Fujifilm CR-IR346RU User manual

CR-IR346RU Service Manual

Troubleshooting (MT)

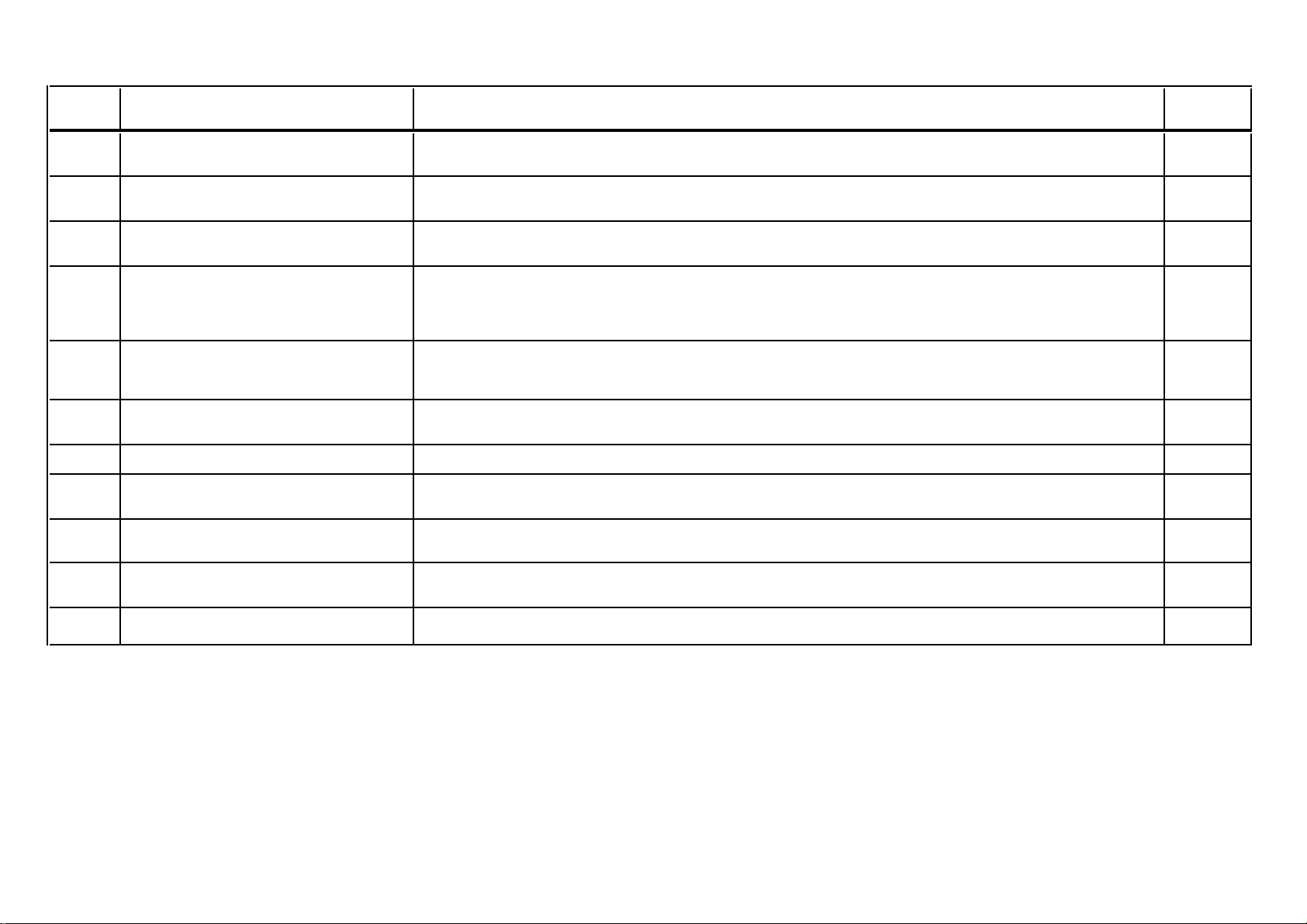

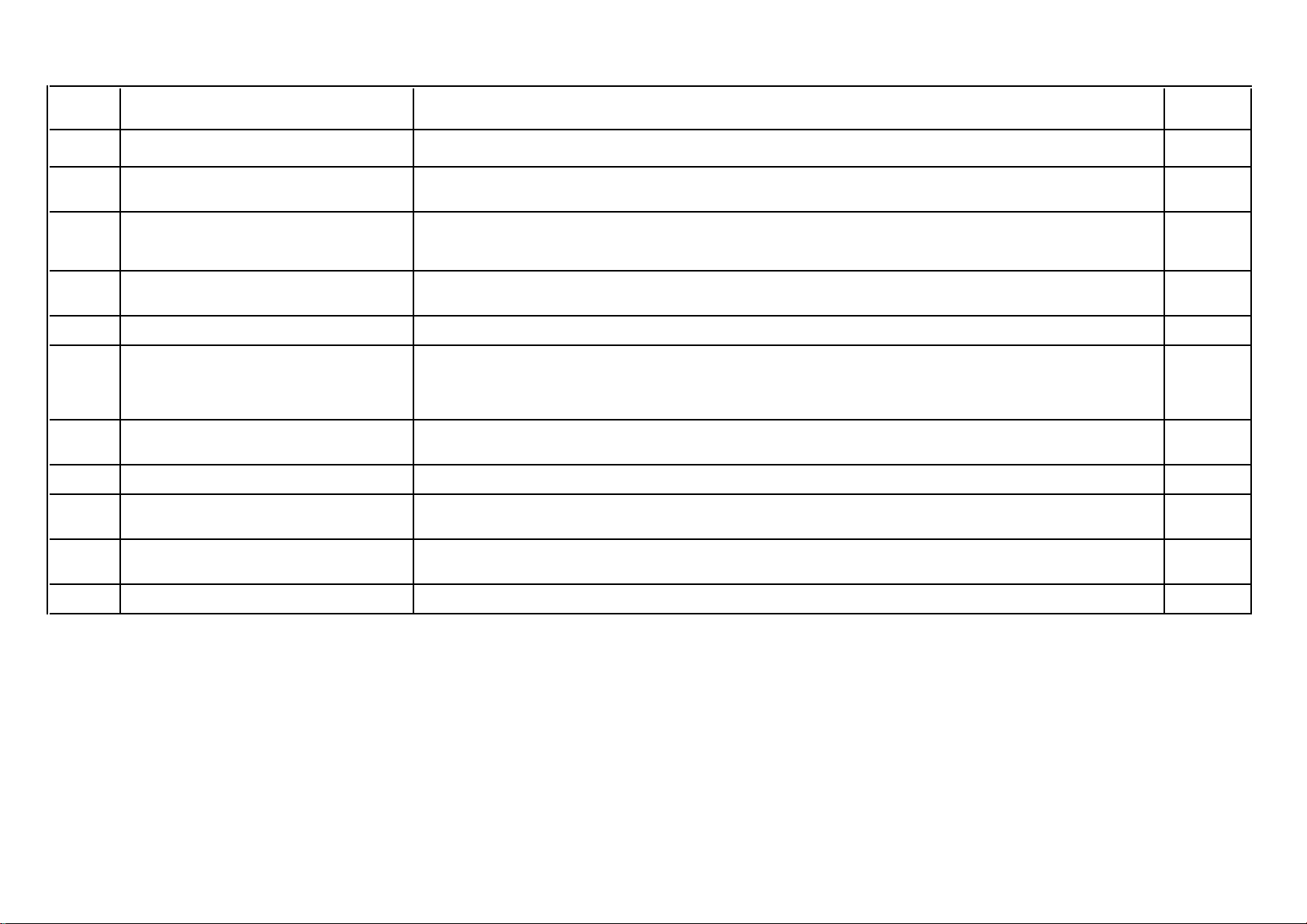

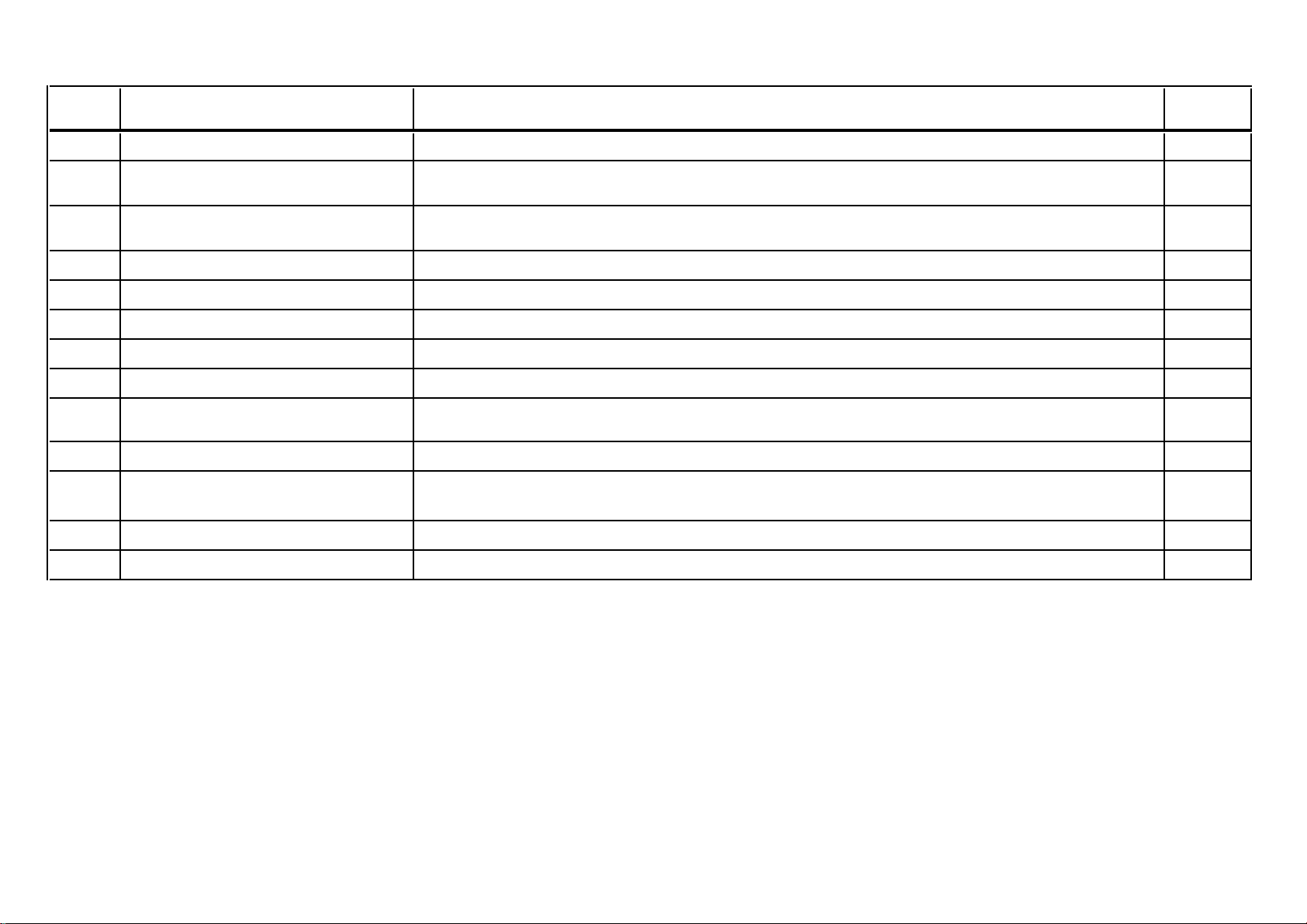

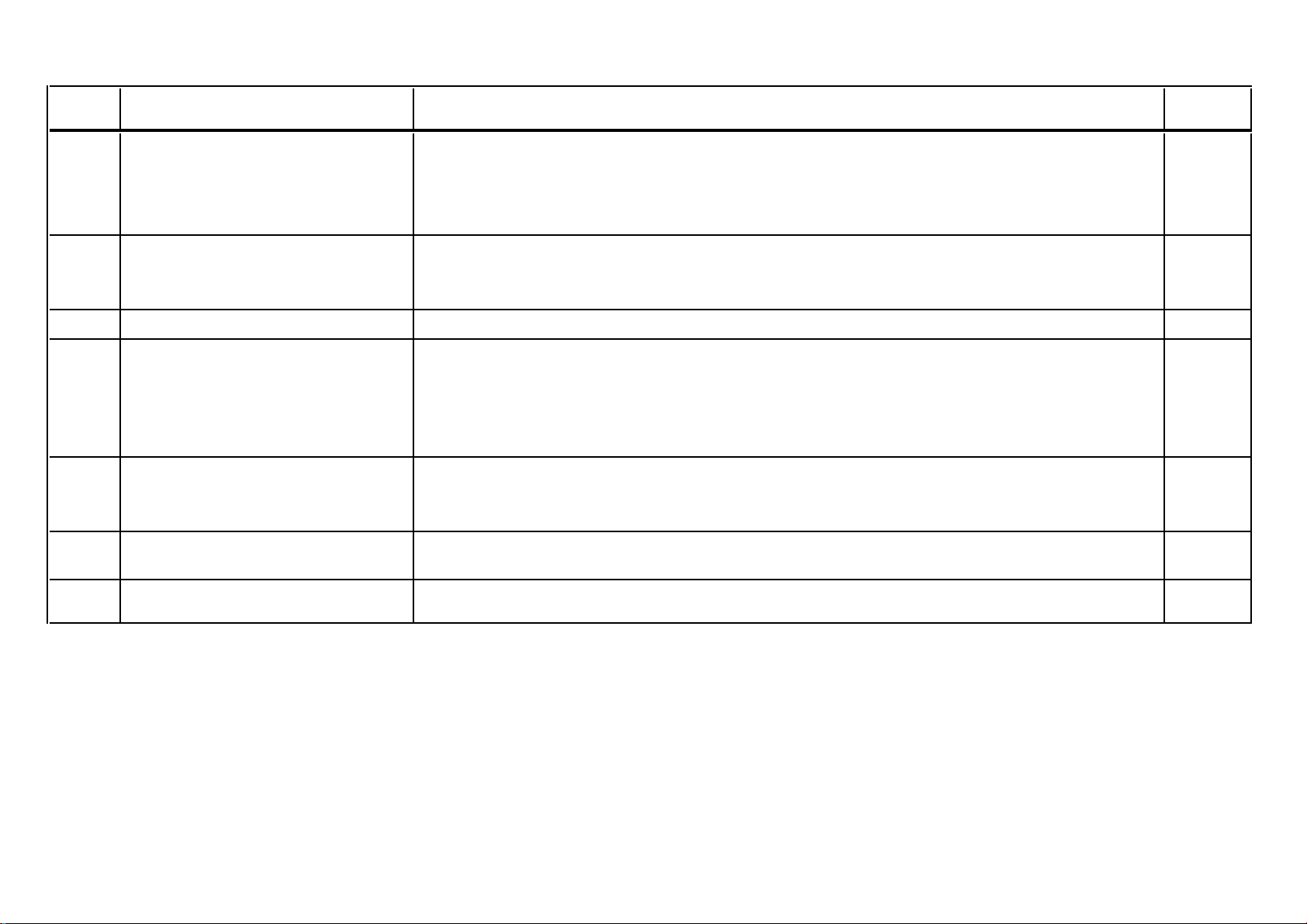

CR-IR346RU Service Manual – Contents

Troubleshooting (MT)

1. Overview of Troubleshooting ..........................................................................................MT-2

1.1 Flow of Troubleshooting........................................................................................MT-2

1.2 How to Understand Error Log...............................................................................MT-4

2. Error Code Table...............................................................................................................MT-7

3. Detail Code .....................................................................................................................MT-48

3.1 How to Understand Detail Code .........................................................................MT-48

3.2 Detail Codes for Scanner Errors.........................................................................MT-50

4. Error Code Analysis Flow (Mechanism).......................................................................MT-52

10300, 10302,12302 ........................................................................................................MT -52

10301, 12301 ...................................................................................................................MT-53

0.1

10303, 10304, 10305, 11303, 12304, 12305....................................................................MT-54

10306, 10307 ...................................................................................................................MT-56

10318, 12318, 12326, 14315, 14316, 14317....................................................................MT-57

10334, 12334, 14331, 14332, 14333................................................................................MT -58

10338, 12338, 14335, 14336, 14337................................................................................MT -59

10340, 10341, 11340, 11341, 14340, 14341....................................................................MT-60

10346, 10348, 10353, 10355, 12346, 12348, 12353, 13355, 14346, 14348,

14354, 14355 ...................................................................................................................MT-62

10347, 10349, 10354, 10356, 10357, 12347, 12349, 12352, 12354, 12355,

12356, 12357, 14347, 14349, 14356, 14357....................................................................MT-64

10370, 10371 ...................................................................................................................MT-66

