Fujifilm X-M1 Service Manual

DIGITAL CAMERA

X-M1

SERVICE MANUAL

US/EE/EG/ME/RU/CH/JP-model

USE THE DESIGNATED AFTER-SALES PARTS AND THE DESIGNATED LEAD-FREE

THE COMPONENTS IDENTIFIED WITH THE MARK “

CAUTION

SOLDER WHEN PERFORMING REPAIRS. BECAUSE THIS PRODUCT COMPLIES WITH

RoHS LEAD-FREE. (Refer to page 3)

WARNING

AND THE PARTS LIST ARE CRITICAL FOR SAFETY.

” IN THE SCHEMATIC DIAGRAM

REPLACE THOSE COMPONENTS ONLY WITH THE COMPONENTS SPECIFIED IN THE

SCHEMATIC DIAGRAM AND THE PARTS LIST.

IF YOU USE PARTS NOT SPECIFIED, IT CAN RESULT IN A FIRE AND AN ELECTRICAL

SHOCK.

Ref.No.: ZM01086-107

Revised on 14 Aug 2014

Confidential: FUJIFILM Service Center Use Only

A

X-M1 Service Manual

SAFETY CHECK-OUT

During repair and safety checking, conduct the followings.

1. Check if there are unsoldered or poorly

soldered connections. Check the entire

board surface for solder splasher and

bridges.

2. Check the inter-board wiring to ensure that

no wires are "pinched" or contact highwattage resistors.

3. Look for unauthorized replaced parts,

particularly transistors that were installed in

a previous repair. Point this out to a

customer and recommend replacing with

authorized parts.

4. Look for parts which, though functioning,

signs of deterioration. Point this out to a

customer and recommend replacing with

new parts.

5. Check the B + voltage to see if it is the

correct value.

6. Check leakage current see if exposed parts

are insulated from power supply before

returning a camera to a customer.

7.

2.5A 125V

2.5A 125V

RISK OF FIREREPLACE FUSE

S MARKED

8.

CAUTION:

FOR PROTECTION

AGAINST FIRE HAZARD,

REPLACE ONLY WITH

SAME TYPE 2.5 AMPERES

125V/250V FUSE.

ATTENTION:

AFIN D'ASSURER UNE

PROTECTION

PERMANENTE CONTRE

LES RISQUES D'INCENDIE,

REMPLACER

UNIQUEMENT PAR UN

FUSIBLE DE MEME, TYPE

2.5 AMPERES, 125/250

VOLTS.

WARNING:

TO AVOID THE ELECTRIC

SHOCK, BE CAREFUL TO

TOUCH THE PARTS.

WARNING!

HIGH VOLTAGE

2

Confidential: FUJIFILM Service Center Use Only

X-M1 Service Manual

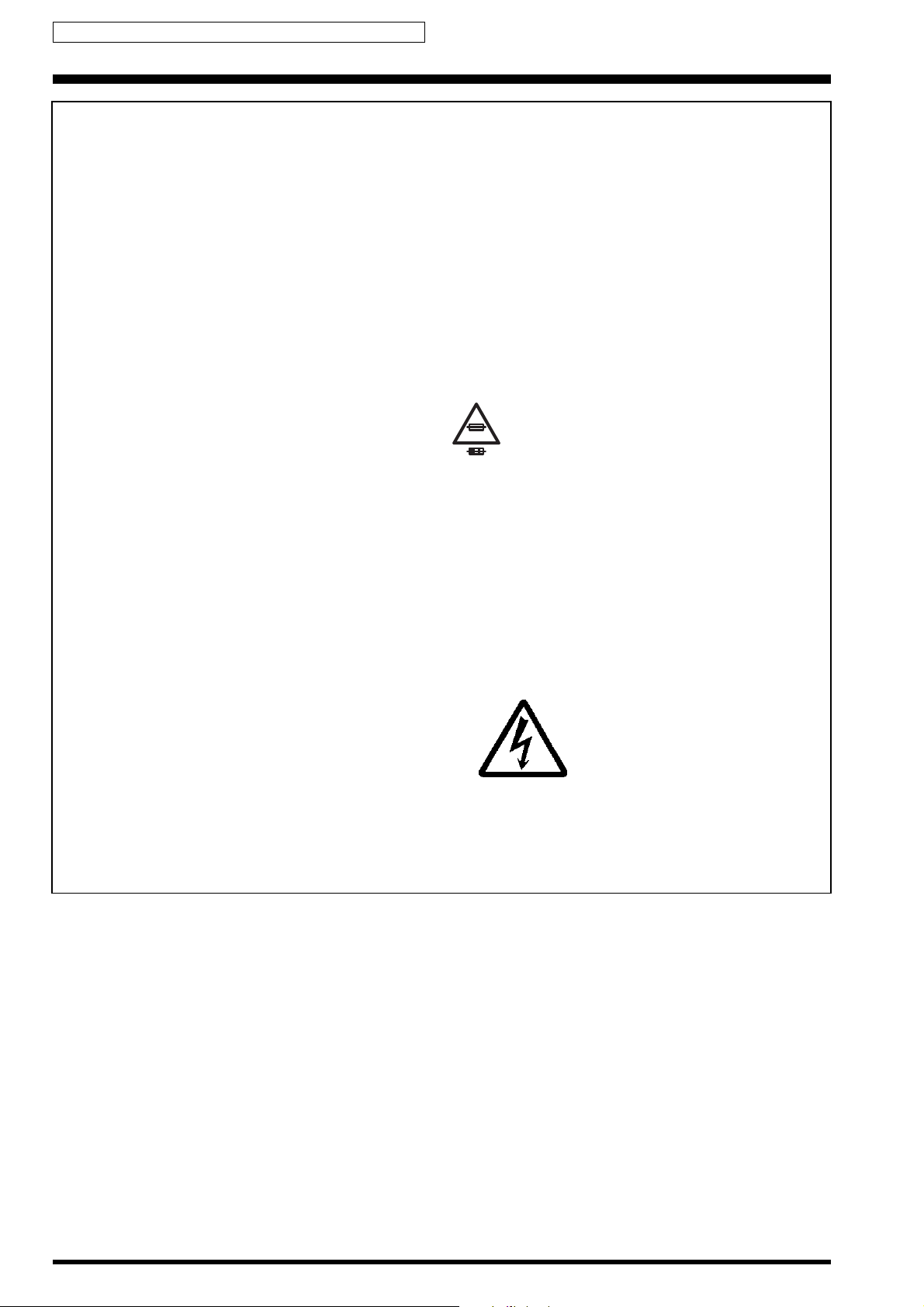

RoHS lead-free compliance

With the exception of parts and materials expressly excluded from the RoHS directive, all the internal con nections and

component parts and materials used in this product are lead-free compliant under the European RoHS directive (*1). Use the

specified parts and the specified lead-free solder when repairing.

*1: Definition of lead-free

A lead content ratio of 0.1 wt% or less in the applicable locations (solder, terminals, electronic components, etc.)

<Lead-free soldering>

When lead-free solder is used, soldering can be less working efficiency than when eutectic solder is used. When repairing,

use a specific lead-free solder, bearing in mind the difference between eutectic soldering and lead-free soldering.

Differences between lead-free and eutectic soldering

Melting point

Eutectic solder (Sn-Pb)

183°C 220°C

Lead-free solder

(Sn-Ag-Cu)

Remark

Soldering iron

temperature

Wetting

Surface

Example of recommended equipment and solder

Maintenance of soldering iron

Because of the high soldering iron temperature when lead-free soldering, Carbonization of the flux adhered to the tip of

the soldering iron proceeds faster than eutectic soldering.

(1) Always cover the tip of the soldering iron with solder when it is not used.

(2) If the tip becomes black by carbonization, wipe it gently with a paper towel soaked in alcohol so that the solder can

wet.

283°C 320°C

Good Poor

Gloss Matte

This should be determined by heat capacity

at a connecting portion and working

efficiency.

lead-free

Wire diameter

Solder type

(Displayed symbol)

SnAgCu

3

Confidential: FUJIFILM Service Center Use Only

X-M1 Service Manual

MEMO

4

Confidential: FUJIFILM Service Center Use Only

X-M1 Service Manual

CONTENTS

1. List of Jigs····································································································1-1

2. Disassembly ·································································································2-1

3. Adjustments ·································································································3-1

4. Inspection·····································································································4-1

5. Parts List······································································································5-1

5-1. Packing and Accessories·······································································5-1

5-2. Mechanical Block 1 ···············································································5-2

5-3. Mechanical Block 2 ···············································································5-3

5-4. Mechanical Block 3 ···············································································5-4

5-5. Electrical Parts ·····················································································5-5

