Page 1

MJ45 and MJ45-2

Frymaster

™

®

Gas Fryers

Models

M J45 M J45-2

Project

Item

Quantity

CSI Sec tion 11400

Approval

Date

MJ45 and MJ45-2 Gas Fryers

Shown with optional computer and casters

Specifications

Specifically designed for high-volume

frying

The MJ45 has a minimum 40-Ibs. (20 liters*) and maximum

50-Ibs. (25 liters*) shortening capacity. The frying area i s

14 x 15 in. (356 x 381 mm) at sho rtening level. This 122,00 0

BTU/hr. (30,730 kCa l/hr.) (35.8 kW) mode l is specifically

designed for h igh-volume frying an d produces 80 lbs. of

french fries per hour frozen to done. The exclusive 1° action

thermostat a nticipates rapid rate of temperature rise,

reducing temp erature overshoot, exten ding shortening

life and produ cing a more uniformly- cooked product.

Centerline th ermostat mounting perm its quick sensing (7

to 10 seconds ) of cold food placed in either basket. Maste r

Jet burner has no burner tube rad iants to burn out. No

burner clea ning or air shutter ad justment is required. The

open stainle ss steel frypot has a large heat transfer a rea

to fry more product per load. The ope n-pot design has no

hard-to-cl ean tubes. Every inch of the frypot and cold zone

can be clean ed and wiped down by h and.

The large cold zone catches crumbs an d sediment from the

frying are a. These particles are tr apped in the cold zone

where they do not carbonize, contami nate shortening or

cling to fri ed products. The standard fro nt flush feature

deflects o il out around the pot, moving sediment to the

front drain va lve for easy and thoroug h removal. A Power

Standard Features

• Open-pot design, no tubes, easy to clean

• Durable centerline thermostat

• 7-to-10 second response to loads, 1°

anticipating action, reduced temperature

overshoot

• Deep cold zone, 1-1/4 in. (32 mm) IPS

ball-type drain valve

• Master Jet burner, no burner tube radi-

ants to burn out, no cleaning or adjusting

air shutters

• Rounded corners for easy-to-clean “Euro”

look

Options & Accessories

Computer, basket lift timer, digital or

solid state controller

Electronic ignition (must use one of

the above controllers)

Frypot cover

Sediment tray

Shower® feature can be substituted for the front flush

feature at time of order.

The MJ45 and MJ45G models use a mi llivolt temperature

control circuit . The MJ45GBL automatic ba sket lift motor

uses 120V (2 30V or 240V for CE/Exp ort). The MJ45E model

uses a 120V (220V-240V for export ) supply system to ac-

commodate add itional accessories. Mu lti-product comput-

ers, shorte ning melt cycle contro ls and automatic basket

lifts are ava ilable. FootPrint PRO® filt ration is available wit h

up to six fr yers batteried togeth er into a single system, or

with a singl e MJ45 fryer and a s preader cabinet. The spread-

er can inclu de an optional heat l amp and dump station.

The heat lamp can be a choice of rod style or bulb type.

The dump stat ions can use either c afeteria-style or scoo p-

type pan. The he at lamp and pans are i ntegrated into the

cabinet, mak ing a complete warmi ng station. Solid-stat e

controls, elec tronic ignition and me lt cycle are available.

Each side of the MJ45-2 split pot fryer operates on 63 ,500

BTU/hr. (15,995 kc al/hr.) (18.6 kW), ha s a maximum shorten -

ing capacit y of 25 lbs. (12 liters ) and has a frying area of

6-1/2 x 15 i nches (165 x 381 mm). The fryer h as all of the

features and o ptions of the MJ45 and gives the operator

the discretio n of using only half the fryer.

*Liter conversions are for solid shortening @ 70°F

Full size basket in lieu of twin

baskets

Fryer’s Friend clean-out rod

Screen-type basket support

Fishplate

Piezo ignitor

Shortening melt cycle control

3/4” x 48” (19 x 1219 mm) quick

disconnect with gas line and

adapter

3/4” x 36” (19 x 914 mm) quick

disconnect with gas line and

adapter

Automatic basket lifts

Stainless steel apron drain with

basket (interchangeable right or

left side)

