fujifilm DRYPIX 6000 User Manual

Fuji Medical Dry Laser Imager

For Safe Operation

(DRYPIX 6000)

Reference Guide

8th Edition : February 2017

Product Overview

Basic Operation

Utility

Troubleshooting

Care and

Maintenance

Appendix

897N102437G

Maintenance and

Inspection

This Manual describes details on how to operate the DRYPIX Smart

and cautions to be observed when operating it. Please read this manual

thoroughly before actually operating the DRYPIX Smart After reading this

manual, store it nearby the DRYPIX Smart so that you can see it whenever

necessary.

DRYPIX Smart Reference Guide 897N102437G

ii

Introduction

CAUTIONS

This manual provides detailed explanations of operation methods and cautions to promote proper

understanding of functions and more effective usage.

Accompanying documents were originally drafted in the English language.

Installation may only be conducted by authorized service personal.

This manual is applicable to the following software.

• DRYPIX Smart Main Software V. 1.0 or later

Indications for use (for U.S.)

Fuji Medical Dry Laser Imager, model DRYPIX Smart (DRYPIX 6000) is indicated for use in

providing diagnostic quality medical images on lm for aid in physician diagnosis, including the

printing of images and associated identication information from various digital imaging source

modalities, including but not limited to,Computed Tomography (CT), Magnetic Resonance Imaging

(MRI), Ultrasound,Computed Radiography, Digital Radiography, Digital Mammography and Nuclear

Medicine.

Intended use (for European Union and other countries.)

Fuji Medical Dry Laser Imager DRYPIX Smart (DRYPIX 6000) is a device that prints digital image

data transferred via the DICOM network from the FCR/FDR Image Reader or DR, CT, MRI and

other imaging modalities onto the Fuji Medical Dry Laser Image Film.

Note : The above statements were determined by applicable medical device regulations which vary

throughout the world. These statements are subject to revision when additional clearance or

approval is obtained.

1. No part or all of this manual may be reproduced in any form without prior permission.

2. The information contained in this manual may be subject to change without prior notice.

3. FUJIFILM Corporation shall not be liable for malfunctions and damages resulting from

installation, relocation, remodeling, maintenance, and repair performed by other than

dealers specied by FUJIFILM Corporation.

4. FUJIFILM Corporation shall not be liable for malfunctions and damages of FUJIFILM Corporation

products due to products of other manufacturers not supplied by FUJIFILM Corporation.

5. FUJIFILM Corporation shall not be liable for malfunctions and damages resulting from

remodeling, maintenance, and repair using repair parts other than those specied by

FUJIFILM Corporation.

6. FUJIFILM Corporation shall not be liable for malfunctions and damages resulting from

negligence of precautions and operating methods contained in this manual.

7. FUJIFILM Corporation shall not be liable for malfunctions and damages resulting from use

under environment conditions outside the range of using conditions for this product such

as power supply, installation environment, etc. contained in this manual.

8. FUJIFILM Corporation shall not be liable for malfunctions and damages resulting from

natural disasters such as res, earthquakes, oods, lightning, etc.

Caution : Rx Only in the United States (Federal law restricts this device to sale by or on the

order of a physician.)

Open-Source Software Used in This Product

This product uses third party’s software that is made available as open source software or free software.

SUCH SOFTWARE IS PROVIDED “AS IS” WITH NO WARRANTY OF ANY KIND AS TO ITS

MERCHANTABILITY OR FITNESS FOR ANY PARTICULAR PURPOSE.

For information on open source software used in this product, please see the attached CD.

Source codes for certain type of open source software used in this product are available at delivery

cost. If you would like to receive such source codes, please contact FUJIFILM dealer or the service

representatives at the agency from which you purchased this product.

(Please be noted that any inquiries concerning the contents of source codes should be directed to

original licensers of open source software.)

Trademark

FCR is a trademark or a registered trademark of FUJIFILM Corporation.

Other holder’s trademarks

All other company names and product names described in this manual are the trademarks or

registered trademarks of their respective holders.

Copyright © 2012-2017 FUJIFILM Corporation. All rights reserved.

DRYPIX Smart Reference Guide 897N102437G

iii

DRYPIX Smart Manuals

DRYPIX Smart Reference Guide

DRYPIX Smart Quality Control Function Reference Guide

DRYPIX Smart Quality Control for Mammography Reference Guide

DRYPIX Smart Reference Guide 897N102437G

iv

Contents at a Glance

For Safe Operation

Chapter

Chapter

Chapter

Chapter

1

2

3

4

This chapter presents Warnings and Cautions we wish you to observe for the

safe operation of this equipment.

Product Overview

This chapter presents overview and major features of this equipment.

Basic Operation

This chapter describes routine operation procedures, including how to start up/

shut down this equipment and also how to replace a lm pack.

Utility

This chapter describes the lm density calibration, date and time setting as well

as other functions.

Chapter

Chapter

5

6

Appendix

Troubleshooting

This chapter explains how to troubleshoot an error.

Care and Maintenance

This chapter describes daily care and maintenance we wish you to perform so

that you can use the equipment optimally.

Appendix A Specications

This chapter presents major specications of this equipment.

