Page 1

*81965

67*

PREP EQUIPMENT

Frymaster

Heated Landing Zone (HLZ)

Models HLZ18, HLZ22

Model HLZ

Daily maintenance tasks

PR 10 D1 Clean HLZ

Monthly maintenance tasks

PR 10 M1 Clean filter screen

Semi-annual maintenance tasks

PR 10 S1 Calibrate HLZ

D

PR 10

Frymaster Heated Landing Zone (HLZ) Models HLZ18, HLZ22 PR 10

C

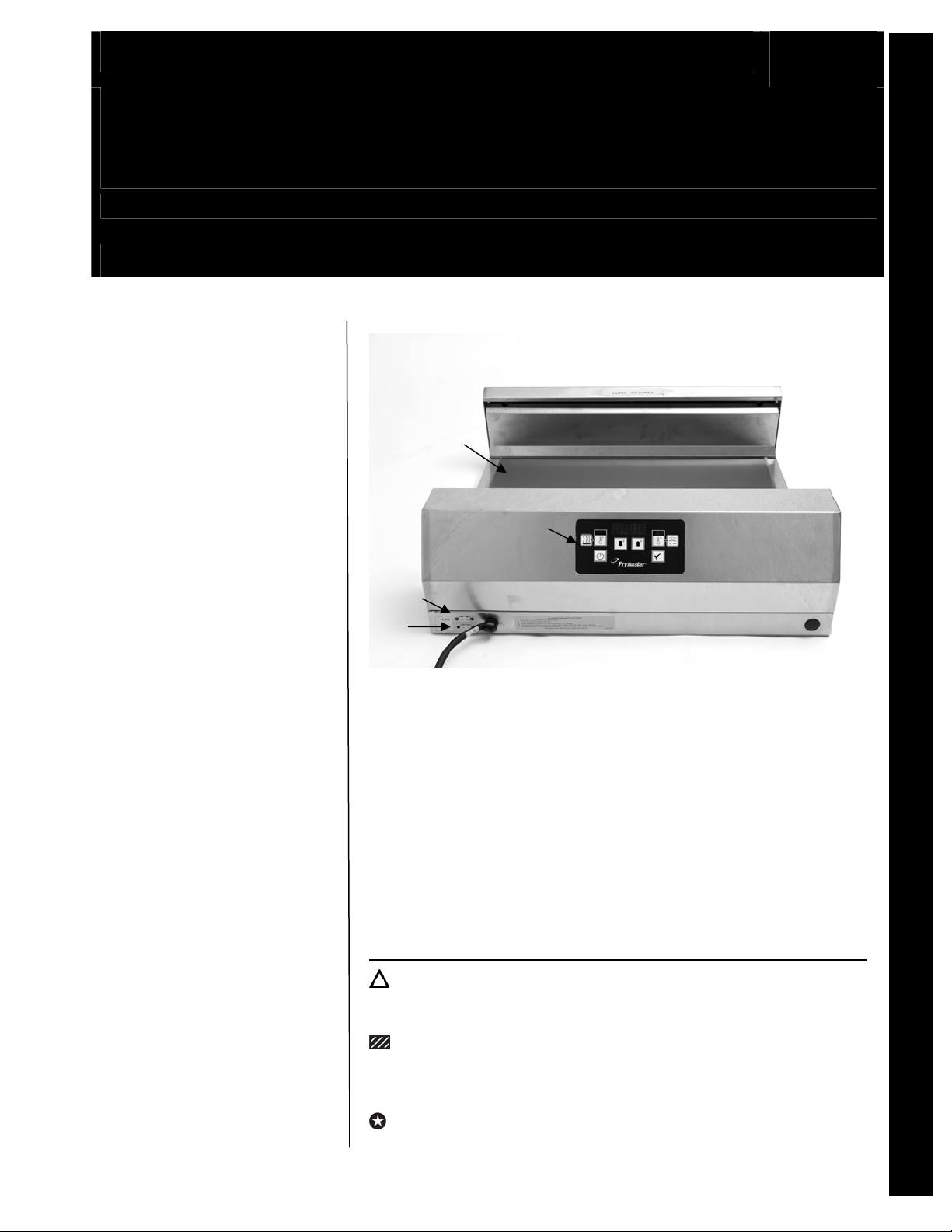

A

B

A. Heater plate calibration socket, B. Air heater calibration socket, C. Controller, D. Heater plate

NOV 2009

Hazards

These icons alert you to a possible risk of personal injury.

