Page 1

OPERATIONS MANUAL

MTB-310A TEST BOX

168°C / 335°F

143°C / 289°F

97°C / 206°F

79°C / 175°F

3°C / 37°F

VARIABLE

SHORT

OFF

NOTE: TEMPERATURES MAY VARY

±2°F / ±1°C FROM ACTUAL.

BASKET

LIFT

CMIII

CMII

LEFT

S

O

U

N

D

The Frymaster Corporation, 8700 Line Avenue

TEL 318-865-1711 FAX 318-868-5987

HEAT

350°F / 177°C

375°F / 191°C

391°F / 199°C

414°F / 212°C

OPEN

VARIABLE

ALARM

OFF

RELAY

POWER

168°C / 335°F

143°C / 289°F

OFF

97°C / 206°F

79°C / 175°F

3°C / 37°F

SHORT

ALARM

P

O

W

E

R

OFF

RIGHT

BASKETHEAT

LIFT

TESTON

OFF

MTB310A

VARIABLE

350°F / 177°C

375°F / 191°C

391°F / 199°C

414°F / 212°C

OPEN

VARIABLE

1A F.B.

FUSE

24-Hour Service Hotline

1-800-551-8633

MAR 11

*8195162*

Page 2

TABLE OF CONTENTS

Page #

INTRODUCTION 3

PARTS ORDERING 3

PARTS LIST 4

CONTROL PANEL DIAGRAM 5

COMPUTER MAGIC III.5 / DEAN Compu-Fry TEST PROCEDURE 6

SOLID STATE CONTROLLER TEST PROCEDURE 8

M2000 TEST PROCEDURE 9

DIGITAL CONTROLLER TEST PROCEDURE 12

ELECTRONIC TIMER TEST PROCEDURE 13

CM4-S TEST PROCEDURE 14

KFC-1 / SMS TEST PROCEDURE 15

2

Page 3

INTRODUCTION

The MTB-310A Test Box is a tester designed to test most Frymaster cooking

computers and controllers for correct operating and controlling functions.

PARTS ORDERING

Parts orders must be placed directly with your local Factory Authorized Parts

Distributor. If you do not have a Factory Authorized Service Center list, please

contact Frymaster Service Department at 1-800-551-8633 or 1-318-865-1711.

To speed up your order, the following information is required:

Model Number: __________________

Part Number: __________________

Quantity Required: __________________

PARTS ORDERING/SERVICE INFORMATION CANADA – Garland Commercial

Ranges, Ltd., 1177 Kamato Road, Mississauga, Ontario L4W 1X4.

NOTE: RETAIN AND STORE THIS MANUAL IN A SAFE PLACE FOR FUTURE

USE. ADDITIONAL COPIES MAY BE OBTAINED FROM YOUR FACTORY

AUTHORIZED SERVICE CENTER.