10390, 10391, 10392, 10393, 12390, 12391, 12392, 12393, 12394, 12395,

13391, 13392 ...................................................................................................................MT-68

10394 ...............................................................................................................................MT-70

11310, 11311, 14310, 14312............................................................................................MT-71

11312 ...............................................................................................................................MT-72

11319, 11320, 11321, 11322, 14319, 14320, 14321, 14322 ............................................MT-74

10360, 10361, 11323, 14323............................................................................................MT-76

11325, 12325 ...................................................................................................................MT-77

11342, 11343, 11344 .......................................................................................................MT-78

11350 ...............................................................................................................................MT-79

11362 ...............................................................................................................................MT-80

11363 ...............................................................................................................................MT-81

11371, 11372 , 11373, 14372, 14373...............................................................................MT -82

11380 ...............................................................................................................................MT-83

11387 ...............................................................................................................................MT-84

12313, 13314 ...................................................................................................................MT-85

010-051-01

08.30.2001 FM3058 (1)

CR-IR346RU

Service Manual

0.1

0.2

12345 ...............................................................................................................................MT-86

12324, 14324 ...................................................................................................................MT-87

5. Error Code Analysis Flow (Scanner)............................................................................MT-88

10230 ...............................................................................................................................MT-88

10231 ...............................................................................................................................MT-90

10232 ...............................................................................................................................MT-92

10233 ...............................................................................................................................MT-94

10234 ...............................................................................................................................MT-96

10235 ...............................................................................................................................MT-98

10236 .............................................................................................................................MT-100

10281, 12201, 12281, 13201, 14281 .............................................................................MT-102

10298, 14298 ................................................................................................................MT -104

11208, 11272, 11273, 12212, 12272, 12273, 13208, 13212, 14283 ..............................MT -106

12202, 12255, 13202 .....................................................................................................MT-108

12211, 12217, 12251, 12252, 13211, 13217, 14211, 14251 ..........................................MT-110

10261, 12213, 12262 , 12263, 12264, 13210, 14261 .....................................................MT -112

12256 .............................................................................................................................MT-114

10271, 14271 .................................................................................................................MT -116

6. Error Code Analysis Flow (Electrical) ........................................................................MT-118

6.1 Error Code Analysis Flow between the CPU12A Board and CL....................MT-118

6.2 Error Code Analysis Flow between the SNS12A Board and CPU12A BoardMT-118

6.3 Error Code Analysis Flow between the SCN12A Board and CPU12A Board .MT-119

6.4 Error Code Analysis Flow between the Erasure Unit and INV12B Board.....MT-120

11731, 11751, 11781 .....................................................................................................MT-120

11732, 11752, 11782 .....................................................................................................MT-122

11737, 11757, 11767 .....................................................................................................MT-123

12730, 12733, 12743, 12753..........................................................................................MT-124

12735 .............................................................................................................................MT-125

12736, 12756, 12766, 18741..........................................................................................MT-126

12800 .............................................................................................................................MT-127

7. Error Code Analysis Flow (Software).........................................................................MT-128

7.1 Initializing the Configuration Setup (A04 or Later) .........................................MT-128

7.2 Action to be Taken When the RU Application Software is Damaged ............MT-132

7.3 Procedures for Changing the IP Address of the CL .......................................MT-134

010-051-01

08.30.2001 FM3058 (1)

CR-IR346RU

Service Manual

0.2

0.3

8. Board Tests in M-Utility................................................................................................MT-148

9. Checking the Voltage ...................................................................................................MT-149

9.1 Checking the Voltage on Board Test Pins (Connectors).................................MT-149

9.2 Checking the Voltage on the Power Supply Unit.............................................MT-152

10. Checking the Fuses .....................................................................................................MT-154

10.1 Sensor-Related Fuses .......................................................................................MT-154

10.2 Motor-Related Fuses .........................................................................................MT-156

10.3 Actuator-Related Fuses.....................................................................................MT-158

10.4 Scanner-Related Fuses .....................................................................................MT-160

10.5 Erasure Lamp and Cooling Fan Fuses ............................................................MT-162

10.6 LED12A Board and Barcode Fuses..................................................................MT-164

10.7 Board Check Pin Fuses.....................................................................................MT-166

11. Checking the Sensors .................................................................................................MT-168

11.1 Checking SA1, SA2, SA3, SA4, SA5, and SB1 .................................................MT-168

11.2 Checking SC1, SC2, SC3, and SC4...................................................................MT-170

11.3 Checking SZ2, SZ3, SZ4, and SZ5 ....................................................................MT-172

12. Checking the Motors....................................................................................................MT-174

12.1 Checking MA1 and MB1 ....................................................................................MT-174

12.2 Checking MC1, MC2, and MC3..........................................................................MT-176

12.3 Checking MZ2 and MZ3 .....................................................................................MT-178

12.4 Checking the FFM12A Board ............................................................................MT-180

13. Checking the Actuators...............................................................................................MT-182

14. Checking the Scanner I/O............................................................................................MT-184

14.1 Checking the Laser (LDD) .................................................................................MT-184

14.2 Checking the Polygonal Mirror (POL) ..............................................................MT-186

14.3 Checking the Start-Point Sensor (SYN) ...........................................................MT-188

14.4 Checking the Leading-Edge Sensor (SED)......................................................MT-190

14.5 Checking the Light-Collecting Unit (PMT) .......................................................MT-192

15. Bootup Failure Analysis Flow.....................................................................................MT-194

15.1 RU Bootup Failure .............................................................................................MT-194

15.2 Checking the LED on the CPU12A Board........................................................MT-195

15.3 Checking the IP Address...................................................................................MT-196

16. Troubleshooting Based on Scratches or Streaks in the

IP Conveyance Direction .............................................................................................MT-197

010-051-01

08.30.2001 FM3058 (1)

CR-IR346RU

Service Manual

0.3

0.4

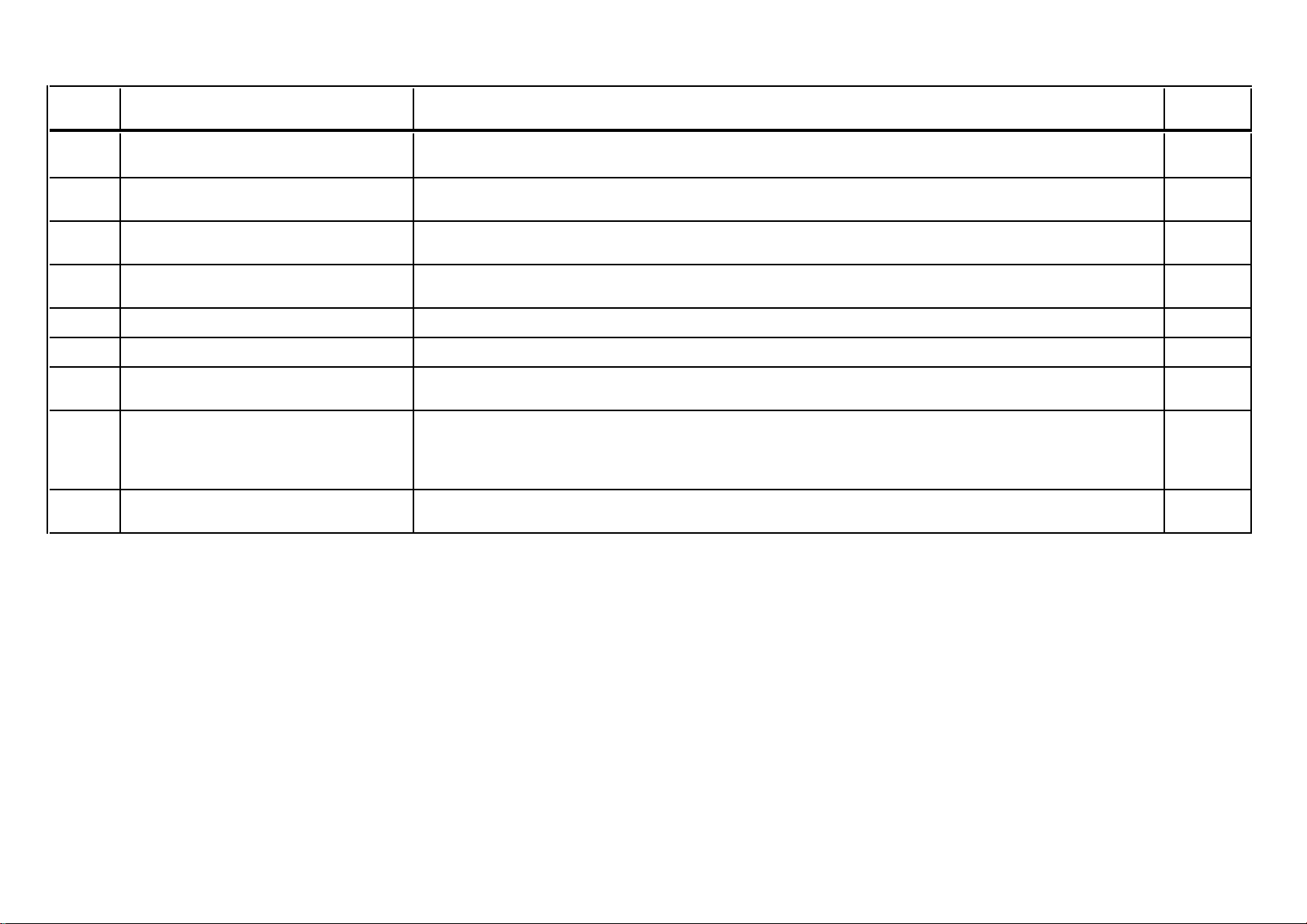

16.1 Troubleshooting Based on Scratches or Streaks on the

IP Fluorescent Face (White)..............................................................................MT-197

16.2 Troubleshooting Based on Scratches or Streaks on the

IP Back Face (Blac k)..........................................................................................MT-200

16.3 Checking the Resistance Value of the Solenoid Connector ..........................MT-203

17. Image T roubleshooting Flow .......................................................................................MT -204

010-051-01

08.30.2001 FM3058 (1)

CR-IR346RU

Service Manual

0.4

Troubleshooting (MT) Control Sheet

Control Sheet

Issue date

10/10/2000 00 New release (FM2887) All pages

08/30/2001 01 Corrections (FM3058) All pages

Revision number Reason Pages affected

MT - 1

010-051-01

08.30.2001 FM3058

CR-IR346RU

Service Manual

MT - 1

MT - 2

FR6H2516.EPS

Error

Code

Analysis

flow

Detail

Code

Error Name

Error code

Occurrence Condition

Error name

Reference destination,

such as analysis flow,

check flow, etc.

Summary of the error,

its presumable cause, etc.

MT-30

10.2

Reference page or reference section number

Reference page

Section number

MT- 30

MT - 30

010-051-00

10.15.2000 FM2887

CR-IR346RU

Service Manual

4.

Error Code Analysis Flow (Mechanism)

10300, 10302, 12302

10300 IP Sensor Logical Inconsistency

During initialization, the remaining IP is ejected, but the sensor having

logical inconsistency for its IP sensor result is detected.

10302 Broken sensor detected

During initialization, the result of IP search detects the presence of an

IP, but the backup memory information indicates that there is no IP in

the machine. The backup memory has a record indicating that the IP

conveyance was performed before power recovery.

12302 IP location information logical failure

During initialization, the result of IP search indicates the presence of an

IP, but the backup memory information indicates that there is no IP in

the machine. Because there is no result of clearing the CMOS, it is

logically inconsistent.

■ I/O Locations

■ Analysis Flow

<Error Code Analysis Flow>

CPU12A, DRV12A, and SNS12A

boards tested in M-Utility normal?

Y

Y

Y

N

FR6H2418.EPS

[Preparation procedures]

1. Secure space for servicing the machine.

2. Remove the covers.

3. Turn OFF the high-voltage switch of the SCN12A board.

Check the error code table again

and troubleshoot.

Power supply error

(12810-12893) occurs?

Sensors SB1, SC3, and SC4

normal?

Y

N

Reseat the error-causing board

and check if the error occurs

again.

Y

N

Replace the power supply.

Voltage on the CPU12A and

DRV12A board normal?

N

1

1

"2. Error Code Table"

Error recurs?

N

Replace the boards in the order named.

1. SNS12A

2. DRV12A

3. CPU12A

4. MTH12A

1

"8. Board Tests in M-Utility"

Y

"1.2 How to Understand Error Code"

"Check, Replacement, and Adjustment Volume:

11.8 Power Supply"

Replace the error-causing board.

Replace the sensor.

The indicated error is at the

beginning of the error log?

N

Y

"11. Checking the Sensors"

"9.1 Checking the Voltage

on the Board Test Pins (Connectors)"

"Service Parts List Volume"

Check the error log in M-Utility.

N

Check the error code table again for the error

at the beginning, and troubleshoot.

"2. Error Code Table"

"Check, Replacement, and Adjustment Volume"

"11.5 SNS12A Board"

"11.6 DRV12A Board"

"11.2 CPU12A Board"

"11.7 MTH12A Board"

"Check, Replacement, and

Adjustment Volume"

"11.2 CPU12A Board"

"11.6 DRV12A Board"

"11.5 SNS12A Board"

M

M

M

M

FRONT

FR6H2223.EPS

Side-positioning conveyor

C unit

Erasure conveyor

B unit

IP sensor SC3

IP sensor SC4

IP sensor SB1

1. Overview of Troubleshooting

1.1 Flow of Troubleshooting

■ Overall Flow

When a trouble occurs, refer to the Troubleshooting Volume along the flow shown below to take

remedial action, such as parts replacement, as needed.

Trouble occurred

010-051-01

010-051-00

08.30.2001 FM3058

10.10.2000 FM2887 (4)

Error code is displayed Bootup failure

“2. Error Code Table”

<Error Code Analysis Flow>

“4. Error Code Analysis Flow (Mechanism)"

“5. Error Code Analysis Flow (Scanner)"

“6. Error Code Analysis Flow (Electrical)"

“7. Error Code Analysis Flow (Software)"

<Remedial Action>

"Check, Replacement, and Adjustment Volume”

"Service Parts List Volume”

"15. Analysis Procedures for

Bootup Failure”

<Check Flow>

“8. Board Tests in M-Utility”

“9. Checking the Voltage”

“10. Checking the Fuses”

“11. Checking the Sensors”

“12. Checking the Motors”

“13. Checking the Actuators”

“14. Checking the Scanner I/O”

FR6H2515.EPS

CR-IR346RU

■ How to Use the Analysis Flow

(1) Check the error code.

“1.2 How to Understand Error Log”

(2) Refer to the Error Code Table.

If any reference page is found in the “Error Code Analysis Flow” column of the Error Code

Table, proceed to its relevant error code analysis flow.

Service Manual

[1.1] MT - 2

(3) Troubleshoot according to the analysis flow.

◆

NOTE

◆

When troubleshooting, refer to the Check Flow that describes the checking procedures for troubleshooting individual I/O parts, as well as “Check, Replacement, and Adjustment Volume.”

<Error Code Analysis Flow>

Check the error log in M-Utility.

MT - 3

The indicated error is

at the beginning of the error log?

Power supply error

(12810-12893) occurs?

Y

"1.2 How to Understand Error Log

Y

Check the error code table

again and troubleshoot.

"2. Error Code Table"

N

N

Check the error code table again for the error

at the beginning, and troubleshoot.

1

Voltage on the CPU12A and

DRV12A board normal?

CPU12A, DRV12A, and SNS1

2A boards tested in M-Utility

normal?

Motor MZ1 normal?

Error recurs?

"2. Error Code Table"

[Preparation procedures]

1. Secure space for servicing the machine.

2. Remove the covers.

3. Turn OFF the high-voltage switch of the SCN12A board.

N

Y

"9.1 Checking the Voltage

on the Board Test Pins (Connectors)"

N

Y

"8. Board Tests

in M-Utility"

N

Y

"12.4 Checking the FFM12A Board "

N

Y

Replace the boards in the order named.

1. SNS12A

2. DRV12A

3. CPU12A

4. MTH12A

"Check, Replacement, and Adjustment Volume"

"11.6 DRV12A Board"

"11.2 CPU12A Board"

"11.7 MTH12A Board"

Replace the power supply.

"Check, Replacement, and Adjustment Volume:

10.9 Power Supply"

Reseat the error-causing board

and check if the error occurs

again.

Y

Replace the error-causing

board.

Replace the motor MZ1.

1

Return to the Error Analysis Flow

section number or indicated page.

1

Voltage on the CPU12A and

DRV12A board normal?

Y

"9.1 Checking the Voltage

on the Board Test Pins (C

CPU12A, DRV12A, and SNS1

2A boards tested in M-Utility

normal?

N

1

N

N

B

Repl

<Check Flow>

A

Proceed to the section number.

A

9. Checking the Voltage

WARNING

To avoid possible electric shock hazard from high voltage, observe the following precautions.