6. Appendix······································································································6-1

5

Confidential: FUJIFILM Service Center Use Only

X-M1 Service Manual

MEMO

6

Confidential: FUJIFILM Service Center Use Only

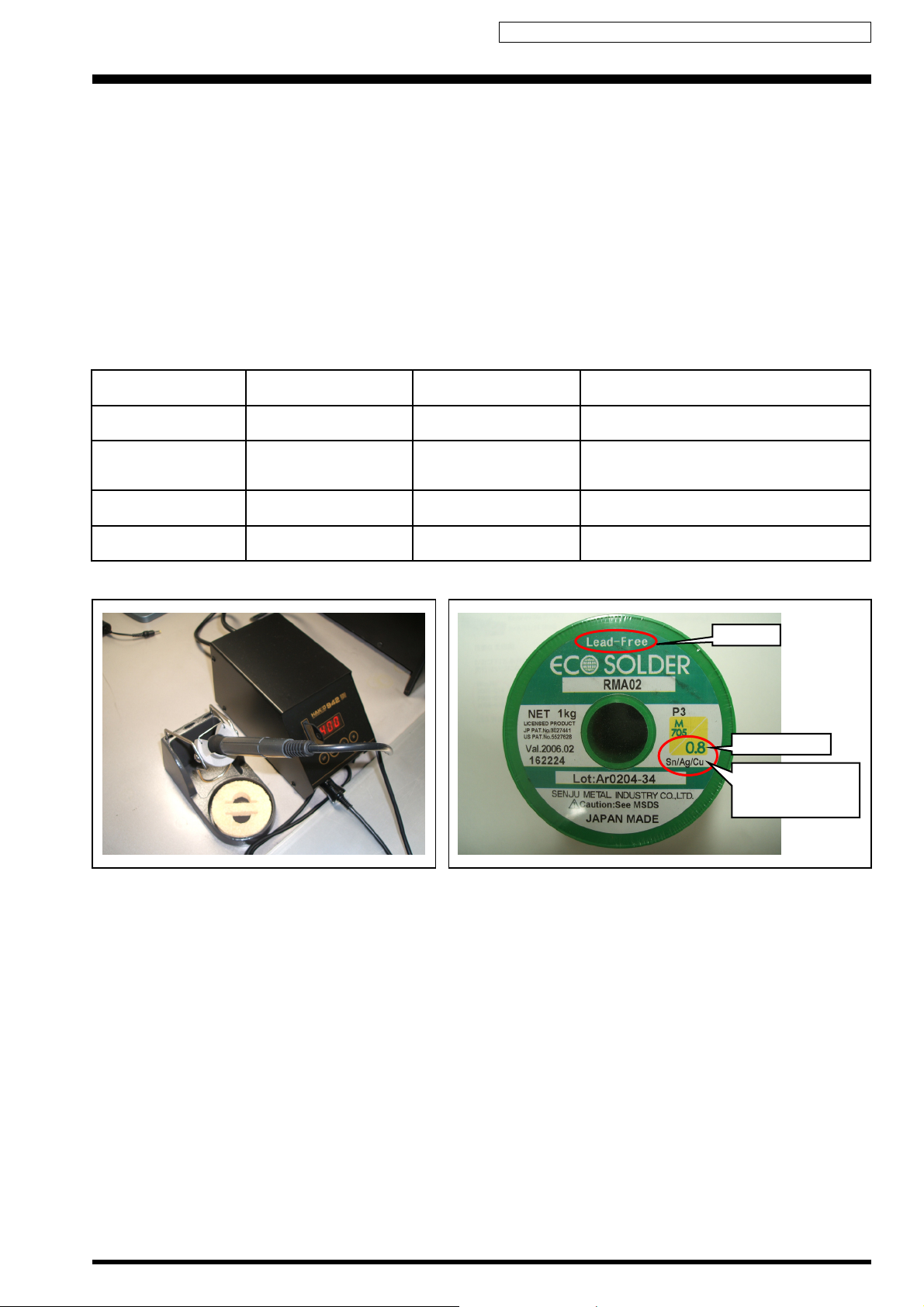

1. List of Jigs X-M1 Service Manual

1. List of Jigs

1-1. Tool list

Parts No. Name Image Comment Remarks MUST/WANT

ZJ02083-100 SCREWDRIVER (+) 1.5X40L General repair MUST

ZJ02033-100 TORQUE DRIVER Used in torque management MUST

ZJ02070-100 VESSEL M160082 +BIT 0*82 Used in torque management MUST

ZJ00581-100 Discharger Discharge for FLASH UNIT MUST

ZJ01923-100 Grip press tool Type A General repair MUST

ZJ01924-100 Grip press tool Type B General repair MUST

ZJ01925-100 Grip press tool Type C General repair MUST

ZJ01926-100 Grip press tool Type D General repair MUST

ZJ01927-100 Grip press tool Type E General repair MUST

No Image

1-2. Auxiliary materials list

Parts No. Name Image Comment Remarks MUST/WANT

ZS00143-100 UL TAPE (BLACK) 19MM General repair UL TAPE (BLACK) 19MM MUST

No Image

ZS00144-100 UL TAPE (CLEAR) 9MM General repair UL TAPE (CLEAR) 9MM MUST

ZS00145-100 UL TAPE (CLEAR) 15MM General repair UL TAPE (CLEAR) 15MM MUST

ZS00169-100 UL TAPE CLEAR 30MM General repair UL TAPE CLEAR 30MM MUST

ZS00126-100 UL Bond SC950 General repair Bond MUST

ZS00175-100 KONISHI BOND SL220W General repair Bond MUST

ZS00135-200 CFD-409Z (LUBRICANT)

ZS00177-100 CRS-811 (GREASE)

ZS00185-100 HI-LUBE FG-600T General repair Lubricant MUST

ZJ02233-100 X-A1 PET SHEET General repair MUST

No Image

No Image

No Image

No Image

No Image

General repair Lubricant MUST

General repair Lubricant MUST

No Image

No Image

1-1

: Revised

Confidential: FUJIFILM Service Center Use Only

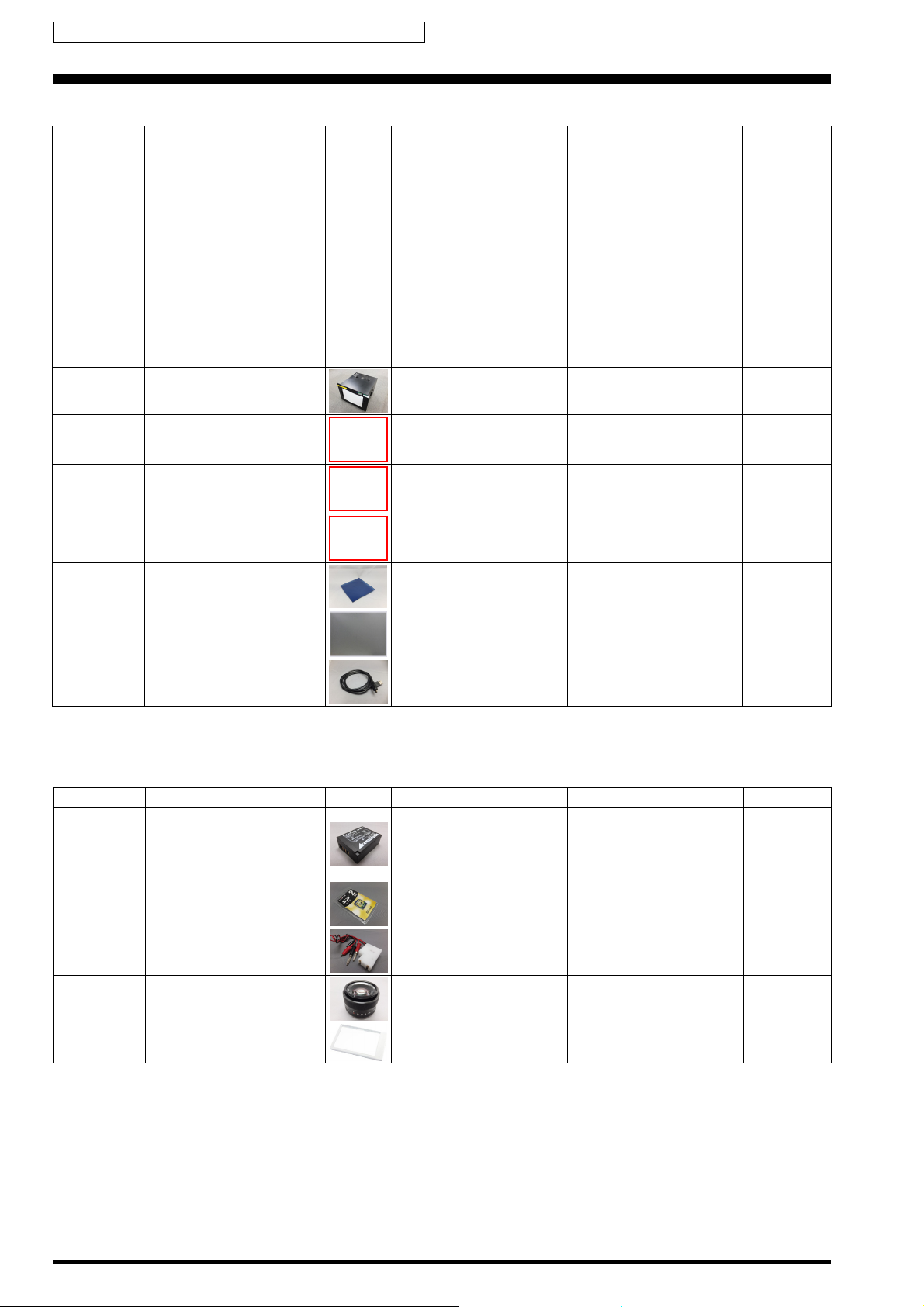

X-M1 Service Manual 1. List of Jigs

1-3. Adjustments

Parts No. Name Image Comment Remarks MUST/WANT

• DSC JIG Driver

ZJ00684-100

or

ZJ02197-100

DSC JIG Driver

FJIG DRIVER for Win7

----

USB JIG Driver

Use the ZJ00684-100 from

*1

web.

• FJIG DRIVER for Win7

Refer to the BULLETIN No.

2013-058.

*1

MUST

ZJ02216-100 X-M1 W PC Soft Ver.1.00

ZJ02217-100 X-M1 SD BOOT Soft

ZJ02219-100 MOUNT Data for X-M1

---- PTB450F Camera adjustment Pattern box MUST

FZ00330-200 AC Cable (For US/JP) Camera adjustment

FZ03982-100 AC Cable (For EG) Camera adjustment

FZ03983-100 AC Cable (For EU) Camera adjustment

ZJ00699-100 Filter LB145 Camera adjustment

ZJ00254-100 Gra y Chart (Reflective type) Flash adjustment

---- Micro USB cable General adjustment Commercially available item MUST

----

----

----

No Image

No Image

No Image

General adjustment New jig *1 MUST

Main PWB Initialize New jig *1 MUST

Mount Data Write New jig *1 MUST

Use it with PTB450F and a

*2

set

Use it with PTB450F and a

*2

set

Use it with PTB450F and a

*2

set

Common with the

8mmVTR/FinePix F700

Common with the

8mmVTR/FinePix F700

MUST

MUST

MUST

MUST

MUST

*1: Please download the software from Web server (https://cs-support-eid.fujifilm.co.jp).

*2: Select one the power cable suitable each country.

1-4. Adjustment/Inspection

Parts No. Name Image Comment Remarks MUST/WANT

FZ09206-100

or

FZ09206-200

or

FZ09206-300

ZPU0512-100 SD CARD ULTRA2 1GB

ZJ01936-100 NP-W126 Battery Jig

----

---- LED viewer

BATTERY PACK NP-W126J

BATTERY PACK NP-W126U

BATTERY PAC K NP-W126W

FUJINON LENS XF35mmF1.4

R

This is bundled to the product. MUST

Common with the X-Pro1 MUST

• CMOS Defect Correction

• CMOS Dust Inspection

To check inspection SD

recording

Products available from stock

(Use the latest version of the

firmware).

ST-N3 (FUJIFILM) W ANT

MUST

MUST

1-2

Confidential: FUJIFILM Service Center Use Only

1. List of Jigs X-M1 Service Manual

1-5. Inspection

Parts No. Name Image Comment Remarks MUST/WANT

---- Power supply

---- Digital voltmeter

Regulated power supply MUST

For general use MUST

---- Ammeter

ZJ01848-100 FxX100 Line Chart

ZS00172-100 Cleaning paper CMOS Cleaning WANT

ZJ02219-100

ZJ02218-100

X-M1 W Dust Inspection Soft

Ver.1.00

No Image

----

CMOS Dust Inspection New jig

For general use (able to

measure 1mA or less)

Common with the FinePix

X100

*1

*1: Please download the software from Web server (https://cs-support-eid.fujifilm.co.jp).

MUST

MUST

WANT

1-3

: Revised

Confidential: FUJIFILM Service Center Use Only

X-M1 Service Manual 1. List of Jigs

MEMO

1-4

Confidential: FUJIFILM Service Center Use Only

2. Disassembly X-M1 Service Manual

2. Disassembly

2-1. Removing the SHEET GRIP

(1) Peel off the SHEET GRIP R RIGHT2.

(2) Peel off the SHEET GRIP R RIGHT1.