3

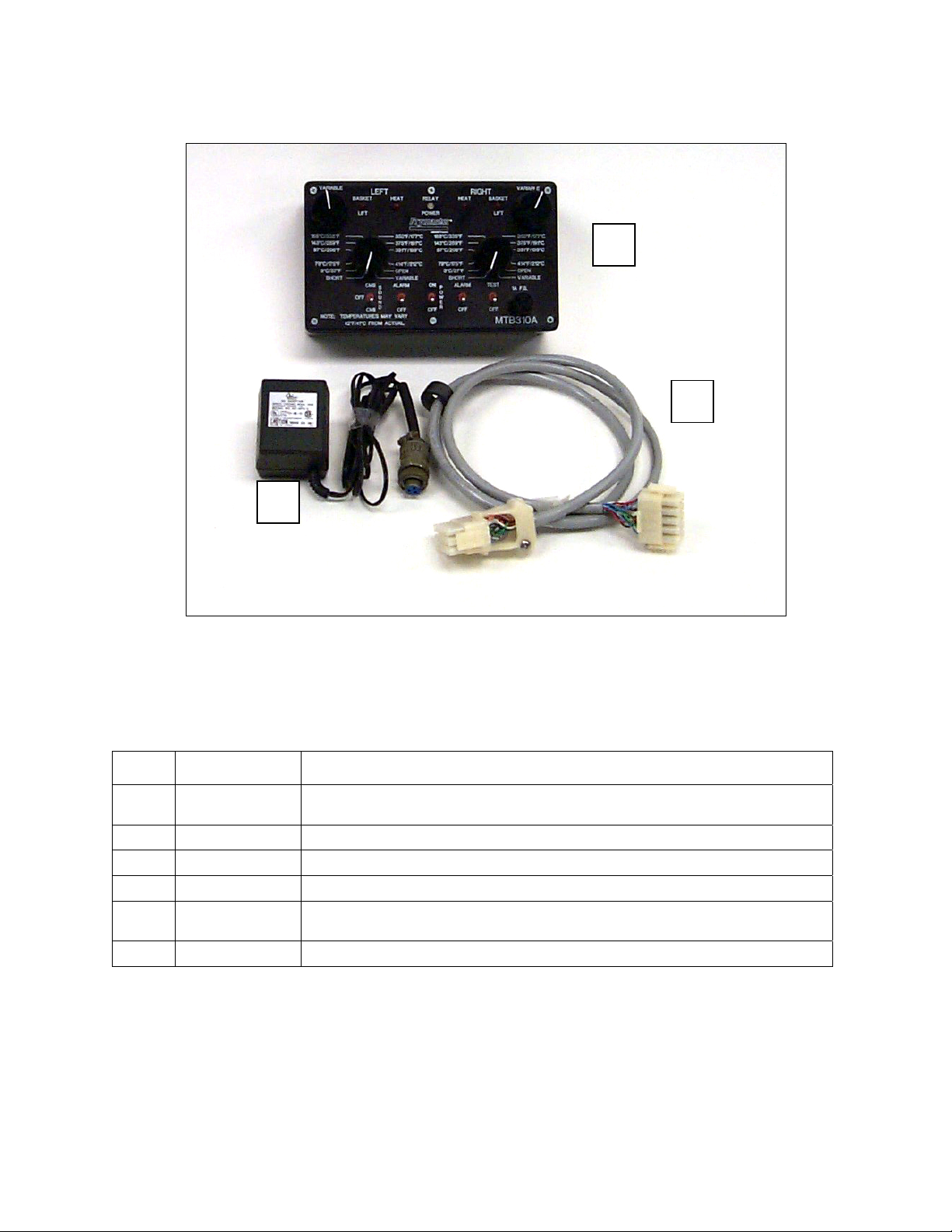

Page 4

2

1

3

PARTS LIST

Item Part Number Description

1 806-5093

2 806-5023 Transformer Assembly 120/12V Domestic

3 806-5095 Cable Assembly, Frymaster Computers Only

* 806-4803 Cable Assembly, Dean Compu-Fry Computer Only

* 806-5094

* 806-5096 Transformer Assembly 240/12V International

* Not Illustrated

Test Box MTB-310A 120/12V Domestic (Includes cable and

transformer assembly.)

Test Box MTB-310A 240/12V International (Includes cable and

transformer assembly.)