Equipment alerts

Look for this icon to find information about how to avoid damaging the

equipment while doing a procedure.

Tips

Look for this icon to find helpful tips about how to do a procedure.

©McDonald’s Corporation · Planned Maintenance Manual · Revised Nov 2009

Page 2

Clean HLZ Daily PR 10 D1

Why

To maintain effectiveness of the heating unit

Frymaster Heated Landing Zone (HLZ) Models HLZ18, HLZ22

Time required

Time of day

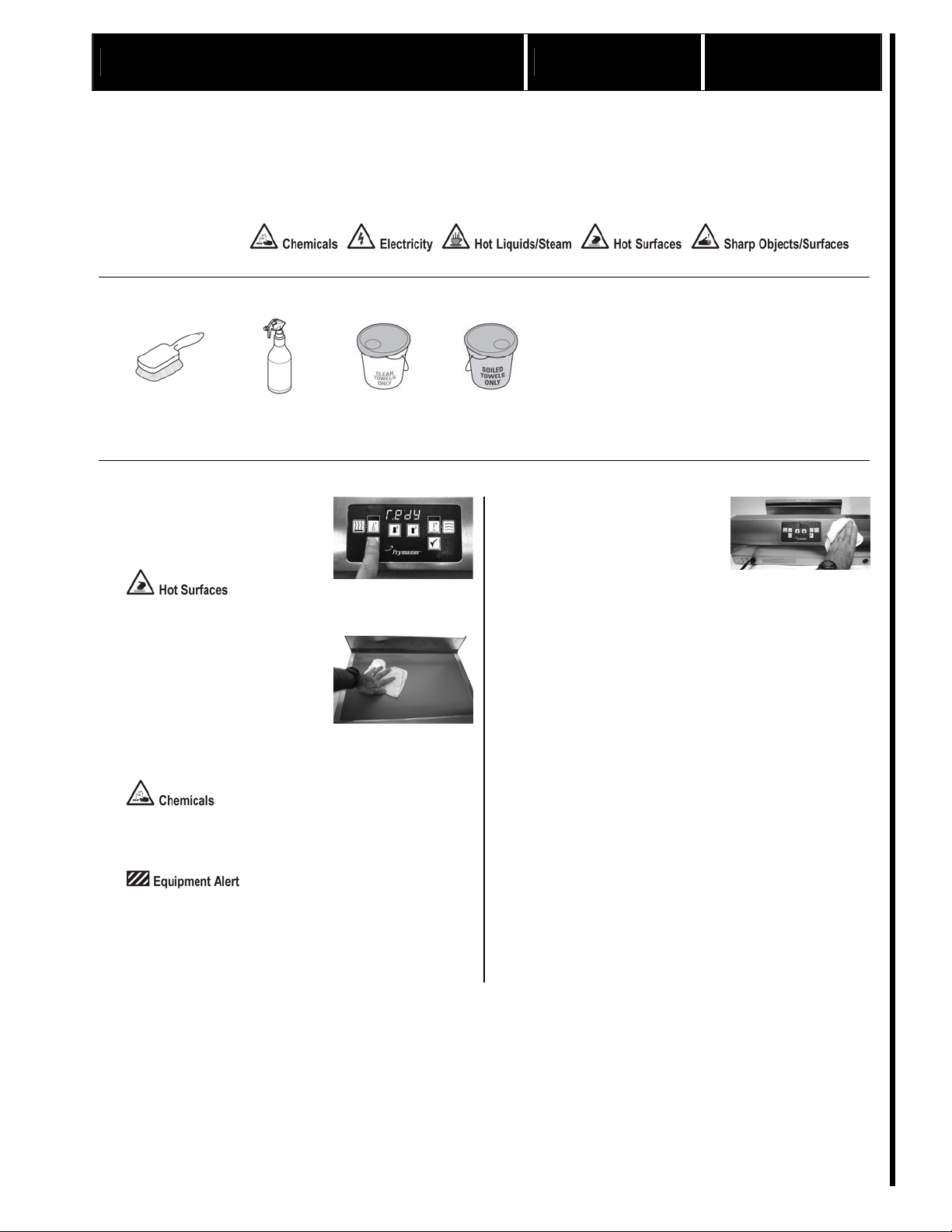

Hazard icons

Tools and supplies

Brush, pot, nylon

Procedure

Turn off HLZ and allow to cool.