• Do not touch the power supply terminals.

• When making voltage measurements, do not touch the probe (metal portion) of a tester.

[2] Checking the Voltage on the CPU12A Board Test Pin (TP1)

CPU12A board

MT- 1

9.1 Checking the Voltage on Board Test Pins (Connectors)

[1] Analysis Flow

START

Power OFF

Remove the front cover

and lower light protect plate.

Turn OFF the high-voltage switch.

Voltage on the INV12B

board checked?

Test pin voltage on each

board normal?

B

Turn ON the high-voltage switch.

010-051-00

10.10.2000 FM2887

Y

Remove the left-hand side cover

and light protect plate.

"Check, Replacement, and

Adjustment Volume: 4.1 INV12B Board"

Power ON.

Y

[2], [3], [4], [5]

Reinstall the front cover

and lower light protect plate.

END

Return to the error

code analysis flow.

N

Remove the support plate (board retainer).

N

Voltage on the power supply

unit normal?

Y

"9.2 Checking the Voltage

on the Power Supply Unit"

"Check, Replacement, and

Adjustment Volume:

11.1 Controller"

N

Replace the power supply unit.

"Check, Replacement, and

Adjustment Volume:

11.8 Power Supply"

FR6H2502.EPS

CR-IR346RU

Service Manual

CN6

CN5

TP1

Test pin TP1 Voltage

TP1 1-2 +5V

TP1

S1

2

GND

1

+5V(A)

Should be within a range from +4.95 to 5.20 V.

: GND

Reference voltage

S2

F

R

O

N

T

FR6H2501.EPS

MT - 1

010-051-00

010-051-01

10.10.2000 FM2887 (4)

08.30.2001 FM3058

CR-IR346RU

Service Manual

FR6H2517.EPS

[1.1] MT - 3

MT - 4

*** ERROR LOG ALL ***CODE DATE

13603 2000.08.25 14:51:45 00DC05 toammoni_3D0004 commonitar_Op.c 258

10921 2000.08.25 14:50:33 00C014 toamerrsnd_0 microtfnc,c 2138

•

•

•

10921 2000.08.25 14:45:25 00C013 toamerrsnd_0.END 1.NEXT(DEFAULT=1) : 1

CODE DATE

13603 2000.08.25 14:20:15 00DC05 toammoni_3D0004 commonitar_Op.c 258

10921 2000.08.25 14:05:01 00C014 toamerrsnd_0 microtfnc,c 2138

•

•

•

10921 2000.08.25 13:50:30 00C013 toamerrsnd_0.END 1.NEXT(DEFAULT=1) : 0

FR6H2564.EPS

*** ERROR LOG ALL ***CODE DATE

[13603] 2000/08/25 14:51:45 00DC05 toammoni_:3D0004 commonitar_Op.c 258

[10921] 2000/08/25 14:50:33 00C014 toamerrsnd_:0 microtfnc,c 2138

•

•

•

[10921] 2000/08/25 14:45:25 00C013 toamerrsnd_0.END 1.NEXT(DEFAULT=1) : 1

CODE DATE

[13603] 2000/08/25 14:20:15 00DC05 toammoni_:3D0004 commonitar_Op.c 258

[10921] 2000/08/25 14:05:01 00C014 toamerrsnd_:0 microtfnc,c 2138

•

•

•

[10921] 2000/08/25 13:50:30 00C013 toamerrsnd_0.END 1.NEXT(DEFAULT=1) : 0

FR6H2565.EPS

*** ERROR LOG ALL ***CODE DATE

[13603] 2000/08/25 14:51:45 00DC05 <SR> T02:3D0004 commonitar_Op.c 258

[10921] 2000/08/25 14:50:33 00C014 <BR> T99:0 microtfnc,c 2138

•

•

•

[10921] 2000/08/25 14:45:25 00C013 <BR> T90.END 1.NEXT(DEFAULT=1) : 1

CODE DATE

[13603] 2000/08/25 14:20:15 00DC05 <SW> T02:3D0004 commonitar_Op.c 258

[10921] 2000/08/25 14:05:01 00C014 <BR> T99:0 microtfnc,c 2138

•

•

•

[10921] 2000/08/25 13:50:30 00C013 <BR> T990.END 1.NEXT(DEFAULT=1) : 0

FR6H2566.EPS

1.2 How to Understand Error Log

When an error code is displayed, check the error log.

■ How to Understand the Error Log List

When multiple errors occurred, the error at the beginning that occurred at the same time (with a

margin of about 2 minutes) is the most likely cause that is directly responsible for the trouble.

Check the error log to see which is the error at the beginning.

● Error log format

Error code Occurrence date

12256 2000.10.07 13:12:19 00257D tiphscan____

3D0004 ScnCmFnc.c 2817

12255 2000.10.07 13:12:10 00258D tiphscan____

3D0004 400000,00 00 00 609C 6098

FR6H2518.EPS

● How to identify the error code at the beginning

The error log presented below is an example where two causes (A and B) were logged.

• Errors that occurred at the same time (with a margin of about two minutes) are categorized as

the same error occurrence group.

• An error that occurred first (at the earliest time) within a certain error occurrence group is considered as the first-occurred error.

(Example)

• Error occurrence groups A and B are judged as separate error occurrence groups, because the

difference between their error occurrence times is 14 minutes.

• The error that first occurred in group A is “13200”.

Below is shown, by way of example, how to identify the error code for software version A02.

Error codes displayed on the CL screen

Note, however, that the display of the error log differs depending on the software version.

• Display: For A02

• Display: For A03 and A04

• Display: For A05

Error code that occurred last

A

Error code at the beginning:

It should be analyzed first.

B

010-051-01

010-051-00

08.30.2001 FM3058

10.10.2000 FM2887 (4)

Error code that

occurred third

Error code that

occurred second

FR6H2520.EPS

CR-IR346RU

Service Manual

[1.2] MT - 4

■ Error Code Detail ● Y: Error category

0: OS (operating system software), libraries

1XYZZ

● X: Error level

Error level notations

00 to 99 : Reference number for each error category

0 to 9 : Error category

0 to 4 : Error level

1 : 1 for all RU errors

FR6H2519.EPS

1: Image processing CPU

2: Scanner control

3: Conveyance control

4: Overall control

5: Network control

6: Reserved

7: Electrical/hardware related

8: Reserved

9: Others (software installation, version update, etc.)

MT - 5

FATAL error: 0 or 9

• The user is notified of an error occurrence.

• Level of error where the routine processing cannot be resumed.

• It is necessary to immediately troubleshoot and take remedial action.

WARNING: 2

• An error is logged, but the user is not notified.

• Level of error where the function associated with the error is rendered unusable.

• It is necessary to immediately troubleshoot and take remedial action.

WARNING: 1

• The user is notified of an error occurrence.

• Errors that occur due to erroneous user operation (incorrect loading of the cassette or IP, etc.).

• If this level of error occurred at the same time with another level of warning, it is necessary to

troubleshoot and take remedial action.

WARNING: 4

• An error is logged, but the user is not notified.

• Errors that occur when a retry operation is performed.

• If the same error occurs frequently and if this level of error occurs at the same time with another

level of warning, it is necessary to troubleshoot and take remedial action.

WARNING: 3

• An error is logged, but the user is not notified.

• Errors that occur when servicing procedures are performed.

● ZZ: Reference number

It is managed according to each error category.