(3) Peel off the SHEET GRIP R LEFT.

3

2

1

[Notes on Assembly]

• SHEET GRIP is not reusable.

• Refer to [2-9. Attaching the SHEET GRIP] for the affix the SHEET GRIP procedure.

2-1

Confidential: FUJIFILM Service Center Use Only

X-M1 Service Manual 2. Disassembly

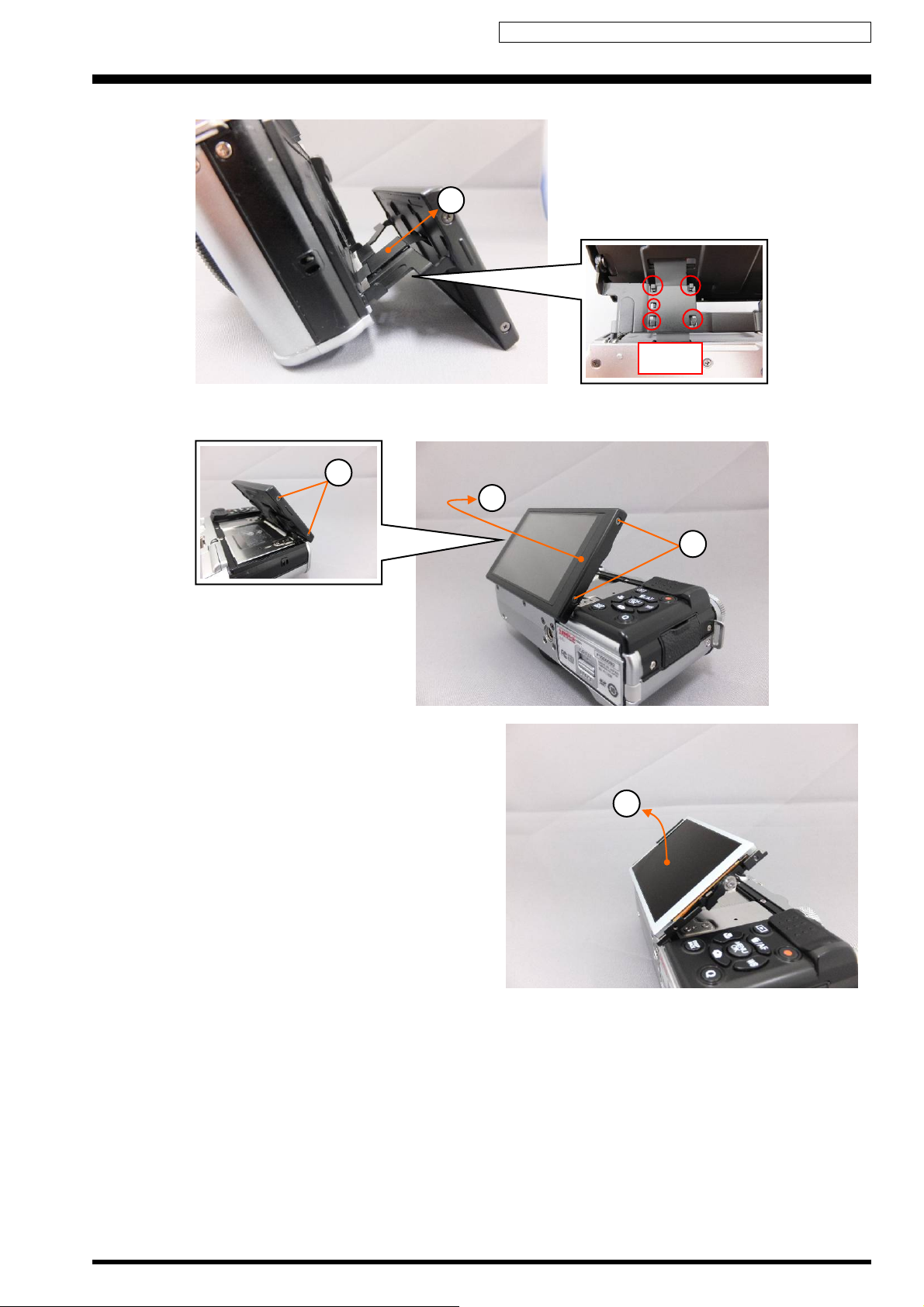

2-2. Removing the LCD

(1) Raise the LCD in the direction of the arrow.

(2) Peel off the SHEET INSULATE MAIN.

1

2

[Notes]

If TAPE INSULATE CENTER is affixed, peel it off.

[Notes on Assembly]

SHEET INSULATE MAIN is not reusable.

[Affixing position for the SHEET INSULATE MAIN]

Affix the SHEET INSULATE MAIN on the DSCAMERA

BASE as shown in the figure.

2-2

Confidential: FUJIFILM Service Center Use Only

2. Disassembly X-M1 Service Manual

(3) Remove the Hooks, and remove the HOLDER LCD FPC in the direction of the arrow.

3

Hooks

(4) Remove the 4 screws (MSGM1.7X2.5B).

(5) Remove the WINDOW LCD ASSY in the direction of the arrow.

(6) Raise the LCD in the direction of the arrow.

4

5

4

6

2-3

Confidential: FUJIFILM Service Center Use Only

X-M1 Service Manual 2. Disassembly

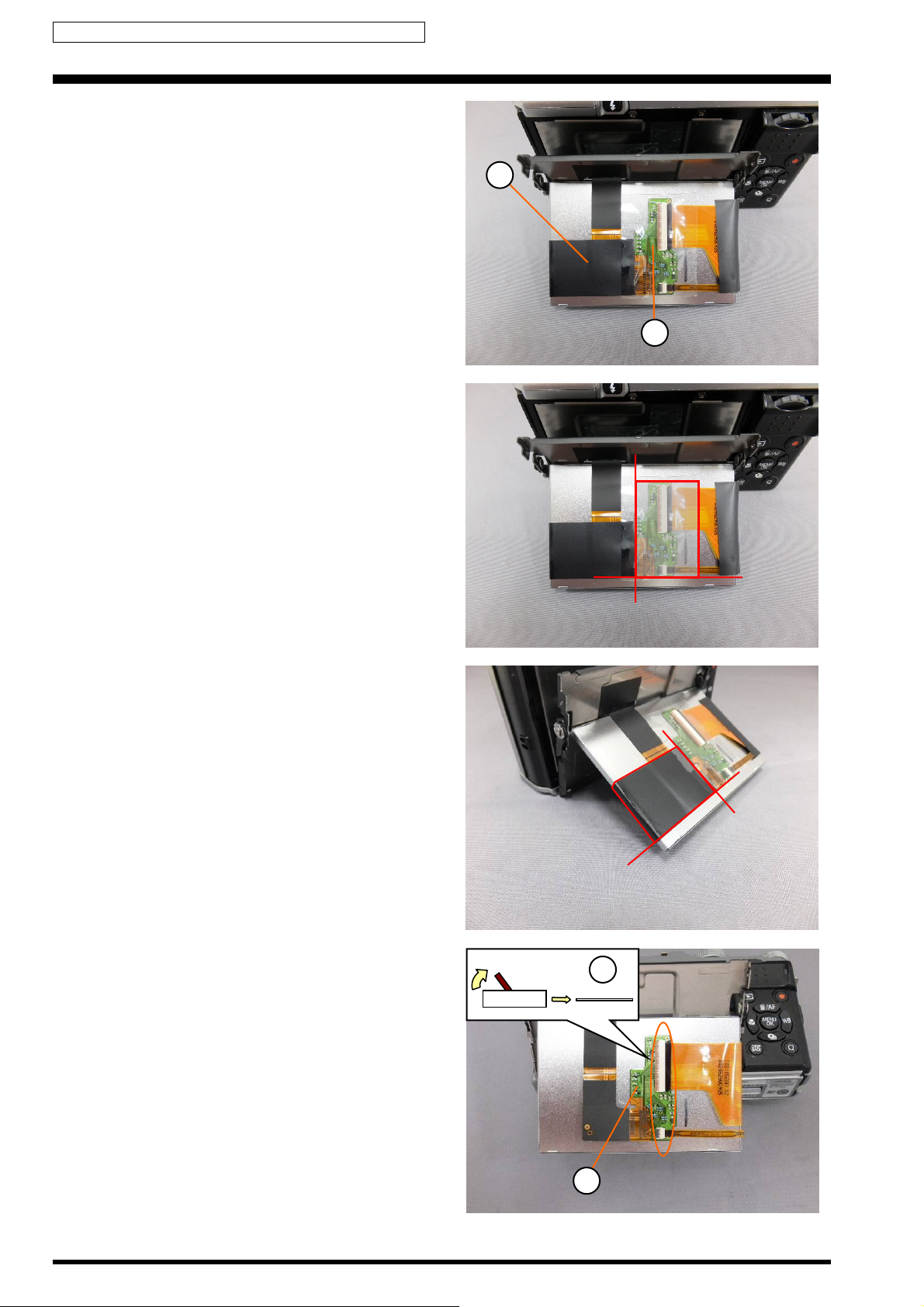

(6) Peel off the UL TAPE (30X37mm).

(7) Peel off the SHEET FPC LCD 1.

[Notes on Assembly]

UL TAPE (30X37mm) and SHEET FPC LCD 1 are not

reusable.

[Affixing position for the UL TAPE (30X37mm)]

Affix the UL TAPE (30X37mm) on the TILT_ASSY as shown

in the figure.

UL TAPE (CLEAR): ZS00169-100 (Width: 30mm)

7

6

[Affixing position for the SHEET FPC LCD 1]

Affix the SHEET FPC LCD 1 on the TILT_ASSY as shown in

the figure.

(8) Unlock the connector and remove the FPC.

(9) Peel off the TILT_ASSY and remove the LCD.