1

Allow 30 minutes for the

HLZ to cool.

Do not clean a hot HLZ.

Clean heated surfaces.

2

Clean all heated surfaces with

a clean, sanitized towel

soaked in McD APSC

solution. Use a nylon pot

brush for stubborn stains or

soil.

30 minutes to prepare 3 minutes to complete

After close For 24-hour restaurants: during low-volumes times

McD All Purpose

Super Concentrate

(APSC) solution

Bucket, clean and

sanitized towels

Bucket, soiled towels

3

Clean other surfaces.

Clean the stainless steel

surfaces with a fresh clean,

sanitized towel soaked in

McD APSC solution.

Sanitizer solution,

McD APSC

Do not use McD Sanitizer,

no-scratch pads, scrapers, or

other brushes. They can

damage the surface.

Daily PR 10 D1

©McDonald’s Corporation · Planned Maintenance Manual · Revised July 2007 Page 1 of 1

Page 3

Clean filter screen Monthly PR 10 M1

Why

To maintain hot air flow

Frymaster Heated Landing Zone (HLZ) Models HLZ18, HLZ22

Time required

Time of day

Hazard icons

Tools and supplies

Brush, nylon, pot

Procedure

Turn off HLZ and allow to cool.

1

Allow 30 minutes for the

HLZ to cool.

Do not attempt to remove the

filter screen from a hot HLZ.

30 minutes to prepare 5 minutes to complete

After close For 24-hour restaurants: during low-volume times

McD All Purpose

Super Concentrate

(APSC) solution

Bucket, clean and

sanitized towels

Bucket, soiled towels

Reinstall filter screen.

5

Slip the wire guides on the

bottom of the screen into the

slots on the tower.

Remove filter screen.

2

Lift the screen up and away

from the tower.

Clean filter screen.

3

Clean the screen with a clean,

sanitized towel soaked with

McD APSC solution. Use a

nylon pot brush for stubborn

stains or soil.

Sanitizer solution,

McD APSC

Wipe filter screen with clean,

4

sanitized towel.

Wipe the filter screen with a

fresh clean, sanitized towel.

Monthly PR 10 M1

©McDonald’s Corporation · Planned Maintenance Manual · Revised July 2007 Page 1 of 1

Page 4

Calibrate HLZ Semi-annual PR 10 S1

Why

To ensure correct holding temperature and accuracy of computer controls

Frymaster Heated Landing Zone (HLZ) Models HLZ18, HLZ22

Time required

Time of day

Hazard icons

Tools and supplies

Pyrometer with dual

male connectors

Procedure

Make sure HLZ is clean and at

1

proper operating temperature.

Make sure the HLZ is clean

and has been turned on for at

least 20 minutes. The display

should read “REdY”.

20 minutes to prepare 10 minutes to complete

During low-volume times For 24-hour restaurants: During low-volume times

4

Plug pyrometer connector into

“PLATE” receptacle on HLZ.

Plug pyrometer connector into

2

“AIR” receptacle on HLZ.

The HLZ is hot.

Read and compare air

3

temperatures.

Wait 3 minutes for the pyrometer readout to stabilize.

Press the heater temperature

switch once to display the

HLZ air temperature readout.

Compare the two temperature

readings. If the two temperatures are more than 15°F

(9°C) apart, contact your

Factory-Authorized Service

Center.

Read and compare plate

5

temperatures.

Wait 3 minutes for the pyrometer readout to stabilize.

Press the heater temperature

switch once to display the

HLZ plate temperature readout.

Compare the two temperature

readings. If the two temperatures are more than 10°F

(5°C) apart, contact your

Factory-Authorized Service

Center.

Semi-annual PR 10 S1

©McDonald’s Corporation · Planned Maintenance Manual · Revised July 2007 Page 1 of 1

Loading...

Loading...