010-051-01

010-051-00

08.30.2001 FM3058

10.10.2000 FM2887 (4)

CR-IR346RU

Service Manual

[1.2] MT - 5

BLANK PAGE

MT - 6

010-051-00

010-051-01

10.10.2000 FM2887 (4)

08.30.2001 FM3058

CR-IR346RU

Service Manual

[1.2] MT - 6

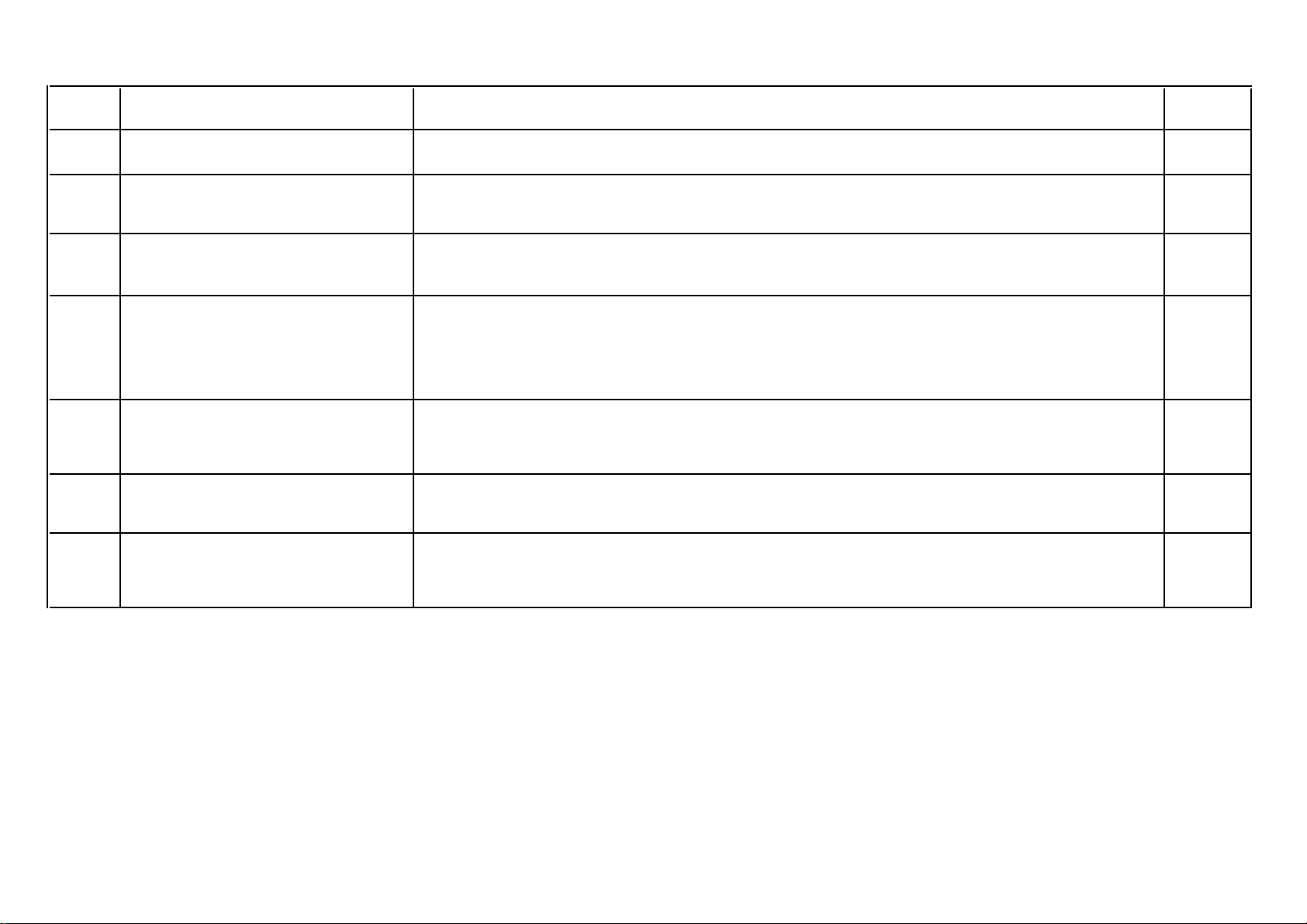

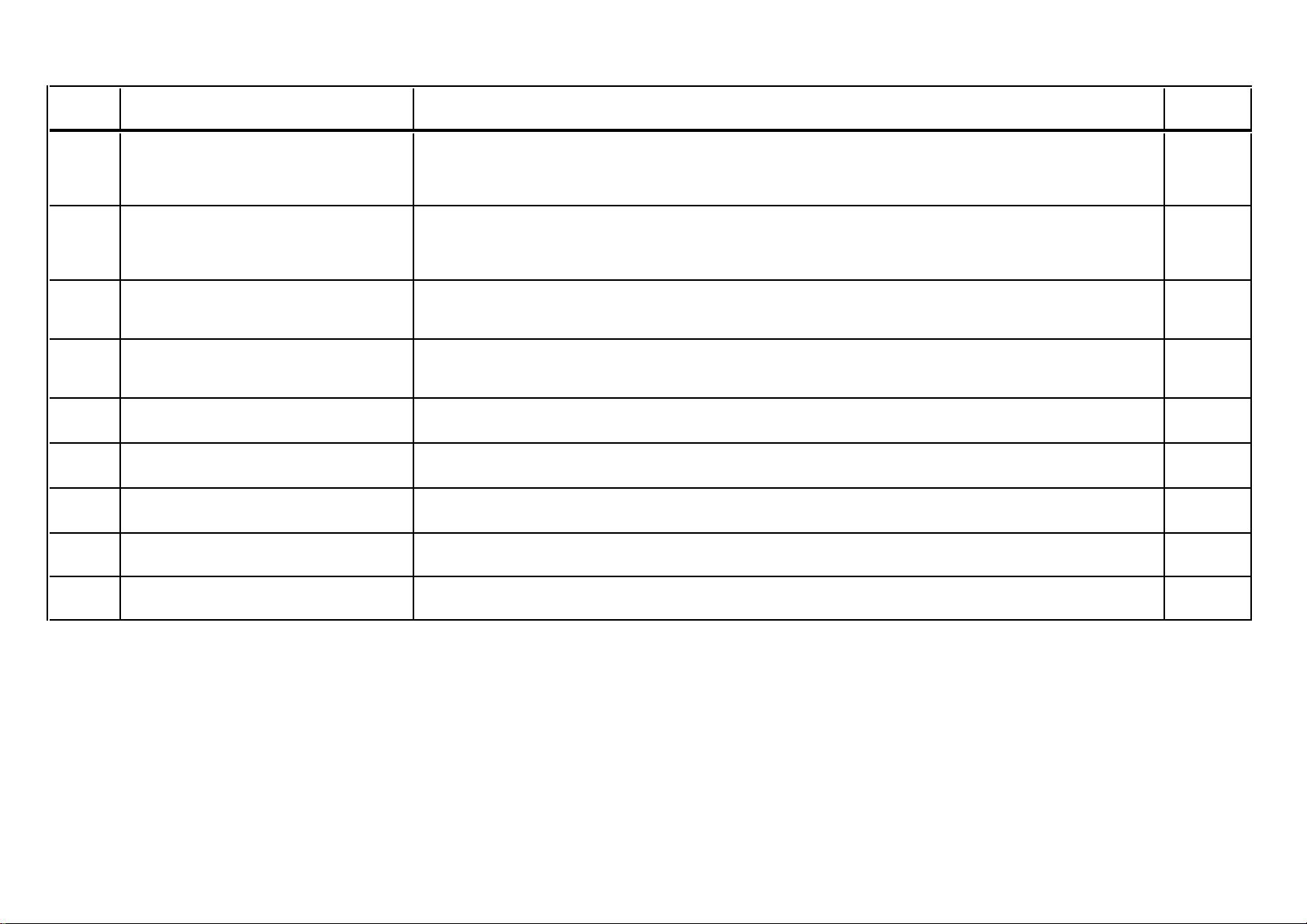

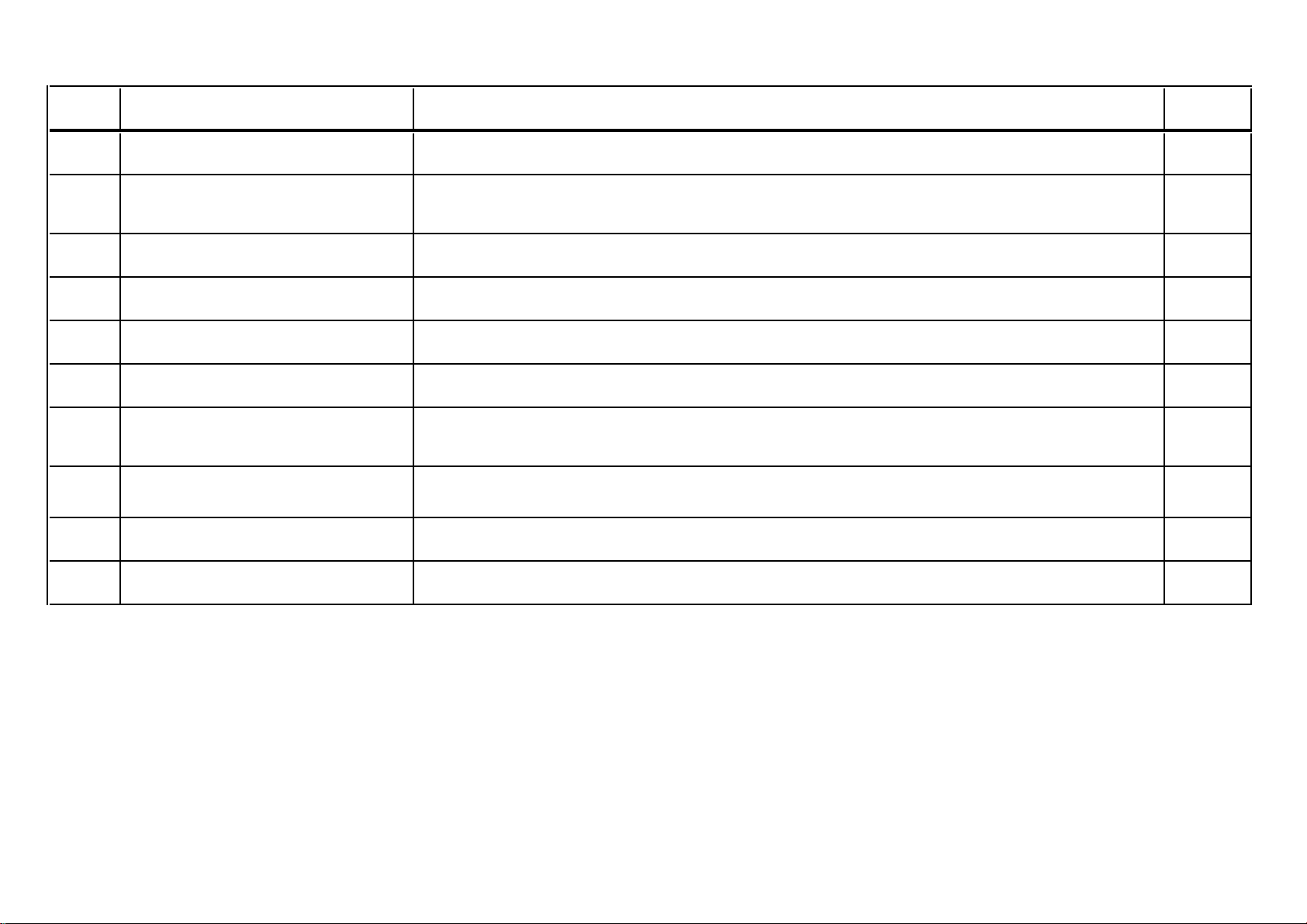

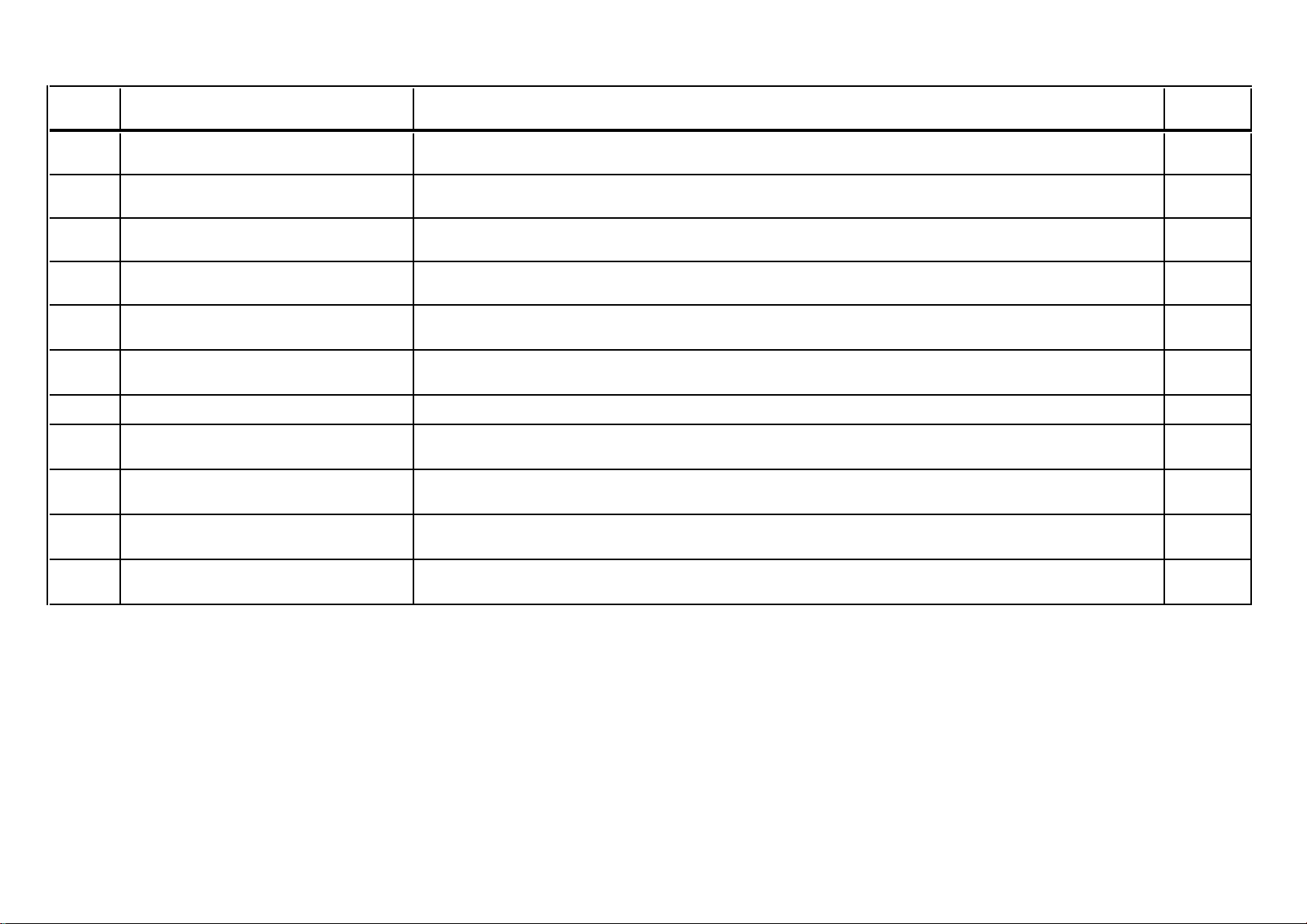

2. Error Code Table

MT-7

Error

Code

Error Name Occurrence Condition

10026 Machine configuration error

10100 Image processing initialization error

10120 Image processing CPU sequence error

10230 Scanner power supply error during bootup

10231 Scanner power supply error during bootup (1)

10232 Scanner power supply error during bootup (2)

During bootup, the configuration file in the flash ROM on the CPU12A board is defective, so that installation is not

automatically performed from the FTP server running on the CL.

When an attempt is made to initialize the image processing section of the CPU board during the machine initialization

routine, either of the errors ranging from 12101 to 12108 is detected.

Because error, from 12101 to 12108, is detected three times or more, fatal error results.

During IP read processing, an attempt is made to activate the sub-CPU (image processing section) of the CPU board,

but error, from 12121 or 12125, is detected.

Because error, from 12101 to 12108, is detected three times or more, fatal error results.

During bootup, because the connector (CN1 on the PMT12A board, CNE1 on the scanning optics unit, CNE2 on the

scanning optics unit, CN1 on the SYN12A board, or CN1 on the LDD12A board) is disconnected, the laser (LDD), startpoint detection (SYN), and photomultiplier (PMT) functions are disabled. Because the laser is not enabled, the leadingedge detection (SED) cannot be performed (detail code: D0F603). Note that if the HV is OFF, the detail code is D0F403.

During bootup, because +15V is not supplied to the SCN12A board due to blow of the fuse (H11 on the MTH board) or

+15V power supply error, most of the functions, except for the polygonal mirror (POL) and laser (LDD), are disabled

(detail code: A0DF03). Note that if the HV is OFF, the detail code is A0DD03.

During bootup, because the fuse (H12 on the SCN12A board) is blown, the photomultiplier (PMT) and start-point

detection (SYN) functions are disabled (detail code: 809603). Note that if the HV is OFF, the detail code is 809403.

Analysis

Flow

6.1

8

8

MT-88

MT-90

MT-92

10233 Scanner power supply error during bootup (3)

010-051-01

08.30.2001 FM3058 CR-IR346RU Service Manual

During bootup, because the fuse (J11 on the MTH12A board) is blown or because -15V is not supplied to the SCN12A

board, the photomultiplier (PMT), start-point detection (SYN), and laser (LDD) functions are disabled. Because the laser

(LDD) is not enabled, the leading-edge detection (SED) cannot be performed (detail code: C1DD03).

MT-94

[2.] MT-7

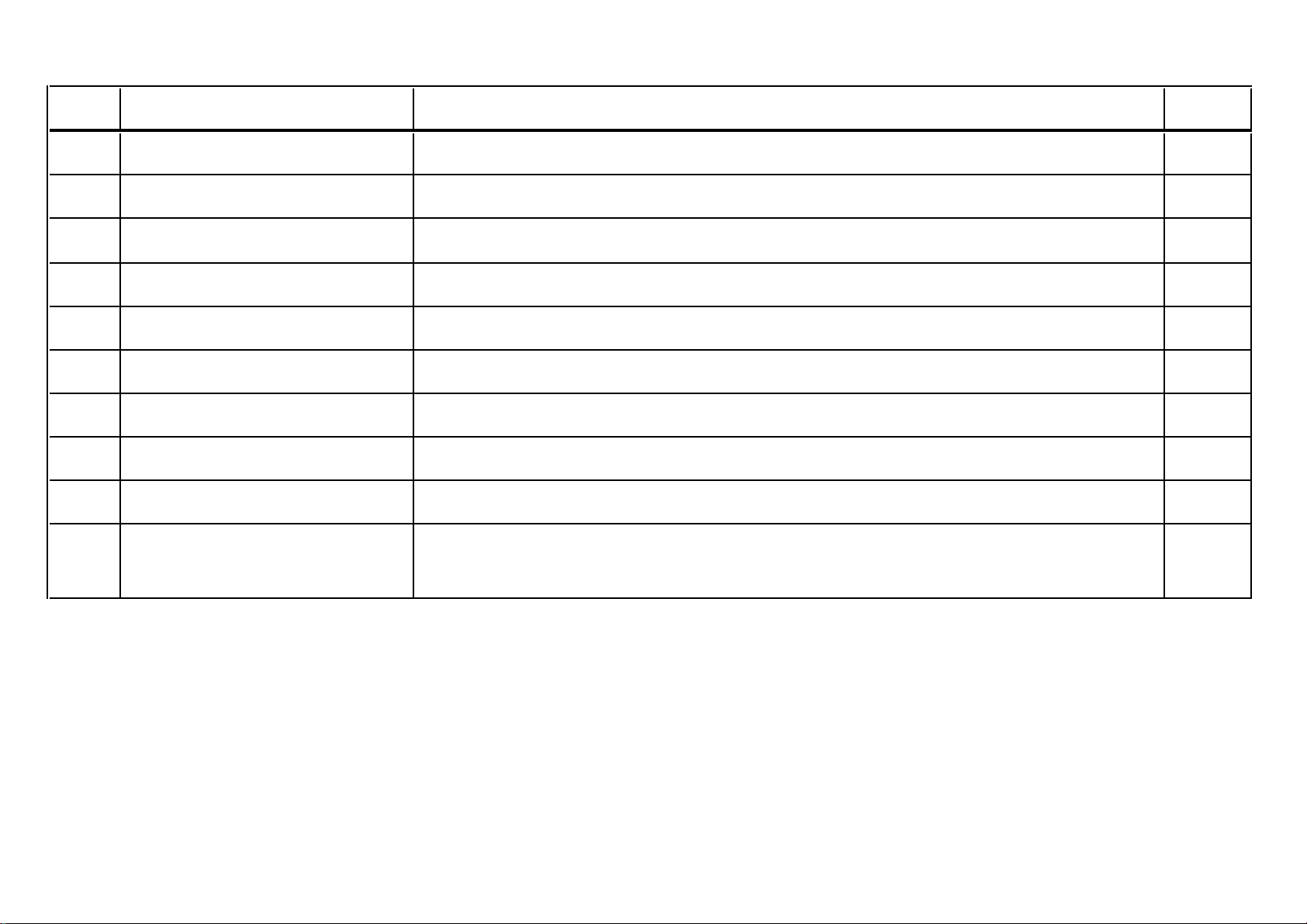

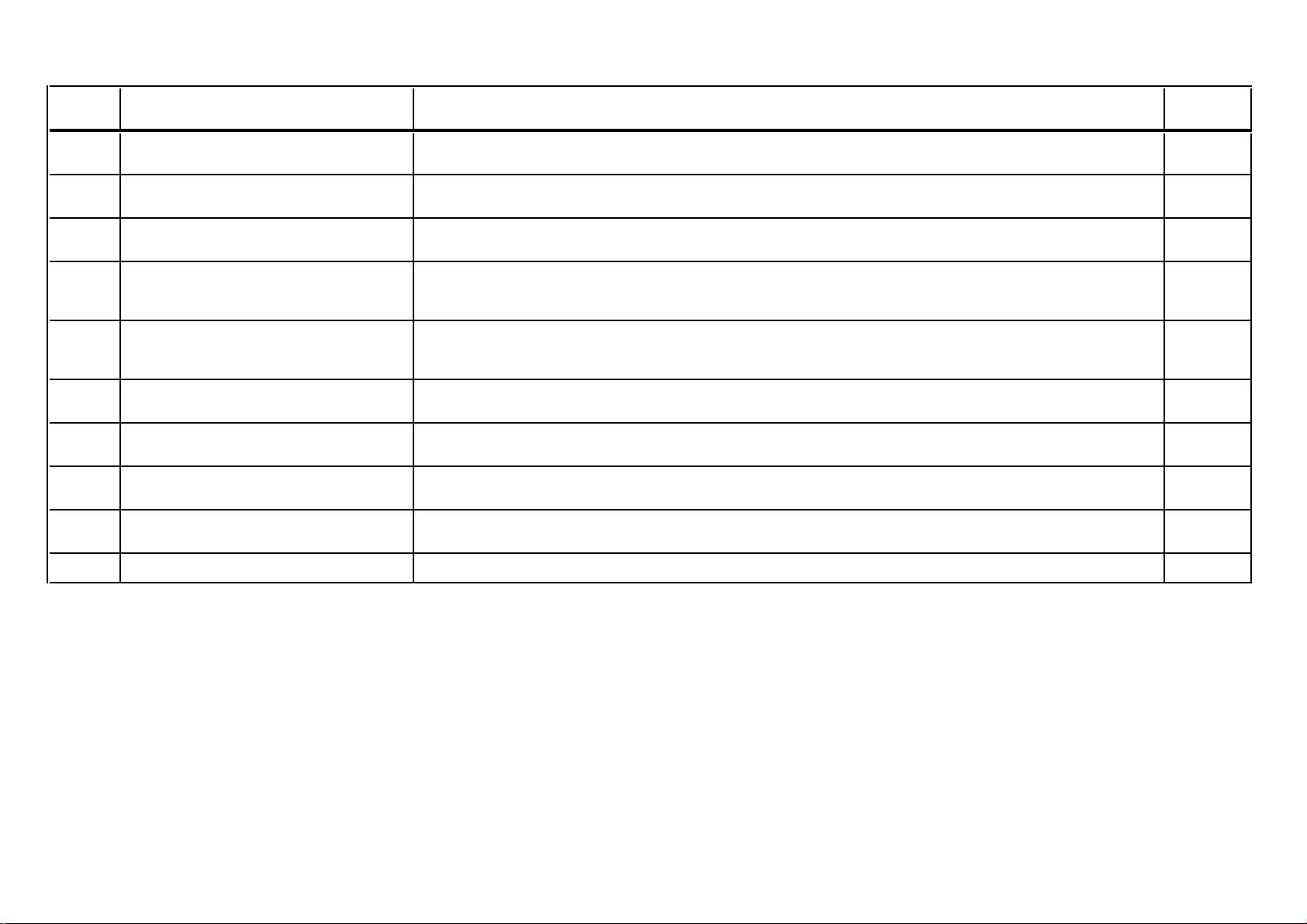

2. Error Code Table

Duri

15V i

SCN12A b

(J11

MTH12A b

)

MT-8

Error

Code

Error Name Occurrence Condition

10234

10236 Scanner power supply error during bootup (6)

• During bootup, because the fuse (J12 on the SCN12A board) or the fuse (H12 on the SCN12A board) is blown, ±15V is

not supplied to the SCN12A board, and the photomultiplier (PMT), start-point detection (SYN), laser (LDD), and SCN

board (PLL) functions are disabled. Because the laser (LDD) is not enabled, the leading-edge detection (SED) cannot

be performed (detail code: C0DC03).