Maintenance and Inspection

DRYPIX Smart Reference Guide 897N102437G

v

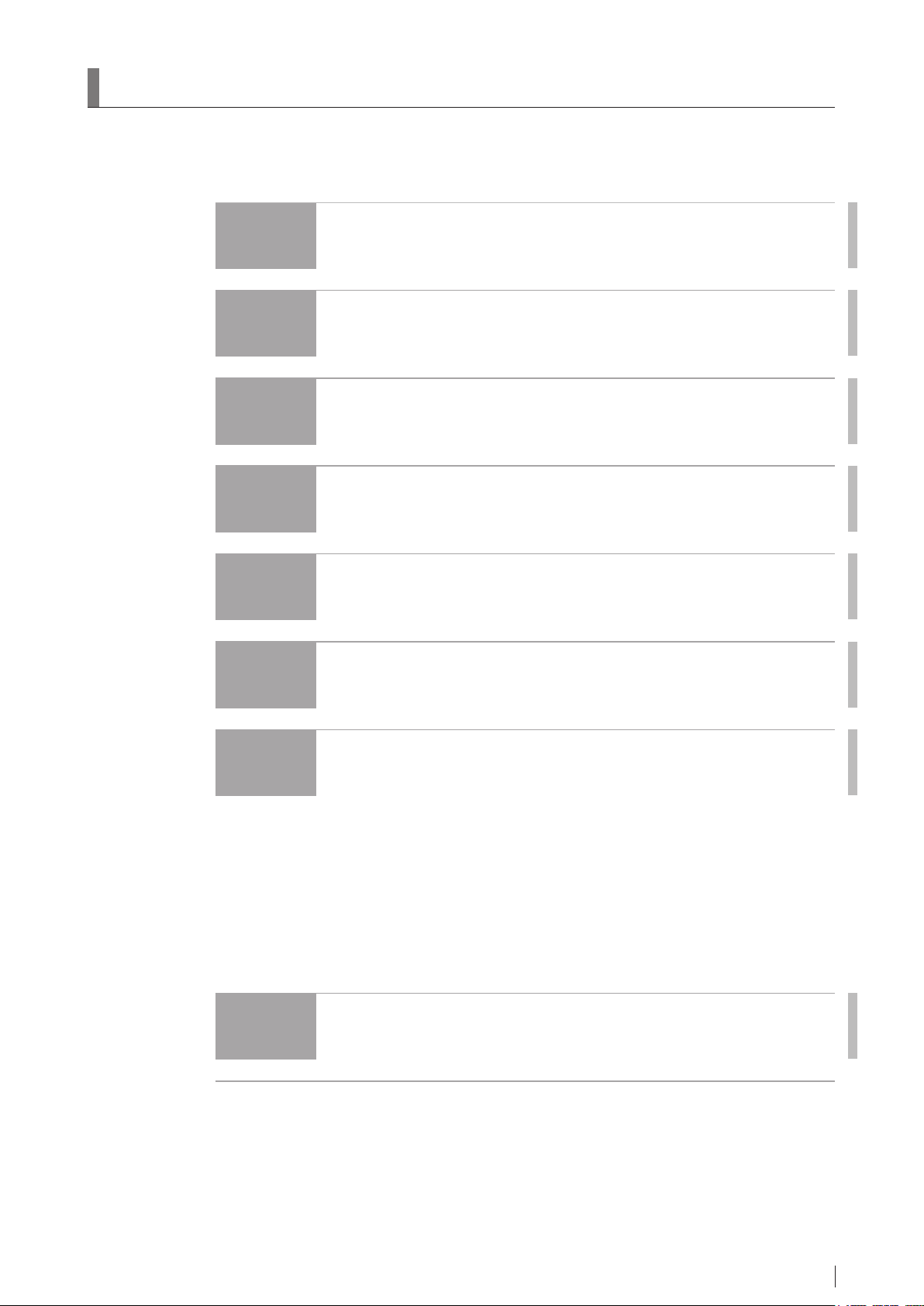

How to Read This Manual

CAUTIONS

Basic page conguration

Please have a good grasp of the basic page conguration of this Manual, as illustrated below, for

you to use it more efciently.

Operation

procedure

Describes an operation

procedure according to

sequential numbers.

Section title

Shows the title of an

operation procedure

described in the section.

Lead

Describes information we wish you to

know in advance of your operating the

system or information that may help

you to operate it.

3.2 Replacing the Film Pack

When it is printed with the lm in the lm tray set to “0”, “EP1” (Film Tray 1) or “EP2” (Film Tray 2) is

displayed in the Display panel. Prepare Fuji Medical Dry Laser Image Film “DI -HL” or “DI-ML”, pull out

the lm tray, and replace the lm pack.

1 When the lm in the lm tray runs out

during the lm feedin g, the lm being fed is

automatically out put and “EP1” or “EP2” is

displayed in the Display pane l.

2 Press the Enter bu tton and unlock the lm

tray lock.

“oPn” appears on the Display panel.

Be sure to pull the lm tray out o nly

after it has bee n unlocked. Other wise, a

system malfunction wi ll result.

3 When an error occ urs during lm feeding ,

rst the lm being fed i s automatically

output, and the n the error code appe ars on

the Display panel.

When the stand-by Switc h, Enter Button or Utility

Button is pressed to stop the al arm and clear the

error, “EP1” or “EP2” appears on t he Display panel.

4 Pull the lm tray out ca refully (1.), and

remove the protective mat erial together

with the lm cushioning c ardboard (2.).

Discard the removed protect ive material and lm

cushioning cardboard.

Film cushioning

cardboard

Protective material

5 Make sure that the ar row mark on the new

lm pack points to the ba ck side of the lm

tra y.

Film pack side

Check the arrow

mark direction.

6 Raise one end of the l m pack to tear off

the label (1.), and open both ends of the lm

pack (2.), as illustrated.

1. Tear off the label.

2. Open both ends.

Index

A caption that facilitates

you to open a desired

[Chapter] quickly.

3

Basic Operation

Illustrated operation

procedure

Operation steps are

presented in the illustration

following specified order.

Multiple sub-steps that

consist of an operation step

is numbered, 1., 2. .....

DRYPIX Smart Reference Guide 897N102437G

vi

1. Pull out.

2. Remove.

DRYPIX Smart Reference Guide 897N102437G

Page number

Displayed in

conjunction with the

chapter number.

3-3

Marks

WARNING

CAUTIONS

HINT

Information items to be observed when you are operating this system and the supplementary

remarks are described in this manual with the respective marks.

For the safe system operation, be sure to observe Warning/Caution.

Indicates hazardous situations that may lead to serious injury or even

death if the precaution is not or could not be followed.

Indicates hazardous situations that may lead to mild or moderate injury

or physical damages if the caution is not or cannot be followed.

Indicates information that should be noted.

Indicates information that may be helpful.

Shows a more detailed operation method or an item that describes additional

information.

Expressions

Messages appear on the display panel as shown below.

