Page 1

MEH 533

1

Page 2

deal combination of power and multiple-function.

I

Dynamic torque-vector control promises

optimum motor control under any operating conditions.

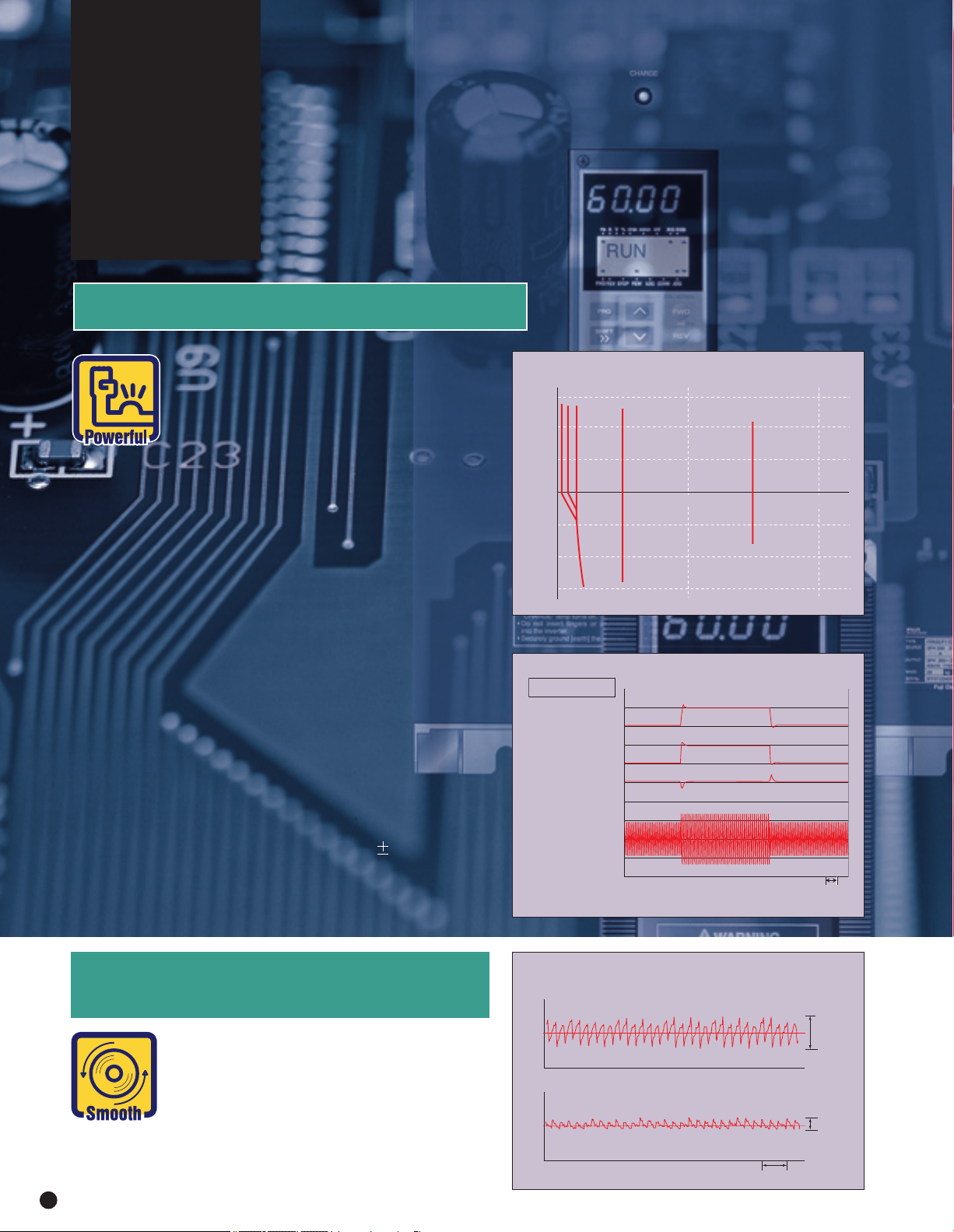

1. Dynamic torque-vector control

Dynamic torque-vector control system

performs high-speed calculation to determine the required motor power for the load

status. Our key technology is optimal

control of voltage and current vectors for

maximum output torque.

● A high starting torque of 200% at 0.5Hz.*

* 180% for 40HP or larger models.

● Achieves smooth acceleration/

deceleration in the shortest time for the

load condition.

● Using a high-speed CPU quickly

responds to an abrupt load change,

detects the regenerated power to control

the deceleration time. This automatic

decerelation function greatly reduces the

inverter tripping.

● Feedback control with PG

Enables the inverter to execute “vector

control with PG” by adding an optional PG

feedback card to obtain higher performance.

• Speed control range : 1:1200

• Speed control accuracy :

• Speed control response : 40Hz

0.02%

300

200

100

0

100

Output torque [%]

200

300

PG Vector Control

Actual torque [%]

Torque reference [%]

Motor speed [r/min]

Motor current [A]

Torque characteristics with Dynamic torque-vector control

(Sample: 5HP)

1000 2000

Motor speed

[r/min]

Step load response (Sample : 5HP)

100

0

100

0

500

400

20

0

320msTime

2. Reduced motor wow at low speed

● Motor wow at low speed (1Hz) reduced to

less than 1/2 of that achieved by

conventional inverters, with the dynamic

torque-vector control system, in

combination with the Fuji’s unique digital

AVR.

2

Wow characterisics(Sample: 5HP)

Conventional Fuji inverter

0

FRN-G11S

0

Time

14 r/min

5 r/min

500ms

Page 3

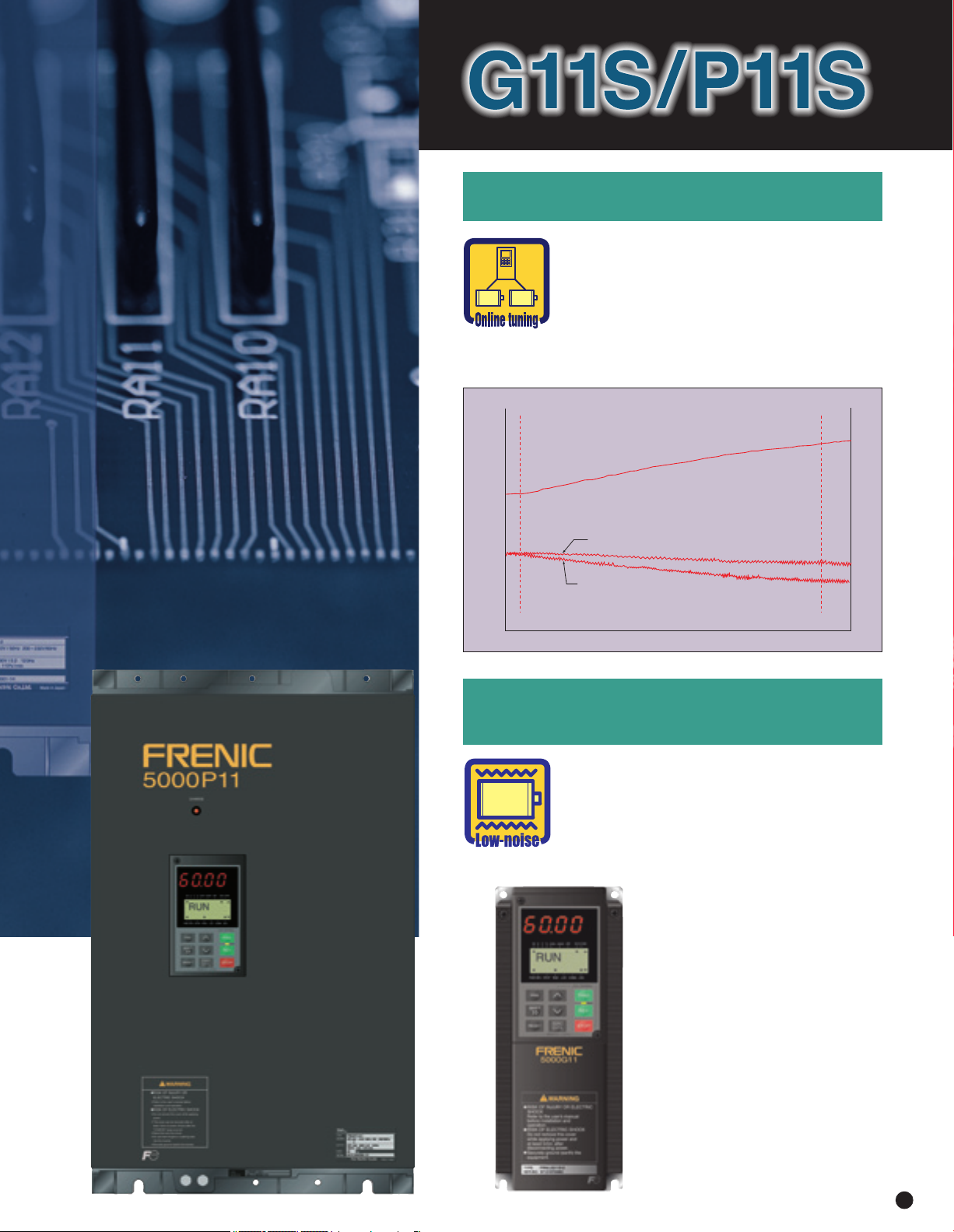

3. New on-line tuning system

● On-line tuning to continuously check for

variation of motor characteristics during

running for high-precision speed control.

● This tuning function also available for a

second motor, which allows high-precision

driving of the second motor by changeover

operation between two motors.

Motor temperature vs speed variation (Sample: 5HP)

70°C

(158°F)

30°C(86°F)

With on-line tuning

Motor speed [r/min]

Without on-line tuning

Time [min]

800

4. Environment-friendly features

● Provided with low-noise control power

supply systems which minimize noise

interference on peripheral devices such as

sensors.

● Equipped with terminals for connecting DC

REACTOR that can suppress harmonics.

● Complied with EMC Directive (Emission) when

connected to optional EMCcompliance filter.