4

Page 5

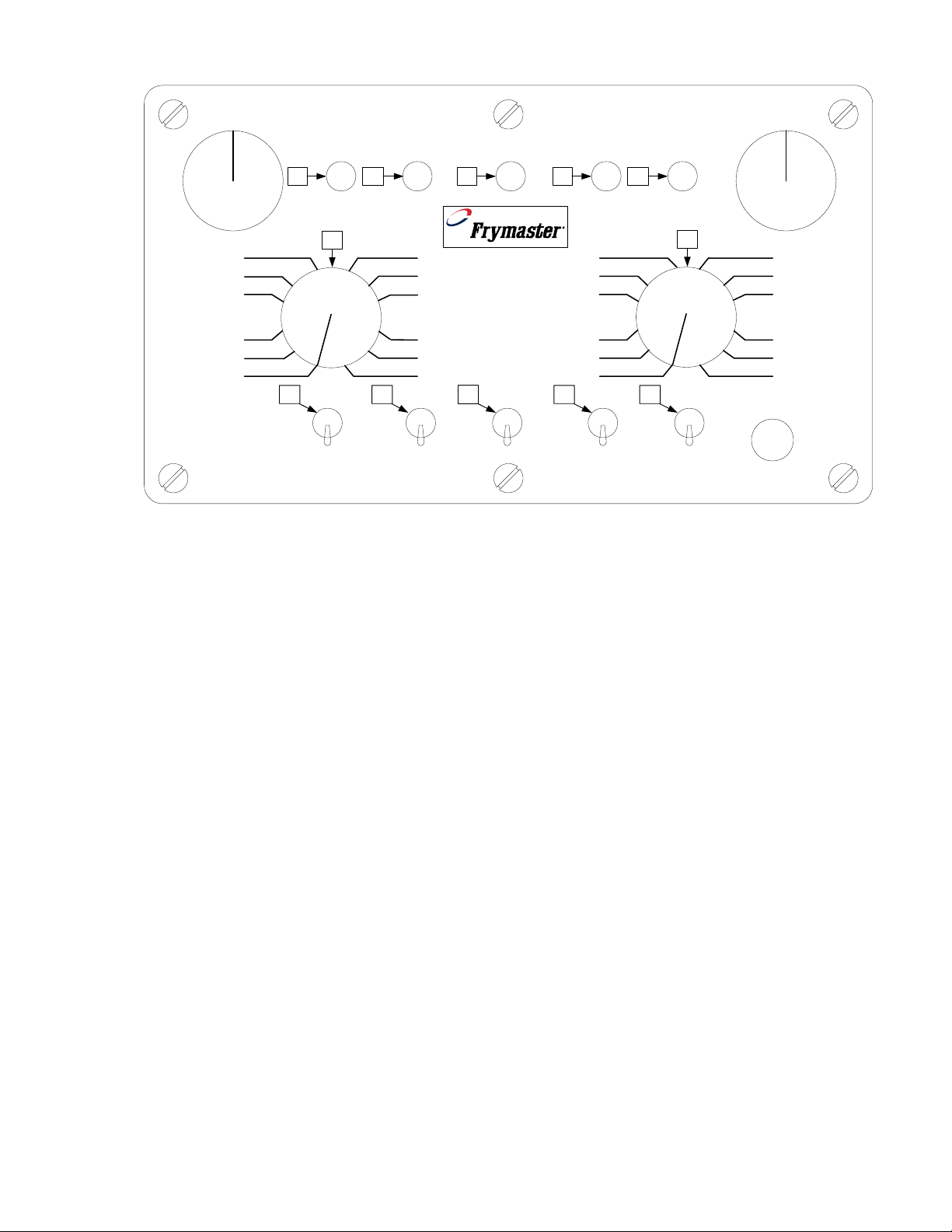

VARIABLE

BASKET

LIFT

LEFT

21

HEAT

3

RELAY

POWER

HEAT

RIGHT

BASKET

54

VARIABLE

LIFT

12

7

TEST

OFF

168°C / 335°F

143°C / 289°F

97°C / 206°F

79°C / 175°F

3°C / 37°F

SHORT

CMIII

8

OFF

CMII

NOTE: TEMPERATURES MAY VARY

±2°F / ±1°C FROM ACTUAL.

6

SHORT

ALARM

11

OFF

168°C / 335°F

350°F / 177°C

375°F / 191°C

391°F / 199°C

414°F / 212°C

OPEN

VARIABLE

ALARM

9

S

O

U

N

D

OFF

143°C / 289°F

ON

10 P

OFF

97°C / 206°F

79°C / 175°F

3°C / 37°F

O

W

E

R

CONTROL PANEL

1. Left Basket Lift Indicator

Basket Lift Motor Drive

Not used for M2000 or

KFC-1/SMS computers.

2. Left Heat Indicator

ON When Heating

3. Power On Indicator

Power to Fryer Relays &

Computer

4. Right Heat Indicator

ON When Heating

5. Right Basket Lift Indicator

Basket Lift Motor Drive

Not used for M2000 or

KFC-1/SMS computers.

6. Left Probe Switch

Simulates Temperature

NOTE: For power other than 120VAC 60Hz, use 240V transformer.

7. Right Probe Switch

Simulates Temperature

8. Sound Switch

Select Computer Type

9. Left Alarm Switch

Simulates Alarm Signal Input

10. Tester ON/OFF Switch

Power To MTB-310A Test Unit

11. Right Alarm Switch

Simulates Alarm Signal Input

12. Test Switch

Places Computer in Special Test Mode.

To be used by Factory Certified

Technicians or other qualified

technicians with assistance from the

Frymaster Service Department.