● A message displayed on the display panel (sample)

-----------------------------

“U-1”

DRYPIX Smart Reference Guide 897N102437G

vii

Contents

Introduction .......................................................................................................................... iii

DRYPIX Smart Manuals ...................................................................................................... iv

Contents at a Glance ............................................................................................................ v

How to Read This Manual ................................................................................................... vi

Chapter 1 For Safe Operation

1.1 Precautions Before Operating This Equipment ......................................................... 1-1

1.1.1 Precautions to be Observed When Using the Electric Medical Equipment................ 1-2

1.2 Safety ........................................................................................................................ 1-3

1.3 Electromagnetic Compatibility (EMC) ........................................................................1-5

1.4 Handling and Storing Cautions for lms for the Fuji Dry Imager ............................... 1-9

1.5 Locations of labels and signs .................................................................................. 1-10

1.5.1 Locations .................................................................................................................. 1-10

1.5.2 Safety and Other Signs ............................................................................................ 1-13

1.6 Equipment Installation Space .................................................................................. 1-14

1.6.1 Installation Space ..................................................................................................... 1-14

1.6.2 Space Required for Maintenance Work .................................................................... 1-14

1.7 Precautions on DRYPIX Smart Operations ............................................................. 1-15

1.7.1 Precautions for Use .................................................................................................. 1-15

1.7.2 Precautions When Outputting Film Prints ................................................................ 1-16

Chapter 2 Product Overview

2.1 Overview of the DRYPIX Smart ................................................................................ 2-1

2.2 Features of the DRYPIX Smart ................................................................................. 2-3

2.3 Units Names and the Functions ................................................................................2-4

2.3.1 DRYPIX Smart Main Unit ...........................................................................................2- 4

2.3.2 Operation Panel ..........................................................................................................2-6

Chapter 3 Basic Operation

3.1 Starting / Shutting Down the Equipment ................................................................... 3-1

3.1.1 Starting the Equipment ...............................................................................................3-1

3.1.2 Shutting Down the Equipment ....................................................................................3-2

3.2 Replacing the Film Pack ............................................................................................3-3

3.3 Replacing Film Tray ...................................................................................................3-6

Chapter 4 Utility

4.1 Utility List ................................................................................................................... 4-1

4.2 Starting Up the Utility ................................................................................................ 4-2

4.3 Quitting the Utility ...................................................................................................... 4-3

4.4 Automatically Calibrating the Film Density ................................................................4-4

4.5 Outputting a QC Test Pattern ....................................................................................4-5

4.6 Resetting the Remaining Film Counter .....................................................................4-6

4.7 Setting the Sensitive Material Correction Parameter ................................................4-7

4.8 Setting the Date and Time ........................................................................................4-9

DRYPIX Smart Reference Guide 897N102437G

viii

4.9 Outputting the SMPTE pattern ................................................................................ 4-10

4.10 Outputting the Mammography QC Pattern .............................................................. 4-12

Chapter 5 Troubleshooting

5.1 In Case a Problem May Arise ...................................................................................5-1

5.2 The Equipment Cannot be Powered ON ................................................................... 5-2

5.2.1 The Equipment Does Not Start Up Normally ..............................................................5-2

5.3 The Power to the Equipment Does Not Turn OFF .....................................................5-3

5.4 Error Code List ..........................................................................................................5-4

5.5 When a Film Jam Occurred ......................................................................................5-5

5.5.1 Film jamming when the error code “221” or “223” is displayed ................................. 5-6

5.5.2 Film jamming when the error code “226” or “227” is displayed ................................ 5-10

5.5.3 Film jamming when the error code “228” is displayed .............................................. 5 -11

5.5.4 Film jamming when the error code “230” is displayed .............................................. 5 -12

5.5.5 Film jamming when the error code “232” is displayed .............................................. 5-13

Chapter 6 Care and Maintenance

6.1 Cleaning the Inside and Surroundings of the Equipment .......................................... 6-1

6.1.1 Cleaning a lm tray .....................................................................................................6-2

6.1.2 Cleaning the Air Filter .................................................................................................6-3

6.1.3 Washing the Cleaning Roller (Optional) with Water .................................................. 6-4

6.1.4 Image Verication ...................................................................................................... 6-6

6.2 Users Checksheet (Care and Maintenance).............................................................. 6-7

6.3 About Preventive Maintenance..................................................................................6-8

Appendix A Specications

A.1 Specications ............................................................................................................A-1

A.2 External View and Weight ........................................................................................ A-2

Maintenance and Inspection

DRYPIX Smart Reference Guide 897N102437G

ix

DRYPIX Smart Reference Guide 897N102437G

x

Chapter 1

WARNING

For Safe Operation

1.1 Precautions Before Operating This

Equipment

Before using this equipment, please read “Precautions Before Operating This Equipment” carefully so

that you can operate it correctly.

Whenever you operate this equipment, be sure to observe those precautions. Failure to do so may

cause you to subject to injuries or property damage to occur.

Do not connect any unspecied device.

This system is classied as a medical device under EC Directive 93/42/EEC.

This equipment has been designed on the assumption that the patient would not

come into direct contact with it or for operation by appropriately trained operator.

The operator of this equipment must comprehend the contents shown in the labels

or on the monitor.

Process waste correctly, as stipulated by local law or any regulations that apply.

When discarding the DRYPIX Smart that incorporates the lithium battery, be sure to

contact a licensed waste disposal contractor because it cannot be disposed of as a

general waste.

Not doing so may cause environmental pollution.

1

For Safe Operation

To install or relocate the equipment, request it to a designated service supplier.

Cautions on Network

After connecting this system to the network with other systems, conrm that the

other systems are not affected. If they are affected, take countermeasures such as

network separation.

Precautions on External Network Connection

When a setting of the network to which the equipment is connected has been

changed, check that the change does not affect the system operation and take

measures if necessary.

The setting change may include the following:

- Change of connection destination

- Addition of devices

- Removal of devices

- Update of devices

- Upgrade of devices

DRYPIX Smart Reference Guide 897N102437G

1-1

1.1.1 Precautions to be Observed When Using the Electric

1

For Safe Operation

Medical Equipment

• Do not remodel the equipment.