•

ng bootup, because or -15V (SLOT4) power supply error, the photomultiplier (PMT), start-point detection (SYN), and laser (LDD) functions

are disabled. Because the laser (LDD) is not enabled, the leading-edge detection (SED) cannot be performed (detail

code: C0D400

• During bootup, because ±15V is not supplied, except for the laser (LDD), due to blow of the fuse (J11 on the MTH12A

board, or J12, H12, or H14 on the SCN board), the photomultiplier (PMT), start-point detection (SYN), and laser (LDD)

functions are disabled. Because the laser (LDD) is not enabled, the leading-edge detection (SED) cannot be performed

(detail code: C0D603). Note that if the HV is OFF, the detail code is C0D400.

• During bootup, because 24V is not supplied to the SCN12A board due to blow of the fuse (K11 on the MTH12A board) or

24V (SLOT5) power supply error, the polygonal mirror (POL) function is disabled (detail code: D01403).

• During bootup, because the fuses (H14 and A22 on the SCN board) are blown or because 5V is not supplied to the

SYN12A board and SED12A board, the leading-edge detection (SED) and start-point detection (SYN) functions are

disabled (detail code: C01403).

During bootup, because ±15V is not supplied to the SYN12A board, PMT12A board, and LDD12A board due to blow of

the fuses (J12 and H12 on the SCN board), the photomultiplier (PMT), start-point detection (SYN), and laser (LDD)

functions are disabled. Because the laser (LDD) is not enabled, the leading-edge detection (SED) cannot be performed

(detail code: 819603). Note that if the HV is OFF, the detail code is 819403.

.

s not supplied to the

oard due to blow of the fuse

on the

oard)

Analysis

Flow

MT-96Scanner power supply error during bootup (4)

MT-9810235 Scanner power supply error during bootup (5)

MT-100

10244 Scanner control board error (4)

010-051-01

08.30.2001 FM3058 CR-IR346RU Service Manual

For self-diagnostic during bootup, an SCN board diagnostic error associated with polygon error is detected. Because

the PLL on the SCN12A does not oscillate, a polygon sync signal cannot be detected.

-

[2.] MT-8

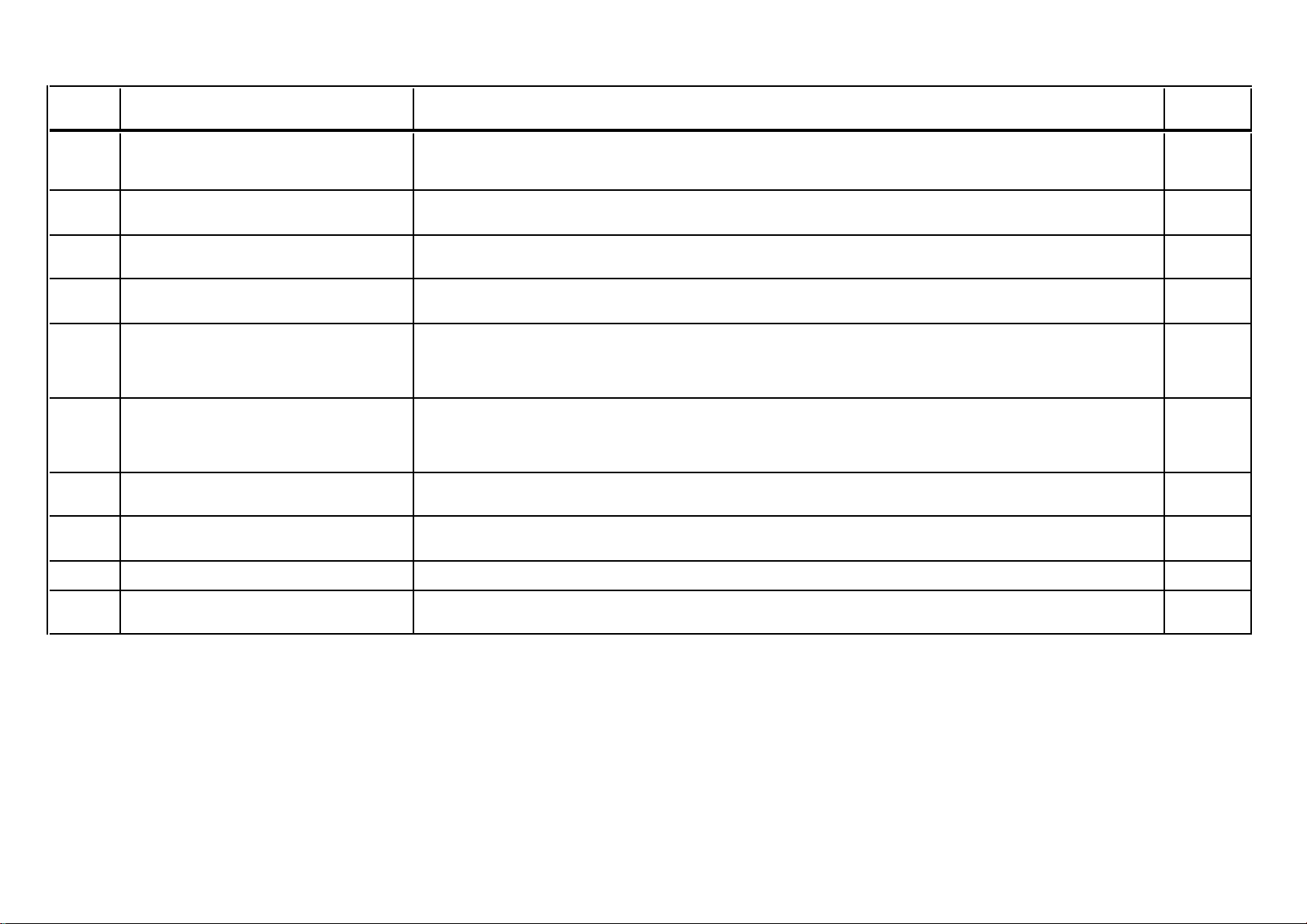

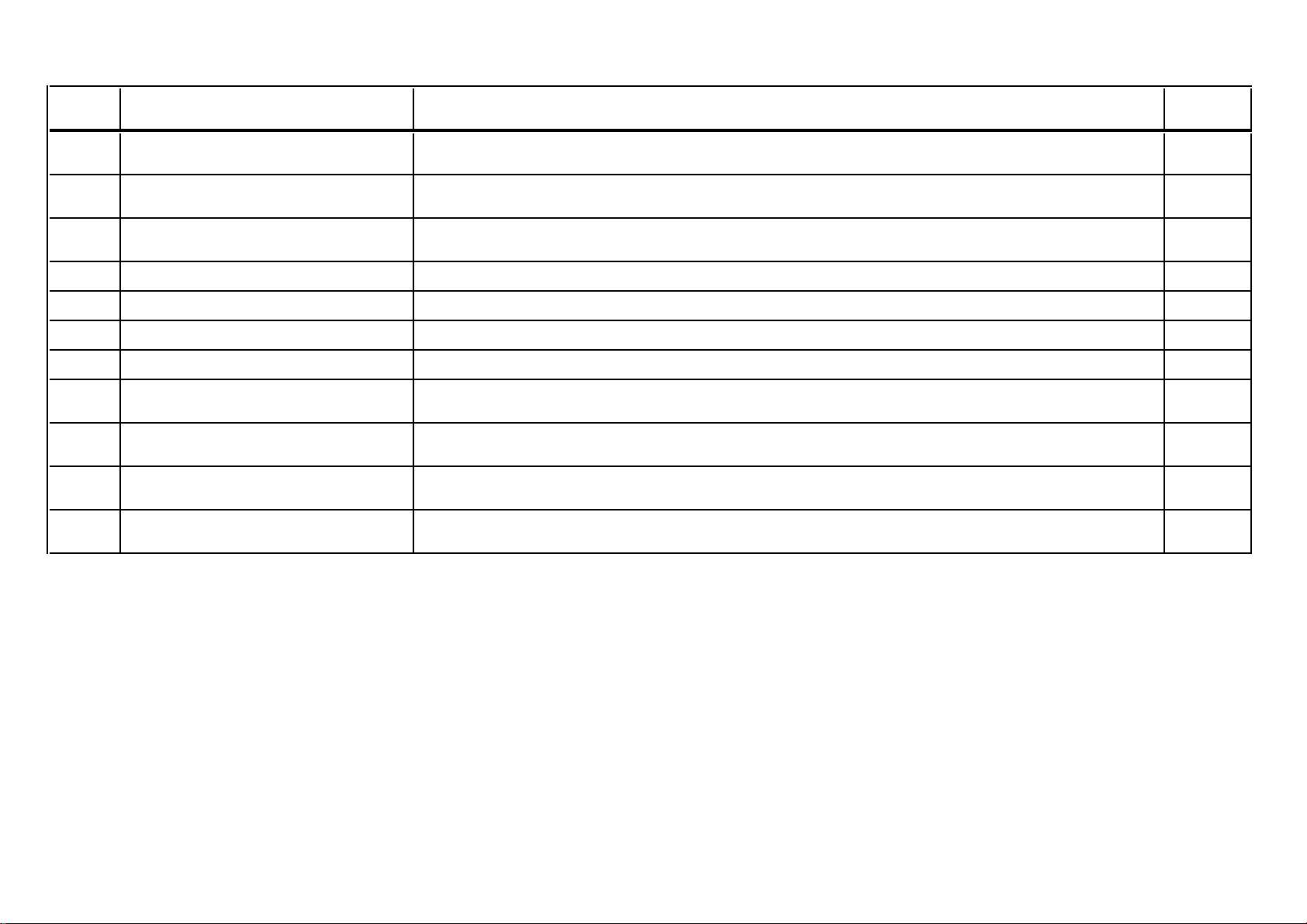

2. Error Code Table

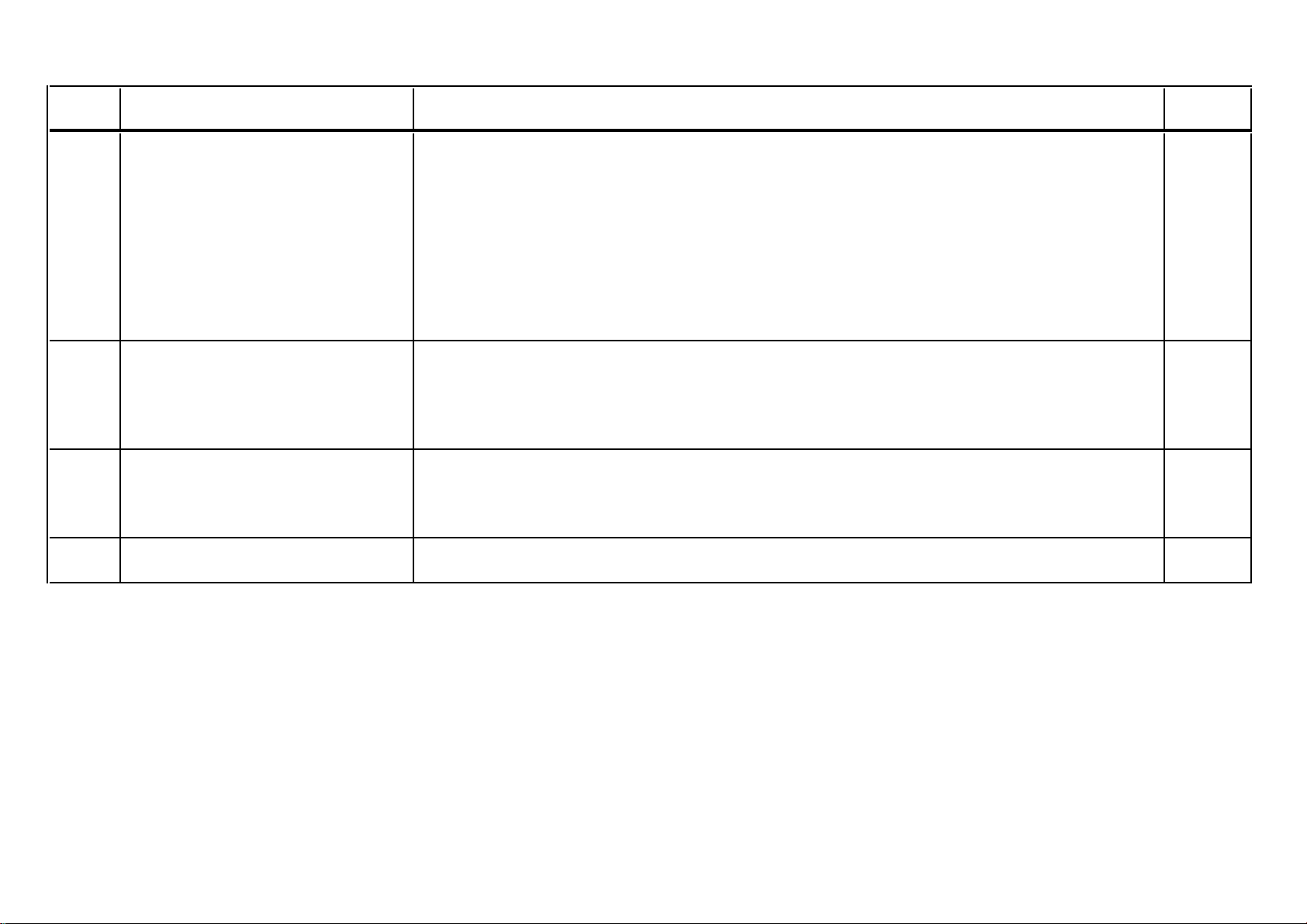

MT-9

Error

Code

Error Name Occurrence Condition

10261 Polygon stop/rotation error (1)

10271 Laser unlit error (1)

10281 Start-point detection error during bootup (1)

10283 Scanning optics unit board error (1)

10298 Before-reading scanner retry error

10300 IP sensor logical inconsistency

10301 Sensor error

10302 Broken wire sensor detected

10303 IP initialization search error

During routine processing, error for the polygon lock signal (PONL, POKL) is detected so that the polygonal mirror

function is disabled. The start-point detection (SYN) and leading-edge detection (SED) functions are also disabled

(detail code: D03403).

During routine processing, the laser (LDD) and start-point detection (SYN) functions are disabled due to blow of the fuse

(H13 on the SCN board) or laser failure (detail code: 815403).

During bootup, because the signal from the start-point detection (SYN) is faulty, the SCN12A board does not operate

normally (detail code: 801C03).

For self-diagnostics prior to reading during routine processing, an SCN board diagnostic error (C05401 or C07403)

associated with polygon error is detected. The laser is unlit due to a disconnected connector at the scanning optics

unit, etc., so that an error related to the polygon error occurs, as well.

During routine processing, because the scanner-related error is detected, the IP is returned to the cassette and the

scanner is initialized. The routine processing is retried again, but the scanner-related error recurs.

During bootup, the remaining IP is ejected, but the sensor having logical inconsistency for its IP sensor result is

detected.

During bootup, the sensor is turned OFF after the timeout of the mechanical operation is detected, but the sensor does

not transition to CLOSE.

During bootup, the result of IP search detects the presence of an IP, but the backup memory information indicates that

there is no IP in the machine. The backup memory has a record indicating that the IP conveyance was performed before

power recovery.

During bootup, the result of location information confirmation for IP search indicates the absence of an IP, but the

backup memory information indicates the presence of an IP in the machine. System shutdown is selected via user

intervention.