8700 Line Avenue 71106

P. O. Box 51000 7113 5-1000

Shreveport, LA USA

Tel: 318-865-17 11

Tel: 1-800-221- 4583

Fax: 318-86 8-5987

E-mail: in fo@frymaster.com

www.frymast er. com

Bulletin N o. 818-0057 11/06

Page 2

Frymaster

™

®

MJ45 and MJ45-2 Gas Fryers

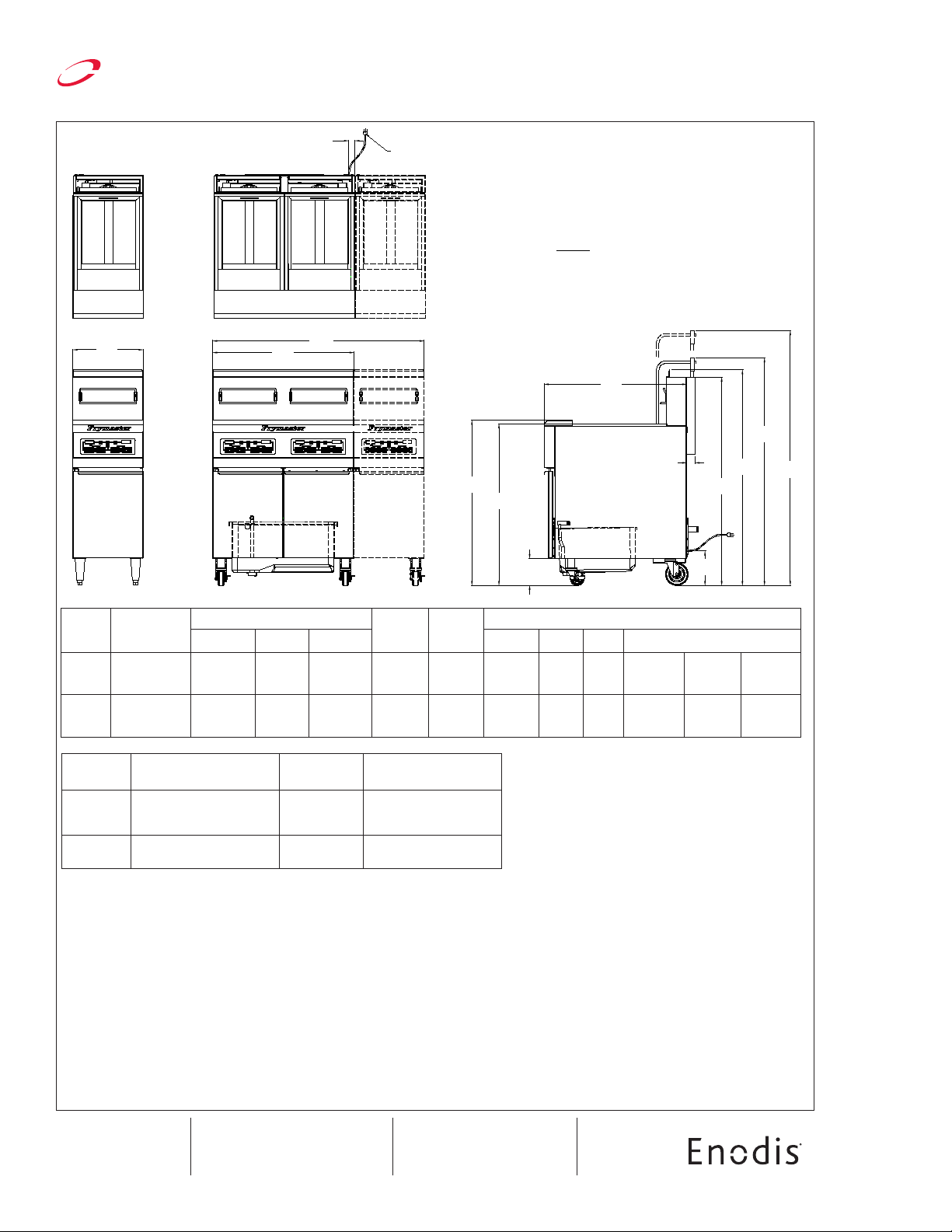

15.62

(397)

31.24

(794)

46.86

(1190)

31.55

(801)

35.75

(908)

6.10

(155)

36.50

(927)

46.00

(1168)

47.67

(1211)

49.12

(1248)

57.82

(1469)

3.00

(76)

6.00

(152)

CORDSET

8.40

(213)

INCHES

(MM)

DIMENSIONS

MODEL

Wit hout

Basket

Basket

NO.