8

FPC

9

2-4

Confidential: FUJIFILM Service Center Use Only

2. Disassembly X-M1 Service Manual

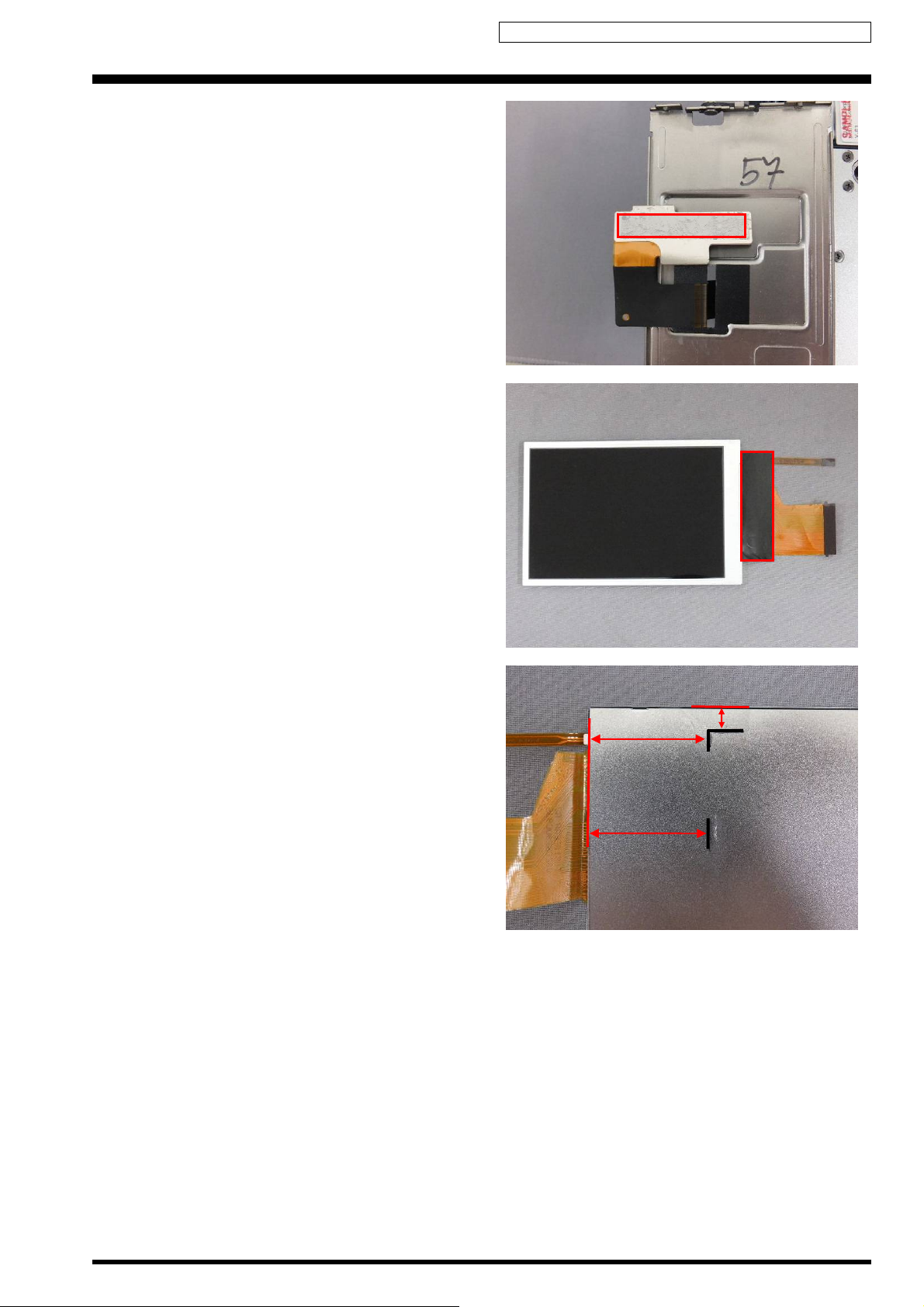

[Notes on Assembly]

TAPE FPC LCD is not reusable.

[Affixing position for the TAPE FPC LCD]

Affix the TAPE FPC LCD on the TILT_ASSY as shown in the

figure.

[Precaution when replacing LCD]

1. SHEET FPC LCD 2 is not reusable.

[Affixing position for the SHEET FPC LCD 2]

Affix the SHEET FPC LCD 2 on the LCD as shown in the

figure.

2. Mark the lines as shown in the picture for the position of

the TILT_ASSY.

[Assembly]

Assemble procedure is reverse of the disassembly

procedure.

24mm

24mm

5mm

2-5

Confidential: FUJIFILM Service Center Use Only

X-M1 Service Manual 2. Disassembly

2-2-1. Disassembling the WINDOW LCD ASSY

(1) Remove the WINDOW LCD.

(2) Peel off the CUSHION LCD.

1

2

[Notes on Assembly]

TAPE WINDOW LCD and CUSHION LCD are not

reusable.

[Affixing position for the SHEET FPC LCD 2]

Affix the SHEET FPC LCD 2 on the CASE LCD F as shown

in the figure.

[Affixing position for the CUSHION LCD]

Affix the CUSHION LCD on the WINDOW LCD as shown in

the figure.

[Assembly]

Assemble procedure is reverse of the disassembly

procedure.

2-6

Confidential: FUJIFILM Service Center Use Only

2. Disassembly X-M1 Service Manual

2-3. Removing the CONST REAR

(1) Remove the 4 screws (MSGM1.7X2.5).

(2) Remove the UNIT HINGE LCD.

(3) Remove the 2 screws (MS2M1.7X4.0B).

(4) Remove the screw (MS2M1.7X2.5).

(5) Remove the 2 screws (MS2M1.7X3.5).

2

1

5

(6) Remove the 4 screws (MSGM1.7X2.5B).

3

5

4

6

2-7

Confidential: FUJIFILM Service Center Use Only

X-M1 Service Manual 2. Disassembly

(7) Remove the CONST REAR in the direction of the arrow.

7

(8) Remove the REAR_FFC.

[Assembly]

Assemble procedure is reverse of the disassembly

procedure.

8

FFC

2-8

Confidential: FUJIFILM Service Center Use Only

2. Disassembly X-M1 Service Manual

2-4. Removing the FRAME MAIN

(1) Remove the SPEAKER.

(2) Remove the 3 screws (MSGM1.7X2.5).

(3) Remove the FRAME MAIN in the direction of the arrow.

3

1

[Notes on Assembly]

TAPE SPK is not reusable.

[Affixing position for the TAPE SPK]

Affix the TAPE SPK on the SPEAKER as shown in the

figure.

2

2

(4) Remove the COVER HINGE.

4

2-9

Confidential: FUJIFILM Service Center Use Only

X-M1 Service Manual 2. Disassembly

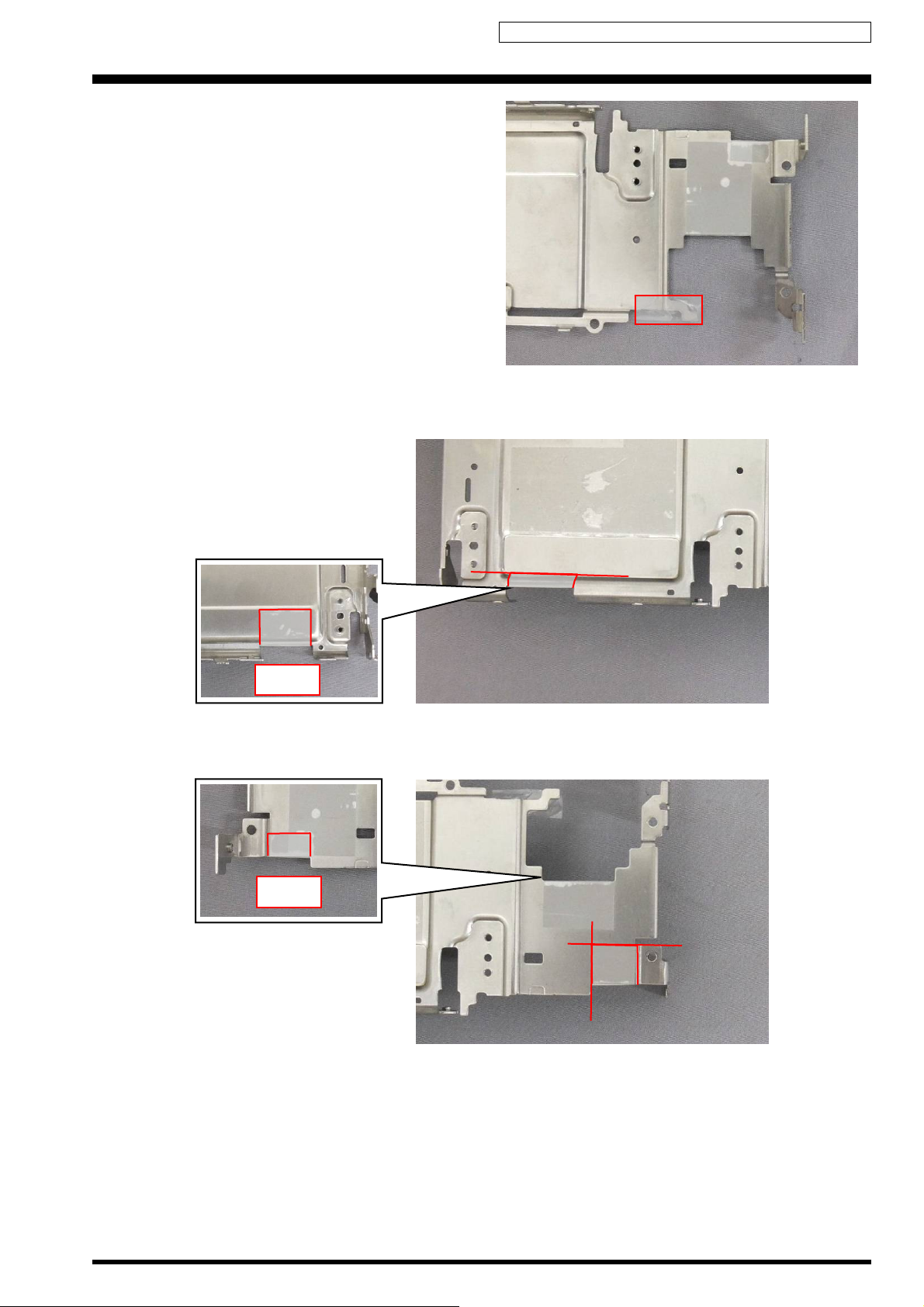

[Precaution when replacing FRAME MAIN]

UL TAPE (15X30mm), CUSHION SPEAKER, UL TAPE (6X13mm), UL TAPE (15X13mm) and UL TAPE (9X15mm) are

not reusable.

[Affixing position for the UL TAPE (15X30mm)]

Affix the UL TAPE (15X30mm) on the FRAME MAIN as shown in the figure.

UL TAPE (CLEAR): ZS00145-100 (Width: 15mm)

Back

[Affixing position for the CUSHION SPEAKER]

Affix the CUSHION SPEAKER on the FRAME MAIN as shown in the figure.

CUSHION SPEAKER

[Affixing position for the UL TAPE (6X13mm)]

Affix the UL TAPE (6X13mm) on the FRAME MAIN as shown in the figure.

UL TAPE (CLEAR): ZS00144-100 (Width: 9mm)

Back

2-10

Confidential: FUJIFILM Service Center Use Only

2. Disassembly X-M1 Service Manual

[Affixing position for the UL TAPE (6X13mm)]

Affix the TAPE (6X13mm) on the FRAME MAIN as shown in

the figure.

UL TAPE (CLEAR): ZS00144-100 (Width: 9mm)

[Affixing position for the UL TAPE (15X13mm)]

Affix the UL TAPE (15X13mm) on the FRAME MAIN as shown in the figure.

UL TAPE (CLEAR): ZS00145-100 (Width: 15mm)

Back

[Affixing position for the UL TAPE (9X15mm)]

Affix the UL TAPE (9X15mm) on the FRAME MAIN as shown in the figure.

UL TAPE (CLEAR): ZS00144-100 (Width: 9mm)

Back

[Assembly]

Assemble procedure is reverse of the disassembly procedure.