Temperature [°C(°F)]

3

Page 4

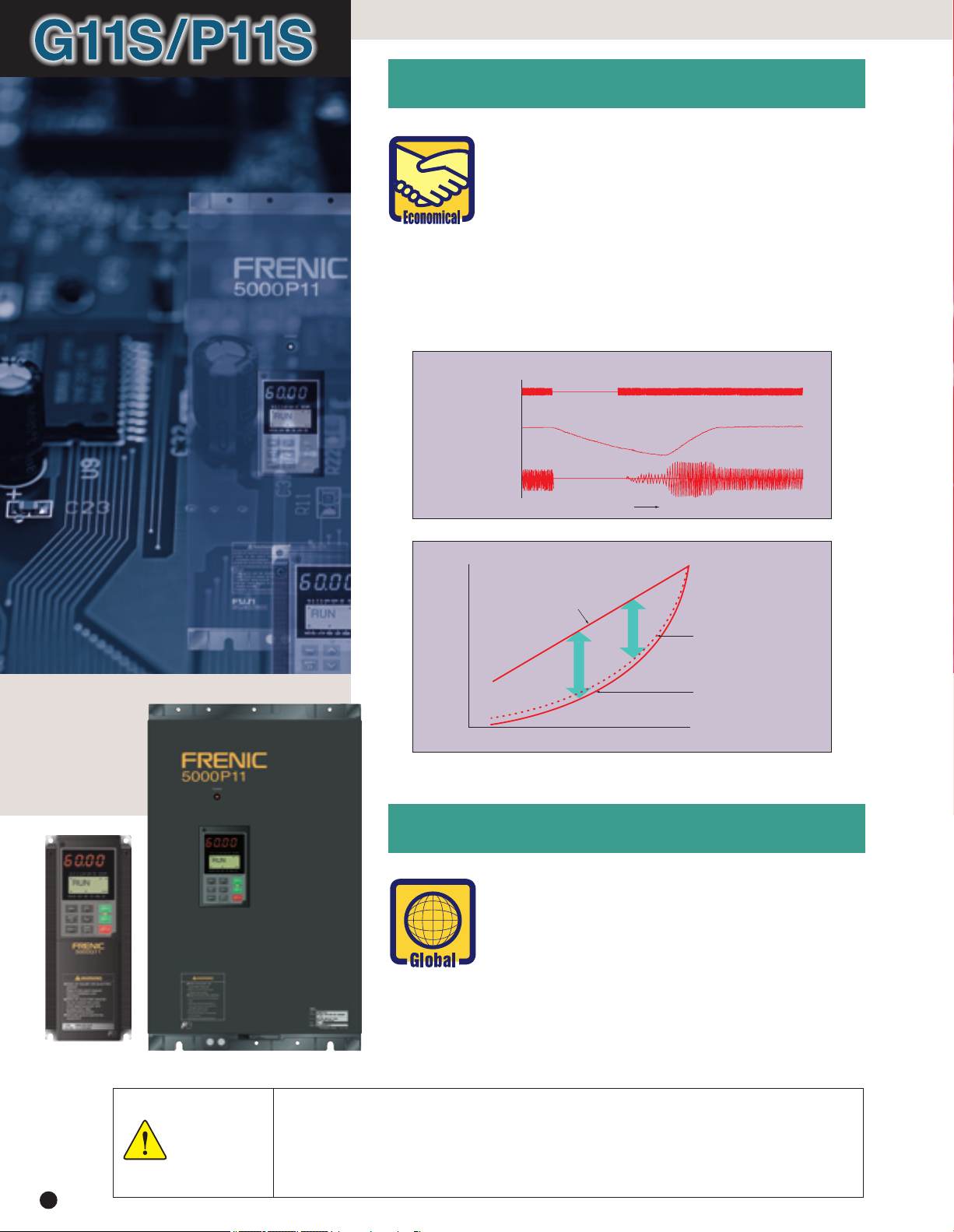

5.

Advanced, convenient functions

● 16-step speed with timer control, rotating motor

pick-up control for conveyance machinery

● Automatic energy-saving operation, PID control,

cooling fan on/off control, line/

inverter changeover operation for fans and pumps

● Rotating motor pick-up control:

Restarts motor without any shocks, by detecting motor speed

where motor is coasting after momentary power failure occurs.

● Automatic energy-saving operation function:

Minimizes inverter and motor loss at light load.

Rotating motor pick-up control characteristics (Sample:5HP)

Power source

Motor speed [r/min]

Output current [A]

Time

100

Required power [%]

0

6.

Global products, communication

Energy saving effect

Damper control

Energy

saved

Flow rate [%]

Inverter control

(V / f control)

Inverter control

(Automatic energy-saving

control)

100

● Conforms to major world safety standards: UL,

cUL, TÜV (up to 30HP), EN (CE marking)

● Equipped with RS-485 interface as standard.

● Connection to field bus: PROFIBUS-DP, Interbus-

S, DeviceNet, Modbus Plus (Option)

● Universal DI/DO : Monitors digital I/O signal

status and transmits to a host controller, helping

to simplify factory automation.

1. Use the contents of this catalog only for selecting product types and models. When using a product, read the Instruction

Manual beforehand to use the product correctly.

Safety

Precautions

4

2. Products introduced in this catalog have not been designed or manufactured for such applications in a system or equipment

that will affect human bodies or lives. Customers, who want to use the products introduced in this catalog for special systems

or devices such as for atomic-energy control, aerospace use, medical use, and traffic control, are requested to consult the

Fuji's Sales Division. Customers are requested to prepare safety measures when they apply the products introduced in this

catalog to such systems or facilities that will affect human lives or cause severe damage to property if the products become

faulty.

Page 5

7.

Intelligent Keypad panel

G11S/P11S

9. Extensive product line

● Copy function: Easily copies

function codes and data to other

inverters.

● Six languages (English, French,

German, Italian, Spanish, and

Japanese) are available as standard.

● Jogging (inching) operation from the Keypad

or external signal

● Remote operation using optional extension

cable (CBIII-10R-¤¤¤)

8. Protective functions,

Maintenance

Protection

● Two series are available: G11S

series ranging from 1/4 to 600HP

for general industrial machines

and P11S series ranging from

7.5 to 800HP for fans and

pumps.

● Totally-enclosed casing (NEMA1) (up to 30HP

as standard).

● Optional NEMA1 enclosure available for 40HP

or larger models.

10. Other useful functions

● Side-by-side mounting (up to 30HP) saves

space when inverters are installed in a panel.

● The uniform height (10.24inch(260mm)) of

products (up to 10HP) makes it easy to design

panels.

● User-definable control terminals: Digital input (9

points), transistor output (4points), and relay

contact output (1point).

● Active drive feature: Performs prolonged

acceleration at reduced torque, monitoring the

load status to prevent tripping.

● Stall prevention function is provided as standard. Active or inactive can be also selected.

● Motors with various characteristics

can be used by setting thermal

time constant for the electronic

thermal overload protection.

● Input phase loss protective function protects

the inverter from damage caused by disconnection of power supply lines.

● Motor is protected with a PTC thermistor.

● Input terminals for auxiliary control power

supply (2HP or larger models) : Alarm signal

output will be held even if main circuit power

supply has shut down.

Excellent maintainability

The items below can be monitored on the

Keypad panel and making it easy to analyze the

cause of trip and to take preventive measures.

● Input/output terminals check

● Life expectancy of main-circuit capacitors

● Inverter on-load factor

● Accumlated operation time

● Inverter operating condition (output current,

heat sink temperature, input power, etc.)

● Detailed data on trip cause

Torque characteristics with Dynamic torque-vector control

100% of output torque refers

to the rated torque of the motor

200

Continuous operation torque

(with dynamic torque-vector control)

up to 10HP

100

90

Output torque [%]

50

1 6 1520 60 120

* The above graph shows an example of torque

characteristics when combining FRENIC5000G11S

(up to 30HP at dynamic torque-vector control) with

Fuji standard three-phase motor (8-type series, 4

poles). Continuous operation torque is for limits of

allowable load torque for using the motor within the

allowable temperature range and is not for motor

output torque.

The motor output torque is shown by the short-time

operation torque.

15 to 30HP

Output frequency [Hz]

driven at 60Hz.

Short-time operation torque

(with dynamic torque-vector control)

5

Page 6

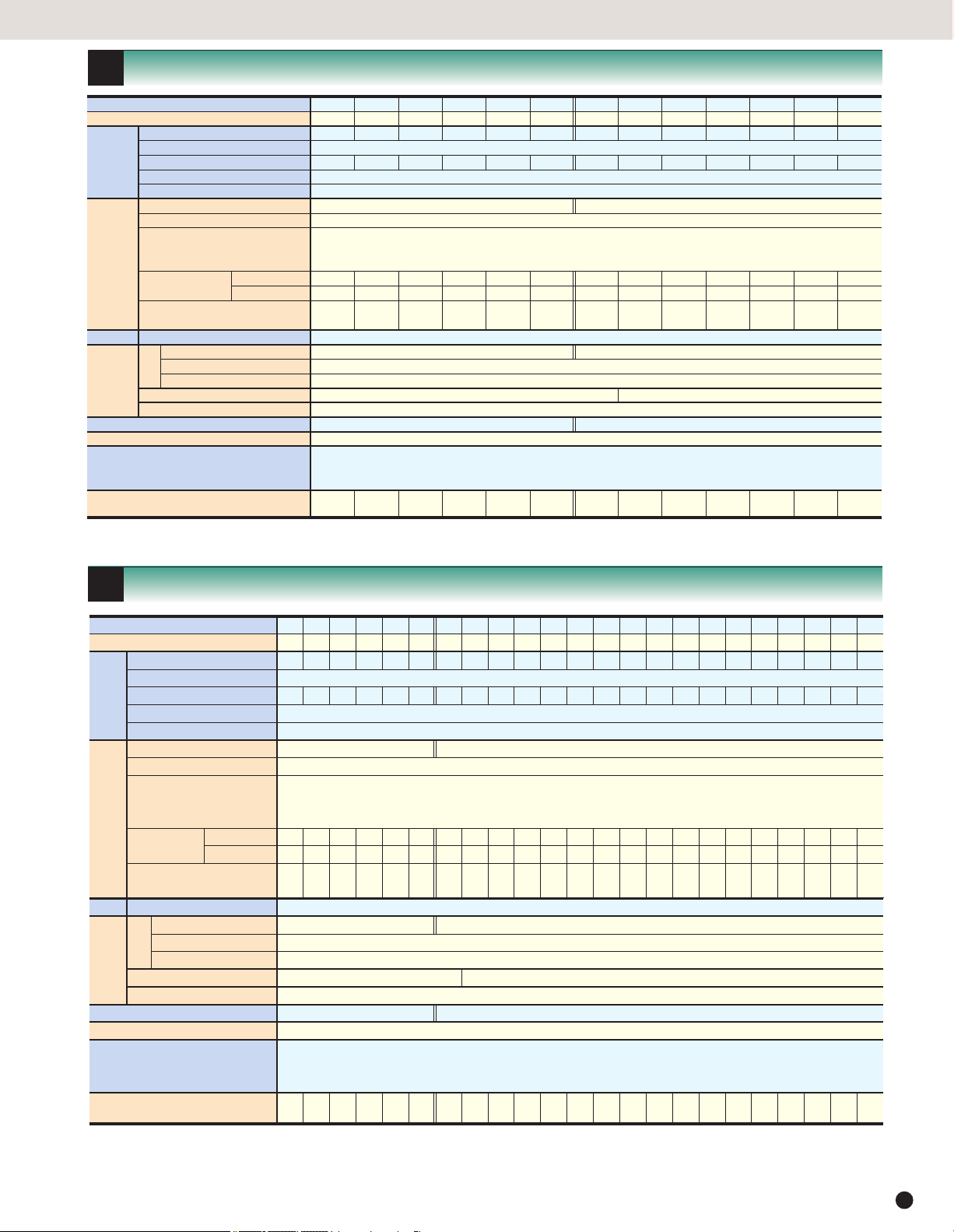

Variation

Easy to apply to customer systems. A consistent design concept in all models from 1/4HP to 800HP.