Analysis

Flow

MT-112

MT-116

MT-102

-

MT-104

MT-52

MT-53

MT-52

MT-54

010-051-01

08.30.2001 FM3058 CR-IR346RU Service Manual

[2.] MT-9

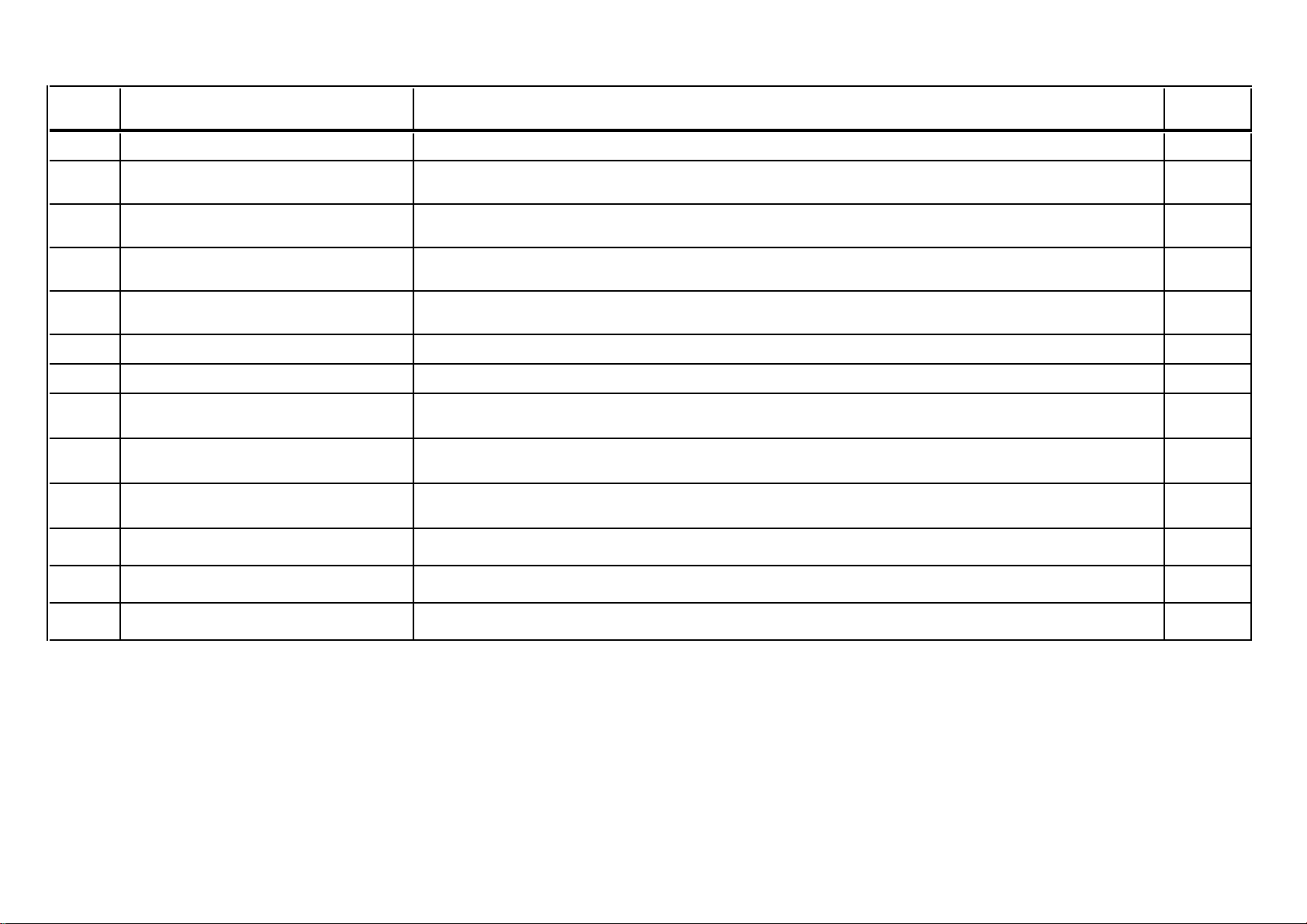

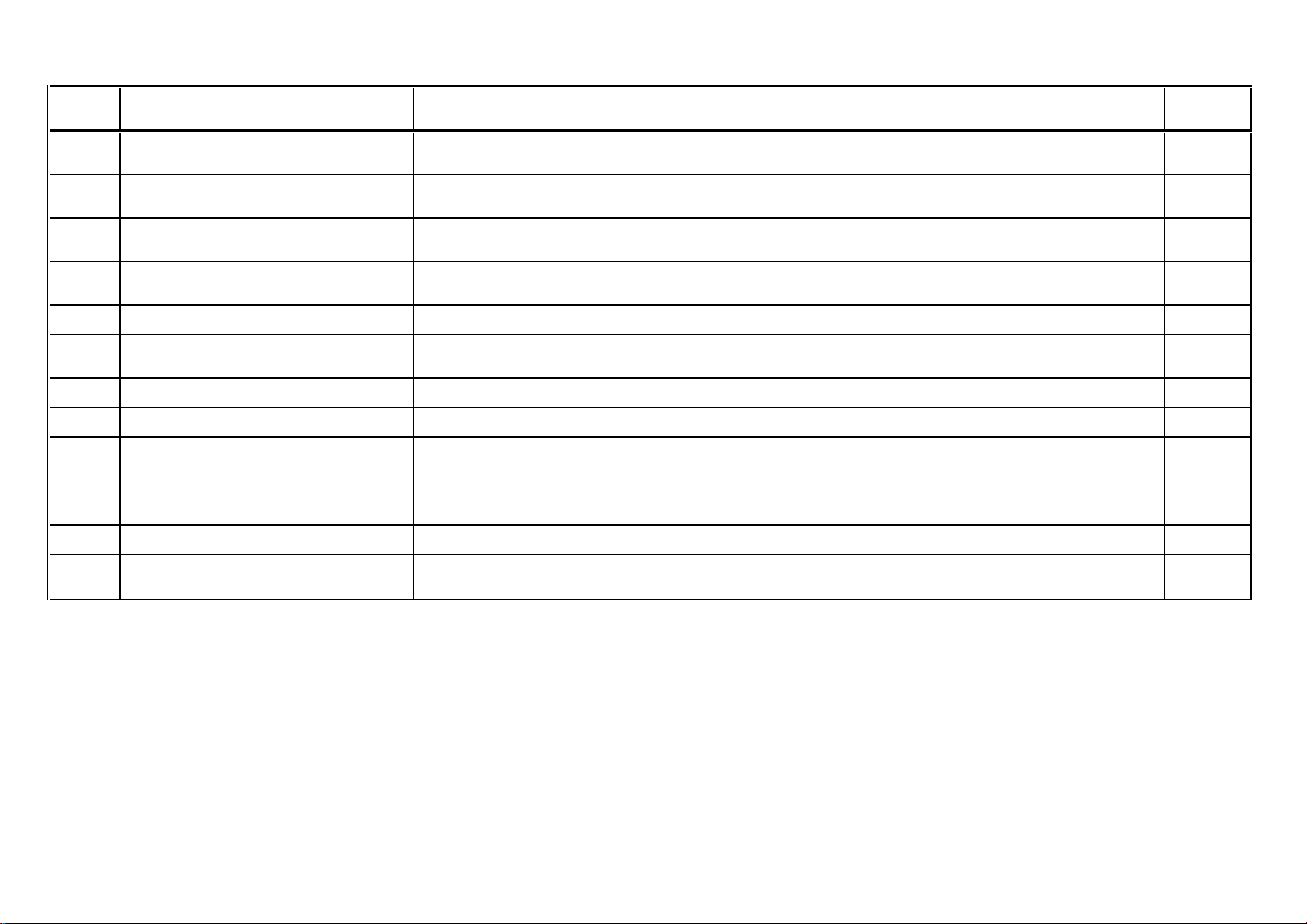

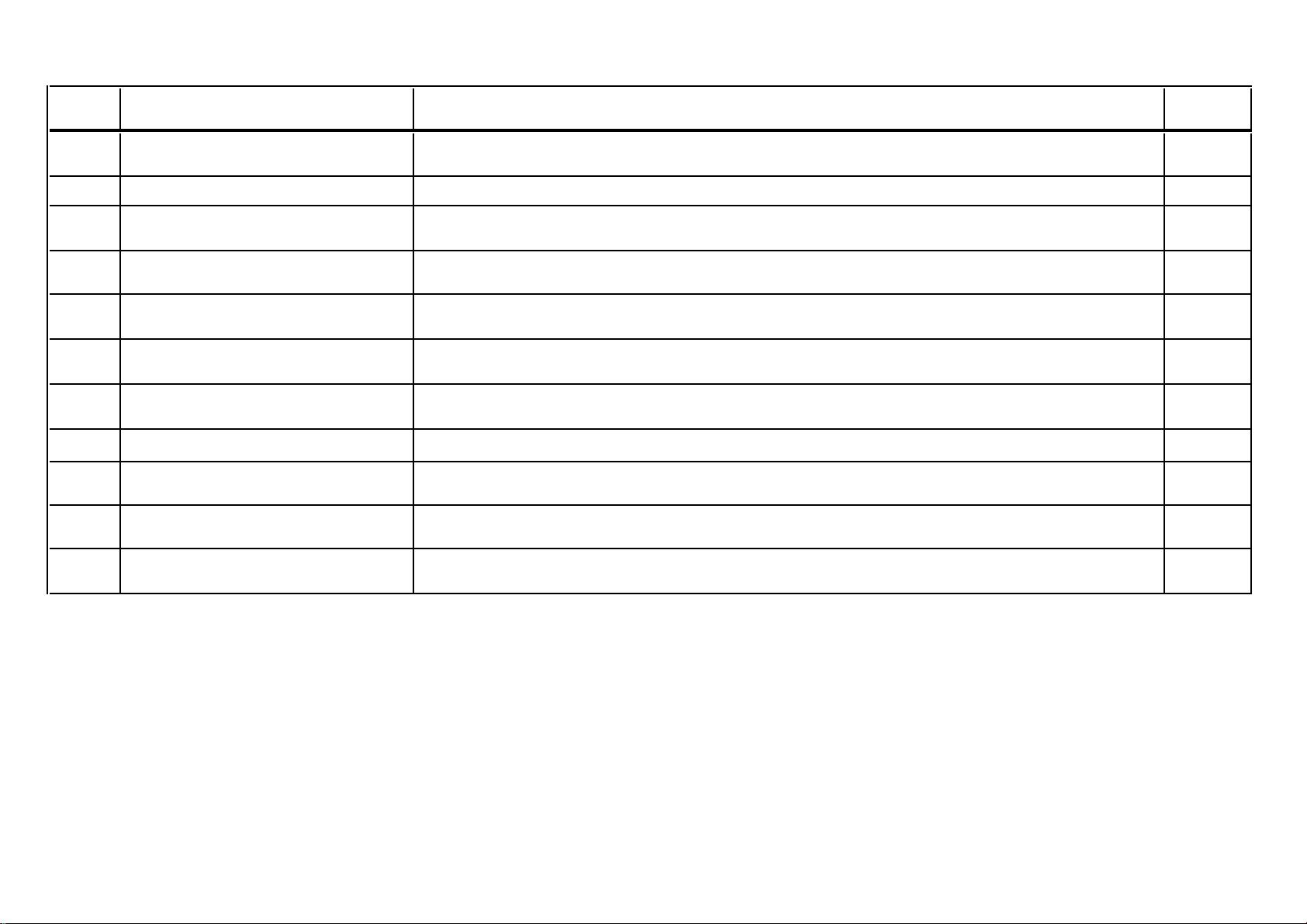

2. Error Code Table

MT-10

Error

Code

Error Name Occurrence Condition

10304 IP conveyance error During bootup (1)

10305 IP conveyance error During bootup (2)

10306

10307

IP positioning error at side-positioning

conveyor During bootup

Length-measurement conveyance error

During bootup

10318 Suction cup HP operation error

10334 Side-positioning HP operation error

10338 Side-positioning grip HP operation error

10340 IP stopper protrusion error

During bootup, the IP search detects the presence of an IP. The CLOSE state of the SB1, SC3, and SC4 is detected,

and the MB1 and MC3 are driven, but any of the sensors does not transition to OPEN. The backup memory has a record

indicating the presence of an IP in the machine.

During bootup, the IP search detects that there is an IP in the machine that is difficult to convey. The backup memory

has a record indicating the absence of an IP in the machine. IP conveyance is not performed before power-OFF. It is

presumed that the backup memory has been cleared.

During bootup, the MB1 and MC3 are driven (clockwise) to perform side-positioning operation for remaining IP

processing, but the SC3 does not transition to CLOSE within the specified period of time.

During bootup, the MZ1, MC3, and MB1 are driven (counterclockwise) to measure the IP size for remaining IP

processing, but the SC3 does not transition to CLOSE within the specified period of time. Alternatively, it transitions to

CLOSE but not to OPEN.

During bootup or routine processing, because error (14315, 14316, 14317) is detected, retries (four times or more) are

performed, but error (fatal error) results.

During bootup or routine processing, because error (14331, 14332, 14333) is detected, retries (four times or more) are

performed, but error (fatal error) results.

During bootup or routine processing, because error (14335, 14336, 14337) is detected, retries (four times or more) are

performed, but error (fatal error) results.

During bootup, the SolZ1 is turned ON to protrude the stopper, but the SZ4 does not transition to OPEN within the

specified period of time. Retries (six times or more) are performed, but error results.

Analysis

Flow

MT-54

MT-54

MT-56

MT-56

MT-57

MT-58

MT-59

MT-60

10341 IP stopper retreat error

010-051-01

08.30.2001 FM3058 CR-IR346RU Service Manual

During bootup and shutdown processing, the SolZ1 is turned OFF to retreat the stopper, but the SZ4 does not transition

to CLOSE within the specified period of time. Retries (six times or more) are performed, but error results.

MT-60

[2.] MT-10

2. Error Code Table

MT-11

Error

Code

Error Name Occurrence Condition

10346 Driving shaft grip error

10347 Driven shaft grip error

10348 Both grip release error

10349 Driven shaft grip release error

10353 Driving shaft correction grip error

10354 Initialization grip movement (1) error

10355 Initialization grip movement (2) error

10356 Ejection grip error

10357 No-load running error

10360 After-erasure conveyance error

During bootup, the MZ2 is driven to grip the driving shaft, but the SZ2 does not transition to OPEN within the specified

period of time. Retries (two times or more) are performed, but error results.

During bootup, the MZ2 is driven to grip the driven shaft, but the SZ3 does not transition to CLOSE within the specified

period of time. Retries (two times or more) are performed, but error results.

During bootup, the MZ2 is driven to release both grips, but the SZ2 does not transition to CLOSE within the specified

period of time. Retries (two times or more) are performed, but error results.

During bootup, the MZ2 is driven to release the driven shaft grip, but the SZ3 does not transition to OPEN within the

specified period of time. Retries (two times or more) are performed, but error results.

During bootup, the MZ2 is driven to correct the speed, but the SZ2 does not transition to OPEN within the specified

period of time.

During bootup, the MZ2 is driven to check the grip state, but the SZ2 does not transition to OPEN within the specified

period of time. Retries (two times or more) are performed, but error results

During bootup, the MZ2 is driven to check the grip state, but the SZ2 does not transition to CLOSE or the SZ3 does not

transition to CLOSE within the specified period of time. Retries (two times or more) are performed, but error results.

During bootup, the MZ2 is driven to perform ejection grip, but the SZ3 does not transition to CLOSE within the specified

period of time. Retries (two times or more) are performed, but error results.

During bootup, the MZ2 is driven to perform no-load running, but the SZ3 does not transition to OPEN within the

specified period of time. Retries (two times or more) are performed, but error results.

During routine processing, the SB1 cannot detect the IP leading edge for after-erasure conveyance (the MB1 is driven

counterclockwise). The MB1 is driven (counterclockwise) to perform load conveyance, but the SB1 does not transition

to CLOSE within the specified period of time (20 sec).

Analysis

Flow

MT-62

MT-64

MT-62

MT-64

MT-62

MT-64

MT-62

MT-64

MT-64

MT-76

010-051-01

08.30.2001 FM3058 CR-IR346RU Service Manual

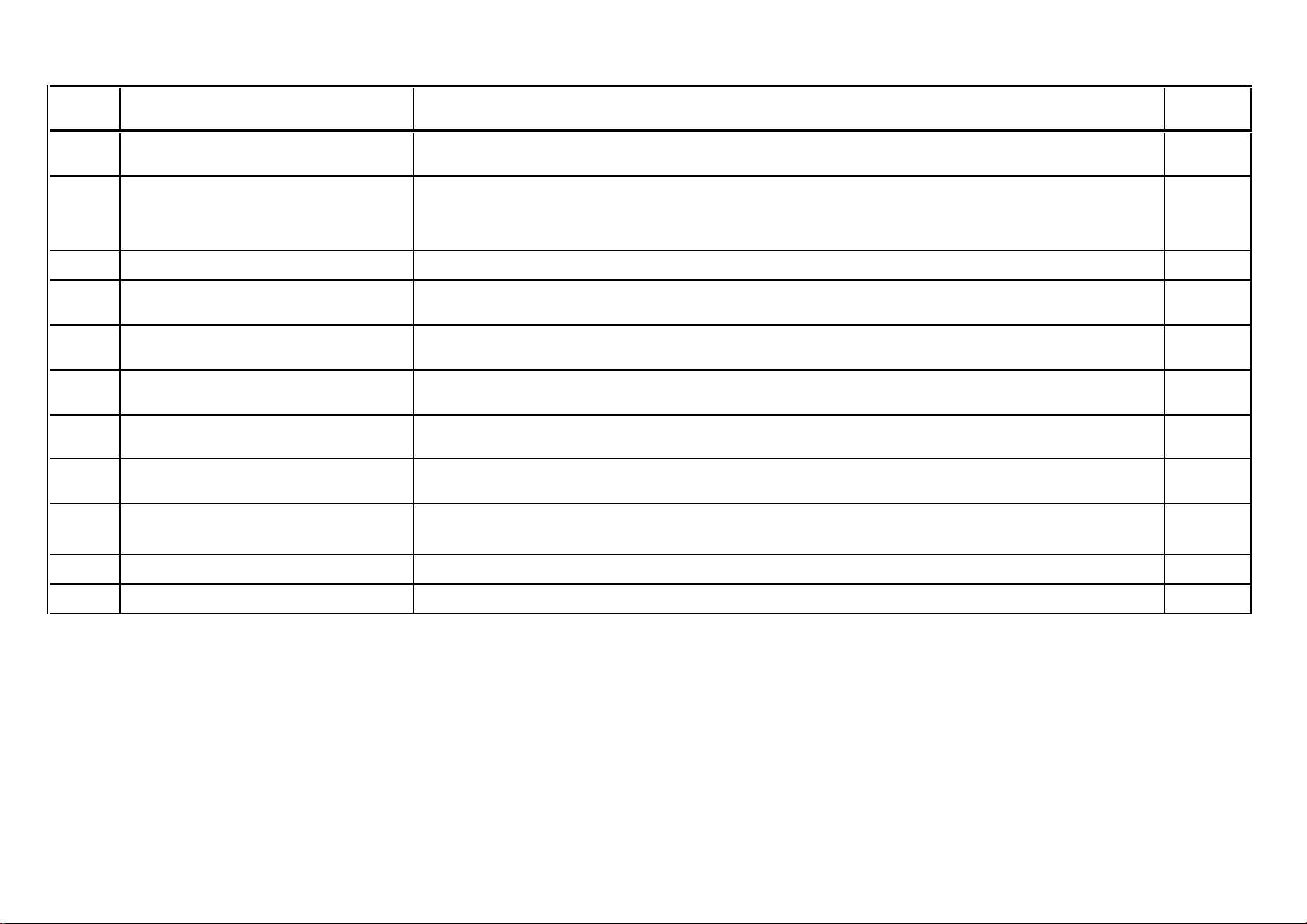

[2.] MT-11

2. Error Code Table

MT-12

Error

Code

Error Name Occurrence Condition

10361 After-recovery-erasure conveyance error

10370 Load positioning error

10371 Recovery load positioning error

10390 Dust removal operation error (1)

10391 Dust removal mechanism lock (1)

10392 Dust removal mechanism lock (2)

10393 Dust removal operation error (4)

10394 Dust removal CCW drive error

During error handling, the SB1 cannot detect the IP leading edge. The MB1, MC1, and MZ1 are driven

(counterclockwise) for load conveyance, but the SB1 does not transition to CLOSE within the specified period of time

(20 sec). (The SB1 is in OPEN status.)

