in an operating

position?

YES

Are the documents loaded

correctly on the ADF paper

chute?

YES

Is the ADF completely

closed?

YES

Is the interface cable

connected correctly?

NO

NO

NO

NO

Place the Shipping Lock

correctly.

(See the Operator’s Guide,

p. 2-4)

Insert the documents into the

slot.

Completely close the ADF.

TROUBLESHOOTING

Connect the interface cable

correctly.

YES

4-5

Page 46

Is the scanner the last

device of the SCSI chain?

YES

NO

The termination should be

turned off via the front panel.

Is the SCSI ID set

correctly?

YES

Is the baud rate of the

system 4800 bps?

(When you use the Fujitsu

video interface board.)

YES

CHECK

Is the CHECK indicator lit?

Is an Alarm displayed?

YES

Contact the manufacturer’s authorized

service center.

NO

NO

NO

Set the SCSI ID correctly.

Use the operator panel to

change the ID.

Contact the manufacturer’s

authorized service center to

set the correct baud rate.

The scanner works normally.

4-6

Page 47

Symptom 4

Pictures and photographs are not read correctly.

Is the “Photo” mode

selected?

YES

Is halftone or dither

processing selected?

YES

Are the Document bed,

Document holding pad,

glass, and sheet guides

clean?

YES

NO

NO

NO

Select the “Photo” mode

(White level following “Off”)

through the scanner setting

menu in the software.

Select the halftone or

dithering mode from the host

computer.

Clean the dirty parts.

(See p. 2-5, p. 2-7, p. 2-10)

TROUBLESHOOTING

Contact the manufacturer’s authorized

service center.

4-7

Page 48

Symptom 5

Characters and lines are not read correctly.

NO

3mm

Is the “Line Art” mode

selected?

YES

Is there any printed text on

the first 3mm of the

document?

NO

Are the Document bed,

Document holding pad,

glass, and sheet guides

clean?

YES

YES

NO

Select the “Line Art” mode

from the host computer.

Select the “Photo” mode

(White level following “Off”)

via software.

Clean the dirty parts.

(See p. 2-5, p. 2-7, p. 2-10)

Contact the manufacturer’s authorized

service center.

4-8

Page 49

Symptom 6

Images are distorted or unclear.

missing

Are the Document bed,

Document holding pad,

glass and sheet guides

clean?

YES

During rear read operation

with the ADF, is the top of

the ADF being pressed or

is there anything heavy on

it?

NO

Is the scanner on an even

and flat surface or are any

rubber feet of the scanner

missing?

YES

NO

YES

NO

Clean the dirty parts.

(See p. 2-5, p. 2-7, p. 2-10)

Do not press the top of the

ADF or put anything heavy on

it.

Place the scanner on a flat,

even surface or attach the

rubber feet.

TROUBLESHOOTING

Contact the manufacturer’s authorized

service center.

4-9

Page 50

Symptom 7

Images have vertical lines.

Did you scan the

document using the

Flatbed?

Are the lines white?

NO

Are the lines black?

NO

Contact the manufacturer’s authorized

service center.

YES

Contact the manufacturer’s

authorized service center.

YES

Clean the ADF Glass.

4-10

Page 51

Symptom 8

Immediately after power is turned on, the Check

indicator is on.

CHECK

Is the Shipping Lock

placed in operating

position?

YES

Turn off the power once

and then try to turn on the

CHECK

power again. Is the

CHECK lamp still on? Or is

an Alarm displayed?

YES

Contact the manufacturer’s authorized

service center.

NO

Place the Shipping Lock

correctly.

(See Operator’s Guide.)

NO

The scanner works normally.

TROUBLESHOOTING

4-11

Page 52

Symptom 9

“Please clean Pick-roller” is displayed.

YES

Is the Pick roller dirty?

NO

Do documents meet

specification described in

the Operator’s Guide?

YES

Is the Pad assembly dirty

or worn out?

NO

Clean the Pick roller.

(See p. 2-6)

NO

Flatten the curl or use the

Flatbed to read the document.

YES

Clean or replace the Pad

assembly.