FRENIC 5000G1

industrial plant

Nominal

applied

motors [HP]

1/4

1/2

1

2

3

5

7.5

10

15

20

25

30

40

50

60

75

100

125

150

200

250

300

350

400

450

500

600

700

800

FRENIC5000G11S series

for general industrial machines

FRNF25G11S-2UX

FRNF50G11S-2UX

FRN001G11S-2UX

FRN002G11S-2UX

FRN003G11S-2UX

FRN005G11S-2UX

FRN007G11S-2UX

FRN010G11S-2UX

FRN015G11S-2UX

FRN020G11S-2UX

FRN025G11S-2UX

FRN030G11S-2UX

FRN040G11S-2UX

FRN050G11S-2UX

FRN060G11S-2UX

FRN075G11S-2UX

FRN100G11S-2UX

FRN125G11S-2UX

FRNF50G11S-4UX

FRN001G11S-4UX

FRN002G11S-4UX

FRN003G11S-4UX

FRN005G11S-4UX

FRN007G11S-4UX

FRN010G11S-4UX

FRN015G11S-4UX

FRN020G11S-4UX

FRN025G11S-4UX

FRN030G11S-4UX

FRN040G11S-4UX

FRN050G11S-4UX

FRN060G11S-4UX

FRN075G11S-4UX

FRN100G11S-4UX

FRN125G11S-4UX

FRN150G11S-4UX

FRN200G11S-4UX

FRN250G11S-4UX

FRN300G11S-4UX

FRN350G11S-4UX

FRN400G11S-4UX

FRN450G11S-4UX

FRN500G11S-4UX

FRN600G11S-4UX

FRENIC5000P11S series

for fans and pumps (variable torque loads)

460V230V460V230V

FRN007P11S-2UX

FRN010P11S-2UX

FRN015P11S-2UX

FRN020P11S-2UX

FRN025P11S-2UX

FRN030P11S-2UX

FRN040P11S-2UX

FRN050P11S-2UX

FRN060P11S-2UX

FRN075P11S-2UX

FRN100P11S-2UX

FRN125P11S-2UX

FRN150P11S-2UX

FRN007P11S-4UX

FRN010P11S-4UX

FRN015P11S-4UX

FRN020P11S-4UX

FRN025P11S-4UX

FRN030P11S-4UX

FRN040P11S-4UX

FRN050P11S-4UX

FRN060P11S-4UX

FRN075P11S-4UX

FRN100P11S-4UX

FRN125P11S-4UX

FRN150P11S-4UX

FRN200P11S-4UX

FRN250P11S-4UX

FRN300P11S-4UX

FRN350P11S-4UX

FRN400P11S-4UX

FRN450P11S-4UX

FRN500P11S-4UX

FRN600P11S-4UX

FRN700P11S-4UX

FRN800P11S-4UX

Fans

●

Air-conditioning system (for

factory, building, office,

hospital, clean room, shop,

and cattle barn)

●

Dryer

●

Boiler fan

●

Fans for controlling furnace

temperature

●

Roof fans controlled as a

group

●

Refrigerator

●

Compressor

●

Built-in blower in a filmmanufacturing machine

●

Cooling-tower fans

●

Ventilating fans

●

Air-conditioning equipment

How to read the model number

Code Series name

FRN FRENIC 5000 series

FRN F50 G 11 S - 4 UX

Code Nominal applied motors [HP]

F25 1/4HP

F50 1/2HP

001 1HP

002 2HP

to to

800 800HP

6

Code Application range

G General industrial machines

P Fans and pumps

Code Developed inverter series

11 11 series

Code Protective structure

S Standard

Code Version

UX UX

Code Input power source

2 Three-phase 230V

4 Three-phase 460V

Food processing machines

●

Food mixing machine

●

Food slicer

●

Grain milling machine

(bread, cake, noodles)

●

Tea making machine

●

Rice cleaning machine

Page 7

1S/P11S can be used for almost all

and equipment areas.

G11S/P11S

G11S/P11S

Machine tools

●

Grinding machine

●

Sanding machine

●

Milling machine

●

Lathe

●

Drilling machine

●

Tu rn ta bl e

●

Work positioning machine

●

PC board drilling machine

●

Winding machine

●

Press

Conveyance machinery

●

Crane (traveling, traversing, hoisting)

●

Automated warehouse

●

Conveyor (belt, chain, screw, roller)

●

Lift

●

Car parking facility

●

Elevator, escalator

●

Automatic door

●

Shutter equipment

●

Speed-change gear

Chemical machinery/wood

working machines

●

Fluid mixing machine

●

Extruder

●

Vibrator

●

Centrifugal separator

●

Coating machine

●

Take-up roller

●

Routing machine

●

Sanding machine

●

Planing machine

Electric pumps

●

Tankless water supply system

●

Submersible motor pump

●

Vacuum pump

●

Fountain pump

●

Cooling water pump

●

Circulating hot water pump

●

Well pump

●

Agricultural storage pump

●

Water treatment system

●

Constant-flow pump

●

Sludge pump

Packaging machinery

●

Individual packaging/innerpackaging machine

●

Packing machine

●

Outer-packaging machine

Paper making/

textile machinery

●

Spinning machine

●

Knitting machine

●

Textile printing

machine

●

Industrial sewing

machine

●

Synthetic fiber

manufacturing plant

Other machinery

●

Automated feed/medicine mixer

●

Commercial-use washing

machine

●

Offset printing press

●

Book-binding machine

●

Car-washing machine

●

Shredder

●

Dishwasher

●

Test equipment

●

Crusher

7

7

Page 8

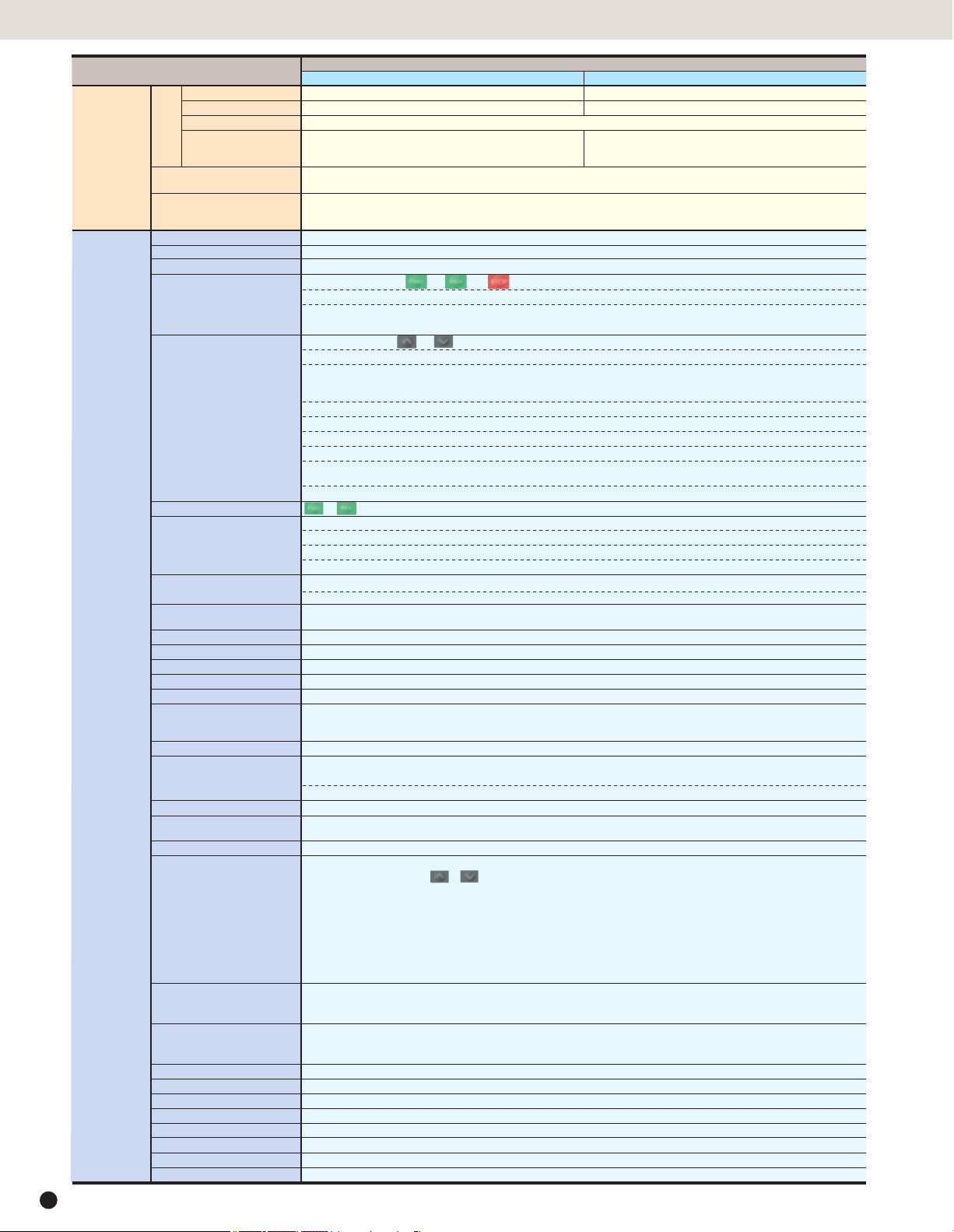

Standard Specifications

FRENIC5000G11S 230V, for general industrial machines

Type FRN

Nominal applied motor HP

Output

ratings

Input

ratings

Control Starting torque 200% (with Dynamic torque-vector control selected)

Braking

Enclosure (

Cooling method Natural cooling Fan cooling

Standards

Weight lbs(kg)

Rated capacity *1) kVA

Rated voltage *2) V 3-phase 200V/50Hz 200, 220V, 230V/60Hz

Rated current *3) A

Overload capability 150% of rated current for 1min. 150% of rated current for 1min.

Rated frequency Hz 50, 60Hz

Phases, Voltage, Frequency 3-phase 200 to 230V 50/60Hz

Voltage / frequency variations Voltage : +10 to –15% ( Voltage unbalance *6) : 2% or less ) Frequency :+5 to –5%

Momentary voltage dip capability *7)

Rated current *8)

Required power

supply capacity *9)

Standard

Braking torque (

DC injection braking Starting frequency: 0.1 to 60.0Hz Braking time: 0.0 to 30.0s Braking level: 0 to 100% of rated current

IEC 60529

G11S-2UX

¤¤¤

(with DCR)

(without DCR)

A

kVA

Braking torque 150% 100% 20% *10) 10 to 15% *10)

Time s 10 5 5 No limit

Duty cycle % 10535 32 32 No limit

Using options

) IP 40 (NEMA1) IP 00 ( NEMA1: Option )

) 150% 100%

F50

F25

1/2

1/4

1.2

0.6

1.5 3.0 5.0 8.0 11 17 25 33 46 59 74 87 115 145 180 215 283 346

200% of rated current for 0.5s 180% of rated current for 0.5s

When the input voltage is 165V or more, the inverter can be operated continuously.

When the input voltage drops below 165V from rated voltage, the inverter can be operated for 15ms .

The smooth recovery method is selectable.

0.94 1.6 3.1 5.7 8.3 14.0 19.7 26.9 39.0 54.0 66.2 78.8 109 135 163 199 272 327

1.8 3.4 6.4 11.1 16.1 25.5 40.8 52.6 76.9 98.5 117 136 168 204 243 291 - -

0.4 0.6 1.1 2.0 2.9 4.9 6.9 9.4 14 19 23 28 38 47 57 69 95 114

-UL/cUL -Low Voltage Directive -EMC Directive TÜV (up to 30HP)

-IEC 61800-2 (Ratings, specifications for low voltage adjustable frequency a.c. power drive systems)

-IEC 61800-3 (EMC product standard including specific test methods)

4.9

4.9

(2.2)

(2.2)

001

1

2.0

5.5

(2.5)

002

2

3.2

8.4

(3.8)

003

3

4.4

8.4

(3.8)

005

5

6.8

8.4

(3.8)

010

007

10

7.5

13

9.9

13.4

13.4

(6.1)

(6.1)22(10)22(10)

015

15

18

020

20

23

025

25

29

23.1

(10.5)

030

23.1

(10.5)

040

50

40

30

36

58

46

3-phase 200 to 220V/50Hz (220 to 230V/50Hz) *5)

200 to 230V/60Hz

180% (with Dynamic torque-vector control selected)

63.9

79.4

(29)

(36)97(44)

60

72

75

86

101.4

(46)

100

113

154.3

(70)

125

138

253.5

(115)

125

100

075

060

050

FRENIC5000G11S 460V, for general industrial machines

F50

001

002

003

005

Type FRN

Nominal applied motor HP

Output

ratings

Input

ratings

Control

Braking

Enclosure (IEC 60529)

Cooling method

Standards

Weight lbs(kg)

NOTES: *1) Inverter output capacity (kVA) at 460V in 460V, 230V in 230V. *2) Output voltage is proportional to the power supply vol tage and cannot exceed the power supply

voltage. *3) Current derating may be required in case of low impedance loads such as high frequency motor. *4) When the inp ut voltage is 380V/50Hz or 380 to 415V/60Hz, the tap

of the auxiliary transformer must be changed. *5) Order individually. *6) Refer to the IEC 61800-3( 5.2.3 ). *7) Tested a t standard load condition (85% load). *8) This value is

under FUJI original calculation method. (Refer to the Technical Information.) *9) When power-factor correcting DC reactor is used. *10) With a nominal applied motor, this value is

average torque when the motor decelerates and stops from 60Hz. (It may change according to motor loss.)