• In an emergency, disconnect the power plug or the inlet.

Ensure sufcient space around the power plug or the inlet.

• An additional MULTIPLE SOCKET-OUTLET or extension cord shall not be connected to this

device.

• If the network is shut down due to a network device failure or any other cause, image data is no

longer transferred to this device.

DRYPIX Smart Reference Guide 897N102437G

1-2

1.2 Safety

WARNING

CAUTIONS

WARNING

Before using the DRYPIX Smart, read this section thoroughly to ensure that you use the product

properly.

Laser Handling Precautions

This equipment is a Class 1 Laser Product (IEC 60825-1/EN 60825-1).

This device contains an embedded laser with the following specication:

Class : 3B

Medium : Semiconductor laser

Wavelength : 659nm (TYP)

Maximum output - Specication of Laser Diode : 130mW (CW)

Maximum output - Fault Condition : 400mW (CW)

Beam emittance : 20°

To prevent the user from being exposed to laser beams, always observe the following

precautions.

● Never remove any covers other than the front cover, right-side cover and bottom right-side

cover of the equipment.

● When opening covers for coping with lm jams, strictly observe procedures set forth in this

manual. Never perform any other procedures.

● Always contact Fujilm service personnel immediately if a malfunction is suspected in the

equipment.

1

For Safe Operation

Use of controls or adjustment or performance of procedures other than those specied herein

may result in hazardous radiation exposure.

Electric Shock Warnings

The power supply to the DRYPIX Smart is AC 100/110/120V in North America and AC

200/220/230/240V in other countries.

To avoid electric shocks, users should always take the following precautions:

● Only allow a trained operator to use the printer.

● Install the printer in a location where it will not be exposed to water.

● Check that the printer is securely earthed.

● Check that all of the cords and cables are completely and securely connected.

● When using the equipment within the environment where the patient may get into touch

with it, optionally connect additional protective earth conductor.

● When using the equipment within the environment where the patient may get into touch

with it, the user must not touch the equipment’s exterior, such as covers and metal

sections, and the patient at the same time. In addition, take care that the patient does not

touch the equipment.

● To avoid risk of electric shock, this equipment must only be connected to a supply mains

with protective earth.

DRYPIX Smart Reference Guide 897N102437G

1-3

1

WARNING

CAUTIONS

CAUTIONS

Never remove the printer cover.

The printer contains high-voltage components that could cause an electric shock.

Ventilation precautions

For Safe Operation

Be sure to install this equipment in a well-ventilated environment.

Good ventilation must be ensured (at least 54m3/hour for one unit).

Precaution about High Temperature

Be careful with units where High-temperature Caution Labels are afxed as those units may

be hot during operation.

Declaration of Conformity

This equipment is in conformance with the following standards:

North America

● UL 60601-1

Other countries

● IEC 60601-1/EN60601-1

● IEC 60601-1-2/IEC 60601-1-2

Classication

1) According to the type of protection against electric shock

CLASS 1 EQUIPMENT

2) According to the degree of protection against electric shock

NO APPLIED PART

3) Protection against harmful ingress of water or particulate matter

IP00

4) According to the degree of safety of application in the presence of a ammable anesthetics

mixture with air or with oxygen or nitrous oxide.

Equipment not suitable for use in the presence of a ammable anesthetics mixture with air or

with oxygen or nitrous oxide.

5) According to the mode of operation

CONTINUOUS OPERATION

DRYPIX Smart Reference Guide 897N102437G

1-4

1.3 Electromagnetic Compatibility (EMC)

This equipment has been tested and found to comply with the limits for medical devices to the

IEC60601-1-2+A1 (North America), IEC60601-1-2+A1 (EN60601-1-2+A1), IEC60601-1-2, Medical

Device Directive 93/42/EEC (other than North America).

These limits are designed to provide reasonable protection against harmful interference in a typical

medical installation.

This equipment generates, uses and can radiate radio frequency energy and, if not installed and

used in accordance with the instructions, may cause harmful interference to other devices in the

vicinity.

However, there is no guarantee that interference will not occur in a particular installation.

If this equipment does cause harmful interference to other devices, which can be determined by

tuning the equipment off and on, the user is encouraged to try to correct the interference by one or

more of the followingmeasures:

• Reorient or relocate the receiving device.

• Increase the separation between the equipment.

• Connect the equipment into an outlet on a circuit different from that to which the other device(s)

are connected.

Consult the manufacturer or eld service technician for help.

Further information for IEC 60601-1-2 (EN60601-1-2)

1

For Safe Operation

• Medical electrical equipment needs special precautions regarding EMC and needs to be installed

and put into service according to the EMC information provided in the accompanying documents.

• Portable and mobile RF communications equipment should not be used near this medical

electrical equipment, as such communications equipment can affect this equipment and the

images.

• Information regarding the cable affecting EMC is as follows.

Name General Specication

Network Cable Cat5e or more,

UTP type and straight cable

• The use of accessories, transducers and cables other than those specied, with the exception

of transducers and cables sold by FUJIFILM Corporation as replacement parts for internal

components, may result in increased emissions or decreased immunity of the DRYPIX Smart.

• The DRYPIX Smart should not be used adjacent to or stacked with other equipment.

If adjacent or stacked use is necessary, the DRYPIX Smart should be observed to verify normal

operation in the conguration in which it will be used.

Guidance and manufacturer’s declaration - electromagnetic emissions

The DRYPIX Smart is intended for use in the electromagnetic environment specied below.

The customer or the user of the DRYPIX Smart should assure that it is used in such an environment.

Emissions test Compliance Electromagnetic environment - guidance

The DRYPIX Smart uses RF energy only for its internal

RF emissions

CISPR 11

RF emissions

CISPR 11

Harmonic emissions

IEC61000-3-2

Voltage uctuations/

icker emissions

IEC61000-3-3

Group 1

Class A

Class A

Complies

function.

Therefore, its RF emissions are very low and are not likely

to cause any interference in nearby electronic equipment.