2-11

Confidential: FUJIFILM Service Center Use Only

X-M1 Service Manual 2. Disassembly

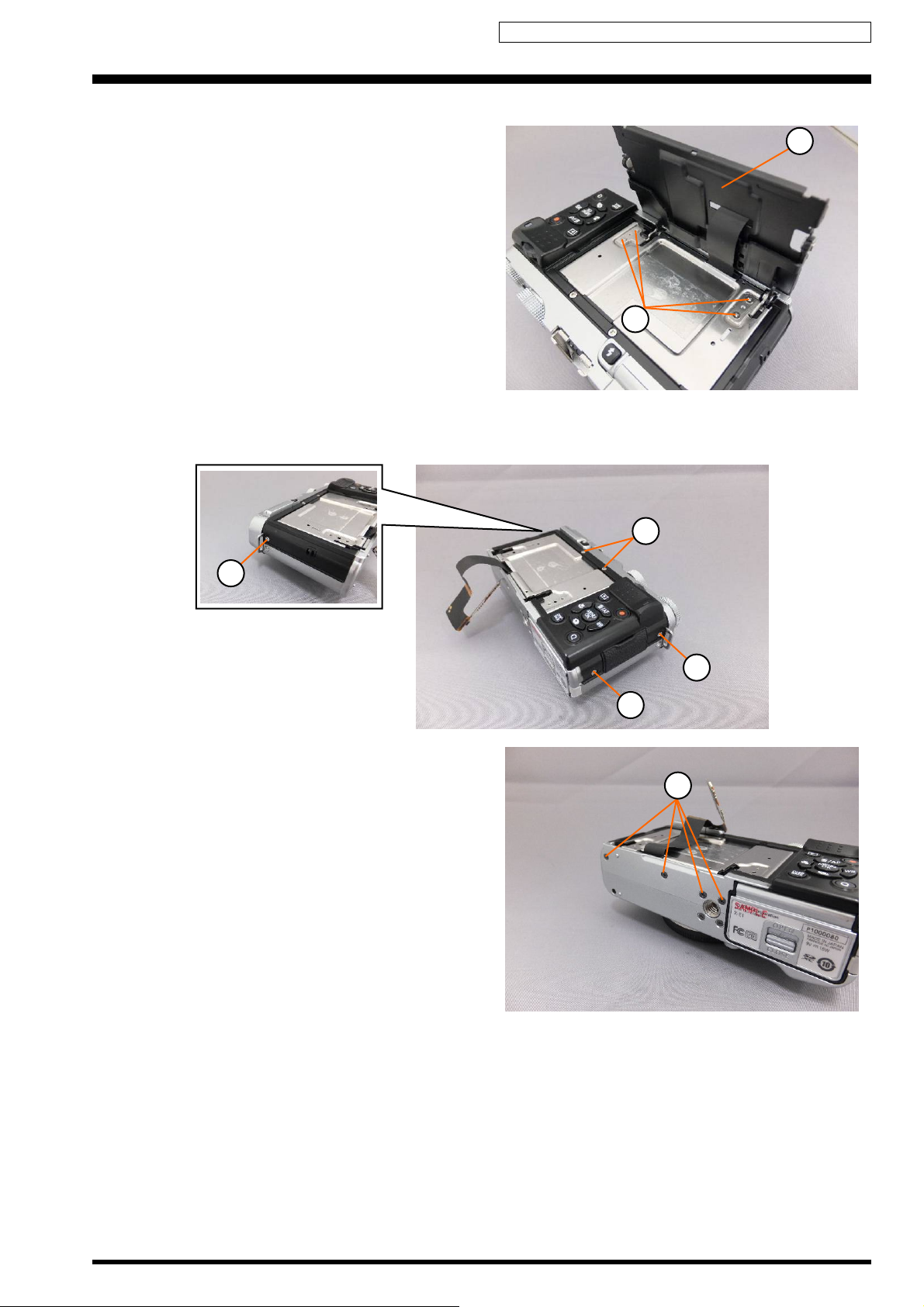

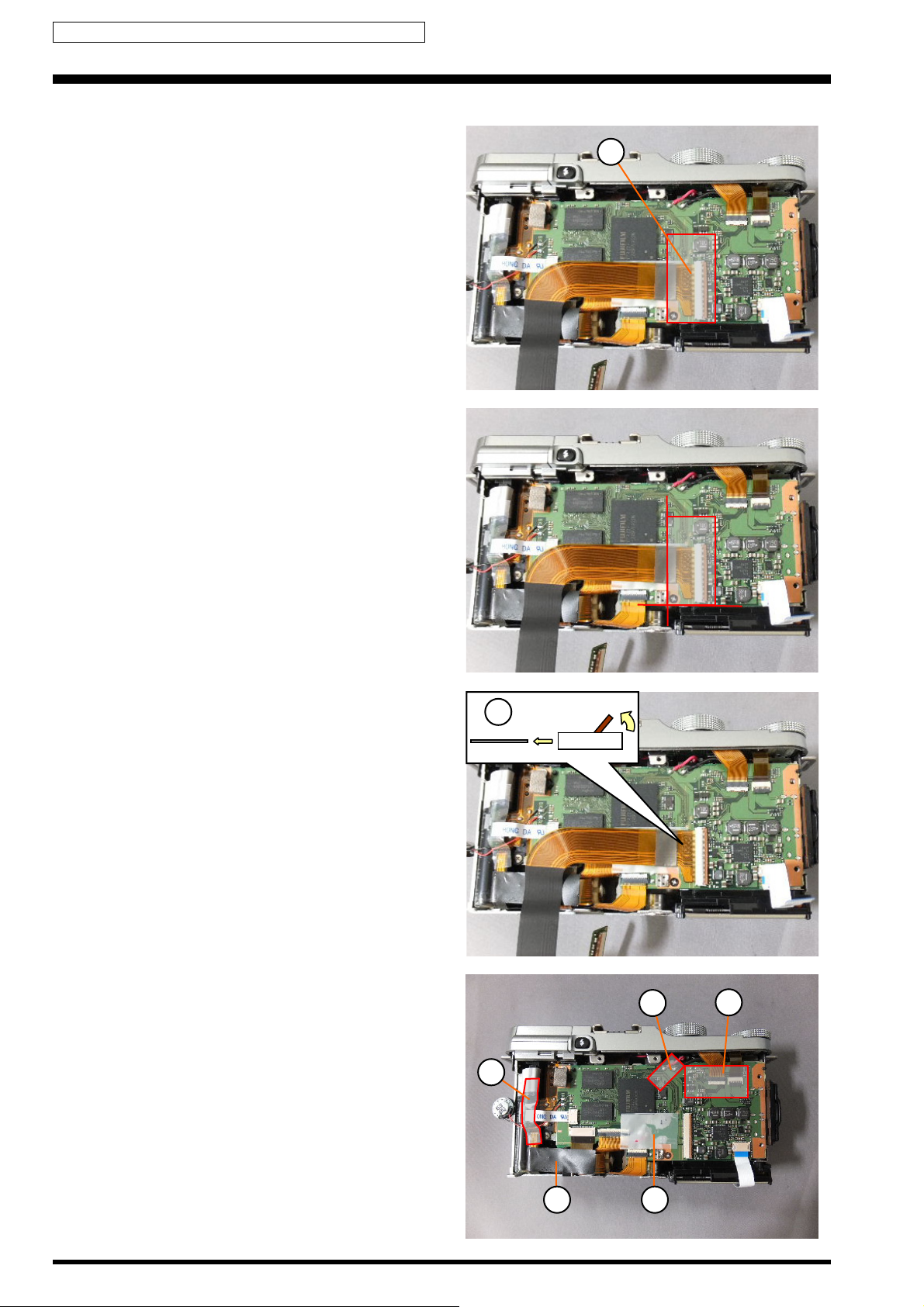

2-5. Removing the MAIN_ASSY

(1) Peel off the UL TAPE (15X30mm).

[Notes on Assembly]

UL TAPE (15X30mm) is not reusable.

[Affixing position for the UL TAPE (15X30mm)]

Affix the UL TAPE (15X30mm) on the MAIN_ASSY as

shown in the figure.

UL TAPE (CLEAR): ZS00169-100 (Width: 30mm)

1

(2) Unlock the connector and remove the TILT_ASSY.

(3) Peel off the SHEET FPC LCD 4.

(4) Peel off the UL TAPE (15X40mm).

(5) Peel off the UL TAPE (9X15mm).

(6) Peel off the UL TAPE (15X25mm).

(7) Peel off the UL TAPE (15X21mm).

2

FPC

5

6

4

2-12

7 3

Confidential: FUJIFILM Service Center Use Only

2. Disassembly X-M1 Service Manual

[Notes on Assembly]

SHEET FPC LCD 4, UL TAPE (15X40mm), UL TAPE

(9X15mm), UL TAPE (15X25mm) and UL TAPE

(15X21mm) are not reusable.

[Affixing position for the SHEET FPC LCD 4]

Affix the SHEET FPC LCD 4 on the CONST FRONT as

shown in the figure.

[Affixing position for the UL TAPE (15X40mm)]

Affix the UL TAPE (15X40mm) on the SPEAKER as shown

in the figure.

UL TAPE (CLEAR): ZS00145-100 (Width: 15mm)

[Affixing position for the UL TAPE (9X15mm)]

Affix the UL TAPE (9X15mm) on the MAIN_ASSY as shown

in the figure.

UL TAPE (CLEAR): ZS00144-100 (Width: 9mm)

[Affixing position for the UL TAPE (15X25mm)]

Affix the UL TAPE (15X25mm) on the MAIN_ASSY as

shown in the figure.