8

¤¤¤

G11S-4UX

1/2

Rated capacity *1) kVA

Rated voltage *2) V

Rated current *3) A

Overload capability

Rated frequency Hz

Phases, Voltage, Frequency

Voltage / frequency variations

Momentary voltage dip

capability *7)

Rated current *8)

Required power

supply capacity *9)

Starting torque

Braking torque

Time s

Duty cycle %

Standard

Braking torque (Using options)

DC injection braking

(with DCR)

A

(without DCR)

1.2

3-phase 380, 400, 415V/50Hz 380, 400, 440, 460V/60Hz

1.5

150% of rated current for 1min.

200% of rated current for 0.5s

50, 60Hz

3-phase 380 to 480V 50/60Hz 3-phase 380 to 440V/50Hz 380 to 480V/60Hz *4)

Voltage : +10 to –15% ( Voltage unbalance *6) : 2% or less ) Frequency :+5 to –5%

When the input voltage is 310V or more, the inverter can be operated continuously.

When the input voltage drops below 310V from rated voltage, the inverter can be operated for 15ms.

The smooth recovery method is selectable.

0.82

1.8

0.6

kVA

200% (with Dynamic torque-vector control selected)

150%

5

Starting frequency: 0.1 to 60.0Hz Braking time: 0.0 to 30.0s Braking level: 0 to 100% of rated current

Natural cooling

-UL/cUL -Low Voltage Directive -EMC Directive TÜV (up to 30HP)

-IEC 61800-2 (Ratings, specifications for low voltage adjustable frequency a.c. power drive systems)

-IEC 61800-3 (EMC product standard including specific test methods)

4.9

(2.2)

(2.5)

1

2

2.0

2.9

2.5

3.7

1.5

2.9

3.5

6.2

1.1

2.1

35532

5.5

8.4

(3.8)

(3.8)

007

3

5

4.4

7.2

5.5

9

4.2

7.1

10.0

9.2

14.9

21.5

3.0

5.0

100% 20% *10)

5 No limit

150% 100%

IP 40 (NEMA1) IP 00 ( NEMA1: Option )

8.4

8.4

14.3

(3.8)

(6.5)

010

7.5

10

10

14

13

18

13.5

27.9

7.0

9.4

14.3

(6.5)22(10)22(10)

015

15

19

24

19.8

39.1

14

020

20

24

30

26.8

50.3

19

025

25

31

39

33.2

59.9

24

23.1

(10.5)

030

040

050

060

075

100

125

150

200

250

30

40

50

60

75

100

125

150

200

250

36

48

60

73

89

120

140

167

202

242

45

60

75

91

112

150

176

210

253

304

150% of rated current for 1min.

180% of rated current for 0.5s

39.3

54

67

81

100

134-160-196-232-282-352-385-491-552-624-704

69.3

86

104

124

150

28

38

47

57

70

93 111 136 161 196 244 267 341 383 433 488

180% (with Dynamic torque-vector control selected)

10 to 15% *10)

No limit32

Fan cooling

23.1

63.9

(29)75(34)86(39)

(10.5)

88.2

(40)

105.8

(48)

154.3

(70)

154.3

(70)

220.5

(100)

220.5

(100)

300

300

300

377

308.6

(140)

350

350

331

415

308.6

(140)

400

400

414

520

551.2

(250)

450

450

466

585

551.2

(250)

500

500

518

650

793.7

(360)

600

600

590

740

-

793.7

(360)

Page 9

G11S/P11S

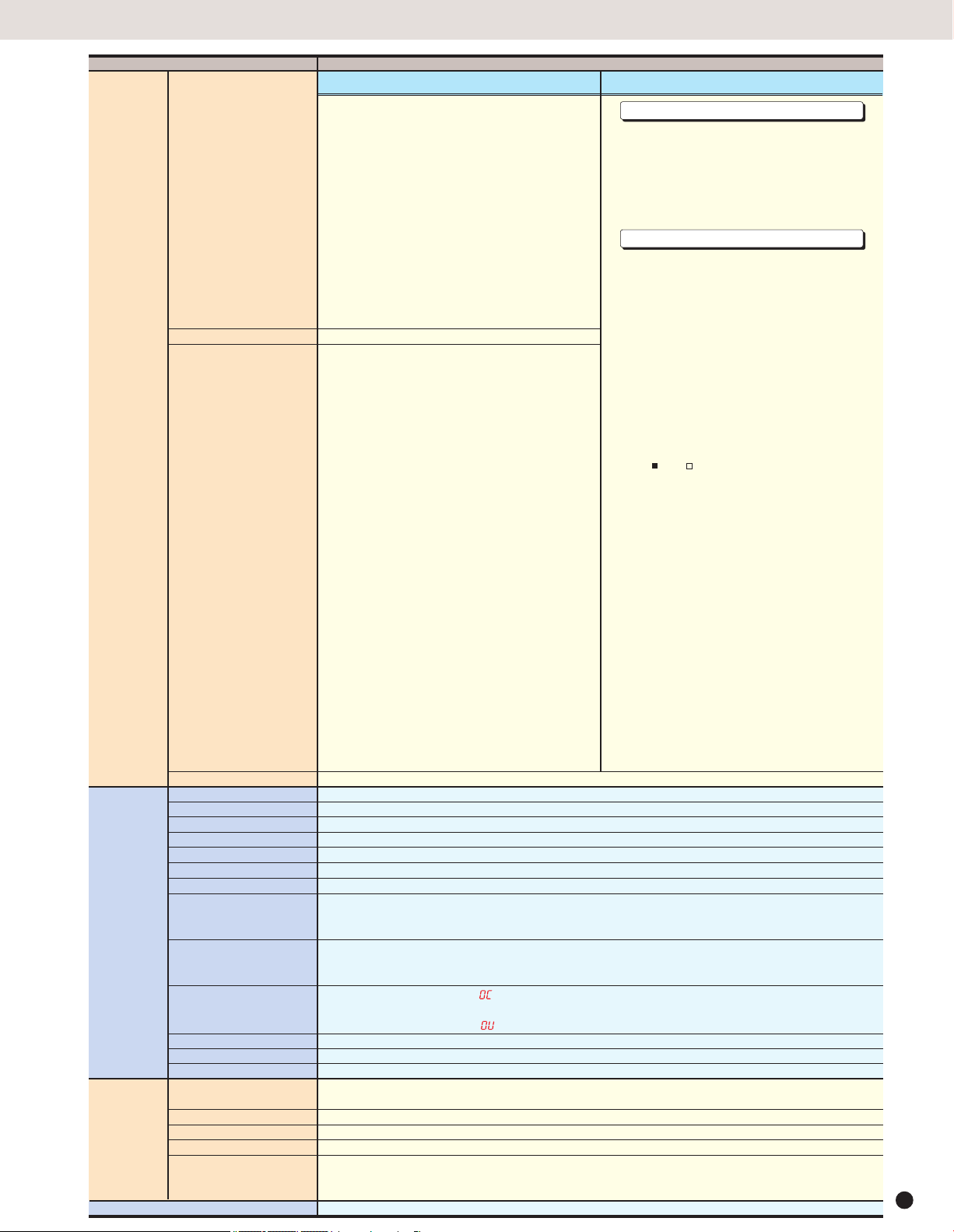

FRENIC5000P11S 230V, for fans and pumps

100

075

060

050

040

030

Type

Nominal applied motor HP

Output

ratings

Input

ratings

Control Starting torque 50%

Braking

Enclosure (IEC 60529) IP 40 (NEMA1) IP 00 ( NEMA1 : Option )

Cooling method Fan cooling

Standards

Weight lbs(kg)

FRN

¤¤¤

P11S-2UX

Rated capacity *1) kVA

Rated voltage *2) V 3-phase 200V/50Hz 200, 220V, 230V/60Hz

Rated current *3) A 22 29 42 55 67 78 115 145 180 215 283 346 415

Overload capability 110% of rated current for 1min

Rated frequency Hz 50, 60Hz

Phases, Voltage, Frequency 3-phase 200 to 230V 50/60Hz

Voltage / frequency variations Voltage : +10 to –15% ( Voltage unbalance *6) : 2% or less ) Frequency :+5 to –5%

Momentary voltage dip capability *7)

Rated current *8)

Required power

supply capacity *9)

Braking torque *10) 20% 10 to 15%

Time s No limit

Duty cycle % No limit

Standard

Braking torque (Using options) 100% 70%

DC injection braking Starting frequency: 0.1 to 60.0Hz Braking time: 0.0 to 30.0s Braking level: 0 to 80% of rated current

(with DCR) 19.7 26.9 39.0 54.0 66.2 78.8 109 135 163 199 272 327 400

A

(without DCR) 40.8 52.6 76.9 98.5 117 136 168 204 243 291

007

7.5

8.8

When the input voltage is 165V or more, the inverter can be operated continuously.

When the input voltage drops below 165V from rated voltage, the inverter can be operated for 15ms .

The smooth recovery method is selectable.

kVA 6.9 9.4 14 19 23 28 38 47 57 69 95 114 139

-UL/cUL -Low Voltage Directive -EMC Directive TÜV (up to 30HP)

-IEC 61800-2 (Ratings, specifications for low voltage adjustable frequency a.c. power drive systems)

-IEC 61800-3 (EMC product standard including specific test methods)

12.6

(5.7)

015

010

12.6

(5.7)

15

10

17

12

12.6

(5.7)22(10)22(10)

020

20

22

025

25

27

30

46

31

3-phase 200 to 220V/50Hz (220 to 230V/50Hz) *5) 200 to 230V/60Hz

23.1

63.9

(10.5)

(29)

63.9

58

(29)

72

79.4

(36)97(44)

86

113

---

101.4

(46)

100

75

60

50

40

125

125

138

154.3

(70)

150

150

165

253.5

(115)

FRENIC5000P11S 460V, for fans and pumps

007

010

015

020

025

030

040

050

060

075

100

125

150

200

250

300

350

400

450

500

600

700

700

668

793.7

(360)

800

800

764

-

793.7

(360)

Type FRN

Nominal applied motor HP

Output

ratings

Input

ratings

Control

Braking

Enclosure (IEC 60529)

Cooling method

Standards

Weight lbs(kg)

NOTES: *1) Inverter output capacity (kVA) at 460V in 460V, 230V in 230V. *2) Output voltage is proportional to the power supply vol tage and cannot exceed the power supply

voltage. *3) Current derating may be required in case of low impedance loads such as high frequency motor. *4) When the inp ut voltage is 380V/50Hz or 380 to 415V/60Hz, the tap

of the auxiliary transformer must be changed. *5) Order individually. *6) Refer to the IEC 61800-3( 5.2.3 ). *7) Tested a t standard load condition (85% load). *8) This value is

under FUJI original calculation method. (Refer to the Technical Information.) *9) When power-factor correcting DC reactor (DC R) is used. *10) With a nominal applied motor, this

value is average torque when the motor decelerates and stops from 60Hz. (It may change according to motor loss.)