350°F / 177°C

375°F / 191°C

391°F / 199°C

414°F / 212°C

OPEN

VARIABLE

1A F.B.

FUSE

MTB310A

5

Page 6

COMPUTER MAGIC III.5 / DEAN Compu-Fry* TEST PROCEDURE

A. INITIAL TEST SET-UP

1. Set-up MTB-310A as follows:

(a) Set ALARM switches (9 & 11) to OFF.

(b) Set PROBE switches (6 & 7) to 97 °C/206°F. If using a Solid-State or

Digital Controller, set to 79°C/175°F.

(c) Set POWER switch (10) to OFF.

(d) Set SOUND switch (8) as required for each computer type.

(e) Connect 120/24V transformer to 120VAC outlet or 240/24V

transformer to 240VAC outlet.

2. Set computer/controller up as follows:

(a) Set POWER switches to OFF.

(b) Set MELT switches to OFF. (Solid state controller only)

(c) Connect MTB-310A 15-pin connector to rear of computer or

controller.

3. Set MTB-310A POWER switch (10) to ON

(a) If using a CMIII.5, CM4-S or KF C1/SMS computer, program the set

point to 375°F/191°C. If using an M2000 computer, use

programming instructions in fryer service manual to program “FR

FRIES” set point temperature to 168°C/335°F. If using a Digital

Controller or an Electronic Timer/Basket Lift, program the setpoint to

350°F/177°C.

*Note: Some of the test setups are the

same for various computers found in

this manual.

B. TEST POWER TO FRYER INTERFACE BOARD

1. Press Computer/Controller ON/OFF switch to ON.

2. RELAY POWER indicator (3) should illuminate.

NOTE: If testing a split vat computer or dual vat controller, complete previous

step utilizing both computer/controller power switches (one ON at a time unless

an M2000 computer or Electronic Timer/Basket Lift is being tested. Both sides

of these computers can be tested at the same time.).

C. TEST MELT-CYCLE FUNCTION

1. Press Computer/Controller ON/OFF switch to ON.

2. Set MTB-310A PROBE switches (6 & 7) to 79°C/175°F.

(a) RELAY POWER indicator (3) will illuminate.

(b) HEAT indicators (2 & 4) should cycle on and off with the computer

heating indicator (decimal point on computers and digital

controllers). “CYCL”, “LOW TEMP” or “LOW” will be displayed on

the computers depending on the model.

3. Set MTB-310A PROBE switches (6 & 7) to 97°C/206°F.

(a) HEAT indicators (2 & 4) should illuminate continuously.

(b) Computer/Controller heat indicators (decimal point) will illuminate

continuously and display either “°.-Lo”, “LOW” or a blank display

depending on the model.

NOTE: On a full vat computer, only RIGHT HEAT indicator (4) will function.

6

Page 7

D. TEST CONTROLLING FUNCTION

1. Press Computer ON/OFF switch to ON (set point = 375°F).

2. Set MTB-310A PROBE switches (6 & 7) to VARIABLE.

(a) RELAY POWER indicator (3) will illuminate.

(d) Rotate VARIABLE knob counterclockwise until computer indicates °-

Lo.

(c) Rotate VARIABLE knob slowly clockwise until computer indicates

----.

(d) Press Temperature Check Switch. Computer should indicate a

temperature from one (1) to twenty (20) degrees below set point

(375°F/191°C). If not, rotate the VARIABLE knobs counterclockwise

very slowly until HEAT indicators (2 & 4) and computer decimal

points cycle ON. Stop VARIABLE knobs.

(e) HEAT indicators (2 & 4) and computer decimal points should now

cycle ON and OFF very slowly.

E. TEST CONTROLLER HIGH LIMIT

1. Press Computer/Controller ON/OFF switch to ON.

2. Set MTB-310A PROBE switches (6 & 7) to 414°F/212°C.

(a) RELAY POWER indicator (3) will illuminate.

(b) Set Switch (8) to CMIII.

(c) Controller should indicate either “°-HI -Hot”, “HI”, “HOT”,

“414°F/212°C”, “HELP”,“HI TEMP” or a combination of these

phrases with alarm sounding.