During routine processing, the MB1 is driven (counterclockwise) to perform load conveyance, but the SB1 does not

transition to OPEN within the specified period of time.

During error handling, the MB1, MC1, and MZ1 are driven (counterclockwise) for load conveyance after the IP leading

edge is detected by the SB1, but the SB1 does not transition to OPEN within the specified period of time (20 sec).

During bootup or U-Utility dust removal operation, the MZ3 is driven (clockwise), but the SZ5 does not transition to

CLOSE within the specified period of time (30 sec).

During bootup or U-Utility dust removal operation, the MZ3 is driven (counterclockwise) to measure the length of the hole

(x2) of the drive gear, but a mechanism lock results. Subsequently, the MZ3 is driven (clockwise), but the SZ5 does not

transition from CLOSE to OPEN within the specified period of time (30 sec).

During bootup or U-Utility dust removal operation, the MZ3 is driven (counterclockwise) to measure the length of the hole

(x2) of the drive gear, but a mechanism lock results. Subsequently, the MZ3 is driven (clockwise), but the SZ3 does not

transition from OPEN to CLOSE within the specified period of time (30 sec).

During bootup or U-Utility dust removal operation, the MZ3 is driven (counterclockwise) to perform home positioning, but

the SZ5 does not transition from CLOSE to OPEN within the specified period of time (30 sec).

During bootup or U-Utility dust removal operation, the MZ3 is driven (counterclockwise), but two or more retries occur.

However, driving in the clockwise direction is normal.

Analysis

Flow

MT-76

MT-66

MT-66

MT-68

MT-68

MT-68

MT-68

MT-70

10400 Network board error During bootup and routine processing, error is detected on the Ethernet section on the CPU12A board of the RU. 6.1

10700 SDRAM test error

010-051-01

08.30.2001 FM3058 CR-IR346RU Service Manual

During bootup, when the SDRAM, or the main memory of the CPU12A board, is tested, error is detected. The warning is

recorded and retries (up to two times) are performed, but error is detected again.

[2.] MT-12

8

2. Error Code Table

MT-13

Error

Code

Error Name Occurrence Condition

Analysis

Flow

10799 CPU bus error During bootup and routine processing, an unthinkable state is detected by the main CPU on the CPU12A board. 8

10900 Conveyance-related driver error

10901 Conveyance-related common function error

10902 Conveyance-related standard function error

10903 Conveyance-related device OPEN error

During bootup and routine processing, the driver used for conveyance-related software processing between the

CPU12A and SNS12A boards causes ERROR to be returned as a return value.

During bootup and routine processing, ERROR is returned as a return value for the common function used for

conveyance-related software processing between the CPU12A and SNS12A boards.

During bootup and routine processing, ERROR is returned as a return value for the standard function used for

conveyance-related software processing between the CPU12A and SNS12A boards.

During bootup and routine processing, ERROR is returned as a return value for device OPEN used for conveyancerelated software processing between the CPU12A and SNS12A boards.

6.2

6.2

6.2

6.2

10921 Watchdog error During bootup and routine processing, the watchdog timer on the CPU12A board times out. 8

10991 Device open error During bootup and routine processing, the device open error on the CPU12A board occurs. 8

11024 Machine application update

11025 Machine configuration update

11094 Socket error

11208 Laser drive current error

Writing of the RU APPL software from the FTP server of the CL to the CPU12A board flash ROM of the RU is completed

normally.

Writing of the RU configuration data from the FTP server of the CL to the CPU12A board flash ROM of the RU is

completed normally.

During bootup, error related to socket communication is detected. Socket communication cannot be performed

normally due to software bugs.

During bootup and routine processing, the laser drive current value (LDIF) is more than 1.4 times the factory default

value.

MT-106

-

-

-

11272 Insufficient laser light intensity During bootup, laser OK signal (LD1OKH, LD1OKL) error is detected. MT-106

11273 Laser life warning

010-051-01

08.30.2001 FM3058 CR-IR346RU Service Manual

During bootup and routine processing, the laser drive current value (LDIF) is more than 1.4 times the factory default

value.

[2.] MT-13

MT-106

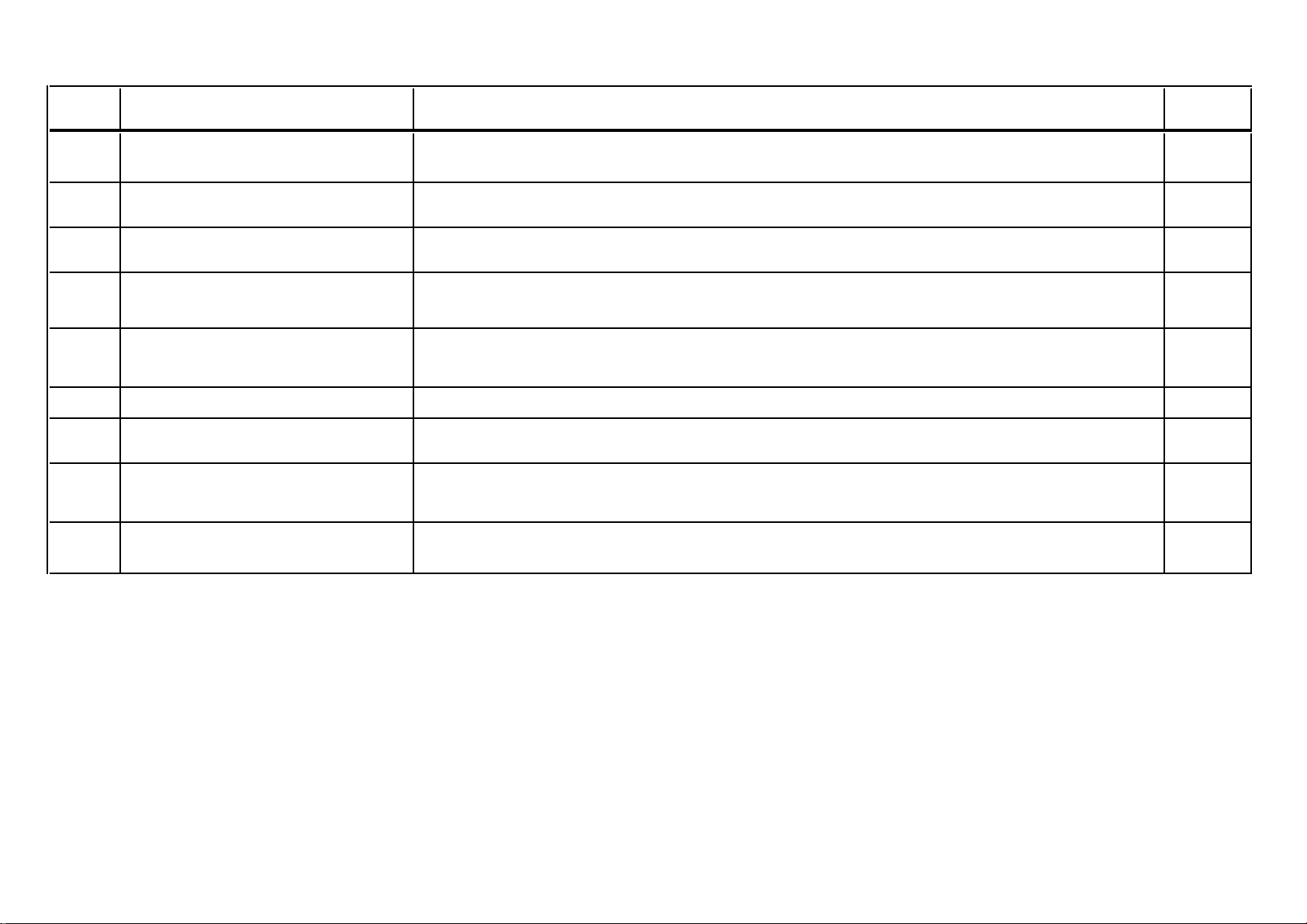

2. Error Code Table

Duri

MA1 is dri

PA1 is t

MT-14

Error

Code

Error Name Occurrence Condition

11303 IP initialization search error

11309 Cassette setting error (3)

11310 Cassette setting error (1)

11311 Cassette setting error (2)

11312 Cassette hold release error

11319 Feed IP suction error

11320 Feed IP drop

11321 Feed IP grip error

11322 Feed conveyance error

During bootup, the IP search determines that there is no IP. However, the conveyance backup memory has a record

indicating the presence of an IP in the machine for routine processing.

Because the cassette is inserted into the RU while the CL is in "Unacceptable (cassette cannot be accepted)" condition,

the cassette is fed once and ejected without reading; as a result, a message notifying that reading has not be done is

displayed on the CL.

During routine processing, the SA2 transitions to CLOSE, and after the SolA1 is turned OFF, the SA3 does not transition

to OPEN. Retries (six times or more) are performed, but error results.

During routine processing, the SA2 transitions to CLOSE, and after the SolA1 is turned ON, the cassette is moved, but

the SA2 does not transition to CLOSE within the specified period of time. However, the SA1 is CLOSE.

During routine processing, the SolA1 is turned ON to release the cassette hold, but the SA3 does not transition to

CLOSE within the specified period of time. Retries (six times or more) are performed, but error results.

ng routine processing, the

the SA5 does not transition to CLOSE within the specified period of time. Retries (four times or more) are performed, but

error results.

During bootup and routine processing, the MA1 and MB1 are driven (clockwise) to feed the IP from the cassette, but the

SA5 transitions to OPEN at the time when the IP is griped by the rollers. Retries (two times or more) are performed, but

error results.

During bootup and routine processing, the MB1 is driven (clockwise) to perform IP feed leak and conveyance, but the

SB1 does not transition to CLOSE within the specified period of time. Retries (four times or more) are performed, but

error results.

During routine processing, the MB1 and MC3 are driven (clockwise) to perform IP high-speed conveyance, but the SC3

transitions to OPEN. Retries (four times or more) are performed, but error results.

ven (counterclockwise) and the

urned ON to perform IP feed leak, but

Analysis

Flow

MT-54

-

MT-71

MT-71

MT-72

MT-74

MT-74

MT-74

MT-74

11323 Length-measurement conveyance error

010-051-01

08.30.2001 FM3058 CR-IR346RU Service Manual

During routine processing, the MB1 and MC3 are driven (clockwise) to determine the IP size, but the SB1 transitions to

OPEN. Retries (four times or more) are performed, but error results.

MT-76

[2.] MT-14

2. Error Code Table

MT-15

Error

Code

Error Name Occurrence Condition

11325 Load leak error

11340 IP stopper protrusion error

11341 IP stopper retreat error

11342 Reading IP leading-edge detection error

11343 Subscanning conveyance error (1)

11344 Subscanning conveyance error (2)

11350 End-of-image timeout

11362 After-reading conveyance error

11363 Erasure conveyance error

During routine processing, the SVA1 is turned ON and the PA1 is turned OFF to leak the IP after loading it into the

cassette, but the SA5 does not transition to OPEN.

During routine processing, the SOLZ1 is turned ON to protrude the IP stopper after IP feed leak, but the SZ4 transitions

to CLOSE. SZ4 checks are retried (two times or more), but error results.

During routine processing and U-Utility dust removal operation, the SOLZ1 is turned OFF to retreat the IP stopper, but

the SZ4 transitions to OPEN. SZ4 checks are retried (six times or more), but error results.

During routine processing, the MZ1 is driven (clockwise) to perform read processing, but the SZ1 transitions to OPEN.

Subsequently, the laser is turned OFF, and when IP conveyance is performed to isolate the error, the SC3 transitions to

OPEN.

During routine processing, the MZ1 is driven (clockwise) to perform read processing, but the SZ1 transitions to OPEN.

Subsequently, the laser is turned OFF, and when IP conveyance is performed to isolate the error, the SC3 transitions to

CLOSE.

During routine processing, the SC3 does not transition to OPEN within the specified period of time before the end-ofimage interrupt after reading is initiated.

During routine processing, the end-of-image interrupt from the scanner board is not processed within the specified

period of time after reading is initiated.

During routine processing, the MZ1, MC3, and MB1 are driven (counterclockwise) to convey the IP to the erasure unit

after reading is completed, but the SC4 does not transition to CLOSE within the specified period of time.

During routine processing, the MC3 and MB1 are driven (counterclockwise) to perform erasure conveyance of the IP

after reading, but the SC4 does not transition to OPEN.

Analysis

Flow

MT-77

MT-60

MT-60

MT-78

MT-78

MT-78

MT-79

MT-80

MT-81

11366 Overexposed IP detected During routine processing, an overexposed IP is detected. -

010-051-01

08.30.2001 FM3058 CR-IR346RU Service Manual

[2.] MT-15

2. Error Code Table

Duri

MB1 is dri

Duri

MA1 is dri

,

Duri

PA1 is t

MA1 is dri

,

Duri

j

MT-16

Error

Code

Error Name Occurrence Condition

11371 Load IP drop

11372 Load IP suction error

11373 Load IP drop

ng bootup and routine processing, the

(14373) or load IP suction failure retry (14372), but the SB1 does not transition to OPEN within the specified period of

time.

ng routine processing, the PA is turned ON and the

cassette, but the SA5 transitions to OPEN within the specified period of time. Retries (four times or more) are

performed

cassette, but the SA5 transitions to OPEN at the time when the IP is released. Retries (four times or more) are

performed

but error results.

ng routine processing, the

but error results.

urned ON and the

ven (counterclockwise) to reload the IP due to the load IP drop retry

ven (counterclockwise) to load the IP into the

ven (counterclockwise) to load the IP into the

Analysis

Flow

MT-82

MT-82

MT-82

11380 Maximum empty cassette setting During bootup, an attempt is made to eject (load) the remaining IP into the cassette, but the cassette has not been set. MT-83

11387 Recovery IP processing During bootup, the remaining IP that has not been erased is detected. MT-84

11400 Unread IP ejection (1) During routine processing, the IP is ejected, without being read, to the cassette for some reason on the CL side. -

11401 Unread IP ejection (2) During routine processing, the IP is ejected, without being read, to the cassette for some reason on the RU side. -

ng routine processing, an attempt is made to retransmit the unsent image data from the RU to the CL after

11402 Retransmission retry failure cassette ejection

11731

11732

11737

Thermistor failure detection (during erasure

initialization)

Thermistor status error detection (during

erasure initialization)

Lamp unlit detection (during erasure

initialization)

communication down processing with the CL, the CL rejects it, so that the image data is lost, and the cassette is

e

ected.

During bootup, it is detected that temperature control of the erasure unit is disabled due to temperature thermistor

(THB1) error.

During bootup, the temperature thermistor (THB1) detects an abnormal range. Temperature control of the erasure unit is

disabled.

During bootup, the erasure lamps are turned on to check their lighting, but a single center lamp (socket L2) of the three

erasure lamps is unlit. Or, two or more erasure lamps are unlit.