UL TAPE (CLEAR): ZS00145-100 (Width: 15mm)

2-13

Confidential: FUJIFILM Service Center Use Only

X-M1 Service Manual 2. Disassembly

[Affixing position for the UL TAPE (15X21mm)]

Affix the UL TAPE (15X21mm) on the MAIN_ASSY as

shown in the figure

UL TAPE (CLEAR): ZS00145-100 (Width: 15mm)

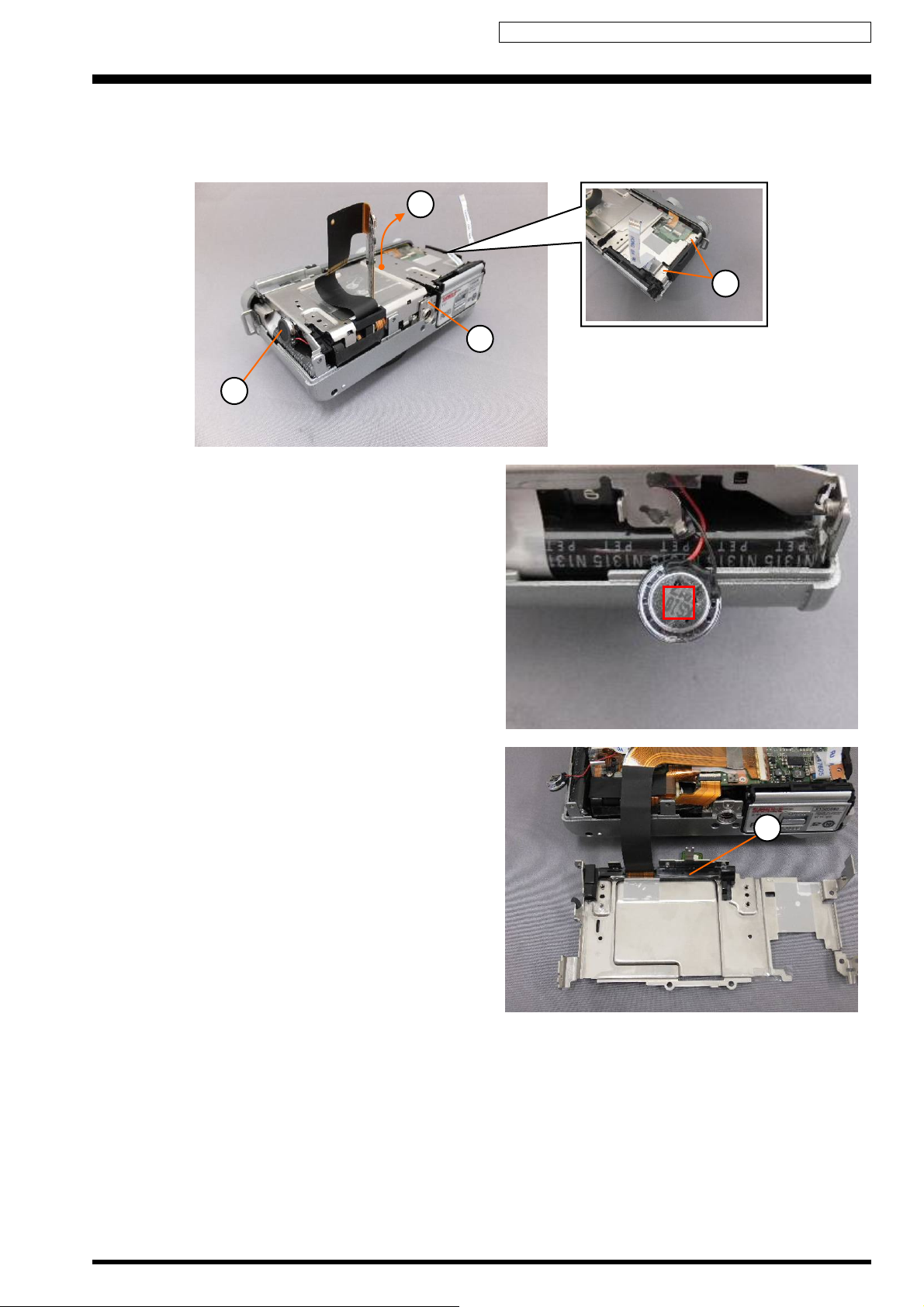

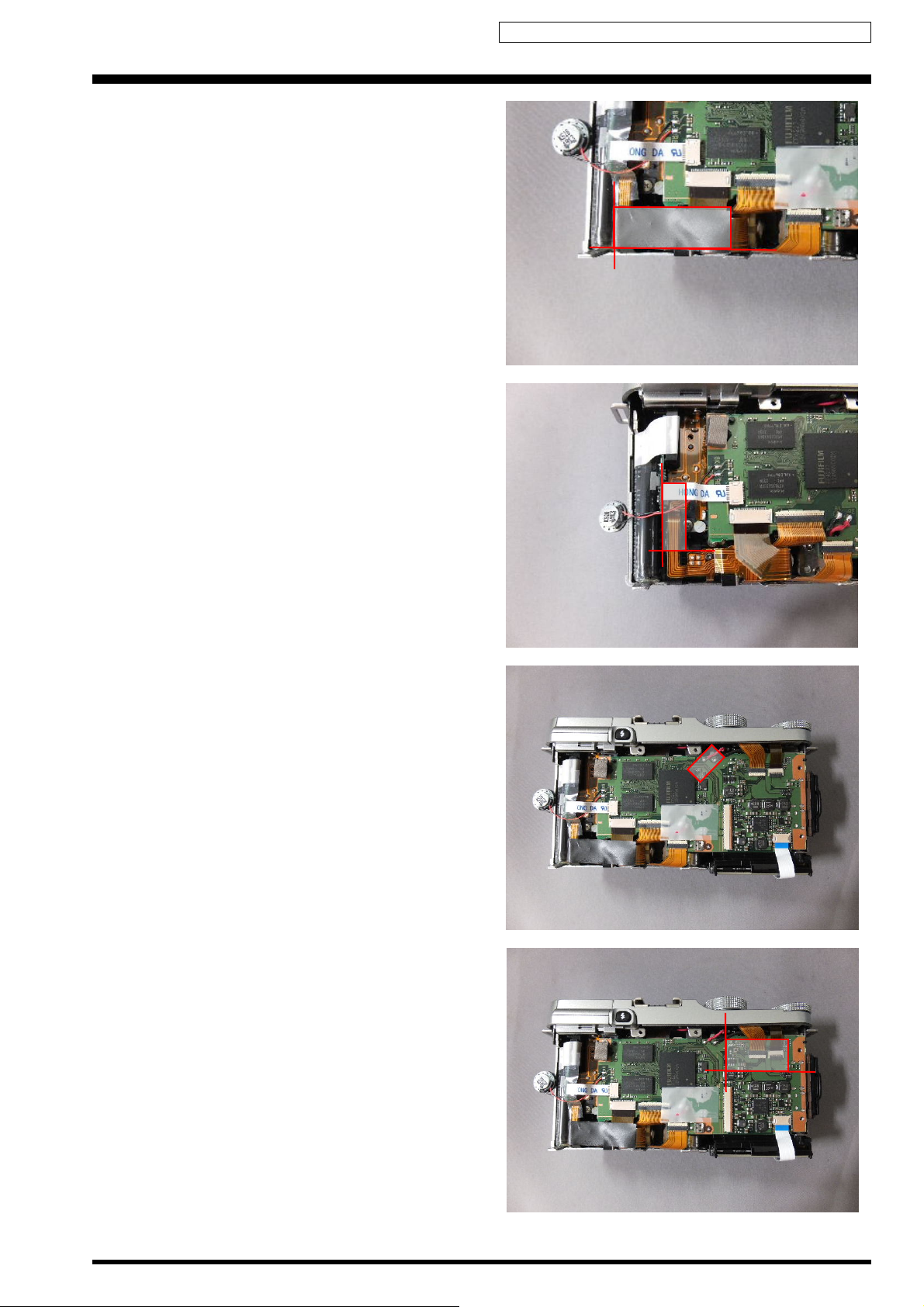

(8) Remove the FLASH_FFC.

8

FFC

(9) Remove 6 solders.

8

FFC

9

2-14

Confidential: FUJIFILM Service Center Use Only

2. Disassembly X-M1 Service Manual

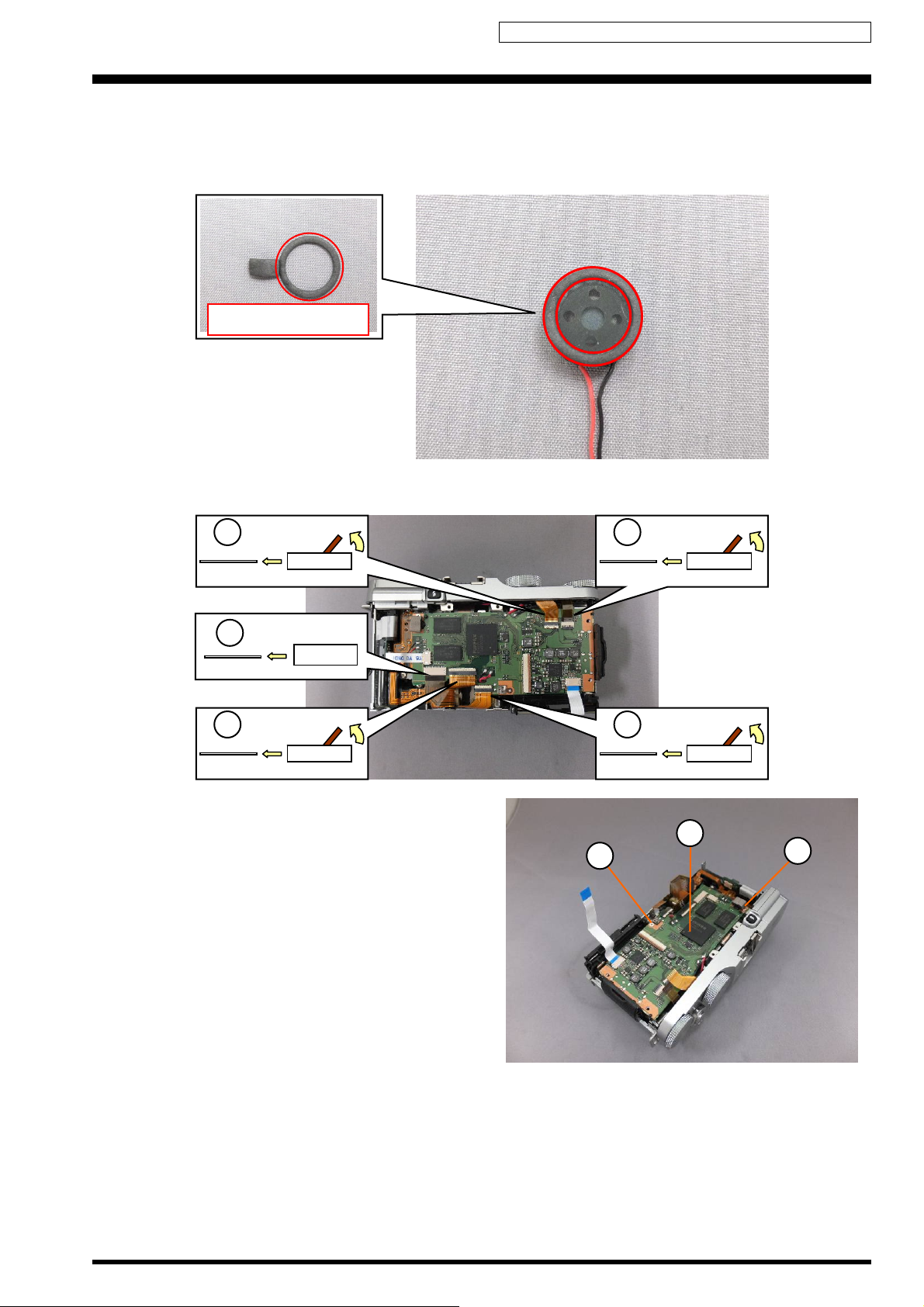

[Precaution when replacing SPEAKER]

CUSHION SPEAKER is not reusable.

[Affixing position for the CUSHION SPEAKER]

Affix the CUSHION SPEAKER on the SPEAKER as shown in the figure.

CUSHION SPEAKER

(10) Unlock the connector and remove the FPC.