F. TEST ALARM FUNCTION

1. Press Computer/Controller ON/OFF switch to ON.

2. Set MTB-310A PROBE switches (6 & 7) to 168°C/335°F.

3. Set ALARM switches (9 & 11) ON. Set Switch (8) to CMIII.

4. Computer/Controller should indicate “°-LO -HELP”, “IGNITION FAILURE”

or “HELP” with alarm sounding.

G. TEST PROBE FAILURE MALFUNCTION

1. Press Computer/Controller ON/OFF switch to ON.

2. Set MTB-310A PROBE switches (6 & 7) to OPEN.

(a) Computer/Controller should indicate “°-HI -Prob”, “PROBE

FAILURE”, “Prob” or “HIGH TEMP PROBE FAILURE”.

3. Set MTB-310A PROBE switches (6 & 7) to SHORT.

(a) Computer/Controller should indicate “CYCL -Prob”, “PROBE

FAILURE” or “Prob”.

7

Page 8

H. TEST BASKET LIFT OPERATION

1. Press Computer ON/OFF switch to ON.

2. Program computer “L” and “R” cook timer switches greater than 00.

3. Set MTB-310A PROBE switches (6 & 7) to 375°F /191°C.

4. Press “L” switch on computer.

(a) MTB-310A LEFT BASKET LIFT indicator (1) should illu minate.

(b) Computer timer should count down.

5. Press “R” switch on computer.

(a) MTB-310A RIGHT BASKET LIFT indicator (5) should illuminate.

(b) Computer timer should count down.

I. REPROGRAM COMPUTER TO SET POINT - 340°F/171°C

NOTE: On a split vat computer, reprogram set point to 340°F/171°C on both

sides of computer.

1. Set MTB-310A PROBE switches (6 & 7) to 97°C/206°F.

2. Reprogram computer set point to 340°F/171°C.

3. Computer test is now complete.

SOLID-STATE CONTROLLER TEST PROCEDURE

A. INITIAL TEST SET-UP

See page 5 for instructions to run initial test set-up.

B. TEST POWER TO FRYER INTERFACE BOARD

See page 5 for instructions to test power to fryer interface board.

C. TEST MELT-CYCLE FUNCTION

See page 5 for instructions to test melt-cycle function.

D. TEST CONTROLLING FUNCTION

1. Set Controller POWER switch to ON.

2. Set Controller temperature knob to 168°C/335°F.

3. Set Controller MELT switch to OFF.

4. Set MTB-310A PROBE switches (6 & 7) to 168°C/335°F.

(a) RELA Y POWER indicator (3) will illuminate.

(b) HEAT indicators (2 & 4) should cycle on and off very slowly.

5. Set MTB-310A PROBE switches (6 & 7) to 375°F/191°C.

6. Set Controller temperature knob to 375°F/191°C.

(a) RELA Y POWER indicator (3) will illuminate.

(b) HEAT indicators (2 & 4) should cycle on and off very slowly.

8

Page 9

NOTE: The Controller temperature knob may require calibration adjustment to

pass the preceding test.

E. TEST FIRST HIGH LIMIT

1. Set Controller Power switches to ON.

2. Set MTB-310A ALARM switches (9 & 11) to ON.

3. Set MTB-310A PROBE switches (6 & 7) to 414°F/212°C.

(a) RELA Y POWER indicator (3) will illuminate.

(b) Controller “?” (trouble) indicator should illuminate.

F. TEST ALARM FUNCTION

1. Set Controller Power switches to ON.

2. Set MTB-310A PROBE switches (6 & 7) to 375°F/191°C.

3. Set MTB-310A ALARM switches (9 and/or 11) to ON.

(a) Controller “?” (trouble) indicator should illuminate.

G. TEST PROBE FAILURE MALFUNCTION

1. Set Controller Power switches to ON.

2. Set MTB-310A PROBE switches (6 & 7) to OPEN.

(a) Controller “?” (trouble) indicator should illuminate.

H. TEST SECOND HIGH LIMIT – H52 ONLY

1. Set Controller Power switches to ON.

2. Set MTB-310A PROBE switches (6 & 7) to 414°F/212°C.

(a) RELA Y POWER indicator (3) will illuminate.

(b) Controller “?” (trouble) indicator should illuminate.

3. Set MTB-310A ALARM switches (9 & 11) to ON.

4. Press “Hi-Limit” test switch to position 2 and hold.

The following Controller lights will be activated:

(a) “Power” light ON.