The DRYPIX Smart is suitable for use in all establishments

other than domestic and those directly connected to the

public low-voltage power supply network that supplies

buildings used for domestic purposes.

DRYPIX Smart Reference Guide 897N102437G

1-5

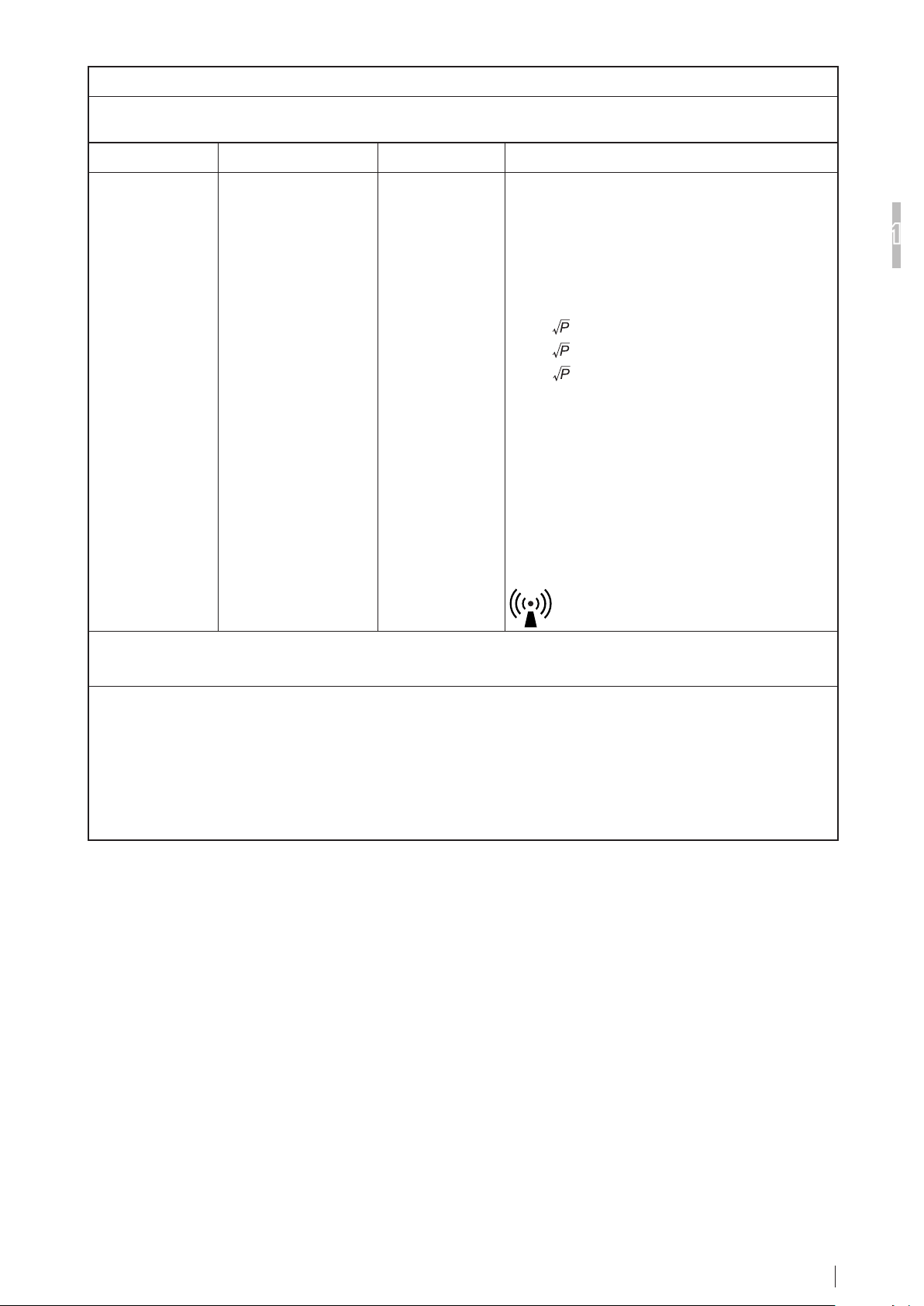

Guidance and manufacturer’s declaration - electromagnetic immunity

The DRYPIX Smart is intended for use in the electromagnetic environment specied below.

The customer or the user of the DRYPIX Smart should assure that it is used in such an environment.

Immunity test IEC 60601 test level Compliance level

Electrostatic

1

discharge

(ESD)

IEC61000-4-2

For Safe Operation

Electrical fast

transient/burst

IEC61000-4-4

Surge

IEC61000-4-5

Voltage dips, short

interruptions and

voltage variations on

power supply input

lines

IEC61000-4-11

Power frequency

(50/60Hz) magnetic

eldIEC61000-4-8

NOTE: U

±2kV contact

±4kV contact

±6kV contact

±8kV air

±6kV contact

±2kV air

±4kV air

±8kV air

±2kV for power supply

lines

±1kV for input/output

lines

±1kV differential mode

±2kV common mode

<5% U

T

(>95% dip in UT)

for 0.5 cycle

40% U

T

(60% dip in UT)

for 5 cycles

70% U

T

(30% dip in UT)

for 25 cycles

<5% U

T

(>95% dip in UT)

for 5 s

±2kV for power supply

lines

±1kV for input/output

lines

±1kV differential mode

±2kV common mode

<5% U

T

(>95% dip in UT)

for 0.5 cycle

40% U

T

(60% dip in UT)

for 5 cycles

70% U

T

(30% dip in UT)

for 25 cycles

<5% U

T

(>95% dip in UT)

for 5 s

3 A/m 3 A/m

is the a.c. mains voltage prior to application of the test level.

T

Electromagnetic environment -

guidance

Floors should be wood, concrete or

ceramic tile. If oors are covered with

synthetic material, the relative humidity

should be at least 30%.

Mains power quality should be that

of a typical commercial or hospital

environment.

Mains power quality should be that

of a typical commercial or hospital

environment.

Mains power quality should be that

of a typical commercial or hospital

environment. If the user of the DRYPIX

Smart requires continued operation

during power mains interruptions, it is

recommended that the DRYPIX Smart

be powered from an uninterruptible

power supply or a battery.