(11) Remove the FPC.

10

FPC

11

FPC

10

FPC

(12) Remove the screw (BT2M1.7X3.0).

(13) Remove the screw (MSGM1.7X2.5).

(14) Remove the MAIN_ASSY.

10

FPC

10

FPC

14

12

13

2-15

Confidential: FUJIFILM Service Center Use Only

X-M1 Service Manual 2. Disassembly

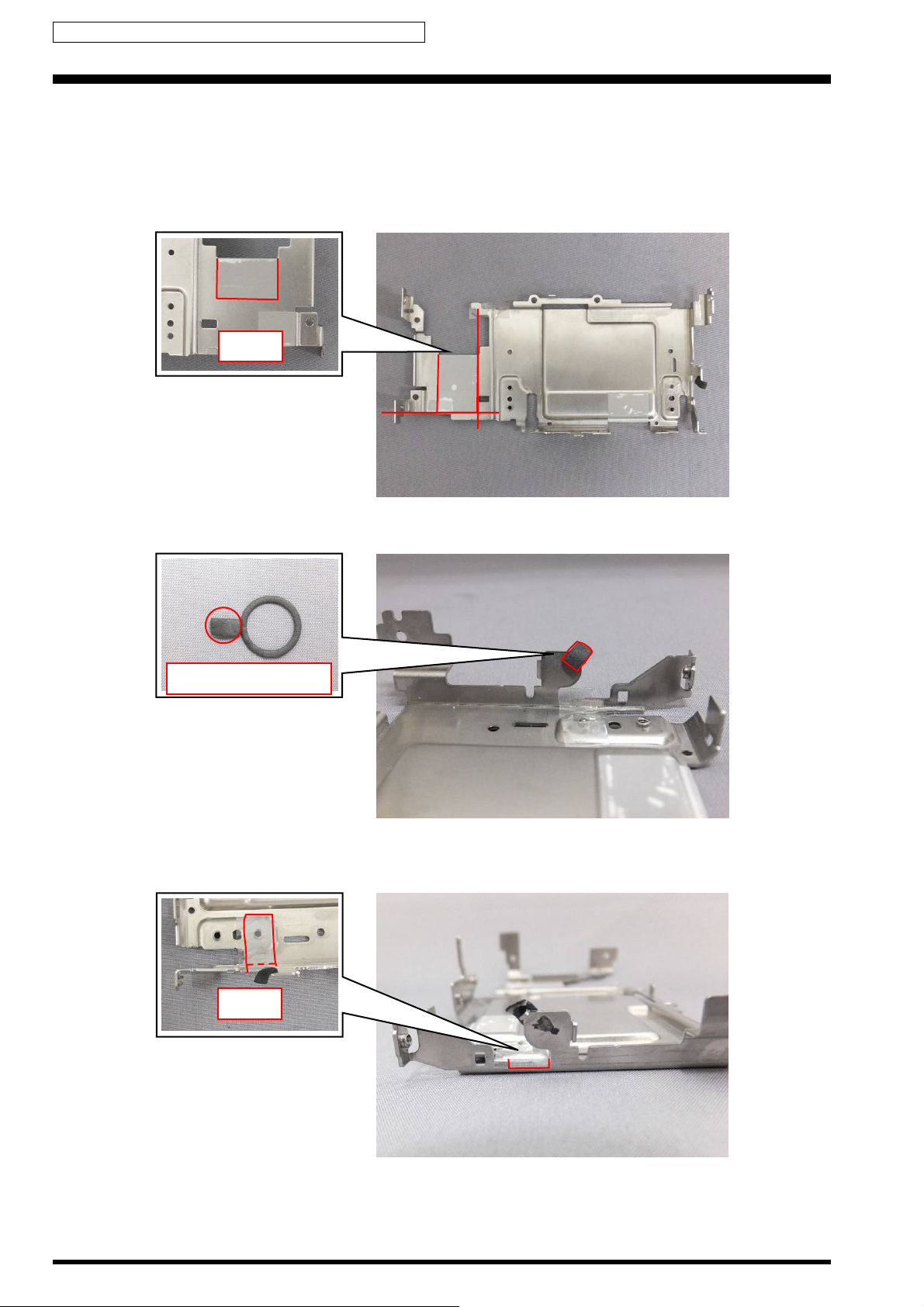

[Precaution when replacing MAIN_ASSY]

1. The MOUNT data (8 digits) is required for adjustment

by Mount Data Write.

To obtain the MOUNT data, refer to [3-5-1. Obtaining

the MOUNT data].

2. GASKET MAIN 1 and GASKET MAIN 2 are not

reusable.

[Affixing position for the GASKET MAIN 1]

Affix the GASKET MAIN 1 to MAIN_ASSY and apply the

bond as shown in the figure.

KONISHI BOND SL220W: ZS00175-100

MOUNT number

Bonding position

[Affixing position for the GASKET MAIN 2]

Affix the GASKET MAIN 2 on the MAIN_ASSY as shown in

the figure.

(15) Remove the REAR_FFC.

16

FFC

2-16

Confidential: FUJIFILM Service Center Use Only

2. Disassembly X-M1 Service Manual

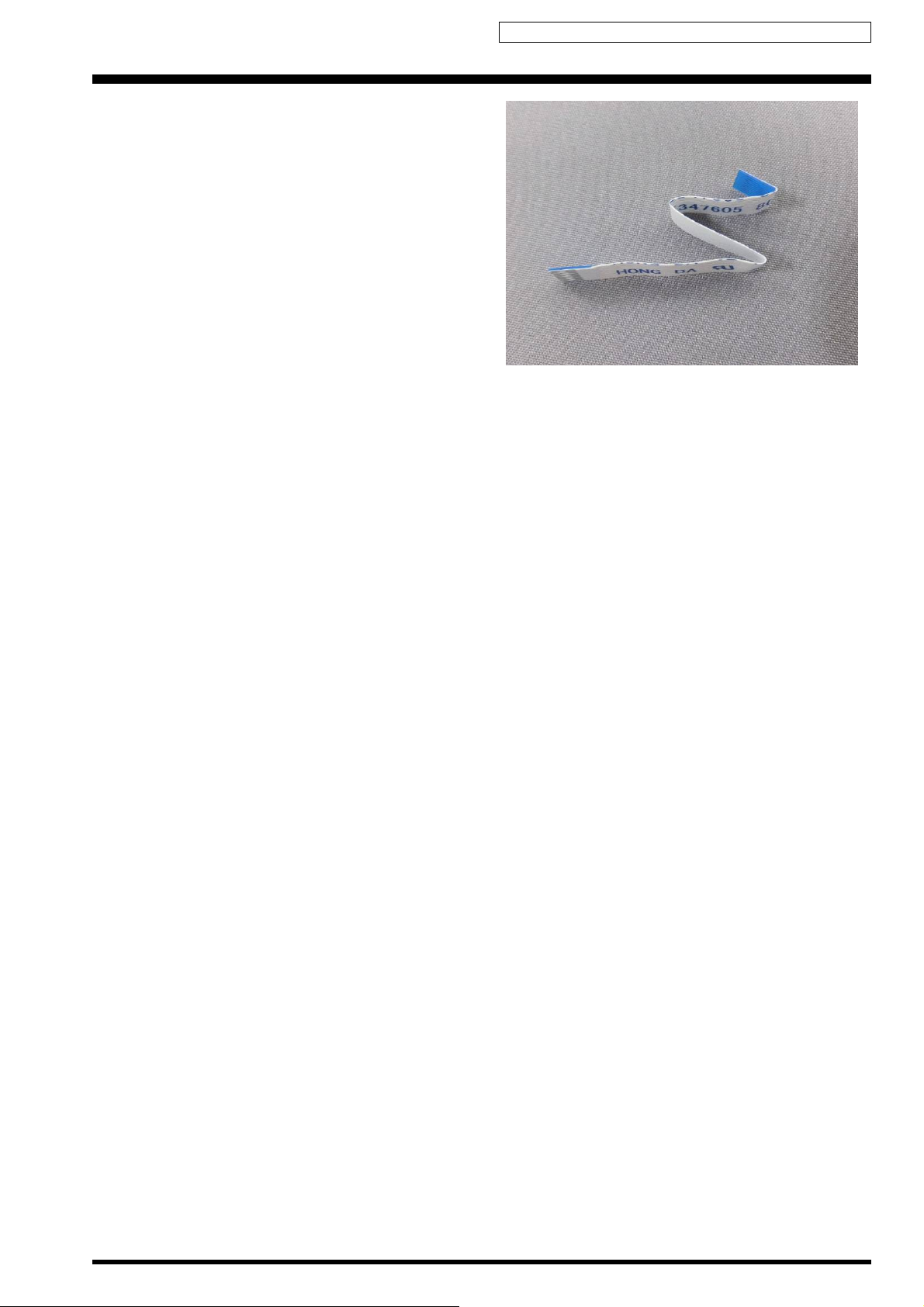

[Notes on Assembly]

Affix the REAR_FFC after folding it like the picture below.

[Assembly]

Assemble procedure is reverse of the disassembly

procedure.