¤¤¤

P11S-4UX

7.5

10

15

20

25

30

40

50

60

75

100

125

10

13

18

24

29

35

48

60

72

89

119

Rated capacity *1) kVA

Rated voltage *2) V

Rated current *3) A

Overload capability 110% of rated current for 1min

Rated frequency Hz 50, 60Hz

Phases, Voltage, Frequency

Voltage / frequency variations

Momentary voltage

dip capability *7)

Rated current *8)

Required power

supply capacity *9)

Starting torque 50%

Braking torque *10)

Time s

Duty cycle %

Standard

Braking torque (Using options)

DC injection braking

(with DCR)

A

(without DCR)

3-phase 380, 400, 415V/50Hz 380, 400, 440, 460V/60Hz

16.5 23 30 37 44 60 75 91 112 150 176 210 253 304 377 415 485 520 650 740 840 960

12.5

3-phase 380 to 480V 50/60Hz

Voltage : +10 to –15% ( Voltage unbalance *6) : 2% or less ) Frequency :+5 to –5%

When the input voltage is 310V or more, the inverter can be operated continuously.

When the input voltage drops below 310V from rated voltage, the inverter can be operated for 15ms.

The smooth recovery method is selectable.

13.5

19.8

26.8

10.0

27.9

21.5

7.0

kVA

Starting frequency: 0.1 to 60.0Hz Braking time: 0.0 to 30.0s Braking level: 0 to 80% of rated current

-UL/cUL -Low Voltage Directive -EMC Directive TÜV (up to 30HP)

-IEC 61800-2 (Ratings, specifications for low voltage adjustable frequency a.c. power drive systems)

-IEC 61800-3 (EMC product standard including specific test methods)

13.4

(6.1)

39.1

9.4

14

20% 10 to 15%

IP 40 (NEMA1) IP 00 ( NEMA1 : Option )

13.4

13.4

(6.1)

(6.1)22(10)22(10)

33.2

50.3

59.9

19

24

100% 70%

3-phase 380 to 440V/50Hz 380 to 480V/60Hz *4)

39.3

54

67

81

100

69.3

86

104

124

150

28

38

47

57

70

63.9

23.1

(10.5)

63.9

(29)

(29)75(34)86(39)

140

134-160-196-232-282-352-385-491-552-624-704-792-880

93 111 136 161 196 244 267 341 383 433 488 549 610

No limit

No limit

Fan cooling

88.2

105.8

(48)

(40)

150

167

154.3

(70)

200

201

154.3

(70)

250

242

220.5

(100)

300

300

220.5

(100)

350

330

308.6

(140)

400

386

308.6

(140)

450

414

308.6

(140)

500

517

551.2

(250)

600

589

551.2

(250)

9

Page 10

Common Specifications

Item

Output

frequency

Control

Note: (*) Option *1) Inverter may automatically reduce carrier frequency, in accordance with ambient temperature or output current for protecting inverter.

10

Maximum frequency

Base frequency

Starting frequency

Carrier frequency *1)

Setting

Accuracy (Stability)

Setting resolution

Control method

Voltage / freq. (V/f) characteristic

Torque boost

Operation method

Frequency setting

(Frequency command)

Jogging operation

Running status signal

Acceleration / Deceleration time

Active drive

Frequency limiter

Bias frequency

Gain for frequency setting

Jump frequency control

Rotating motor pick up (Flying start)

Auto-restart after momentary power

failure

Line / Inverter changeover operation

Slip compensation

Droop operation

Torque limiting

Torque control

PID control

Automatic deceleration

Second motor’s setting

Energy saving operation

Fan stop operation

Universal DI

Universal DO

Universal AO

Zero speed control (*)

Positioning control (*)

Synchronized operation (*)

0.75 to 15kHz (75HP or smaller)

0.75 to 10kHz (100HP or larger)

• Analog setting : ±0.2% of Maximum frequency (at 25±10°C(77±50°F))

• Digital setting : ±0.01% of Maximum frequency (at –10 to +50°C(14 to 122°F))

• Analog setting : •

• Digital setting : 0.01Hz at Maximum frequency of up to 99.99Hz (0.1Hz at Maximum frequency of 100Hz and above)

• LINK setting : • 1/20000 of Maximum frequency ex.) 0.003Hz at 60Hz, 0.006Hz at 120Hz, (0.02Hz at 400Hz: G11S) • 0.01Hz (Fixed)

• V/f control (Sinusoidal PWM control) • Dynamic torque-vector control (Sinusoidal PWM control) • Vector control with PG (*) (G11S only)

Adjustable at base and maximum frequency, with AVR control : 320 to 480V (460V), 80 to 240V (230V)

Selectable by load characteristics: Constant torque load (Auto/manual), Variable torque load (Manual)

• KEYPAD operation : or key, key

• Digital input signal operation : FWD or REV command, Coast-to-stop command, etc.

• LINK operation : RS-485 (Standard)

• KEYPAD operation: or key

• External potentiometer (*) : 1 to 5kΩ (1/2W)

• Analog input : 0 to +10V DC (0 to +5V DC), 4 to 20mA DC

(Reversible)

• UP/DOWN control : Output frequency increases when UP signal is ON, and decreases when DOWN signal is ON.

• Multistep frequency : Up to 16 different frequencies can be selected by digital input signal.

• Pulse train input (*) : 0 to 100kp/s

• Digital signal (parallel ) (*) : 16-bit binary

• LINK operation : RS-485 (Standard)

• Programmed PATTERN operation: Max. 7 stages

Transistor output (4 points) : RUN, FAR, FDT, OL, LU, TL, etc.

Relay output (2 points) : • Same as transistor output • Alarm output (for any fault)

Analog output (1 point) : Output frequency, Output current, Output torque, etc.

Pulse output (1 point) : Output frequency, Output current, Output torque, etc.

0.01 to 3600s : • Independently adjustable acceleration and deceleration • 4 different times are selectable.

Mode select : Linear, S-curve (weak), S-curve (strong), Non-linear

When the acceleration time reaches 60s, the motor output torque is automatically reduced to rated torque. Then the motor operation mode is changed to torque limiting operation.

The acceleration time is automatically extended up to 3 times.

High and Low limiter can be preset.

Bias frequency can be preset.

Gain for frequency setting can be preset. (0.0 to 200.0%) ex.) Analog input 0 to +5V DC with 200% gain results in maximum frequency at 5V DC.

Jump frequency (3 points) and its common jump hysteresis width (0 to 30Hz) can be preset.

A rotating motor (including inverse rotating mode) can be smoothly picked up without stopping the motor (speed search method).

Automatic restart is available without stopping motor after a momentary power failure (speed search method). When "Smooth recovery" mode is

selected, the motor speed drop is held minimum. (The inverter searches the motor speed, and smoothly returns to setting frequency. Even if the motor

circuit is temporarily opened, the inverter operates without a hitch. )

Controls the switching operation between line power and inverter. The inverter has sequence function inside.

The inverter output frequency is controlled according to the load torque to keep motor speed constant. When the value is set at

"0.00" and "Torque-vector" is set at "active", the compensation value automatically selects the Fuji standard motor.

Slip compensation can be preset for the second motor.

The motor speed droops in proportion to output torque (–9.9 to 0.0Hz)......G11S only.

•

• Torque limiting 1 and 2 can be individually set, and are selectable with a digital input signal.

Output torque (or load factor) can be controlled with an analog input signal.....G11S only.

This function can control flowrate, pressure, etc. (with an analog feedback signal.)

• Reference• KEYPAD operation ( or key) : Setting freq. / Max. freq. X 100 (%)• PATTERN operation

signal • Voltage input (Terminal 12 ) : 0 to +10V DC • DI option input (*): •

• Feedback signal • Terminal 12 (0 to +10V DC or +10 to 0V DC)

Torque limiter 1 (Braking) is set at "F41: 0" (Same as Torque limiter 2 (Braking) ).

•

• In constant speed operation : Based on regenerative energy, the frequency is increased and tripless operation is active.

This function is used for two motors switching operation.

• The second motor’s V/f characteristics (base and maximum frequency) can be preset.

• The second motor’s circuit parameter can be preset. Torque-vector control can be applied to both motors.

This function minimizes inverter and motor losses at light load.

This function is used for silent operation or extending the fan's lifetime.

Transmits to main controller of LINK operation.

Outputs command signal from main controller of LINK operation.

Outputs analog signal from main controller of LINK operation.

The stopped motor holds its rotor angle.....G11S only.

The SY option card can be used for positioning control by differential counter method.

This function controls the synchronize operation between 2 axes with PGs.

(Inverse)

or key, FWD or REV digital input signal

When the motor torque reaches a preset limiting level, this function automatically adjusts the output frequency to prevent the inverter from tripping due to an overcurrent.

• Current input (Terminal C1 ) : 4 to 20mA DC • Binary, full scale/

Reversible operation with polarity (Terminal 12)

•

•

Reversible operation with polarity (Terminal 12 + V1 )

• Inverse mode operation (Terminal 12 ) : +10 to 0V DC

• Inverse mode operation (Terminal C1 ) : 20 to 4mA DC

In deceleration : The deceleration time is automatically extended up to 3 times the setting time for tripless operation even if braking resistor not used.

G11S

50 to 400Hz

25 to 400Hz

1/1000 of Maximum frequency ex.) 0.06Hz at 60Hz, 0.12Hz at 120Hz, (0.4Hz at 400Hz: G11S) • 1/3000 for 40HP and above

T-Link (FUJI private link), PROFIBUS-DP, Interbus-S, DeviceNet, Modbus Plus, JPCN1 (Option)

0 to ±10V DC (0 to ± 5V DC) ....Reversible operation by polarized signal can be selected.

+10 to 0V DC, 20 to 4mA DC......Inverse mode operation can be selected.

T-Link (FUJI private link), RPOFIBUS-DP, Interbus-S, DeviceNet, Modbus Plus, JPCN1 (Option)

• Terminal C1 (4 to 20mA DC or 20 to 4mA DC)

0.1 to 60Hz, Holding time: 0.0 to 10.0s

Explanation

: 0 to ±10V DC •

: 0 to ±10V DC •

P11S

50 to 120Hz

25 to 120Hz

0.75 to 15kHz (30HP or smaller)

0.75 to 10kHz (40 to 100HP)

0.75 to 6kHz (125HP or larger)

: Setting freq./Max. freq. X 100 (%)

BCD, setting freq./Max. freq. X

Multistep frequency setting

RS-485

: Setting freq./Max. freq. X 100 (%)

: Setting freq./Max. freq. X 100 (%)

100

(%)

100

(%)

Page 11

G11S/P11S

Item

Indication

Protection

Condition

(Installation

and

operation)

Storage condition -Temperature : –25 to +65 °C(-13 to 149°F), -Humidity : 5 to 95%RH (non-condensing)

Operation mode (Running)

• Output frequency 1 (Before slip compensation) (Hz)

• Output frequency 2 (After slip compensation) (Hz)

• Setting frequency (Hz)

• Output current (A)

• Output voltage (V)

• Motor synchronous speed (r/min)

• Line speed (m/min)

• Load shaft speed (r/min)

• Torque calculation value (%)

• Input power (kW)

• PID reference value

• PID reference value (remote)

• PID feedback value

• Trip histor y

Stopping

Trip mode

Charge lamp

Overload

Overvoltage

Undervoltage

Input phase loss

Overheating

Short-circuit

Ground fault

Motor overload

DB resistor overheating

Stall prevention

Output phase loss

Motor protection by PTC thermistor When the motor temperature exceeds allowable value, the inverter trips automatically.

Auto reset

Installation location*

Altitude 3300ft(1000m) or less. Applicable to 9800ft(3000m) with power derating (-10%/3300ft(1000m))

Ambient temperature

Ambient humidity 5 to 95%RH (non-condensing)

Vibration

Selected setting value or output value

Displays the cause of trip by codes as follows.