(See p. 3-2, p. 3-3)

Contact the manufacturer’s authorized

service center.

4-12

Page 53

NOTES

NOTES

• Remove paper clips and staples. Flatten the staple holes.

• Read the following types of documents using the Flatbed:

- Paper with clips or staples.

- Paper with wet ink.

- Paper of uneven thickness (for example, envelopes).

- Paper with large rumples or curls.

- Paper with folds or tears.

- Tracing paper.

- Coated paper.

- Carbon paper.

- Paper shorter than A8 size (portrait) or larger than A3 or 11 x 17 inches.

- Materials other than paper (for example, cloth, sheet metal, or OHP film).

- Photographic paper.

- Paper with perforations on its sides.

- Non-rectangular paper.

- Very thin paper.

• The leading edge of all documents fed by the ADF should be straightened so the curl of the

paper meets the specifications below:

Less than

More than 30mm

3mm

Top of the paper Read surface

• Do not mix documents of different widths.

Feed direction

Less than

5mm

More than 30mm

Feed direction

Read surface

Top of the paper

TROUBLESHOOTING

4-13

Page 54

Symptom 10

Paper double feed occurs frequently.

Does the condition of the

documents meet the

requirements described in

the Operator’s Guide?

YES

When double feed

detection is ON, are all the

documents of the same

length?

YES

Are the documents fanned

before being loaded on the

ADF paper chute?

YES

NO

Flatten the curl or use the

Flatbed to read the

documents.

NO

Set double feed detection to

“Off”. (See the Operator’s

Guide)

NO

Fan the documents before

loading, or reduce the batch

size.

4-14

Have the documents

recently been printed by

copier or laser printer?

NO

YES

Fan the stack 3 or 4 times to

remove the static charge

applied to the paper.

Page 55

Is the document stack less

than 0.32” (8mm) in

height?

YES

Is the Pad dirty?

NO

Is the Pad worn out?

NO

NO

YES

YES

Reduce the batch size of the

documents.

Clean the Pad assembly.

(See p. 2-4)

Replace the Pad assembly.

(See p. 3-2)

TROUBLESHOOTING

Contact the manufacturer’s authorized

service center.

4-15

Page 56

Symptom 11

Mispick occurs frequently.

Do the conditions of the

documents meet the

requirements described in

the Operator’s Guide?

YES

Have the documents been

fanned before loading them

on the ADF paper chute?

YES

Is the Pad assembly

installed correctly?

YES

NO

Flatten the curl or use the

Flatbed to read the

documents.

NO

Fan the documents before

loading, or reduce the batch

size.

NO

Install it correctly.

(See p. 3-2)

4-16

Page 57

Is the Pick roller dirty?

NO

Is the Pick roller worn out?

NO

YES

Clean the Pick roller.

(See p. 2-6)

YES

Replace the Pick roller.

(See p. 3-4)

Contact the manufacturer’s authorized

service center.

TROUBLESHOOTING

4-17

Page 58

Symptom 12

Paper jams occur frequently.

Does the condition of the

document meet the

requirements on page

4-13?

YES

Are there any foreign

particles in the ADF?

NO

Contact the manufacturer’s authorized

service center.

NO

Flatten the curl or use the

Flatbed to read the document.

YES

Clean the ADF (see p. 2-4) or

remove the foreign particles.

4-18

Page 59

Symptom 13

“Please clean ADF glass” is displayed.

Is the ADF glass dirty?

NO

Contact the manufacturer’s authorized

service center.

YES

Clean the ADF glass.

(See p. 2-5)