(b) “Heat” light ON.

(c) “Trouble” light ON.

(d) Second “Hi-Limit” light ON.

M2000 TEST PROCEDURE

A. INITIAL TEST SET-UP

See page 5 for instructions to run initial test set-up.

B. TEST POWER TO FRYER INTERFACE BOARD

See page 5 for instructions to test power to fryer interface board.

C. TEST MELT-CYCLE FUNCTION

See page 5 for instructions to test melt-cycle function.

9

Page 10

D. TEST CONTROLLING FUNCTION

1. Press Computer ON/OFF switches to ON .

2. Set MTB-310A PROBE switches (6 & 7) to VARIABLE.

(a) RELAY POWER indicator (3) will illuminate.

(b) Rotate VARIABLE knob counterclockwise until computer indicates

“LOW and TEMP” alternately.

(c) Rotate VARIABLE knob slowly clockwise until computer indicates

“LOW” steady.

(d) Press Temperature Check Switch. Computer should indicate a

temperature from one (1) to twenty (20) degrees below set point

(168°C/335°F). If not, rotate the VARIABLE knobs clockwise very

slowly until HEAT indicators (2 & 4) and computer heat indicators

come ON. Stop VARIABLE knobs.

(e) Rotate the VARIABLE knobs clockwise again very slowly until

HEAT indicators (2 & 4) and computer heat indicators come ON.

Stop VARIABLE knobs.

HEAT indicators (2 & 4) and computer heat indicators should now

cycle ON and OFF very slowly.

(f) When the computer displays “--------“, the computer has reached

setpoint.

E. TEST FIRST HIGH LIMIT

1. Press Computer ON/OFF switch to OFF.

2. Press

3. CODE shows in the left display.

4. Press 9999 for full vat or right side of split pot. Note: The test can only

be conducted with the temperature set above 180°F (82°C), or the

computer will display “TOO COLD”.

5. Set MTB-310A PROBE switches (6 & 7) to VARIABLE.

(a) RELAY POWER indicator (3) will illuminate.

6. “HIGH LIMIT” shows in the right display.

7. Press computer #1 Right Operate Switch and hold while rotating right

VARIABLE knob slowly clockwise.

(a) Right side display of computer will alternate between “HIGH

LIMIT” and the temperature display. The display will rise as

VARIABLE knob is rotated clockwise until reaching 410°F/210°C.

(b) At 410°F/210°C, computer will indicate 410°F/210°C and “HI-1”.

8. Repeat steps E.3. through E.4. for left side of computer. Enter 8888 for

left side computer. Substitute the word “left” where “right” appears.

10

Page 11

F. TEST SECOND HIGH LIMIT

1. Press Computer ON/OFF switch to OFF.

2. Press

3. “CODE” shows in the left display.

4. Press 9999 for full vat or right side of split pot. Note: The test can only

be conducted with the temperature set above 180°F (82°C), or the

computer

displays “TOO COLD”.

5. Set MTB-310A PROBE switches (6 & 7) to VARIABLE.

(a) RELAY POWER indicator (3) will illuminate.

6. “HIGH LIMIT” shows in the right display.

7. Press the computer’s right cook channel button and hold while

rotating the right VARIABLE knob slowly clockwise.

(a) Right side display of computer will alternate between “HIGH

LIMIT” and temperature displays until hi-limit opens. The display

will rise as VARIABLE knob is rotated clockwise.

8. When computer indicates 450°F/232°C, stop rotating the VARIABLE

knob and set Right ALARM Switch to ON.

(a) Right side of computer should indicate “HI-2” and 450°F/232°C

alternately.

9. Repeat steps F.3. through F.4. for left side of computer. Substitute the

word “left” where “right” appears.

2

G. TEST ALARM FUNCTION

See page 6 for instructions to test alarm function.

H. TEST PROBE FAILURE MALFUNCTION

See page 6 for instructions to test probe failure malfunction.

I. REPROGRAM COMPUTER TO SET POINT - 335°F/168°C

NOTE: A M2000 computer that is used on a split vat fryer must be

programmed to a set-point temperature of 335°F/168°C for “FR FRIES” on

both sides.