2-17

Confidential: FUJIFILM Service Center Use Only

X-M1 Service Manual 2. Disassembly

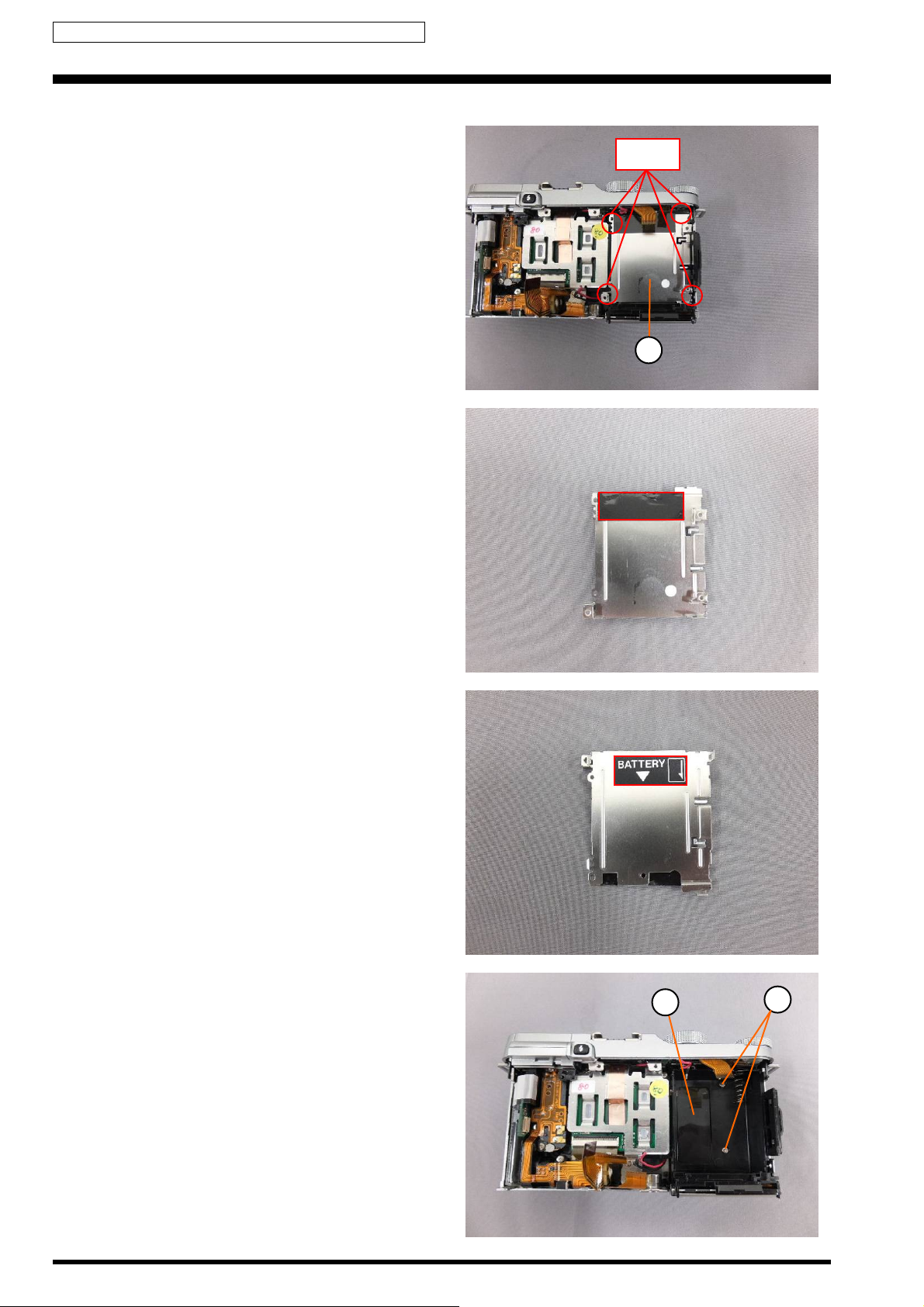

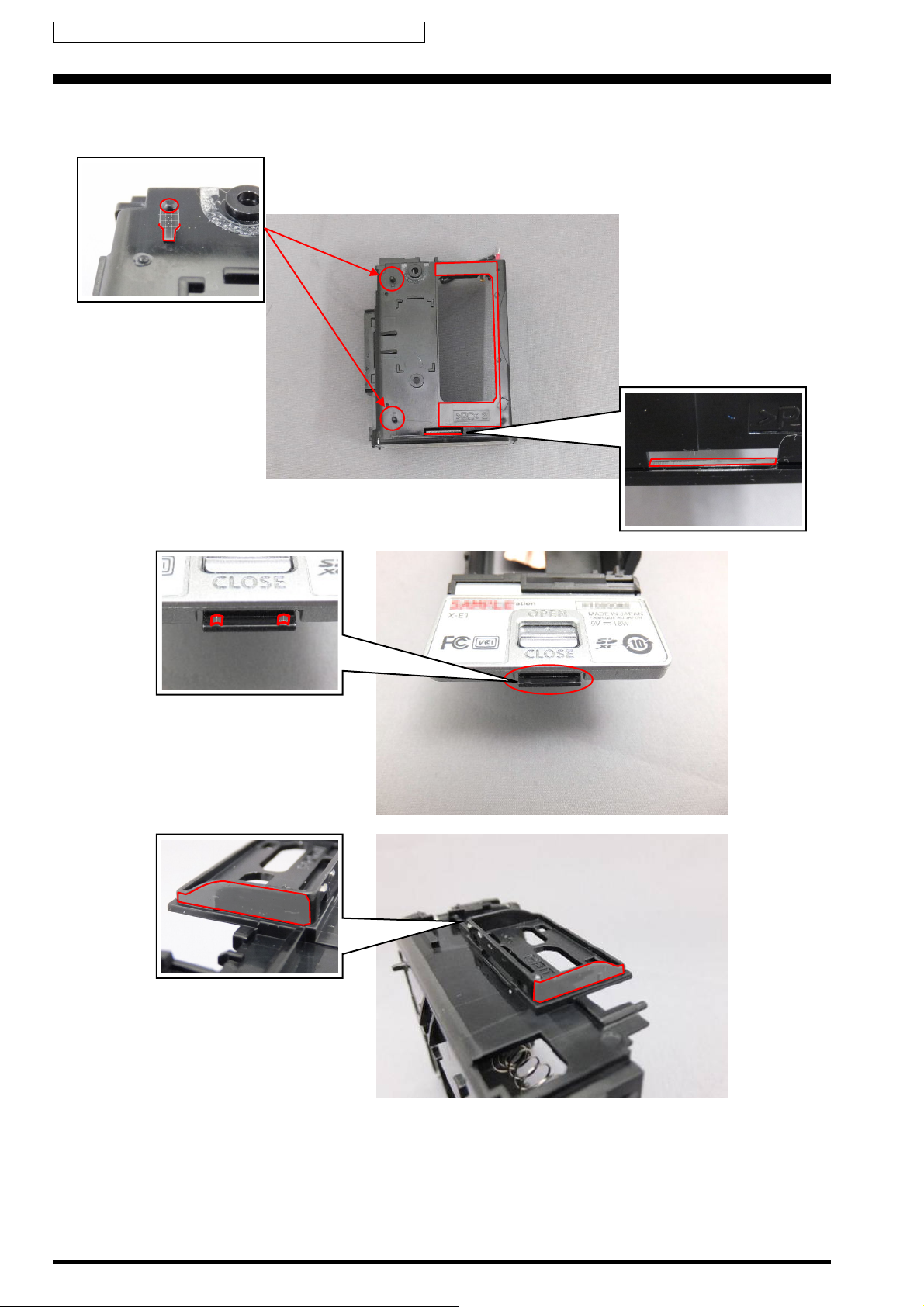

2-6. Removing the HOLDER BATTERY

(1) Remove the Hooks, and remove the PLATE HOLDER

BATT.

[Precaution when replacing PLATE HOLDER BATT]

UL TAPE (9X30mm) and LABEL BATT are not reusable.

[Affixing position for the UL TAPE (9X30mm)]

Affix the UL TAPE (9X30mm) on the PLATE HOLDER BATT

as shown in the figure.

UL TAPE (BLACK): ZS00143-100 (Width: 19mm)

Hooks

1

[Affixing position for the LABEL BATT]

Affix the LABEL BATT on the PLATE HOLDER BATT as

shown in the figure.

(2) Remove the 2 screws (BT2M1.7X4.5).

(3) Peel off the SHEET HEAT SINK 1.

3

2

2-18

Confidential: FUJIFILM Service Center Use Only

2. Disassembly X-M1 Service Manual

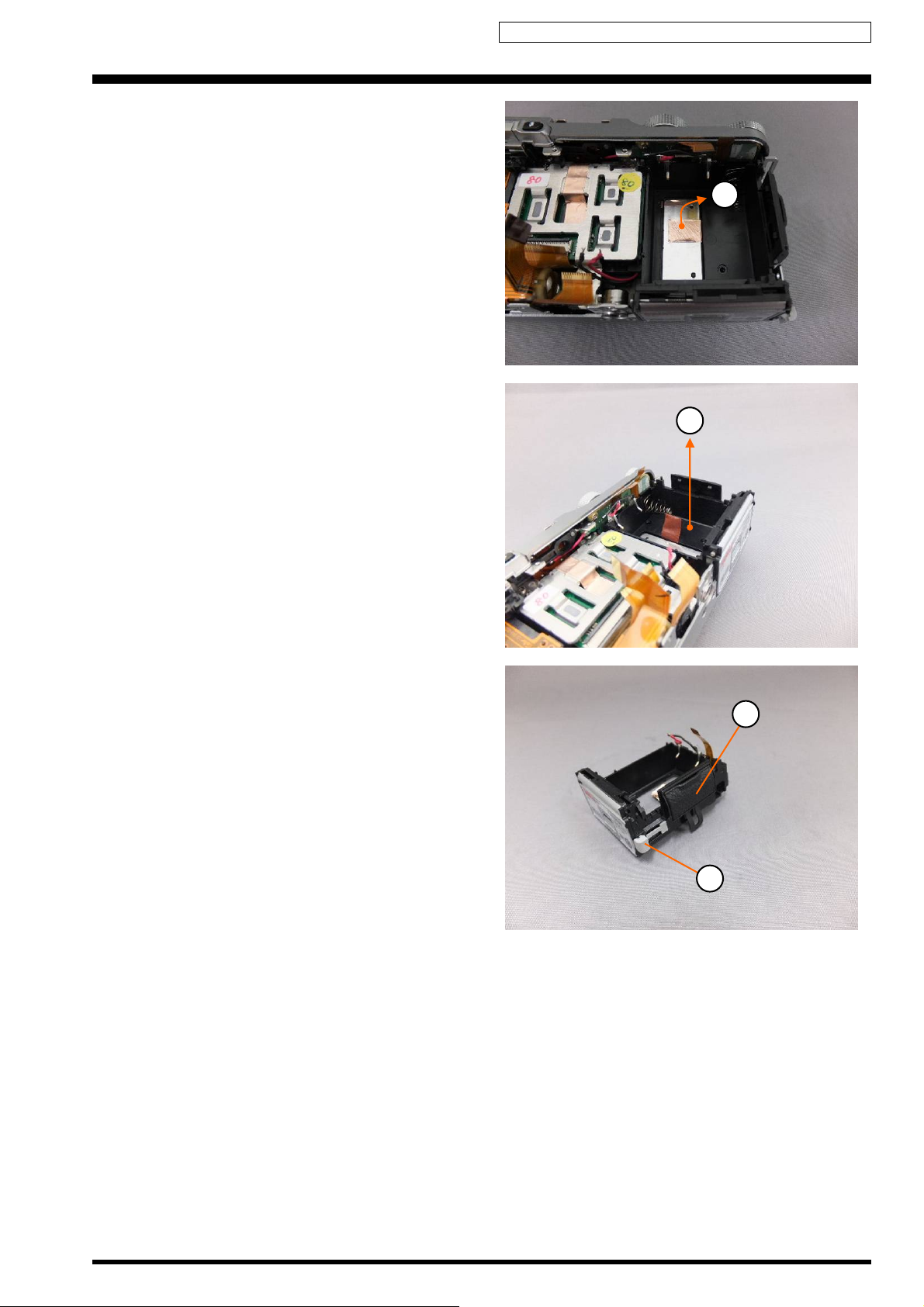

(4) Peel off the SHEET HEAT WLAN.

(5) Remove the CONST BATT in the direction of the arrow.

4

5

(6) Remove the COVER DC COUPLER.

(7) Remove the COVER JACK.

6

7

2-19

Confidential: FUJIFILM Service Center Use Only

X-M1 Service Manual 2. Disassembly

[Notes on Assembly]

Be sure to apply the lubricant to the CONST BATT.

• Lubricant: ZS00135-200 (SANKOL (CFD-409Z))

2-20

Loading...

Loading...