TROUBLESHOOTING

4-19

Page 60

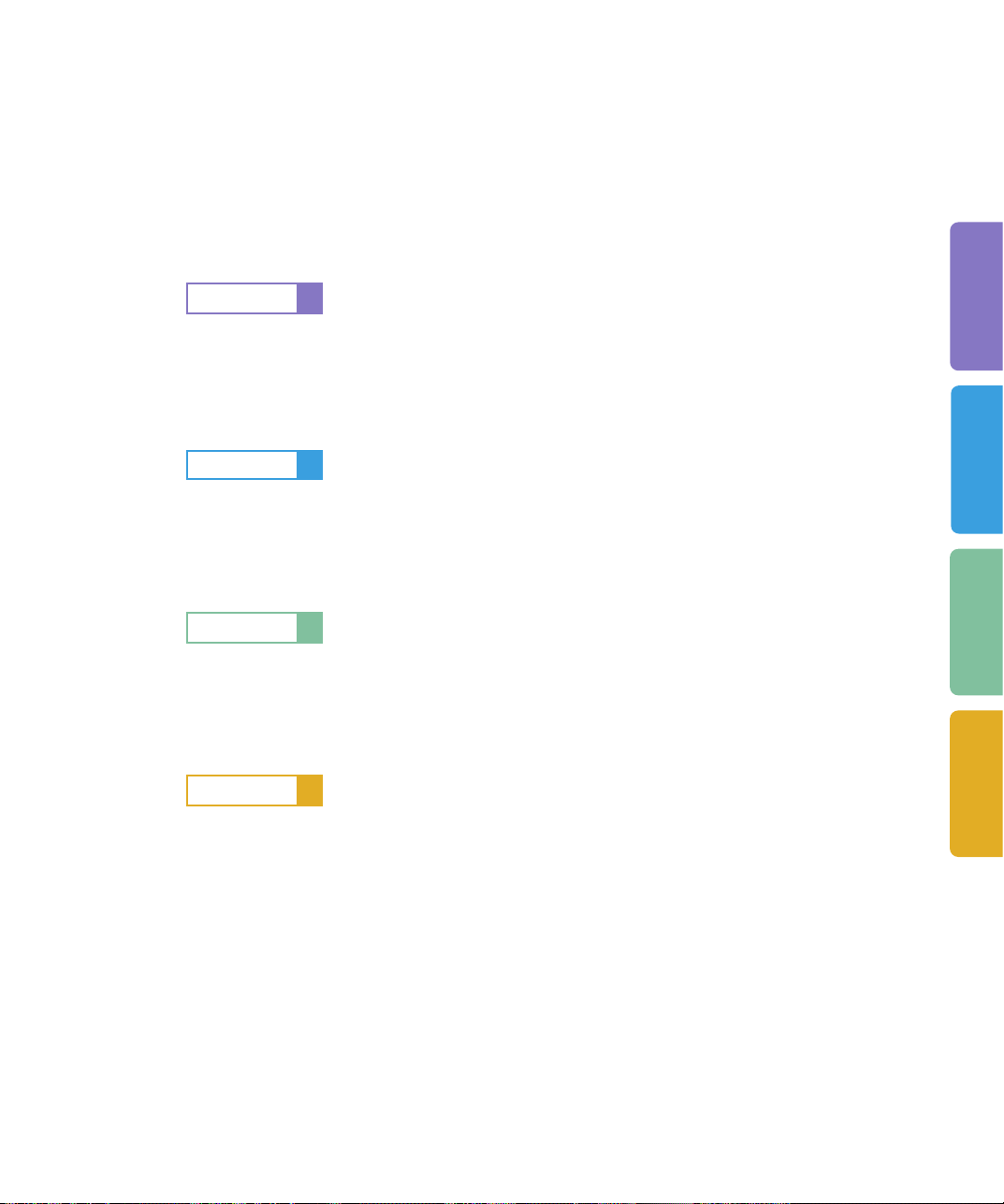

Problem Checklist

Before contacting the manufacturer’s authorized service center, please fill in the following items.

General

Model

Part number

Serial number

Manufactured date

Revision

A

0

123456789

B

0

123456789

C

0123456789

Date of purchase

Symptoms

Persistent problem?

Serviced before (when and how)?

Error status

Transport error

Type of document.

What is your daily usage?

Date of last cleaning.

Date of the consumable replacement.

(Example) fi-4640S

(Example) CA05951-6420

(Example) 00002

(Example) 2001-7

The revision is printed on the label

located at the left corner of the back.

The revision is indicated by the double line.

This example shows the revision A2.

Image error

Interface controller model

Software/application name

Can you send the original and output of

sheet by facsimile or by mail?

4-20

Page 61

Loading...

Loading...