Power frequency magnetic elds should

be at levels characteristic of a typical

location in a typical commercial or

hospital environment.

DRYPIX Smart Reference Guide 897N102437G

1-6

Guidance and manufacturer’s declaration - electromagnetic immunity

The DRYPIX Smart is intended for use in the electromagnetic environment specied below.

The customer or the user of the DRYPIX Smart should assure that it is used in such an environment.

Immunity test IEC 60601 test level Compliance level Electromagnetic environment - guidance

Conducted RF

IEC61000-4-6

Radiated RF

IEC61000-4-3

3 Vrms

150 kHz to 80 MHz

3 V/m

80 MHz to 2.5 GHz

3 Vrms

3 V/m

Portable and mobile RF communications

equipment should be used no closer to any part

of the DRYPIX Smart, including cables, than the

recommended separation distance calculated from

the equation applicable to the frequency of the

transmitter.

Recommended separation distance

d = 1.2

d = 1.2 80 MHz to 800 MHz

d = 2.3

where P is the maximum output power rating of the

transmitter in watts (W) according to the transmitter

manufacturer and d is the recommended separation

distance in metres (m).

Field strengths from xed RF transmitters, as

determined by an electromagnetic site survey,

should be less than the compliance level in each

frequency range.

vicinity of equipment marked with the following

800 MHz to 2.5 GHz

b

Interference may occur in the

1

For Safe Operation

a

symbol:

NOTE 1: At 80 MHz and 800 MHz, the higher frequency range applies.

NOTE 2: These guidelines may not apply in all situations. Electromagnetic propagation is affected by absorption and

reection from structures, objects and people.

a Field strength from xed transmitters, such as base stations for radio (cellular/cordless) telephones and land

mobile radios, amateur radio, AM and FM radio broadcast and TV broadcast cannot be predicted theoretically with

accuracy. To assess the electromagnetic environment due to xed RF transmitters, an electromagnetic site survey

should be considered. If the measured eld strength in the location in which the DRYPIX Smart is used exceeds

the applicable RF compliance, the DRYPIX Smart should be observed to verify normal operation. If abnormal

performance is observed, additional measures may be necessary, such as reorienting or relocating the DRYPIX

Smart.

b Over the frequency range 150 kHz to 80 MHz, eld strength should be less than 3 V/m.

DRYPIX Smart Reference Guide 897N102437G

1-7

Recommended separation distances between

Portable and mobile RF communications equipment and the DRYPIX Smart

The DRYPIX Smart is intended for use in the electromagnetic environment in which radiated RF disturbances are

controlled.

The customer or the user of the DRYPIX Smart can help prevent electromagnetic interference by maintaining a

minimum distance between portable and mobile RF communications equipment (transmitters) and the DRYPIX Smart

as recommended below, according to the maximum output power of the communications equipment.

1

For Safe Operation

Rated maximum output

power of transmitter

0.01 0.12 0.12 0.23

0.1 0.38 0.38 0.73

1 1.2 1.2 2.3

10 3.8 3.8 7.3

100 12 12 23

For transmitters rated at a maximum output power not listed above, the recommended separation distance d in metres

(m) can be estimated using the equation applicable to the frequency of the transmitter, where P is the maximum

output power rating of the transmitter in watts (W) according to the transmitter manufacturer.

NOTE 1: At 80 MHz and 800 MHz, the separation distance for the higher frequency range applies.

NOTE 2: These guidelines may not apply in all situations.

Electromagnetic propagation is affected by absorption and reection from structures, objects and people.

W

Separation distance according to frequency of transmitter

150 kHz to 80 MHz

d = 1.2

m

80 MHz to 800 MHz

d = 1.2

800 MHz to 2.5 GHz

d = 2.3

DRYPIX Smart Reference Guide 897N102437G

1-8

1.4 Handling and Storing Cautions for

films for the Fuji Dry Imager

Please be aware of the following cautions for handling and storing of the lm.

Precautions for storing or handling unused lms

1 Use only the “Fuji Medical Dry Laser Image Film DI-HL” or “Fuji Medical Dry Laser Image Film

DI-ML” that is compatible with this equipment. If a lm other than DI-HL or DI-HM is used, a

malfunction may be caused to the equipment.

2 Be sure to store unused lms contained in the lm pack in a cool, dry and dark place of low

temperature and low humidity (temperature: 25°C or lower), avoiding radioactivity and reactive

gases, same as for the conventional wet-type lm.

3 The DI-HL lms are light-sensitive. Do not open a lm pack before it is loaded properly in the

equipment.

4 Do not touch unused lms with bare hands, otherwise adverse effects can appear on recorded

images.

5 Do not take unused lms out of the lm pack that has once been loaded into the equipment and

opened or add lms to the lm pack loaded, which will result in misoperation or failure of the

equipment.

6 The lm pack contains a protective sheet, in addition to the specied number of recording

lms. This protective sheet will remain in the lm pack even after those recording lms have

been printed and it cannot be used for image recording. Because the protective sheet is a lm,

discard it appropriately together with other used lms.

Precautions for storing or handling recorded lms

1

For Safe Operation

1 Store recorded lms in a cool, dry and dark place of low temperature and low humidity. The

higher the temperature and humidity, the more the density of recorded images will change

sharply. Longterm storage at high temperature, high humidity and/or daylight conditions, such

as in a car or room during summer, may cause discoloration. Using lms in the slide projector

or overhead projector will also cause discoloration.

2 For the long-term storage performance of recorded lms, we assume based on the result of the

acceleration test that it will be over 30 years at the storage temperature of 25ºC and over 25

years at 30ºC, until the portion on an image of density (D) = 1.2 at time of output to change 10%

(ΔD =0.12) .

3 After an image has been recorded, the lm immediately after it was ejected from the machine is

still in the process of image development and the room illumination or light emanating from the

viewing boxwill cause slight changes in the optical density. Due to such optical effect, traces

of overlapped lms or transferred images can be visually recognized temporarily, which will

disappear when those lms are left under the normal light condition.