1. Use programming instructions in fryer service manual to program setpoint temperatures for “FR FRIES”, 335°F/168°C.

2. After reprogramming set-point temperatures, press Computer ON/OFF

switches to OFF.

11

Page 12

DIGITAL CONTROLLER TEST PROCEDURE

A. INITIAL TEST SET-UP

See page 5 for instructions to run initial test set-up.

B. TEST POWER TO FRYER INTERFACE BOARD

See page 5 for instructions to test power to fryer interface board.

C. TEST MELT-CYCLE FUNCTION

See page 5 for instructions to test melt-cycle function.

D. TEST CONTROLLING FUNCTION

1. Press Controller ON/OFF switches to ON (set point = 350°F/177°C).

2. Set MTB-310A PROBE switches (6 & 7) to 350°F/177°C.

(a) RELA Y POWER indicator (3) will illuminate.

(b) HEAT indicators (2 & 4) and controller heat indicators (decimal

points) should cycle on and off very slowly.

E. TEST CONTROLLER HIGH LIMIT

See page 6 for instructions to test controller high limit.

F. TEST ALARM FUNCTION

See page 6 for instructions to test alarm function.

G. TEST PROBE FAILURE MALFUNCTION

See page 6 for instructions to test probe failure malfunction.

H. REPROGRAM CONTROLLER TO SET POINT – AS NECESSARY

1. Set MTB-310A PROBE switches (6 & 7) to 79°C/175°F.

(a) Reprogram controller to desired set-point temperature.

NOTE: On a split vat controller, reprogram set point as necessary on both

sides of controller.

12

Page 13

ELECTRONIC TIMER / BASKET LIFT TEST PROCEDURE

A. INITIAL TEST SET-UP

See page 5 for instructions to run initial test set-up.

B. TEST POWER TO FRYER INTERFACE BOARD

See page 5 for instructions to test initial power to fryer interface board.

C. TEST MELT-CYCLE FUNCTION

See page 5 for instructions to test melt-cycle function.

D. TEST CONTROLLING FUNCTION

1. Press Electronic Timer ON/OFF switches to ON (set point =

350°F/177°C).

2. Set MTB-310A PROBE switches (6 & 7) to 350°F/177°C.

(a) RELA Y POWER indicator (3) will illuminate.

(b) HEAT indicators (2 & 4) and Electronic Timer heat indicators

(decimal points) should cycle on and off very slowly.

E. TEST CONTROLLER HIGH LIMIT

See page 6 for instructions to test controller high limit.

F. TEST ALARM FUNCTION

See page 6 for instructions to test alarm function.

G. TEST PROBE FAILURE MALFUNCTION

See page 6 for instructions to test probe failure malfunction.

H. TEST BASKET LIFT OPERATION

1. Set MTB-310A PROBE switches (6 & 7) to 168°C /335°F.

2. Set MTB-310A ALARM switches (9 & 11) to OFF.

3. Press Electronic Timer ON/OFF switches to ON.

(a) RELAY POWER indicator (3) will illuminate.

(b) Both Electronic Timer indicators indicate XXX cook time.

4. Press Electronic Timer cook switches.

(a) Both BASKET LIFT indicators (1 & 5) on MTB-310A should

illuminate.

(b) Electronic Timer indicators should count down.

(c) When Electronic Timer indicators reach 0 time, both BASKET

LIFT indicators (1 & 5) on MTB-310A will go OFF and alarm will

sound.

(d) Electronic Timer will indicate “COOC”.

13

Page 14

5. Press Electronic Timer cook switches.

(a) Electronic Timer indicators will return to programmed cook time.

I. REPROGRAM ELECTRONIC TIMER TO SET POINT – AS NECESSARY

NOTE: On a split vat Electronic Timer, reprogram set-point temperature as

necessary on both sides of timer.

1. Set MTB-310A PROBE switches (6 & 7) to 79°C/175°F.

2. Set MTB-310A ALARM switches (9 & 11) to OFF.

3. Press Electronic Timer ON/OFF switches to ON.

(a) Reprogram Electronic Timer to desired set-point temperature.

4. Press Electronic Timer ON/OFF switches to OFF.

5. Set MTB-310A POWER switch (10) to OFF.

CM4-S COMPUTER TEST PROCEDURE

A. INITIAL TEST SET-UP

See page 5 for instructions to run initial test set-up.