• OC1 (Overcurrent during acceleration)

• OC2 (Overcurrent during deceleration)

• OC3 (Overcurrent during running at constant speed)

• EF (Ground fault)

• Lin (Input phase loss)

• FUS (Fuse blown)

• OU1 (Overvoltage during acceleration)

• OU2 (Overvoltage during deceleration)

• OU3 (Overvoltage running at constant speed)

• LU (Undervoltage)

• OH1 (Overheating at heat sink)

• OH2 (External thermal relay tripped)

• OH3 (Overtemperature at inside air)

• dBH (Overheating at DB circuit)

• OL1 (Motor 1 overload)

• OL2 (Motor 2 overload)

• OLU (Inverter unit overload)

• OS (Overspeed)

• PG (PG error)

• Er1 (Memory error)

• Er2 (KEYPAD panel communication error)

• Er3 (CPU error)

• Er4 (Option error)

• Er5 (Option error)

• Er6 (Operation procedure error)

• Er7 (Output phase loss error, impedance imbalance)

• Er7. (Charging circuit alarm, 40HP or larger)

• Er8 (RS-485 error)

When the DC link circuit voltage is higher than 50V, the charge lamp is ON.

Protects the inverter by electronic thermal overload function and by detection of inverter temperature.

Detects DC link circuit overvoltage,and stops the inverter. (460V : 800V DC, 230V : 400V DC)

Detects DC link circuit undervoltage,and stops the inverter. (460V : 400V DC, 230V : 200V DC)

Phase loss protection for power line input.

Protects the inverter by detection of inverter temperature.

Short-circuit protection for inverter output circuit

• Ground fault protection for inverter output circuit (3-phase current detection method) • Zero-phase current detection method (40HP or larger)

• The inverter trips,and then protects the motor. • Electronic thermal overload protection can be set for standard motor or inverter motor

• Thermal time constant (0.5 to 75.0 minutes) can be preset for a special motor.

• The second motor's electronic thermal overload protection can be preset for 2-motor changeover operation.

• Prevents DB resistor overheating by internal electronic thermal overload relay (10HP or smaller).

• Prevents DB resistor overheating by external thermal overload relay attached to DB resistor (15HP or larger).

(The inverter stops electricity discharge operation to protect the DB resistor.)

• Controls the output frequency to prevent (overcurrent) trip when the output current exceeds the limit value during acceleration.

• Lowers the output frequency to hold almost constant torque when the output current exceeds the limit value during operation at constant speed.

• Controls the output frequency to prevent (overvoltage) trip when the DC link circuit voltage exceeds the limit value during deceleration.

When the inverter executes auto-tuning, detects each phase impedance imbalance.

When the inverter is tripped, it resets automatically and restarts.

Free from corrosive gases, flammable gases, oil mist, dusts, and direct sunlight.

Indoor use only.

–10 to +50 °C(14 to 122°F). For inverters of 30HP or smaller, remove the ventilation covers when operating it at a temperature of 40°C(104°F) or above.

3mm at from 2 to less than 9Hz, 9.8m/s

2m/s2 at from 20 to less than 55Hz (2m/s2 at from 9 to less than 55Hz :G11S 125HP, P11S 150HP or more)

1m/s

:Cause of trip by code (Even when main power supply is off,

trip history data of the last 4 trips are retained.)

2

at from 55 to less than 200Hz,

LED monitor

2

at from 9 to less than 20Hz,

Explanation

LCD monitor

Operation monitor

• Displays operation guidance

• Bargraph: Output frequency (%), Output current (A), Output torque (%)

Alarm monitor

• The alarm data is displayed when the inverter trips.

Function setting

Displays function codes and its data or data code, and changes the data value.

Operation condition

• Output frequency (Hz)

• Output current (A)

• Output voltage (V)

• Torque calculation value (%)

• Setting frequency (Hz)

• Operation condition

(FWD / REV, IL, VL / LU, TL)

Tester function

(I/O check)

• Digital I/O : (ON), (OFF)

• Analog I/O: (V), (mA), (H), (p/s)

Maintenance data

• Operation time (h)

• DC link circuit voltage (V)

• Temperature at inside air (°C)

• Temperature at heat sink (°C)

• Maximum current (A)

• Main circuit capacitor life(%)

• Control PC board life (h)

Load factor calculation

• Measurement time (s)

• Maximum current (A)

Alarm data

• Output frequency (Hz)

• Output current (A)

• Output voltage (V)

• Torque calculation value (%)

• Setting frequency (Hz)

• Operation condition

(FWD / REV, IL, VL / LU, TL)

• Operation time (h)

• DC link circuit voltage (V)

* If the inverter has to be used in an atmosphere including

(Japanese, English, German, French, Spanish, Italian)

Operation monitor & Alarm monitor

Function setting & monitor

• Motor synchronous speed (r/min)

• Load shaft speed (r/min)

• Line speed (m/min)

• PID reference value

• PID feedback value

Driving torque limiter setting vaiue (%)

•

• Braking togue limiter setting value

• Cooling fan operation time (h)

• Communication error times

(KEYPAD,RS-485, Option)

• ROM version

(Inverter, KEYPAD, Option)

• Average current (A)

• Average braking power (%)

• Temperature at inside air (°C)

• Hest sink temperature (°C)

• Communication error times

(KEYPAD,RS-485, Option)

• Digital input terminal condition

(Remote, Communication)

• Transistor output terminal condition

• Trip history code

• Multiple alram exist

the hydrogen sulfide gases, a special model might be available.

Contact Fuji Electric FA.

(%)

11

Page 12

Terminal Functions

Terminal Functions

12

Main

circuit

Analong

input

Digital

input

Symbol

L1/R, L2/S,L3/T

U, V, W

P1, P(+)

P(+), N(-)

P(+), DB

G

R0, T0

13

12

V2

C1

11

FWD

REV

X1

X2

X3

X4

X5

X6

X7

X8

X9

(SS1)

(SS2)

(SS4)

(SS8)

(RT1)

(RT2)

(HLD)

(BX)

(RST)

(THR)

(JOG)

(Hz2/Hz1)

(M2/M1)

(DCBRK)

(TL2/TL1)

(SW50)

(SW60)

(UP)

(DOWN)

(WE-KP)

(Hz/PID)

(IVS)

(IL)

(Hz/TRQ)

(LE)

(U-DI)

(STM)

(PG/Hz)

(SYC)

(ZERO)

(STOP1)

(STOP2)

(EXITE)

PLC

CM

Terminal name

Power input

Inverter output

For DC REACTOR

For BRAKING UNIT

For EXTERNAL

BRAKING RESISTOR

Grounding

Auxiliary control

power supply

Potentiometer power supply

Voltage input

(Torque control)

(PID control)

(PG feedback)

Voltage input

Current input

(PID control)

Common

Forward operation

command

Reverse operation

command

Digital input 1

Digital input 2

Digital input 3

Digital input 4

Digital input 5

Digital input 6

Digital input 7

Digital input 8

Digital input 9

Multistep freq.

selection

ACC / DEC time selection

3-wire operation

stop command

Coast-to-stop

command

Alarm reset

Trip command

(External fault)

Jogging operation

Freq. set 2 / Freq. set 1

Motor 2 / Motor 1

DC brake command

Torque limiter 2 /

Torque limiter 1

Switching operation

between line and inverter

UP command (UP) - CM: ON ..... The output frequency increases.

DOWN command

Write enable for KEYPAD

PID control cancel

Inverse mode changeover

Interlock signal for 52-2

TRQ control cancel

Link enable (RS-485, Bus)

Universal DI This signal is transmitted to main controller of LINK operation.

Pick up start mode

SY-PG enabled

Syuhronization command

Zero speed command

Forced stop command

Forced stop command

with Deceleration time4

Pre-exciting command:

PLC terminal

Common

Connect a 3-phase power supply.

Connect a 3-phase induction motor.

Connect the DC REACTOR for power-factor correcting or harmonic current reducing.

• Connect the BRAKING UNIT (Option).

• Used for DC bus connection system.

Connect the EXTERNAL BRAKING RESISTOR (Option)

Ground terminal for inverter chassis (housing).

Connect the same AC power supply as that of the main circuit to back up the control circuit

power supply.

+10V DC power supply for frequency setting POT ( POT: 1 to 5kΩ )

• 0 to +10V DC/0 to 100% (0 to +5V DC/0 to 100% )

• Reversible operation can be selected by function setting.

0 to ±10V DC /0 to ±100% (0 to ±5V DC/0 to ±100% )

• Inverse mode operation can be selected by function setting or digital input signal.

+10 to 0V DC/0 to 100%

Used for torque control reference signal.

Used for PID control reference signal or feedback signal.

Used for reference signal of PG feedback control (option)

Frequency is set according to the analog input voltage supplied from an external circuit

• 0 to +10V DC/0 to 100% • Reverse operation: +10 to 0V DC/0 to 100%

* It can be used only one terminal "V2" or "C1" alternatively * Input resistance: 22kΩ

• 4 to 20mA DC/0 to 100%

• Inverse mode operation can be selected by function setting or digital input signal.

20 to 4mA DC/0 to 100%

Used for PID control reference signal or feedback signal.

Common for analog signal

FWD - CM: ON ..... The motor runs in the forward direction.

FWD - CM: OFF ..... The motor decelerates and stops.

REV - CM: ON ..... The motor runs in the reverse direction.

REV - CM: OFF ..... The motor decelerates and stops.

These terminals can be preset as follows.

(SS1) : 2 (0, 1) different frequencies are selectable.

(SS1,SS2) : 4 (0 to 3) different frequencies are selectable.

(SS1,SS2,SS4) : 8 (0 to 7) different frequencies are selectable.

(SS1,SS2,SS4,SS8) : 16 (0 to 15) different frequencies are selectable.

(RT1) : 2 (0, 1) different ACC / DEC times are selectable.

(RT1,RT2) : 4 (0 to 3) different ACC / DEC times are selectable.

Used for 3-wire operation.

(HLD) - CM: ON ..... The inverter self-holds FWD or REV signal.

(HLD) - CM: OFF ..... The inverter releases self-holding.

(BX) - CM: ON ..... Motor will coast-to-stop. (No alarm signal will be output.)

(RST) - CM: ON ..... Faults are reset. (This signal should be held for more than 0.1s.)

(THR) - CM: OFF ..... "OH2 trip" occurs and motor will coast-to-stop.

(JOG) - CM: ON ..... JOG frequency is effective.

(Hz2/Hz1) - CM: ON ..... Freq. set 2 is effective.

(M2/M1) - CM: ON ..... The motor circuit parameter and V/f characteristics are changed

(DCBRK) - CM: ON ..... The DC injection brake is effective. (In the inverter deceleration mode)

(TL2/TL1) - CM: ON ..... Torque limiter 2 is effective.

(SW50(SW60)) - CM: ON .....The motor is changed from inverter operation to line operation.

(SW50(SW60)) - CM: OFF ..... The motor is changed from line operation to inverter operation.

(DOWN) - CM: ON ..... The output frequency decreases.

• The output frequency change rate is determined by ACC / DEC time.

• Restarting frequency can be selected from 0Hz or setting value at the time of stop.

(WE-KP) - CM: ON ..... The data is changed by KEYPAD.

(Hz/PID) - CM: ON ..... The PID control is canceled,and frequency setting by KEYPAD

( or )is effective.

(IVS) - CM: ON ..... Inverse mode is effective in analog signal input.

Connect to auxiliary contact (1NC) of 52-2.

(Hz/TRQ) - CM: ON ..... The torque control is canceled, and ordinary operation is effective.

(LE) - CM: ON ..... The link opereation is effective. Used to switch operation between ordinary

(STM) - CM: ON ..... The "Pick up" start mode is effective.