6.1

6.4

6.4

6.4

010-051-01

08.30.2001 FM3058 CR-IR346RU Service Manual

[2.] MT-16

2. Error Code Table

Duri

idl

MT-17

Error

Code

11751

11752

11757

11767

Error Name Occurrence Condition

Thermistor failure detection (during IP

processing)

Erasure unit temperature status

inconsistency (during IP processing)

Lamp unlit detection (during erasure idle

temperature control)

Lamp unlit detection (during IP erasure

lighting)

During routine processing, error for the temperature thermistor (THB1) is detected. 6.4

During routine processing, error for the temperature states (LED: D15, D11, D10, D13) in the erasure unit is detected.

Temperature control of the erasure unit is disabled.

ng machine

their lighting, but a single center lamp (socket L2) of the three erasure lamps is unlit. Or, two or more erasure lamps are

unlit.

During IP erasure, the erasure lamps are turned on to check their lighting, but a single center lamp (socket L2) of the

three erasure lamps is unlit. Or, two or more erasure lamps are unlit.

e state, in order to perform erasure temperature control, the erasure lamps are turned on to check

Analysis

Flow

6.4

6.4

6.4

11781 Thermistor failure detection (during idling) During idle state after machine bootup, error for the temperature thermistor (THB1) is detected. 6.4

11782

Erasure unit temperature status

inconsistency (during idling)

During bootup, error for the temperature states (LED: D15, D11, D10, D13) in the erasure unit is detected. Temperature

control of the erasure unit is disabled.

6.4

11890 Power supply C31 error During bootup and routine processing, the blow of the fuse C31 on the MTH12A board is detected. 10.5

12026 Image transfer timeout During routine processing, the image data is not sent from the sub-CPU of the CPU12A board to the CL. (Timeout error) 6.1

Initialization of the backup memory on the CPU12A board is executed.

12028 Backup SRAM initialization warning

• The machine that has been powered OFF for several months is booted up.

• The machine is booted up after the backup memory is cleared in M-Utility.

• The machine is booted up after erasure mode switching and resetting are performed and the backup memory is

cleared.

-

12033 Barcode data reading error Because an attempt to read the barcode data on the CPU12A board, a retry is performed. 8

12035 Preheat warning during erasure lamp lighting

010-051-01

08.30.2001 FM3058 CR-IR346RU Service Manual

During bootup and routine processing, because the erasure lamps are turned on without preheating them, the erasure

lamps are not lit.

6.4

[2.] MT-17

2. Error Code Table

MT-18

Error

Code

Error Name Occurrence Condition

12036 Scanner communication timeout

12037 Scanner communication checksum error

12040 Failure to register reset switch interrupt

12062 HOST alternative function warning

12063 Image processing CPU error during operation

12070 Backup SRAM write error

During bootup and routine processing, a timeout occurs for communication between the main CPU (CPU12A board) and

scanner H8CPU (SCN12A board).

During bootup and routine processing, a checksum error occurs for communication between the main CPU (CPU12A

board) and scanner H8CPU (SCN12A board).

During bootup and routine processing, because an attempt to register the reset switch interrupt on the CPU12A board

fails, the reset switch does not function.

Service job log

• The machine is booted up after erasure mode switching and resetting are performed and the backup memory is

cleared.

• The image output function is activated by using the M-Utility function on the RU side.

During routine processing, because the data sent from the sub-CPU of the CPU12A board has an insufficient or excess

number of pixels, the software performs processing to supplement or cut the insufficient or excess number of pixels in

the line direction.

During bootup and routine processing, an attempt to write to the backup memory (SRAM) fails. Or, a write to the backup

SRAM is performed during backup memory test.

Analysis

Flow

6.3

6.3

12071 Flash ROM write error An attempt to write the flash ROM on the CPU12A board fails. 8

12090 Software logic warning

12092 FTP server access error

During bootup and routine processing, the software executes an abnormal case. Although the process may be resumed

as is, its error log is generated.

During bootup and routine processing, the FTP server cannot be accessed for communication from the RU to the CL.

Or, the FTP server may be accessed, but a connection cannot be established.

6.1

8

-

8

8

-

12093 FTP server file acquisition error

12094 ACK timeout

010-051-01

08.30.2001 FM3058 CR-IR346RU Service Manual

During bootup and routine processing, the FTP server cannot be accessed for communication from the RU to the CL.

Or, the FTP server may be accessed, but a file cannot be obtained.

During bootup and routine processing, a FTP server connection timeout error occurs for communication from the RU to

the CL.

6.1

6.1

[2.] MT-18

2. Error Code Table

MT-19

Error

Code

12101 Image processing CPU data output shortage 6.2

12148 Image frame clock timeout

12149 Image processing pixel clock excess error

12150 Image processing pixel clock shortage error

12151 Image processing line clock excess error

12152 Image processing line clock shortage error

12153 Image processing frame clock error

Error Name Occurrence Condition

• A warning log indicating that dummy data was sent from the CPU12A board due to image data shortage.

• During routine processing, the image data sent from the SCN12A board to the CPU12A board is insufficient.

A timeout of the frame clock lock (information indicative of the beginning of the image data) from the SCN12A board is

detected by the sub-CPU. (30 seconds)

An error is detected for the pixel clock from the sub-CPU to the SCN12A board.

• The pixel clock that is larger than the parameter value is detected.

• The pixel clock, which is part of image data, denotes the number of pixels per one line of the image data.

During routine processing, when the image data from the SCN12A board is processed, an insufficient number of pixels

for a certain line is detected by the sub-CPU.

During routine processing, when the image data from the SCN12A board is processed, an excess number of lines is

detected.

During routine processing, when the image data from the SCN12A board is processed, an insufficient number of lines is

detected, or even when five seconds have passed after the trailing edge of a certain line clock, the trailing edge of its

subsequent line clock cannot be detected.

During routine processing, when an image processing command is accepted from the SCN12A board to the sub-CPU,

the sub-CPU have already received the frame clock from the SCN.

Analysis

Flow

6.3

6.3

6.3

6.3

6.3

6.3

12154 Image processing overrun error During routine processing, the main CPU loses some of the image data from the sub-CPU. 8

12164 FIFO data count shortage error

During routine processing, the sub-CPU completes its processing normally, but the number of pixels received by the

main CPU via the FIFO is insufficient.

8

12165 FIFO data count excess error

During routine processing, the sub-CPU completes its processing normally, but the number of pixels received by the

main CPU via FIFO is excessive.

8

12201 Start-point detection error During bootup and routine processing, error for the start-point detection signal (SSH, SSL) is detected. MT-102

010-051-01

08.30.2001 FM3058 CR-IR346RU Service Manual

[2.] MT-19

2. Error Code Table

MT-20

Error

Code

Error Name Occurrence Condition

Analysis

Flow

12202 Leading-edge detection error During bootup and routine processing, only error for the leading-edge detection signal (SED1, SED2L) is detected. MT-108

12203 SCN sync signal error

12204 Polygon index signal error

12211 PMT analog power supply error

For self-diagnostics prior to reading during bootup, an SCN board diagnostic error (no main-scan sync signal is

generated) associated with polygon error occurs.

For self-diagnostics prior to reading during bootup, an SCN board diagnostic error (no polygon index signal is generated)

associated with polygon error occurs.

During bootup and routine processing, only error for the PMT analog power supply signal (+15VOKH, +15VOKL) is

detected.

-

-

MT-110

12212 Laser light intensity error During bootup and routine processing, only error for the laser OK signal (LD1OKH, LD1OKL) is detected. MT-106

12213 Polygon lock error During bootup and routine processing, only error for the polygon lock signal (POKL, PONL) is detected. MT-112

12214 Polygon rotation error

During bootup and routine processing, error is detected only for the polygon rotation detection function on the SCN12A

board.

14.2

12215 PLL function error During bootup and routine processing, error is detected only for the PLL function on the SCN12A board. 14.2

12216

Start-point interval error

During bootup and routine processing, error is detected only for the start-point interval function on the SCN12A board.

14.2

14.3

12217 High-voltage power supply error During bootup and routine processing, error is detected only for the high-voltage power supply signal (HVOKH/L). MT-110

12218 High-voltage command value error

During bootup and routine processing, error is detected only for the high-voltage command value diagnostics signal on

the SCN12A board.

8

12225 Reading status error During bootup and routine processing, error is detected only for the VSYNC signal on the SCN12A board. 8

12226 Operation line status error During bootup and routine processing, error is detected only for the SEDTM/FCLKTM signal on the SCN12A board. 8

010-051-01

08.30.2001 FM3058 CR-IR346RU Service Manual

[2.] MT-20

2. Error Code Table

Duri

(POKL, PONL) f

(POL) is detected

MT-21

Error

Code

12241

Scanner control board error (1)

Error Name Occurrence Condition

12242 Scanner control board error (2)

12243 Scanner control board error (3)

12251 Photomultiplier control board error (1)

During routine processing, error is detected for the PLL function, polygon rotation function, start-point interval function

on the SCN12A board.

During routine processing, because the PMT high-voltage value is not set correctly on the SCN12A board, error is

detected for the high-voltage command diagnostics.

During bootup self-diagnostics, error is detected for the start-point mask signal generated from the SCN12A board and

the index signal (PINDXL) from the polygonal mirror (POL).

During routine processing, only error for the PMT analog power supply signal (+15VOKH, +15VOKL) is detected (detail

code: 008200). Note that if the HV is OFF, the detail code is 008000.

Analysis

Flow

14.2

14.3

14.5

14.3

MT-110

12252 Photomultiplier control board error (2) During routine processing, only error for the high-voltage power supply signal (HVOKH, HVOKL) is detected. MT-110

12255 Leading-edge detection error During bootup, only error for the leading-edge detection signal (SED1, SED2L) is detected. MT-108

12256 Leading-edge detection timing error

12262 Polygon rotation error (2)

12263 Polygon rotation error (3)

During routine processing, IP conveyance overrun occurs due to mechanical error or SCN12A board control error, and

only error for the SEDTM and FCLKTM signals on the SCN12A board is detected.

• During routine processing, error for the signals (PONL, POKL, PINDXL) from the polygonal mirror (POL) and the startpoint interval function on the SCN12A board is detected (detail code: 003400).

• During routine processing, error for the polygon lock signal (PONL, POKL) and error for the start-point interval function

and polygon rotation detection function on the SCN12A board are detected (detail code: 003400).

ng routine processing, only error for the lock signal

(detail code: 002000). If error for the SEDTM or FCLKTM signal on the SCN12A board is detected, the detail code is

002003.

rom the polygonal mirror

MT-114

MT-112

MT-112

010-051-01

08.30.2001 FM3058 CR-IR346RU Service Manual

[2.] MT-21

2. Error Code Table

MT-22

Error

Code

Error Name Occurrence Condition

12264 Polygonal rotation error (4)

12272 Insufficient laser light intensity (1)

12273 Laser life warning

12281 Start-point detection error (1)

12282 Start-point detection error (2)

12291 Reading sequence error

During routine processing, error for the signals (PONL, POKL, PINDXL) from the polygonal mirror and the SEDTM signal

on the SCN12A board is detected (detail code: 001002). Alternatively, error for the index signal (PINDXL) from the

polygonal mirror and the SEDTM and FCLKTM signals on the SCN12A board is detected (detail code: 0010030).

Alternatively, error for the signals (POKL, PINDXL) from the polygonal mirror and the SEDTM signal on the SCN12A

board is detected (error code: 001002).

During routine processing, the laser light intensity is less than 50%, and the laser light intensity error signal (LD1OKL,

LD1OKH) is detected (detail code: 004000). Alternatively, the laser light intensity error signal (LD1OKL, LD1OKH) and

laser drive current value (LDIF) error are detected (detail code: 014000).

During bootup and routine processing, the laser drive current value (LDIF) is more than 1.4 times the factory default

value.

During routine processing, the disabled state of the start-point detection (SYN) function, and error for the PLL function

and polygon rotation detection function on the SCN12A board are detected (detail code: 801C03). Alternatively, the

disabled state of the start-point detection (SYN) function, and error for the PLL function on the SCN12A board are

detected (detail code: 800C03). Alternatively, during routine processing, the disabled state of the start-point detection

(SYN) function, and error for the PLL function and polygon rotation detection function on the SCN12A board are

detected (detail code: 801401).

During bootup and routine processing, only error for the start-point interval function on the SCN12A board is detected

(detail code: 000400). Alternatively, error for the start-point interval function and polygon rotation detection function on

the SCN12A board is detected (detail code: 001400).

During routine processing, error for the VSYNC signal on the SCN12A board is detected after IP reading is completed

(detail code: 000002).

Analysis

Flow

MT-112

MT-106

MT-106

MT-102

14.3

8

12292 Reading sequence error during routine (2)

010-051-01

08.30.2001 FM3058 CR-IR346RU Service Manual

Reading is completed by any interrupt other than the leading-edge detection interrupt or end-of-screen interrupt. At the

same time, an insufficient number of output lines and a too-early start of reading are detected.

-

[2.] MT-22

2. Error Code Table

MT-23

Error

Code

Error Name Occurrence Condition

12299 Error for scanner, etc.

12301 Sensor error

12302 IP location information logical failure

12304

12305

IP movement error at scanner unit During

bootup

IP movement error at erasure conveyor/sidepositioning conveyor During bootup

12313 Cassette not detected

For self-diagnostics prior to reading during routine processing, a combination of errors that should not have logically

occurred were generated.

During routine processing, the sensor is turned OFF after the timeout of the mechanical operation is detected, but the

sensor does not transition to CLOSE.

During bootup, the result of IP search indicates the presence of an IP, but the backup memory information indicates

that there is no IP in the machine. Because there is no result of clearing the CMOS, it is logically inconsistent.

During bootup, the MB1, MC3, and MZ1 are driven (clockwise) for IP search, but the SC3 does not transition to OPEN

within the specified period of time.

During bootup, the MB1 and MC3 are driven (clockwise) for IP search, but the SC3 does not transition to CLOSE within

the specified period of time.

During routine processing, while the SolA1 is tuned ON to hold the cassette, the cassette is pulled all the way out of the

shutter, and SA1 transitions to OPEN.

Analysis

Flow

-

MT-53

MT-52

MT-54

MT-54

MT-85

12318 Suction cup return error During bootup and routine processing, SA4 does not transition to CLOSE for suction cup HP check. MT-57

12324 Barcode reading error

12325 Feed leak error

12326 HP return error during ejection

During routine processing, an attempt to read the barcode for feed conveyance fails. Retries (four times or more) are

performed, but error results.

During bootup and routine processing, the SVA1 is turned ON and the PA1 is turned OFF to perform IP feed leak, but the

SA5 does not transition to OPEN.

During routine processing, the MA1 is driven (counterclockwise) to perform suction cup home positioning after the

cassette is ejected, but the SA4 does not transition to CLOSE.

MT-87

MT-77

MT-57

12334 Side-positioning operation error

010-051-01

08.30.2001 FM3058 CR-IR346RU Service Manual

During routine processing, the MC1 is driven (clockwise) to perform side-positioning home positioning, but the SC1 does

not transition to CLOSE.

MT-58

[2.] MT-23

2. Error Code Table

MT-24

Error

Code

Error Name Occurrence Condition

12338 Side-positioning grip operation error

During routine processing, the MC2 is driven (counterclockwise) to perform side-positioning grip home positioning, but

the SC2 does not transition to CLOSE.

Analysis

Flow

MT-59

12345 FFM drive W.F. disorder During routine processing, wow-flutter error (irregular revolutions) of the FFM motor is detected. MT-86

12346 Driving shaft grip error

12347 Driven shaft grip error

12348 Both grip release error

12349 Driven shaft grip release error

12352 Driving shaft grip error stop

12353 Driving shaft correction grip error

12354 Driving shaft grip disorder

12355 Driving shaft grip malfunction

During routine processing, the MZ2 is driven to perform driving-shaft slow grip after driven-shaft grip is completed, but

the SZ2 does not transition from CLOSE to OPEN.

During routine processing, the MZ2 is driven to grip the driven shaft after side-positioning is completed, but the SZ3

does not transition to CLOSE. Retries (two times or more) are performed, but error results.

During bootup and routine processing, the MZ2 is driven to release both grips, but the SZ2 does not transition to

CLOSE. Retries (two times or more) are performed, but error results.

During routine processing, the MZ2 is driven to release the driven shaft slow grip after reading, but the SZ3 does not

transition to OPEN.

During bootup and routine processing, the grip time for the driving shaft grip deviates by ±3% relative to its specified

value, but the SZ2 is CLOSE.

During routine processing, the MZ2 is driven to perform driving-shaft correction grip, but the SZ2 does not transition to

OPEN.

During routine processing, the MZ2 is driven to perform driving-shaft slow grip and the SZ2 transitions from CLOSE to

OPEN, but the grip time deviates by ±3% relative to its specified value.