B. TEST POWER TO FRYER INTERFACE BOARD

See page 5 for instructions to test initial power to fryer interface board.

C. TEST MELT-CYCLE FUNCTION

See page 5 for instructions to test melt-cycle function.

D. TEST CONTROLLING FUNCTION

1. Press Computer ON/OFF switch to ON (set point = 375°F).

2. Set MTB-310A PROBE switches (6 & 7) to VARIABLE.

(a) RELAY POWER indicator (3) will illuminate.

(b) Rotate VARIABLE knob counterclockwise until the computer

indicates “LOW”. HEAT indicators (2 & 4) should cycle on and off

with the computer heat indicators.

(c) Rotate VARIABLE knob slowly clockwise until the computer

indicates ----.

(d) Press the Temperature Check Switch. Computer should indicate a

temperature from one (1) to twenty-five (25) degrees below set

point (375°F/191°C). If not, rotate the VARIABLE knobs

counterclockwise very slowly until the HEAT indicators (2 & 4) and

computer decimal points cycle ON. Stop rotating the VARIABLE

knobs.

14

Page 15

(e) HEAT indicators (2 & 4) and computer decimal points should now

cycle ON and OFF very slowly.

E. TEST CONTROLLER HIGH LIMIT

See page 6 for instructions to test controller high limit.

F. TEST ALARM FUNCTION

See page 6 for instructions to test alarm function.

G. TEST PROBE FAILURE MALFUNCTION

See page 6 for instructions to test probe failure malfunction.

H. REPROGRAM COMPUTER TO SET POINT - 340°F/171°C

NOTE: On a split vat computer, reprogram set point to 340°F/171°C on both

sides of computer.

1. Set MTB-310A PROBE switches (6 & 7) to 97°C/206°F.

2. Reprogram computer set point to 340°F/171°C.

3. Computer test is now complete.

KFC-1 / SMS COMPUTER TEST PROCEDURE

A. INITIAL TEST SET-UP

See page 5 for instructions to run initial test set-up.

B. TEST POWER TO FRYER INTERFACE BOARD

See page 5 for instructions to test initial power to fryer interface board.

C. TEST MELT-CYCLE FUNCTION

See page 5 for instructions to test melt-cycle function.

D. TEST CONTROLLING FUNCTION

1. Press Computer ON/OFF switch to ON (set point = 340°F/171°C).

2. Set MTB-310A PROBE switches (6 & 7) to VARIABLE.

(a) RELAY POWER indicator (3) will illuminate.

(b) Rotate VARIABLE knob counterclockwise until computer

indicates “LOW”. HEAT indicators (2 & 4) should cycle on and

off with computer heat indicators.

(c) Rotate VARIABLE knob slowly clockwise until computer

displays a numerical temperature.

(d) Press Temperature Check Switch. Computer should indicate a

temperature from one (1) to eighty-five (85) degrees below set

point (340°F/171°C). If not, rotate the VARIABLE knobs

counterclockwise very slowly until HEAT indicators (2 & 4) and

15

Page 16

computer decimal points cycle ON. Stop rotating the

VARIABLE knobs.

(e) HEAT indicators (2 & 4) and computer decimal points should

now cycle ON and OFF very slowly. The computer will display

“DROP”.

E. TEST CONTROLLER HIGH LIMIT

See page 6 for instructions to test controller high limit.

F. TEST ALARM FUNCTION

See page 6 for instructions to test alarm function.

G. TEST PROBE FAILURE MALFUNCTION

See page 6 for instructions to test probe failure malfunction.

H. REPROGRAM COMPUTER TO SET POINT - 340°F/171°C

NOTE: On a split vat computer, reprogram set point to 340°F/171°C on both

sides of computer.

1. Set MTB-310A PROBE switches (6 & 7) to 97°C/206°F.

2. Reprogram computer set point to 340°F/171°C.

3. Computer test is now complete.

16

Page 17

Page 18

Frymaster, L.L.C Shipping Address: 8700 Line Avenue, Shreveport, Louisiana 71106

TEL 1-318-865-1711 FAX (Parts) 1-318-219-7140

FAX (Tech Support) 1-318-219-7135

PRINTED IN THE UNITED STATES

SERVICE HOTLINE

1-800-551-8633

819-5162

MAR 11

Loading...

Loading...