4 Note that lucid surfaces of recorded lms can be lost or traces of contact with any chemicals

that contain water, alcohol, developer, etc., and with other objects that contain a large amount of

salt may appear on images, if they are handled under high-humidity environment or due to such

undesirable contacts.

5 Do not store lms with its image recording faces attached directly for preventing them from

sticking to each other.

DRYPIX Smart Reference Guide 897N102437G

1-9

1.5 Locations of labels and signs

Locations of labels and signs afxed to the DRYPIX Smart, and the relevant safety signs are shown

below.

1.5.1 Locations

1

For Safe Operation

Class 3B Panel Label #1

Rating Label

HHS Certification and

Identification Label

Caution Label

Caution Label

(other than North America)

High-temperature

Caution Label

Additional

protective

earth mark

Caution Label Caution Label

Class 3B Panel Label #2

Power

(other than North America)

1-10

DRYPIX Smart Reference Guide 897N102437G

North America

1

Class 3B Panel Label #1

For Safe Operation

Rating Label

HHS Certification and Identification Label

Class 3B Panel Labels #2

Be aware that the temperature

may be high in the area where the

following label is affixed.

High-temperature Caution Label

Be sure to use the power cord our

official dealer or local presentative

provided. If an inappropriate cord is

used, it may generate heat or fire.

Caution Label (Inlet)

Do not connect a telephone wire to

the LAN connector. Only UTP-type

straight LAN cables of Category 5e or

higher are appropriate for connection

to this connector.

Caution Label (LAN connector)

DRYPIX Smart Reference Guide 897N102437G

1-11

Other countries

1

For Safe Operation

Class 3B Panel Label #1

Rating Label

HHS Certification and Identification Label

Class 3B Panel Labels #2

Be aware that the temperature

may be high in the area where the

following label is affixed.

High-temperature Caution Label

Be sure to use the power cord our

official dealer or local presentative

provided. If an inappropriate cord is

used, it may generate heat or fire.

Caution Label (Inlet)

Do not connect a telephone wire to

the LAN connector. Only UTP-type

straight LAN cables of Category 5e or

higher are appropriate for connection

to this connector.

Caution Label (LAN connector)

Additional Option Tray

1-12

DRYPIX Smart Reference Guide 897N102437G

Identication Label

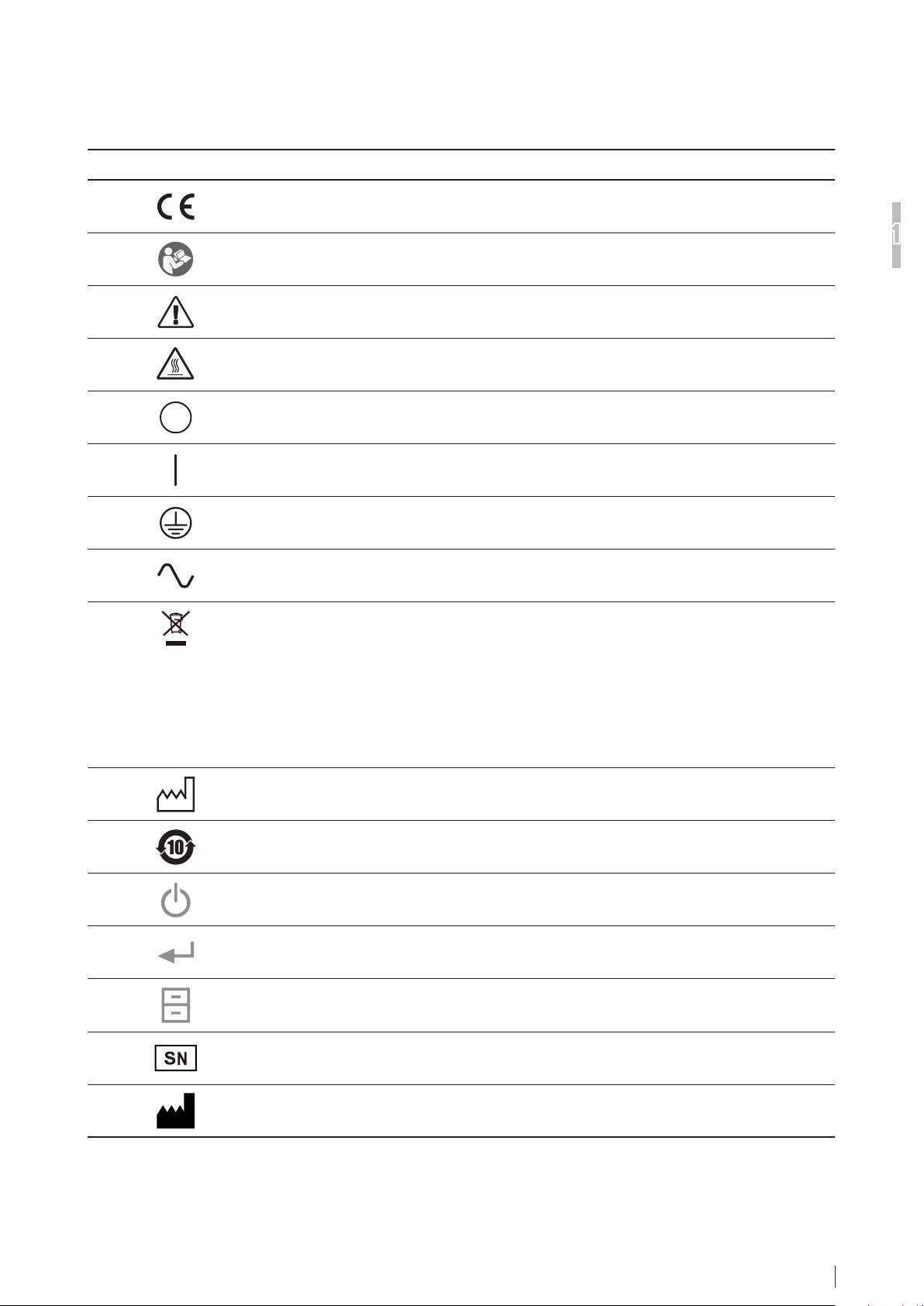

1.5.2 Safety and Other Signs

The following safety signs are used in the DRYPIX Smart labels or on its body.