(PG/Hz) - CM: ON ..... Synchronized operation or PG-feedback operation is effective.

(SYC) - CM: ON ..... The motor is controlled for synchronized operation between 2 axes with PGs.

(ZERO) - CM: ON ..... The motor decelerates and holds its rotor angle.

(STOP1) - CM: ON ..... The motor decelerates and stops.

(STOP2) - CM: ON ..... The motor decelerates and stops with Deceleration time4.

(EXITE) - CM: ON ..... The magnetic flux can be established preliminary before starting at PG

Connect PLC power supply to avoid malfunction of the inveter that has SINK type digital

input,when PLC power supply is off.

Common for digital signal

to the second motor's ones.

operation and link operation to communication.

vector mode.

Function

Remarks

DC REACTOR: 75HP or smaller : Option

BRAKING UNIT (Option): G11S: 15HP or larger, P11S: 20HP or larger

G11S : 10HP or smaller, P11S : 15HP or smaller

1HP or smaller: Not correspond

• Allowable maximum output current : 10mA

• Input impedance: 22kΩ

• Allowable maximum input voltage: ±15V DC

• If input voltage is 10 to 15V DC, the inverter estimates

it to10V DC.

• Input impedance:250kΩ

• Allowable maximum input current: 30mA DC

• If input current is 20 to 30mA DC , the inverter estimates

it to20mA DC.

Isolated from terminals CME and CM.

When FWD and REV are simultaneously ON,the motor

decelerates and stops.

• ON state maximum input voltage: 2V

(maximum source current : 5mA)

• OFF state maximum terminal voltage: 22 to 27V

(allowable maximum leakage current: 0.5mA)

Frequency 0 is set by F01 (or C30).

(All signals of SS1 to SS8 are OFF)

Time 0 is set by F07/F08.

(All signals of RT1 to RT2 are OFF)

Assigned to terminal X7 at factory setting.

• The motor restarts from 0Hz by turning off BX with the

operation command (FWD or REV) ON.

• Assigned to terminal X8 at factory setting.

• During normal operating, this signal is ignored.

• Assigned to X9 at factory setting.

This alarm signal is held internally.

This signal is effective only while the inverter is stopping.

If this signal is changed while the inverter is running,

the signal is effective only after the inverter stops.

If this signal is changed while the inverter is running,

the signal is effective only after the inverter stops.

If the operation command(FWD/REV) is input while DC braking

is effective, the operation command (FWD/REV) has priority.

Main circuit changeover signals are output through Y1 to

Y5 terinal.

When UP and DOWN commands are simultaneously

ON,DOWN signal is effective.

If this signal is changed while the inverter is running, the signal

is effective only after the inverter stops.

RS-485: Standard, Bus: Option

Option

Option

This function can be selected at PG feedback control. Option

Isolated from terminals CME and 11.

100HP or larger : Standard

Page 13

Symbol

FMA

(11)

FMP

Pulse

output

Y1

Y2

Y3

Y4

(RUN)

(FAR)

(FDT1)

(LU)

(B/D)

(TL)

(IPF)

(OL1)

(KP)

(STP)

(RDY)

(SW88)

(SW52-2)

(SW52-1)

(SWM2)

(AX)

(TU)

(TO)

(STG1)

(STG2)

(STG4)

(AL1)

(AL2)

(AL4)

(AL8)

(FAN)

(TRY)

(U-DO)

(OH)

(SY)

(LIFE)

CME

Terminal name

Analog monitor

(Common)

Pulse rate monitor

Transistor output 1

Transistor output 2

Transistor output 3

Transistor output 4

Inverter running

Frequency equivalence

signal

Frequency level detection

Undervoltage

detection signal

Torque polarity

Torque limiting

Auto-restarting

Overload early warning

KEYPAD operation mode

Inverter stopping

Ready output

Line/Inv changeover

(for 88)

Line/Inv changeover

(for 52-2)

Line/Inv changeover

(for 52-1)

Motor2/Motor1

Auxiliary terminal

(for 52-1)

Time-up signal

Cycle completion signal

Stage No indication 1

Stage No indication 2

Stage No indication 4

Alarm indication 1

Alarm indication 2

Alarm indication 4

Alarm indication 8

Fan operation signal

Auto-resetting

Universal DO

Overheat early warning

Synchronization

completion signal

Lifetime alarm

Common (transistor

output)

Function

Output voltage (0 to 10V DC) is proportional to selected function’s value as follows.

The proportional coefficient and bias value can be preset.

• Output frequency 1 (Before slip compensation) ( 0 to max. frequency )

• Output frequency 2 (After slip compensation) ( 0 to max. frequency )

• Output current ( 0 to 200% )

• Output voltage ( 0 to 200% )

• Output torque ( 0 to 200% )

• Load factor ( 0 to 200% )

• Input power ( 0 to 200% )

• PID feedback value ( 0 to 100% )

• PG feedback value ( 0 to max. speed )

• DC link circuit voltage ( 460V : 0 to 1000V)

( 230V : 0 to 500V)

• Universal AO ( 0 to 100%)

• Pulse rate mode : Pulse rate is proportional to selected function’s value* (50% duty pulse)

• Average voltage mode : Average voltage is proportional to selected function’s value*

(2670P/S pulse width control)

* Kinds of function to be output is same as those of analog output (FMA).

Output the selected signals from the following items.

Outputs ON signal when the output frequency is higher than starting frequency.

Outputs ON signal when the difference between output frequency and setting frequency is

smaller than FAR hysteresis width.

Outputs ON signal by comparison of output frequency and preset value (level and hysteresis).

Outputs ON signal when the inverter stops by undervoltage while the operation command is ON.

Outputs ON signal in braking or stopping mode, and OFF signal in driving mode.

Outputs ON signal when the inverter is in torque-limiting mode.

Outputs ON signal during auto restart operation mode.(including "restart time")

• Outputs ON signal when the electronic thermal value is higher than preset alarm level.

• Outputs ON signal when the output current value is higher than preset alarm level.

Outputs ON signal when the inverter is in KEYPAD operation mode.

Outputs ON signal when the inverter is stopping mode or in DC braking mode.

Outputs ON signal when the inverter is ready for operation.

Outputs 88's ON signal for Line/Inverter changeover operation.

Outputs 52-2’s ON signal for Line/Inverter changeover operation.

Outputs 52-1’s ON signal for Line/Inverter changeover operation.

Outputs the motor changeover switch ON signal from motor 1 to motor 2.

Used for auxiliary circuit of 52-1.

(Same function as AX1, AX2 terminal by FRENIC5000G9S series. (40HP or larger))

Outputs time up signal (100ms ON pulse) at every stage end of PATTERN operation.

Outputs one cycle completion signal (100ms ON pulse) at PATTERN operation.

Outputs PATTERN operation’s stage No. by signals STG1, STG2 and STG4.

Outputs trip alarm No. by signals AL1, AL2, AL4, and AL8.

Outputs the inverter cooling fan operation status signal.

Outputs ON signal at auto resetting mode. (Including "Reset interval")

Outputs command signal from main controller of LINK operation.

Outputs ON signal when the heat sink temperature is higher than (trip level – 10°C(14°F)), and

outputs OFF signal when the temperature is lower than (trip level – 15°C(5°F)).

Synchronization completion signal for synchronized operation.

Outputs ON signal when the calculated lifetime is longer than preset alarm level.

Common for transistor output signal.

Remarks

Allowable maximum output current: 2mA

Allowable maximum output current : 2mA

• ON state maximum output voltage : 2V

(Allowable maximum sink current : 50mA)

• OFF state maximum leakage current : 0.1mA

(Allowable maximum voltage : 27V)

Reffer to wiring diagram example.

Option

Isolated from terminals CM and 11.

30A, 30B,

30C

Alarm relay output

Outputs a contact signal when a protective function is activated.

Changeable exciting mode active or non-exciting mode active by function "F36".

• Contact rating :

250V AC, 0.3A, cosø=0.3

Y5A, Y5C Relay output Functions can be selected the same as Y1 to Y4.

Changeable exciting mode active or non-exciting mode active by function "E25".

48V DC, 0.5A, non-inductive

LINK

DXA, DXB,

SD

Connect the RS-485 link signal. RS-485 I/O terminal

(FDT2)

2nd Freq. level

detection

2nd-outputs ON signal by comparison of output frequency and preset value (FDT2 level).

(OL2)

2nd OL level early

warning

2nd-outputs ON signal when the output current value is larger than preset alarm level

(OL2 level).

(C1OFF)

Terminal C1 off signal

Outputs ON signal when the C1 current is smaller than 2mA.

(DNZS)

Speed existance

signal

Outputs ON signal at detection of motor speed when using OPC-G11S-PG/PG2/SY.

Analog

output

(CM)

(Common)

Transistor

output

Relay

output

Terminal Functions

G11S/P11S

13

Page 14

Basic Wiring Diagram

Keypad panel Operation

The following diagram is for reference only. For detailed wiring diagrams, refer to the relevant instruction manual.

Power supply ( *1)

3-phase

200 to 230V

50/60Hz

or

3-phase

400 to 480V

50/60Hz

Auxiliary control power supply( *5)

Potentiometer power supply

Analog input

Analog output (analog monitor)

Digital input

*Option

MCCB or GFCI ( *2)

Grounding

Voltage input

Second voltage input

Current input

Pulse output

(frequency monitor)

Main circuit

G11S:15 to75HP

P11S:7.5 to 75HP

Jumper wire (*3)

G

+DC10V

+DC0~10V

+DC24V

Pulse output

(DXB)

P(+)

CNUX ( )

U1 U2

(DXA)

P1

L1/R

L2/S

L3/T

(R0)

(T0)

Control circuit

[13]

[12]

[11]

[V2]

[C1]

[FMA]

(PLC)

(FWD)

(REV)

(CM)

(X1)

(X2)

(X3)

(X4)

(X5)

(X6)

(X7)

(X8)

(X9)

(CM)

(FMP)

RS-485 interface port

G11S:10HP or smaller

(*3)

N(-)

P(+)

P1

DBR

DB

(*4)

N(-)

N(-)

100HP or larger

DC reactor

(DCR)

(*6)

P(+)

P1

U

V

W

M

Motor*

NOTE:

Common terminals [11], (CM), and

G

<CME> for control circuits are

isolated from one another.

*1) Use the inverter whose rated input

voltage matches the power supply

G

0V

30C

30B

30

30A

Grounding

Alarm output (for any fault)

0V

< Y5C >

Y5A >

<

<

Y4 >

Relay output

< Y3 >

Y2 >

(SD)

<

CME >

<

<

Y1 >

Transistor output

400 to 440V/50Hz, 440 to 480V/60Hz U1 (Factory setting)

380V/50Hz (398V or smaller),

380 to 415V/60Hz (430V or smaller)

voltage.

*2) Use this peripheral device when necessary.

*3) 75HP or smaller:

Terminals [P1] and [P(+)] are connected

with a jumper wire before shipping. When

connecting an optional DC reactor (DCR)*6),

remove the jumper wire that connects the

terminals [P1] and [P(+)].

100HP or larger:

Terminals [P1] and [P(+)] are not connected

at shipment from factory. Be sure to

connect the DC reactor (DCR) *6) standard

provided to these terminals.

*4) For G11S models from 1/4 to 10HP, a

built-in braking resistor (DBR) is connected

to the inverter before shipping. (DBR is not

mounted on G11S models 15HP or larger,

and P11S models.)

*5) Terminals [R0] and [T0] are provided for

G11S models 2HP or larger, and P11S

models. These terminals are not provided for

G11S models 1HP or smaller. Even if

these terminals are not powered, the

inverter can be operated.