Lifts

Wit h

Lifts

SHORTENING

CAPACI TY

min .-max

40- 50 lbs.

(20 -25 lite rs)

40- 50 lbs.

(20 -25 lite rs)

OV ERA LL SIZ E mm DR AIN

HE IGH T WI DTH LE NGT H WE IGH T CL ASS CU. FT. DI MEN SIO NS

46”

(1168)

46”

(1168)

15.62”

(397)

15.62”

(397)

31.55”

(801)

34.55”

(878)

HE IGH T

10.61”

(269)

10.61”

(269)

WE IGH T

145 lbs.

185 lbs.

POWER REQUIREMENTS

MO DEL NAT URA L

AN D L P G AS

MJ45 (-2)

MJ45G (-2)

All Ot her

Models

122,000 BTU /hr. input

(30,730 kCal/hr.) (35. 8 kW )

122,000 BTU /hr. input

(30,730 kCal/hr.) (35. 8 kW )

EL ECT RICA L EX POR T

none re quir ed

for mil livolt

sys tem

120V/60 Hz 2 40V/50 H z 3.5 Amps

230V/50 Hz 2 Amps (CE)

HOW TO SPECIFY

Description: Fryer shall be an open-pot floor model type, capable of cooking a minimum of 80

lbs. of frozen french fries per hour. The frypot is to be constructed of cold rolled or stainless steel

(each optional). Full pot will have a capacity of 40-50 lbs. (20-25 liters) of shortening, with a 14

x 15 inch (356 x 381 mm) frying area; split pot will have a capacity of 20-25 lbs (10-12 liters) of

shortening with a 6-1/2 x 14 inch (165 x 381 mm) frying area. The frypot shall have a large cold

zone without tubes for easy cleaning. The unit is to be provided with a 1-1/4” IPS ball-type drain

valve (full pot)/1” IPS ball-type drain valve (split pot), located 10.6 inches from the floor. The unit

is to be provided with two heavy gauge fry baskets with insulated handles.

The burner system is to incorporate an atmospheric burner with multiple orifices rated at 122,000 BTU/hr. The burner system is to be controlled by a centerline mounted thermostat

with a 1° temperature sensing accuracy. Unit to be equipped with a high-limit safety thermostat.

The unit shall be built and listed to NSF, AGA, CGA and CE standards.

The fryer is to carry a one -year limited warranty on parts and labor with a lifetime

limited warranty on the stainless frypot. The operating thermostat is to be Fenwal type and carry

a two-year limited warranty.

Model supplied to this specification shall be a Frymaster type MJ45/MJ45-2.

8700 Line Avenue 71106

P. O. Box 51000 7113 5-1000

Shreveport, LA USA

We reserve the right to change specifications appearing in this bulletin without incurring any obligation for equipment previously or subsequently sold.

Tel: 318-865-17 11

Tel: 1-800-221- 4583

Fax: 318-86 8-5987

E-mail: in fo@frymaster.com

www.frymast er. com

Bulletin N o. 818-0057 11/06

Litho in U.S.A. ©Frymaster, L.L.C .

NE T

(66 kg)

(84 kg)

177 lbs.

(80 kg)

233 lbs.

(107 kg)

SH IPP ING IN FOR MATI ON

85 19.47 H

85 19.47 46.5”

46.5”

(1080)

(1080)

W

22”

(559)

22”

(559)

L

36”

(914)

36”

(914)

NOTES

• 1/2” (NPT) gas inlet size (with a 3/4” bushing) for

single fryers; for 2 or more fryers, a 1” supply line

should be provided.

• Supply voltage 120V 60 Hz -- Control Voltage 24V

60 Hz. 120 VAC 5 ft. (1.5 m) grounded cord set.

• Check plumbing codes for proper supply line

sizing. Recommended minimum store manifold

pressure to be 6” W.C. for natural gas and 11” W.C.

for L.P. gas. Check plumbing codes for proper

supply line sizing to attain burner manifold pressure of 3.5” W.C. natural or 8.25” W.C. L.P.

CLEARANCE INFORMATION

A minimum of 24” (610 mm) should be provided

at the front of the unit for servicing and proper

operation, and 6” (152 mm) between the sides

and rear of the fryer to any combustible material.

Model #_ ______________

CSI Secti on 11400

Loading...

Loading...