Sign Description

This symbol indicates compliance of the equipment with Directive 93/42/EEC.

Refer to operation manual

Attention, consult ACCOMPANYING DOCUMENTS.

High-temperature caution

Power-OFF

Power-ON

Protective grounding (to the earth)

1

For Safe Operation

Alternating current

This symbol indicates that this product is not to be disposed of with your household waste,

according to the WEEE Directive (2002/96/EC) and your national law. This product should

be handed over to a designated collection point.

Improper handling of this type of waste could have a possible negative impact on the

environment and human health due to potentially hazardous substances that are generally

associated with EEE.

At the same time, your cooperation in the correct disposal of this product will contribute to

the effective usage of natural resources.

For more information about waste, please contact FUJIFILM dealers.

Year of manufacture

Environmentally Friendly Use Period (EFUP)

Stand-by switch

Enter button

Utility button

Serial number

Manufacture

DRYPIX Smart Reference Guide 897N102437G

1-13

1.6 Equipment Installation Space

1.6.1 Installation Space

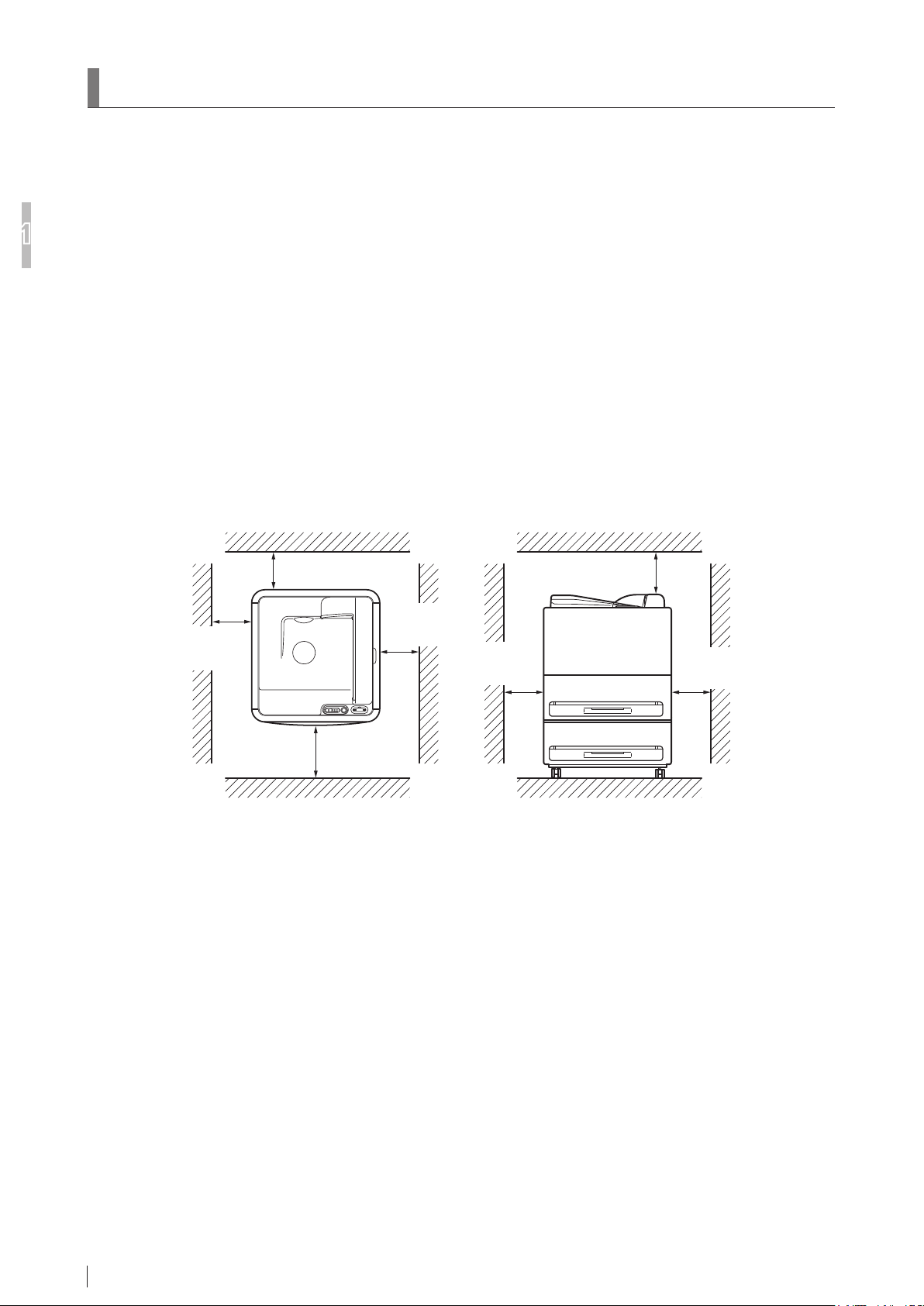

When Not Fixed with Fixtures

n

1

For Safe Operation

1.6.2 Space Required for Maintenance Work

Front : More than 800 mm (31.5 in.)

Rear : More than 100 mm (3.9 in.)

Left : More than 50 mm (1.9 in.)

Right : More than 200 mm (7.87 in.)

When Fixed with Fixtures

n

Front : More than 800 mm (31.5 in.)

Rear : More than 100 mm (3.9 in.)

Left : More than 250 mm (9.8 in.)

Right : More than 250 mm (9.8 in.)

Rear : More

than 600 mm (23.6 in.)

Left : More

than 800 mm

(31.5 in.)

Right : More

than 800 mm

(31.5 in.)

Left : More

than 800 mm

(31.5 in.)

Top : More than

400 mm (15.7 in.)

Right : More

than 800 mm

(31.5 in.)

Front : More

than 1000 mm

(39.3 in.)

1-14

DRYPIX Smart Reference Guide 897N102437G

Loading...

Loading...