Input voltage CNUX connector

U2

14

Terminal Arrangement

• Main circuit terminals

FRNF25G11S-2UX~FRN001G11S-2UX / FRNF50G11S-4UX~FRN001G11S-4UX

FRN002G11S-2UX~FRN005G11S-2UX / FRN002G11S-4UX~FRN005G11S-4UX

FRN007G11S-2UX~FRN010G11S-2UX / FRN007G11S-4UX~FRN010G11S-4UX

FRN007P11S-2UX~FRN015P11S-2UX / FRN007P11S-4UX~FRN015P11S-4UX

FRN015G11S-2UX~FRN030G11S-2UX / FRN015G11S-4UX~FRN030G11S-4UX

FRN020P11S-2UX~FRN030P11S-2UX / FRN020P11S-4UX~FRN030P11S-4UX

FRN040G11S-2UX / FRN040G11S-4UX~FRN075G11S-4UX

FRN040P11S-2UX~FRN50P11S-2UX / FRN040P11S-4UX~FRN100P11S-4UX

L1/R L2/S L3/T DB P1 P(+) N(-) U V W

G

G

Screw size M3.5

R0 T0

Screw size M4

Screw size M5

Screw size M6

Screw size M3.5

Screw size M3.5

U VR0 T0 W

Screw size M8

R0 T0

R0 T0

Screw size M3.5

U V W

L1/R L2/S L3/T DB P1 P(+) N(-) U V W

G G

L1/R L2/S L3/T DB P1 P(+) N(-) U V W

G G

L1/R L2/S L3/T DB P1 P(+) N(-)

G

G

Screw size M4

L1/R L2/S L3/T DB P1 P(+) N(-)

G G

FRN050G11S-2UX~FRN075G11S-2UX / FRN100G11S-4UX~FRN150G11S-4UX

FRN060P11S-2UX~FRN100P11S-2UX / FRN125P11S-4UX~FRN200P11S-4UX

FRN100G11S-2UX

FRN125P11S-2UX

FRN125G11S-2UX / FRN200G11S-4UX~FRN350G11S-4UX

FRN150P11S-2UX / FRN250P11S-4UX~FRN450P11S-4UX

FRN400G11S-4UX~FRN450G11S-4UX

FRN500P11S-4UX~FRN600P11S-4UX

FRN500G11S-4UX~FRN600G11S-4UX

FRN700P11S-4UX~FRN800P11S-4UX

U VR0 T0

L1/R L2/S L3/T DB P1 P(+) N(-)

G G

L1/R L2/S L3/T P1 P(+) N(-) U V W

L1/R L2/S L3/T U V W

G

L1/R L2/S L3/T P1 U V W

L1/R L2/S L3/T P1 U V W

G G

L1/R L2/S L3/T P1 P(+) N(-)

L1/R L2/S L3/T P1 P(+) N(-)

W

Screw size G=M8

Other terminals=M10

R0 T0

Screw size M4

G G

Screw size G=M10

Other terminals=M12

R0 T0

Screw size M4

G

Screw size G=M10

Other terminals=M12

R0 T0

Screw size M4

R0 T0

Screw size R0,T0=M4 G=M10

Other terminals=M12

P1 P(+)

P(+)

N(-)

P(+)

N(-)

U V W

G G

U V W

N(-)

Screw size G=M10

Other terminals=M12

• Control circuit

terminals

30C

30A

30B

Y5A

Y5C

CMY

Y4

Y3

Y2

Y1

11

C1

12

FMA

13

FMP

V2

PLC

CM

X1

CM

X2

FWD

X3

REV

X4

P24

X5

P24

X6

DX-

X7

DX+

X8

SD

X9

Page 15

G11S/P11S

External signal input Operation

The following diagram is for reference only. For detailed wiring diagrams, refer to the relevant instruction manual.

Power supply ( *1)

3-phase

200 to 230V

50/60Hz

or

3-phase

400 to 480V

50/60Hz

Auxiliary control power supply ( *7)

Potentiometer power

Analog input

supply (*2) ( *8)

Second

voltage input

Current input

4 to 20mA

Analog frequency meter

(FM) 0 to 60Hz (*2)

Digital input

Digital frepuency meter

(pulse counter) (*2)

*Option

DC reactor (DCR)

(*2) ( *9)

Main circuit

MCCB or GFCI ( *3)

Grounding

3

2

1

( + )

( 0V )

( + )

( - )

60Hz

G11S:15HP or larger

P11S:7.5HP or larger

External braking resistor (DB) (*2) (*6)

G

G

(*4)

G

+DC10V

+DC0~10V

+DC24V

Pulse output

(DXB)

P(+)

CNUX ( )

U1

(DXA)

P1

L1/R

L2/S

L3/T

(R0)

(T0)

Control circuit

[13]

[12]

[11]

[V2]

[C1]

[FMA]

(PLC)

(FWD)

(REV)

(CM)

(X1)

(X2)

(X3)

(X4)

(X5)

(X6)

(X7)

(X8)

(X9)

(CM)

(FMP)

RS-485 interface port

PPDB

N(-)

U2

0V

30

0V

(SD)

2

1

2

DBP

1

N

Braking unit ( *2) ( *8)

U

V

W

G

30C

30B

Alarm output (for any fault)

30A

< Y5C >

<

<

Y5A >

Relay output

Y4 >

< Y3 >

Y2 >

<

<

<

CME >

Transistor output

Y1 >

G11S:10HP or smaller

External braking resistor (DB) (*2) (*6)

(CM)

2

(CM)

1

DB

(THR)

P

G

(THR)

x x

Motor*

Grounding

P(+)

(*5)

DBR

M

G

N(-)

DB

NOTE:

Common terminals [11], (CM),

and <CME> for control circuits

are isolated from one another.

400 to 440V/50Hz, 440 to 480V/60Hz U1

380V/50Hz (398V or smaller),

380 to 415V/60Hz (430V or smaller)

Input voltage CNUX connector

U2 (Factory setting)

*1)Use the inverter whose rated input voltage matches the power

supply voltage.

*2)An optional device. Use it when necessary.

*3)Use this peripheral device when necessary.

*4)15HP or smaller:

Terminals [P1] and [P(+)] are connected with a jumper wire

before shipping. When connecting an optional DC reactor

(DCR) *9), remove the jumper wire that connects the terminals

[P1] and [P(+)].

100HP or larger:

Terminals [P1] and [P(+)] are not connected at shipment from

factory. Be sure to connect the DC reactor (DCR) *9) standard

provided to these terminals.

*5) For G11S models from 1/4 to 10HP, a built-in braking resistor

(DBR) is connected to the inverter before shipping. (DBR is not

mounted on G11S models 15HP or larger, and P11S models.)

When connecting an optional external braking resistor (DB),

remove the DBR connection cables from [P(+)] and [DB]

terminals. The end of the removed cables (indicated with an X)

must be insulated.

*6) When connecting an optional external braking resistor (DB), be

sure to also use an optional braking unit *8). Connect the

optional braking unit to the [P(+)] and [N(-)] terminals. Auxiliary

terminals [1] and [2] have polarity.

Be sure to connect cables to these terminals correctly. (See the

diagram)

*7) Terminals [R0] and [T0] are provided for G11S models 2HP or

larger, and P11S models. These terminals are not provided for

G11S models 1HP or smaller. Even if these terminals are not

powered, the inverter can be operated.

15

Page 16

Keypad Panel Functions and Operations

Keypad panel

LED monitor

In operation mode:

Displays the setting frequency,

output current, voltage, motor

speed, or line speed.

In trip mode:

Displays code indicating the

cause of trip.

Up/Down keys

In operation mode :

Increases or decreases the

frequency or speed.

In program mode :

Increases or decreases function

code number and data set value.

Program key

Switches the display to a menu

screen or to the initial screen for

operation mode or alarm mode.

LCD monitor

In operation mode :

Displays various items of

information such as operation

condition and function data.

Operation guidance, which

can be scrolled, is displayed

at the bottom.

In program mode :

Displays functions and data.

This LCD monitor has

a back light future.

Unit indication

Displays the unit for the

information shown on the LED

monitor.

FWD/REV keys

In operation mode :

Starts the inverter with

forward or reverse operation

command.

Pressing the FWD or REV

key lights the RUN lamp.

Invalid when the function

code F02 (Operation method)

is set at 1 (External signal

operation).

16

Shift key (Column shift)

In program mode :

Moves the cursor horizontally at

data change. Pressing this key

with the UP or DOWN key, the

screen changes to the next

function block.

Reset key

In program mode :

Cancels the current input data

and shifts the screen.

In trip mode :

Releases the trip-stop state.

Stop key

In operation mode :

Stops the inverter.

Invalid when the function code

F02 (Operation method) is set

at 1 (External signal

operation).

Function/Data Select key

In operation mode :

Changes the displayed values

of LED monitor.

In program mode :

Selects the function code or

stores the data.

Page 17

Procedure for selecting function codes and data codes

The following is a sample procedure for selecting a function code and changing the function data.

1 Press the key to switch the operation monitor screen

to the program menu screen.

2 Select “1. DATA SET” , and press the key.

4 Use the , , and keys to change the

function data to the target value. (Use the key

to move the cursor when you want to enter a numerical

value.)

5 Press the key to store the updated function

data in memory.

The screen shifts for the selection of the next function.

6 Pressing the key switches the screen to the operation

monitor screen.

1) Setting a frequency

When the operation monitor screen is displayed, a frequency can be set by using the or key

in both the operation and stop modes. When the target frequency is displayed, press the key to

enter the frequency in memory.

2) Switching a unit indication

During both operation and stop modes, each time the key is pressed, the value displayed on the

LED monitor changes, and the unit indication on the LCD monitor shifts from Hz to A, V, r/min, m/min,

kW, and % in this order in accordance with the displayed value.

F01 FREQ CMD 1

0

0~11

F00 DATA PRTC

F01 FREQ CMD 1

F02 OPR METHOD

F03 MAX Hz-1

→

1. DATA SET

2. DATA CHECK

3. OPR MNTR

4. I / O CHECK

RUN

FWD

PRG→ PRG MENU

F/D → LED SHIFT

RUN

FWD

PRG→ PRG MENU

F/D → LED SHIFT

3 Press the or key to select a target function

code. To quickly scroll the function select screen, press

key and the or key at the same time.

At the target function, press key.

F02 OPR METHOD

F03 MAX Hz-1

F04 BASE Hz-1

F05 RATED V-1

Keypad panel operation

Perform the wiring shown in the Basic wiring diagram on page 14. Turn on inverter power, and use the or key to

set an output frequency. Press the key, then press the or key.

The inverter starts running using the factory setting function data.

Press the key to stop the inverter.

G11S/P11S

17

Page 18

Function settings

Fundamental Functions

Function

Code Name LCD monitor

Basic

Functions

18

The functions in the yellow boxes can be set while the inverter is running. Other functions must be set while the inverter is stopped.

Data protection

Frequency command 1

Operation method

Maximum frequency 1

Base frequency 1

Rated voltage 1

( at Base frequency 1 )

Maximum voltage 1

( at Maximum frequency 1 )

Acceleration time 1

Deceleration time 1

Torque boost 1

Electronic thermal (Select)

overload protection

for motor 1

(Thermal time constant)

Electronic thermal

overload protection

(for braking resistor)

Restart mode after

momentary power failure

(operation selection)

Frequency (High)

limiter (Low)

Gain (for frequency setting signal)

Bias frequency

DC brake (Starting freq.)

Starting frequency (Freq.)

Stop frequency

Motor sound (Carrier freq.)

FMA (Voltage adjust)

FMP (Pulse rate)

30RY operation mode

Torque limit 1 (Driving)

Torque vector control 1

(Braking level)

(Braking time)